compression ratio ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 436 of 947

Rear Suspension (04.02)

Suspension (04.00)4-2-2 Workshop Manual May 2007

Specifications

Maintenance

RH/LH Rear Hub and Bearing Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove RH/LH rear drivesha ft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

4. Ease caliper pistons to release pads.

5. Remove caliper Allen bolts (x2) release caliper and tie aside.

6. Remove handbrake caliper bolts (x2) and tie caliper aside. 7. Remove brake disc Torx screws (x2), remove disc.

8. Disconnect multiplug fr

om wheel speed sensor.

9. Remove Torx securing wheel speed sensor to vertical link, remove sensor.

10. Remove Allen bolts (x4) se curing hub bearing assembly

in vertical link.

11. Release/remove hub bearing a ssembly from vertical link.

Installation

1. Clean vertical link and mating face on hub bearing

carrier.

2. Install hub bearing assembly. Install and torque tighten Allen bolts (x4).

3. Clean wheel speed sensor.

4. Install wheel speed sensor, install and torque tighten Torx screw.

5. Connect multiplug to wheel sped sensor.

6. Clean disc.

7. Install disc, install and torq ue tighten Torx screws (x2).

8. Install caliper, install and torque tighten Allen bolts (x2).

9. Install handbrake caliper, install and torque tighten

retaining bolts (x2).

10. Install RH/LH driveshaft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

11. Pump brake pedal.

12. Install road wheel(s).

13. Lower vehicle on ramp.

RH/LH Rear Lower Arm Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut, anti-roll bar li nk to lower suspension arm.

Release link.

4. Remove bolt securing damper to lower suspension arm.

5. Remove bolt and nut/bolt, securing lower suspension arm to subframe.

6. Remove nut/bolt securing lower suspension arm to

vertical link.

7. Release/remove lower suspension arm from subframe and vertical link.

Installation

1. Clean lower suspension arm and mating faces on vertical link, subframe, damper and anti-roll bar link.

2. Install lower suspension ar m to subframe and vertical

link.

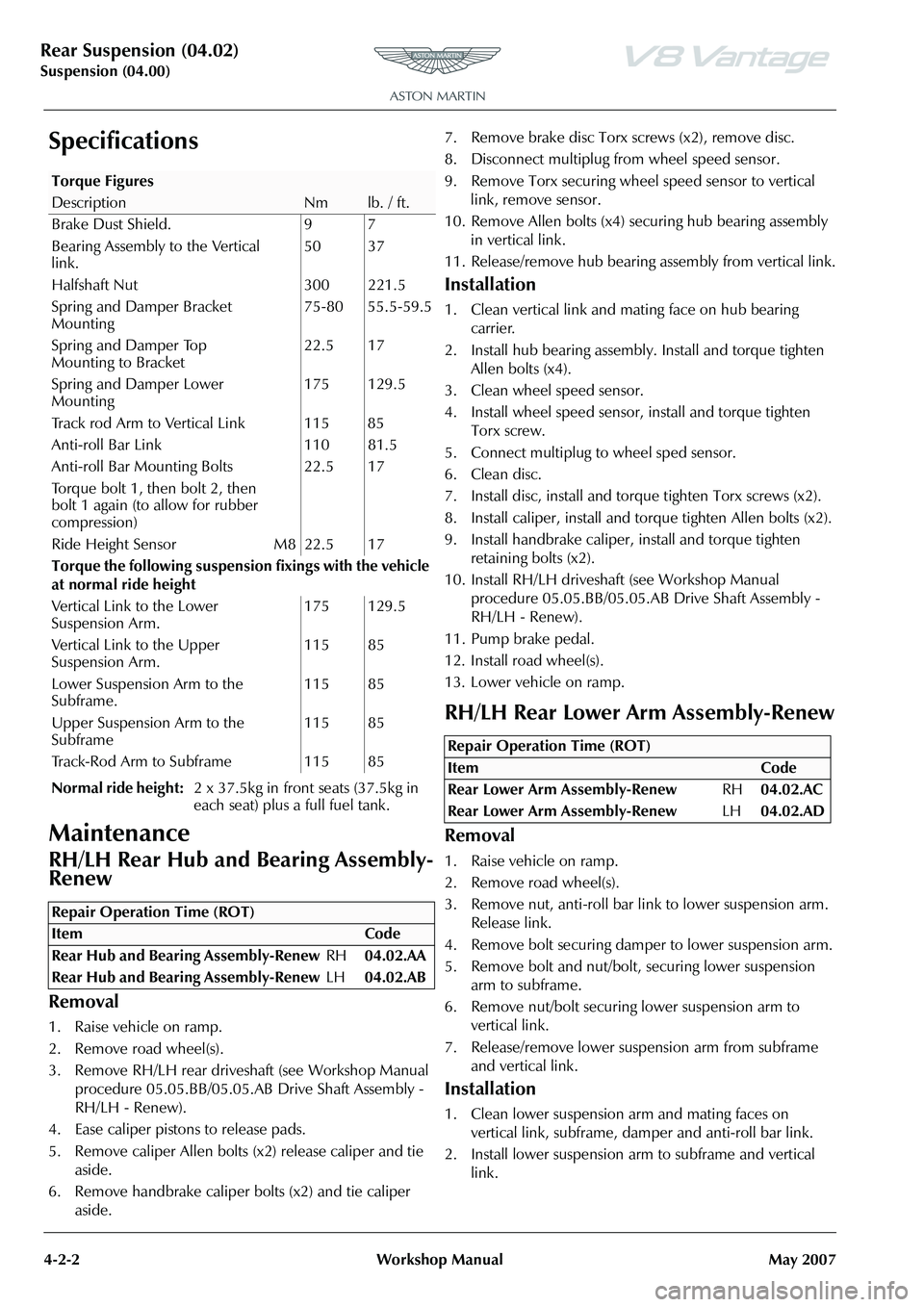

Torque Figures

DescriptionNmlb. / ft.

Brake Dust Shield. 9 7

Bearing Assembly to the Vertical

link. 50 37

Halfshaft Nut 300 221.5

Spring and Damper Bracket

Mounting 75-80 55.5-59.5

Spring and Damper Top

Mounting to Bracket 22.5 17

Spring and Damper Lower

Mounting 175 129.5

Track rod Arm to Vertical Link 115 85

Anti-roll Bar Link 110 81.5

Anti-roll Bar Mounting Bolts

Torque bolt 1, then bolt 2, then

bolt 1 again (to allow for rubber

compression) 22.5 17

Ride Height Sensor M8 22.5 17

Torque the following suspensi on fixings with the vehicle

at normal ride height

Vertical Link to the Lower

Suspension Arm. 175 129.5

Vertical Link to the Upper

Suspension Arm. 115 85

Lower Suspension Arm to the

Subframe. 115 85

Upper Suspension Arm to the

Subframe 115 85

Track-Rod Arm to Subframe 115 85

Normal ride height: 2 x 37.5kg in front seats (37.5kg in

each seat) plus a full fuel tank.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Rear Lower Arm Assembly-Renew RH04.02.AC

Rear Lower Arm Assembly-Renew LH04.02.AD

Page 871 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 25 of 43

VCT Monitor

Variable Cam Timing System Monitor

VCT Hardware

Variable Cam Timing (VCT) enables rotation of the camshaft(s) relative to the crankshaft (phase-shifting)

as a function of engine operating conditions. Intake Only (phase-shifting only the intake cam) is used in

the AML application.

VCT is used primarily to increase internal residua l dilution at part throttle to reduce NOx, and to

improve fuel economy. With Intake Only VCT, the in take camshaft is advanced at part throttle and WOT

(at low to mid-range engine speeds) to open the in take valve earlier for increased residual dilution and

close the intake valve earlier in the compression stroke for increased power. When the engine is cold,

opening the intake valve earlier warms the charge which improves fuel vaporization for less HC

emissions; when the engine is warm, the residua l burned gasses limit peak combustion temperature to

reduce NOx formation.

The VCT system hardware consists of a contro l solenoid and a pulse ring on the camshaft. The PCM

calculates relative cam position using the CMP input to process variable reluctance sensor pulses coming

from the pulse ring mounted on the camshaft. Each pul se wheel has N + 1 teeth where N = the number of

cylinders per bank. The N equally spaced teeth are used for cam phasing; the remaining tooth is used to

determine cylinder # 1 position. Relative cam position is calculated by measuring the time between the

rising edge of profile ignition pickup (PIP ) and the falling edges of the VCT pulses.

VCT Diagnostic

The PCM continually calculates a cam position error value based on the difference between the desired

and actual position and uses this information to cal culate a commanded duty cycle for the VCT solenoid

valve. When energized, engine oil is allowed to flow to the VCT unit thereby advancing and retarding cam

timing. The VCT logic calculates the instantaneous va riance in actual cam position (the squared difference

between actual cam position and commanded cam position), then calculates the long term variance using a

rolling average filter (Exponentially Weighted Moving Average).

If the VCT system is stuck or operates with an consta nt error relative to the target position, the monitor

will detect a variance which will quickly accumulate. There are three variance indices that monitor cam

variance in the retard direction, the advance directi on, and for V engines, the difference between banks. If

any variance index is greater than the malfunction threshold, a VCT target error malfunction will be

indicated (P0011, P0012 Bank 1, P0021, P0022 Bank 2).

The VCT solenoid output driver in the PCM is check ed electrically for open circuit and shorts (P0010

Bank 1, P0020 Bank 2).

VCT Monitor Operation:

Page 873 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 27 of 43

Comprehensive Component Monitor - Engine

General Inputs

Analog inputs such as Ambient Air Temperature (P0072, P0073), Intake Air Temperature (P0112, P0113),

Engine Coolant Temperature (P0117, P0118), Cylinder Head Temperature (P1289, P1290), Mass Air Flow

(P0102, P0103) and Manifold Absolute Pressure (P0107, P0108) are checked for opens, shorts, or out-of-

range values by monitoring the analog -to-digital (A/D) input voltage.

Analog Sensor Check Operation:

DTCs P0072, P0073, P0112, P0113, P0117, P0118, P0102, P0103, P0107, P0108,

P1289, P1290

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds to register a malfunction

Typical analog sensor check malfunction thresholds:

Voltage < 0.20 volts or voltage > 4.80 volts

On Vehicles fitted with Cylinder Head Temperature (CHT ) Sensors, 'Fail Safe Cooling' can be applied if

the cylinder head temperature is too high. The P1299 DTC will be set under these conditions.

Loss of Keep Alive Memory (KAM) power (a separate wire feeding the PCM) results in a P1633 DTC and

immediate MIL illumination.

Loss or corruption of the Vehicle Identification (VID) Block in the PCM results in a P1639 DTC and

immediate MIL illumination.

Ignition

Electronic Ignition systems (Electronic Distributorless Ignition System - EDIS or Coil on Plug - COP)

systems are used on all applications.

The EDIS system, located in the PCM, processes the 36 (or 40) tooth crankshaft position signal to

generate a low data rate PIP signal to control a 4 or 6 terminal 'double-ended' coil pack. The 'double ended'

coils fire a pair of spark plugs simultaneously - one is on its compression stroke, the other on its exhaust

stroke. The COP system also uses the EDIS system in the same way as described above, however each

sparkplug has it’s own coil which is fired only once on the compression stroke.

The ignition system is checked by monitoring three ignition signals during normal vehicle operation:

Profile Ignition Pickup (CKP, commonly known as PIP), the timing reference signal derived from the crankshaft 36-tooth wheel and processed by the EDIS system. PIP is a 50% duty cycle, square

wave signal that has a rising edge at 10 ° BTDC.

Camshaft IDentification (CMP, commonly known at CID), a signal derived from the camshaft to identify the #1 cylinder