Lifting and Jacking

Issue 5, January 2010 Workshop Manual 0-0-9

Lifting and Jacking

Safety

•Recommended procedures for lifting, jacking and

towing must be strictly ob served to ensure personal

safety.

• Always use a vehicle hoist, ramp or pit for working

beneath the vehicle in preference to jacking.

• Never rely on a jack to supp ort a car independently, use

axle stands or blocks carefu lly placed at jacking points

to provide rigid support.

• When working beneath a vehicle, chock wheels as well

as applying handbrake.

• Ensure vehicle is standing on firm, level ground before

jacking or lifting.

• Check lifting equipment has adequate capacity for load

being lifted and is in full working order.

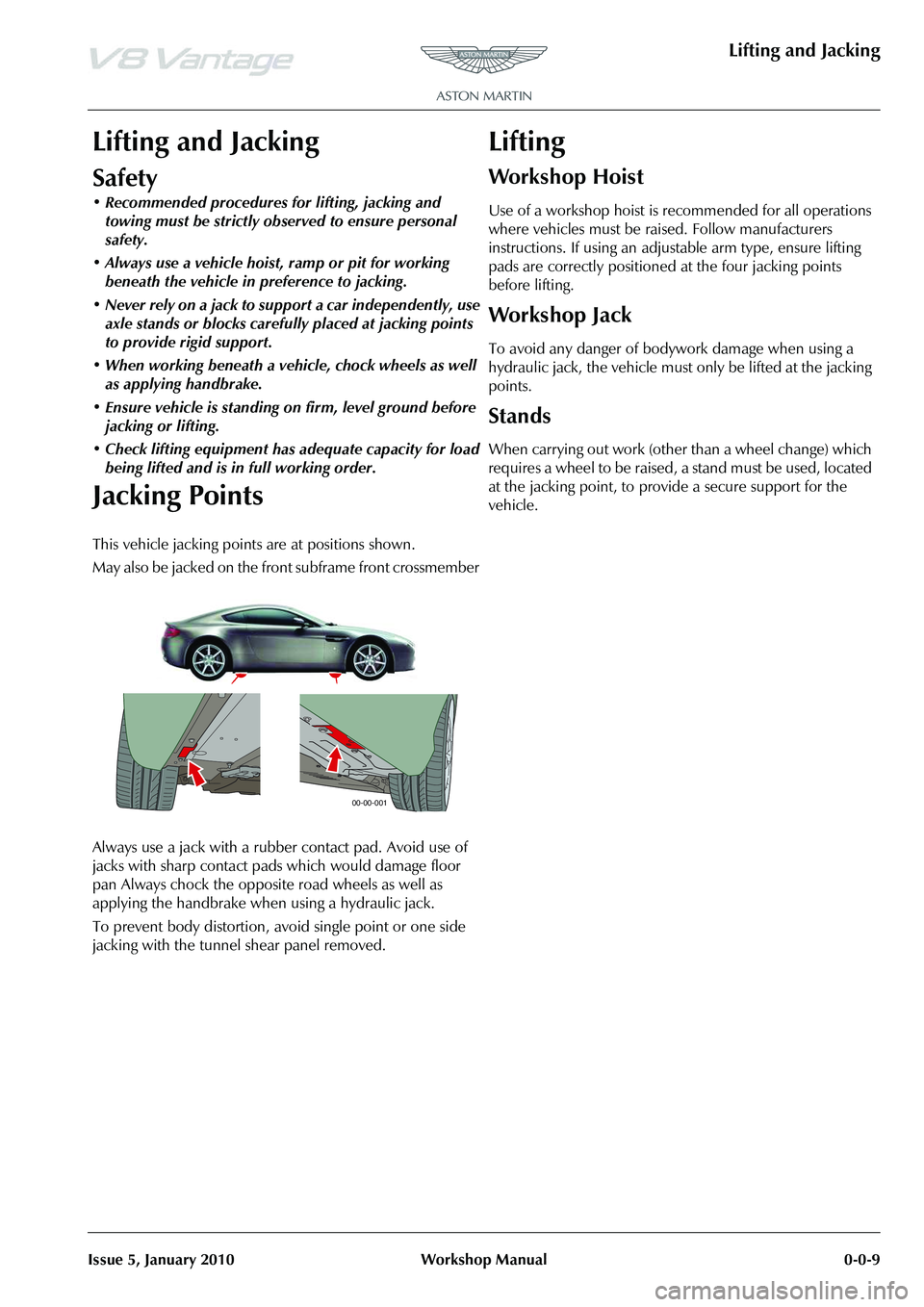

Jacking Points

This vehicle jacking points are at positions shown.

May also be jacked on the front subframe front crossmember

Always use a jack with a rubber contact pad. Avoid use of

jacks with sharp contact pads which would damage floor

pan Always chock the opposite road wheels as well as

applying the handbrake when using a hydraulic jack.

To prevent body distortion, av oid single point or one side

jacking with the tunnel shear panel removed.

Lifting

Workshop Hoist

Use of a workshop hoist is recommended for all operations

where vehicles must be raised. Follow manufacturers

instructions. If using an adjustable arm type, ensure lifting

pads are correctly positioned at the four jacking points

before lifting.

Workshop Jack

To avoid any danger of bodywork damage when using a

hydraulic jack, the vehicle must only be lifted at the jacking

points.

Stands

When carrying out work (other than a wheel change) which

requires a wheel to be raised, a stand must be used, located

at the jacking point, to provide a secure support for the

vehicle.

00-00-001