brake AUDI A3 2020 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2020, Model line: A3, Model: AUDI A3 2020Pages: 400, PDF Size: 107.47 MB

Page 351 of 400

8V2012721BK

Emergency assistance

> Lift the cargo floor using the plastic handle @)

until the cargo floor engages behind the tabs

@ in both side panels > fig. 263 (upper image).

> Fold the cargo floor back before closing the

luggage compartment lid.

Vehicle tool kit and cargo floor cover

Applies to: vehicles with version 2

The vehicle tool kit, tire mobility kit* and com-

pressor* are stored in the luggage compartment

under the cargo floor cover @) > fig. 262.

> Engage the plastic hook () in the luggage com-

partment seal > fig. 263.

> Fold the cargo floor back before closing the

luggage compartment lid.

Z\ WARNING

Applies to: vehicles with jack

Improper use of the vehicle jack can cause se-

rious personal injuries.

— Never use the screw driver hex head to tight-

en wheel bolts, since the bolts cannot attain

the necessary tightening torque if you use

the

hex head, potentially causing an acci-

dent.

— The factory-supplied jack is intended only

for your vehicle model. Under no circum-

stances

should it be used to lift heavy

vehicles or other loads; you risk injuring

yourself.

— Never start the engine when the vehicle is

raised, which could cause an accident.

— Support the vehicle securely with appropri-

ate stands if work is to be performed under-

neath the vehicle; otherwise, there is a po-

tential risk for injury.

— Never use the jack supplied with your Audi

on another vehicle, particularly on a heavier

one. The jack is only suitable for use on the

vehicle it came with.

G) Tips

The vehicle jack* does not require any mainte-

nance.

Vehicle tool kit/tire mobility kit/

eyes

Applies to: vehicles with plug-in hybrid drive

0) Bb + 3

> i a

Fig. 264 Luggage compartment: side trim panel

The vehicle tool kit, tire mobility kit and the com-

pressor are located in the side trim panel @) and

in the luggage compartment.

G) Tips

The vehicle must not be operated without the

tire repair set.

Tire mobility kit

Applies to: vehicles with tire mobility kit

> Read and follow the important safety precau-

tions in > page 348.

> Set the parking brake.

> Move the selector lever into the "P" position.

> Check if a repair with the tire mobility kit is pos-

sible > page 349.

Using the tire mobility kit

Applies to: vehicles with tire mobility kit

B8K-1475

Fig. 265 Tire: tire damage that cannot be repaired

349

Page 354 of 400

Emergency assistance

Replacing wheels

Before changing a wheel

Observe the following precautions for your own

and your passenger's safety when changing a

wheel.

>» After you experience a tire failure, pull the car

well away from moving traffic and try to reach

level ground before you stop > A\.

> All passengers should leave the car and move

toa safe location (for instance, behind the

guardrail) > A\.

> Engage the parking brake to prevent your vehi-

cle from rolling unintentionally > A\.

> Move selector lever to position P > /\.

> If you are towing a trailer, unhitch the trailer

from your vehicle.

> Take the jack* > page 348 and the spare tire*

=> page 357 out of the luggage compartment.

ZA\ WARNING

You or your passengers could be injured while

changing a wheel if you do not follow these

safety precautions:

— If you have a flat tire, move a safe distance

off the road. Turn off the engine, turn the

emergency flashers on and use other warn-

ing devices to alert other motorists.

— Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

—To help prevent the vehicle from moving

suddenly and possibly slipping off the jack*,

always fully set the parking brake and block

the front and back of the wheel diagonally

opposite the wheel being changed. When

one front wheel is lifted off the ground,

placing the Automatic Transmission in P

(Park) will not prevent the vehicle from mov-

ing.

— Before you change a wheel, be sure the

ground is level and firm. If necessary, use a

sturdy board under the jack”.

— Always store the vehicle tool kit, the jack*

and the replaced tire in the luggage com-

partment > page 60.

352

G) Tips

Obey all laws.

Changing a wheel

When you change a wheel, follow the sequence

described below step-by-step and in exactly that

order.

1. Remove the decorative wheel cover*. For

more details see also > page 353, Decorative

wheel covers or > page 353, Wheels with

wheel bolt caps.

2. Loosen the wheel bolts > page 353.

3. Locate the proper mounting point for the

jack* and align the jack* below that point

=> page 354.

4. Raise the car with the jack* > page 354.

Remove the wheel with the flat tire and then

install the spare > page 355.

6. Tighten all wheel bolts lightly.

Lower the vehicle with the jack*.

8. Use the wheel bolt wrench and firmly tighten

all wheel bolts > page 353.

9. Replace the decorative wheel cover*.

wn

=

ZA WARNING

Always read and follow all WARNINGS and in-

formation > A\ in Raising the vehicle on

page 355 and > page 356.

After changing a wheel

A wheel change is not complete without the do-

ing the following.

> Always store the vehicle tool kit, the jack* and

the replaced tire in the luggage compartment

=> page 60.

> Check the tire pressure on the spare wheel im-

mediately after mounting it.

> As soon as possible, have the tightening tor-

ques on all wheel bolts checked with a torque

wrench. The correct tightening torque is

90 ft lb (120 Nm).

> Have the flat tire replaced as soon as possible.

Page 356 of 400

Emergency assistance

Loosening

> Slide the wheel wrench onto the wheel bolt as

far as it will go.

> Take tight hold of the end of the wrench handle

and turn the wheel bolts counter-clockwise

about one single turn in the direction of arrow

> fig. 270.

Tightening

> Slide the wheel wrench onto the wheel bolt as

far as it will go.

> Take tight hold of the end of the wrench handle

and turn each wheel bolt clockwise until it is

seated.

Z\ WARNING

— Do not use force or hurry when changing a

wheel - you can cause the vehicle to slip off

the jack* and cause serious personal injuries.

— Do not loosen the wheel bolts more than

one turn before you raise the vehicle with

the jack*. - You risk an injury.

@® Tips

— Never use the hexagonal socket in the han-

dle of the screwdriver to loosen or tighten

the wheel bolts.

— If a wheel bolt is very tight, you may find it

easier to loosen by carefully pushing down

on the end of the wheel bolt wrench with

one foot only. As you do so, hold on to the

car to keep your balance and take care not

to slip.

354

Raising the vehicle

Applies to: vehicles with jack

The vehicle must be lifted with the jack first be-

fore the wheel can be removed.

Fe) D 8

<4 = @

oO

Fig. 272 Sill: positioning the vehicle jack

> Engage the parking brake to prevent your vehi-

cle from rolling unintentionally.

> Move the selector lever to position P.

>» Find the marking (imprint) on the sill that is

nearest the wheel that will be changed

=> fig. 271. Behind the marking, there is a lift-

ing point on the sill for the vehicle jack.

> Vehicles with a sill: Note the position of the sill

when positioning the vehicle jack > fig. 272.

>» Place the vehicle jack (vehicle tool kit) on a firm

surface. Use a flat, stable support if necessary.

On a slippery surface such as tile, you should

use a non-slip pad (such as a rubber mat) > A\.

> Turn the vehicle jack located under the lifting

point on the sill to raise the jack until its arm @)

> fig. 272 is located under the designated plas-

tic mount > A\, >@.

> Align the jack so that its arm @) ® fig. 272 en-

gages in the designated lifting point in the door

sill and the movable base (8) lies flat on the

ground. The base (8) must be vertical under the

lifting point @).

Page 358 of 400

Emergency assistance

Removing the wheel

>» Use the hexagonal socket in the screwdriver

handle to completely remove the topmost

wheel bolt and set it aside on a clean surface

> fig. 273.

> Screw the threaded end of the alignment pin

from the tool kit hand-tight into the empty bolt

hole > fig. 274.

> Then remove the other wheel bolts as described

above.

> Take off the wheel leaving the alignment pin in

the bolt hole >@).

Putting on the compact spare wheel

> Lift the spare wheel and carefully slide it over

the alignment pin to guide it in place >@.

> Use the hexagonal socket in the screwdriver

handle to screw in and tighten all wheel bolts

slightly.

> Remove the alignment pin and insert and tight-

en the remaining wheel bolt slightly like the

rest.

> Turn the jack handle counter-clockwise to lower

the vehicle until the jack* is fully released.

> Use the wheel bolt wrench to tighten all wheel

bolts firmly > page 353. Tighten them cross-

wise, from one bolt to the (approximately) op-

posite one, to keep the wheel centered.

@) Note

When removing or installing the wheel, the

rim

could hit the brake rotor and damage the

rotor. Work carefully and have a second per-

son help you.

G) Tips

Never use the hexagonal socket in the handle

of the screwdriver to loosen or tighten the

wheel bolts.

— Pull the reversible blade from the screwdriv:

er before you use the hexagonal socket in

the handle to turn the wheel bolts.

— When mounting tires with unidirectional

tread design make sure the tread pattern is

pointed the right way > page 356.

— The wheel bolts should be clean and easy to

turn. Check for dirt and corrosion on the

356

mating surfaces of both the wheel and the

hub. Remove all dirt from these surfaces be-

fore remounting the wheel.

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in the

right direction.

Using a spare tire with a tread pattern

intended for use in a specific direction

When using a spare tire with a tread pattern in-

tended for use in a specific direction, please note

the following:

— The direction of rotation is marked by an arrow

on the side of the tire.

— If the spare tire has to be installed in the incor-

rect direction, use the spare tire only tempora-

rily since the tire will not be able to achieve its

optimum performance characteristics with re-

gard to aquaplaning, noise and wear.

— We recommend that you pay particular atten-

tion to this fact during wet weather and that

you

adjust your speed to match road condi-

tions.

— Replace the flat tire with a new one and have it

installed on your vehicle as soon as possible to

restore the handling advantages of a unidirec-

tional tire.

Notes on wheel changing

Please read the information > page 326 if you

are going to use a spare tire which is different

from the tires on your vehicle.

After you change a tire:

— Check the tire pressure on the spare immedi-

ately after installation.

— Have the wheel bolt tightening torque

checked with a torque wrench as soon as pos-

sible by your authorized Audi dealer ora

qualified service station.

— With steel and alloy wheel rims, the wheel

bolts are correctly tightened at a torque of

90 ft lbs (120 Nm).

Page 363 of 400

8V2012721BK

Fuses and bulbs

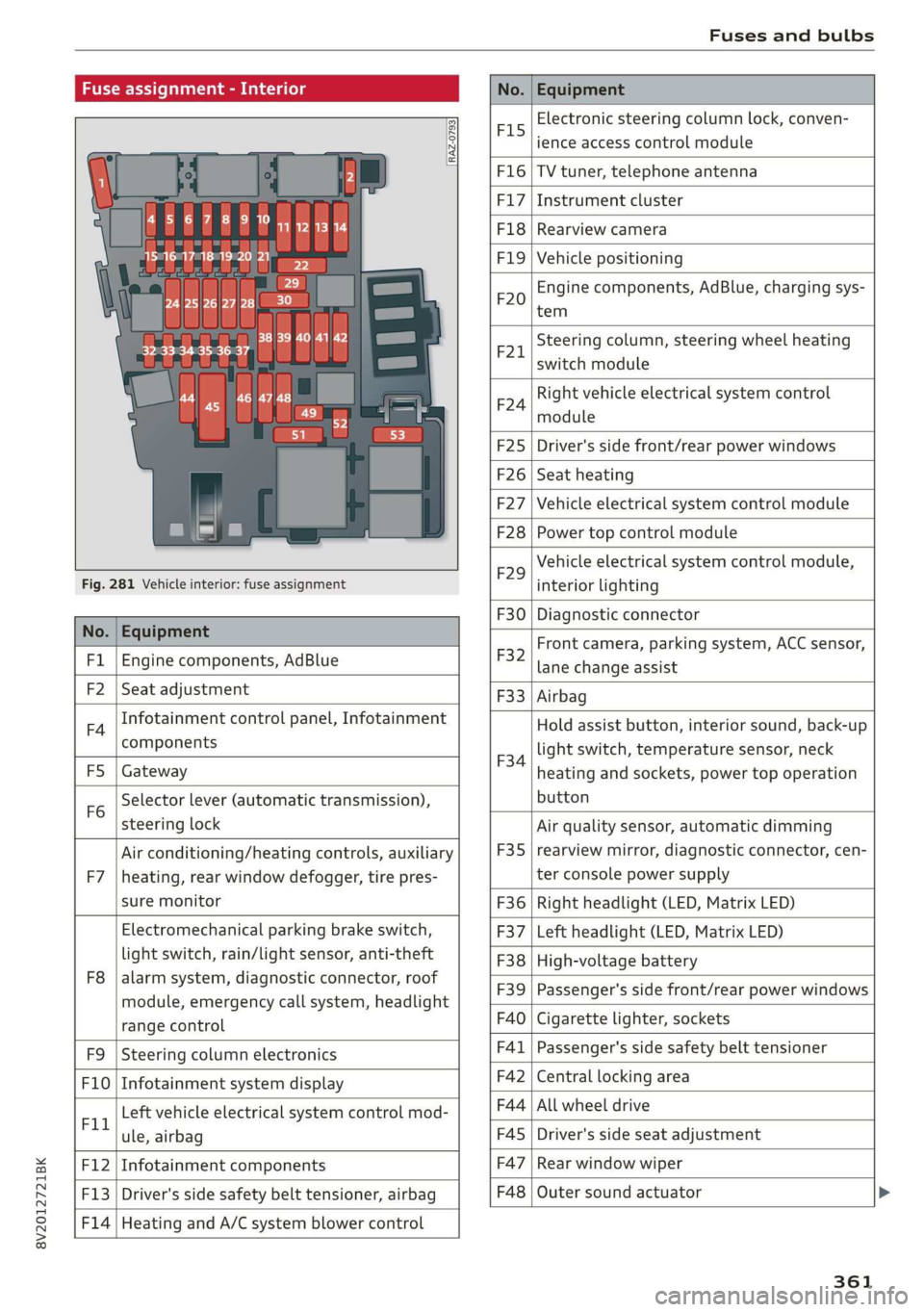

Fuse assignment - Interior

No. Equipment

RAZ-0793,

PO ee

15°16°17-18 19 20 21

PZ ply lip y ips}

ei Hes ole” So}

32°33 34 35 36 37

F15

Electronic steering column lock, conven-

ience access control module

F16 TV tuner, telephone antenna

F17 Instrument cluster

F18 Rearview camera

F1I9 Vehicle positioning

F20

Engine components, AdBlue, charging sys-

tem

F221

Steering column, steering wheel heating

switch module

F24

Right vehicle electrical system control

module

F25 Driver's side front/rear power windows

F26 Seat heating

F27 Vehicle electrical system control module

F28 Power top control module

Fig. 281 Vehicle interior: fuse assignment

F29

Vehicle electrical system control module,

interior lighting

No. Equipment

F30 Diagnostic connector

FL Engine components, AdBlue

F2 Seat adjustment

F32

Front camera, parking system, ACC sensor,

lane change assist

F4

Infotainment control panel, Infotainment

components

F33 Airbag

FS Gateway

Fo

Selector lever (automatic transmission),

steering lock

F34

Hold assist button, interior sound, back-up

light switch, temperature sensor, neck

heating and sockets, power top operation

button

Air conditioning/heating controls, auxiliary F35

Air quality sensor, automatic dimming

rearview mirror, diagnostic connector, cen-

F7 |heating, rear window defogger, tire pres- ter console power supply

sure monitor F36 | Right headlight (LED, Matrix LED)

Electromechanical parking brake switch, F37 | Left headlight (LED, Matrix LED)

light switch, rain/light sensor, anti-theft F38 | High-voltage battery

ae ene eee dent F39 | Passenger's side front/rear power windows

range control F40 | Cigarette lighter, sockets

F9 |Steering column electronics F41 | Passenger's side safety belt tensioner

F10 | Infotainment system display F42 | Central locking area

Tl Left vehicle electrical system control mod- F44 al ee

ule, airbag FAS | Driver's side seat adjustment

F12 | Infotainment components F47 | Rear window wiper

F13 | Driver's side safety belt tensioner, airbag F48 | Outer sound actuator

F14 | Heating and A/C system blower control

361

Page 364 of 400

Fuses and bulbs

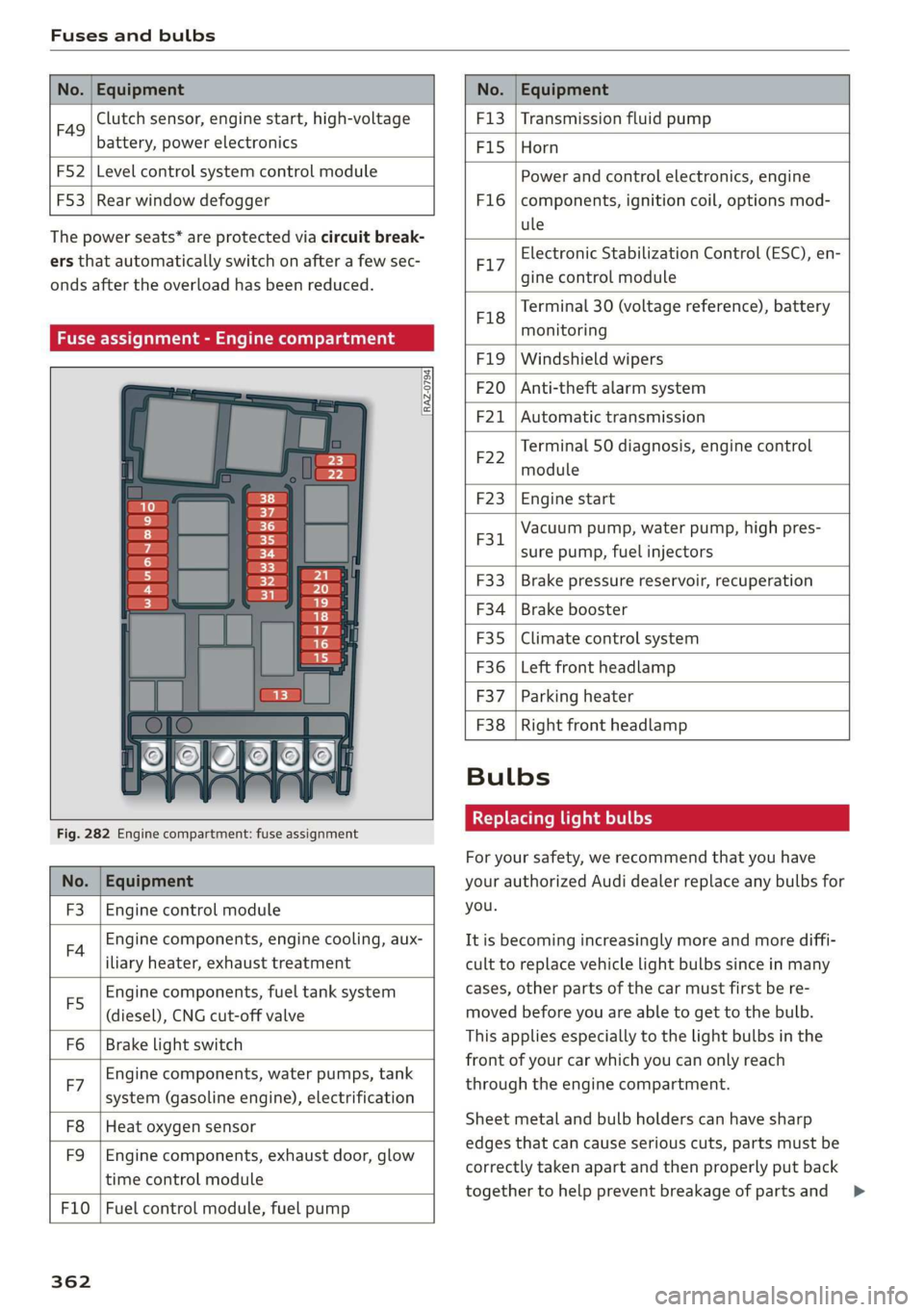

No. | Equipment No. | Equipment

Clutch sensor, engine start, high-voltage

F49 3

battery, power electronics

F52 F53 Level control system control module

Rear window defogger

The power seats* are protected via circuit break-

ers that automatically switch on after a few sec-

onds after the overload has been reduced.

Fuse assignment - Engine compartment

RAZ-0794)

1 0

&

F:}

vi

6

5

4

5}

Fig. 282 Engine compartment: fuse assignment

No. | Equipment

F3 | Engine control module

FA Engine components, engine cooling, aux-

iliary heater, exhaust treatment

Engine components, fuel tank system

(diesel), CNG cut-off valve

Brake light switch

E5

Fo

Engine components, water pumps, tank

F7 ; . ee cae

system (gasoline engine), electrification

F8

F9

Heat oxygen sensor

Engine components, exhaust door, glow

time control module

F10 | Fuel control module, fuel pump

362

F13 | Transmission fluid pump

F15 |Horn

Power and control electronics, engine

components, ignition coil, options mod-

ule

F1l6

Electronic Stabilization Control (ESC), en-

F17

gine control module

Terminal 30 (voltage reference), battery

F18

es

monitoring

FIO F20

F21

Windshield wipers

Anti-theft alarm system

Automatic transmission

Terminal 50 diagnosis, engine control

F22

module

F23 | Engine start

Vacuum pump, water pump, high pres-

F31. 2

sure pump, fuel injectors

F33

F34

F35

F36

F37

Brake pressure reservoir, recuperation

Brake booster

Climate control system

Left front headlamp

Parking heater

F38 | Right front headlamp

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you.

It is becoming increasingly more and more diffi-

cult to replace vehicle light bulbs since in many

cases, other parts of the car must first be re-

moved before you are able to get to the bulb.

This applies especially to the light bulbs in the

front of your car which you can only reach

through the engine compartment.

Sheet metal and bulb holders can have sharp

edges that can cause serious cuts, parts must be

correctly taken apart and then properly put back

together to help prevent breakage of parts and >

Page 367 of 400

8V2012721BK

Emergency situations

Jump start

Applies to: vehicles with plug-in hybrid drive

The

term "vehicle battery" refers to the 12 volt

battery in your vehicle.

rr B z

BS 3 & C3

1 = AT

Fig. 283 Engine compartment: connectors for a charger

and jump start cables

The vehicle is equipped with one vehicle battery

and one high-voltage battery.

If the vehicle battery is drained, it can be charged

with a charger or you can jump start the vehicle

using another vehicle's battery in the same way

as a conventional vehicle.

Read the information about charging the vehicle

battery > page 316 and for jump starting the ve-

hicle > page 364.

> Open the hood > page 305.

» Remove the fuse box cover (8) to access the

positive terminal (4) > page 307.

> Clamp the terminal clamps from the charging

device or jump start cable to the positive termi-

nal @) and to the body ground point @).

(@) Note

You must not give a jump start with your vehi-

cle. This could cause significant damage to

the electrical system in your vehicle.

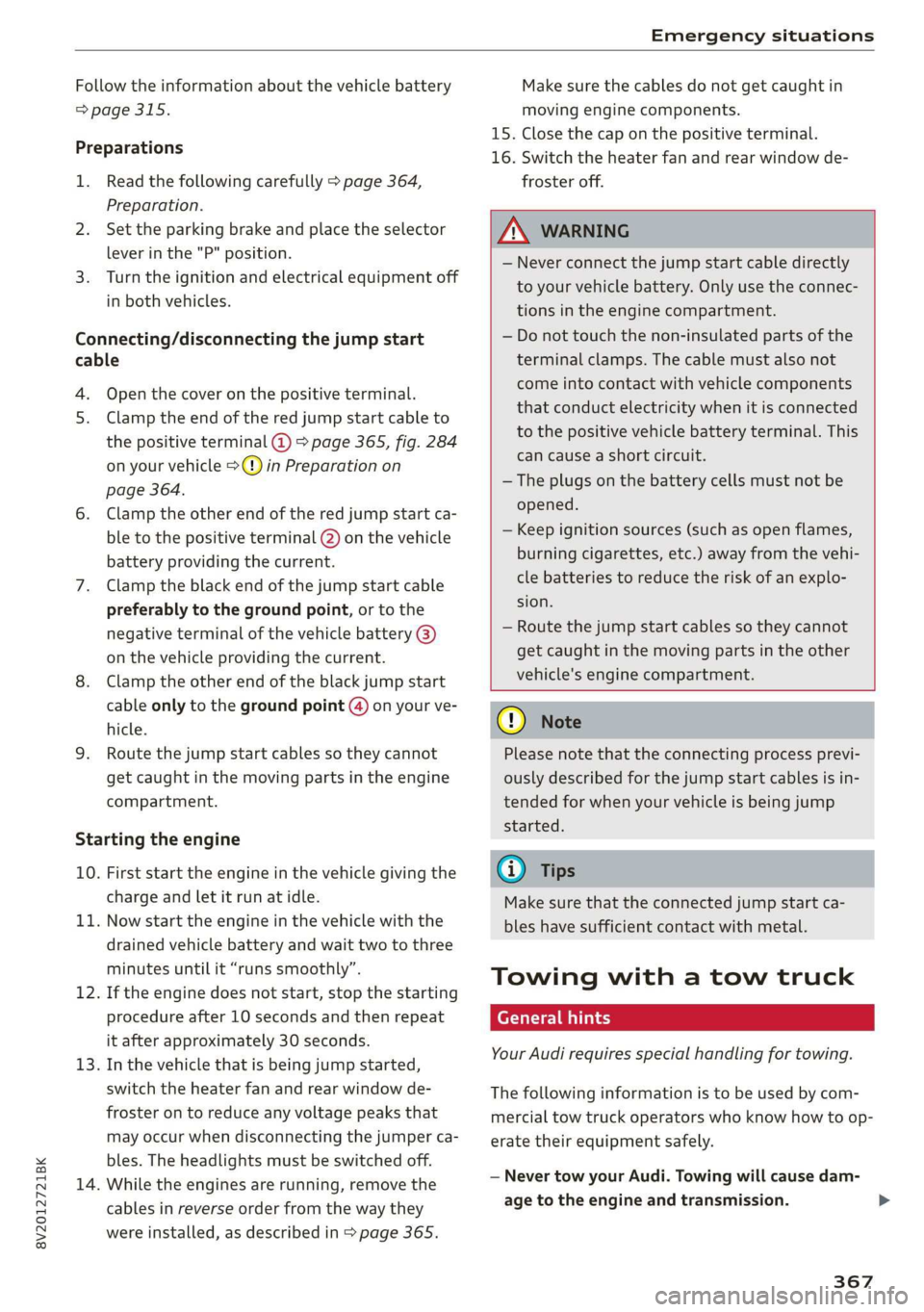

A3 models: jump starting

Applies to: vehicles with conventional drive system

Both jump start cables must be connected in the

correct order.

Fig. 284 Engine compartment: connecting the jump start

cable

The vehicle battery is located on the left front

side of the engine compartment. Open the cover

to access the positive terminal of the vehicle bat-

tery. The procedure for connecting jump start ca-

bles that is described next is designed to help

jump start your vehicle.

Follow the information about the vehicle battery

> page 315.

Preparations

1. Read the following carefully > page 364,

Preparation.

2. Set the parking brake and place the selector

lever in the "P" position.

3. Turn the ignition and electrical equipment off

in both vehicles.

Connecting/disconnecting the jump start

cable

4. Fold the battery cover upward.

5. Clamp the end of the red jump start cable to

the positive terminal @ > fig. 284 on your

vehicle >(@) in Preparation on page 364.

6. Clamp the other end of the red jump start ca-

ble to the positive terminal 2) on the vehicle

battery providing the current.

7. Clamp the black end of the jump start cable

preferably to the ground point, or to the

negative terminal of the vehicle battery @)

on the vehicle providing the current.

365

>

Page 369 of 400

8V2012721BK

Emergency situations

Follow the information about the vehicle battery

=> page 315.

Preparations

1. Read the following carefully > page 364,

Preparation.

2. Set the parking brake and place the selector

lever in the "P" position.

3. Turn the ignition and electrical equipment off

in both vehicles.

Connecting/disconnecting the jump start

cable

4. Open the cover on the positive terminal.

5. Clamp the end of the red jump start cable to

the positive terminal @ > page 365, fig. 284

on your vehicle >@) in Preparation on

page 364.

6. Clamp the other end of the red jump start ca-

ble to the positive terminal (2) on the vehicle

battery providing the current.

7. Clamp the black end of the jump start cable

preferably to the ground point, or to the

negative terminal of the vehicle battery @)

on the vehicle providing the current.

8. Clamp the other end of the black jump start

cable only to the ground point (4) on your ve-

hicle.

9. Route the jump start cables so they cannot

get caught in the moving parts in the engine

compartment.

Starting the engine

10. First start the engine in the vehicle giving the

charge and let it run at idle.

11. Now start the engine in the vehicle with the

drained vehicle battery and wait two to three

minutes until it “runs smoothly”.

12. If the engine does not start, stop the starting

procedure after 10 seconds and then repeat

it after approximately 30 seconds.

13. In the vehicle that is being jump started,

switch the heater fan and rear window de-

froster on to reduce any voltage peaks that

may occur when disconnecting the jumper ca-

bles. The headlights must be switched off.

14. While the engines are running, remove the

cables in reverse order from the way they

were installed, as described in > page 365.

Make sure the cables do not get caught in

moving engine components.

15. Close the cap on the positive terminal.

16. Switch the heater fan and rear window de-

froster off.

ZA\ WARNING

— Never connect the jump start cable directly

to your vehicle battery. Only use the connec-

tions in the engine compartment.

— Do not touch the non-insulated parts of the

terminal clamps. The cable must also not

come into contact with vehicle components

that conduct electricity when it is connected

to the positive vehicle battery terminal. This

can cause a short circuit.

— The plugs on the battery cells must not be

opened.

— Keep ignition sources (such as open flames,

burning cigarettes, etc.) away from the vehi-

cle batteries to reduce the risk of an explo-

sion.

— Route the jump start cables so they cannot

get caught in the moving parts in the other

vehicle's engine compartment.

@) Note

Please note that the connecting process previ-

ously described for the jump start cables is in-

tended for when your vehicle is being jump

started.

(i) Tips

Make sure that the connected jump start ca-

bles have sufficient contact with metal.

Towing with a tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by com-

mercial tow truck operators who know how to op-

erate their equipment safely.

— Never tow your Audi. Towing will cause dam-

age to the engine and transmission. >

367

Page 370 of 400

Emergency situations

— Never wrap the safety chains or winch cables

around the brake lines.

— To prevent unnecessary damage, your Audi

must be transported with a flatbed truck.

— To load the vehicle on to the flatbed, use the

towing loop found in the vehicle tools and at-

tach to the front or rear anchorage > page 368

and > page 368.

Z\ WARNING

A vehicle being towed is not safe for passen-

gers. Never allow anyone to ride in a vehicle

being towed, for any reason.

Front towing loop

2

| = z

a

Fig. 287 Right side of front bumper: installing the towing

loop

The threaded opening for the towing loop is lo-

cated behind a cover on the right side of the front

bumper.

> Remove the towing loop from the vehicle tool

kit > page 348.

> Press inward on the upper left area of the cap

with brief, strong pressure to remove it from

the bumper © fig. 287.

> Insert the towing loop in the threaded opening

until it stops, and then tighten it with the

wheel wrench.

> After using, place the towing loop back in the

vehicle tool kit.

ZA WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and result

in an accident.

368

G) Tips

Depending on the model, the shape of the

cover can vary.

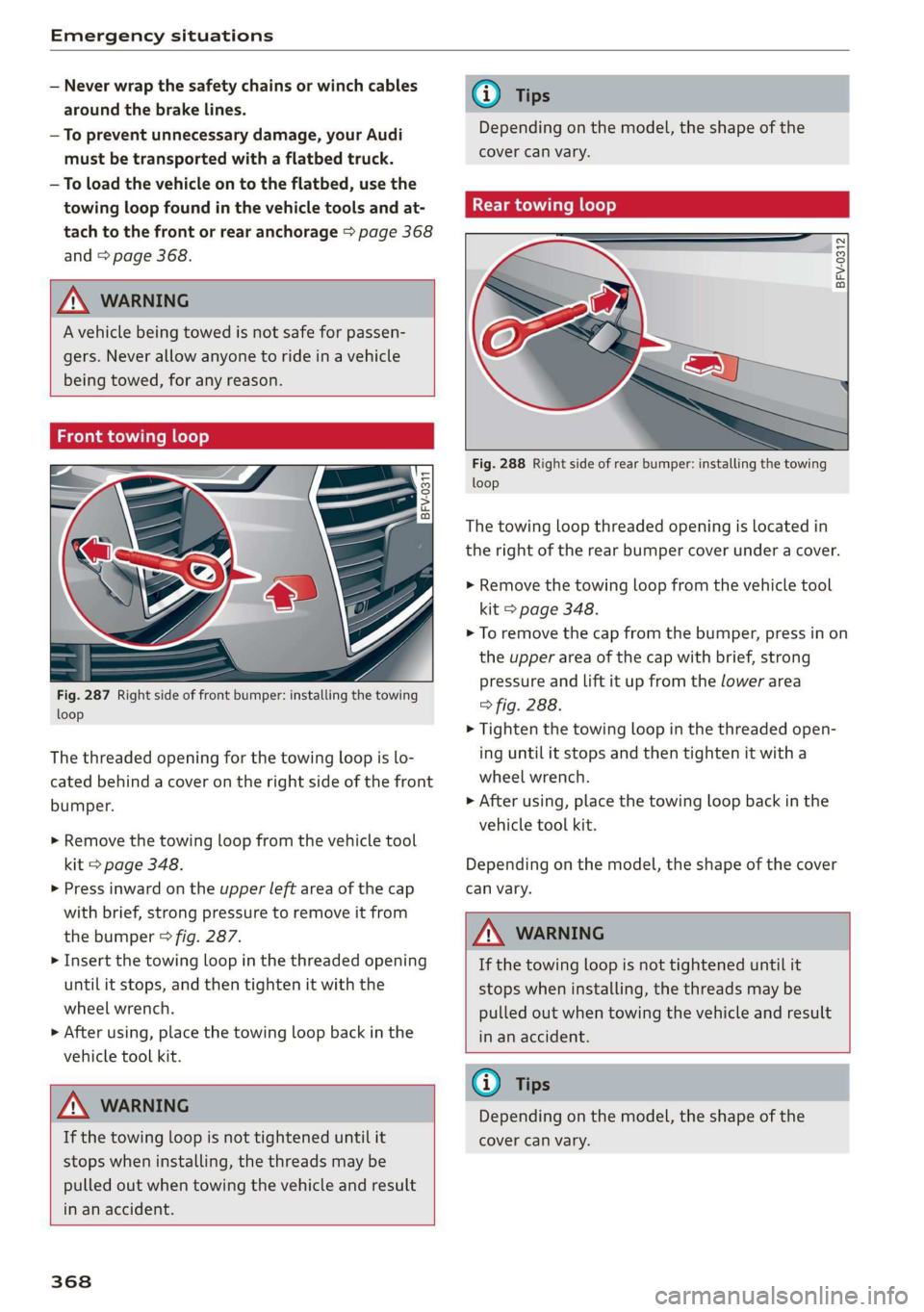

Rear towing loop

a

2

S| > im a

Fig. 288 Right side of rear bumper: installing the towing

loop

The towing loop threaded opening is located in

the right of the rear bumper cover under a cover.

> Remove the towing loop from the vehicle tool

kit > page 348.

> To remove the cap from the bumper, press in on

the upper area of the cap with brief, strong

pressure and Lift it up from the lower area

> fig. 288.

> Tighten the towing loop in the threaded open-

ing until it stops and then tighten it with a

wheel wrench.

> After using, place the towing loop back in the

vehicle tool kit.

Depending on the model, the shape of the cover

can vary.

ZA\ WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and result

in an accident.

@ Tips

Depending on the model, the shape of the

cover can vary.

Page 373 of 400

8V2012721BK

Data privacy

Data privacy

Image recording

Surrounding area monitoring

Applies to: vehicles with surrounding area monitoring

Some vehicle functions require the vehicle’s path

to be detected and evaluated. This is done by

cameras installed permanently on the vehicle

that detect objects in the vehicle's surroundings

(such as obstacles or guard rails). The live images

from the cameras are transmitted to the applica-

ble control module.

The camera images are transmitted to the appli-

cable control module and stored for processing.

The control module analyzes the current camera

image using image evaluation software. This im-

age evaluation software detects anonymized

technical measurements, such as distances to ob-

jects. The control module evaluates these techni-

cal measurements and makes it possible for the

assist systems to control the vehicle, if necessary.

Data memories

Vehicle control modules

5 io. oO Z| x=

+ )

Fig. 292 Driver's side footwell: connection port for the On

Board Diagnostic System (OBD)

Your vehicle is equipped with electronic control

modules for various vehicle systems such as the

airbags. These vehicle control modules store data

while driving normally that is required by an au-

thorized Audi dealer or authorized Audi Service

Facility for diagnosis and repair purposes. Only

certain types of data are recorded for a very short

period of time if a control module has detected a

system event. No noises, conversations, or im-

ages will be recorded in the vehicle.

The data may include information such as the ve-

hicle speed, the direction of travel, and informa-

tion about the brake system, or also the behavior

of the restraint system in the event of an acci-

dent. The stored data can be exported and down-

loaded with special devices, which must be con-

nected directly to the vehicle.

On Board Diagnostic System (OBD)

There is a diagnostic connector socket in the driv-

er's side footwell to read out the various control

modules and the event data recorder. Data re-

garding the function and condition of the elec-

tronic control modules is stored in the event

memory. Only have an authorized Audi dealer or

authorized Audi Service Facility read out and de-

lete the event memory.

ZX WARNING

— Incorrect use of the connection port for the

On Board Diagnostic System can cause mal-

functions, which can then result in accidents

and serious injuries.

— Only allow an authorized Audi dealer or au-

thorized Audi Service Facility to read out the

engine data.

Creu lem eelcel 1g

Event Data Recorder

This vehicle is equipped with an Event Data Re-

corder (EDR). The main purpose of an EDR is to

record, in certain crash or near crash-like situa-

tions,

such as an airbag deployment or hitting a

road obstacle, data that will assist in understand-

ing how a vehicle's system performed. The EDR is

designed to record data related to vehicle dynam-

ics and safety systems for a short period of time,

typically 30 seconds or less. The EDR in this vehi-

cle is designed to record such data as:

— How various systems in your vehicle were oper-

ating;

— Whether or not the driver and passenger safety

belts were buckled/fastened;

— How far (if at all) the driver was depressing the

accelerator and/or brake pedal; and,

— How fast the vehicle was traveling.

371