AUDI A4 1998 B5 / 1.G 01A Transmission Final Drive Gear Set User Guide

Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 31, PDF Size: 0.39 MB

Page 11 of 31

39-155

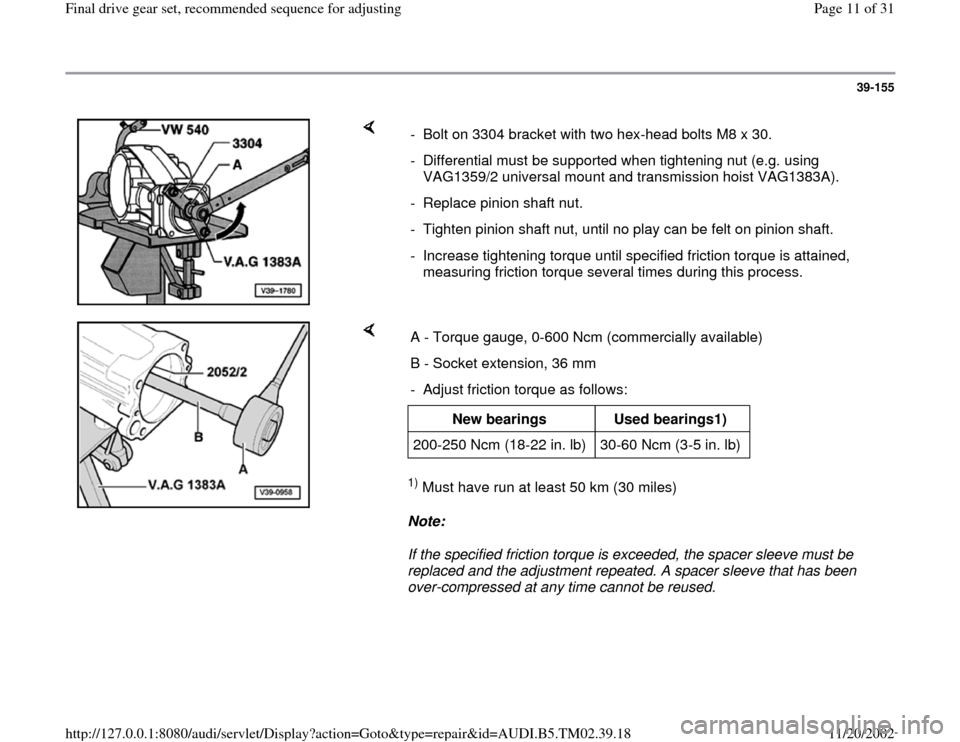

- Bolt on 3304 bracket with two hex-head bolts M8 x 30.

- Differential must be supported when tightening nut (e.g. using

VAG1359/2 universal mount and transmission hoist VAG1383A).

- Replace pinion shaft nut.

- Tighten pinion shaft nut, until no play can be felt on pinion shaft.

- Increase tightening torque until specified friction torque is attained,

measuring friction torque several times during this process.

1) Must have run at least 50 km (30 miles)

Note:

If the specified friction torque is exceeded, the spacer sleeve must be

replaced and the adjustment repeated. A spacer sleeve that has been

over-compressed at any time cannot be reused. A - Torque gauge, 0-600 Ncm (commercially available)

B - Socket extension, 36 mm

- Adjust friction torque as follows:

New bearings

Used bearings1)

200-250 Ncm (18-22 in. lb) 30-60 Ncm (3-5 in. lb)

Pa

ge 11 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 12 of 31

39-156

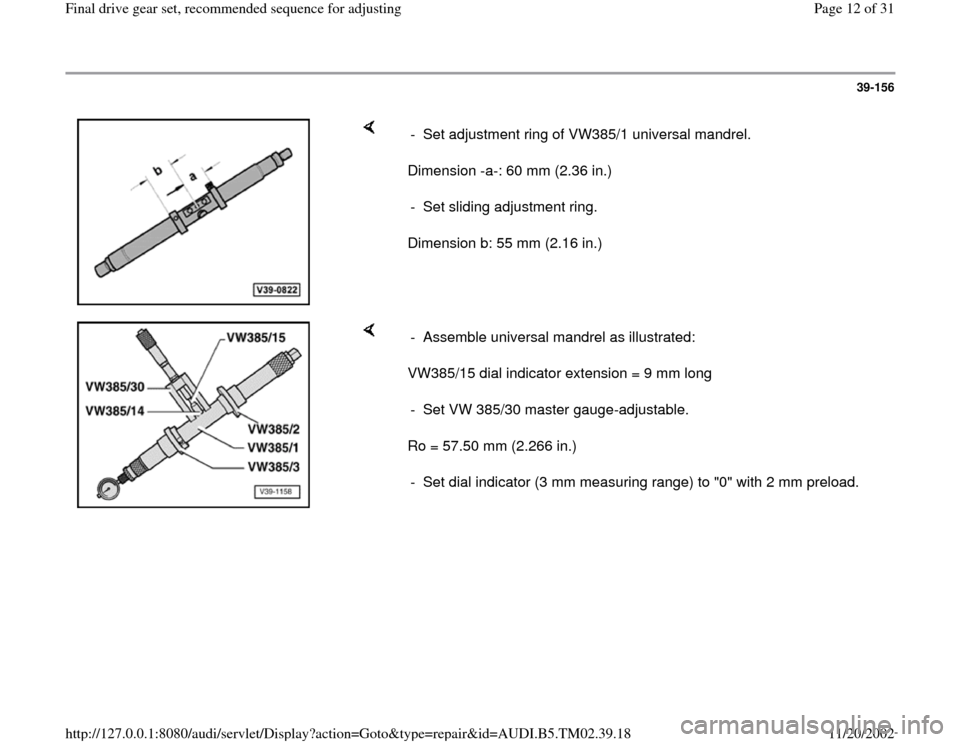

Dimension -a-: 60 mm (2.36 in.)

Dimension b: 55 mm (2.16 in.) - Set adjustment ring of VW385/1 universal mandrel.

- Set sliding adjustment ring.

VW385/15 dial indicator extension = 9 mm long

Ro = 57.50 mm (2.266 in.) - Assemble universal mandrel as illustrated:

- Set VW 385/30 master gauge-adjustable.

- Set dial indicator (3 mm measuring range) to "0" with 2 mm preload.

Pa

ge 12 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 13 of 31

39-157

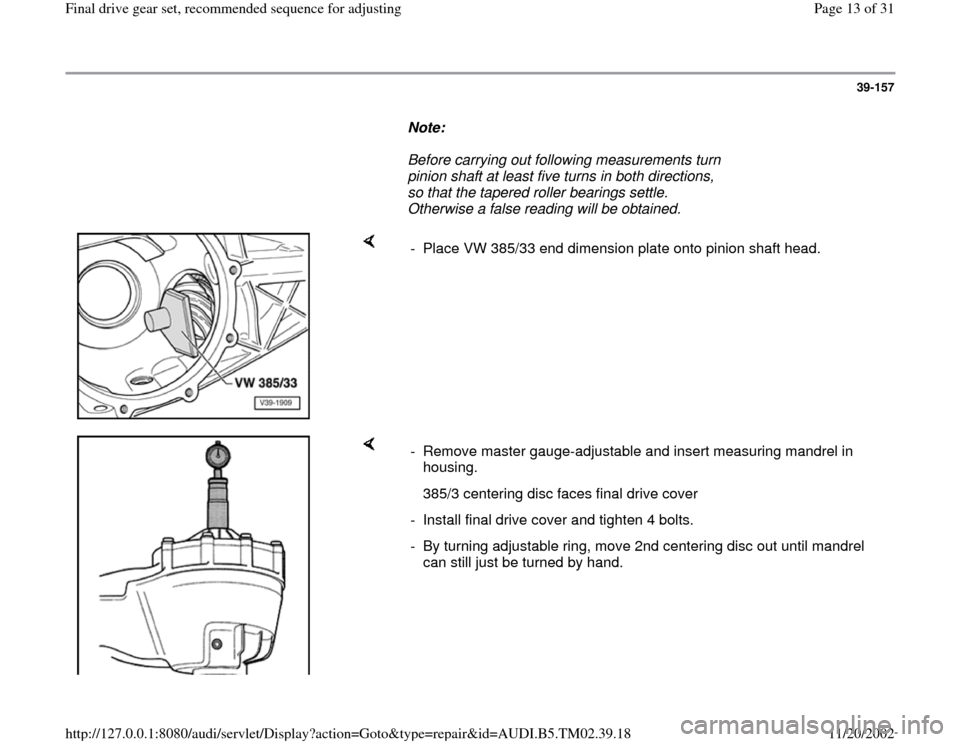

Note:

Before carrying out following measurements turn

pinion shaft at least five turns in both directions,

so that the tapered roller bearings settle.

Otherwise a false reading will be obtained.

- Place VW 385/33 end dimension plate onto pinion shaft head.

- Remove master gauge-adjustable and insert measuring mandrel in

housing.

385/3 centering disc faces final drive cover

- Install final drive cover and tighten 4 bolts.

- By turning adjustable ring, move 2nd centering disc out until mandrel

can still just be turned by hand.

Pa

ge 13 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 14 of 31

39-158

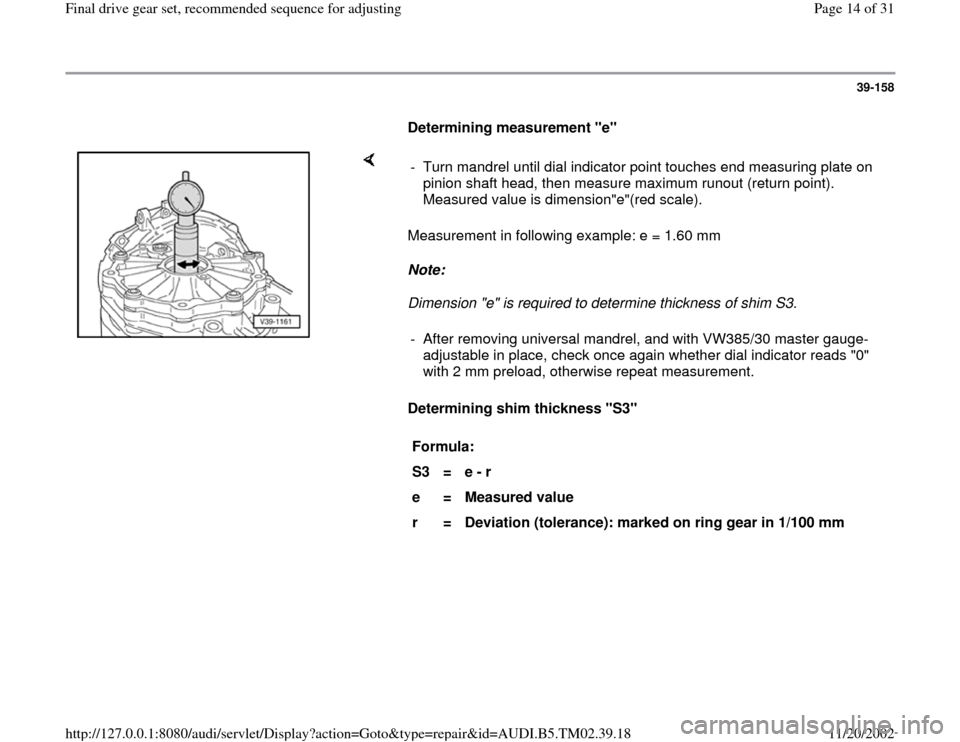

Determining measurement "e"

Measurement in following example: e = 1.60 mm

Note:

Dimension "e" is required to determine thickness of shim S3.

Determining shim thickness "S3" - Turn mandrel until dial indicator point touches end measuring plate on

pinion shaft head, then measure maximum runout (return point).

Measured value is dimension"e"(red scale).

- After removing universal mandrel, and with VW385/30 master gauge-

adjustable in place, check once again whether dial indicator reads "0"

with 2 mm preload, otherwise repeat measurement.

Formula:

S3

=

e - r

e

=

Measured value

r

=

Deviation (tolerance): marked on ring gear in 1/100 mm

Pa

ge 14 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 15 of 31

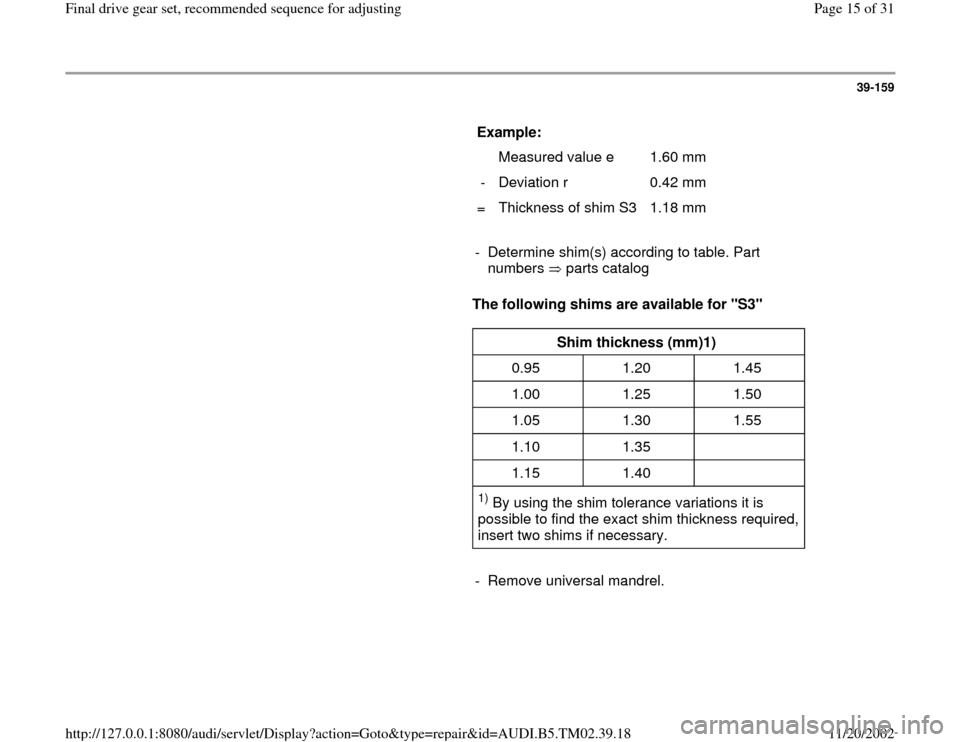

39-159

Example:

Measured value e 1.60 mm

- Deviation r 0.42 mm

= Thickness of shim S3 1.18 mm

- Determine shim(s) according to table. Part

numbers parts catalog

The following shims are available for "S3"

Shim thickness (mm)1)

0.95 1.20 1.45

1.00 1.25 1.50

1.05 1.30 1.55

1.10 1.35

1.15 1.40

1) By using the shim tolerance variations it is

possible to find the exact shim thickness required,

insert two shims if necessary.

- Remove universal mandrel.

Pa

ge 15 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

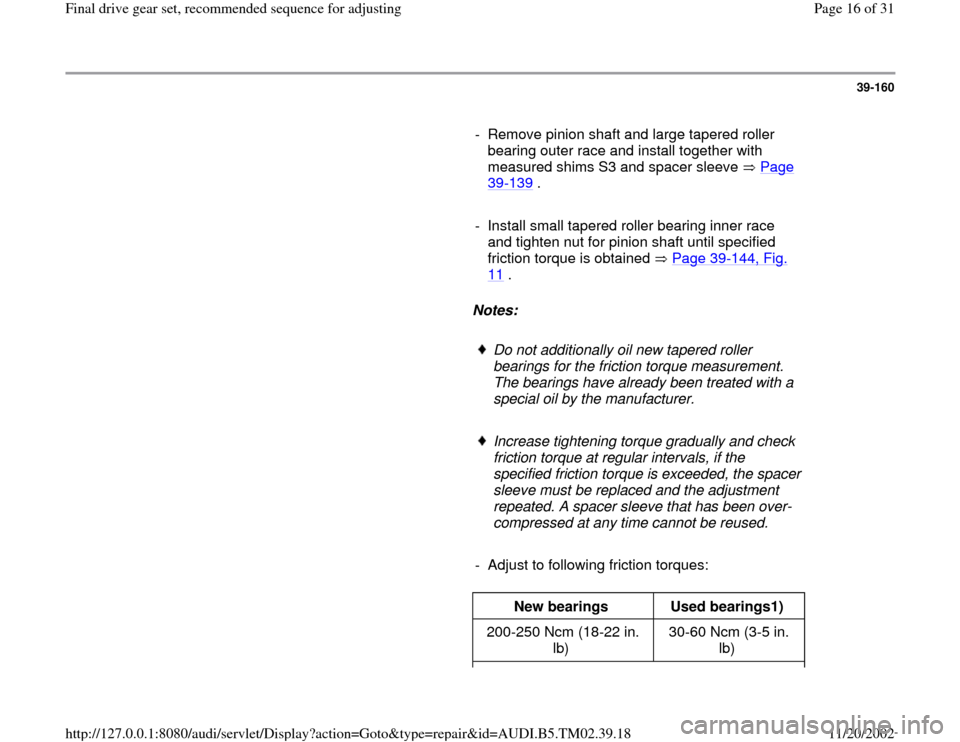

Page 16 of 31

39-160

- Remove pinion shaft and large tapered roller

bearing outer race and install together with

measured shims S3 and spacer sleeve Page

39

-139

.

- Install small tapered roller bearing inner race

and tighten nut for pinion shaft until specified

friction torque is obtained Page 39

-144, Fig.

11

.

Notes:

Do not additionally oil new tapered roller

bearings for the friction torque measurement.

The bearings have already been treated with a

special oil by the manufacturer.

Increase tightening torque gradually and check

friction torque at regular intervals, if the

specified friction torque is exceeded, the spacer

sleeve must be replaced and the adjustment

repeated. A spacer sleeve that has been over-

compressed at any time cannot be reused.

- Adjust to following friction torques:

New bearings

Used bearings1)

200-250 Ncm (18-22 in.

lb) 30-60 Ncm (3-5 in.

lb)

Pa

ge 16 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 17 of 31

1) Must have run at least 50 km (30 miles)

Pa

ge 17 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 18 of 31

39-161

Checking measurements

Checking dimension "r"

- Turn pinion shaft at least 5 turns in both

directions.

If the shims have been correctly selected, the dial indicator should now

display the value of "r" as marked on the ring gear, reading

counterclockwise (red scale), within a tolerance of 0.04 mm. - Insert universal mandrel and carry out check measurement.

- Secure pinion shaft nut using mandrel.

Pa

ge 18 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

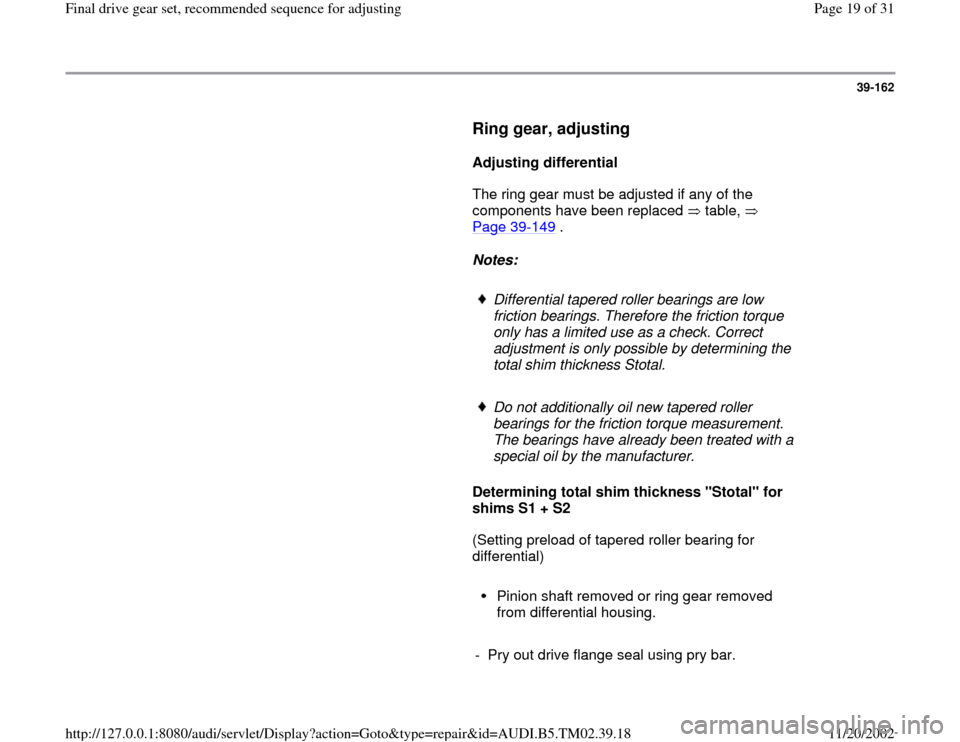

Page 19 of 31

39-162

Ring gear, adjusting

Adjusting differential

The ring gear must be adjusted if any of the

components have been replaced table,

Page 39

-149

.

Notes:

Differential tapered roller bearings are low

friction bearings. Therefore the friction torque

only has a limited use as a check. Correct

adjustment is only possible by determining the

total shim thickness Stotal.

Do not additionally oil new tapered roller

bearings for the friction torque measurement.

The bearings have already been treated with a

special oil by the manufacturer.

Determining total shim thickness "Stotal" for

shims S1 + S2

(Setting preload of tapered roller bearing for

differential)

Pinion shaft removed or ring gear removed

from differential housing.

- Pry out drive flange seal using pry bar.

Pa

ge 19 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 20 of 31

- Remove differential tapered roller bearing outer

races and remove shims Page 39

-121

.

Pa

ge 20 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18