check oil AUDI A4 1998 B5 / 1.G 01A Transmission Final Drive Gear Set Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 31, PDF Size: 0.39 MB

Page 16 of 31

39-160

- Remove pinion shaft and large tapered roller

bearing outer race and install together with

measured shims S3 and spacer sleeve Page

39

-139

.

- Install small tapered roller bearing inner race

and tighten nut for pinion shaft until specified

friction torque is obtained Page 39

-144, Fig.

11

.

Notes:

Do not additionally oil new tapered roller

bearings for the friction torque measurement.

The bearings have already been treated with a

special oil by the manufacturer.

Increase tightening torque gradually and check

friction torque at regular intervals, if the

specified friction torque is exceeded, the spacer

sleeve must be replaced and the adjustment

repeated. A spacer sleeve that has been over-

compressed at any time cannot be reused.

- Adjust to following friction torques:

New bearings

Used bearings1)

200-250 Ncm (18-22 in.

lb) 30-60 Ncm (3-5 in.

lb)

Pa

ge 16 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 19 of 31

39-162

Ring gear, adjusting

Adjusting differential

The ring gear must be adjusted if any of the

components have been replaced table,

Page 39

-149

.

Notes:

Differential tapered roller bearings are low

friction bearings. Therefore the friction torque

only has a limited use as a check. Correct

adjustment is only possible by determining the

total shim thickness Stotal.

Do not additionally oil new tapered roller

bearings for the friction torque measurement.

The bearings have already been treated with a

special oil by the manufacturer.

Determining total shim thickness "Stotal" for

shims S1 + S2

(Setting preload of tapered roller bearing for

differential)

Pinion shaft removed or ring gear removed

from differential housing.

- Pry out drive flange seal using pry bar.

Pa

ge 19 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 25 of 31

39-167

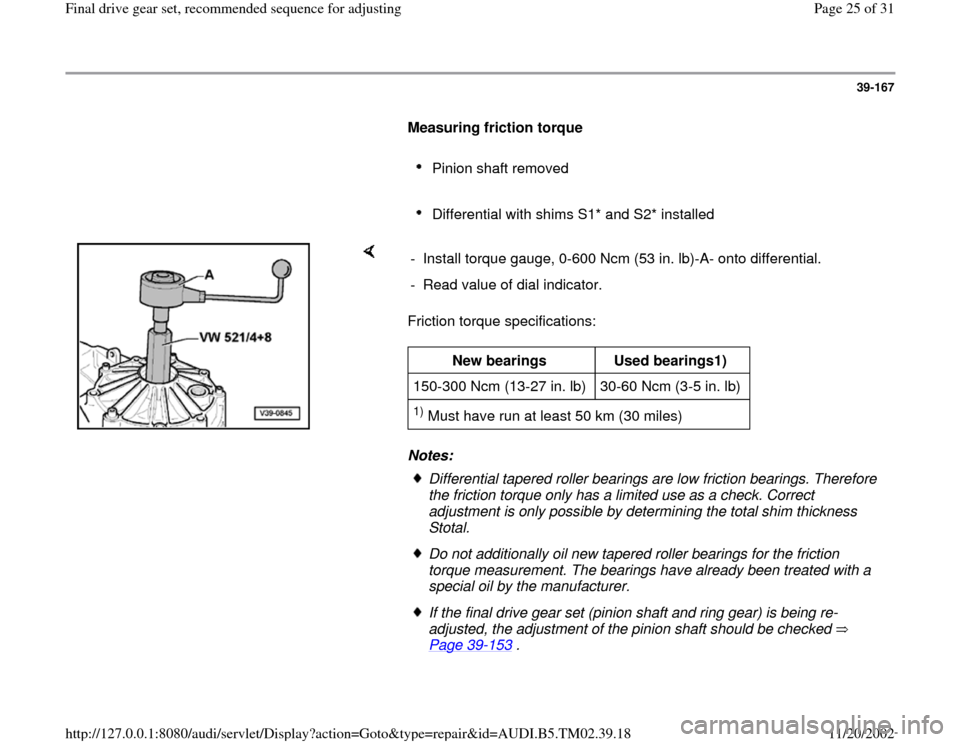

Measuring friction torque

Pinion shaft removed

Differential with shims S1* and S2* installed

Friction torque specifications:

Notes: - Install torque gauge, 0-600 Ncm (53 in. lb)-A- onto differential.

- Read value of dial indicator.

New bearings

Used bearings1)

150-300 Ncm (13-27 in. lb) 30-60 Ncm (3-5 in. lb)

1) Must have run at least 50 km (30 miles) Differential tapered roller bearings are low friction bearings. Therefore

the friction torque only has a limited use as a check. Correct

adjustment is only possible by determining the total shim thickness

Stotal. Do not additionally oil new tapered roller bearings for the friction

torque measurement. The bearings have already been treated with a

special oil by the manufacturer. If the final drive gear set (pinion shaft and ring gear) is being re-

adjusted, the adjustment of the pinion shaft should be checked

Page 39

-153

.

Pa

ge 25 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18