AUDI A4 1998 B5 / 1.G 01A Transmission Input Shaft Assembly Workshop Manual

Manufacturer: AUDI, Model Year: 1998,

Model line: A4,

Model: AUDI A4 1998 B5 / 1.G

Pages: 17, PDF Size: 0.44 MB

AUDI A4 1998 B5 / 1.G 01A Transmission Input Shaft Assembly Workshop Manual

A4 1998 B5 / 1.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/1245/w960_1245-0.png

AUDI A4 1998 B5 / 1.G 01A Transmission Input Shaft Assembly Workshop Manual

Trending: tow, warning, checking oil, check oil, ECU, height, oil

Page 1 of 17

35-1

Input shaft, disassembling

and assembling

Special tools and equipment

VW222A pilot drift

VW295 needle bearing drift

VW295A needle bearing drift

VW401 thrust plate and VW402 thrust plate

VW407 punch and VW408A punch

VW415A tube and 416B tube

VW447I thrust pad

VW771 slide hammer-complete set

30-24 drift

30-100 press tube

Pa

ge 1 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

Page 2 of 17

40-105 thrust piece

40-202 press-out piece

Kukko 17/2 separating tool

Kukko 21/4 extractor

Pa

ge 2 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

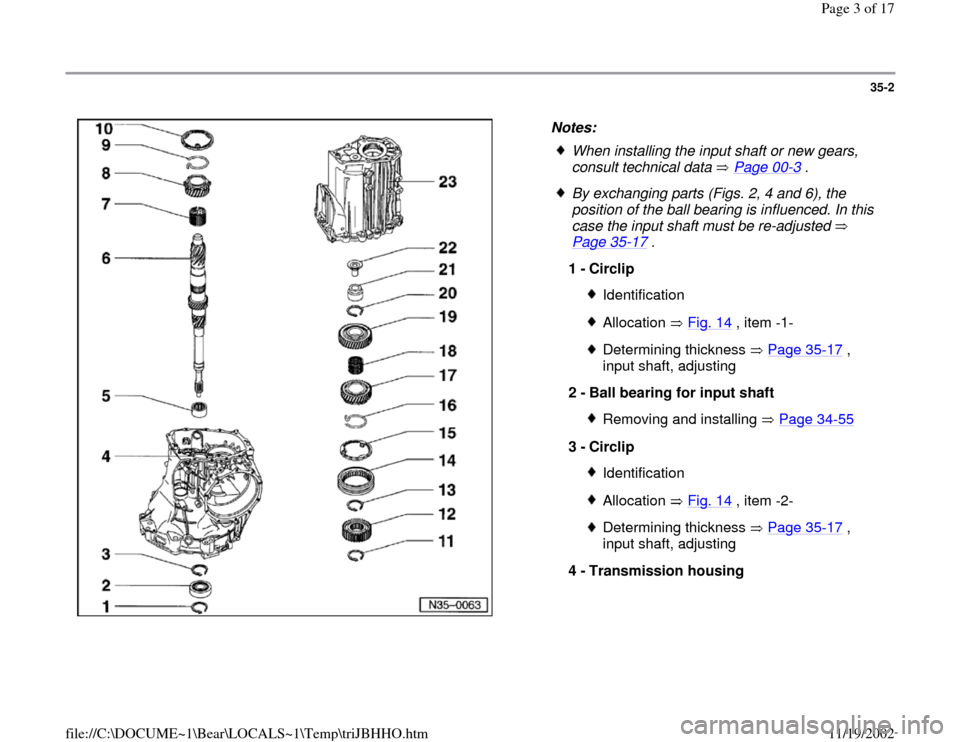

Page 3 of 17

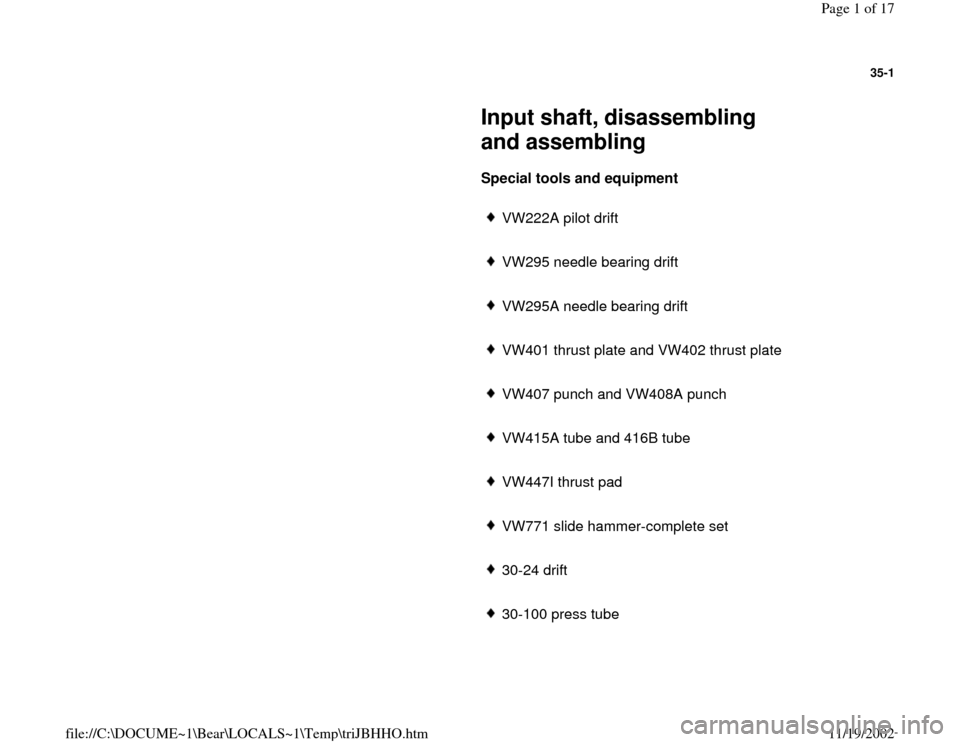

35-2

Notes:

When installing the input shaft or new gears,

consult technical data Page 00

-3 .

By exchanging parts (Figs. 2, 4 and 6), the

position of the ball bearing is influenced. In this

case the input shaft must be re-adjusted

Page 35

-17

.

1 -

Circlip

IdentificationAllocation Fig. 14

, item -1-

Determining thickness Page 35

-17

,

input shaft, adjusting

2 -

Ball bearing for input shaft

Removing and installing Page 34

-55

3 -

Circlip

IdentificationAllocation Fig. 14

, item -2-

Determining thickness Page 35

-17

,

input shaft, adjusting

4 -

Transmission housing

Pa

ge 3 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

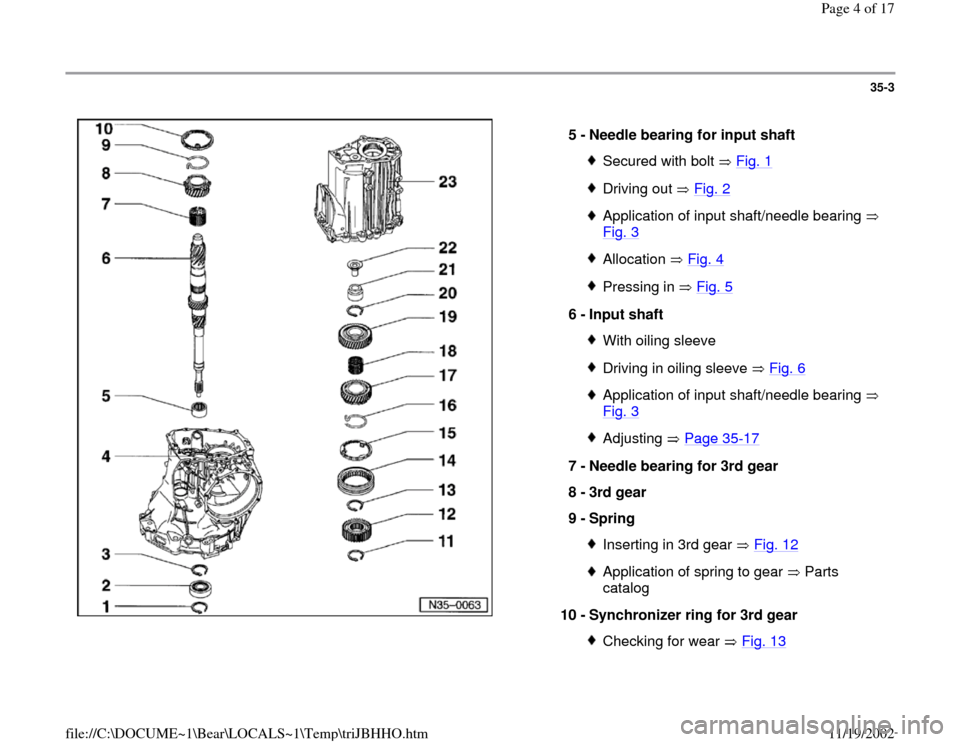

Page 4 of 17

35-3

5 -

Needle bearing for input shaft

Secured with bolt Fig. 1Driving out Fig. 2Application of input shaft/needle bearing

Fig. 3

Allocation Fig. 4Pressing in Fig. 5

6 -

Input shaft

With oiling sleeveDriving in oiling sleeve Fig. 6Application of input shaft/needle bearing

Fig. 3

Adjusting Page 35

-17

7 -

Needle bearing for 3rd gear

8 -

3rd gear

9 -

Spring

Inserting in 3rd gear Fig. 12Application of spring to gear Parts

catalog

10 -

Synchronizer ring for 3rd gear

Checking for wear Fig. 13

Pa

ge 4 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

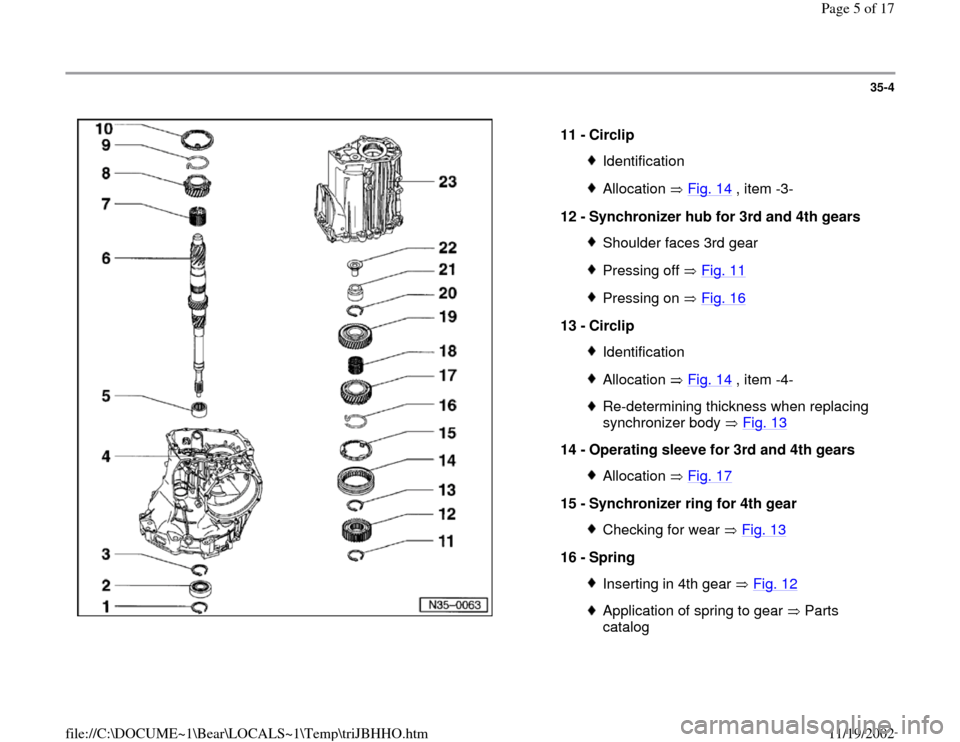

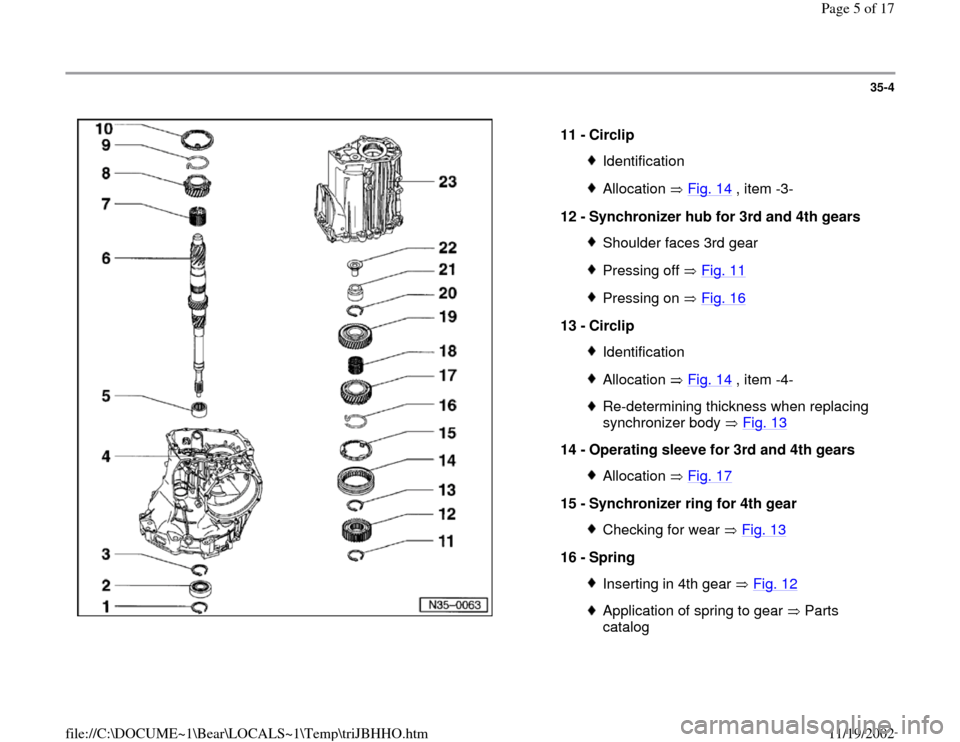

Page 5 of 17

35-4

11 -

Circlip

IdentificationAllocation Fig. 14

, item -3-

12 -

Synchronizer hub for 3rd and 4th gears

Shoulder faces 3rd gearPressing off Fig. 11Pressing on Fig. 16

13 -

Circlip

IdentificationAllocation Fig. 14

, item -4-

Re-determining thickness when replacing

synchronizer body Fig. 13

14 -

Operating sleeve for 3rd and 4th gears

Allocation Fig. 17

15 -

Synchronizer ring for 4th gear

Checking for wear Fig. 13

16 -

Spring

Inserting in 4th gear Fig. 12Application of spring to gear Parts

catalog

Pa

ge 5 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

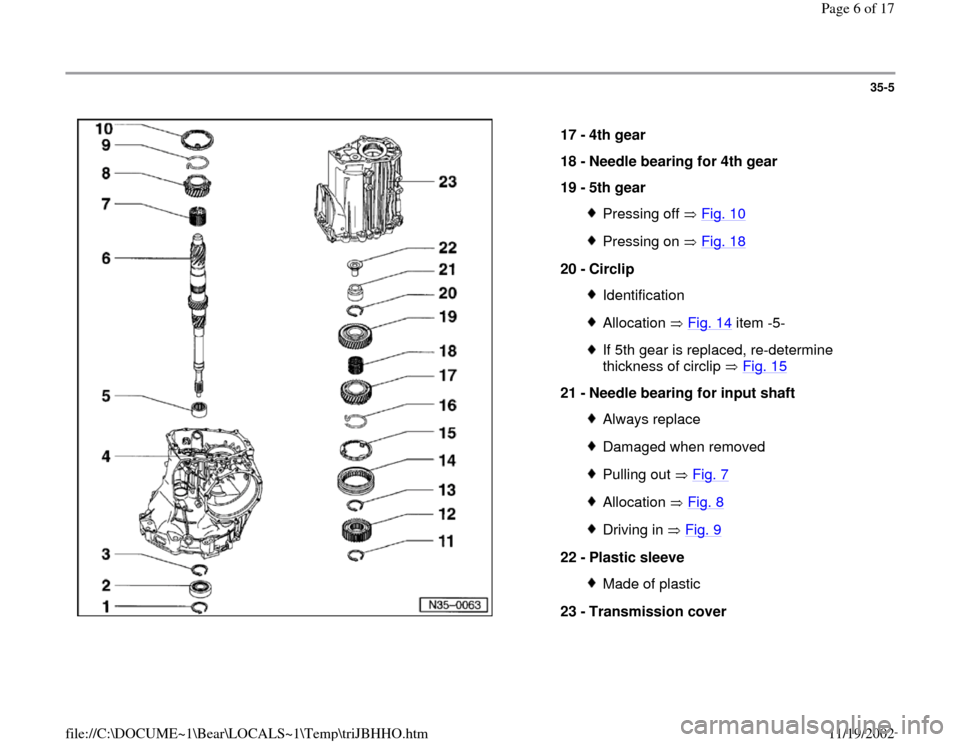

Page 6 of 17

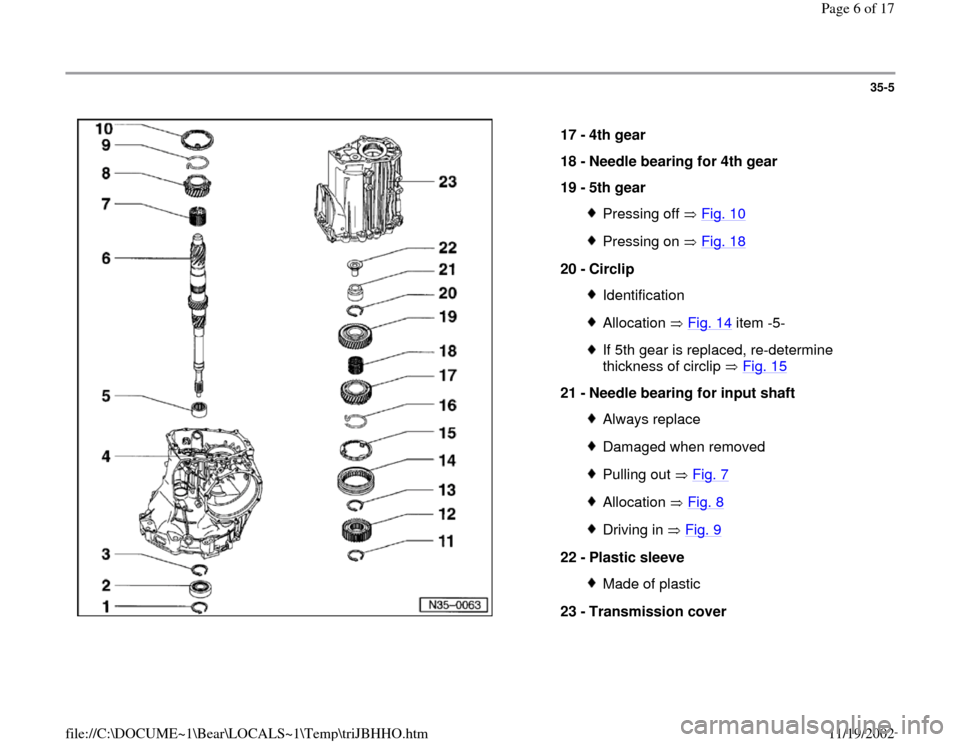

35-5

17 -

4th gear

18 -

Needle bearing for 4th gear

19 -

5th gear

Pressing off Fig. 10Pressing on Fig. 18

20 -

Circlip

IdentificationAllocation Fig. 14

item -5-

If 5th gear is replaced, re-determine

thickness of circlip Fig. 15

21 -

Needle bearing for input shaft

Always replaceDamaged when removedPulling out Fig. 7Allocation Fig. 8Driving in Fig. 9

22 -

Plastic sleeve

Made of plastic

23 -

Transmission cover

Pa

ge 6 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

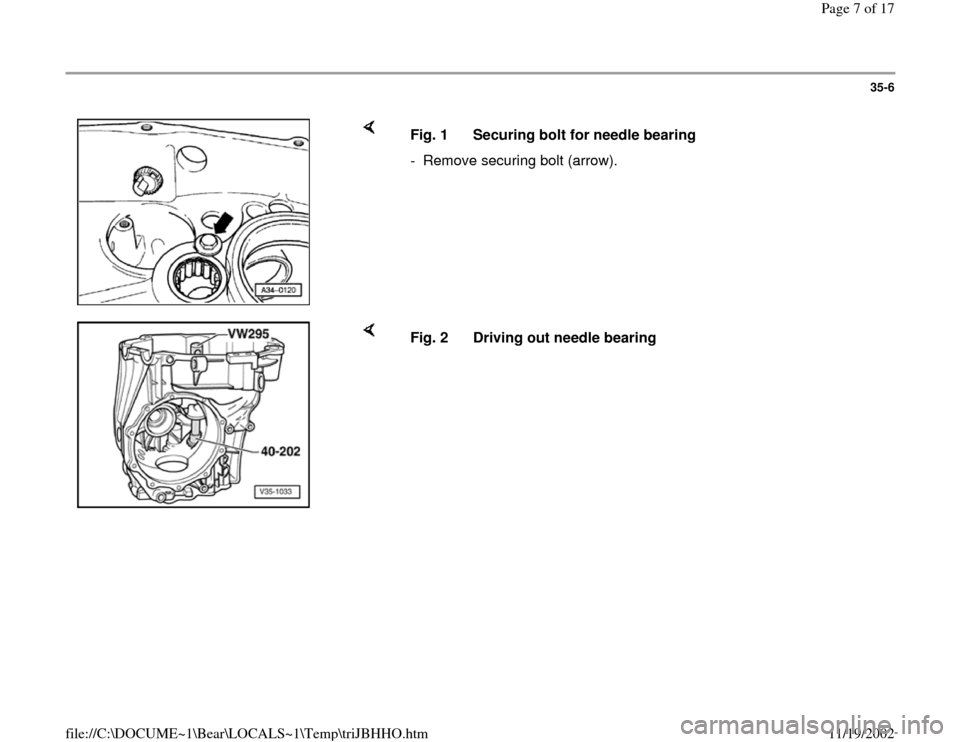

Page 7 of 17

35-6

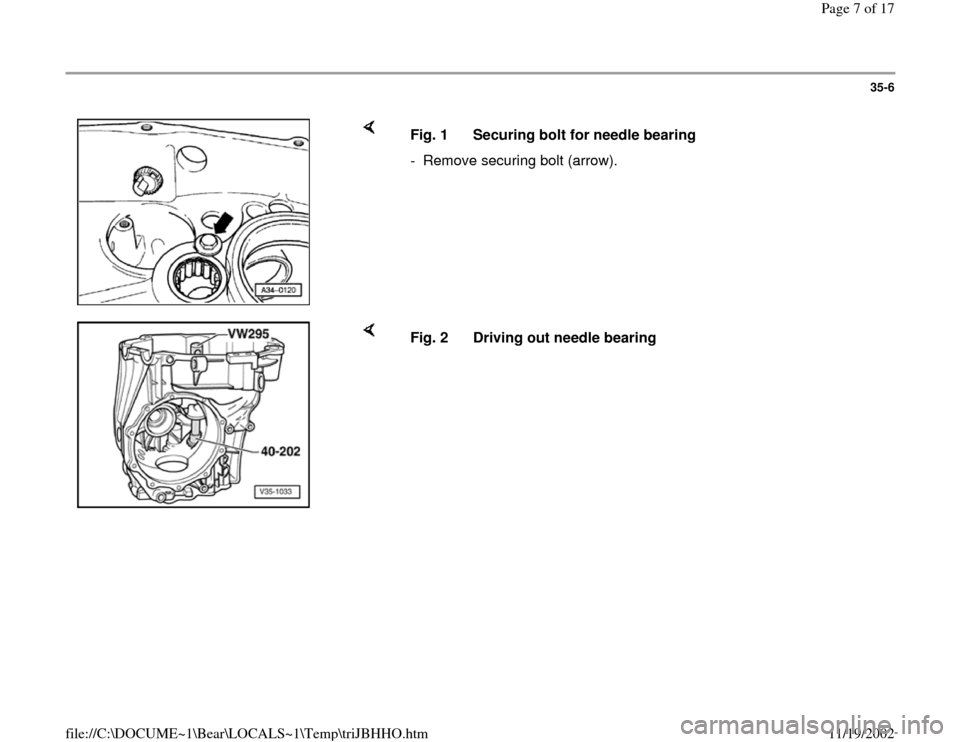

Fig. 1 Securing bolt for needle bearing

- Remove securing bolt (arrow).

Fig. 2 Driving out needle bearing

Pa

ge 7 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

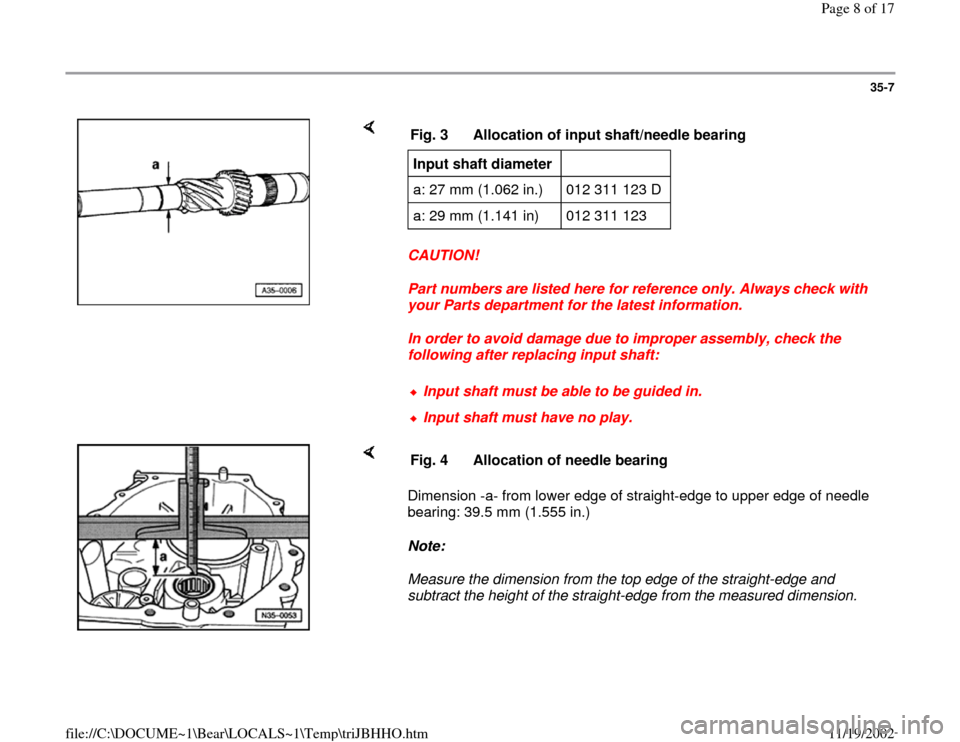

Page 8 of 17

35-7

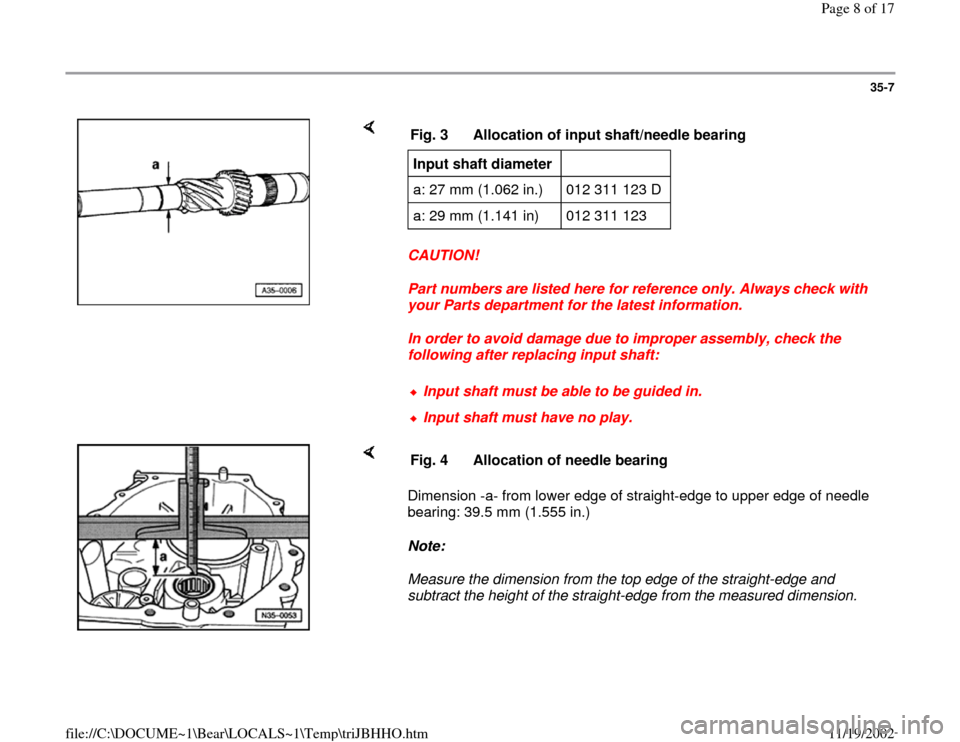

CAUTION!

Part numbers are listed here for reference only. Always check with

your Parts department for the latest information.

In order to avoid damage due to improper assembly, check the

following after replacing input shaft: Fig. 3 Allocation of input shaft/needle bearingInput shaft diameter

a: 27 mm (1.062 in.) 012 311 123 D

a: 29 mm (1.141 in) 012 311 123 Input shaft must be able to be guided in.Input shaft must have no play.

Dimension -a- from lower edge of straight-edge to upper edge of needle

bearing: 39.5 mm (1.555 in.)

Note:

Measure the dimension from the top edge of the straight-edge and

subtract the height of the straight-edge from the measured dimension. Fig. 4 Allocation of needle bearing

Pa

ge 8 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

Page 9 of 17

35-8

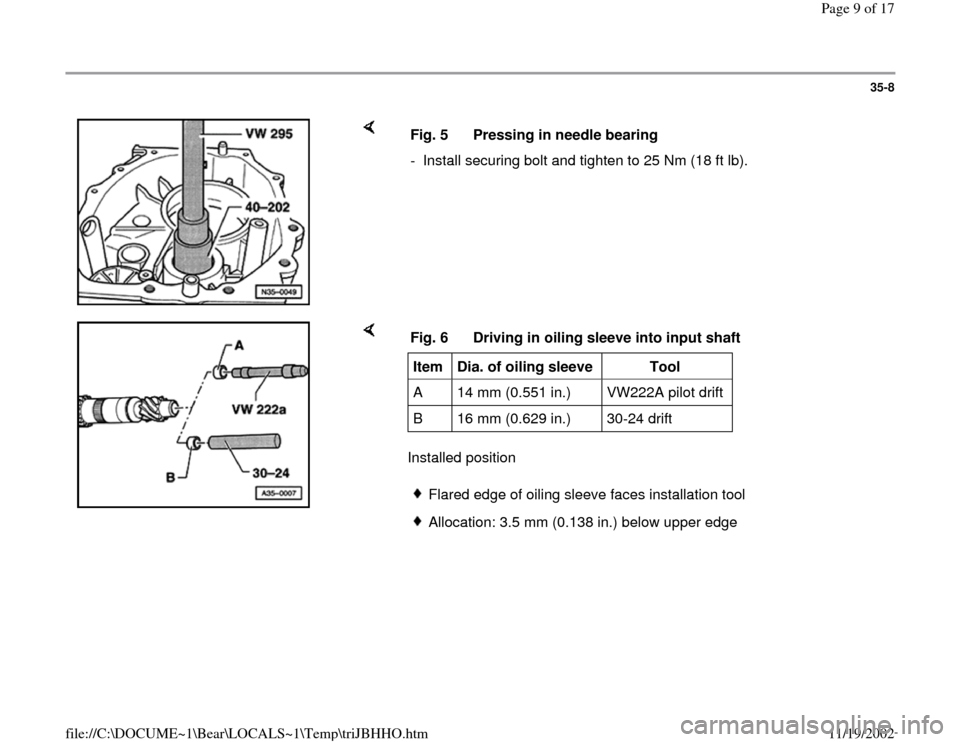

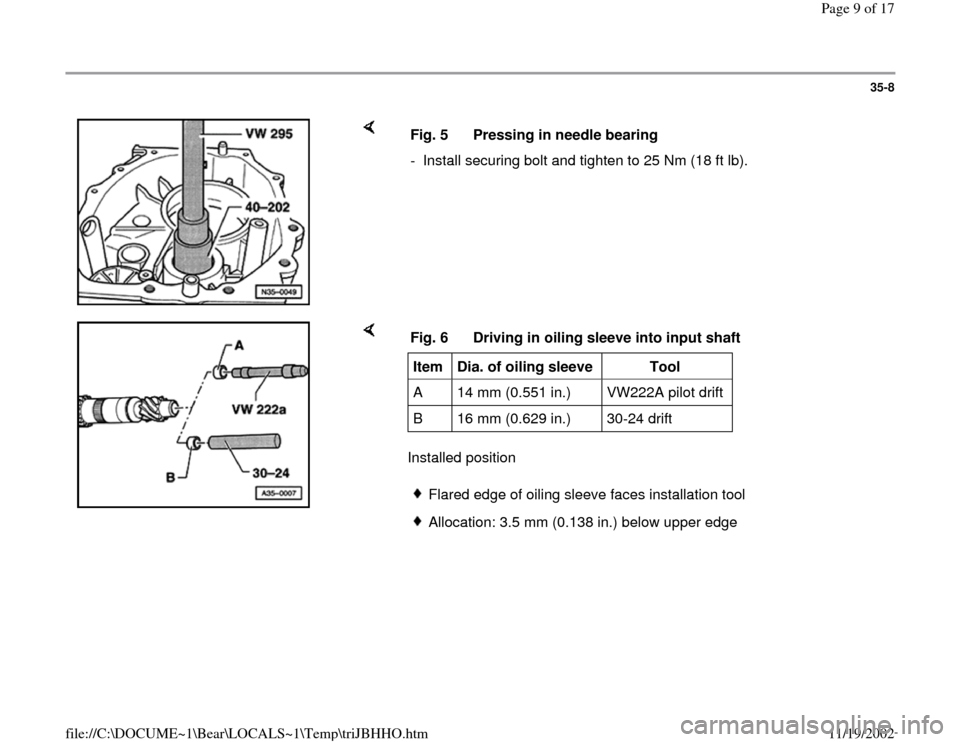

Fig. 5 Pressing in needle bearing

- Install securing bolt and tighten to 25 Nm (18 ft lb).

Installed position Fig. 6 Driving in oiling sleeve into input shaftItem

Dia. of oiling sleeve

Tool

A 14 mm (0.551 in.) VW222A pilot drift

B 16 mm (0.629 in.) 30-24 drift

Flared edge of oiling sleeve faces installation toolAllocation: 3.5 mm (0.138 in.) below upper edge

Pa

ge 9 of 17

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

Page 10 of 17

35-9

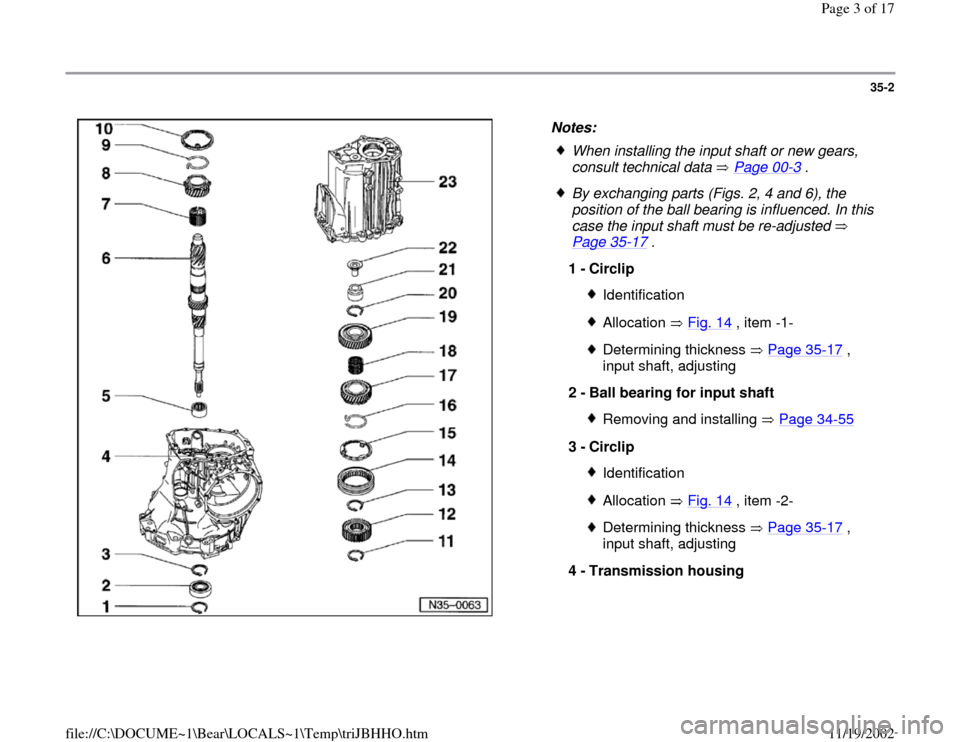

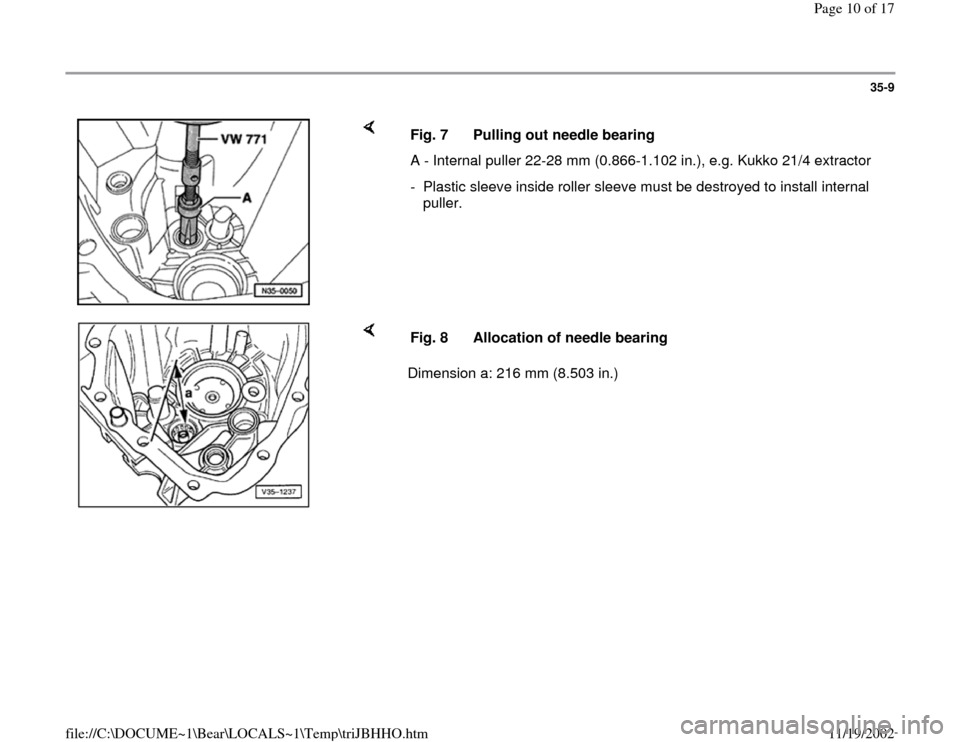

Fig. 7 Pulling out needle bearing

A - Internal puller 22-28 mm (0.866-1.102 in.), e.g. Kukko 21/4 extractor

- Plastic sleeve inside roller sleeve must be destroyed to install internal

puller.

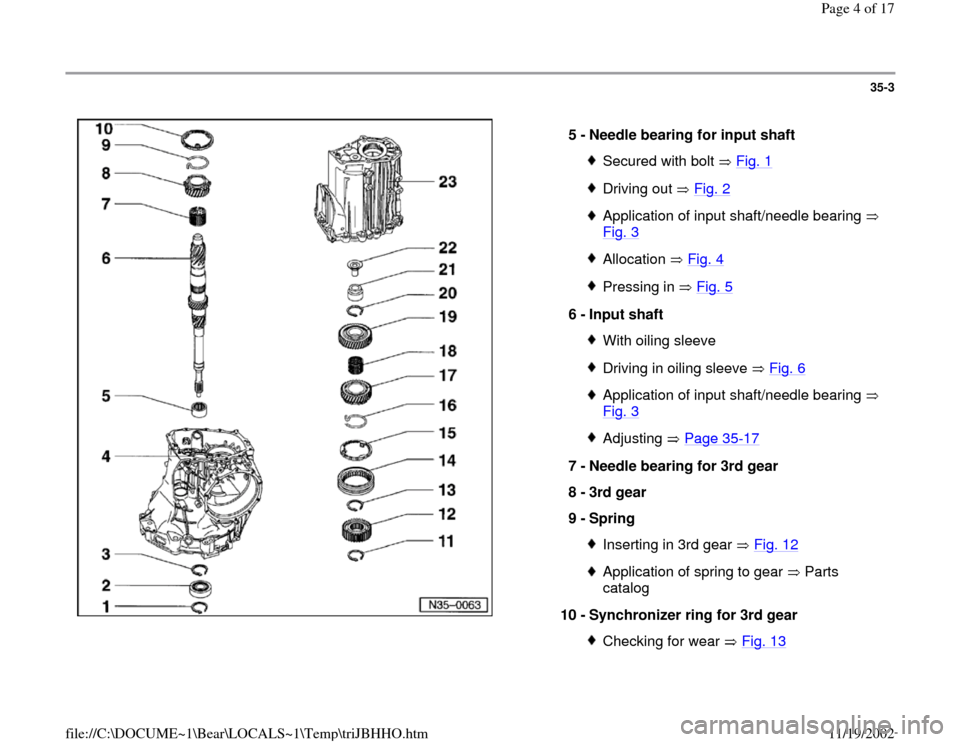

Dimension a: 216 mm (8.503 in.) Fig. 8 Allocation of needle bearing

Pa

ge 10 of 1711/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triJBHHO.htm

Trending: warning, oil, ECU, tow, checking oil, check oil, technical data