lock AUDI A6 2011 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2011, Model line: A6, Model: AUDI A6 2011Pages: 370, PDF Size: 87.15 MB

Page 320 of 370

ffll.,___W_ h_ a_t _ d_ o_ I_d_ o_ n_o _w_ ? ___________________________________________ _

What do I do now?

Trunk escape handle

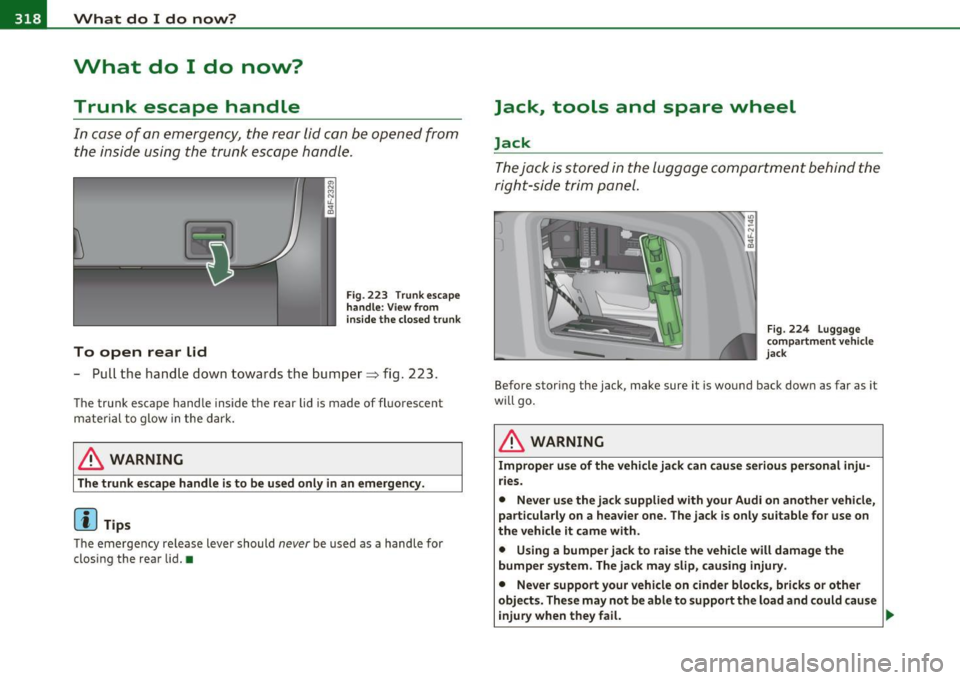

In case of an emergency, the rear lid can be opened from

the inside using the trunk escape handle.

To open rear Lid

Fig . 223 Trunk escape

handle : View from

inside the closed trunk

- Pull the hand le down towards the bumper~ fig. 223.

The trunk escape handle inside the rear lid is made of fl uorescent

material to glow in the dark.

& WARNING

The trunk escape handle is to be used only in an emergency.

(I) Tips

The emergency release lever should never be used as a handle for

closing the rear lid.•

Jack, tools and spare wheel

Jack

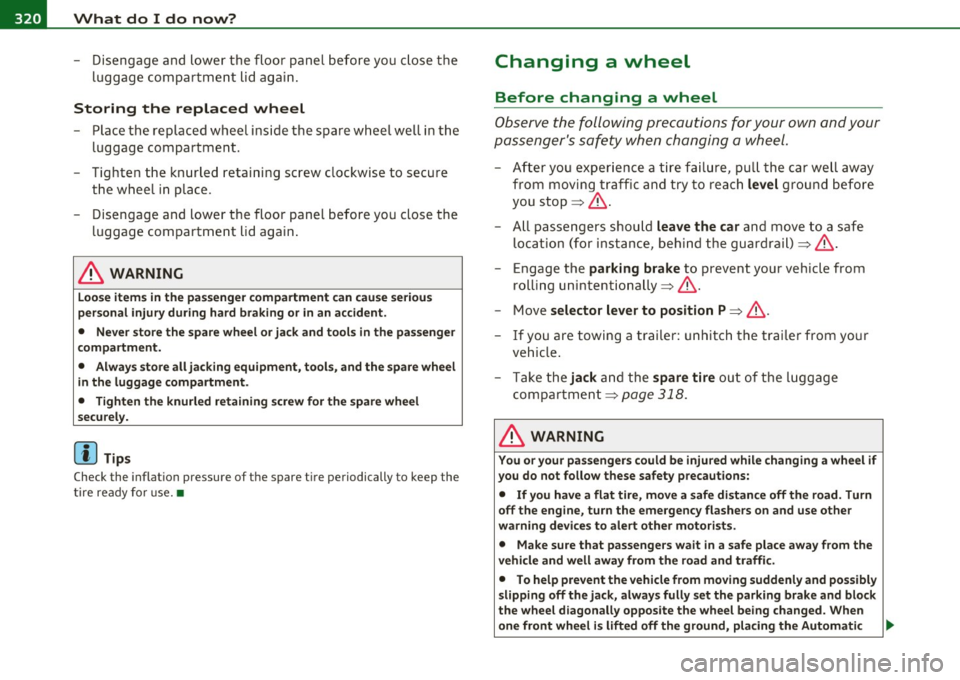

The jack is stored in the luggage compartment behind the

right-side trim panel.

Fig . 224 Luggage

c ompartment vehicle

jack

Before stor ing the jack, make sure it is wound back down as far as it

wi ll go .

& WARNING

Improper use of the vehicle jack can cause serious personal inju

ries.

• Never use the jack supplied with your Audi on another vehicle,

particularly on a heavier one. The jack is only suitable for use on

the vehicle it came with.

• Using a bumper jack to raise the vehicle will damage the

bumper system. The jack may slip, causing injury.

• Never support your vehicle on cinder blocks, bricks or other

objects. These may not be able to support the load and could cause

injury when they fail. _,,.

Page 321 of 370

What do I do now? -______________________________ ____::..:..:..:..::..::....::..::.....::.....:::...::,_ __ __,J

& WARNING (continued)

• Never start or run the engine while the vehicle is supported by

the jack.

• If you must work under the vehicle, always use safety stands

specifically designed for this purpose.

• Never use the hexagonal socket in the handle of the screw

driver to loosen or tighten the wheel bolts.

• Always make sure the spare tire and even a flat tire are secured

in place and not loose, otherwise they could fly forward, causing

personal injury to passengers in the vehicle in an accident or

sudden maneuver. •

Tools

The vehicle tools are stored in the luggage compartment

behind the right-side trim panel.

-

The onboard tool kit includes:

• Hook for removing wheel covers*

• Wheel bolt wrench

• Alignment pin for changing wheels

• Screwdrive r with reve rsible blade

Fig. 225 Luggage

compartment: vehicle

tool kit

Vehicle OP-eration

• Towing eye

[ i] Tips

Some of the onboard items listed above are provided on certain

models only or are optional extras. •

Spare wheel

The spare wheel is stored in the wheel well underneath

the floor panel in the luggage compartment.

Fig. 226 Luggage

compartment spare

wheel

Your vehicle is equipped with a regular spare wheel. It is held

in place by plastic retaining knurled screw .

Taking out the spare wheel

- Raise the floor panel at the plastic handle.

- Securely engage the handle in the luggage compartment

seal as illustrated to keep the floor panel up.

Unscrew the knurled retainer bolt in the wheel center

=> fig. 226. Turn it counter-clockwise.

- Take out the spare wheel.

Vehicle care Do-it-yourself service iTechnical data

Page 322 of 370

lffl!I.___W __ h_a_ t_ d_ o_ I_ d_ o_ n_ o_w_ ? _____________________________________________ _

- Disengage and lower the floor panel before you close the

luggage compartment lid again.

Storing the replaced wheel

-Place the replaced wheel inside the spare wheel well in the

luggage compartment.

Tighten the knurled retaining screw clockwise to secure

the wheel in place.

- Disengage and lower the floor panel before you close the

luggage compartment lid again.

& WARNING

Loose items in the passenger compartment can cause serious

personal injury during hard braking or in an accident.

• Never store the spare wheel or jack and tools in the passenger

compartment.

• Always store all jacking equipment, tools, and the spare wheel

in the luggage compartment.

• Tighten the knurled retaining screw for the spare wheel

securely.

[ i] Tips

Check the inflation pressure of the spare tire periodically to keep the

tire ready for use.•

Changing a wheel

Before changing a wheel

Observe the following precautions for your own and your

passenger's safety when changing a wheel.

- After you experience a tire failure, pull the car well away

from moving traffic and try to reach

level ground before

you stop :::> & .

- All passengers should

leave the car and move to a safe

location (for instance, behind the guardrail) :::>& .

- Engage the

parking brake to prevent your vehicle from

rolling unintentionally:::> &.

- Move

selector lever to position P :::> & .

- If you are towing a trailer: unhitch the trailer from your

vehicle.

- Take the

jack and the spare tire out of the luggage

compartment:::>

page 318.

& WARNING

You or your passengers could be injured while changing a wheel if

you do not follow these safety precautions:

• If you have a flat tire, move a safe distance off the road. Turn

off the engine, turn the emergency flashers on and use other

warning devices to alert other motorists.

• Make sure that passengers wait in a safe place away from the

vehicle and well away from the road and traffic.

• To help prevent the vehicle from moving suddenly and possibly

slipping off the jack, always fully set the parking brake and block

the wheel diagonally opposite the wheel being changed. When

one front wheel is lifted off the ground, placing the Automatic

~

Page 324 of 370

-What do I do now? PWL--....:....:..:::..::....=.::..:..:...::....:....:.___ ___________ _

Applies to veh icles : w ith deco rat ive wheel covers

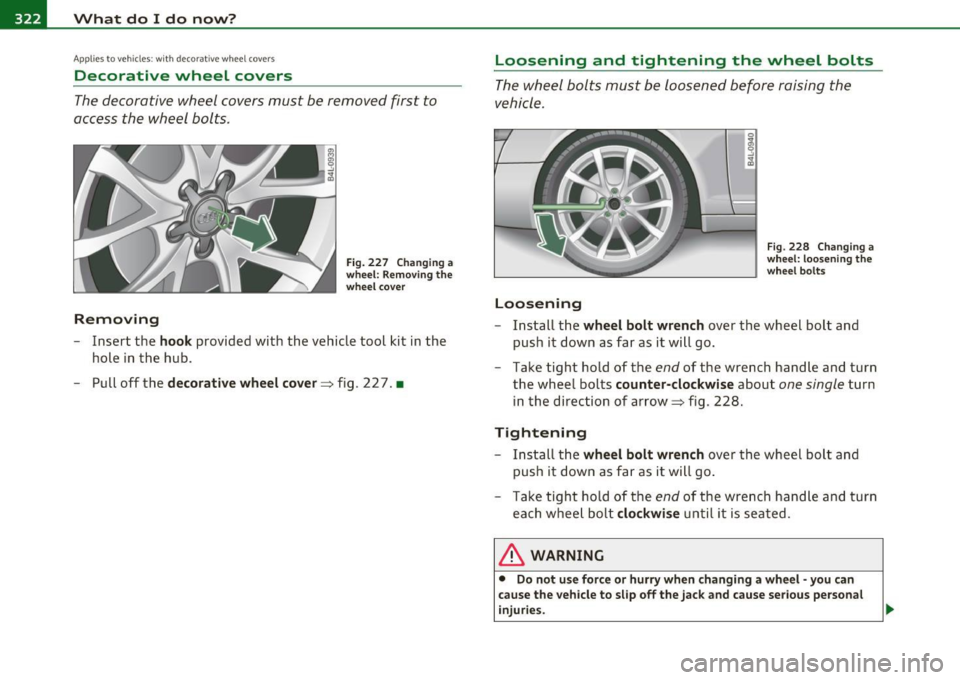

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts .

Removing

Fig. 227 Changing a

wheel: Removing the

wheel cover

-Insert the hook provided with the vehicle tool kit in the

hole in the hub .

- Pull off the

decorative wheel cover => fig . 2 2 7. •

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle.

Loosening

Fig. 228 Changing a

wheel: loosening the

wheel bolts

-Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

the wheel bolts

counter-clockwise about one single turn

in the direction of arrow=> fig . 228.

Tightening

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

each wheel bolt

clockwise until it is seated.

& WARNING

• Do not use force or hurry when changing a wheel -you can

cause the vehicle to slip off the jack and cause serious personal

injuries.

Page 327 of 370

What do I do now? -________________ Vf'.'11

- Screw the threaded end of the alignment pin from the

tool kit hand-tight into the empty bo lt hole~

page 324,

fig. 232.

- Then re m ove the o ther wheel bolts as described above.

- Take off t he w heel leaving the alignment pin i n the bolt

hole.

Putting on the spare wheel

- Lift the spare wheel and carefully slide it over the alig n

ment pi n to guide it in p lace .

- Use the hexagona l socket in the screwdriver handle to

screw in and tighte n all w heel bolts

slightly.

- Remove the alig nment pi n and inse rt an d tighten the

remaining wheel bolt slig htly like the rest.

- Turn the jac k han dle counter-c lockwise to lower the

ve hicle u ntil the jack is fully released.

- Use the wheel bolt wrench to t ighten all whee l bolts firmly

~ page 322. Ti ghten them crosswise, from one bolt to

the (approximately) opposite one, to keep the w heel

centered.

[I] Tips

Never use the hexagonal socket i n the handle of the screwdriver to

loosen or tighten the wheel bolts.

• Pull the reve rsible blade from the screwdriver before yo u use the

hexagonal socket in the handle to t urn the whee l bolts.

• When mounting tires with

unidirectional tread design make sure

t he tread pa ttern is po inted the right way~

page 325.

Safety first

• The wheel bolts should be clea n and easy to turn. Check for dirt

and cor rosion on the mat ing surfa ces o f bo th the whee l and the hub.

Remove all d irt from these surfaces before remounting the wheel. •

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their trea d pattern pointed in the right direction .

Using a spare tire with a tread pattern intended for

use in a specific direction

When using a spare tire w ith a tread pattern intended for use in a

specific direction, p lease note the fo llow ing:

• T he direct ion of rotation is marked by an ar row on the s ide of the

tire.

• If the spare tire has to be installed in the incor rect d irect ion, use

the spare tire only tempo rari ly since the tire wi ll not be ab le to

achieve its optimum pe rforma nce charact erist ics with rega rd to

aquaplaning, noise and wear.

• We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

condit ions.

• Replace the flat t ire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirect iona l tire .•

Notes on wheel changing

Please read the information~ page 307, "New tires and replacing

t ires and wheels" if yo u are go ing to use a spa re t ire wh ich is d iffe rent

from the tires on yo ur vehicle .

After you c hange a ti re:

• Check the tire pressure on the spa re immediately after installa-

tion. ..,

Vehicle care Do-it-yourself service Technical data

Page 330 of 370

-L_!F~U:!_:S~ e~ s ~ a~ n~ d~b~ u~l~b ~s ~-------------------------------------------

Fuse assignment, cockpit driver's side

Fig. 234 Cockpit

driver's side: fuse

panel layout

No. Consume r

3 Engine management

4

5

6

7

8

9

10

12

13

Oil level sensor

Climate control, tire pressure monitoring sys

tem Electronic Stabilization Program (ESP), clutch

sensor

Diagnostic connector

Homelink control unit

Automatic dimming interior mirror

Adaptive Cruise Control Diagnostic connector

Switch module steering column

15 Instrument cluster, control module Gateway

16 Telephone, cell phone

17 Electronic Stabili zation Program (ESP)

18 Headlight electronics, left-side

Amps

5

5

5

5

5

5

s

5

10

10

10

5

10

5

No. Con sum er

19 Rain sensor

20 Heated washer nozzles

21 Seat adjustment (driver)

22 MMI display

23 Electromechanical park ing brake

31

32

33

34

36

37

38

39

40

41

42

43

Back-up light switch, transmission, engine com

ponents

I ntelligent power module driver (footwell light

and front headlights , horn, wiper system, elec

trically adjustable steering wheel)

Intelligent power module driver (lights left-side)

I ntelligent power module driver

(lights right-side)

Headlight washer system

Electronic Stabilization Program (ESP)

Wiper system Door control module left-side

Horn

Heater fan

Control module electronic ignition lock/elec tri

cally adjustable steering wheel

Rear windshield wiper (Avant)

44 Power window opener (left-side)

Amps

5

5

10

5

5

15

30

25

25

30

25

30

15

25

40

30

15

35

-

•

Page 331 of 370

______________________________________________ F _u_s _e_ s_ a_ n_ d _ b _u_l_b _ s_---J _

Fuse assignment, cockpit passenger's side

No . Consumer

Fu se pa nel (bl ack )

1 Control module Convenience key

2 Cigarette lighter front

3 Tire pressure monitoring system

4 Electrical outlet front (center console)

5 Intelligent power module passenger

(glove box lock)

6 Door control module right-s ide

7 Sunroof

8 A/C cont rols

9 Heated seats, front

10 MMI

11 Seat adjustment (passenger)

12 Communication

Fu se pan el (brown )

1 Electr ic fuel pump

Fig . 235 Cockp it

passenger 's side : fuse

pa nel layo ut

Amps

15

20

5

20

15

15

-

20 1 0

30

7 ,5

10

5

20/30

Vehicle OP-eration

No. Consume r .,

2 Adaptive Air Suspension

3 Lane assist

4 Audi side assist

S Adaptive Air Suspens ion

6 Shift gate automatic transmission/clutch switch Parking System

9

10 Control module Gateway

Automatic headlight range control (a

uxiliary

driving lights) , headl ight electronics, right -side

Airbag

11 Heated rear seats

12 Telephone

Amps

15

10

5

5

5

5

5

5

5

5

5

Fuse assignment , luggage compartment

right

F ig. 236 R ight

luggage compartment:

fuse pane l layo ut

Re ad nu mber s of the fuses in the l ug ga ge comp art men t sta rti ng

from below ~ fig . 236.

•

Vehicle care Do-it-yourself service Technical data

Page 336 of 370

lffll.___E_ m_ e_r -=g =- e_ n_c -=y ;..._ s_i_t _u _a _ t_ i_ o _ n_ s ____________________________________________ _

Connect POSITIVE(+) to POSITIVE(+) (red)

- Open the red cover o n the posi tive po le => page 333,

fig . 237 .

1. Connect one end of t he positive cable (red) on the

jump

start bolt=>

page 333, fig. 238 (D (B olts under red cove r

= "positive") of t he vehicle to be star ted @.

2. Con nect t he ot her end to t he positive terminal @ of t he

booster battery @.

Connect NEGATIVE(-) to NEGATIVE(-)

(black)

3 . Co nnect one end to th e n egative t ermin al@ of t he

b oost er batter y@ .

4. Con nect the o ther e nd of th e nega tiv e cabl e (b la ck) to the

jump start bolt© (Bolts wi th hex hea d= "n ega tiv e") of

the v ehic le t o b e sta rted

@ .

Starting the engine

- S ta rt the e ngi ne of t he ve hic le with the booster battery.

R un the e ngi ne at a moderate speed.

- Star t engi ne wi th discha rged vehi cle battery in the usual

ma nner.

- If the engine fails to start: do not keep t he star ter

c ran kin g f or l onge r tha n 1 0 seco nds . W ait f or a bo ut

3 0 seco nds an d the n try aga in .

- Wi th eng ine ru nn ing , rem ove jum per cables from bot h

v ehic les i n the exact

re ve rs e orde r.

- C lose the red cover on the posi tive po le.

The battery is vented to the outside to prevent gases from enter ing

th e ve hicl e int erior. Ma ke sure th at th e jum per cl amp s are well

connected w ith t he ir

metal parts in full contact w ith the batte ry

terminals .

& WARNING

To avoid serious personal injury and damage to the vehicle, heed

all warnings and instructions of the jumper cable manufacturer. If

in doubt, call for road service.

• Jumper cables must be long enough so that the vehicles do not

touch.

• When connecting jumper cables , make sure that they cannot

get caught in any moving parts in the engine compartment .

• Before you check anything in the engine compartment, always

read and heed all WARNINGS~

page 271, "Engine compart

ment ".

0 Note

Improper hook-up of jumpe r cables can ruin the generator.

• Always connect POSI TIVE(+) to POSI TIV E(+ ), and NEGA TIVE( -)

to NEGATIVE( -) ground post of the batte ry manage r contro l unit.

• Check t hat all sc rew p lugs on the battery cells are screwed in

firmly . If not, tighten plugs prior to co nnecting clam p on negative

battery terminal.

• P lease note th at the p roce dure for connec ting a jumper cab le as

described

a bove ap pli es specifically to the case o f yo ur vehicle be ing

jump starte d. When you are giving a j ump sta rt to anot her vehicle, do

not con nect the negative (-) cab le to t he negat ive (-) termina l on the

discharged battery ©~

page 333, fig. 238. Instea d, secure ly

c o nnec t the neg ative (- ) cable to ei ther a soli d met al c o m ponen t that

is firm ly bolted to the eng ine b lock or to the eng ine b lock itself .

If the

b att ery th at is being ch arged does not

ven t to th e ou tside, es caping

battery gas could ignite and exp lode! •

Page 340 of 370

lffll.___E_ m_ e_ r-' g=- e_n_ c=-y _ s_it _ u _ a_t_ i_ o _ n_ s ______________________________________________ _

in. WARNING

• To reduce the risk of serious injury and vehicle damage.

-Always lift the vehicle only at the special workshop hoist and

floor jack lift points illustrated=>

page 337, fig. 243 and

=>

page 337, fig. 244.

- Failure to lift the vehicle at these points could cause the

vehicle to tilt or fall from a lift if there is a change in vehicle

weight distribution and balance. This might happen, for

example, when heavy components such as the engine block or

transmission are removed.

• When removing heavy components like these, anchor vehicle

to hoist or add corresponding weights to maintain the center of

gravity. Otherwise, the vehicle might tilt or slip off the hoist,

causing serious personal injury.

0 Note

• Be aware of the following points before lifting the vehicle :

-The vehicle should never be lifted or jacked up from under

neath the engine oil pan, the transmission housing, the front or

rear axle or the body side members. This could lead to serious

damage.

- To avoid damage to the underbody or chassis frame, a rubber

pad must be inserted between the floor jack and the lift points.

- Before driving over a workshop hoist, check that the vehicle

weight does not exceed the permissible lifting capacity of the hoist.

- Before driving over a workshop hoist, ensure that there is sufficient clearance between the hoist and low parts of the

vehicle. •

Page 350 of 370

___ C=-.:: o...:.n...:. s =-.:: u:..:m...:....:. e.::..:.. r:....: I:.. n:...:....:. f...:.o :....:r...:. m...:....:. a.::.:....:: t...:.io .::..:. n-=-----------------------------------------------

& WA RNING (conti nu ed )

• Always rem ove the ignition key before anyone get s under the

vehicle .

• Always support your vehicle with safety stands if it i s nece ssary

to work underneath the vehicl e. Th e jack supp lied with the vehicle

is not adequate for thi s purpose and could collap se causing

seriou s personal injury .

• If you must work underneath the vehicle with the wheels on

the ground, a lway s make sure the vehicle is on level ground, that

the wheels are alway s securely blocked and that the engine cannot

be started .

• Always make sure the transmi ssion selector lever (automatic

tran smission ) is in "P " (Park po sition ) and the park brake is firmly

applied.

For the sake of the environment

• Changing the engine settings will adversely affect emission levels .

Thi s is det rimenta l to the envi ronme nt and increases fue l co nsump

tion.

• Always observe enviro nmental regulations when disposing of old

engine oi l, used brake fl uid, dirty engine coo lant, spent batteries or

worn out t ires.

• Undep loyed a irbag modules an d pretens ioners migh t be classified

as Pe rchlorate Mater ia l -spec ial handling may apply, see

www.dtsc.ca.gov/hazardouswaste/perchlorate . When the vehicle or

parts of the rest raint system includ ing a irbag modu les safety belts

w ith pretens ioners are scrapped, all applicable laws and regulat ions

must be obse rved. Yo ur author ized Aud i dealer is f amiliar wi th t hese

req uirements and we recommend that you have your dealer perform

t his se rvi ce f or yo u.•

Additional accessories,

modifications and parts

replacement

Additional accessories and parts replacement

A lways consult an autho riz ed Au di dealer bef ore

purchasing access ories.

Your vehicle incorporates the latest safety desig n featu res ens uring a

hig h standard of active and passive safety .

Th is safety co uld be compromised by non-app roved changes to the

vehicle. Fo r this reaso n, if par ts have to be replaced, p lease observe

the following points when installing addit ional accessories :

Approved Audi accessories and genuine Aud i parts are available from

author ized Aud i dea lers.

T hese dea lers a lso have the necessary fac ilities, tools and tra ined

specialists to i nstall the parts and a ccessor ies p roperly.

& WARNING

Using the wrong spare parts or u sing non-approved acces sorie s

can cause damage to the vehicle and serious personal injury.

• Use only accessories expressly approved by Audi and genuine

Audi spare parts

• These parts and accessories have been specially designed to be

used on your vehicle .

• Never install accessories such as telephone cradles or beverage

holder s on airbag covers or within the airbag deployment zones .

Doing so will increase the r isk of injury if airbags are triggered in

an accident!

• Before you check anything in the engine compartment , always

read and heed all WARNINGS~

page 271. _..