transmission AUDI A6 2012 Owner's Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2012, Model line: A6, Model: AUDI A6 2012Pages: 298, PDF Size: 74.43 MB

Page 268 of 298

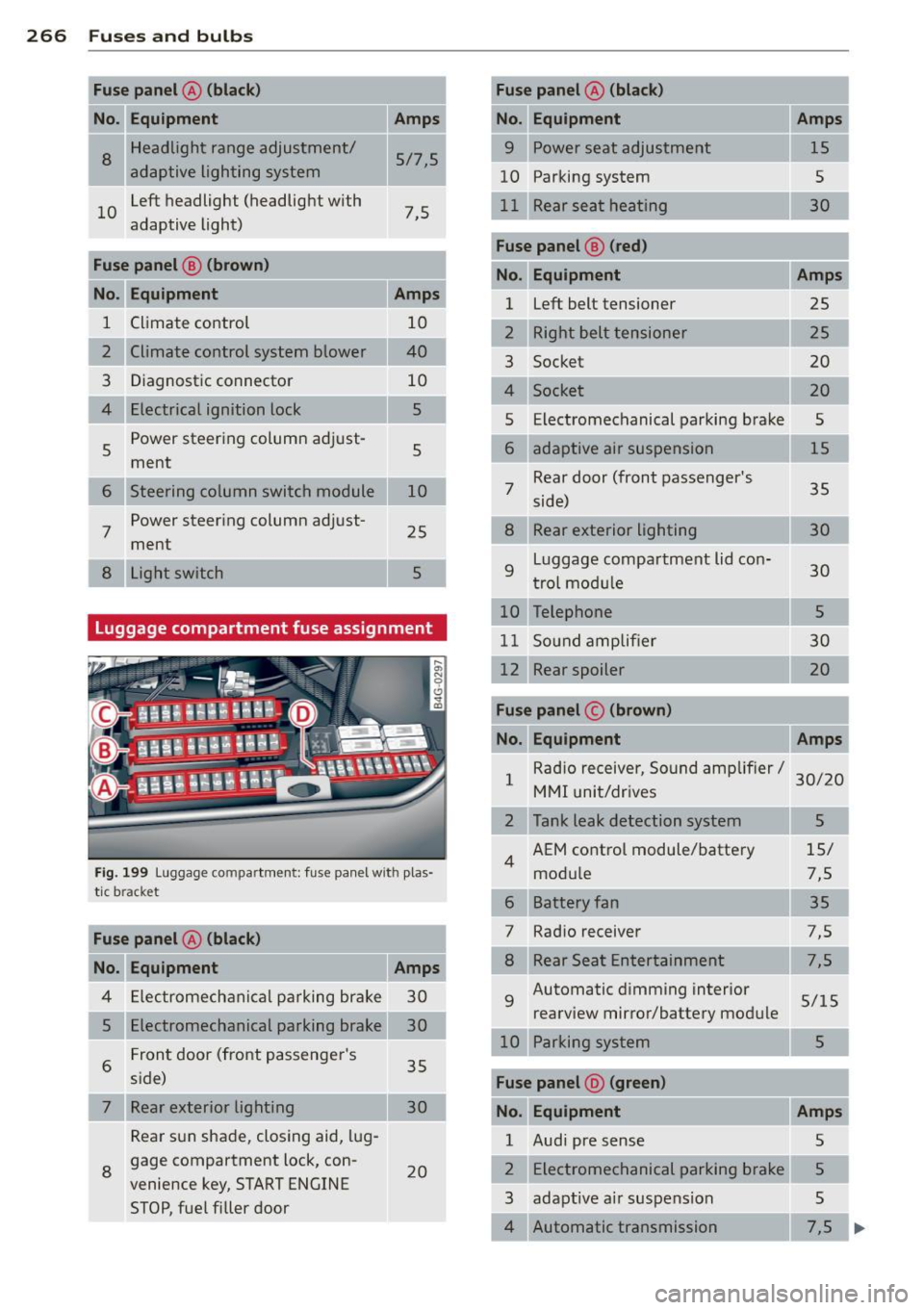

266 Fuses a nd bulb s

Fuse panel @ (black )

No . Equ ipment Amps

=

8

Headlight range adjustment/

5/7,5

adaptive lighting system

10 Left headlight (headlight with

7,5

adaptive light)

Fuse p anel

@ (brown )

No .II Equ ipm ent

II Amp s

1 Climate control 10

2 Climate control system blower 40

3 Diagnostic connector 10

4 Electrical ignition lock 5

5 Power steering column adjust-

ment

5

Steering column switch module 10

7 Power steer

ing column adjust-

ment 25

8 Light switch

Luggage compartment fuse assignment

Fig. 199 Luggage compartment: fuse panel with plas·

tic bracket

Fuse panel @ (bl ack )

No. II Equipment

I[ Amp s

4 E lectromechanical parking brake 30

5 Electromechanical parking brake 30

6 Front door (front passenger's

35

side)

7 Rear exterior lighting Rear sun shade, closing aid, lug

s gage compartment lock, con

venience key, START ENGINE

STOP, fuel filler door 30

20

-Fuse pane

l@ (blac k) I

No. Equipm ent Amps

=· 9 Power seat adjustment 15

10 Parking system

s

30

Fus e pane l

B (red)

No . Equipment Amps

1 Left belt tensioner

25

Right belt tensioner 25

3 Socket 20

20

Electromechanical parking brake

5

adaptive air suspension 15

7 Rear door (front passenger's

35

side)

Rear exterior lighting 30

9

Luggage compartment lid con-

30

t rol module

10 Telephone 5

11 Sound amp lifier 30

12 Rear spoiler 20

Fuse pane l c (b rown )

No. Equipment Amps

1 Rad

io receiver, Sound amplif ier/

30/20

MMI unit/dr ives

2 Tank leak detection system 5

AEM control module/battery 15/

4

module 7,5

6 Battery fan 35

Rad io receiver

7,5

7,5

9

Automatic dimming interior

5/15

rearview mirror/battery module

Parking system 5

Fu se pan el o (gre en)

No. Equipment Amps

1 Audi pre sense 5

2 Electromechanical parking brake 5

3 adaptive a

ir suspension

5

Automatic transmission 7,5

...

Page 270 of 298

268 Emergency situations

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equipment to

perform these ope rations.

Starting by pushing or

towing

Q;) Note

Vehicles w ith an automatic transmission

cannot be started by pus hing o r tow ing.

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumpe r cables to start the en

g ine .

Jumper cables

Use only jumper cables of sufficiently large

cross section to carry the starter current safe

ly. Refer to the manufacturer's specif ications.

Use only jumper cables with

insulated termi

na l clamps which are distinctly marked:

plus(+) cable in most cases colored red

minu s(-) cable

in most cases colored black .

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal

inju ry. Follow the instructions below for

safe handling of your veh icle's battery.

- Always shield you r eyes and avoid lean

ing over the battery whenever possible.

- A discharged battery can freeze at tem

peratures just be low 32 °F (0 °C). Before connecting a

jumper cable, you must

thaw the frozen battery complete ly, oth

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin. Flush any contacted area with

water immediately.

- Improper use of a booster battery to start a vehicle may cause an explosion.

- Vehicle batteries generate explosive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any vehicle with a low acid level in the battery.

- The vo ltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery . Use of batteries of d ifferent voltage

or substantially different "Ah" rating

may cause an exp losion and personal in

jury.

- Never charge a frozen batte ry. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batter ies of different voltage or

substantially different capacity (Ah) rat

ing may cause an exp losion and injury.

The capacity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed a ll

WARNINGS¢

page 214, Engine com

partment.

«I) Note

-Applying a higher voltage booster bat

tery will cause expensive damage to sen

sitive electronic components, such as

contro l units, relays, rad io, etc.

- There must be no electrical contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

positive(+) terminals are connected. ..,_

Page 272 of 298

2 70 Emergency situations

-When connecting jumper cables, make

sure that they cannot get caught in any

moving parts in the engine compart

ment.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS c:>

page 214, Engine com

partment.

(D Note

Improper hook-up of jumper cables can ru

in the generator.

-Always connect POSITIVE(+) to POSI TIVE(+), and NEGATIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery

cells are screwed in firmly . If not, tighten

plugs prior to connecting clamp on nega

tive battery terminal.

- Please note that the procedure for con

necting a jumper cable as described

above applies specifically to the case of

you r vehicle being jump started. When

you are giving a jump start to another ve

hicle, do

not connect the negative(-) ca

ble to the negative(-) terminal on the

discharged battery@c:>

fig. 201. In

stead, securely connect the negative(-)

cable to either a solid metal component

that is firmly bolted to the engine block

or to the engine block itself. If the bat

te ry that is being charged does not vent

to the outside, escaping battery gas

could ignite and explode!

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

tng.

The follow ing information is to be used by

commercia l tow truck operators who know

how to operate their equipment safely.

-Never tow your Audi. Towing will cause

damage to the engine and transmission .

- Never wrap the safety chains or winch ca

bles around the brake lines.

- To prevent unne cessary damage , your Audi

must be transported with a flat bed truck.

- To load the vehicle on to the flat bed, use

the towing loop found in the vehicle tools

and attach to the front or rear anchorage

c:>page 270 and c:>page 271.

.&_ WARNING

=

A vehicle being towed is not safe for pas-

-

sengers. Never allow anyone to ride in a

vehicle be ing towed, for any reason.

Front towing loop

Only install the front towing loop when it is

needed.

Fig. 202 Front bumpe r: cove r

Fig. 203 Front bumper: installing the towing loop

There are threads located behind the right

s ide of the front bumper where a towing loop

can be installed. The threads are located be

hind a cover.

.,. Remove the tow ing loop from the vehicle

tool kit.

Page 274 of 298

272 Emergency situations

@ Tips

Check carefully to make sure the hook- up

is sec ure before moving the ca r up the flat

bed truck ramp.

Lifting vehicle

Lifting with workshop hoist and with

floor jack

T he vehi cle may only be li~ed at the lifting

points illustra ted .

Fig. 207 Fr ont lift in g po int

Fi g. 208 Rear lift ing point

• Read and heed WARNING q &_ .

• Locate lifting points q fig. 207 and

qfig. 208.

• Adjust lift ing arms of workshop hoist or

floor jack to match vehicle lifting points.

• Inse rt a r ubber pad betw een the floor jack/

wor kshop hoist and the lifti ng points.

If you must lift your vehicle with a floor jack

to work underneath, be sure the vehicle is

safely supported on stands intended for thi s

purpose .

Front lifting point

The lifting point is located on t he floor pan re

i n forcement about at the same level as the j

ac k mounting po int

~ fig. 20 7. Do not lift

the veh icle at the vertical sill reinforcement .

Rear lifting point

The lifti ng po int is located o n the vert ica l rein

f orcemen t of the lowe r sill for the on- boar d

j a ck

q fig . 208.

Lifting with vehicle jack

Refer to ¢ page 261.

A WARNING

-- To reduce the risk of s erio us injury and

ve hicl e damage.

- Always lift the vehicle only at the spe

c ia l workshop hoist and floor jack lift

po ints illustrated

¢ fig. 207 and

q fig. 208.

-Fail ure to lift the ve hicle at these

po ints could cause the vehicle to tilt or

fall from a lift if there is a change i n ve

h icle weight distribution and balanc e.

T his mig ht happen, fo r example, whe n

h eavy com ponen ts such as the eng ine

b lo ck o r trans mission a re remove d.

- W hen removi ng heavy compone nts like

t hese, anch or vehicle to h oist or ad d cor

resp onding we ig hts t o main tain t he cen

t er of gravity. Oth erwise, t he ve hicle

might tilt or slip off the ho ist , ca using

serio us personal injury.

(D Note

- B e aw are o f the followin g poin ts before

li ft ing t he vehicle:

-The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission housing, the

front or rear axle or the body side

members. This could lead to serious

damage .

- To avoid damage to the underbody or

chas sis frame, a rubber pad must be

inserted between the floor jack and

the lift points.

-

- Before driving over a workshop hoist,

check that the vehicle weight doe s not .,..

Page 276 of 298

2 7 4 General information

General information

Explanation of

technical data

Some of the technical data listed in this man

ual requires further explanation .

The technical data for your vehicle is listed in

the charts starting on

r:::> page 2 76. This sec ·

tion provides general information, notes and restrictions which apply to this data .

Vehicle identification

The key data is given on the vehicle identifica·

tion number (VIN) plate and the vehicle data

sticker.

Fig. 209 Veh icle Ide ntific atio n Number (VlN) p late: lo

cation on driver 's sid e das h panel

Fig. 210 Th e vehicle identi fication label -inside the

luggage co mpa rtmen t

The Vehicle Identification Number (VIN)

is located on the driver's side so that it is visi

b le from the outside through the windshield

r:::> fig . 209. You can also display the Vehicle

Identification Number of your vehicle in the

MMI. Select: Function button

ICAR ! > Car sys

tems

> VIN number . The

vehicle identification label

is located in the luggage compartment in the

spare wheel wel l.

The label¢

fig. 210 shows the following vehi

cle data :

(D Production control No .

@ Vehicle identification No.

® Type code number

@ Type designation/engine output in Kilo·

watts

® Engine and transmission code letter

@ Paint No./Interior

(f) Optional equipment No.'s

Vehicle data 2 to 7 are also found in your War·

ranty

& Maintenance booklet.

The safety compliance sticker

is you r assurance that your new vehicle com

plies with all applicable Federal Motor Vehicle

Safety Standards which were in effect at the

time the vehicle was manufactured . You can

find this sticker on the left door jamb.

It

shows the month and year of production and

the ve hicle ident ification number of your vehi ·

cle (perforation) as well as the Gross Vehicle

Weight Rating (GVWR) and the Gross Axle

Weight Rating (GAWR) .

The high voltage warning label

is located on the lock carr ier .

The spark ignition system complies with

the Canadian standard ICES-002.

Weights

Gross Vehicle Weight Rating

The Gross Vehicle Weight Rating (GVWR), and

the Gross Axle Weight Rating (GAWR) for

front and rear are Listed on a sticker on the

left door jamb.

The Gross Vehicle Weight Rating includes the

weight of the basic vehicle plus full fuel tank,

oi l and coolant, plus maximum load, wh ich in·

eludes passenger weight (lSO lbs/68 kg per

Ill>

Page 282 of 298

28 0 Con sum er Inf ormation

-Always make sure the transmission se

lector lever (automatic transmiss ion) is

in "P" (Park position) and the park brake

is f irmly app lied .

@) For the sake of the environment

-Changing the engine settings wi ll ad

versely affect em iss ion levels. This is det

rimental to the environment and increas

es fuel consumption .

- Always observe env ironmental regula

tions when dispos ing of old engine oil,

used brake fluid, dirty engine coolant,

spent batteries or worn o ut tires.

- Undeployed airbag modules and preten

s ioners might be classified as Perchlo

rate Material -spec ial handling may ap

ply, see www.dtsc.ca .gov/hazardous

was te/perch lorate . When the veh icle or

parts of the res traint system including

airbag modules safety belts wit h preten

sioners are scrapped, all applicable laws

and regulations must be observed. Your

authori zed Aud i dea ler is familiar with

these requirements and we recommend

that you have your dealer perform this

serv ice for you .

Additional accessories,

modifications and

parts replacement

Additional accessories and parts

replacement

Always consult an authorized Audi dealer be

fore purchasing accessories.

Your veh icle incorporates the latest safety de

sig n featu res ensu ring a high standard of a c

tive and passive safety .

This safety could be comp romised by non-ap

proved changes to the ve hicle. For this reason ,

if pa rts have to be replaced , please obse rve

the following points when install ing addition

a l accessories: Approved Audi accessories and genuine Aud

i

parts are available from authorized A udi deal

ers.

T hese dea le rs a lso have the necessary facili

ties, tools and tra ined specialists to install the

parts and acc essories proper ly .

A WARNING

-Using the wrong spare parts or using non-

approved accessories can cause damage to

the veh icle and ser ious persona l injury.

- Use on ly accessories express ly approved

by Audi and gen uine Audi spare parts

- These parts and accessories have been

specia lly designed to be used on yo ur ve

h icle .

- Never install accessor ies such as tele

phone crad les or beverage ho lders on a ir

bag covers or within the airbag deploy

ment zones . Do ing so will increase the

risk of injury if a irbags are triggered in an

accident!

- Before you check anything in the engine

compa rtment, always read and heed a ll

WARNI NGS

9 page 214 .

(D Note

-If items other than genu ine Audi spare

parts, add-on equipment and accessory

items are used or if repair work is not

performed accord ing to specified meth

ods, this can resu lt in seve re damage to

your vehicle's eng ine and body (such as

corrosion) and adversely affect yo ur vehi

cle's warranty .

- If emergency repairs must be performed

elsewhere, have the vehicle examined by

an authorized Audi dealer as soon as

possible .

- The manufacturer cannot be held liable

for damage wh ich occ urs due to failure

to comply with these stipu lations.

Page 286 of 298

28 4 Index

Automatic transmission . . . . . . . . . 10 1, 106

Automatic Shift Lock (ASL) . . . . . 103, 109

Driving . . . . . . . . . . . . . . . . . . . . . 101, 107

Dynamic shift program . . . . . . . . 104, 110

Emergency mode . . . . . . . . . . . . . 106, 111

Emergency release . . . . . . . . . . . . 106, 112

Kick-dow n . . . . . . . . . . . . . . . . . . . 104, 109

M anual sh ift program . . . . . . . . . 105, 1 10

Selec to r l eve r . . . . . . . . . . . . . . . . 102 , 108

Shift b uttons . . . . . . . . . . . . . . . . 105, 1 11

Steer ing whee l w ith mu lti tronic ... .. . 105

Steering whee l with tiptronic ....... . 11 1

Automatic wipe rs ........... ... .. ... . 46

Auto Safety Hotline . . . . . . . . . . . . . . . . . 131

Average consumption ....... .. .. .... .. 24

Average speed . . . . . . . . . . . . . . . . . . . . . . . 24

Avoid damaging the vehicle . ... ... ... . 197

B

Battery ..... .. . .. ..... ... .. .. .... . 230

Charging .... .. .. ..... ... .. .. .... . 233

Important warnings . ... .. .. ... ... . 23 1

Jump starting .............. .. .... . 268

Locat ion . ............... .. .. .... . 231

low . .. .. .. ... .. ..... ... .... .. .. . 194

Replacing the battery ......... .. ... 234

State of charge ..... ...... .. .. .. .. . 194

W inter operation ......... .. .. .. .. . 230

Wo rking on the battery .... .. .. .. .. . 231

Before driving . . . . . . . . . . . . . . . . . . . . . . 123

Blended gasoline .. ..... ... .. .. .... . 215

Blower (automatic climate cont rol) .. .. .. 67

Blower (climate control) . . . . . . . . . . . . . . . 64

Body cav ity sealing ....... .. .. .. .. .. . 209

Booster seats .............. ... .. .. . 177

Brake fl uid

Changing the brake fl uid ... .. .. .... .

230

Check ing the brake fluid level . .. ..... 229

What is the correct brake flu id leve l? .. 229

What should I do if the brake fluid warn -

ing light comes on? ........ ..... .. .

229

Brake system

Anti-lock braking system ... .... .... ..

19

Brake ass ist system ....... .. .. .. .. . 189

Brake booster .. .... ...... .. .. .. .. . 192

Brake fl uid . ..... ......... ... .. ... 229

B rake fluid specifications fo r r efill and re -

placement . ..... .. ... ..... ... .. ..

230

Brake light defective . . . . . . . . . . . . . . . . 21

Brake pads .... .. ............. .... 196

Electromechanical parking brake . .... . 73

Fluid reservo ir . .. ................ . 229

How does moisture or road salt affect the

brakes? ....... .. .. ........ ...... .

191

Warning/ind icator lights ...... .. .. .. . 14

Worn b rake pads symbo l ........ .. .. . 20

braking guard . .. .. .......... ...... .. 78

Messages ... .. .. .. ... .. ... ..... .. . 85

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Break -in period .. .. ... .......... .. .. 196

Brake pads .... .. ............. .... 196

Tires ...... ... .. .. ... ........... . 196

Bulbs . ... .. .... .. .. ... ..... ... .. .. 267

C

Cali forn ia Proposition 65 Warn ing . .... 221

Battery specific . ... ... ..... ... .. .. 232

Capac,t,es ...... .. .. ... ........... . 276

Engine oil . .. .. .. ............. .. .. 2 22

Car care .... .... .. ............. .... 204

Exterior . .. .. ... ... ... .. ... ... .. .. 204

Interior ...... ... .. .............. . 210

Cargo area ...... .. ... .. .. ... .... . .. 129

Cargo ne t ... .. .. .. .. ........... .... . 61

Catalytic converter . ............. .. .. 197

Center armrest

Cockpit ... .... .. .. .... . ... ... .. .. .

51

Central lock ing .. .. ............. .. ... 32

E mergency loc king ............... .. . 36

Certification ...... ............... .. 281

Changing a wheel . ... ... ..... ... .. .. 258

Changi ng engine oil ................ . 226

Chassis (undercoat ing) ............. .. 209

Checking

Engine coolant level ..... .... ... .. ..

227

Tire pressure ..... ... .. ..... .... . .. 241

Child rest raints

Danger of using child rest rain ts in t he

fron t seat . . . . . . . . . . . . . . . . . . . . . . . .

144

Where can I get additional in format ion

about child restraints and their use? . .

186

Child rest raint system a nchors .. .. .. .. 182

Page 295 of 298

Tire pressure monitoring system .... .. . 253

Loss of air pressure .......... ... .. . 254

Malfunct ion ..... ....... .... ... .. . 254

Resetting tire pressures .... .. .. .. .. . 255

Tires .. .... .. .. ............. .. .. ... 235

Service life . . . . . . . . . . . . . . . . . . . . . . . 245

Speed rating letter code ............ 247

T ire manufacturing date ............ 247

Tire specifications ........ .. .. .. .. . 247

Tread depth ............. .... .. ... 245

Uniform tire quality grading .. .. ... .. 249

W inter t ires ..... .. ...... .. .. .. .. . 250

T ires and vehicle load limits ... ... .. .. . 243

Tires and wheels Checking tire pressure ..... .. .. .. .. . 241

Cold tire inflation pressure ....... .. . 239

Dimensions ................. ... ... 246

General notes .................. ... 23S

Glossary of tire and loading terminolo-

gy .. .. ... . .... ............. .. .. . 236

Low aspect ratio tires ...... .. .. .. .. . 252

New tires and wheels ......... .... .. 246

Replacing ............ ...... .... .. 247

Snow chains ............. .... .. ... 251

Tires and vehicle load lim its .. .. .. .. . 243

Wheel bolts ............. .. .. .. .. . 252

Winter tires ................ ... ... 250

Tire serv ice life ............. ... ... .. 245

T ools . .... .. .. ............. .. .. ... 257

Torn or frayed safety belts ..... .. .. .. . 136

T ouch-up paint ............. ... ... .. 208

Towing Tow truck procedures ......... ..... . 270

TPMS Tire pressure monitoring system .. .. . 254

Trailer towing ................ ... ... 201

Operating instructions ..... .. .. .. .. . 201

Technical requirements . . . . . . . . 201, 202

Trailer towing tips ........ .. .. .. .. . 202

Transmission multitronic ........... ...... .... .. 101

tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . 106

T ransmission ma lfunction (indicator

light) . . . . . . . . . . . . . . . . . . . . . . . . 106, 111

Transport Canada .................. . 131

Tread Wear Indicator (TWI) ...... . ... . 245

Inde x 293

Trip odometer ..... .................. 26

What does it mean when DEF appears in

the tr ip odometer display? ........ .. . 26

T runk

refer to Luggage compartment ... .. .. . 59

Trunk escape handle ..... ....... .... . 256

Trunk lid

refer to Rear lid . . . . . . . . . . . . . . . . . . . . 36

T urn signals . .. .. .. .... ........... .. . 43

Warning/indicator lights ............. 22

u

Undercoating ... .. ................. 209

Unfastening safety belts ............. 138

Unidirectional tires ... ............... 235

Uniform tire quality grading .......... 249

Unlocking Power locking switch ........... .... . 35

Remote control . . . . . . . . . . . . . . . . . . . . 34

Using the key .. ... ...... ........... 35

V

Valet parking . . . . . . . . . . . . . . . . . . . . . . . . 38

Vanity mirrors ..... .................. 45

Vehicle-care products .. .. .... ........ 204

Vehicle electrical system . . . . . . . . . . . . . . 17

Vehicle identification label .......... .. 274

Vehicle Identification Number (VIN) .. .. 274

Vehicle jack .......... ......... 257,261

Vehicle literature ...... ......... .. .. .. 5

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . 63

w

Warning/indicator lights . . . . . . . . . . . . . . 12

Airbag system . .. .. ............... . 18

Anti-lock braking system (ABS) ... .. .. . 19

Brake system . . . . . . . . . . . . . . . . . . . . . . 14

Cruise control . . . . . . . . . . . . . . . . . . . . . . 22

Electromechanical parking brake ... .. . 16

Electronic power control . . . . . . . . . . . . . 20

Electronic stabilization program (ESP) . . 19

Generator . . . . . . . . . . . . . . . . . . . . . . . . . 17

Instrument cluster . . . . . . . . . . . . . . . . . . 11

Malfunction Indicator Lamp (MIL) ... .. 20

•

•