Level AUDI A6 ALLROAD 1999 C5 / 2.G Pneumatic Suspension System

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A6 ALLROAD, Model: AUDI A6 ALLROAD 1999 C5 / 2.GPages: 64, PDF Size: 3.12 MB

Page 39 of 64

39

¥ Environmentally friendly, uses air

¥ Good operating safety due to great

stability.

¥ Electronic control system with

comprehensive self-diagnosis functions

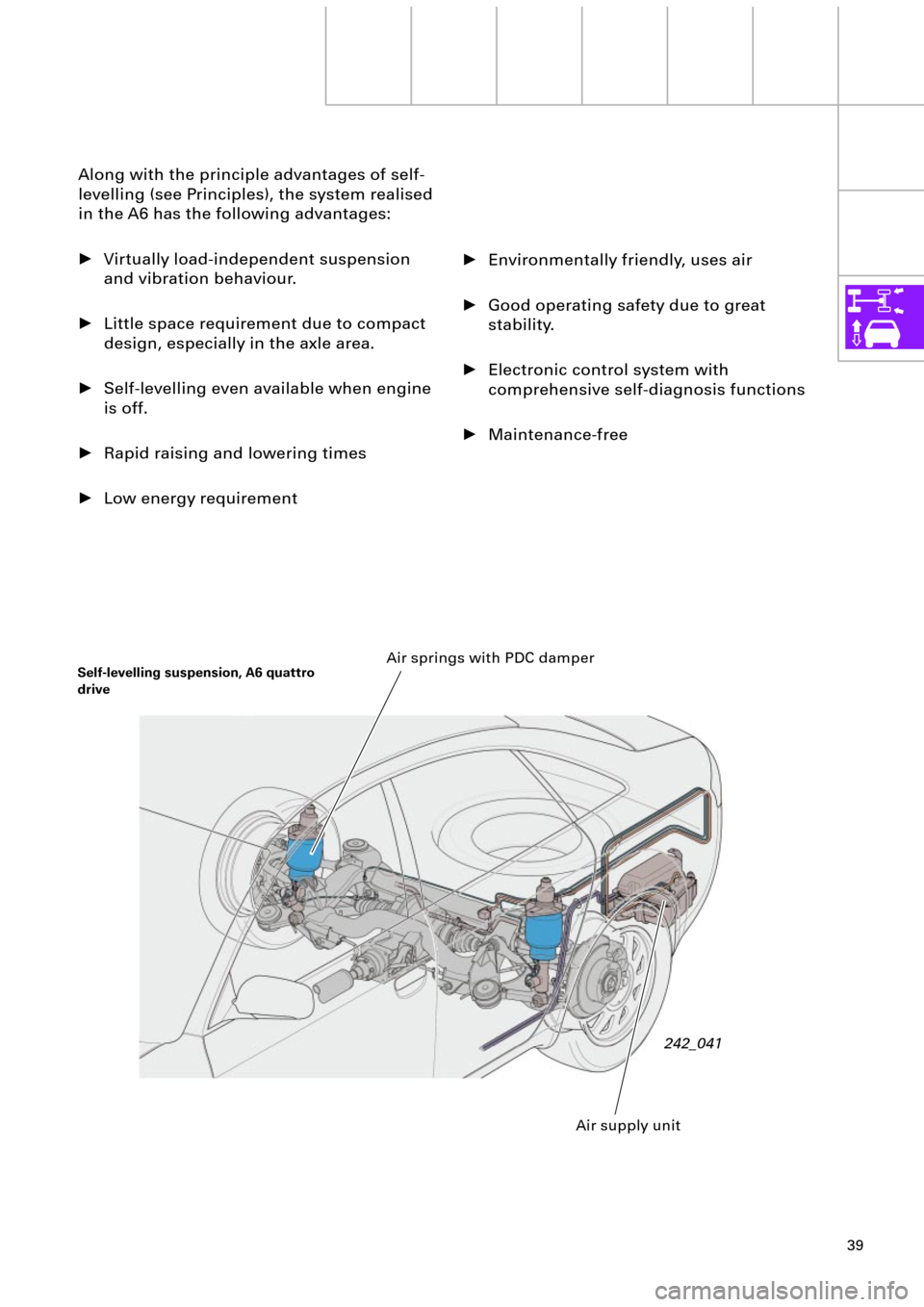

¥ Maintenance-free Along with the principle advantages of self-

levelling (see Principles), the system realised

in the A6 has the following advantages:

¥ Virtually load-independent suspension

and vibration behaviour.

¥ Little space requirement due to compact

design, especially in the axle area.

¥ Self-levelling even available when engine

is off.

¥ Rapid raising and lowering times

¥ Low energy requirement

Air springs with PDC damperSelf-levelling suspension, A6 quattro

drive

Air supply unit242_041

Page 40 of 64

40

The air springs

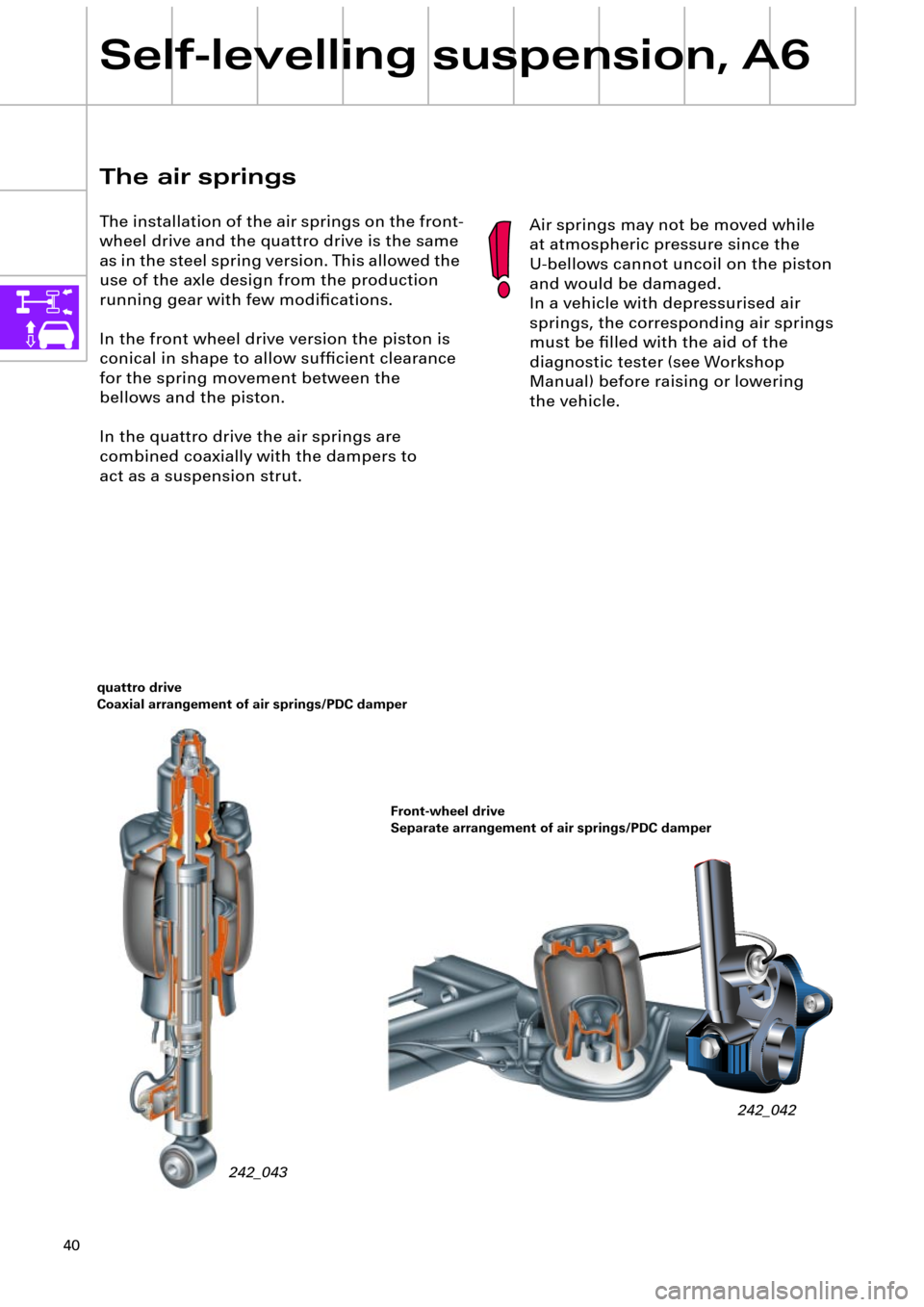

The installation of the air springs on the front-

wheel drive and the quattro drive is the same

as in the steel spring version. This allowed the

use of the axle design from the production

running gear with few modiÞcations.

In the front wheel drive version the piston is

conical in shape to allow sufÞcient clearance

for the spring movement between the

bellows and the piston.

In the quattro drive the air springs are

combined coaxially with the dampers to

act as a suspension strut.

Self-levelling suspension, A6

242_043

quattro drive

Coaxial arrangement of air springs/PDC damper

242_042

Front-wheel drive

Separate arrangement of air springs/PDC damper

Air springs may not be moved while

at atmospheric pressure since the

U-bellows cannot uncoil on the piston

and would be damaged.

In a vehicle with depressurised air

springs, the corresponding air springs

must be Þlled with the aid of the

diagnostic tester (see Workshop

Manual) before raising or lowering

the vehicle.

Page 42 of 64

42

Self-levelling suspension, A6

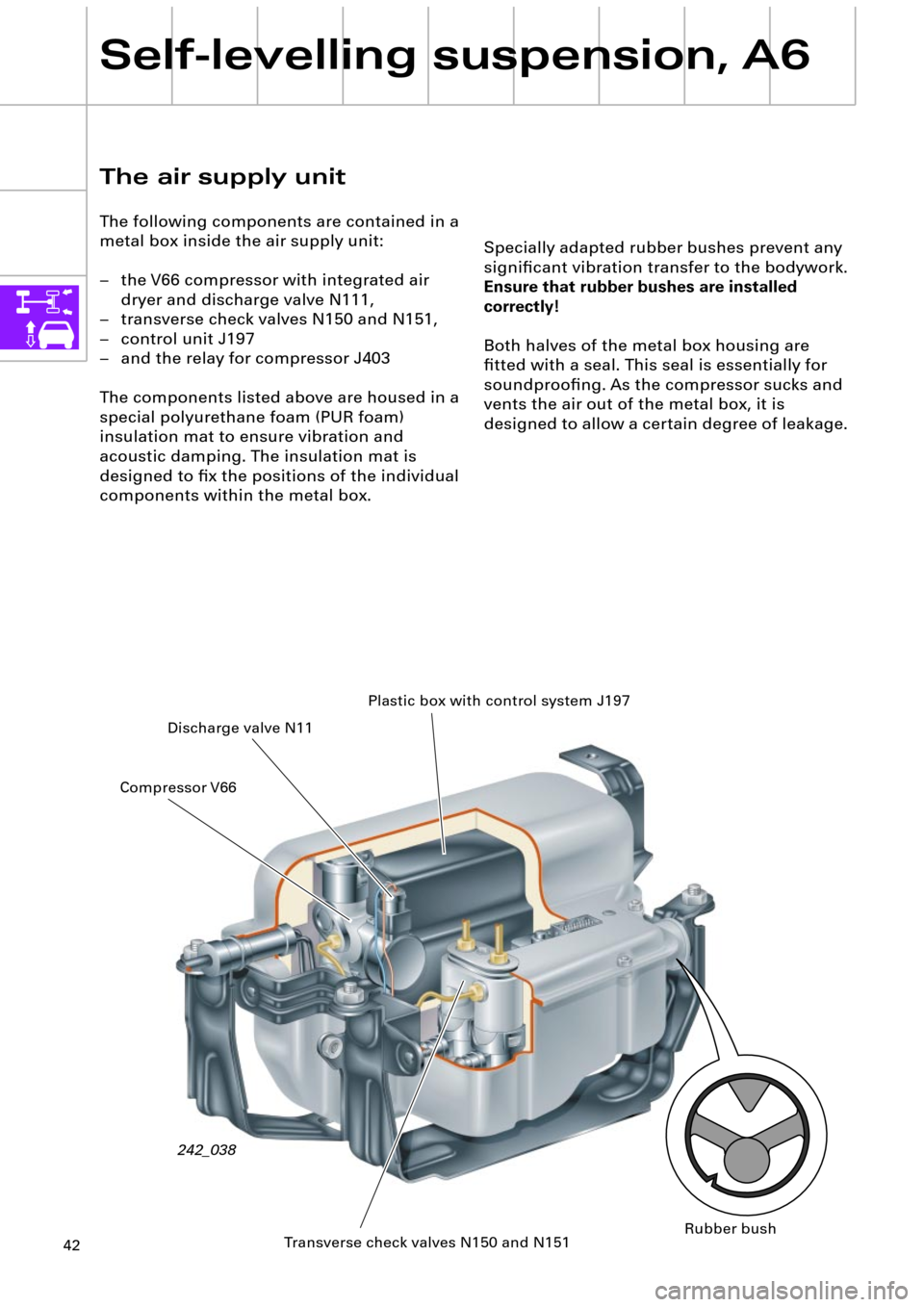

Specially adapted rubber bushes prevent any

signiÞcant vibration transfer to the bodywork.

Ensure that rubber bushes are installed

correctly!

Both halves of the metal box housing are

Þtted with a seal. This seal is essentially for

soundprooÞng. As the compressor sucks and

vents the air out of the metal box, it is

designed to allow a certain degree of leakage.

The air supply unit

The following components are contained in a

metal box inside the air supply unit:

Ð the V66 compressor with integrated air

dryer and discharge valve N111,

Ð transverse check valves N150 and N151,

Ð control unit J197

Ð and the relay for compressor J403

The components listed above are housed in a

special polyurethane foam (PUR foam)

insulation mat to ensure vibration and

acoustic damping. The insulation mat is

designed to Þx the positions of the individual

components within the metal box.

242_038Plastic box with control system J197

Discharge valve N11

Transverse check valves N150 and N151 Compressor V66

Rubber bush

Page 44 of 64

44

Self-levelling suspension, A6

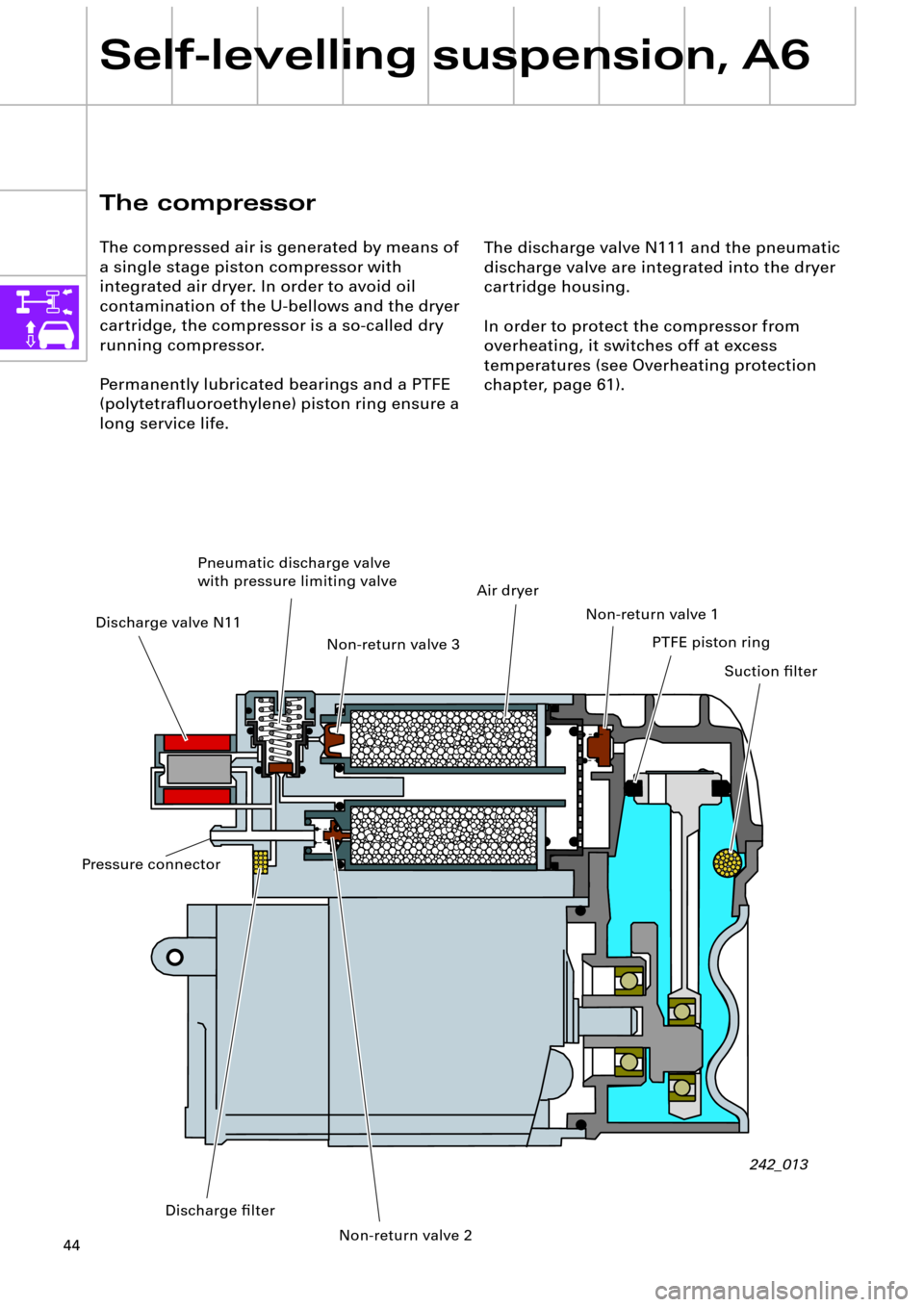

The compressor

The compressed air is generated by means of

a single stage piston compressor with

integrated air dryer. In order to avoid oil

contamination of the U-bellows and the dryer

cartridge, the compressor is a so-called dry

running compressor.

Permanently lubricated bearings and a PTFE

(polytetraßuoroethylene) piston ring ensure a

long service life.The discharge valve N111 and the pneumatic

discharge valve are integrated into the dryer

cartridge housing.

In order to protect the compressor from

overheating, it switches off at excess

temperatures (see Overheating protection

chapter, page 61).

Discharge valve N11Pneumatic discharge valve

with pressure limiting valve

Non-return valve 3Air dryer

Non-return valve 1

PTFE piston ring

Suction Þlter

Discharge Þlter

Pressure connector

242_013

Non-return valve 2

Page 46 of 64

46

Self-levelling suspension, A6

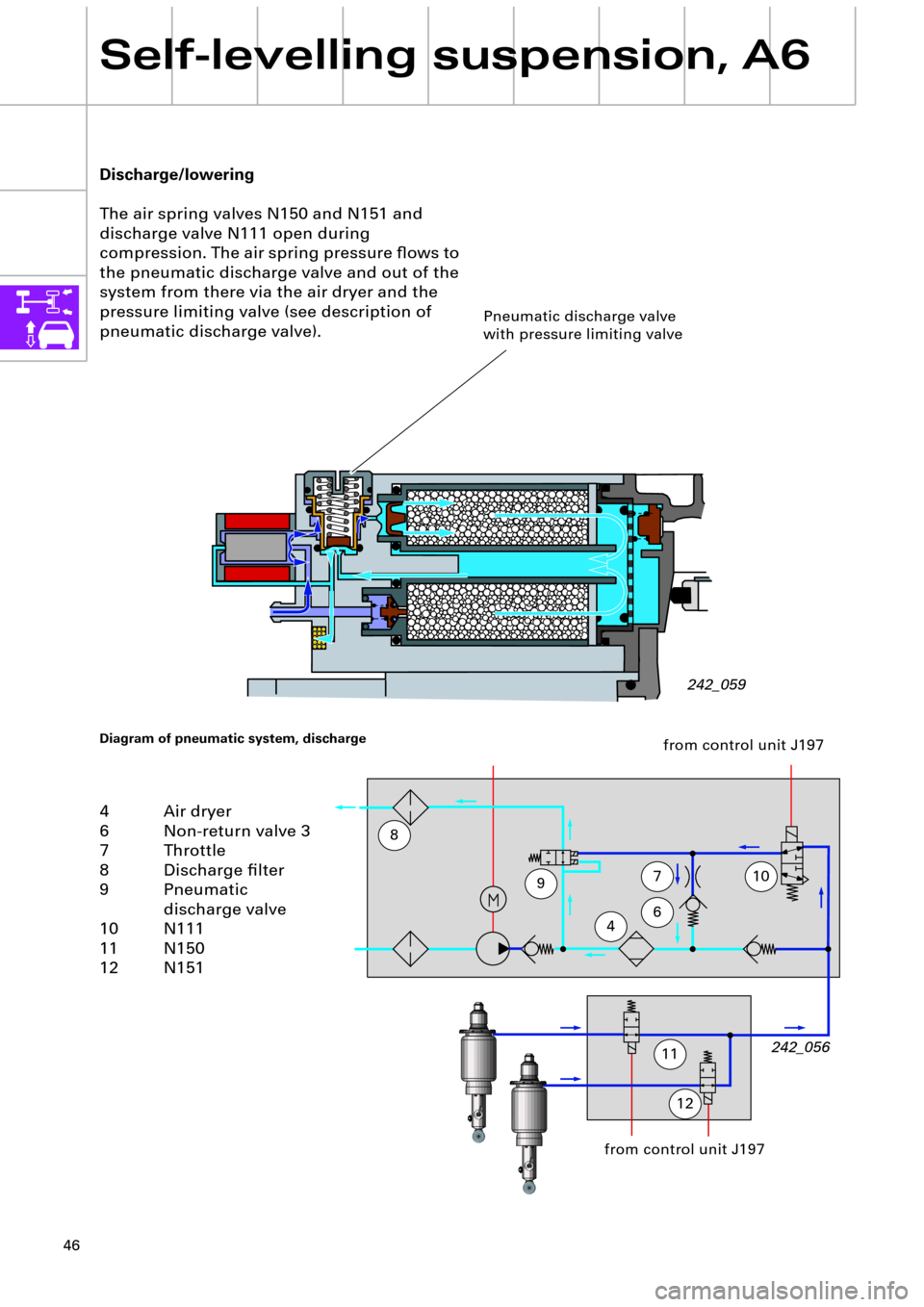

Discharge/lowering

The air spring valves N150 and N151 and

discharge valve N111 open during

compression. The air spring pressure ßows to

the pneumatic discharge valve and out of the

system from there via the air dryer and the

pressure limiting valve (see description of

pneumatic discharge valve).

242_056 Pneumatic discharge valve

with pressure limiting valve

Diagram of pneumatic system, discharge

11

12

107

64

9

8

4 Air dryer

6 Non-return valve 3

7 Throttle

8 Discharge Þlter

9 Pneumatic

discharge valve

10 N111

11 N150

12 N151

from control unit J197from control unit J197

242_059

Page 48 of 64

48

Self-levelling suspension, A6

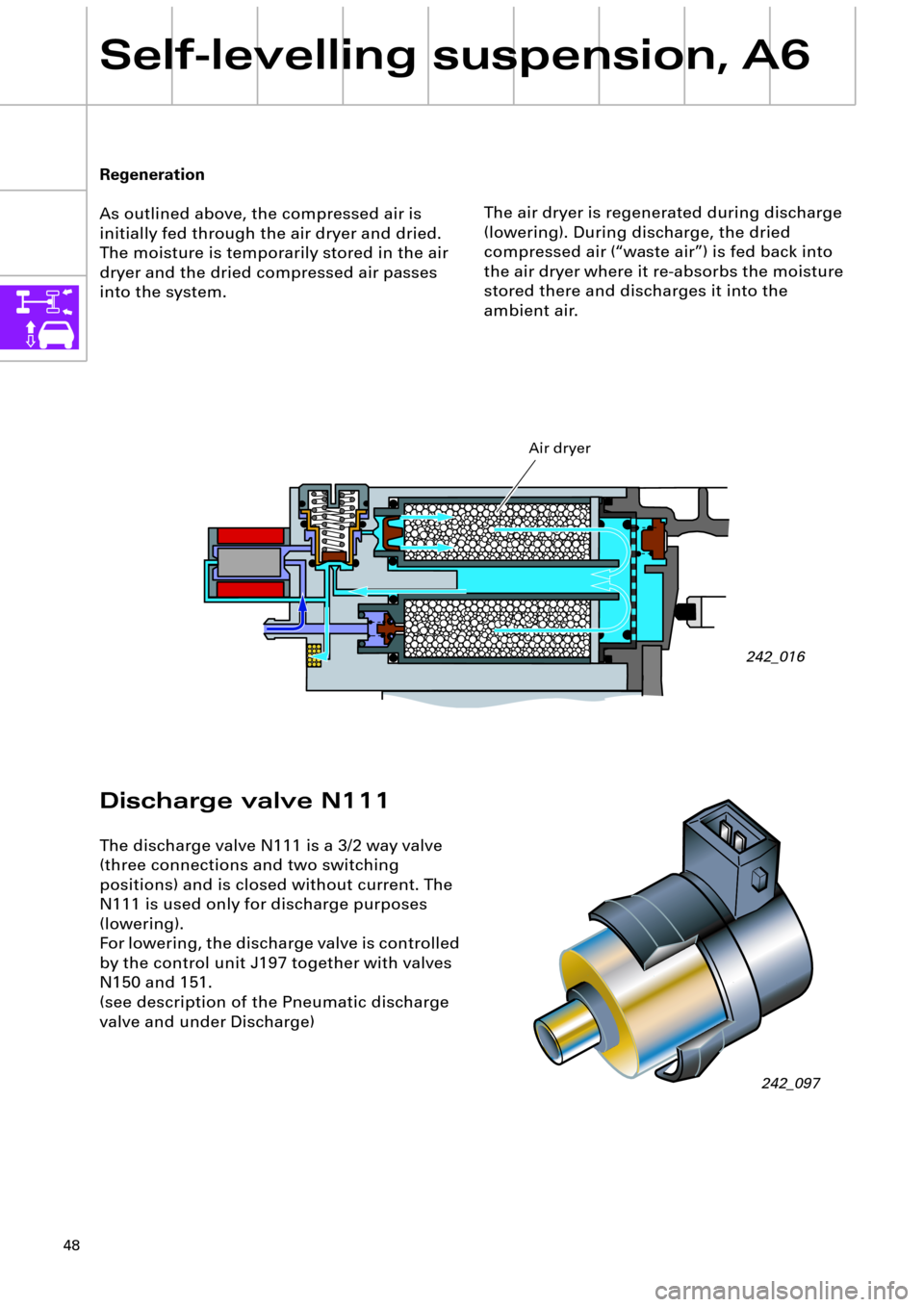

Regeneration

As outlined above, the compressed air is

initially fed through the air dryer and dried.

The moisture is temporarily stored in the air

dryer and the dried compressed air passes

into the system.

Discharge valve N111

The discharge valve N111 is a 3/2 way valve

(three connections and two switching

positions) and is closed without current. The

N111 is used only for discharge purposes

(lowering).

For lowering, the discharge valve is controlled

by the control unit J197 together with valves

N150 and 151.

(see description of the Pneumatic discharge

valve and under Discharge)

242_097

The air dryer is regenerated during discharge

(lowering). During discharge, the dried

compressed air (Òwaste airÓ) is fed back into

the air dryer where it re-absorbs the moisture

stored there and discharges it into the

ambient air.

Air dryer

242_016

Page 50 of 64

50

Self-levelling suspension, A6

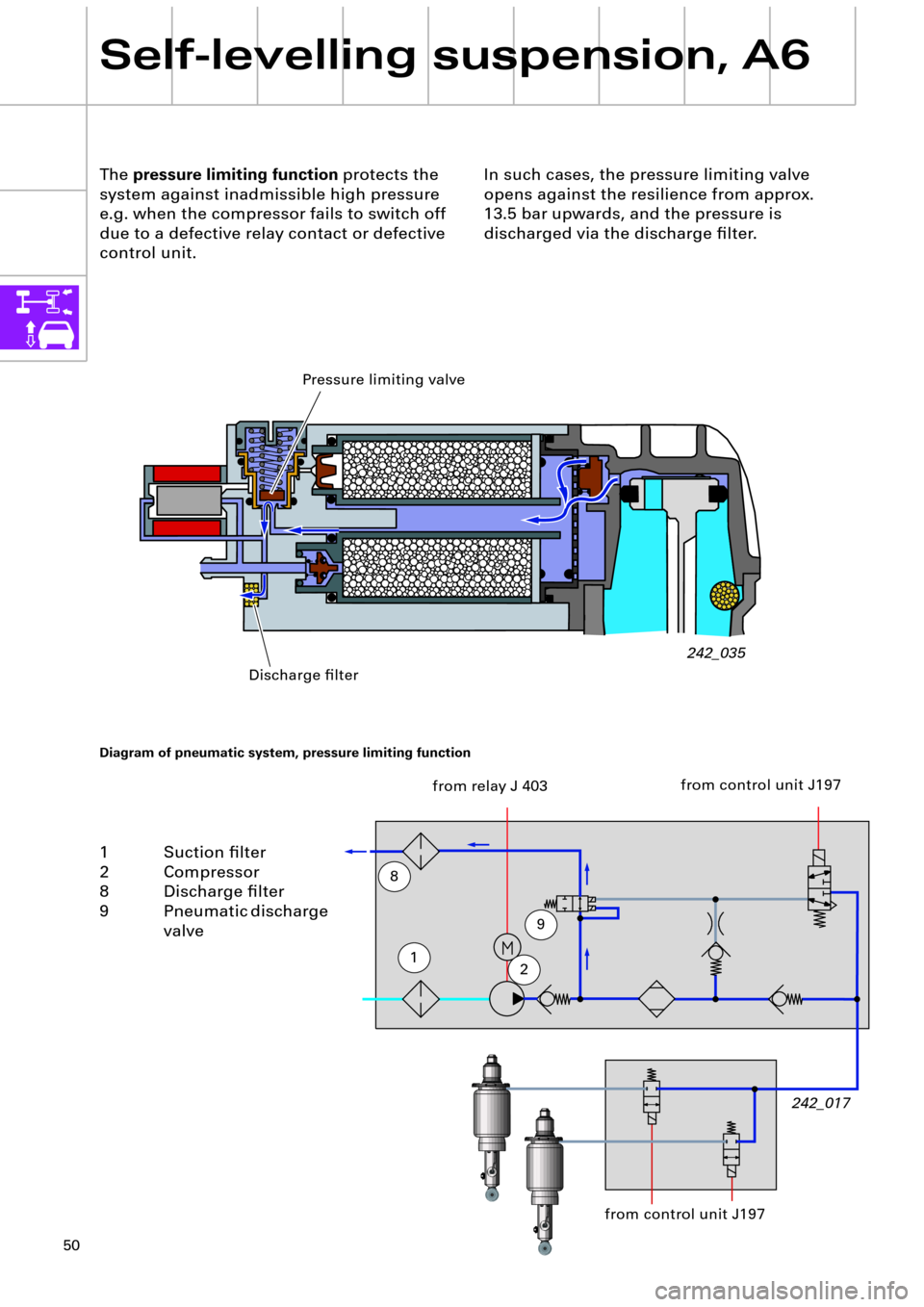

The pressure limiting function protects the

system against inadmissible high pressure

e.g. when the compressor fails to switch off

due to a defective relay contact or defective

control unit.

242_035

242_017

Diagram of pneumatic system, pressure limiting function

12

9

8

1 Suction Þlter

2 Compressor

8 Discharge Þlter

9 Pneumatic discharge

valve

from relay J 403

In such cases, the pressure limiting valve

opens against the resilience from approx.

13.5 bar upwards, and the pressure is

discharged via the discharge Þlter.

Pressure limiting valve

Discharge Þlter

from control unit J197

from control unit J197

Page 51 of 64

51

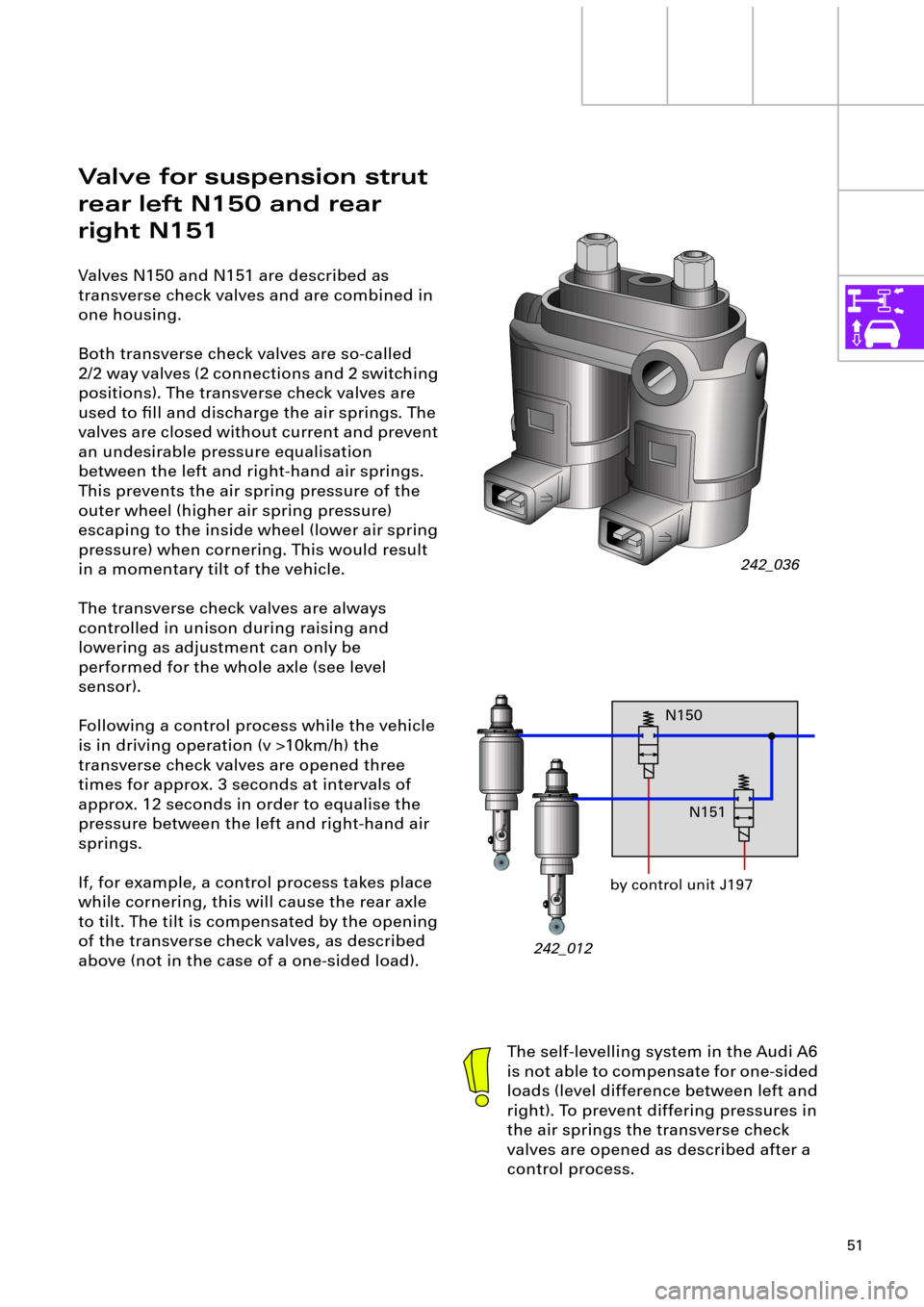

Valve for suspension strut

rear left N150 and rear

right N151

Valves N150 and N151 are described as

transverse check valves and are combined in

one housing.

Both transverse check valves are so-called

2/2 way valves (2 connections and 2 switching

positions). The transverse check valves are

used to Þll and discharge the air springs. The

valves are closed without current and prevent

an undesirable pressure equalisation

between the left and right-hand air springs.

This prevents the air spring pressure of the

outer wheel (higher air spring pressure)

escaping to the inside wheel (lower air spring

pressure) when cornering. This would result

in a momentary tilt of the vehicle.

The transverse check valves are always

controlled in unison during raising and

lowering as adjustment can only be

performed for the whole axle (see level

sensor).

Following a control process while the vehicle

is in driving operation (v >10km/h) the

transverse check valves are opened three

times for approx. 3 seconds at intervals of

approx. 12 seconds in order to equalise the

pressure between the left and right-hand air

springs.

If, for example, a control process takes place

while cornering, this will cause the rear axle

to tilt. The tilt is compensated by the opening

of the transverse check valves, as described

above (not in the case of a one-sided load).

242_036

The self-levelling system in the Audi A6

is not able to compensate for one-sided

loads (level difference between left and

right). To prevent differing pressures in

the air springs the transverse check

valves are opened as described after a

control process.

242_012by control unit J197N150

N151

Page 52 of 64

52

Self-levelling suspension, A6

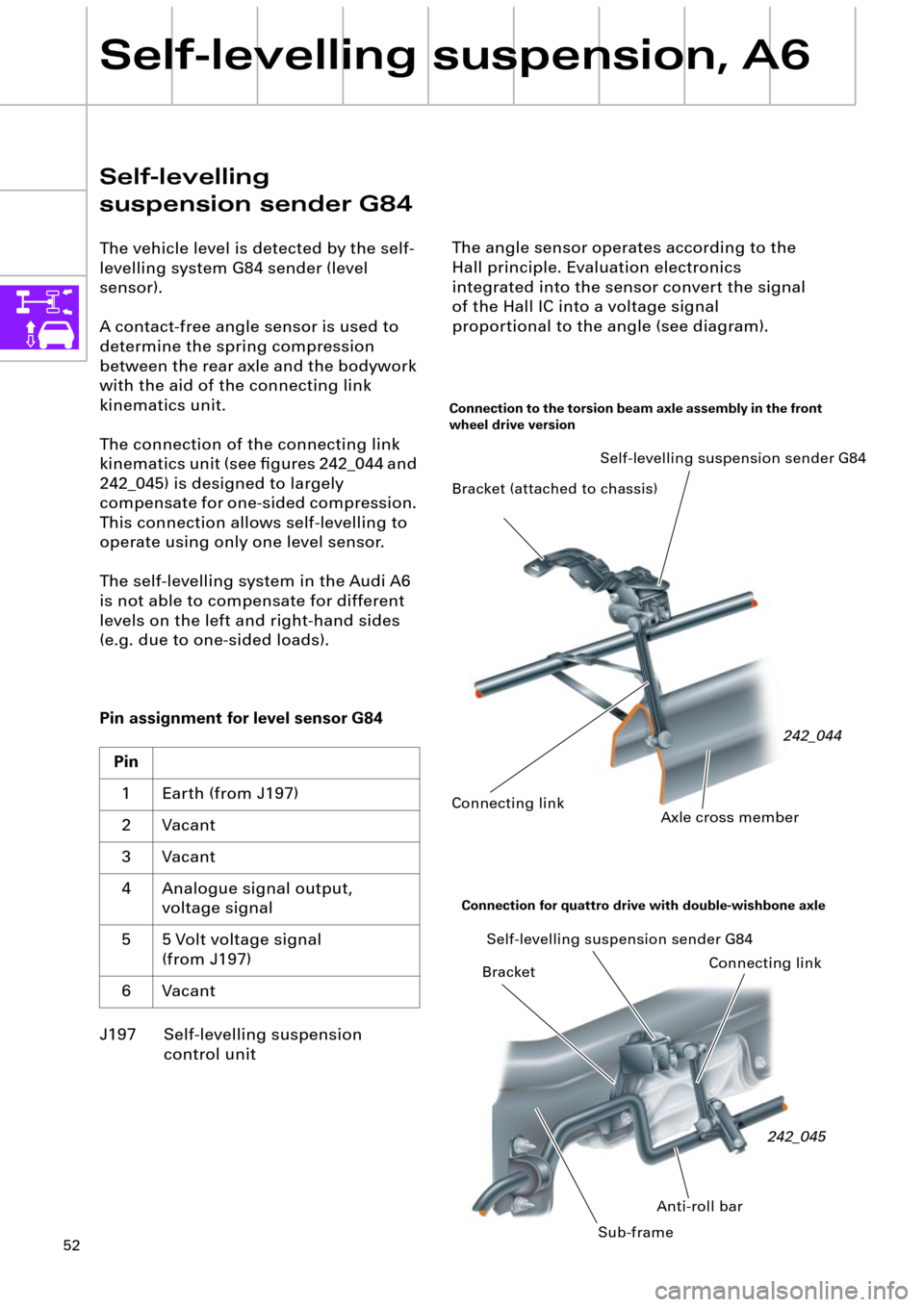

Self-levelling

suspension sender G84

The vehicle level is detected by the self-

levelling system G84 sender (level

sensor).

A contact-free angle sensor is used to

determine the spring compression

between the rear axle and the bodywork

with the aid of the connecting link

kinematics unit.

The connection of the connecting link

kinematics unit (see Þgures 242_044 and

242_045) is designed to largely

compensate for one-sided compression.

This connection allows self-levelling to

operate using only one level sensor.

The self-levelling system in the Audi A6

is not able to compensate for different

levels on the left and right-hand sides

(e.g. due to one-sided loads).

Pin assignment for level sensor G84

J197 Self-levelling suspension

control unit Pin

1 Earth (from J197)

2 Vacant

3 Vacant

4 Analogue signal output,

voltage signal

5 5 Volt voltage signal

(from J197)

6 Vacant

242_044 Self-levelling suspension sender G84

Connecting link

Axle cross member

Connection to the torsion beam axle assembly in the front

wheel drive version

Bracket (attached to chassis)

Connecting link Self-levelling suspension sender G84

Bracket

Anti-roll bar

Connection for quattro drive with double-wishbone axle

242_045

Sub-frame

The angle sensor operates according to the

Hall principle. Evaluation electronics

integrated into the sensor convert the signal

of the Hall IC into a voltage signal

proportional to the angle (see diagram).

Page 53 of 64

53

0,5 2,5 4,5

0°

70°

0

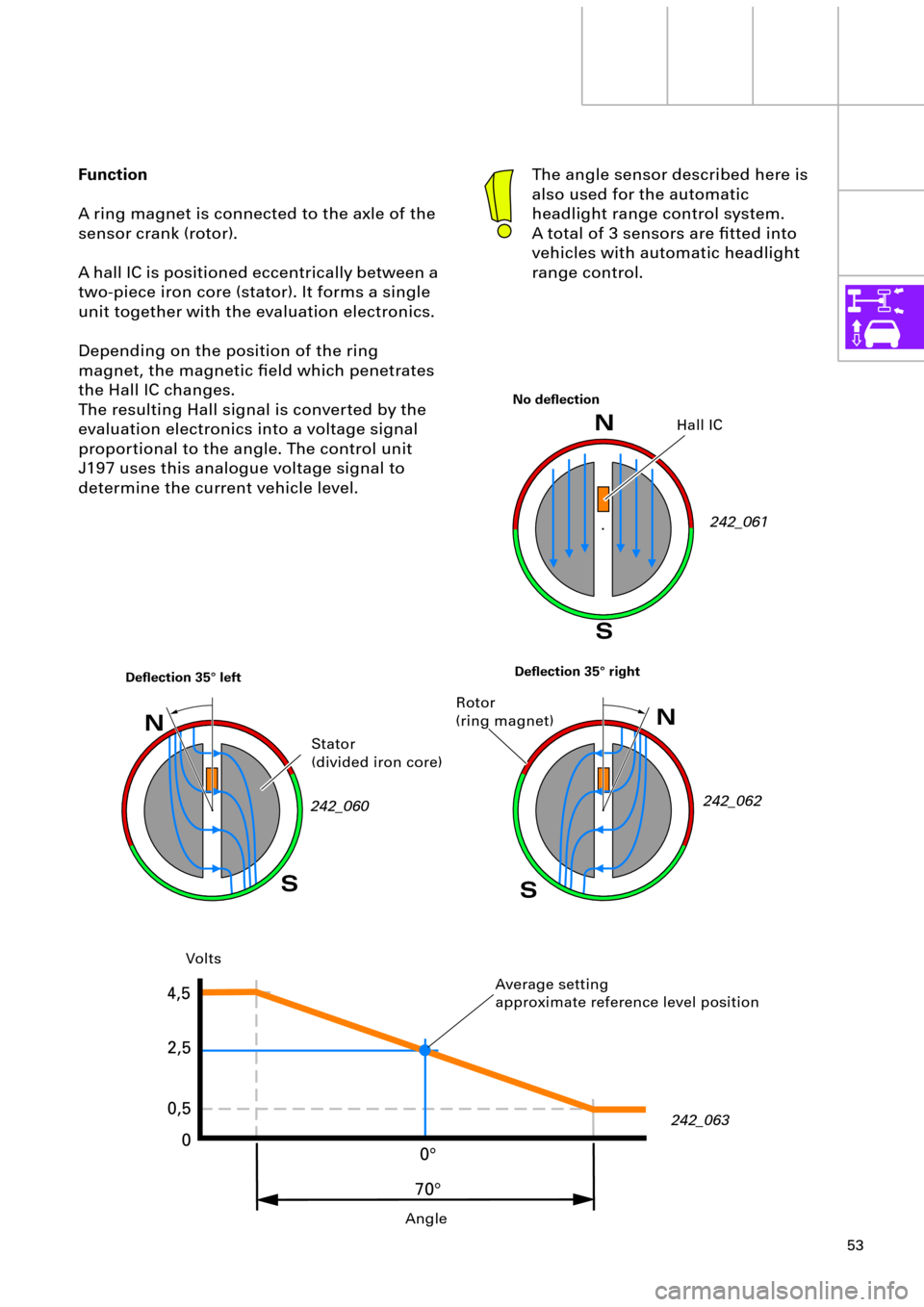

Function

A ring magnet is connected to the axle of the

sensor crank (rotor).

A hall IC is positioned eccentrically between a

two-piece iron core (stator). It forms a single

unit together with the evaluation electronics.

Depending on the position of the ring

magnet, the magnetic Þeld which penetrates

the Hall IC changes.

The resulting Hall signal is converted by the

evaluation electronics into a voltage signal

proportional to the angle. The control unit

J197 uses this analogue voltage signal to

determine the current vehicle level.

242_062242_061

242_060

Deßection 35¡ right No deßection

Deßection 35¡ left

Rotor

(ring magnet)

Stator

(divided iron core)

N

SN

S

N

S

Angle VoltsHall IC

Average setting

approximate reference level position

242_063

The angle sensor described here is

also used for the automatic

headlight range control system.

A total of 3 sensors are Þtted into

vehicles with automatic headlight

range control.