clutch AUDI A8 2003 D3 / 2.G Technical Features Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2003, Model line: A8, Model: AUDI A8 2003 D3 / 2.GPages: 96, PDF Size: 5.51 MB

Page 30 of 96

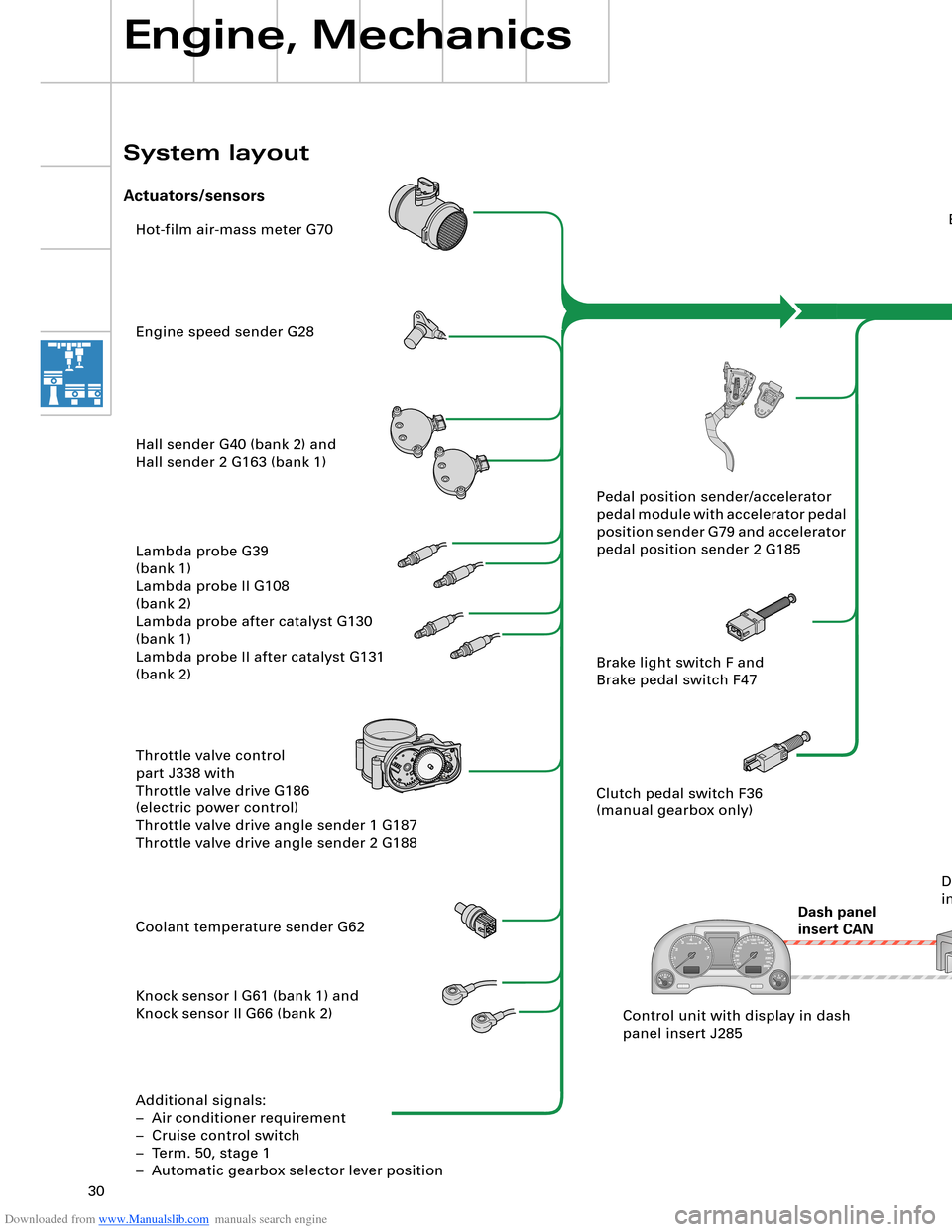

Downloaded from www.Manualslib.com manuals search engine 30

Hot-film air-mass meter G70

Engine speed sender G28

Hall sender G40 (bank 2) and

Hall sender 2 G163 (bank 1)

Lambda probe G39

(bank 1)

Lambda probe II G108

(bank 2)

Lambda probe after catalyst G130

(bank 1)

Lambda probe II after catalyst G131

(bank 2)

Throttle valve control

part J338 with

Throttle valve drive G186

(electric power control)

Throttle valve drive angle sender 1 G187

Throttle valve drive angle sender 2 G188

Coolant temperature sender G62

Knock sensor I G61 (bank 1) and

Knock sensor II G66 (bank 2)

Additional signals:

– Air conditioner requirement

– Cruise control switch

– Term. 50, stage 1

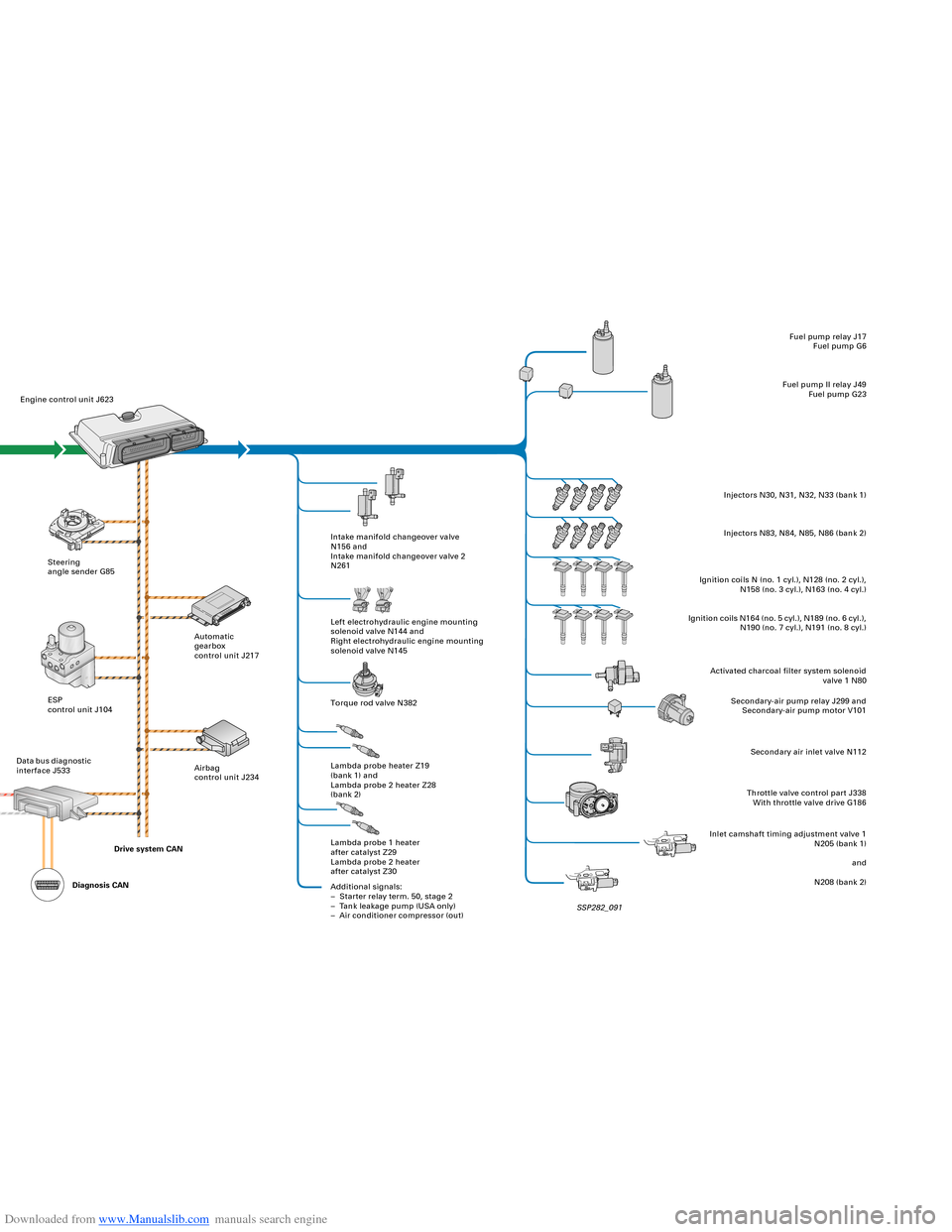

– Automatic gearbox selector lever positionEngine control unit J623

Steering

angle sender G85

ESP

control unit J104

Dash panel

insert CANAutomatic

gearbox

control unit J217

Airbag

control unit J234Intake manifold changeover valve

N156 and

Intake manifold changeover valve 2

N261

Left electrohydraulic engine mounting

solenoid valve N144 and

Right electrohydraulic engine mounting

solenoid valve N145

Torque rod valve N382

Lambda probe heater Z19

(bank 1) and

Lambda probe 2 heater Z28

(bank 2)

Lambda probe 1 heater

after catalyst Z29

Lambda probe 2 heater

after catalyst Z30

Additional signals:

– Starter relay term. 50, stage 2

– Tank leakage pump (USA only)

– Air conditioner compressor (out)Fuel pump relay J17

Fuel pump G6

Fuel pump II relay J49

Fuel pump G23

Injectors N30, N31, N32, N33 (bank 1)

Injectors N83, N84, N85, N86 (bank 2)

Ignition coils N (no. 1 cyl.), N128 (no. 2 cyl.),

N158 (no. 3 cyl.), N163 (no. 4 cyl.)

Ignition coils N164 (no. 5 cyl.), N189 (no. 6 cyl.),

N190 (no. 7 cyl.), N191 (no. 8 cyl.)

Activated charcoal filter system solenoid

valve 1 N80

Secondary-air pump relay J299 and

Secondary-air pump motor V101

Secondary air inlet valve N112

Throttle valve control part J338

With throttle valve drive G186

Inlet camshaft timing adjustment valve 1

N205 (bank 1)

and

N208 (bank 2) Pedal position sender/accelerator

pedal module with accelerator pedal

position sender G79 and accelerator

pedal position sender 2 G185

Brake light switch F and

Brake pedal switch F47

Clutch pedal switch F36

(manual gearbox only)

Control unit with display in dash

panel insert J285Data bus diagnostic

interface J533

Engine, Mechanics

System layout

Actuators/sensors

SSP282_091 Drive system CAN

Diagnosis CAN

Page 31 of 96

Downloaded from www.Manualslib.com manuals search engine 30

Hot-film air-mass meter G70

Engine speed sender G28

Hall sender G40 (bank 2) and

Hall sender 2 G163 (bank 1)

Lambda probe G39

(bank 1)

Lambda probe II G108

(bank 2)

Lambda probe after catalyst G130

(bank 1)

Lambda probe II after catalyst G131

(bank 2)

Throttle valve control

part J338 with

Throttle valve drive G186

(electric power control)

Throttle valve drive angle sender 1 G187

Throttle valve drive angle sender 2 G188

Coolant temperature sender G62

Knock sensor I G61 (bank 1) and

Knock sensor II G66 (bank 2)

Additional signals:

– Air conditioner requirement

– Cruise control switch

– Term. 50, stage 1

– Automatic gearbox selector lever positionEngine control unit J623

Steering

angle sender G85

ESP

control unit J104

Dash panel

insert CANAutomatic

gearbox

control unit J217

Airbag

control unit J234Intake manifold changeover valve

N156 and

Intake manifold changeover valve 2

N261

Left electrohydraulic engine mounting

solenoid valve N144 and

Right electrohydraulic engine mounting

solenoid valve N145

Torque rod valve N382

Lambda probe heater Z19

(bank 1) and

Lambda probe 2 heater Z28

(bank 2)

Lambda probe 1 heater

after catalyst Z29

Lambda probe 2 heater

after catalyst Z30

Additional signals:

– Starter relay term. 50, stage 2

– Tank leakage pump (USA only)

– Air conditioner compressor (out)Fuel pump relay J17

Fuel pump G6

Fuel pump II relay J49

Fuel pump G23

Injectors N30, N31, N32, N33 (bank 1)

Injectors N83, N84, N85, N86 (bank 2)

Ignition coils N (no. 1 cyl.), N128 (no. 2 cyl.),

N158 (no. 3 cyl.), N163 (no. 4 cyl.)

Ignition coils N164 (no. 5 cyl.), N189 (no. 6 cyl.),

N190 (no. 7 cyl.), N191 (no. 8 cyl.)

Activated charcoal filter system solenoid

valve 1 N80

Secondary-air pump relay J299 and

Secondary-air pump motor V101

Secondary air inlet valve N112

Throttle valve control part J338

With throttle valve drive G186

Inlet camshaft timing adjustment valve 1

N205 (bank 1)

and

N208 (bank 2) Pedal position sender/accelerator

pedal module with accelerator pedal

position sender G79 and accelerator

pedal position sender 2 G185

Brake light switch F and

Brake pedal switch F47

Clutch pedal switch F36

(manual gearbox only)

Control unit with display in dash

panel insert J285Data bus diagnostic

interface J533

Engine, Mechanics

System layout

Actuators/sensors

SSP282_091 Drive system CAN

Diagnosis CAN

Page 41 of 96

Downloaded from www.Manualslib.com manuals search engine 41

Automatically controlled

starting

The automatic start control is integrated into

the engine control unit.

A new feature is that starter control is no

longer implemented by way of the ignition/

starter switch D (switching of terminal 50),

but rather it is performed automatically by

the engine control unit.

Release for starter actuation is always

transmitted by the entry and start

authorisation control unit J518 to the engine

control unit J623.

In addition to general release by the

immobilizer, the following start release

conditions also have to be satisfied:

– Start signal from entry and start

authorisation switch E415 or entry and

start authorisation button E408

– Clutch pedal pressed, signal from clutch

pedal switch F194 (manual gearbox only)

– Selector lever position P or N (automatic

gearbox control unit J217)

– In the event of start signal via entry and

start authorisation button E408, brake

must be pressed (signal from brake light

switch F via separate interface)

As a safeguard, P/N signal or signal from

clutch pedal switch F194 must be applied

to the separate interfaces of the two

control units (J623 and J518).

Additional safeguard, as entry and start

authorisation button E408 can be

actuated by front passenger.

1

2 1

1

2

Page 42 of 96

Downloaded from www.Manualslib.com manuals search engine 42

Engine, Mechanics

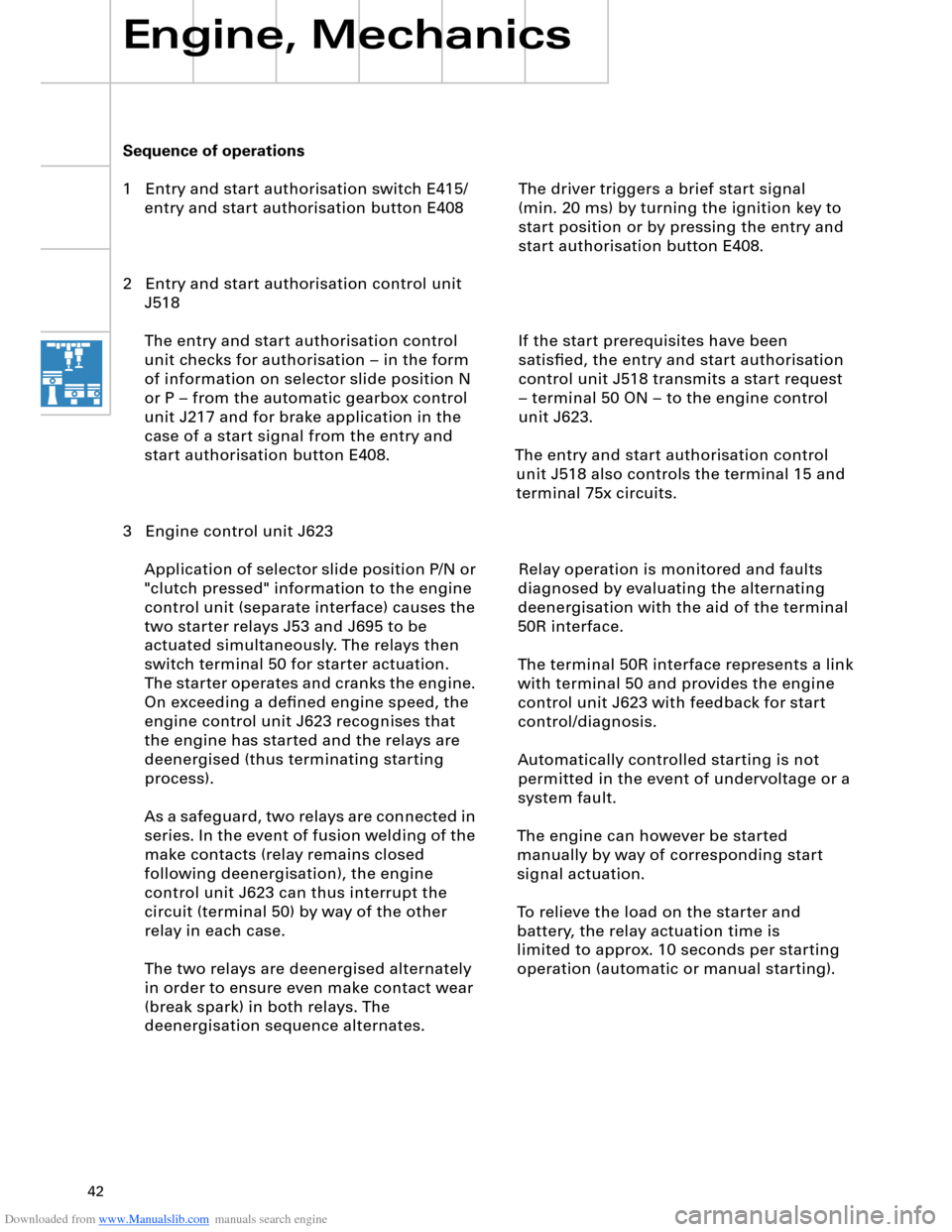

Sequence of operations

1 Entry and start authorisation switch E415/entry and start authorisation button E408

2 Entry and start authorisation control unit J518

The entry and start authorisation control

unit checks for authorisation – in the form

of information on selector slide position N

or P – from the automatic gearbox control

unit J217 and for brake application in the

case of a start signal from the entry and

start authorisation button E408.

3 Engine control unit J623 Application of selector slide position P/N or

"clutch pressed" information to the engine

control unit (separate interface) causes the

two starter relays J53 and J695 to be

actuated simultaneously. The relays then

switch terminal 50 for starter actuation.

The starter operates and cranks the engine.

On exceeding a defined engine speed, the

engine control unit J623 recognises that

the engine has started and the relays are

deenergised (thus terminating starting

process).

As a safeguard, two relays are connected in

series. In the event of fusion welding of the

make contacts (relay remains closed

following deenergisation), the engine

control unit J623 can thus interrupt the

circuit (terminal 50) by way of the other

relay in each case.

The two relays are deenergised alternately

in order to ensure even make contact wear

(break spark) in both relays. The

deenergisation sequence alternates. The driver triggers a brief start signal

(min. 20 ms) by turning the ignition key to

start position or by pressing the entry and

start authorisation button E408.

If the start prerequisites have been

satisfied, the entry and start authorisation

control unit J518 transmits a start request

– terminal 50 ON – to the engine control

unit J623.

The entry and start authorisation control unit J518 also controls the terminal 15 and

terminal 75x circuits.

Relay operation is monitored and faults diagnosed by evaluating the alternating

deenergisation with the aid of the terminal

50R interface.

The terminal 50R interface represents a link

with terminal 50 and provides the engine

control unit J623 with feedback for start

control/diagnosis.

Automatically controlled starting is not

permitted in the event of undervoltage or a

system fault.

The engine can however be started

manually by way of corresponding start

signal actuation.

To relieve the load on the starter and

battery, the relay actuation time is

limited to approx. 10 seconds per starting

operation (automatic or manual starting).

Page 43 of 96

Downloaded from www.Manualslib.com manuals search engine 43

D1

30

15

J329J53J695J694

75xE415

N376

6x

J623

J518

50R

50R

3

12

12

E408

STOP START

58s

210 210

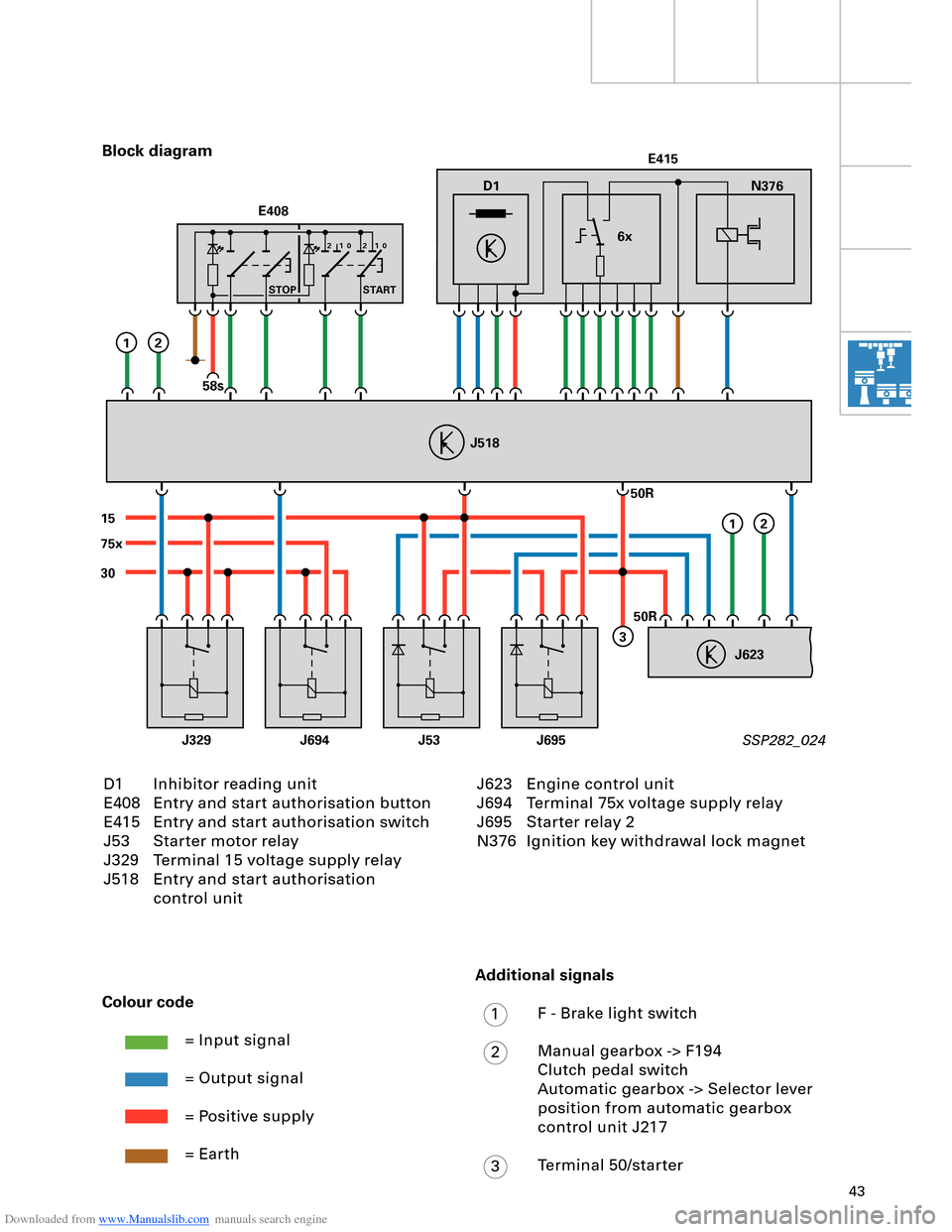

D1 Inhibitor reading unit

E408 Entry and start authorisation button

E415 Entry and start authorisation switch

J53 Starter motor relay

J329 Terminal 15 voltage supply relay

J518 Entry and start authorisation

control unit Block diagram

SSP282_024

Colour code

= Input signal

= Output signal

= Positive supply

= Earth

J623 Engine control unit

J694 Terminal 75x voltage supply relay

J695 Starter relay 2

N376 Ignition key withdrawal lock magnet

Additional signals

F - Brake light switch

Manual gearbox -> F194

Clutch pedal switch

Automatic gearbox -> Selector lever

position from automatic gearbox

control unit J217

Terminal 50/starter

1

2

3

Page 45 of 96

Downloaded from www.Manualslib.com manuals search engine 45

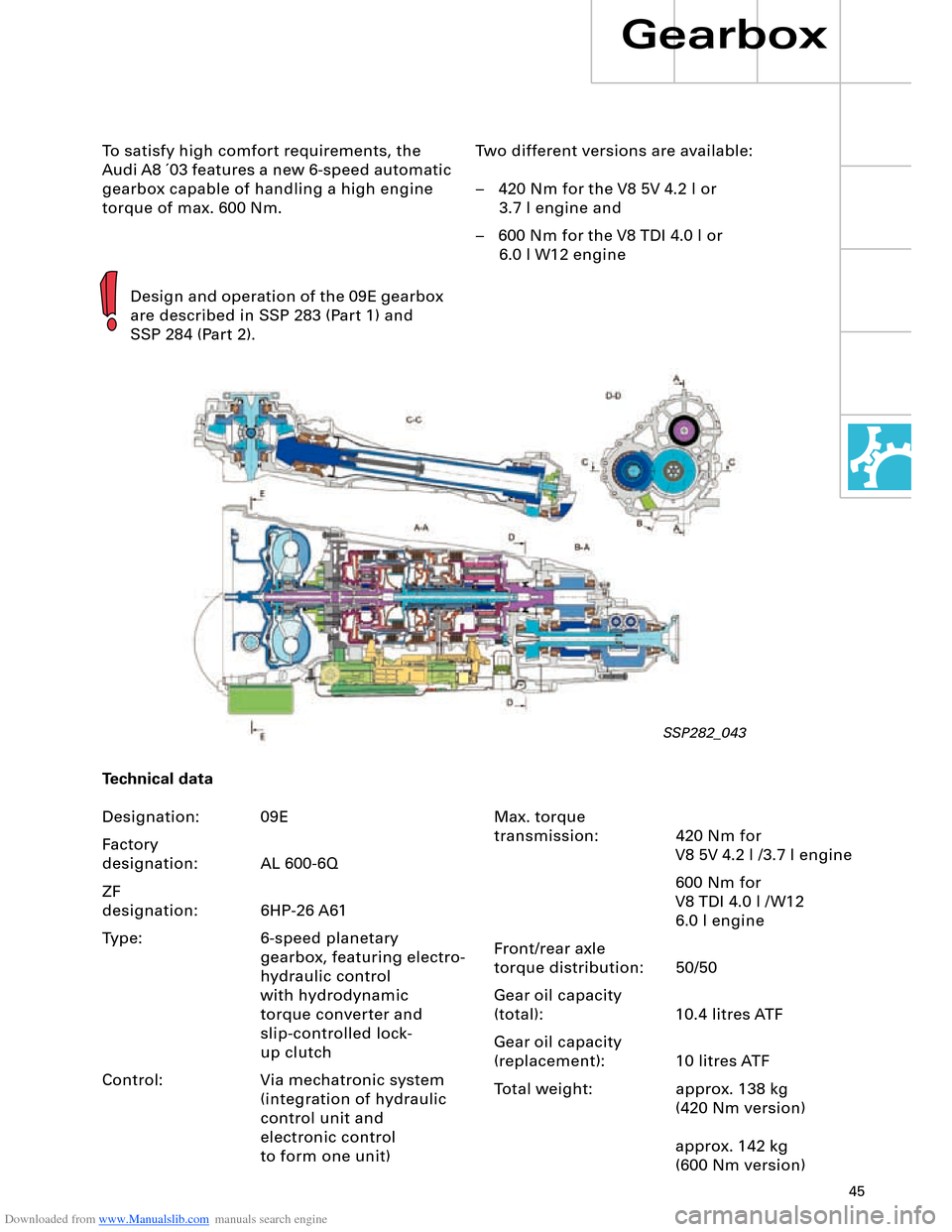

Two different versions are available:

– 420 Nm for the V8 5V 4.2 l or

3.7 l engine and

– 600 Nm for the V8 TDI 4.0 l or

6.0 l W12 engine To satisfy high comfort requirements, the

Audi A8 ´03 features a new 6-speed automatic

gearbox capable of handling a high engine

torque of max. 600 Nm.

Gearbox

Design and operation of the 09E gearbox

are described in SSP 283 (Part 1) and

SSP 284 (Part 2).

SSP282_043

Technical data

Designation: 09E

Factory

designation: AL 600-6Q

ZF

designation: 6HP-26 A61

Type: 6-speed planetary

gearbox, featuring electro-

hydraulic control

with hydrodynamic

torque converter and

slip-controlled lock-

up clutch

Control: Via mechatronic system

(integration of hydraulic

control unit and

electronic control

to form one unit)Max. torque

transmission: 420 Nm for

V8 5V 4.2 l /3.7 l engine

600 Nm for

V8 TDI 4.0 l /W12

6.0 l engine

Front/rear axle

torque distribution: 50/50

Gear oil capacity

(total): 10.4 litres ATF

Gear oil capacity

(replacement): 10 litres ATF

Total weight: approx. 138 kg

(420 Nm version)

approx. 142 kg

(600 Nm version)