change wheel AUDI A8 2011 User Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2011, Model line: A8, Model: AUDI A8 2011Pages: 302, PDF Size: 76.07 MB

Page 260 of 302

258 Tires and wheels

pressure label~ page 242 . Driving on a

significantly under-inflated tire causes

the tire to overheat and can lead to tire

failure. Under-inflation also is likely to

impair the vehicle's handling and stop

ping ability.

- The driver is responsible for maintaining

the correct tire pressures. You must

check the tire pressures regularly.

- Under certain cond itions (such as a spor

ty driving style, winter condit ions or un

paved roads), the pressure monitor indi

cator may be delayed.

- Ask your author ized Audi dealer if run

flat tires may be used on your veh icle.

Your vehicle registration becomes invalid

if you use these tires when not permit

ted. Damage to your vehicle or accidents

cou ld also result.

(D Tips

- The tire pressure monitoring system

stops working when there is an ESP/ABS

malfunction.

- Using snow chains may result in a system

malfunction.

- To ensure a proper TPMS function use

AUDI Original Tires which are marked

with "AO" or "RO" on the tire sidewall.

~p age 249.

- The tire pressure monitoring system on

your Audi was syntonized using tires with

the "AO" or "RO" identification. We rec

ommend using these tires.

Reset tire pressure monitoring system

App lies to vehicles: with tire pressure monitoring system

If the tire pressure is adjusted, wheels are ro

tated or changed, the TPMS must be reset via

MMI .

.. Switch on the ignition .

.. Se lect in the MMI: !CAR !function button>

Car systems contro l button > Servicing &

checks > Tire pressure monitoring > Store

tire pressures > Yes, store now.

(D Tips

Before resetting the TPMS, the current

pressures of all four tires must correspond

to the specif ied values. Adjust the tire

pressure and reset the pressure in the tire

pressure monitoring system according to

the load you are carrying~ page 242.

- Do not store the tire pressures if you are

dr iving with snow chains. Otherwise, a

system malfunction may occur.

Page 265 of 302

other warning devices to alert other mo

torists.

- Make sure that passengers wait in a safe

place away from the vehicle and well

away from the road and traffic.

- To help prevent the vehicle from moving

suddenly and possibly slipping off the

jack, always fully set the parking brake

and block the wheel diagonally opposite

the wheel being changed. When one

front wheel is lifted off the ground, plac

ing the Automatic Transmission in "P"

(Park) will

not prevent the vehicle from

moving.

- Before you change a wheel, be sure the

ground is level and firm. If necessary,

use a sturdy board under the jack.

- After installing the spare wheel, make

sure that you replace the flat tire/wheel

in its storage area properly and tighten

the knurled retaining screw securely.

@ Tips

Before changing the wheel, you must acti·

vate the jacking mode, so that the auto

matic controls for the Adaptive Air Sus

pension do not make it more difficult to

lift the vehicle with the jack ¢

page 265.

Changing a wheel

When you change a wheel, follow these

quence described below step-by-step and in

exactly that order.

1. Activate the vehicle jack mode

¢ page 265.

2. Remove the decorative wheel cover*. For

more details see also¢

page 264, Deco

rative wheel covers

or ¢ page 264,

Wheels with wheel bolt caps.

3 . Loosen the wheel bolts¢ page 264 .

4. Locate the proper mounting point for the

jack and align the jack below that point

¢page 265.

5. Raise the car with the jack¢ page 265.

6. Remove the wheel with the flat tire and

then install

the spare ¢ page 266.

What do I do now? 263

7. Tighten all wheel bolts lightly.

8.

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly

tighten all wheel bolts¢ page 264.

10. Replace the decorative wheel cover*.

11. Deactivate the vehicle jack mode in the

MMI:

ICARI function button > Car systems

control button > Servicing & checks> Air

susp.: jack mode> Off .

The vehicle jack mode switches off automati

cally at speeds above 10 km/h .

A WARNING

Always read and follow all WARNINGS and

information¢ .&

in Raising the vehicle on

page 265

and ¢ page 267.

After changing a wheel

A wheel change is not complete without the

doing the following.

.. Store and secure the wheel you replaced in

the spare wheel well.

.. Replace the tools and the jack in their prop

er location.

.. Check the

tire pressure on the spare wheel

immediately after mounting it.

.. As soon as possible, have the

tightening

torques

on all wheel bolts checked with a

torque wrench. The correct tightening tor

que is 90

ft lb (120 Nm).

.. Have the flat tire

replaced as soon as possi

ble .

(D Tips

-If you notice that the wheel bolts a re

corroded and difficult to turn while

changing a tire, they should be replaced

before you check the tightening torque.

- Drive at reduced speed until you have the

tightening torques checked.

•

•

Page 267 of 302

@ Tips

-Never use the hexagonal socket in the

handle of the screwdriver to loosen or

tighten the wheel bolts.

- If a whee l bolt is very tight, you may find

it easier to loosen by carefully pushing

down on the end of the wheel bolt

wrench w ith

one foot only. As you do so,

hold on to the car to keep your ba lance

and take ca re not to slip.

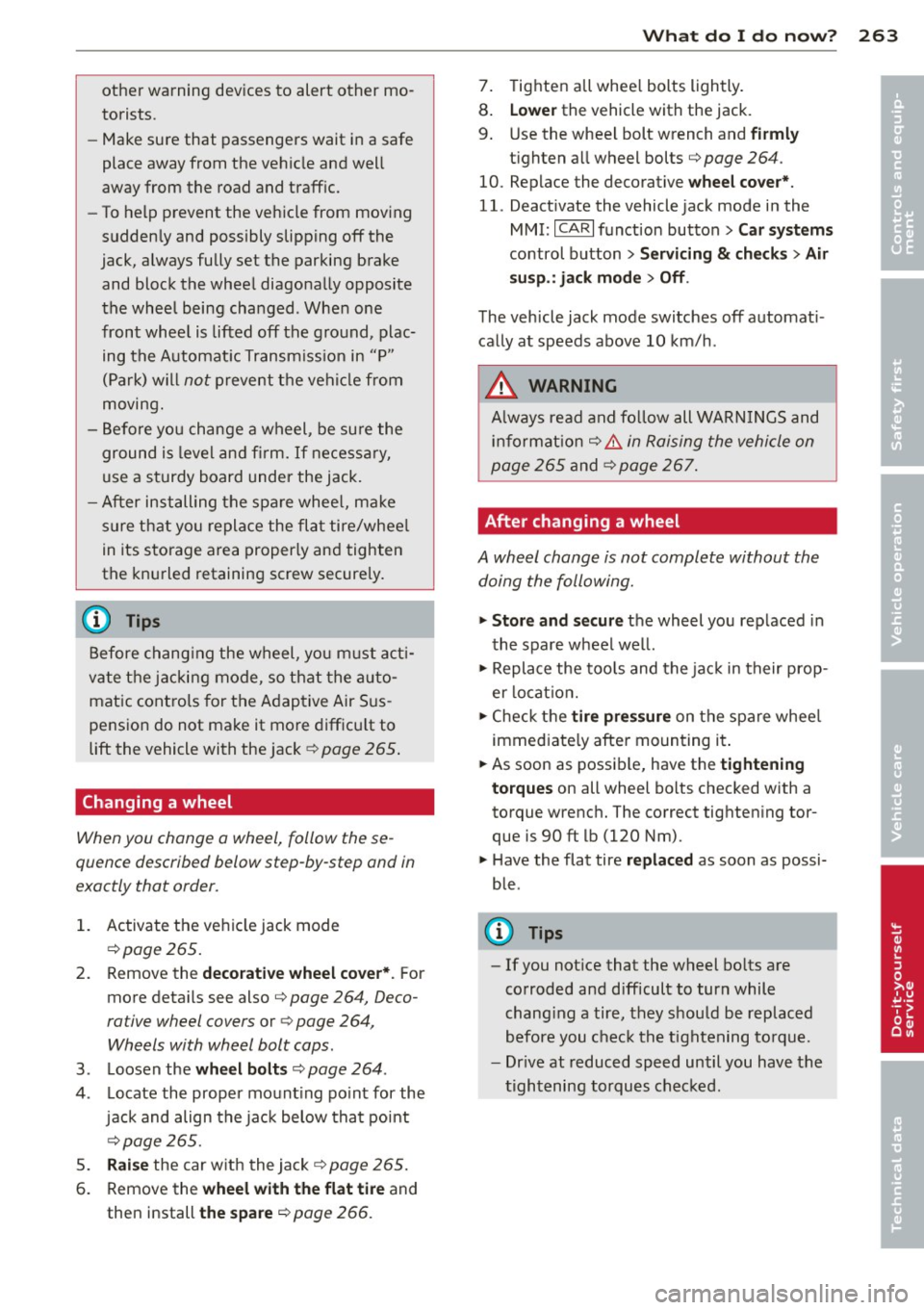

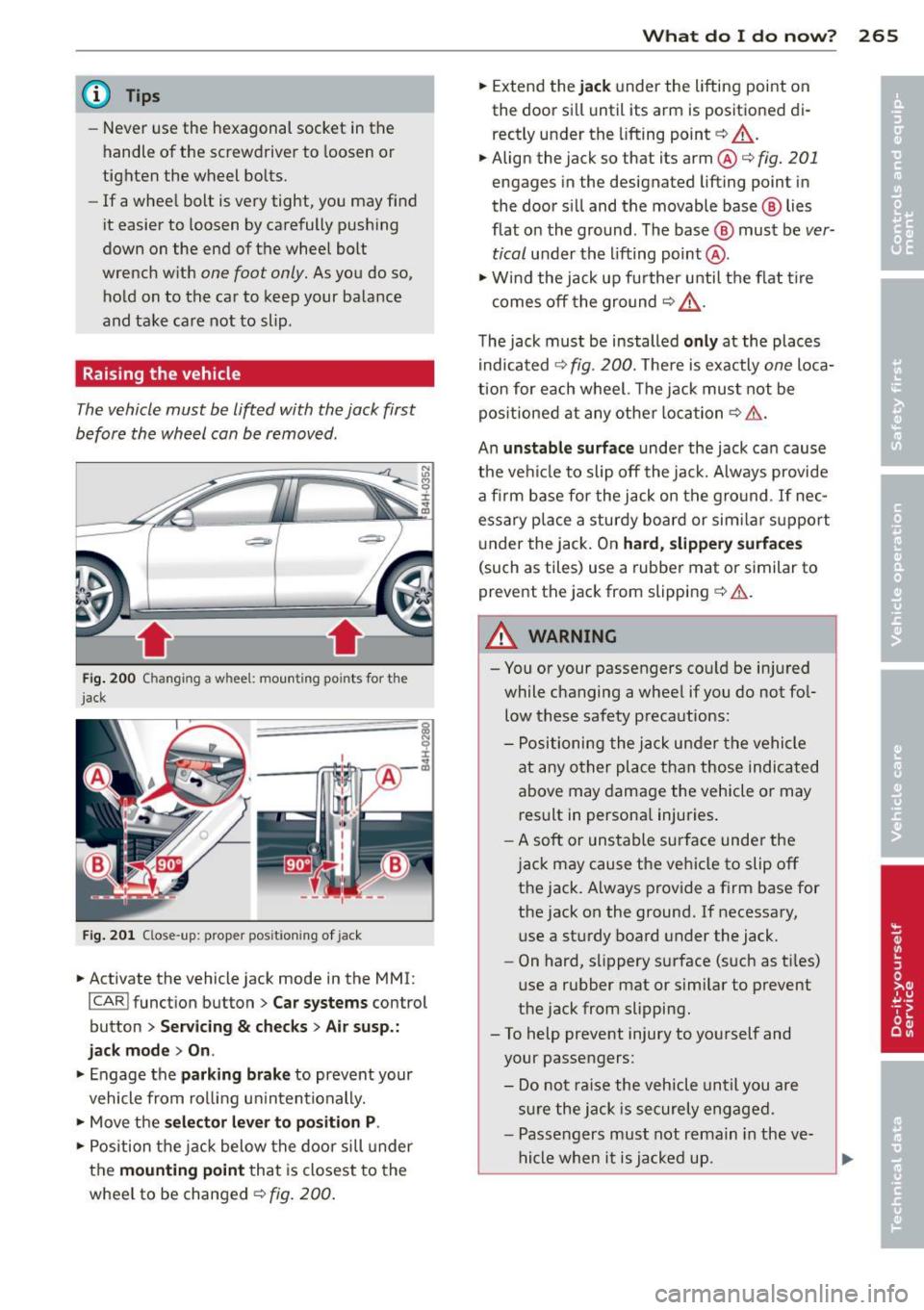

Raising the vehicle

The vehicle must be li~ed with the jack first

before the wheel can be removed .

-itr·--

Fi g. 200 Changing a whee l: mou nting po ints fo r the

jack

F ig . 20 1 Close -up: proper positioning of jack

.. Activate the vehicle jack mode in the MMI:

I CAR I function button> Car systems control

button

> Servicing & ch ecks > Ai r susp.:

jack mod e> On.

.. Engage the parking brake to prevent your

vehicle from rol ling un intentionally.

.. Move the

se lector le ver to pos ition P.

.. Position the j ack below the door sill under

the

mounting point that is closest to the

whee l to be changed ¢

fig. 200 .

What do I d o now ? 265

.. Extend the jack under the lifting point on

the door sill until its arm is positio ned di

rectly under the lifting point ¢

A.

.. Align the jack so that its arm@¢ fig. 201

engages in the designated lifting point in

the doo r si ll and the movable base @ lies

flat o n the ground. The base @ must be

ver

tical

under th e lifting point @.

.. Wi nd the jack up fu rther until the flat t ire

comes off the gro und

¢ A_ .

The jack must be installed only at the places

i ndicated

¢ fig . 200. The re is exactly one loca

tion for each wheel. The j ack mus t not be

pos it ioned at any other location

¢ & .

An unstable surface under the jack ca n cause

the vehicle to slip off the jack. Always provide

a firm base for the jack on t he g ro und . If nec

essary p lace a sturdy board or sim ilar support

u nder the jack . On

hard, slipper y surface s

(such as tiles) use a rubbe r mat or similar to

prevent the jack from slipping

¢ & .

A WARNING

- You or your passengers co uld be in jured

while c hanging a wheel if you do not fo l

low these safety precautions:

- Positioning the j ack under the vehicle

at any o ther place than those indicated

above may damage the vehicle or may result in persona l injuries .

- A soft or uns table surf ace unde r the

j ac k may cause the vehicle to slip off

the jack. Always provide a f irm base for

the jack on the ground. If necessary, use a sturdy board under the jack.

- On hard, s lippery surface (such as ti les)

use a rubber mat or similar to prevent

the jack from slipping.

- To help prevent injury to yo urself and

your passengers:

- Do n ot ra ise the veh icle until you are

s ur e the jack is securely engaged .

- Passe ngers must not remain in the ve

h icle when i t is ja cked up.

Page 268 of 302

266 What do I do now ?

-Make sure that passengers wait in a

safe p lace away from the vehicle and

well away from the road and traffic.

- Make sure jack position is correct, ad

just as necessary and then continue to ra ise the jack.

- Changes in temperature or load can af

fect the height of the vehicle.

@ Tips

The vehicle jack mode switches off auto

matica lly at speeds above 10 km/h.

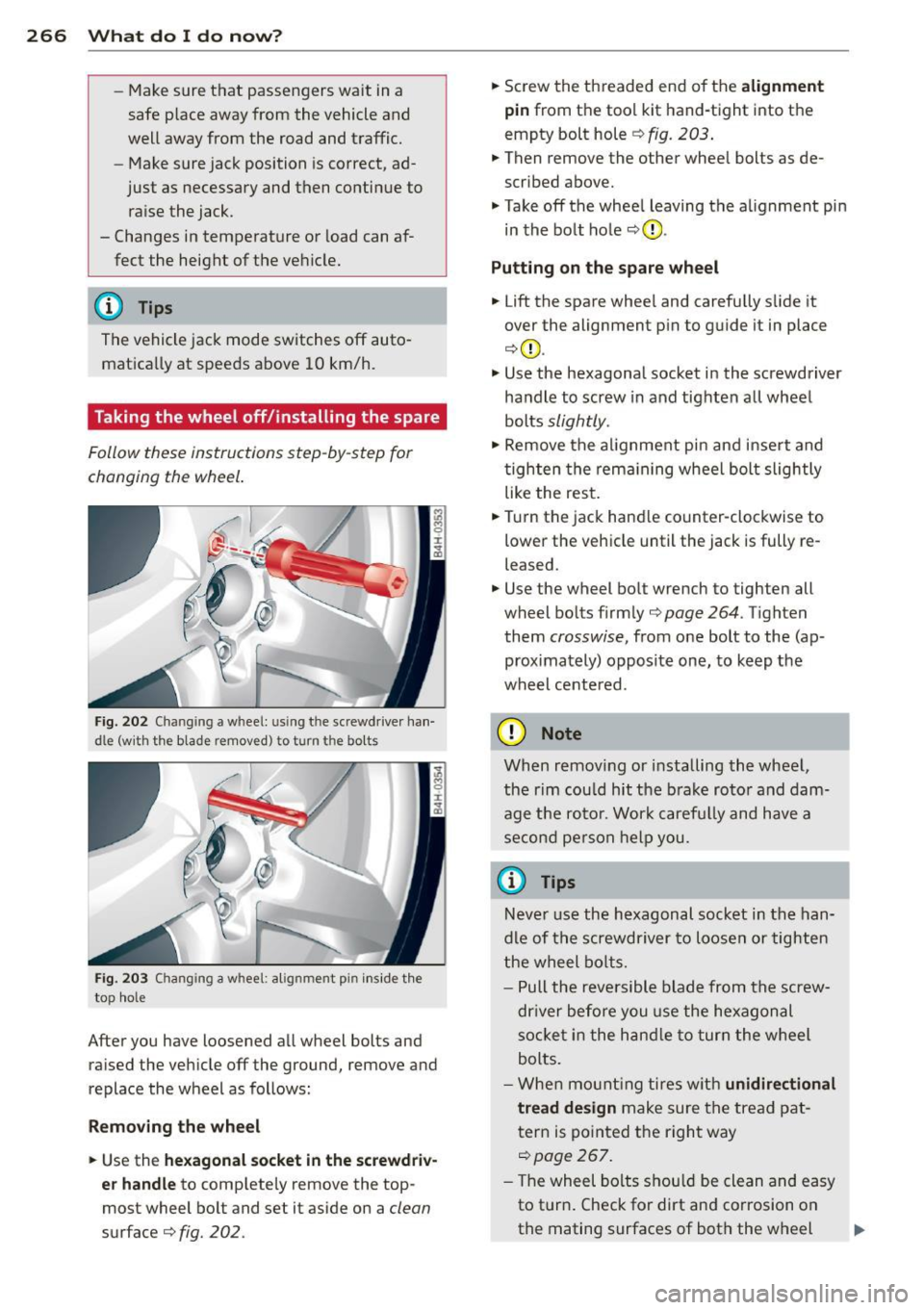

Taking the wheel off/installing the spare

Follo w thes e instruct ions st ep-by -step for

changing th e wh eel .

Fig. 2 02 Chan gin g a w hee l: u sing t he sc rewdr ive r ha n

dl e (w it h th e bla de r emoved ) to tu rn th e bolts

Fi g. 20 3 Changin g a w heel : a lignm en t pin inside th e

t o p hole

After you have loosened a ll wheel bolts and

ra ised the vehicle off the ground, remove and

replace the wheel as follows:

R emoving the wheel

• Use the hexagonal socket in the screwd riv

e r handle

to comp lete ly remove the top

most wheel bolt and set it aside on a

clean

surface ¢fig. 202.

• Sc rew the th readed end of the alignment

pin

from t he tool k it hand-tight into t he

empty bolt hole

r::;, fig . 203 .

• Then remove the other whee l bolts as de

scribed above.

• Takeoff the whee l leaving the a lignment pin

in the bo lt hole

r::;, (D .

Putting on the spare wheel

• Lift the spare whee l and carefu lly s lide it

over the alignment p in to g uide it in place

¢ (D .

.,. Use the hexagonal socket in the screwdriver

ha ndle to screw in and tighten a ll whee l

bolts

slightly .

.,. Remove the alignment pin and inse rt and

tighten the rem aining wheel bol t slightly

like the res t.

• Turn the jack hand le co unter-clockwise to

lower the veh icle until the jack is fully re

leased .

.,. Use the wheel bo lt wrench to tighten all

wheel bolt s firm ly

r::;, page 264 . Tigh ten

them

crosswise, from one bolt to the (ap

proximately) opposite one, to keep the

wheel cente red .

(D Note

When remov ing or installing the whe el,

the rim cou ld hit the b rake roto r and dam

age t he ro to r. Wor k caref ully and have a

s eco nd pers on h elp you.

{i) Tips

Neve r use the hexagonal socket in the han

dle of t he s crewdr iver to lo ose n or t igh ten

t he wheel bo lts .

- P ull the revers ible blade from the screw

dr iver be fore y ou use the hexagon al

so cket in the han dle to tur n the w heel

bolts.

- W he n m oun tin g ti res w ith

unidirectional

tread design

make sure t he trea d pat

t ern is poin ted t he righ t way

r::;, page267.

- T he wheel bolts shou ld be clean and easy

to t urn. Check for dirt an d corrosion on

the mating surfaces of both the w heel .,,.

Page 284 of 302

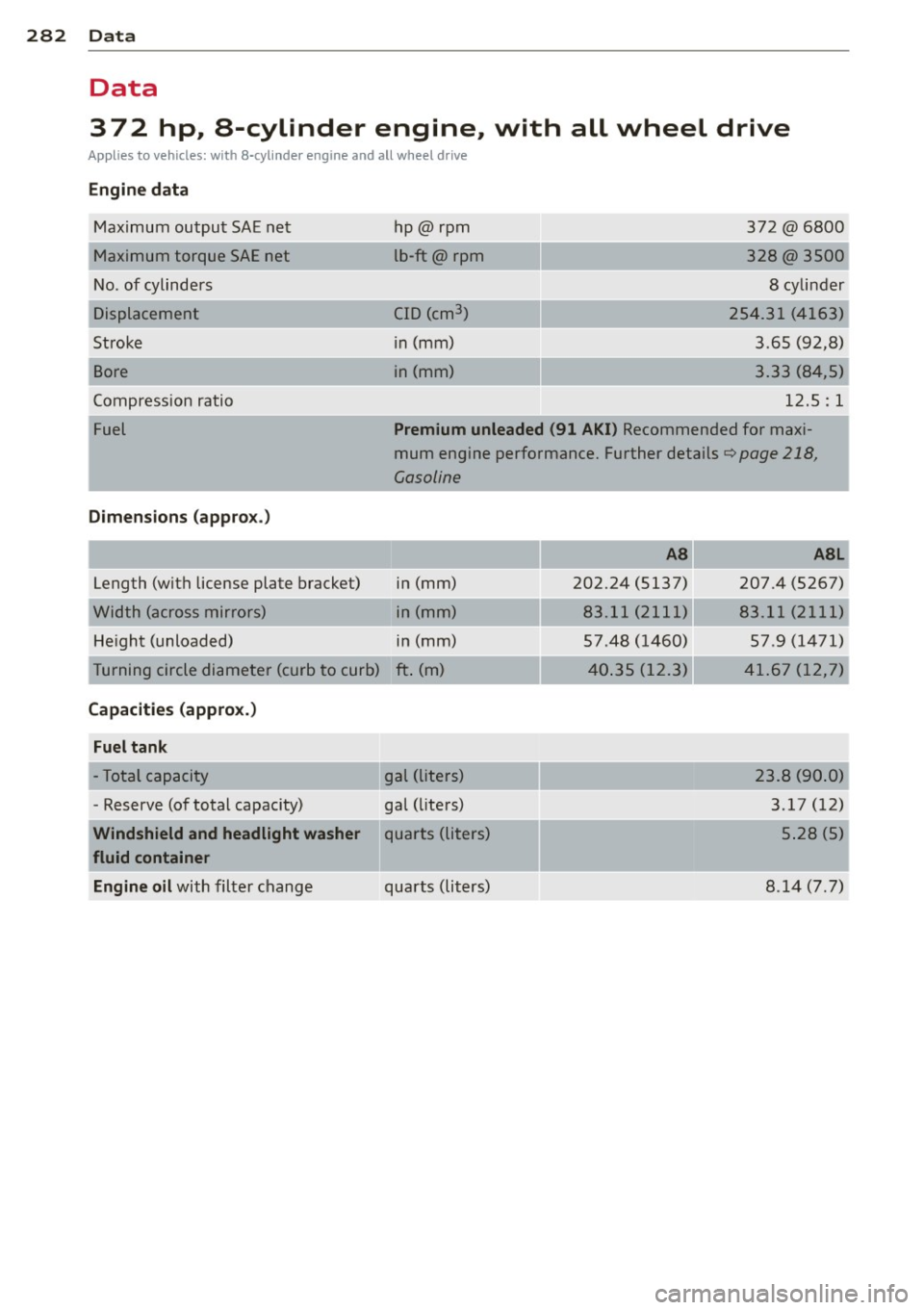

282 Data

Data

372 hp, a-cylinder engine, with all wheel drive

Appl ies to vehicles: with 8-cy linder engine and a ll whee l drive

Engine data

Maximum output SAE net

Maximum torque SAE net

No . of cylinders

Displacement

Stroke

Bore

Compression ratio hp@rpm

l

b-ft@ rpm

CID (cm

3 )

in (mm)

i n (mm)

372 @6800

328@3500

8 cylinder

254.3 1 (4163)

3 .65 (92,8)

3.33 (84,5)

12.5: 1

Fuel Premium unleaded (91 AKI)

Recommended for maxi

mum engine performance. Further details<=>

page 218,

Gasoline

Dimen sion s (appro x.)

Length (with license plate bracket)

Width (across mirrors)

He ight (unloaded) in (mm)

in (mm)

in (mm)

T urning circle diameter (curb to curb) ft . (m)

Capacities (approx.) Fuel tank

- Total capacity gal (liters)

- Reserve (of total capacity) gal (liters)

Windshield and headlight washer quarts (liters)

fluid container

Engine oil with filter change quarts (liters)

AS

202.24 (5137)

83.11 (2111)

57 .48 (1460)

4 0.35 (12.3)

ASL

207 .4 (5267)

83.1 1 (2111)

57 .9 (1471)

4 1.67 (12, 7)

23.8 (90 .0)

3 .17 (12)

5 .28 (5)

8 .14 (7.7)