lock AUDI Q2 2021 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2021, Model line: Q2, Model: AUDI Q2 2021Pages: 364, PDF Size: 87.77 MB

Page 304 of 364

Checking and topping up fluids

Coolant additive

The coolant additive contains anti-freeze and cor

rosion protection agent. Only use one of the

fol

lowing coolant additives. It is possible to mix

these additives.

Topping up coolant

Coolant additive

G13

G12++

Specification

TL774J

TL 774

G

The amount of coolant additive which needs to

be mixed with the water depends on the temper

atures to be expected in the winter season. If the

anti-freeze concentration is too Low, the coolant

can freeze and cause engine damage.

Hot regions

Cold regions

Coolant

additive

min.

40%

max. 45 %

min.

50%

max. 55 %

Frost protec

tion

min.-25°C

max. -40 °C

(T)

CAUTION

- Have your qualified workshop check the

cooling system before the winter season to

make sure that the anti-freeze concentra

tion is adequate for the conditions to be ex

pected.

This applies particularly if

you

drive

into a colder climate zone.

- To prevent damage to the engine, do not

use a different type of anti-freeze additive if

the approved type of additive is not availa

ble.

In this case use only water and bring

the coolant concentration back up to the

correct level as soon as possible by putting

in the specified additive.

- Always top up with fresh, unused coolant.

- Radiator sealants must not be added to the

coolant.

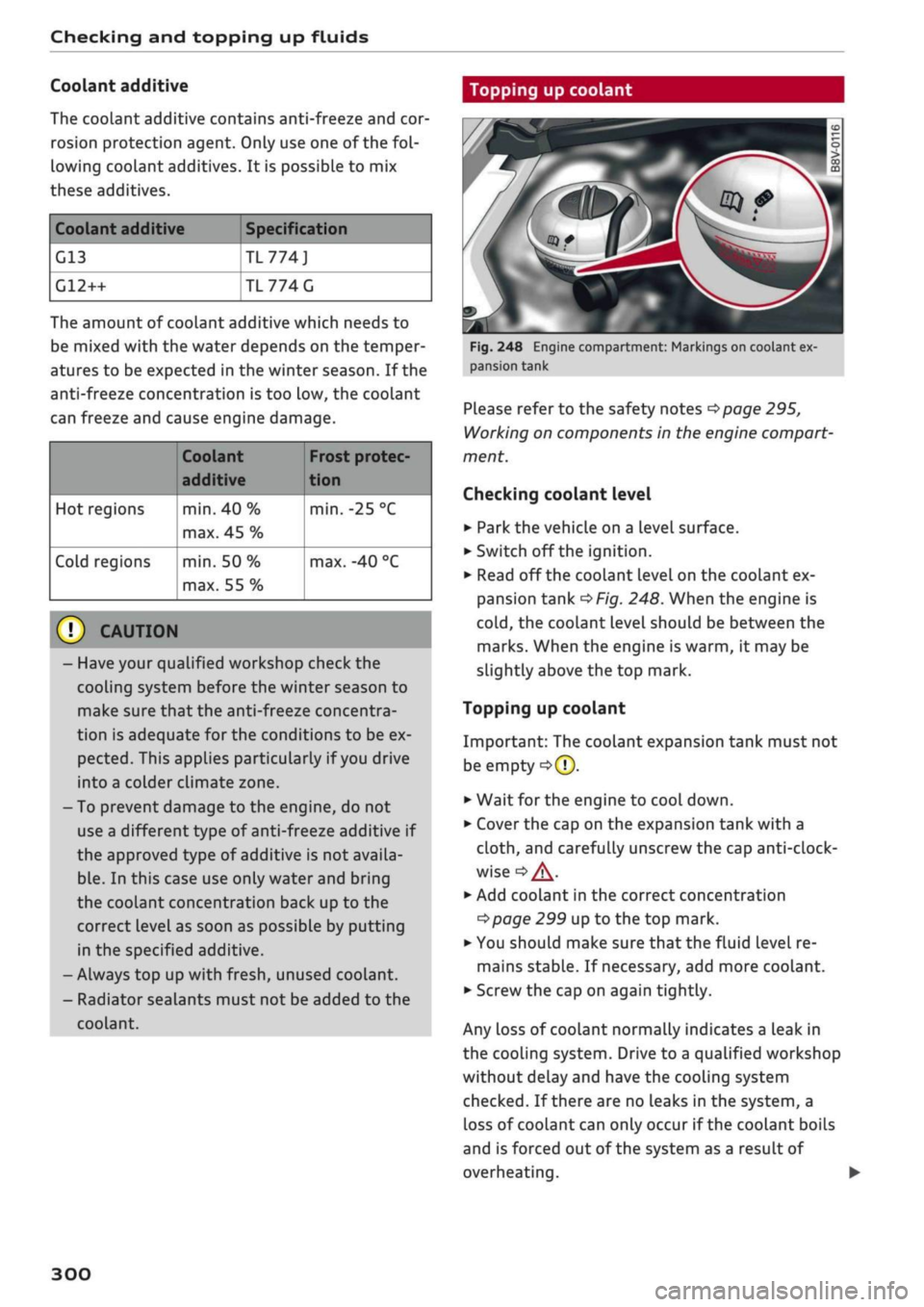

Fig.

248 Engine compartment: Markings on coolant ex

pansion tank

Please refer to the safety notes

^page

295,

Working on components in the engine compart

ment.

Checking coolant level

•

Park the vehicle on a level surface.

•

Switch off the ignition.

•

Read off the coolant level on the coolant ex

pansion tank

^>Fig.

248. When the engine is

cold,

the coolant level should be between the

marks. When the engine is warm, it may be

slightly above the top mark.

Topping up coolant

Important: The coolant expansion tank must not

be empty

•=>([).

•

Wait for the engine to cool down.

•

Cover the cap on the expansion tank with a

cloth,

and carefully unscrew the cap

anti-clock

wise

<=>

/K.

*-

Add coolant in the correct concentration

tapage

299 up to the top mark.

•

You should make sure that the fluid level re

mains stable. If necessary, add more coolant.

•

Screw the cap on again tightly.

Any loss of coolant normally indicates a Leak in

the cooling system. Drive to a qualified workshop

without delay and have the cooling system

checked.

If there are no leaks in the system, a

loss of coolant can only occur if the coolant boils

and is forced out of the system as a result of

overheating.

300

Page 305 of 364

Checking and topping up fluids

A WARNING

CO

rN

IV

rN

•-i

00

- The cooling system is under pressure. Do

not unscrew the cap on the expansion tank

when the engine is hot: you could be

scal

ded by escaping steam.

- The coolant and coolant additive can be a

health hazard. Store the coolant additive in

the original container in a safe place out of

reach of children - risk of poisoning.

- When working in the engine compartment

be aware that the radiator fan may start

running suddenly, even if the ignition is

switched off- risk of injury!

Brake fluid

© CAUTION

Do not add coolant if the expansion tank is

empty. Air could have got into the cooling

system - risk of engine damage! In this case,

do NOT drive on. Obtain professional assis

tance.

- Have your qualified workshop check the

cooling system before the winter season to

make sure that the anti-freeze concentra

tion is adequate for the conditions to be ex

pected.

This applies particularly if

you

drive

into a colder climate zone.

-To prevent damage to the engine, do not

use a different type of anti-freeze additive if

the approved type of additive is not availa

ble.

In this case use only water and bring

the coolant concentration back up to the

correct level as soon as possible by putting

in the specified additive.

- Always top up with fresh, unused coolant.

- Radiator sealants must not be added to the

coolant.

ëB

k

DOT

4

A

•9

o

o

:>

li-

Fig.

249 Engine compartment: Cap of brake fluid reservoir

Please refer to the safety notes

^page

295,

Working on components in the engine compart

ment.

Checking brake fluid level

Read off the brake fluid level on the brake fluid

reservoir

^>page

297, Fig. 245. The brake fluid

level must be between the MIN and MAX marks

<=>A.

The brake fluid

level

is also automatically moni

tored.

In right-hand drive vehicles the brake fluid reser

voir is on the other side of the engine compart

ment.

Changing brake fluid

Have the brake fluid changed regularly by a quali

fied workshop.

WARNING

-If the brake fluid Level is under the MIN

mark, the effectiveness of the brakes and

therefore the safety of the vehicle may be

impaired - risk of accident! Do not drive on.

Obtain professional assistance.

- Heavy use of the brakes may cause a vapour

lock if old brake fluid is left in the system.

This would seriously impair the effective

ness of the brakes and the safety of the car

- risk of accident!

© CAUTION

- If the brake fluid level is above the MAX

mark, brake fluid may escape via the cap on •

301

Page 309 of 364

Wheels

WheeLs

Tyres and rims

General notes

•

Inspect the tyres regularly for damage (cuts,

cracks or blisters, etc.). Remove any foreign

bodies embedded in the treads.

•

If

you

have to drive over

a

kerb or similar obsta

cle,

drive very slowly and as near as possible at

a right angle to the kerb.

• Damaged rims or tyres must be replaced imme

diately.

•

Keep grease, oil and fuel off the tyres.

•

Mark the wheels before taking them off so that

they rotate in the same direction when refitted.

•

When removed, the wheels should be stored

flat in a

cool,

dry and preferably dark place.

CO

<

O

rN

IV

rN

t-H

o <

(l)

CAUTION

- Please note that summer and winter tyres

are optimised for the prevailing road condi

tions at different times of

year.

We recom

mend that you use winter tyres during the

winter months. At low temperatures, sum

mer tyres lose their elasticity and grip, and

braking performance also suffers as a re

sult. Cracks can form in the tread block on

summer tyres if they are used at very cold

temperatures, and this can cause perma

nent damage to the tyres. An increase in

rolling noise and tyre imbalance may result

from this damage.

- Machined, polished or chrome-plated rims

must not be used in winter conditions. The

process used to manufacture these types of

wheel rim does not provide adequate sur

face protection against corrosion, and the

rims can be permanently damaged by road

salt or similar.

New wheels or tyres

It is best to have all servicing of wheels and tyres

performed by a qualified workshop, since they

have the necessary special tools and replacement

parts in addition to trained personnel.

•

New tyres do not yet give maximum grip. When

driving with new tyres, drive at moderate

speeds and be especially careful during the first

500 km.

•

All four wheels must be fitted with tyres of the

same type, size (rolling circumference) and

preferably the same tread pattern.

• Tyres should be replaced in pairs and not

indi

vidually (i.e. both front tyres or both rear tyres

together).

•

We recommend the use of Audi Genuine Tyres.

If

you

wish to use other tyres, please note that

the actual size can differ from the nominal size

marked on the tyre

•=> /\.

•

If

you

wish to purchase a different combination

of rims and tyres than the ones fitted on the ve

hicle during production, it is advisable to

con

sult

a

qualified workshop beforehand

<=> /\.

The sizes of the rims and tyres approved

for

your

vehicle are listed in the vehicle's documents (e.g.

EC

Certificate of Conformity or COC

document1)).

The vehicle documents vary depending on the

country in which the vehicle is registered.

If the spare wheel* is

not

the same type as the

tyres fitted on the car (for example if the car has

winter tyres or wide-section tyres) you should on

ly use the spare wheel* if

a

puncture occurs, and

then

only

for

a

short period of time. In this case,

please drive with extra care. Refit

a

normal road

wheel as soon as possible.

Applies to vehicles with four-wheel drive: All four

wheels must always be fitted with tyres of the

same type, make and tread pattern, as the drive-

line could otherwise be damaged by variations in

the wheel speeds. For the same reason, only use

a spare wheel* which has the same rolling cir

cumference as the normal road wheels.

Manufacturing date

The manufacturing date is indicated on the tyre

sidewall (possibly only on the inner side of the

wheel): •

15 COC

= Certificate of conformity

305

Page 325 of 364

Mobility

CO

rN

IV

rN

•-i

00

- Do not drive faster than 80 km/h.

- Avoid heavy acceleration, hard braking and

fast cornering.

-Vehicle handling could be impaired.

- If the tyre is too badly damaged, you should

seek professional assistance.

Removing the hubcap/wheel bolt caps

(#) For

the sake of the environment

A used can of sealing compound can be re

turned to your qualified workshop for dispos

al.

Note ©

After repairing a tyre, remember to buy

a

new

tyre sealant can at

a

qualified workshop.

Changing a wheel

Preparations

Certain preparations must be made before you

change the wheel.

• Please refer to the important safety notes on

^page

318.

• Apply the parking brake.

• Manual gearbox: Engage first gear.

• Automatic gearbox: Move the selector Lever to

position P.

• If

you

are towing a trailer, unhitch

it

from your

vehicle.

• Take out the tools

^>page

319 and spare

wheel*

^>page

324.

A WARNING

If

you

have to use the jack* on a gradient or

off-road track, block the wheel diagonally op

posite the wheel being changed by placing

suitable objects underneath both the front

and rear of the wheel to prevent the vehicle

from rolling away.

0

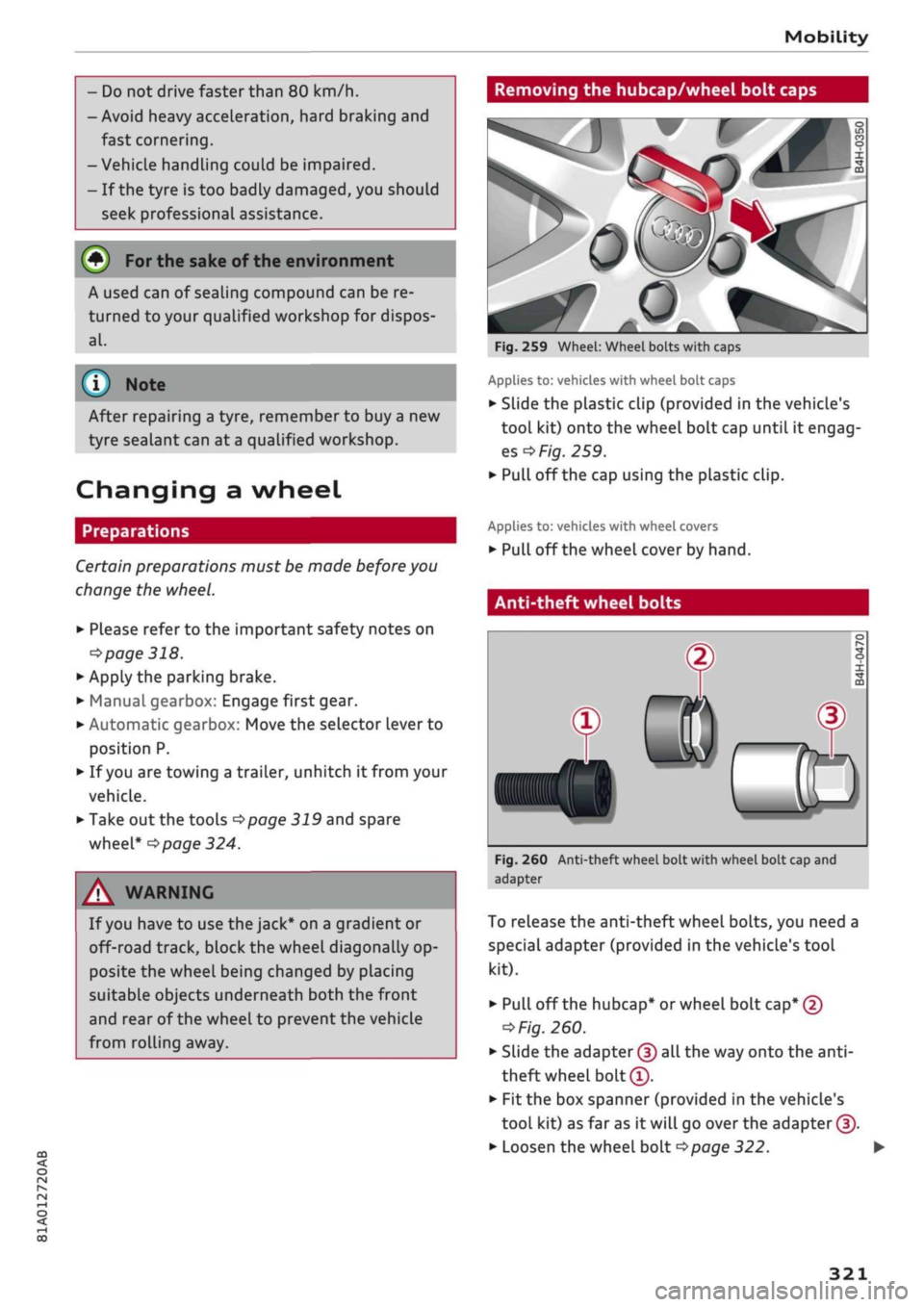

Fig.

259 Wheel: Wheel bolts with caps

Applies to: vehicles with wheel bolt caps

• Slide the plastic clip (provided in the vehicle's

tool kit) onto the wheel bolt cap until it engag

es

^F/'g.

259.

• Pull off the cap using the plastic clip.

Applies to: vehicles with wheel covers

• Pull off the wheel cover by hand.

Anti-theft wheel bolts

T

0)

®

Fig.

260 Anti-theft wheel bolt with wheel bolt cap and

adapter

To release the anti-theft wheel bolts, you need a

special adapter (provided in the vehicle's tool

kit).

• Pull off the hubcap* or wheel bolt

cap*

@

^>

Fig.

260.

• Slide the adapter

©

all the way onto the

anti-

theft wheel bolt®.

• Fit the box spanner (provided in the vehicle's

tool kit) as far as it will go over the adapter ©.

• Loosen the wheel bolt

^>page

322.

321

Page 326 of 364

Mobility

\J Note

Note the code number of the anti-theft wheel

bolt and keep it in a safe place - not in your

vehicle. If

you

need a replacement adapter,

give the code number to your Audi dealer.

Loosening the wheel bolts

Raising the vehicle

Fig.

261 Wheel: Loosening the wheel bolts

•

Fit

the box spanner (provided in the vehicle's

tool kit) as far as it will go over the wheeL

bolt1'.

• Turn the wheel bolt approx. one turn

anti

clockwise -arrow-. To apply the necessary tor

que,

hold the box spanner

near

the end. If the

wheel bolt is very tight, you may be able to

loosen it by pushing down the end of the span

ner carefully with your foot. Hold on to the car

for support and take care not to slip.

WARNING

To avoid accidents, the wheel bolts should on

ly be loosened slightly (one turn) before rais

ing the vehicle with the jack*.

:v<

:

Fig.

262 Sills: markings (example)

Fig.

263 Door

sill:

Applying the jack under the door sill

• Always provide a firm base for the jack* on the

ground.

(The jack can be found in the vehicle's

tool kit). If necessary use a large, strong board

or similar support. On a

hard,

slippery surface

(such as tiles) use a rubber mat or similar to

prevent

the

jack from slipping

^> /\.

• Locate the marking (recess or rib) on the door

sill closest to the wheel being changed

^>Fig.

262. The jacking point is located behind

the marking under the door

sill.

• Wind up

the

jack* under

the

jacking point until

the claw

(A)

•=>

Fig.

263 of the jack is directly

be

low the jacking point.

• Align

the

jack* so

that

the

claw

(A)

grips the

jacking point under the door sill and the mova

ble base plate of the jack

(B)

is flat on the

ground.

The base plate

(B)

must be positioned

vertically underneath

the

jacking point®.

• Raise the vehicle until the defective wheel is

clear of the ground.

11

An adapter is required to unscrew or tighten the anti-theft

wheel bolts

opage

321.

322

Page 329 of 364

Mobility

CO

rN

IV

rN

•-i

00

Removing the spare wheel

• Lift the floor panel up by the plastic handle un

til the panel is fixed in position behind the re

taining tabs on the two side sections

©

*

Fig.

266.

• Applies to vehicles with bass box in spare wheel

well:

Remove the bass box*. Please first check

the connector to establish which bass box is fit

ted in your vehicle: version 1)

*page

325 or

version 2)

*page

326.

• Turn the plastic knob anti-clockwise.

• Take out the spare wheel.

Snow chains

For technical reasons, snow chains must not be

used on the compact temporary spare wheel.

Should you have a puncture on one of the front

wheels when using snow chains, fit the compact

temporary spare wheel in place of one of the rear

wheels. You can then attach the snow chains to

the wheel taken from the rear and use this wheel

to replace the punctured front wheel.

A WARNING

- The tyre pressure must be checked as soon

as possible after fitting the spare wheel - an

incorrectly inflated tyre can increase the risk

of accident. You can find the tyre pressures

here

*page

307, Fig. 253.

- Do not drive faster than 80 km/h when the

compact temporary spare wheel is fitted -

higher speeds can cause an accident.

-Avoid heavy acceleration, hard braking and

fast cornering when the compact temporary

spare wheel is fitted - risk of accident!

- Never use two or more compact spare tyres

at the same time - risk of accident!

- No other type of tyre (normal summer or

winter tyres) may be fitted on the compact

temporary spare wheel.

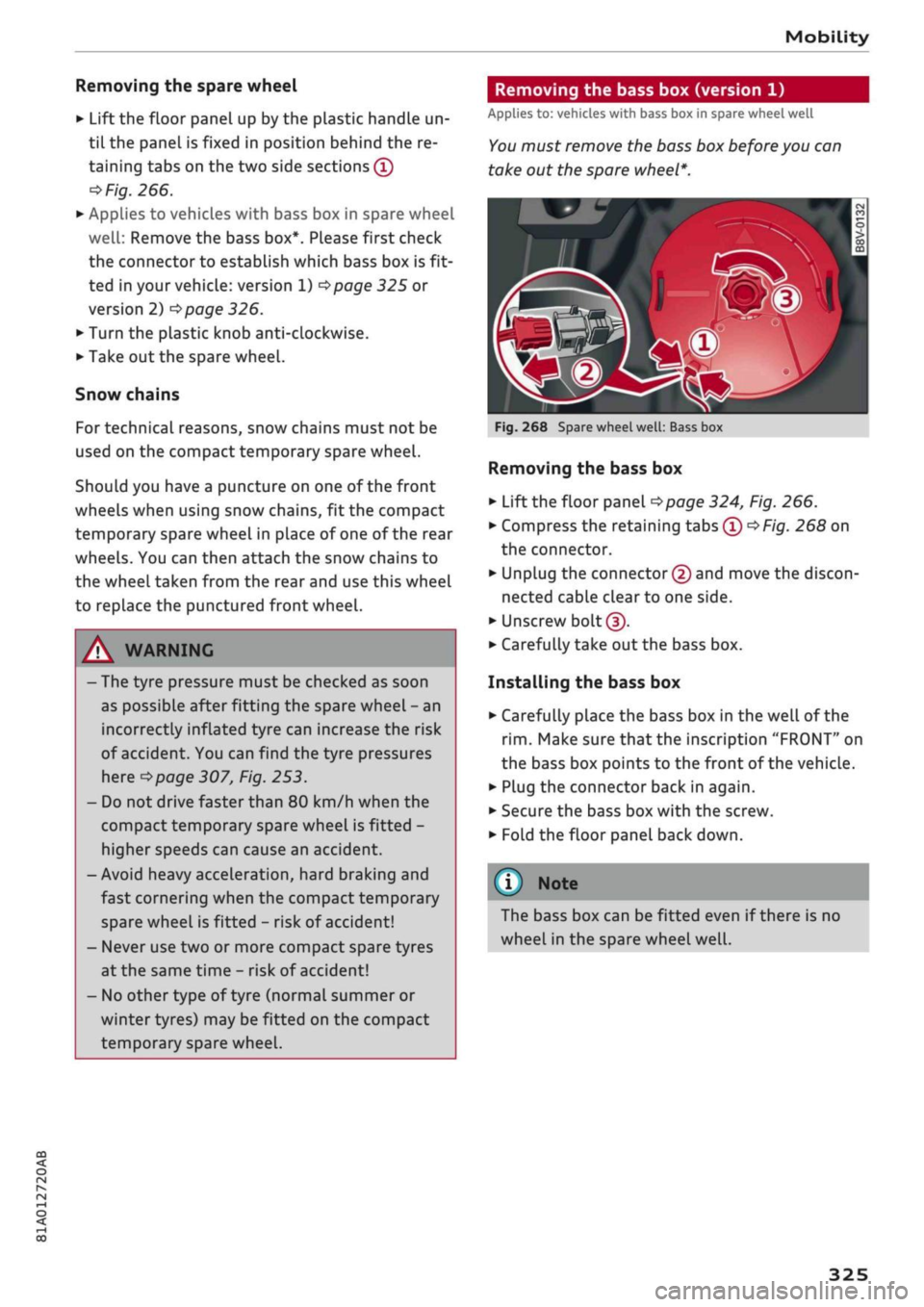

Removing the bass box (version 1)

Applies to: vehicles with bass box in spare wheel well

You

must remove the bass box before you can

take out the spare wheel*.

«

Fig.

268 Spare wheel

well:

Bass box

Removing the bass box

• Lift the floor panel

<=>page

324, Fig. 266.

• Compress the retaining

tabs©*Fig.

268 on

the connector.

• Unplug the connector © and move the discon

nected cable clear to one side.

• Unscrew

bolt©.

• Carefully take out the bass box.

Installing the bass box

• Carefully place the bass box in the well of the

rim.

Make sure that the inscription "FRONT" on

the bass box points to the front of the vehicle.

• Plug the connector back in again.

• Secure the bass box with the screw.

• Fold the floor panel back down.

(T) Note

The bass box can be fitted even if there is no

wheel in the spare wheel

well.

325

Page 331 of 364

Mobility

CO

rN

IV

rN

•-i

00

- Keep sparks, flame and lit cigarettes away

from vehicle batteries: the gases given off

can cause an explosion.

- Do not attach the negative cable to parts of

the fuel system or to the brake pipes.

© CAUTION

- The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected and

the boosting battery could be discharged.

- If the jump leads are not connected correct

ly this can result in serious damage to the

electrical system of the vehicle.

- The discharged vehicle battery must be

properly connected to the vehicle's electri

cal system.

- Please note that the method described

be

low for connecting the leads is intended for

jump-starting your vehicle. If jump-starting

another vehicle, you should not connect the

negative lead (-) to the negative terminal of

the discharged battery, but directly to the

engine block or

a

solid metal part bolted to

the engine block. If the battery of the other

vehicle does not have a gas vent, there is a

risk that

a

mixture of oxygen and hydrogen

gas can accumulate and cause an explosion.

© Note

Switch off the car telephone if necessary. De

tails will be given in the manufacturer's in

structions for the car telephone.

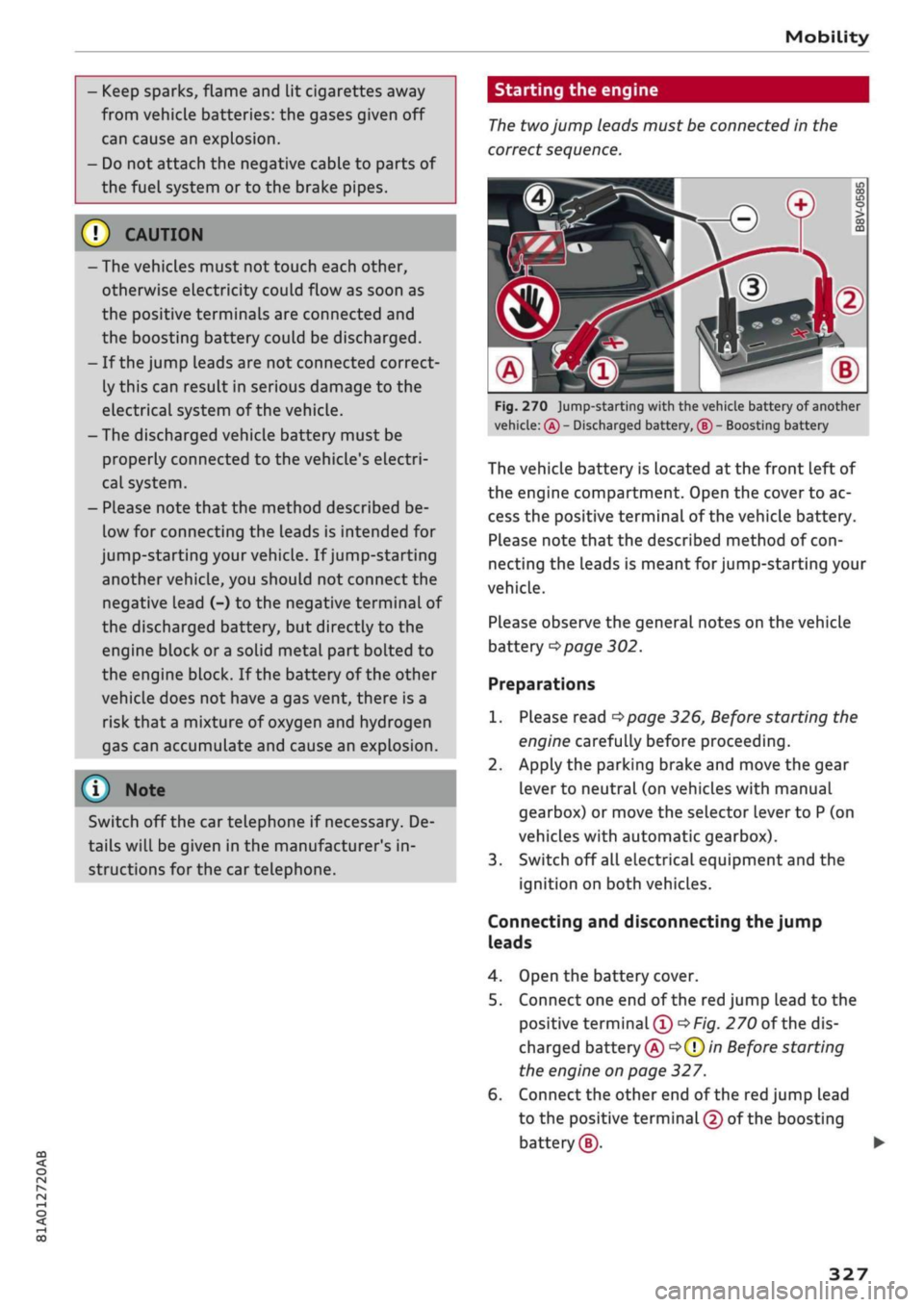

Starting the engine

The two

jump leads must be connected in the

correct

sequence.

Fig.

270 jump-starting with the vehicle battery of another

vehicle:

®

- Discharged battery, ® - Boosting battery

The vehicle battery is located at the front Left of

the engine compartment. Open the cover to ac

cess the positive terminal of the vehicle battery.

Please note that the described method of

con

necting the leads is meant for jump-starting your

vehicle.

Please observe the general notes on the vehicle

battery

*page

302.

Preparations

1.

Please read

*page

326, Before starting the

engine carefully before proceeding.

2.

Apply the parking brake and move the gear

lever to neutral (on vehicles with manual

gearbox) or move the selector lever to

P

(on

vehicles with automatic gearbox).

3. Switch off all electrical equipment and the

ignition on both vehicles.

Connecting and disconnecting the jump

leads

4.

Open the battery cover.

5. Connect one end of the red jump lead to the

positive

terminal®

*Fig.

270 of the dis

charged battery

© oQ)

in Before starting

the engine on page 327.

6. Connect the other end of the red jump lead

to the positive terminal

©

of the boosting

battery®.

327

Page 333 of 364

Mobility

CO

rN

IV

rN

•-i

00

Additional notes on towing by breakdown

truck

If one of the axles has to be raised in order to

tow the vehicLe, please refer to the following ta

ble to determine the appropriate axle

for

your

gearbox/drive combination:

Manual

gearbox

Automatic

gearbox

Front-wheel

drive

Front or rear

axle

Front axle

Four-wheel

drive

Front or rear

axle

Front axle

Applies to vehicles with four-wheel drive: If the

vehicle is to be towed with one of the axles

raised,

the ignition must be switched off; other

wise the drive train can be damaged.

Notes on tow-starting

Applies to vehicles with automatic gearbox: For

technical reasons, your vehicle must not be tow-

started.

Applies to vehicles with manual gearbox: As a

general rule, tow-starting is not recommended.

If the engine will not start, it is best to try start

ing it using the battery of another vehicle

*>page

326 before attempting to tow start. If

this is not possible, you can try to push-start or

tow-start the vehicle

*page

330, Tow-starting.

A WARNING

There is a high risk of accidents when towing/

tow-starting, as the towed vehicle can easily

be driven into the towing vehicle.

UTION

- If it is not possible to tow the vehicle as de

scribed above (e.g. due to a gearbox failure

or if the vehicle has to be towed further

than 50 km), it must be transported on a

special car transporter or trailer.

- Towing a vehicle with the wrong axle raised

can cause serious damage to the gearbox.

- Applies to vehicles with automatic gearbox:

It is not possible to move the selector lever

out of position

P

if the electrical power sup

ply fails. Before the vehicle can be recov

ered/manoeuvred you must manually re

lease the selector lever; left-hand drive

vehicles

*page

93, right-hand drive

vehicles

*page

94.

- Please observe the relevant regulations

when towing or tow-starting.

Towing away

Please observe the important safety warnings on

*

page 328.

Preparations

• Attach the tow-rope or the tow-bar only to the

towing anchorages provided

for

this purpose

opage

330,

*page

331.

• Please ensure that the tow-rope is not twisted

as it could otherwise unscrew the towline an

chorage while the vehicle is being towed.

• The hazard warning lights of both vehicles

must normally be switched on

*page

52. How

ever, observe any regulations to the contrary.

Towing vehicle (front)

• Ensure that the tow-rope is taut before you

drive off.

• Manual gearbox: Engage the clutch very gently

when starting to move and accelerate with par

ticular care.

• Automatic gearbox: Accelerate slowly and

grad

ually.

• Avoid unnecessary braking and manoeuvres.

Vehicle being towed (rear)

• Ensure that the ignition is switched on, the

steering wheel is not locked, and

that

you can

operate the turn signals, horn or windscreen

wipers if necessary

<=>/t\-

• The brake servo only works when the engine is

running.

The power steering only works when

329

Page 334 of 364

Mobility

the ignition is on and the vehicle is moving1'.

Otherwise you will need to press the brake

ped

al significantly harder and apply more force to

move the steering wheel.

• Please ensure that the steering wheel is un

locked and that it moves freely.

• Release the parking brake

*page

82.

• Applies to vehicles with manual gearbox: Put

the gear lever in neutral.

• Applies to vehicles with automatic gearbox:

Move the selector lever to position N.

• Ensure that the tow-rope remains taut at all

times when towing.

© CAUTION

A WARNING

If the vehicle has no electrical power, do NOT

use a tow-bar or tow-rope to tow the vehicle

© Note

You can use the turn signals to indicate a

change of direction (or lane) even when the

hazard warning lights are on. The hazard

warning lights will be interrupted temporari-

Ly.

Tow-starting

Please observe the important safety warnings on

*page

328.

Important: Your vehicle must be fitted with a

manual gearbox. If your vehicle has a petrol en

gine,

it must not be towed further than 50 me

tres

*(J).

• Attach the tow-rope or the tow-bar only to the

towing anchorages provided

for

this purpose

*page

330,

*

page 331.

• Engage second or third gear before moving off.

• Press the clutch and hold the pedal down.

• Switch on the ignition.

• Once both vehicles are moving, release the

clutch.

• As soon as the engine starts, press the clutch

pedal and put the gear lever in neutral.

When tow-starting the vehicle, do not tow it

further than 50 metres; otherwise the cata

lytic converter could be damaged.

Front towline anchorage

»

Fig.

271 Front bumper (right side): Removing cover cap

Fig.

272 Front bumper (right side): Towline anchorage

screwed in

The screw connection for the towline anchorage

is located behind a cover cap on the right side of

the front bumper.

• Take the towline anchorage out of the vehicle's

tool kit

*

page 319.

• Press the cover cap briefly but firmly inwards

-arrow-, detach it from the bumper and take it

out*Fig.

271.

• Screw the towline anchorage into the screw

connection as far as

it

will go

*Fig.

272 and

tighten it with the box spanner.

• Put the towline anchorage back in the tool kit

after use.

11

Important: The vehicle battery must be adequately charg

ed.

330

Page 337 of 364

Fuses and bulbs

: -•.

-

i:i

m

R2 R3

F22

F-XII

F31

F30

:-:-.'

'.,

FM F43

F49

F!)3

F52

F51

R!,

a

R6

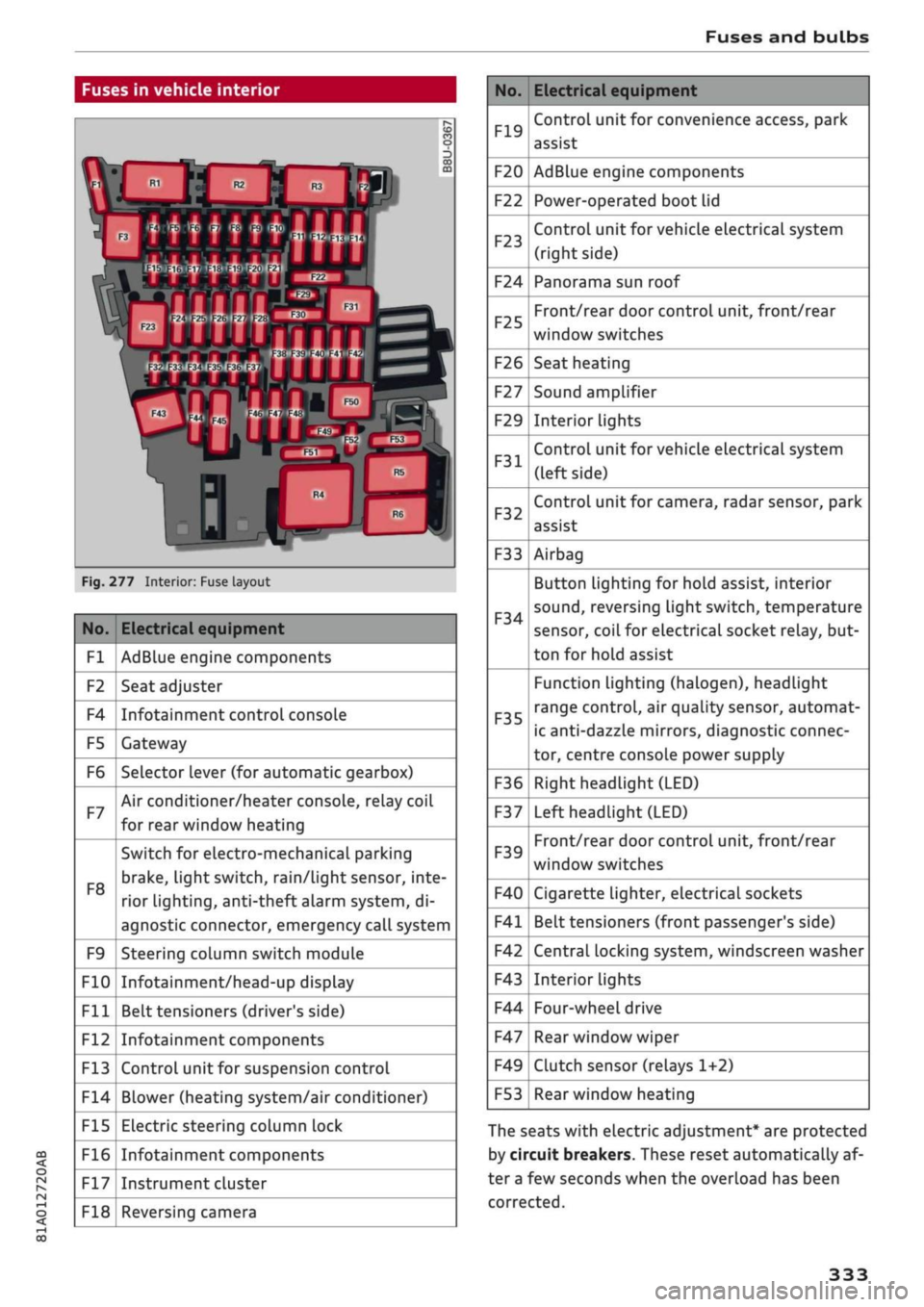

Fig.

277 Interior: Fuse layout

No.

Fl

F2

F4

F5

F6

F7

F8

F9

F10

Fll

F12

F13

F14

F15

F16

F17

F18

Electrical equipment

AdBlue engine components

Seat adjuster

Infotainment control console

Gateway

Selector lever (for automatic gearbox)

Air conditioner/heater console, relay coil

for rear window heating

Switch for electro-mechanical parking

brake,

light switch,

rain/Light

sensor, inte

rior lighting, anti-theft

aLarm

system, di

agnostic connector, emergency call system

Steering column switch module

Infotainment/head-up display

Belt tensioners (driver's side)

Infotainment components

Control unit for suspension control

Blower (heating system/air conditioner)

Electric steering column lock

Infotainment components

Instrument cluster

Reversing camera

No.

F19

F20

F22

F23

F24

F25

F26

F27

F29

F31

F32

F33

F34

F35

F36

F37

F39

F40

F41

F42

F43

F44

F47

F49

F53

Electrical equipment

Control unit for convenience access, park

assist

AdBlue engine components

Power-operated boot lid

Control unit for vehicle electrical system

(right side)

Panorama sun roof

Front/rear door control unit, front/rear

window switches

Seat heating

Sound amplifier

Interior lights

Control unit for vehicle electrical system

(left side)

Control unit for camera, radar sensor, park

assist

Airbag

Button Lighting for hold assist, interior

sound,

reversing light switch, temperature

sensor, coiL for electrical socket reLay, but

ton for hold assist

Function lighting (halogen), headlight

range control, air quality sensor, automat

ic anti-dazzle mirrors, diagnostic connec

tor, centre console power supply

Right headlight (LED)

Left headlight (LED)

Front/rear door control unit, front/rear

window switches

Cigarette lighter, electrical sockets

Belt tensioners (front passenger's side)

Central locking system, windscreen washer

Interior lights

Four-wheel drive

Rear window wiper

Clutch sensor (relays 1+2)

Rear window heating

The seats with electric adjustment* are protected

by circuit breakers. These reset automatically af

ter a few seconds when the overload has been

corrected.

333