warning AUDI Q5 2018 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2018, Model line: Q5, Model: AUDI Q5 2018Pages: 392, PDF Size: 60.56 MB

Page 357 of 392

u co ..... N r-N .....

~ 0 co

(D Tips

The vehicle jack mode* switches off automatically at speeds above 6 mph (10 km/h) .

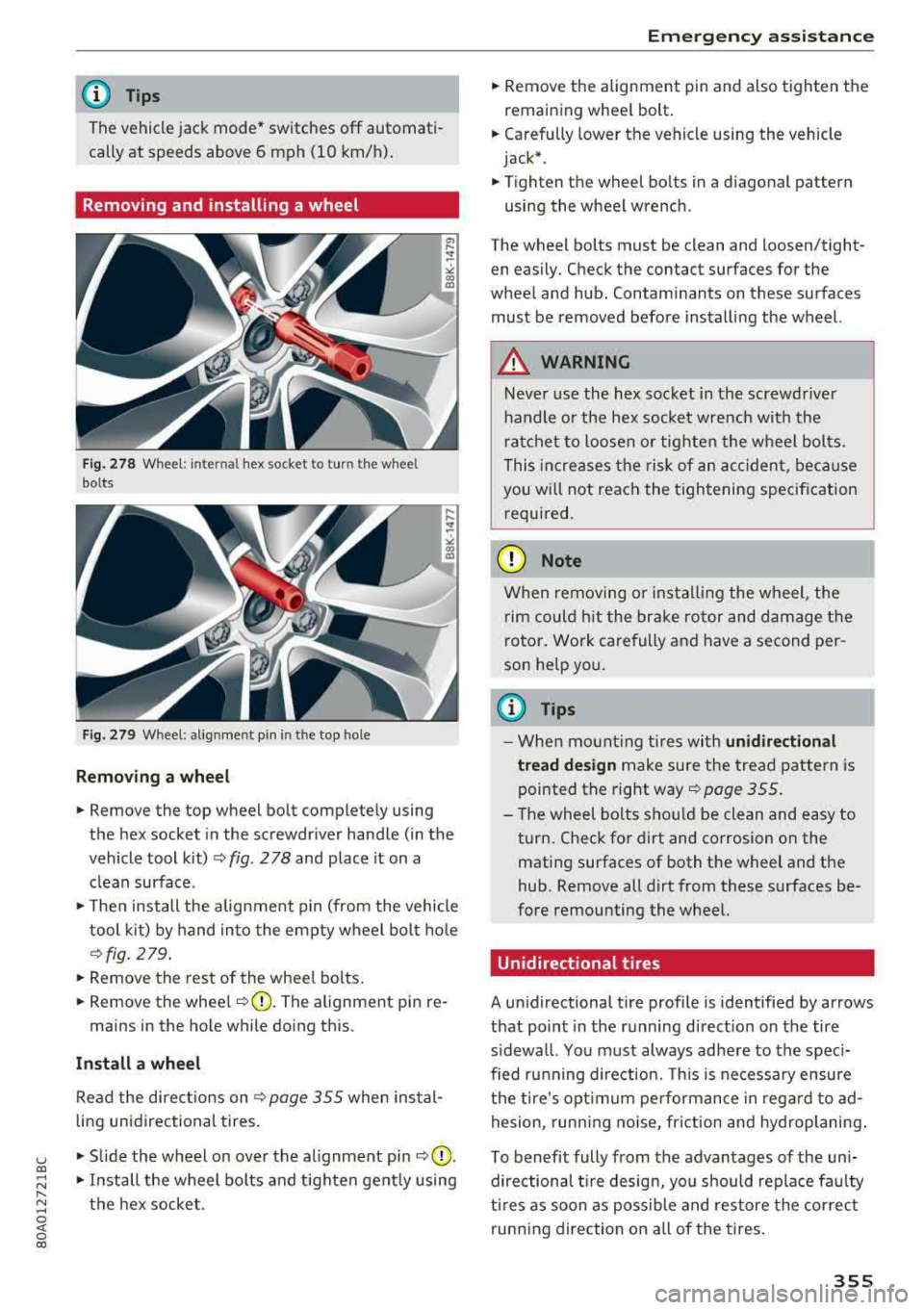

Removing and installing a wheel

Fig. 278 Wh eel: i nt ern al hex so cket to turn th e w hee l

b olts

Fig. 279 Wheel: alignment pin in the top hole

Remo ving a wheel

.,. Remove the top wheel bolt complete ly using

the hex socket in the screwdriver handle (in the

vehicle tool kit)

c::> fig. 2 78 and place it on a

clean surface .

.,. The n install the alignment pin (from the vehicle

tool kit) by hand into the empty wheel bolt ho le

c::>fig . 279.

.,. Remove the rest of the wheel bolts .

.,. Remove the wheel c::>G). The al ignm ent pi n re-

mains in the hole while doing this.

Install a wheel

Read the direct ions on c::> page 355 when ins tal

ling unidirectional tires .

.,. Slide the wheel on over the alignment pin c::> 0 .

.,. Install the wheel bo lts and tighten gen tly using

t h e hex socket .

Emergen cy as sis tanc e

.,. Remove the alignment pin and also tighten the

remaining whee l bolt .

.,. Carefully lower the vehicle using the vehicle

jack* .

.,. T ighten the wheel bolts in a diagonal pattern

using the wheel wrench .

The wheel bolts must be clean and loosen/tight

en easily. Check the contact surfaces for the

whee l and hub. Contam inants on the se surfaces

must be removed before install ing the whee l.

A WARNING ~

Never use the hex socket in the screwdriver

handle o r the hex socket wrench with the

ra tc het to loosen or tighten the wheel bolts.

This increases the risk of an ac cident, because

you will not reach the tightening specif ication

required .

(D Note

When removing o r instal lin g the wheel, the

rim co uld h it the br ake rotor and damage t he

rotor . Work carefully and have a second per

son help you .

(D Tips

-When mount ing tires with unidirectional

tread de sign

make sure the tread pattern is

pointed the right way

c::> page 355 .

- T he wheel bolts sho uld be clean and easy to

t u rn. Check for dirt and corrosion on the

mating surfaces of both the wheel and the

hub. Remove all dirt from these s urfaces

be

fore remounting the wheel.

Unidirectional tires

-

A un idirectional t ire profi le is identified by arrows

that point in the r unning direct ion on the tire

s idewa ll. You must always adhe re to the spec i

fied ru nning direction. Th is is necessary ensure

the tire's opt imum pe rformance in reg ard to

ad

hesion, runni ng no ise, friction and hydroplaning .

T o benefit fully from the advantages of the uni

directional t ire design, yo u should replace fa ulty

t ir es as soon as possible and restore the correc t

runn ing direction on all of the t ires.

355

Page 358 of 392

Emergency assistance

Finishing

.,. Reinstall the caps on the whee l bolts if neces

s ar y.

.,. Store the vehicle tool kit i n its design ate d

p lace .

.,. If the removed whee l does not fit in the spare

whee l we ll, store it sec ure ly in t he luggage

compartment

c::> page 257.

.,. Check the tire press ure on the installed whee l

as soon as possible .

.,. Correct the tire pressure a nd s to re i t in the I n

fota inment system

c::> page 343 .

.,. The w heel bo lt tig hte ning spe cifica tion mus t be

1 00 f t lbs ( 140 N m). C heck it as soon as p ossi

ble wi th a t orq ue w rench . Drive care fully unti l

then .

.,. Have the faulty wheel rep laced as quick ly as

poss ib le .

(D Tips

- If you notice t hat the w hee l bo lts are cor

r oded and diffic ult to t urn wh ile chan ging a

tire, they sh ould be replaced before you

chec k the tig htening torque.

- D rive at reduced speed until you have the

tig htening torques c hec ke d .

Notes on wheel changing

Please read the info rmation c::> page 332 if you

are go ing to use a replaceme nt tir e w hich is dif

f er ent fro m the tires on your v ehicle.

Afte r you change a t ire:

- Check the tire pressure on the replacement

tire immediately after installation.

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as pos

sible by your authorized Audi dealer or quali

fied workshop.

- With steel and alloy wheel rims , the wheel

bolts are correctly tightened at a torque of

100 ft lbs (140 Nm) .

- If you notice that the wheel bolts are corroded

and difficult to turn while changing a tire,

they should be replaced before you check the

tightening torque.

356 -

Replace the flat tire with a new one and have

it installed on your vehicle as soon as possi

ble. Remount the wheel cover.

Until then, drive with extra care and at reduced

speeds.

_&. WARNING

- If you are going to equip yo ur vehicle with

tires or r ims which diffe r from those which

were facto ry installed, then be sure to read

the information

c::> page 332 .

- Always make sure the damage d w heel or

even a flat tire and the jack* and too l kit are

properly secured in the luggage compart

m en t and a re not loos e in the pass eng er

compa rtm ent .

- In a n accide nt or sudden maneuv er they

could fly forward, i njuring anyo ne in the ve

hicle .

- Always s to re damaged wh eel, jack* an d

t oo ls sec urely in th e luggage com partm ent .

O the rwise, in an a ccide nt or sud den ma neu

v er they co u ld fl y forw ard, c ausi ng injur y to

pa ssengers in the ve hicl e.

-

Collapsible spare tire

App lies to: vehicles wit h co llapsible spare t ire

The co llaps ib le spa re tir e is i nte nded fo r sho rt

t e rm use o nly. H ave the d amage d tire checked

a nd rep lac ed , if necess ary, by an autho riz ed Audi

d ealer or au thor ized A udi Se rvi ce Fac ility as soo n

as possible.

T here a re so me restr ictions o n the use of the co l

lap sib le spar e tir e. The coll apsible spar e tir e h as

b een desig ned s pecif ic a lly for your type o f vehi

cl e. Do not rep lace it wit h the co llaps ible spa re

ti re from a nother type of vehicle .

T he collapsibl e spar e tir e is l oc at e d i n the l ug

g age co mpa rtmen t under the ca rgo floo r cover .

Requireme nt: t he v ehicl e too l ki t

c::> pag e 350 and

th e co mpr ess or m ust b e laid out.

Removing

.,. Fold th e cargo floor cove r back c::> page 350 ,

fig. 270 .

Page 359 of 392

u co .... N ,..._

N ..... 0 <( 0 00

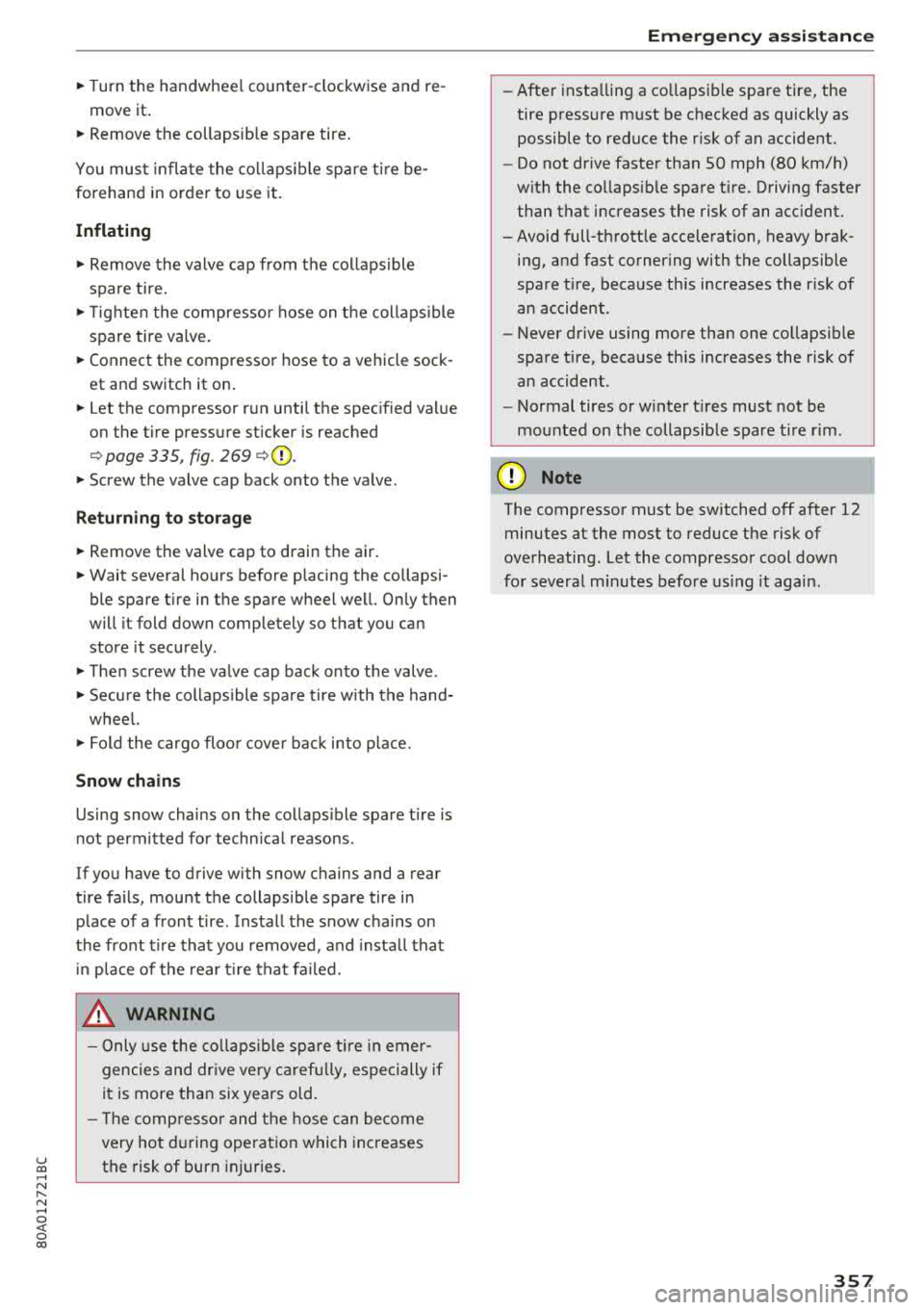

~ Turn the handwheel counter -clockwise and re-

move it .

~ Remove the collapsible spare tire.

You must inflate the co ll apsible spa re ti re be

forehand in order to use it.

Inflating

~ Remove the valve cap from the collaps ible

spare tire.

~ T ighten the compressor hose on the collapsible

spare tire va lve.

~ Connect the compressor hose to a vehicle sock

et and switch it on.

~ Let the compressor run until the specified value

on the tire pressure sticker is reached

<=> page 335 , fig. 269 <=>@.

~ Screw the valve cap back onto the valve .

Returning to stora ge

~ Remove the valve cap to drain the air.

~ Wait several hours before placing the collapsi

ble spare t ire in the spare wheel well. Only then

will it fold down completely so that you can

store it securely .

~ Then screw the valve cap back onto the valve .

~ Secure the collapsible spare t ire w ith the hand-

wheel.

~ Fold the cargo floor cove r bac k into p lace.

Snow chains

Using snow chains on the collaps ible spare t ire is

not permitted for techn ica l reasons .

If you have to drive with snow chains and a rear

tire fa ils, mount the collapsible spare tire in

place of a front tire . Install the snow chains on

the fro nt t ire that you removed, and insta ll that

i n p lace of the rear t ire that fa iled .

.8, WARNING

- Only use the co llaps ible sp are t ire in eme r

gencies and dr ive very caref ully, especially if

it is more than six years old.

- T he comp ressor and the hose can become

very hot d uring operat ion which in creases

the risk of burn injuries .

-

Emergenc y ass is tanc e

-After insta lling a co llapsib le spare tire, the

tire pressure m ust be checked as quickly as

possible to reduce the r isk of an accident.

- Do not drive faster than SO mph (80 km/h)

with the collapsib le spare tire . Driving faster

than that increases the risk of an acc ident.

- Avoid full-throttle acceleration, heavy brak ing, and fast cornering with the collapsible

spare tire, because this increases the risk of

an accident .

- Never drive using more than one collapsible

spare tire, because this increases the risk of

an accident .

- Normal tires or w inter t ires must not be

mounted on the collapsible spare tire r im .

@ Note

The compressor must be switched off after 12

minutes at the most to reduce the risk of

overheating. Let the compressor cool down

for several m inutes before us ing it aga in .

357

Page 361 of 392

u co .-, N r-N .-,

~ 0 co

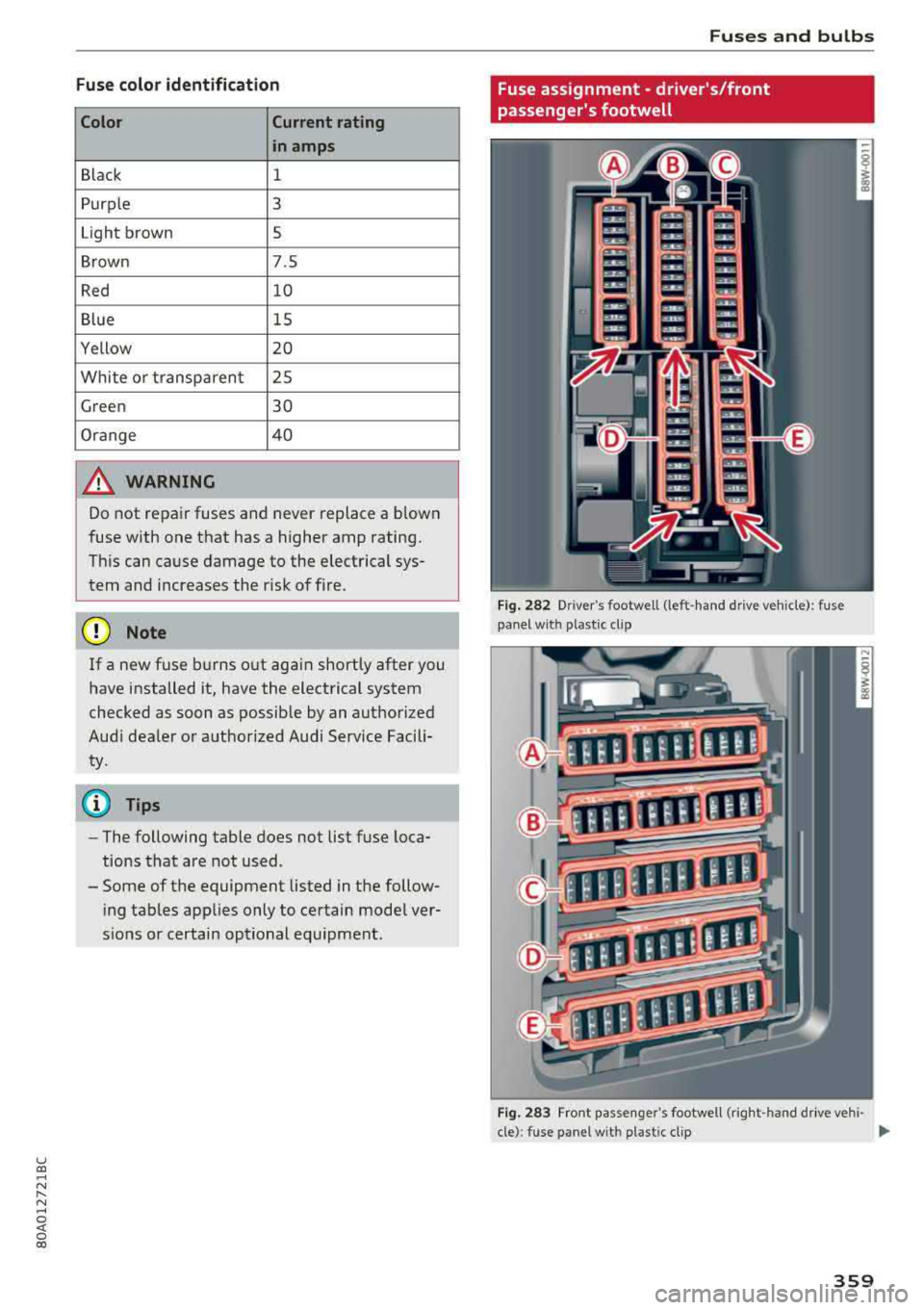

Fuse color identification

Color Current rating

in amps

Black 1

Purple 3

Light brown 5

Brown 7.5

Red 10

Blue 15

Yellow 20

White or transparent 25

Green 30

Orange 40

A WARNING

Do not repair fuses and never replace a blown

fuse with one that has a higher amp rating.

This can cause damage to the electrical sys

tem and increases the risk of fire.

(D Note

If a new fuse burns out again shortly after you

have installed it, have the electrical system

checked as soon as possible by an authorized

Audi dealer or authorized Audi Service Facili ty.

(D Tips

- The following table does not list fuse loca

tions that are not used.

- Some of the equipment listed in the follow

ing tables applies only to certain model ver

sions or certain optional equipment.

Fuses and bulbs

Fuse assignment - driver's/front

passenger's footwell

Fig. 282 Drive r's footwell (left -hand dr ive vehicle): fuse

panel with plastic clip

Fig. 283 Front passenger's footwell (right -hand drive vehi -

cle): fuse panel wit h plastic clip

II>-

359

Page 364 of 392

Fuses and bulb s

Fuse panel © (brown )

4 Audi side assist

8 Smart module (tank)

9 Climatized cup holder

11 12 Volt battery

12 Homelink

13 Rea rview camera, per ipheral cameras

14 Right tail lights

16 Right safety belt tensioner

Fu se panel ® (red )

No . Equipm ent

2 Sound-amplifier

3 AdBlue heating

s Trailer h itch (right light)

7 Trailer hitch

8 Trailer h itch (left lig ht)

9 Trailer hitch (socket)

1 0 Sport differential

11 AdBlue heating

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you.

It is becoming increasingly more and more diff i

cult to replace vehicle light bulbs s ince in many

cases, other parts of the ca r must fi rst be re

moved before you a re able to get to the bu lb.

This applies espec ially to the light bu lbs in the

front of your car which you can only reach

through the engine compartment .

Sheet metal and bulb ho lde rs can have sha rp

edges that can cause ser ious cuts, parts must be

correct ly taken apart and then properly put back

together to he lp prevent breakage of parts and

long term damage from water that can enter

housings that have not been properly resea led.

F or your safety, we recommend that you have

your authorized Audi dealer replace any bu lbs for

3 6 2

you, since your dealer has the proper tools, the

correct bu lbs and the expertise.

Ga s di sc harg e lamp s (Xeno n ligh ts):

Due to the high electr ical voltage, have the bulbs

rep laced by a qualified technician . Headlights

with Xenon light a re identified by the hig h volt

age sticker.

L ED he adligh ts*

LED headlights requ ire no maintenance. Please

contact your author ized Audi dealer if a bulb

needs to be replaced .

A WARNING

Changing Xenon lamps without the necessary

equ ipment can cause serious personal injury.

-Bulbs are pressurized and can explode when

be ing changed. Potent ial r isk of injury!

-O n veh icles equipped with gas discharge

bulbs (Xenon light) l ife-threaten ing injuries

can resu lt from improper handling of the

h igh-vo ltage portions of such lamps!

-O nly your author ized Audi dealer or quali

fied wo rkshop shou ld change the bulbs in

gas discharge lamps. The re a re parts w ith

sha rp edges on the open ings and on the

bu lb holders that can cause serious cuts. If

you are uncertain about what to do, have the work performed by an authorized Audi

dea ler or qualified workshop. Serious per

sonal injury may result from improperly per

formed work.

(D Tips

-If you still prefer to replace the light bulbs

yourself, be aware that the engine compart ment is a hazardous area to work

i n c:> .&. in

Working in the engine compartment on

page 314.

-It is best to ask your authorized Audi dealer

whenever you want to change a bulb .

Page 365 of 392

u co .... N r--N .... 0 <( 0 00

Emergency situations

General

This chapter is intended for trained emergency

crews and working personnel who have the nec

essary tools and equipment to perform these

operations.

Starting by pushing or

towing

~ Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine can be started by con

necting it to the battery of another vehicle.

If the engine should fail to start because of a dis

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

pair of jumper cables to start the engine.

Jumper cables

Use only jumper cables of sufficiently large cross

section

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use only jumper cables with

insulated terminal

clamps which are distinctly marked:

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black.

A WARNING -

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal in

jury. Follow the instructions below for safe

handling of your vehicle's battery.

-Always shield your eyes and avoid leaning

over the battery whenever possible.

- A dead battery can freeze at temperatures

around 32 °F (0 °C). If the vehicle battery is

frozen, you must thaw it before connecting

the jump start cables. If you do not, this in-

Emergency situations

creases the risk of an explosion and chemi

cal burns. After jump starting the vehicle,

drive to an authorized Audi dealer or author

ized Audi Service Facility immediately to

have the vehicle battery checked.

- Do not allow battery acid to contact eyes or

skin. Flush any contacted area with water

immediately.

- Improper use of a booster battery to start a

vehicle may cause an explosion .

- Vehicle batteries generate explosive gases.

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery .

- The voltage of the booster battery must also

have a 12-Volt rating. The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batteries of different voltage or substantial

ly different "Ah" rating may cause an explo

sion and personal injury.

- Never charge a frozen battery. Gas trapped

in the ice may cause an explosion.

- Never charge or use a battery that has been

frozen. The battery case may have be weak

ened.

- Use of batteries of different voltage or sub

stantially different capacity (Ah) rating may

cause an explosion and injury. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

c>page 314.

@ Note

-Applying a higher voltage booster battery

will cause expensive damage to sensitive

electronic components, such as control

units, relays, radio, etc.

- There must be no electrical contact between

the vehicles as otherwise current could al

ready start to flow as soon as the positive

(+) terminals are connected.

363

Page 366 of 392

Emergency situations

@ Tips

The discharged battery must be properly con

nected to the vehicle's electrical system .

When jump starting or charging the battery,

never connect the negative ground cable to

the battery negative post because the battery

manager system must be able to detect the

battery's state of charge. Always connect the

negat ive g round cable to the negative ground

post of the battery manager control unit.

Using the jump start

cable

Both jump start cables must be connected in the

correct order!

Fig. 286 E ngin e compartme nt: co nn ectors for jump start

cables and a charger

Fig. 287 Jump starting with a battery in another vehicle:

@-pro vidi ng current, @-dra ined

The procedure described below for connecting

jumper cables is intended to provide a jump start

for your vehicle.

Vehicle with discharged battery

... Turn off lights and accessories, move automatic

transm ission lever to "N" (Neutral) or "P" (Pa rk)

and set parking bra ke.

364

Connecting the positive cable (red) to the

positive terminal

... Open the red cover on the positive terminal

c:::>fig. 286.

1. Secure one end of the pos itive cable (red) to

the jump start pin

c:::> fig. 287 (J) (pin under

the red cover = "pos itive") on the veh icle that

needs to be started @.

2. Secure the other end of the positive cable

(red) to the posit ive terminal @on the bat

tery provid ing the cur rent @.

Connecting the negative cable (black) to the

negative terminal

3. Secure one end of the negative cable (black)

to the negative terminal @ on the battery

that is providing the current @.

4. Secure the other end of the negative cable

(black) to the jump start

pin @ (hex head pin

= "negative") on the vehicle that needs to be

started @.

Starting the engine

... Sta rt the eng ine on the vehicle providing the

jump start @and let it run at idle .

... Now start the engine on the vehicle with the

drained battery @.

... If the engine does not start, stop the starting

procedure after 10 seconds and then repeat it

after approx imately 30 seconds.

"' Once the engine w it h the drained vehicle bat

tery has been started, remove the cables in the

reverse order from the way they were install ed.

"' Close the red cover on the positive terminal.

The battery is vented to the outside to prevent

gases from enter ing the vehicle inter ior. Make

sure th at the j umper clamps are well connected

with their

metal ports in full contact with the

battery terminals .

A WARNING

-To avoid serious personal injury and damage

to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service .

-Jumper cables must be long enough so that

the vehicles do not touch.

..,.

Page 367 of 392

-When connecting jumper cables, make sure

that they cannot get ca ught in any mov ing

parts in the engine compartment.

- Do not bend over the batteries - danger of

chem ica l burns!

- The battery cell lock ing screws must be

t ightened sec ure ly.

- Be fore you check anything in the e ngine

compartment, a lways read and hee d all

WAR NINGS

q page 314 .

(D Note

Impro per hook -up of jum pe r cables can r uin

the gene rato r.

- Always connect POSITI VE (+ ) to POS ITIV E

( + ), and NEGATIVE( -) to NEGAT IVE( -)

g roun d post of t he battery mana ger contro l

u nit.

- Check that a ll sc rew p lugs on t he battery

cells are screwed in firmly. I f not, t ighten

plugs prior to connecting clamp on negative

batte ry terminal.

- P lease note that the procedure fo r con nect

i ng a jumper cab le as desc ribed above ap

p lies specifica lly to the case of yo ur vehicle

being jump starte d. When you are giv ing a

ju mp s ta rt to anothe r vehicle , d o

not con

n ect the neg ative (-) cab le to the neg ative

(-) t ermin al on the di sch arged b attery @

q fig. 287 . In ste ad , securely connec t the

nega tive ( -) cab le to either a solid me tal

com ponent that is f irm ly bolted to the e n

gine block o r to the engine bloc k itself. If

the battery that is be ing cha rge d does not

vent to the outs ide, escap ing battery gas

could ignite and exp lode!

Towing with a tow truck

General hints

Your Audi requires special handling for towi ng .

The fo llow ing information is to be used by com

mercia l tow tr uck operators who know how to op-

u e rate the ir equip ment safe ly. co .....

~ - Never tow your Audi, towing will cause dam-N

~ age to the engine and transmission .

0 co

Emergency situations

-Never wrap the safety chains or winch cables

around the brake lines .

- To prevent unnecessa ry damage , your Audi

must be transported with a flatbed truck.

- To load the vehicle on to the flatbed, use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

¢ page 365 and ¢ page 366 .

A WARNING

-A veh icle being towed is not safe for passen-

ge rs . Neve r allow anyone to ride in a vehicle

b eing towed, fo r any r eason.

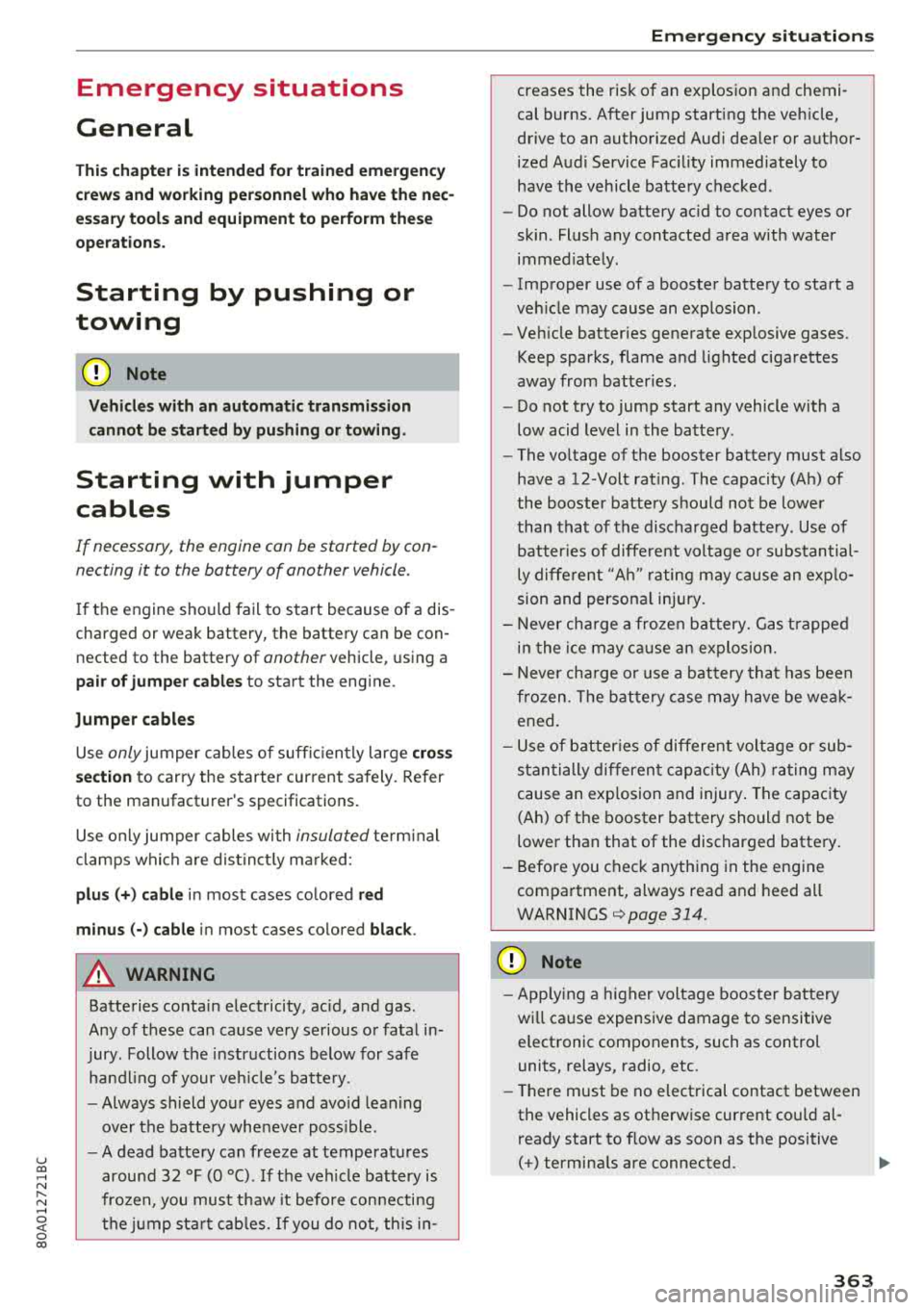

Front towing loop

Only install the front towing loop when it is

needed.

Fig . 288 Front bu mpe r: in sta lling the tow ing loop

T he threaded opening for the towing loo p is lo

cate d on t he righ t side of the front bum per.

.. Remove the towing loop from the vehicle too l

ki t

¢ pag e 350 .

.. Pull s harp ly o n the trim in the dire ct ion o f the

a rrow to remove

¢ fig . 288.

.,. T ig hten t he towi ng loop in the threade d open

in g until it stops and then tighten it with a

wheel wrenc h .

.,. After using, p lace the tow ing loop back in the

veh icle tool k it.

A WARNING

-If the tow ing loop is not tightened until it

stops whe n installing, t he threads may be

pull ed ou t wh en towing the vehicle and th at

could ca use a n accident.

365

Page 368 of 392

Emergency situations

(D Note

The trim is attached to the bumper with sev

eral hooks . To reduce the risk of damage, do

not use any force when removing and instal

ling.

Rear towing loop

F ig . 289 Rear bumper: installing the towing loop

Vehicles with a towing loop

On vehicles without a factory-installed trailer

h itch*, the towing loop threads are located on

the right rear side of the bumper.

... Remove the towing loop from the vehicle tool

kit ¢

page 350.

... Press the cap inward with brief, forcefu l pres

sure ¢ fig. 289. The cap will loosen from the

bumper.

... Tighten the towing loop in the threaded open

ing until it stops and then t ighten it w ith a

wheel wrench.

... After using, place the towing loop back in the

vehicle tool kit.

Vehicles with a trailer hitch*

... Attach the towing bar or the towing cable to

the tra iler hitch.

Vehicles with a factory-installed trailer hitch* are

not equipped with towing loop threads at the

rear.

A WARNING

If the towing loop is not tightened until it

stops when insta lling, the threads may be

pulled out when towing the vehicle and that

could cause an accident.

366

A WARNING

,-

Applies to: vehicles with trailer hitch

- Only use a special towing bar to prevent

damaging the ball hitch. These towing bars

have been spec ially designed for trailer tow

ing hitches.

- Only use special towing cables.

Loading the vehicle onto a flatbed truck

Fig. 290 Veh icle on flatbed t ruck

Front hook up

.,. Align the vehicle with the centerline of the car

carrier ramp .

.,. Attach the winch hook to the front towline eye

previously installed .

Rear hook up

... Align the vehicle with the centerline of the car

carrier ramp.

.,. Attach the w inch hook to the rear towline eye

previously installed .

(D Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

truck ramp .

Page 369 of 392

u co ..... N r-N .....

~ 0 co

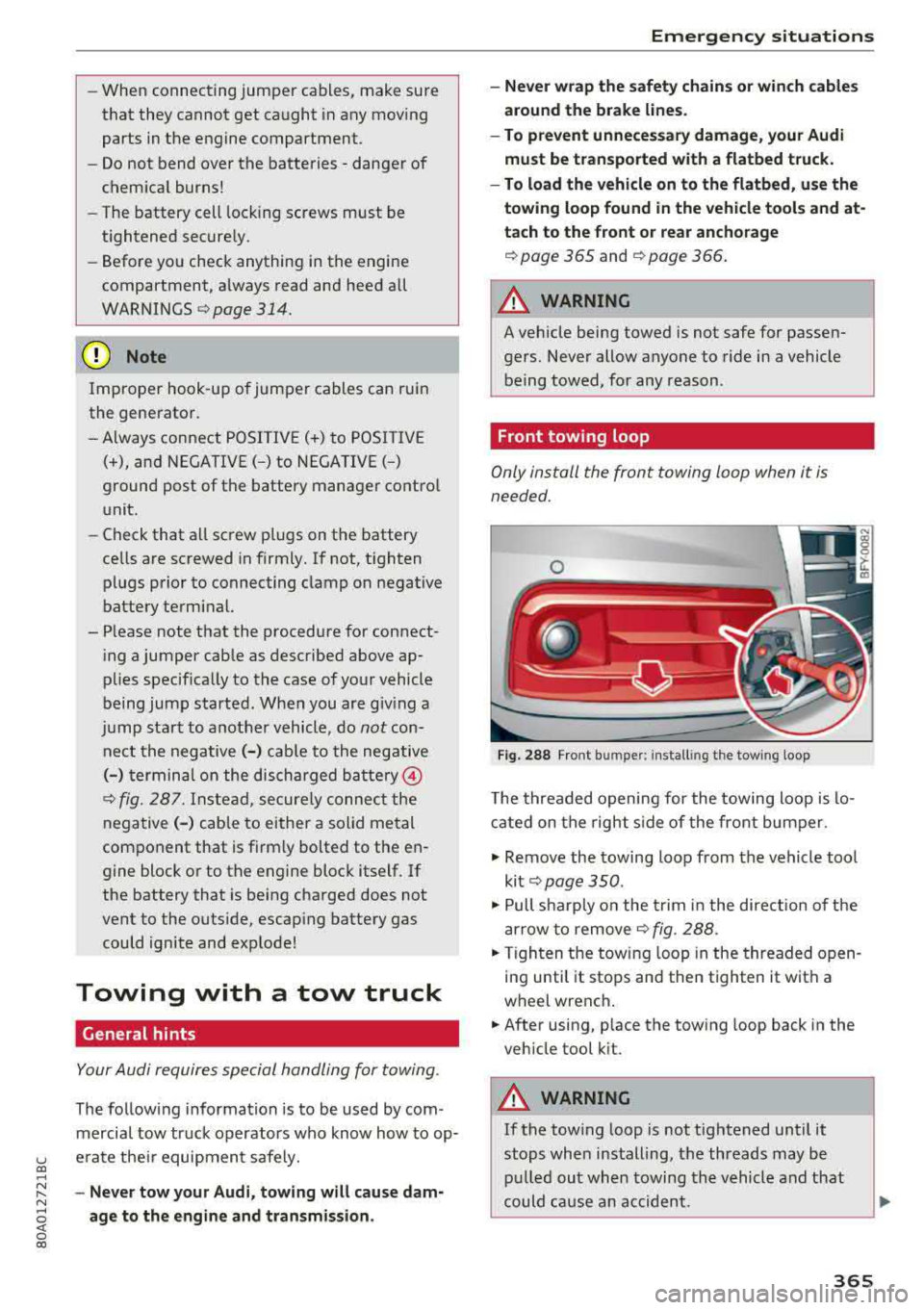

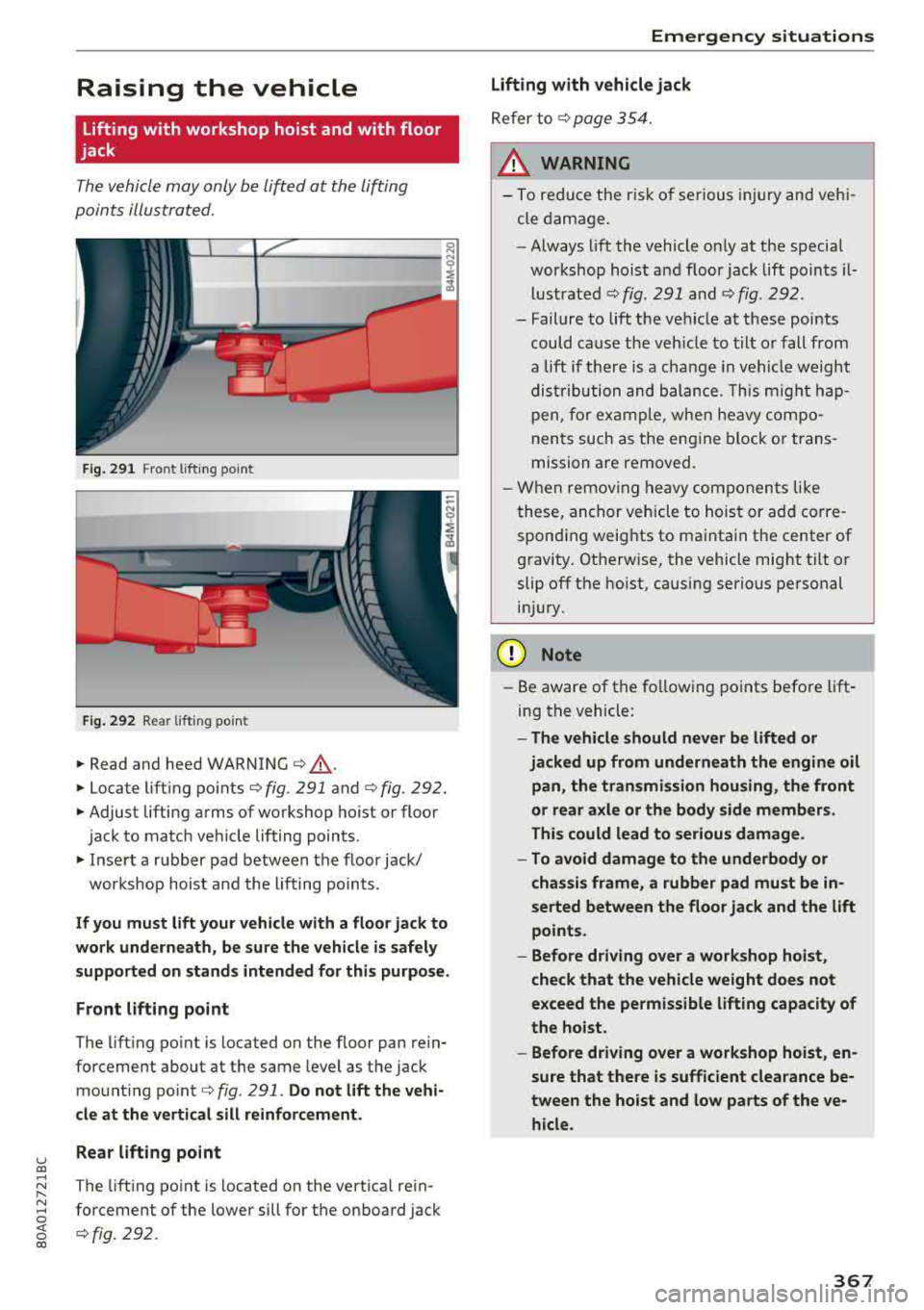

Raising the vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lift ed at the lifting

points illus tr at ed.

......_.__ -+,c___------= ------i

cli

Fig. 291 Fro nt lift in g poin t

Fig. 292 Re ar lift ing poin t

.,. Read and heed WARNING c::> &, .

.. Locate lift ing po in ts c::> fig . 291 and c::>fig. 292.

.. Adjust lifting arms of wo rkshop ho ist or floo r

jac k to match veh icle lifting points .

.. Insert a r ubb er pad b etween t he floor jack/

workshop hois t and the lifting points.

If you must lift your vehicle with a floor jack to

work underneath , be sure the vehicle is safely

supported on stands intended for this purpose.

F ront lifting point

The lift ing po int is located on the floor pan re in

forcement about a t th e same leve l as the jack

mo unt ing po int

c::> fig . 291 . Do not lift the vehi

cle at the vertical sill reinforcement.

Rear lifting point

T he lift ing po int is located on the vert ica l re in

forcement of the lower sill fo r th e on board jack

c::> fig. 292 .

Emergency situations

Lifting with vehicle jack

Refer to c::> page 354.

__&. WARNING

- To red uce the r is k of se riou s injury and veh i

cle dama ge.

- Always lift the vehicle on ly at the special

workshop hois t and floor jack lift poin ts i l

l u stra ted

c::> fig. 291 and c::> fig . 292.

- Failure to lift t he ve hicle at these poi nts

could cause the veh icle to tilt o r fall from

a lift if t here is a change in v ehi cle weight

d is tr ibu tion and b ala nce . T his migh t ha p

pen , for ex am ple, when heavy co mpo

nen ts such as the e ngine block o r trans

mission a re removed.

- Wh en remov ing heavy com ponen ts like

t hese, an chor ve hicle to hoist or ad d corre

spond ing weig hts to ma inta in the center of

g ravi ty . Ot herw ise, the vehicle mig ht tilt or

slip off the hoist, causing serious pe rsonal

in ju ry.

(D Note

- Be aware of the fo llow ing points before lift

in g th e vehicle :

-The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission housing, the front

or rear axle or the body side members .

This could lead to serious damage .

- To avoid damage to the underbody or

chassis frame, a rubber pad must be in

serted between the floor jack and the lift

points.

- Before driving over a workshop hoist ,

check that the vehicle weight does not

exceed the permissible lifting capacity of

the hoist.

- Before driving over a workshop hoist , en

sure that there is sufficient clearance be

tween the hoist and low parts of the ve hicle.

367