service AUDI Q7 2009 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2009, Model line: Q7, Model: AUDI Q7 2009Pages: 426, PDF Size: 97.13 MB

Page 381 of 426

_______________________________________________ W_ h_ a_t _ d_ o_ l _d _o_ n_ o _ w_ ? __ IIIII

•

- Let the compressor run until it has reached 50 PSI (3.5

bar). Switch the compressor off after running for 8

minutes at the most -danger of overheating!

& WARNING

The compressor and the tire filler hose can become extremely hot

while they are running -danger of burns!

0 Note

Switch the compressor off after running for 8 minutes at the most -

danger of overheating! Allow the compressor to cool down for a few

minutes before you use it again.

[ i] Tips

The compressor must not be connected to the cigarette lighter

socket, as this socket does not provide the required power .•

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern intended for use

in a specific direction

When using a spare tire with a tread pattern intended for use in a

specific direction, please note the following:

• The direction of rotation is marked by an arrow on the side of the

tire.

• If the spare tire has to be installed in the incorrect direction, use

the spare tire only temporarily since the tire will not be able to

achieve its optimum performance characteristics with regard to

aquaplaning, noise and wear. •

We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

conditions.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirectional tire. •

Notes on wheel changing

Please read the information => page 359, "New tires and replacing

tires and wheels " if you are going to use a spare tire which is

different from the tires on your vehicle.

After you change a tire :

• Check the tire pressure on the spare immediately after installa

tion.

• Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a

qualified workshop.

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 120 ft lb (160 Nm).

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds .

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to read

the information

=> page 359, "New tires and replacing tires and

wheels". ..

Do-it -yourself service

Page 383 of 426

_________________________________________________ F_ u_ s_ e_s _ a_n _d_ b_ u _ lb_ s _ __._

Fuses and bulbs

Fuses

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

Fig . 307 Ins trument

pa nel left: Face c over

F ig . 308 I nst rume nt

pa nel left: Co ntent

F ac e cover

- Locate the fuse which belongs to the component which

failed.

- Switch off the ignition and the e lectr ica l component

affected. - Carefully p

ry t he face cover off the instr umen t pane l

using the ignition key or a screwdriver~ fig. 307.

- Rem ove the plastic clip @ from i ts retainer in the face

cove r~ fig. 308, p lace i t over the questionable fuse and

remove the fuse.

- Replace a blown fuse (recognizable by the melted metal

str ip inside) wi th a f use of the

same amperage.

The individual circuits are protected by fuses. T he fuse panels with

the fuses are located on the left and right front faces of the instru

ment pane l behind a cover and in the right storage area in the

luggage compartment.

There is a plastic clip @ in the cover on the lef t side of the instru

ment pane l, which can be used to remove the fuses . The crank © is

used for emergency operation of the Panoramic sliding sun roof *.

You w ill also find a label on both covers in the instrument panel with

the fuse layout © for the corresponding fuse panel.

& WARNING

Nev er replac e a fuse with one that ha s a high er amperag e rati ng.

• A fu se w ith a to o high ampe rage could damage the ele ctr ical

pa rt a nd cause a fire .

0 Note

• On no account should fuses be repaired (e .g. patched up wi th tin

foil or wire) as this may cause serious damage elsewhere in the e lec

trica l circuit o r cause fire.

• If a fuse blows repeatedly, do not keep replacing it. Instead , have

the cause of the repea ted short circuit or overload located and fixed.

ti>

Vehicle care Do-it-yourself service Technical data

Page 385 of 426

Fuses and bul bs 11111 ________________________________ ..:....:,:_=-.::..:....:.;.:_.:..:..,_,;__,;____,J

....

No.

1

-

2

3

4

5

6

Eq uipm ent

Headlight electronic system (left side of vehi -

cle)

Adaptive Cruise Control

Not used

Audi lane assis t

Not used

Terminal 15 (interior)

Oil level sensor

8 Diagnostic connector

9 Automatic dipping interior mirror

10 Homelink

1 1 Control module Gateway

12 Headlight range adjustment

Amps

10

5

10

5

5

5

5

5

5

5

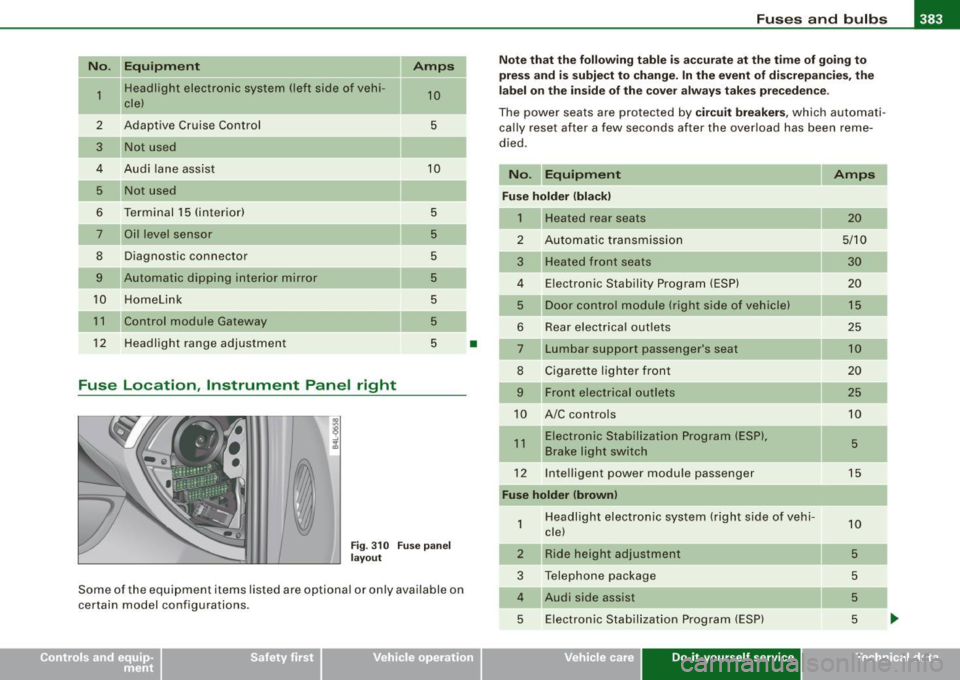

Fuse Location , Instrument Panel right

Fi g. 310 F use pane l

l ayo ut

Some of the equipment items listed are optional or only avai lable on

certain model configurations .

•

Note that th e fo llo wi ng ta ble is acc urate a t the time of goi ng to

pre ss and is subject to change. In th e event of di screpan cies, t he

l a b el on the ins ide o f th e cover a lw ays ta ke s prec eden ce.

The power seats are protected by circ uit breakers , which automati

ca lly reset af ter a few seconds after the overload has been reme

died .

No. Equipm ent

Fu se holder (bla ck )

1 Heated rear seats

2 Automatic transmission

3 Heated front seats

4 E lectronic Stability Program (ESP)

5 Door control module (right side of vehicle)

6 Rear electrical out

lets

7 Lumbar support passenger's seat

8 Cigarette lighter front

9 Front electrical outlets

10 A/C controls

1 1 Electronic Stabilization Prog ram (ESP),

Brake light switch

12 Inte lligent power modu le passenger

Fuse holder (brown )

1

2

3

Headlight electronic system (right side of vehi

cle)

Ride height adjustment

Telephone package

4 Audi side assist 5 E lectronic Stab ilizat ion Program (ESP)

Vehicle care Do-it-yourself service

Amps

20

5/10

30 20

15

25

10

20

25

10

5

15

1 0

5

5

5

5

-

irechnical data

Page 387 of 426

_________________________________________________ F_ u_ s_ e_s _ a_n _ d_ b_ u_lb _ s __ llll

No . Equipm ent Amps No. Equipm ent Amps

Fuse holder (brow n) 10 Trailer hitch (left side of vehicle) 20

1 Not used 11 Trailer hitch (right side of v ehicle) 20

2

Not used 12 Not used •

3 Not used

4 Not used Bulbs

5 K -box (MMll, antenna amplifier 5

Not used Replacing light bulbs

7 Navigation 5 For your safety, we recommend that you have your autho-

Digital Signal Processing (DSP)/ rized Audi dealer replace burned out bulbs for you .

8 BOSE amplifier 30

It is becoming increasingly more and more difficult to replace --

9 Digital Tuner 5 vehic le light bu lbs since in many cases, other parts of the car must

10 Bang & Olufsen amplifier 30 first be removed before you are able to get to the bulb. This applies

especially to the light bulbs in the front of your car which you can

11 Rear view camera 5 only reach through the engine compartment.

12 Not us ed

Sheet metal and bulb holders can have sharp edges that can cause

Fuse holde r (re d ) serious cuts, and parts must be correctly taken apart and then prop -

1 Not used erly put back together to he

lp prevent breakage of parts and long

term damage from water that can enter housings that have not

2 Not used been properly resealed.

3 Not used For your safety, we recommend that you have your authorized Audi

4 Not used dea

ler replace any bu lbs for you, since your dealer has the proper

tools, the correct bulbs and the expertise.

5 Not used Gas disch arge lamp s (Xeno n ligh ts)*:

6 Soft close 20 Due to the high electrica

l voltage, have the bulbs replaced by a qua I -

7 Power rear lid 30 ified technician. Headlights with Xenon light can be identified by the

8 Power rear lid 30 h igh voltage sticker . .,,,

9 Trailer hitch 15

• Do-it-yourself service

Page 389 of 426

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ lll

•

Emergency situations

General

This chapter is intended for trained emergency crews and working

pe rsonnel who have the necessary tools and equ ipment to perform

these operations. •

Starting by pushing or towing

(D Note

You r ve hicle is eq uipped w ith an automatic trans missi on. C o nse

quent ly, the engine cannot be started by pushing or towing .•

Starting with jumper cables

If necess ary, the en gine can b e sta rted by conn ectin g it to

the battery of anothe r vehicle.

If th e engine should fail to start because of a discharged or weak

b at te ry, the batt ery ca n be co nnected t o the ba ttery of

another

vehicle, using a pair of jumper cables to start the engine .

Jumper cables

Use

only jumper cables of sufficiently large cross section to carry the

s tarte r curre nt safely. Refer t o the manu fac tu rer 's specif ica tions.

Use only ju mper cabl es with

insulated terminal clamps whic h are

distinct ly marked:

plus (+l cable in mo st cas es c olored red

minus

(- 1 cable in most cases colored black.

& WARNING

Batteries contain electricity, acid , and gas. Any of the se can cause

very ser ious or fatal injury . Follow the instructions below for safe

handling of your vehicle 's battery .

• Always shield your eyes and avoid leaning over the battery

whenever possible .

• A discharged battery can freeze at temperatures just below

32 °F (0 °C l. Before connecting a jumper cable , you must thaw the

frozen battery completely , otherwise it could explode .

• Do not allow battery acid to conta ct eyes or skin. Flush any

contacted area with water immediately.

• Improper use of a booster battery to start a vehicle may cause

an explosion.

• Vehicle batteries generate explosive gases . Keep sparks , flame

and lighted c igarettes away from batteries.

• Do not try to jump start any vehicle with a low acid level in the

battery.

• The voltage of the booster battery must also have a 12-Volt

rating. The capacity (Ah l of the booster battery should not be

lower than that of the discharged battery . Use of batteries of

different voltage or substantially different "Ah" rating may cause

an explosion and personal injury .

• Never charge a frozen battery. Gas trapped in the ice may cause

an explosion.

• Never charge or use a battery that has been frozen . The battery

c ase may have be weakened .

• Use of batter ies of different voltage or substantially different

c apacity (Ah l rating may cause an explosion and injury . The

capacity (Ahl of the booster batte ry should not be lower than that

of the discharged battery. _..

Do-it -yourself service

Page 391 of 426

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ lfflll

•

Conn ect POSITIVE (+ ) to PO SITIVE (+ ) (r ed )

- Open the red cover on the pos itive pole => page 388,

fig. 312.

1. Connect one end of the positive cable (red) on the

jump

start bolt=>

page 388, fig. 3 13 G) (Bo lts under red cover

= "positive") of the vehicle to be started @.

2. Connect the other end to the positive terminal@ of the

booster battery ®·

Conn ect NEGATIVE (- ) to NEGATIVE (-) (black )

3. Connect one end to the negat ive termi nal 0 of t he

boos ter battery ®·

4 . Connect the other end of the negative cable (black) to the

jump sta rt bolt 0 (Bolts with hex head = "n egative") of

the vehicle to be s tarted @.

Startin g th e e ngin e

-Start the engine of the veh icle w ith the booster battery .

Run t he engine at a moderate speed .

- Start engine with discharged ve hicle battery in the usual

ma nner.

- If the engine fails to s tart: do not keep the star ter

cranking for longer than 10 seconds. Wait f or about

30 seconds and then try again.

- With engine running, remove jumper cables from both

vehicles in the exact reverse order.

- Close the red cover on the positive pole.

The battery is vented to the outside to prevent gases from entering

the vehic le interior . Make sure that the jumper clamps are well connected with their

metal parts in full contact with the battery

t erminals .

& WARNING

To avoid seriou s per sonal in jur y a nd d amage to the vehicle , heed

a ll wa rning s and in stru ction s o f th e jum per ca ble man ufa cturer . If

in doubt , call for ro ad serv ice.

• Jump er c able s must b e lo ng eno ugh s o that the vehi cle s do not

touch .

• When conne cting jumpe r cable s, ma ke sure th at the y cannot

g et caught in an y mo ving p arts i n the engine comp art m ent .

• Before you che ck anyth ing in the en gin e com partm ent , a lwa ys

r ea d and h eed all W ARNIN GS~ pag e 32 4, "E ngine compa rtm ent ".

0 Note

Improper hook -up of jumper cables can ruin the generato r.

• Always connect POSITIVE(+) to POS ITIVE( +), and NEGATIVE( -) to

NEGATIVE( -) ground post of the battery manager control unit.

• Check that al l screw p lugs on the battery ce lls are screwed in

firm ly . If not, tighten plugs prior to connecting clamp on negative

battery termi nal.

• Please note that the procedure for connecting a jumper cab le as

described above applies specifical ly to the case of your vehicle

being jump started. When you are giving a jump start to another

vehicle, do not connect the negative(-) cable to the negative (-1

terminal on the discharged battery©~ page 388, fig. 313. Instead,

securely connect the negative ( -1 cable to either a solid metal

component that is firmly bolted to the engine b lock or to the engine

block itself . If the battery that is being charged does not vent to the

outside, escap ing battery gas could ignite and exp lode! •

Do-it-yourself service

Page 393 of 426

________________________________________________ E_ m ___ e_r .::g :...e_ n _ c_,!y:._ s_ i_t _u _a_ t_ i_o _n_ s _--J_

- Screw the towing loop t ightly into the threaded hole as

far as it will go::::>

page 390, fig. 315.

When it is no longer needed, unscrew the towing loop and put it

back into the vehicle toolkit. Be sure to have the towing loop stored

in the vehicle at all times.

When installing the grill for the air duct, be sure that the tabs on the

gril l are first inserted into their guides on the vehicle above the

fog lamp. Then position the opposite side of the grill

=> page 390,

fig. 314 ® and push it firmly into its guide.

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

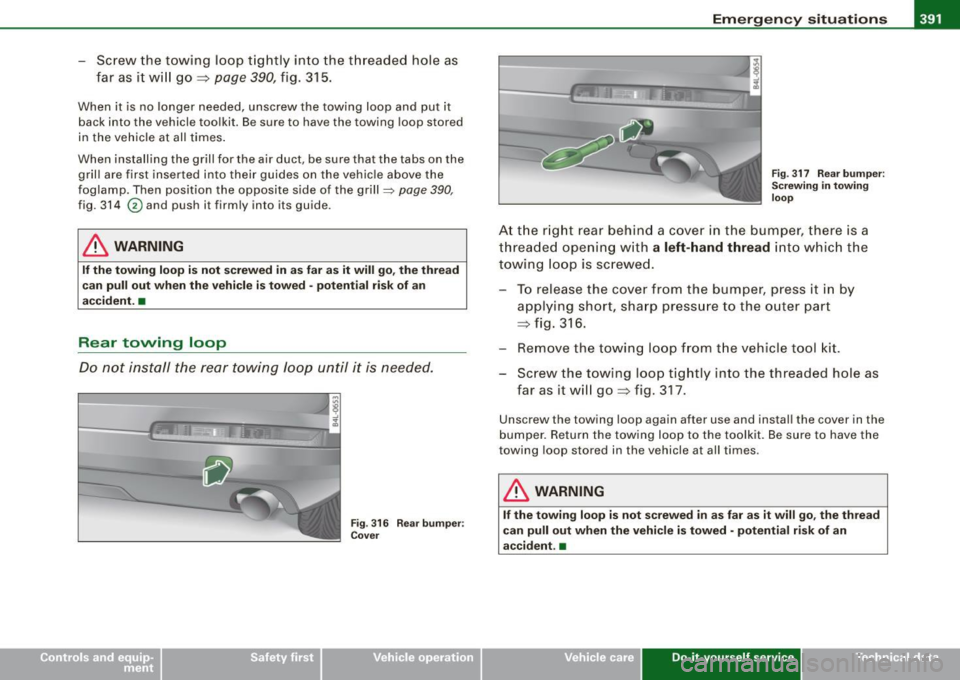

Rear towing loop

Do not install the rear towing loop until it is needed.

Fig. 316 Rear bumper:

Cover Fig

. 317 Rear bumper:

Screwing in towing

loop

At the right rear behind a cover in the bumper, there is a

threaded opening with

a left-hand thread into which the

towing loop is screwed.

- To release the cover from the bumper, press it in by

applying short, sharp pressure to the outer part

==> fig. 316.

- Remove the towing loop from th e vehicle tool kit.

- Screw the towing loop tightly into the threaded hole as

far as it will go ::::> fig. 317.

Unscrew the towing loop again after use and instal l the cover in the

bumper. Return the towing loop to the toolkit. Be sure to have the

towing loop stored in the vehicle at all times .

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

Vehicle care Do-it-yourself service irechnical data

Page 395 of 426

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ lllll

•

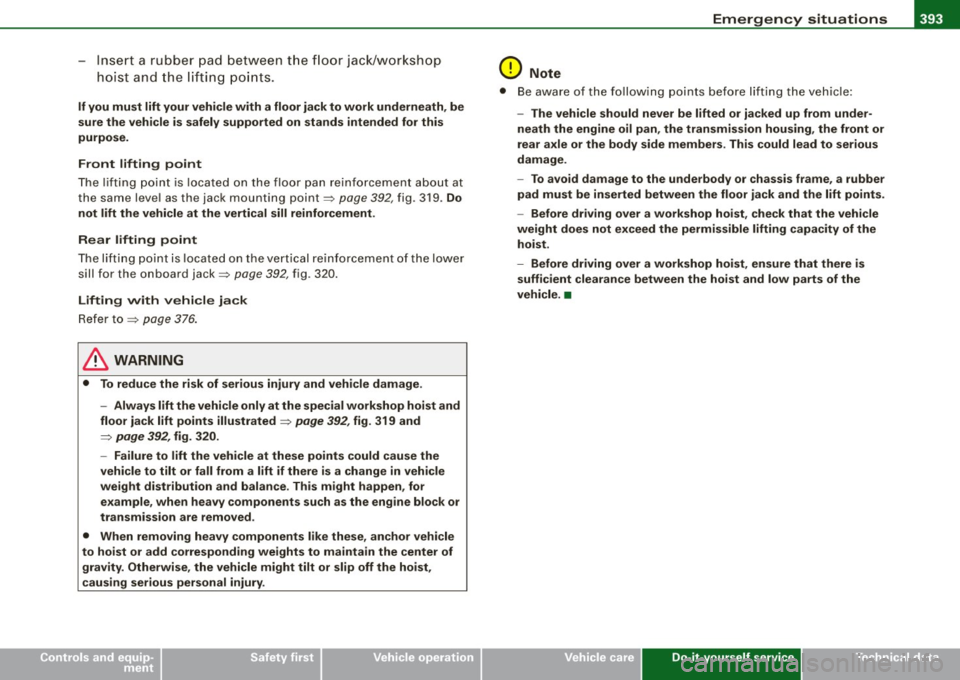

- Inse rt a rubbe r pad betwee n th e floo r ja ck/work shop

h oi st an d the lift ing p oin ts.

If you must lift your vehicle with a floor jack to wo rk underneath , be

sure the veh icle is safely supported on stands intended for this

purpose .

Front lifting point

T he lift ing p oint i s located o n th e flo or pan rei nforce men t about at

the same l eve l as th e jac k m ounting point=> page

392 , fig. 3 19 . Do

not lift the vehicle at the vertical sill reinforcement.

Rear lifting point

The li fti ng poi nt is located on the ve rt ical re in forceme nt of t he low er

sill for the on board jack=> page

392 , fig. 320.

Lifting with vehi cle ja ck

R efer to => page

376 .

& WARNING

• To reduce the risk of serious injury and vehicle damage.

-Always l ift the vehicle only at the special workshop hoist and

floor jack lift points illustrated => page

392 , fig. 319 and

=> page

392 , fig. 320.

- Failure to lift the vehicle at these points could cause the

vehicle to tilt or fall from a lift if there is a change in vehicle

weight distribution and balance . This might happen , for

e x ample , when heavy components such as the engine block or

transmission are removed .

• When remo ving heavy components like these, anchor vehicle

to hoist or add correspond ing we ights to maintain the center of

gravity. Otherwise , the vehicle might tilt or slip off the hoi st,

c ausing serious personal injury .

0 Note

• Be awar e of the fo llow ing po ints before l ifting t he ve hicle:

- The vehicle should never be lifted or jacked up from unde r

neath the engine oil pan , the transmission housing , the front or

rear a xle or the body side members. This could lead to serious

damage.

- To avoid damage to the underbody or chassis frame, a rubber

pad must be in serted between the floor jack and the lift po ints .

- Before driving over a workshop ho ist, check that the vehicle

weight does not exceed the permissible lifting capacity of the hoist.

- Before driving over a workshop hoist , ensure that there is

sufficient clearance between the hoist and low parts of the

vehicle. •

Do-it-yourself service

Page 399 of 426

_________________________________________________ G_ e_ n_ e_r _a _l_ i_n _f_o _ r_ m_ a_ t _i _o _ n __ ll'II

v e hic le identificatio n number of your vehic le (p erforation) as well as

th e G ro ss V ehic le We ight Rat ing (GVWR) an d the Gro ss A xle We ig ht

R ating (GAWRl .

The high voltage warning label is located on the lock carrier.

The spark ignition system complies with the Canadian standard ICES-002 . •

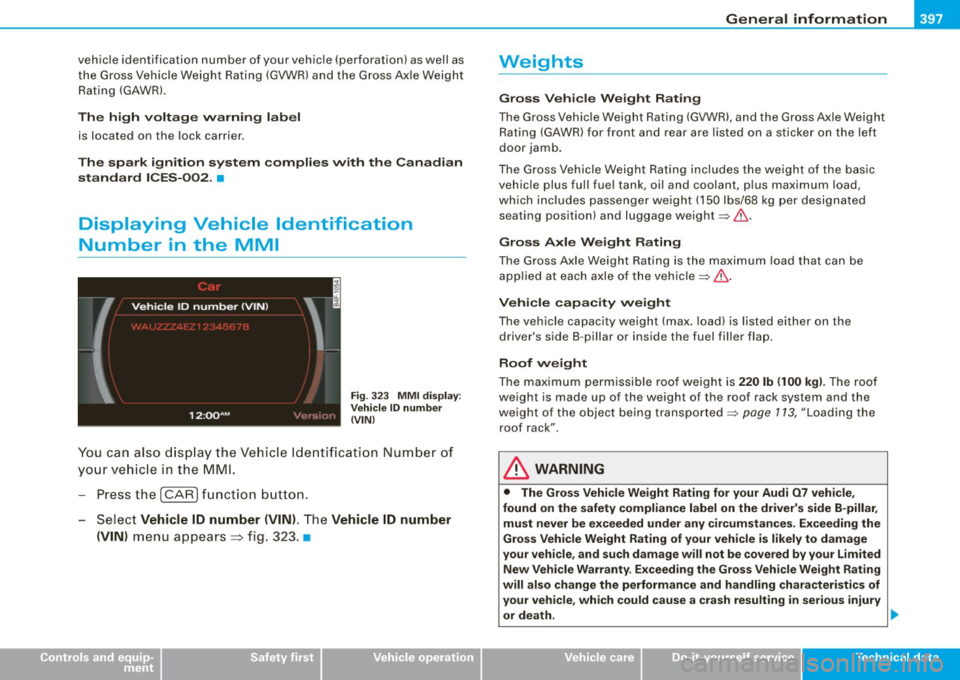

Displaying Vehicle Identification

Number in the MMI

Fig . 323 MMI di splay :

Vehicle ID number

(VIN)

Y ou can also display t he Vehi cle Id ent ifi catio n Num ber of

y o ur vehi cle in the MM I.

- Pre ss th e

(CA RI fun ctio n bu tton.

- Selec t

Vehicle ID number (VIN) . The Vehicle ID number

(VIN)

m enu appea rs=> fig. 3 23 . •

Controls and equip

ment Safety first Vehicle operation

Weights

Gross Vehicle Weight Rating

The G ross Ve hicle We ight Rating (GVWR), a nd the Gross A xle Weight

R ating (GAW R) for front and rear are l isted on a stic ker on the left

doo r jamb .

T he G ross Ve hicle We igh t R ating includes t he weight o f the bas ic

vehic le plus full fue l tank , oil and coo lant, p lus maximum load,

w hi ch includes passe nger we ight (1 50 lbs/68 kg per des ignat ed

seat ing position) and luggage weight:::::,&.

Gross Axle Weight Rating

The Gross Axle Weight Rating is the maximum load that can be

ap plied at each axl e of the vehicle:::::, .&,.

Vehicle capacity weight

The vehic le capacity weig ht (max. load) is list ed e ither on the

driver's side B -pillar or ins ide the fuel fi ller flap.

Roof weight

The maxi mum pe rm is s ible roof we ig ht i s 220 lb (100 kg ). The ro of

we ight is made up of th e wei ght of t he roof rack system an d the

we igh t of t he o bjec t being tra nspo rted :::::, page 1 13, "Lo adi ng the

roo f rack".

& WARNING

• The Gross Vehi cle Weight Rating for your Audi 07 vehi cle ,

found on the safety compliance label on the driver's side B -pillar ,

must never be exceeded under any circumstances . Exceeding the

Gross Vehicle Weight Rating of your vehicle is likely to damage

your vehicle , and such damage will not be covered by your Limited

New Vehicle Warranty . Exceeding the Gross Vehicle Weight Rating

will also change the performance and handling characteristics of

your veh icle , which could cause a crash resulting in serious injury

or death. .,_

Vehicle care Do-it-yourself service Tec hn ica l da ta

Page 401 of 426

_____________________________________________________ D_a_ t_ a __ lffllll

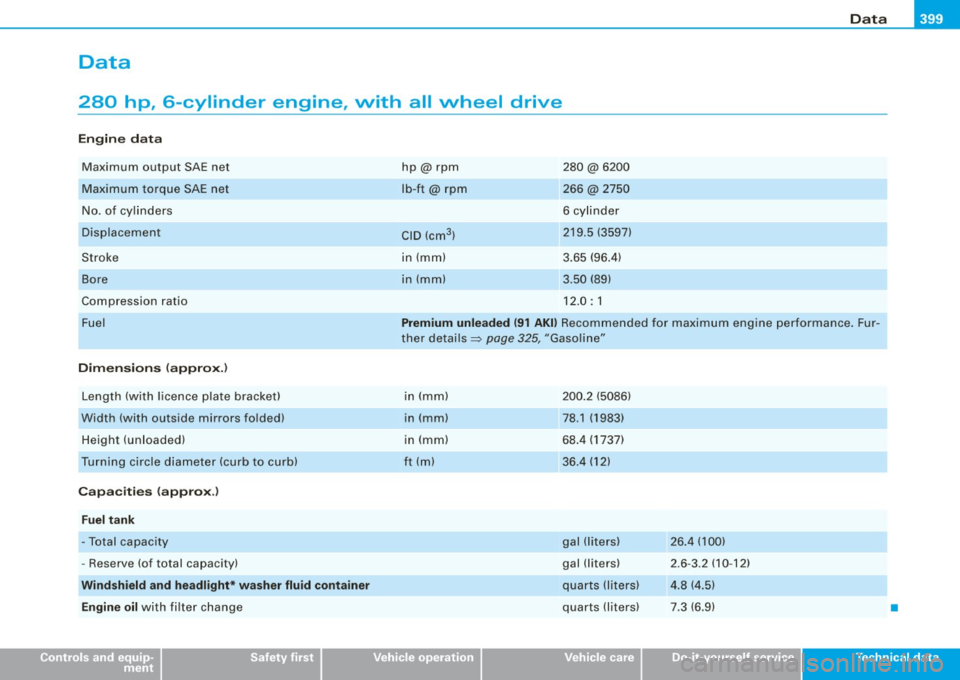

Data

280 hp, 6 -cylinder engine, with all wheel drive

Engine data

Maximum output SAE net

Maximum torque SAE net

No. o f cy li n ders

Displacement

Stroke Bore

Compression ratio

Fuel

Dimensions (approx .)

Length (with lice nce plate bracket)

Width (with outside mirrors fo lded)

Height (unloaded)

Turning circle d iameter (curb to curb)

Capacities (approx .)

Fuel tank

- Total capacity

- Reserve (of total capacity)

Wind shield and headlight * wa sher fluid container

Engine oil

with fi lter change

Controls and equip

ment Safety first

hp@rpm

lb

-ft@ rpm

C ID (cm

3

)

in (mm)

in (mm) 280@ 6200

266@2750

6 cy

lind er

219 .5 (3597)

3 .65 (96 .4)

3.50 (89)

12 .0 : 1

Premium unleaded (91 AKO Recommended for maximum engine pe rformance . Fur

ther details~

page 325, "Gasoline"

i n ( mm)

i n (mm)

in (mm)

ft ( ml 200

.2 (5086)

78 .1 (1983)

68 .4 (1 737)

36.4 (12)

gal ( liters)

gal !liters)

quarts (liters)

quarts !liters) 26

.4 (100)

2 .6 -3 .2 (10 -12)

4.8 (4.5)

7 .3 (6 .9)

•

Vehicle operation Vehicle care Do-it-yourself service Tec hn ica l da ta