AUDI R8 2007 Owners Manual

Manufacturer: AUDI, Model Year: 2007, Model line: R8, Model: AUDI R8 2007Pages: 210, PDF Size: 8.1 MB

Page 181 of 210

Self-help179

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data Your vehicle is equipped with a tyre repair kit: the Tyre Mobility

System (TMS).

In the event of a puncture you will find the TMS, which consists of a

sealing compound and an electric compressor, located under the

floor panel in the luggage compartment.

The TMS will reliably seal tyres damaged by foreign bodies,

provided that the cuts or punctures are no larger than approx. 4 mm

in diameter.

It is not necessary to remove the foreign body from the tyre.

The sealing compound must not be used:

•

on cuts and punctures larger than 4 mm ⇒page 178, fig. 124

•

if the wheel rim has been damaged

•

if you have been driving with very low pressure or a completely

flat tyre .

How to use the TMS is described in the section Repairing a tyre

⇒page 180.

The TMS can be used at outside temperatures down to – 20 °C.

WARNING

After repairing a tyre please note the following points:•

Do not drive faster than 80 km/h.

•

Avoid heavy acceleration, hard braking and fast cornering.

•

Vehicle handling could be impaired.

•

Tyres which have been sealed using the TMS are only suitable

for temporary use. Damaged tyres must be renewed. Therefore,

please drive carefully to the next available qualified workshop.

•

The TMS must NOT be used,

−on cuts and punctures larger than 4 mm

−if the wheel rim has been damaged

−if you have been driving with very low pressure or a

completely flat tyre

•

Seek professional assistance if the repair of a tyre puncture is

not possible with the sealing compound.

•

Do not allow the sealant to come into contact with your eyes,

skin or clothing.

•

If you do come into contact with the sealant immediately rinse

the eyes or skin affected with clean water.

•

Change clothing immediately if it becomes soiled with the tyre

sealant.

•

Make sure you do not breathe in the fumes!

•

If any of the tyre sealant is accidentally ingested, immediately

rinse the mouth thoroughly and drink lots of water.

−Do not induce vomiting. Immediately contact a doctor!

•

If any allergic reactions should occur get medical help immedi-

ately.

•

Keep the sealant away from children.For the sake of the environment

Used sealing compound cans should be disposed of at a proper

facility.

Note

•

If sealant should leak out, leave it to dry. When it has dried, you

can pull it off like a piece of foil.

•

Observe the expiry date stated on the sealing compound can.

Have the sealing compound exchanged by a qualified workshop.

A1

A2

A3

WARNING (continued)

document_0900452a816e6cc9.book Seite 179 Mittwoch, 21. Februar 2007 1:32 13

Page 182 of 210

Self-help 180Preparations

Certain steps must be taken before repairing a tyre.– If you have a flat tyre, stop the car well away from moving

traffic.

– Apply the handbrake firmly.

– Engage a gear.

– Check whether a repair is possible using the Tyre

Mobility System ⇒page 178.

– Ensure that all passengers leave the vehicle and move

away from the danger area ⇒.

– Take the tyre sealant can and the electric compressor out

of the holder under the floor panel ⇒page 178, fig. 123.

– Peel the sticker “max. 80 km/h” off the tyre sealant can

and fix it onto the instrument cluster where the driver will

see it.

WARNING

•

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

•

Make sure your passengers wait in a safe place (for instance

behind the roadside crash barrier).Caution

Take special care if you have to repair a tyre on a gradient.

Note

Please observe the relevant regulations.

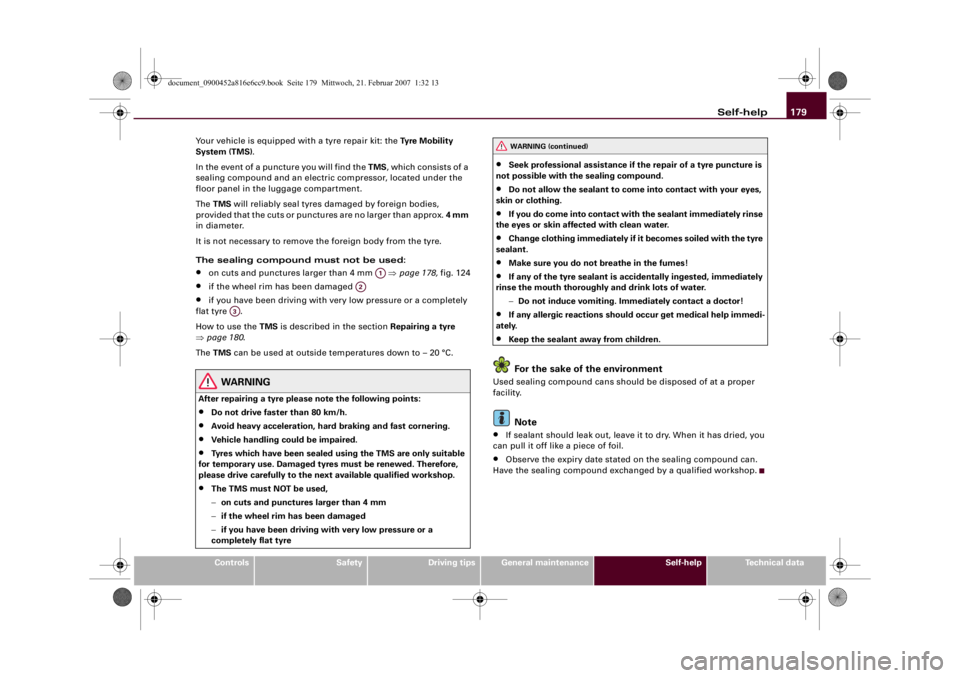

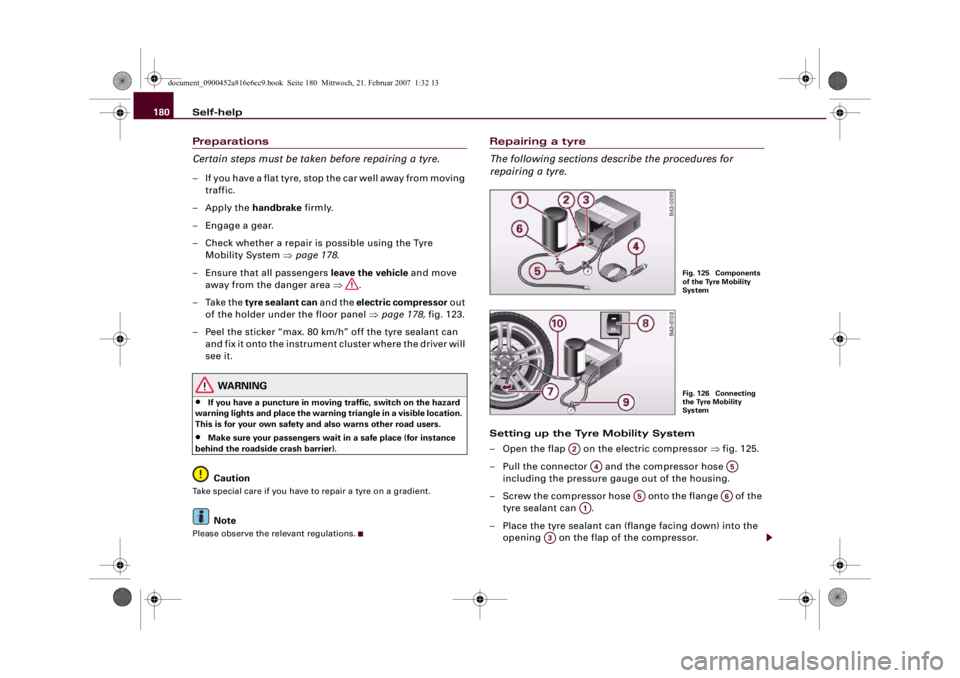

Repairing a tyre

The following sections describe the procedures for

repairing a tyre.Setting up the Tyre Mobility System

– Open the flap on the electric compressor ⇒fig. 125.

– Pull the connector and the compressor hose

including the pressure gauge out of the housing.

– Screw the compressor hose onto the flange of the

tyre sealant can .

– Place the tyre sealant can (flange facing down) into the

opening on the flap of the compressor.

Fig. 125 Components

of the Tyre Mobility

SystemFig. 126 Connecting

the Tyre Mobility

System

A2

A4

A5

A5

A6

A1

A3

document_0900452a816e6cc9.book Seite 180 Mittwoch, 21. Februar 2007 1:32 13

Page 183 of 210

Self-help181

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Unscrew the dust cap from the valve of the damaged

tyre.

– Screw the filler hose onto the valve ⇒page 180,

fig. 126.

– Insert the connector ⇒page 180, fig. 125 into the

cigarette lighter socket.

Inflating the tyre

–Move the switch ⇒page 180, fig. 126 on the

compressor

4) to position I. After 5 minutes tyre pressure

should be at least 1.8 bar.

– Switch off the compressor by moving switch to

position0. If the necessary tyre pressure of at least 1.8

bar is not reached please follow the instructions given in

the section Re-inflating the tyre.

Re-inflating the tyre

– Remove the filler hose from the valve and pull the

connector out of the socket.

– Slowly move the vehicle forwards and backwards about

10 metres. This enables the sealant to be distributed

more evenly.

– Remove the empty tyre sealant can and screw the

compressor hose ⇒page 180, fig. 125 directly onto

the valve.

– Insert the connector into the cigarette lighter socket.– Move the switch ⇒page 180, fig. 126 on the

compressor to position I. After 5 minutes tyre pressure

should be at least 1.8 bar.

– Switch off the compressor by moving switch to

position0. If the necessary tyre pressure of at least 1.8

bar is not reached this means that the tyre cannot be

repaired using the tyre sealant. You should obtain profes-

sional assistance.

Dismantling the Tyre Mobility System

– Remove the filler hose from the valve and pull the

connector out of the socket.

– Screw the dust cap onto the valve.

– Put the empty tyre sealant can back into its original pack-

aging and then secure it in the holder under the floor

panel in such a way that it will not leak.

– Then drive away immediately so that the tyre sealant can

spread evenly in the tyre.

WARNING

•

Please observe the manufacturers' safety notes on the stickers

on the compressor and the tyre sealant can.

•

If it was not possible to build up a tyre pressure of 1.8 bar

within 5 minutes this means that the tyre is too badly damaged.

Do not drive on.

•

Seek professional assistance if the repair of a tyre puncture is

not possible with the sealing compound.

4)The compressor should never be used for longer than 8 minutes.

A10

A7

A4

A8A5A4

A8

document_0900452a816e6cc9.book Seite 181 Mittwoch, 21. Februar 2007 1:32 13

Page 184 of 210

Self-help 182

Note•

Do not use the compressor for longer than 8 minutes at a time,

as it could overheat. When the compressor has cooled down, you

can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off

like foil.

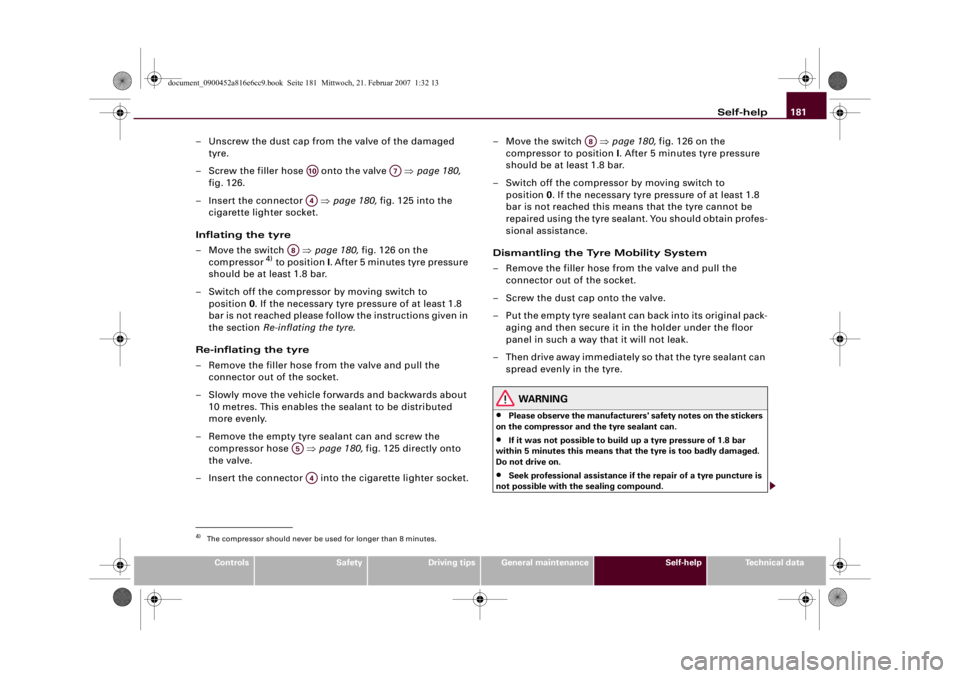

Final checkAfter covering a short distance it is necessary to check the

tyre pressure

– After about 10 minutes stop to check the tyre pressure.

– If tyre pressure is still at least 1.3 bar, pump the tyre up

to the pressure specified (see driver's door pillar) and

drive to the nearest workshop to have the tyre and the

tyre sealant can replaced.

– If tyre pressure is less than 1.3 bar, the tyre is too badly

damaged. Do not drive on. You should obtain profes-

sional assistance.

WARNING

If tyre pressure is less than 1.3 bar after driving about 10 minutes,

the tyre is too badly damaged. Do not drive on. You should obtain

professional assistance.

Note

After carrying out repairs to a tyre, have the tyre sealant can

replaced by a qualified dealer. This will ensure that the Tyre Mobility

System is operative again.

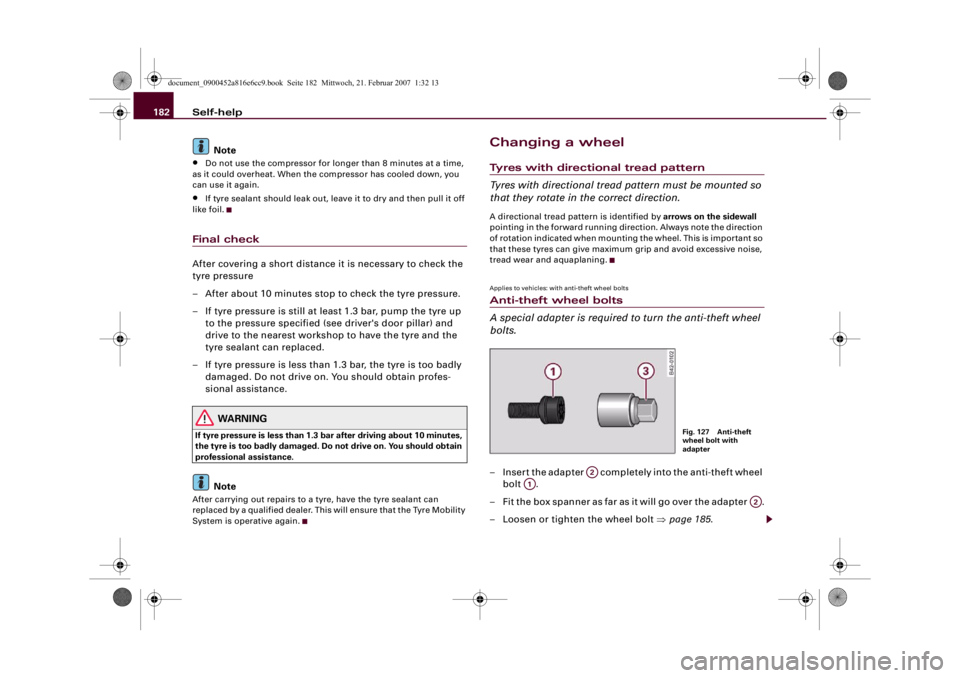

Changing a wheelTyres with directional tread pattern

Tyres with directional tread pattern must be mounted so

that they rotate in the correct direction.A directional tread pattern is identified by arrows on the sidewall

pointing in the forward running direction. Always note the direction

of rotation indicated when mounting the wheel. This is important so

that these tyres can give maximum grip and avoid excessive noise,

tread wear and aquaplaning.Applies to vehicles: with anti-theft wheel boltsAnti-theft wheel bolts

A special adapter is required to turn the anti-theft wheel

bolts.– Insert the adapter completely into the anti-theft wheel

bolt .

– F i t t h e b o x s p a n n e r as fa r as i t w i l l g o o v e r t h e a d a p t e r .

– Loosen or tighten the wheel bolt ⇒page 185.

Fig. 127 Anti-theft

wheel bolt with

adapter

A2

A1

A2

document_0900452a816e6cc9.book Seite 182 Mittwoch, 21. Februar 2007 1:32 13

Page 185 of 210

Self-help183

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data It is advisable to carry the wheel bolt adapter in the vehicle. It should

be stored with the tool kit.

The code number of the anti-theft wheel bolt is stamped on the front

of the adapter. Your Audi R8 dealer will need this number to replace

the adapter if lost.

Note

Note the code number of the anti-theft wheel bolt and keep it in a

safe place – not in your vehicle.Applies to vehicles: with jackRaising the vehicle

The vehicle must be raised with a jack to remove the

wheel.

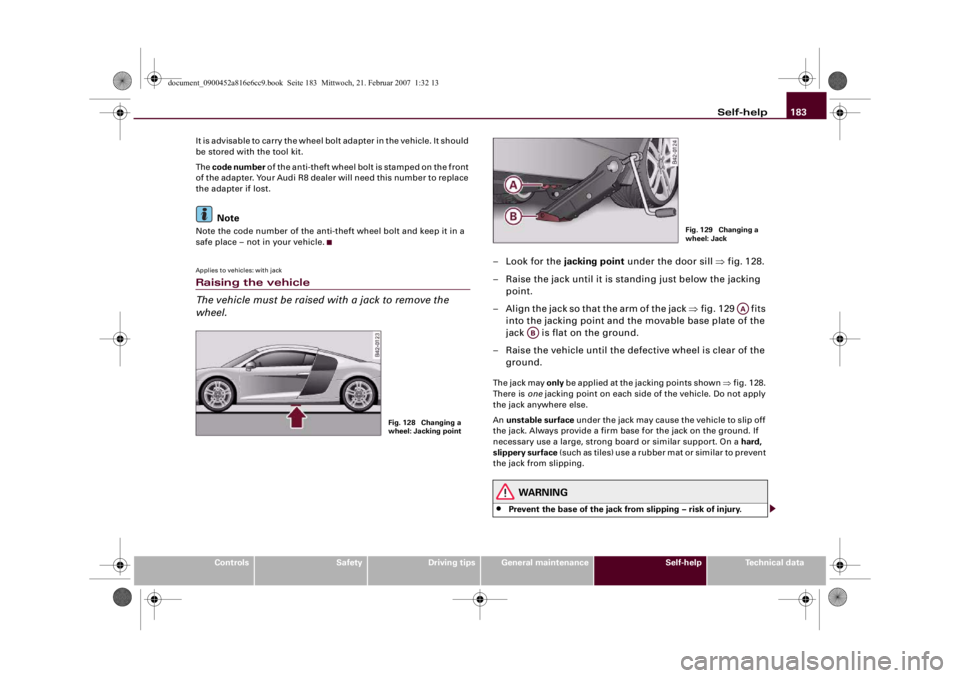

–Look for the jacking point under the door sill ⇒fig. 128.

– Raise the jack until it is standing just below the jacking

point.

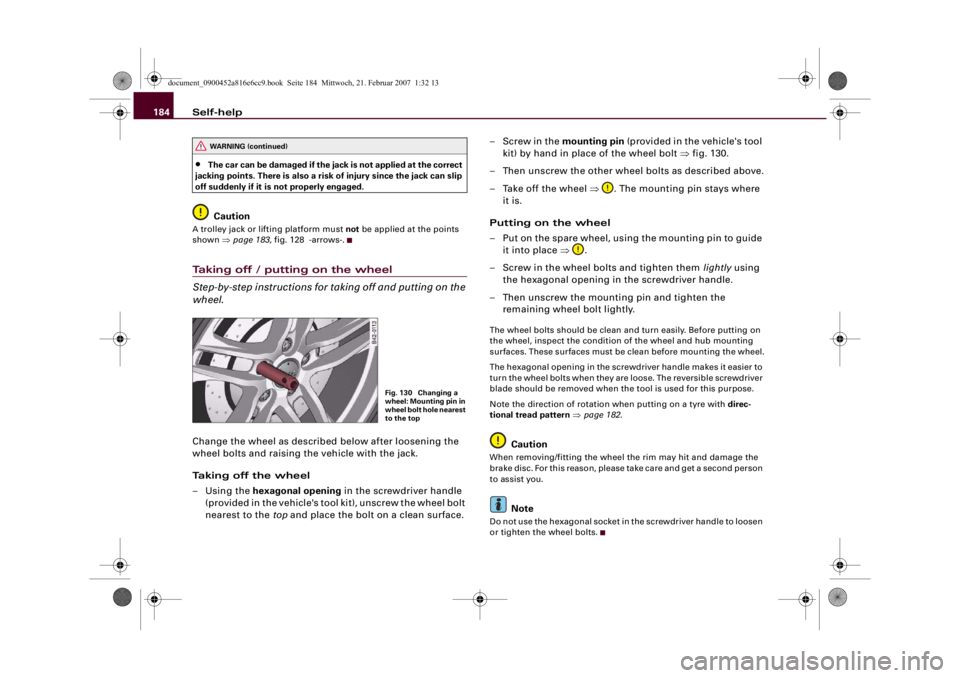

– Align the jack so that the arm of the jack ⇒fig. 129 fits

into the jacking point and the movable base plate of the

jack is flat on the ground.

– Raise the vehicle until the defective wheel is clear of the

ground.The jack may only be applied at the jacking points shown ⇒fig. 128.

There is one jacking point on each side of the vehicle. Do not apply

the jack anywhere else.

An unstable surface under the jack may cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary use a large, strong board or similar support. On a hard,

slippery surface (such as tiles) use a rubber mat or similar to prevent

the jack from slipping.

WARNING

•

Prevent the base of the jack from slipping – risk of injury.

Fig. 128 Changing a

wheel: Jacking point

Fig. 129 Changing a

wheel: Jack

AA

AB

document_0900452a816e6cc9.book Seite 183 Mittwoch, 21. Februar 2007 1:32 13

Page 186 of 210

Self-help 184•

The car can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip

off suddenly if it is not properly engaged.Caution

A trolley jack or lifting platform must not be applied at the points

shown ⇒page 183, fig. 128 -arrows-.Taking off / putting on the wheel

Step-by-step instructions for taking off and putting on the

wheel.Change the wheel as described below after loosening the

wheel bolts and raising the vehicle with the jack.

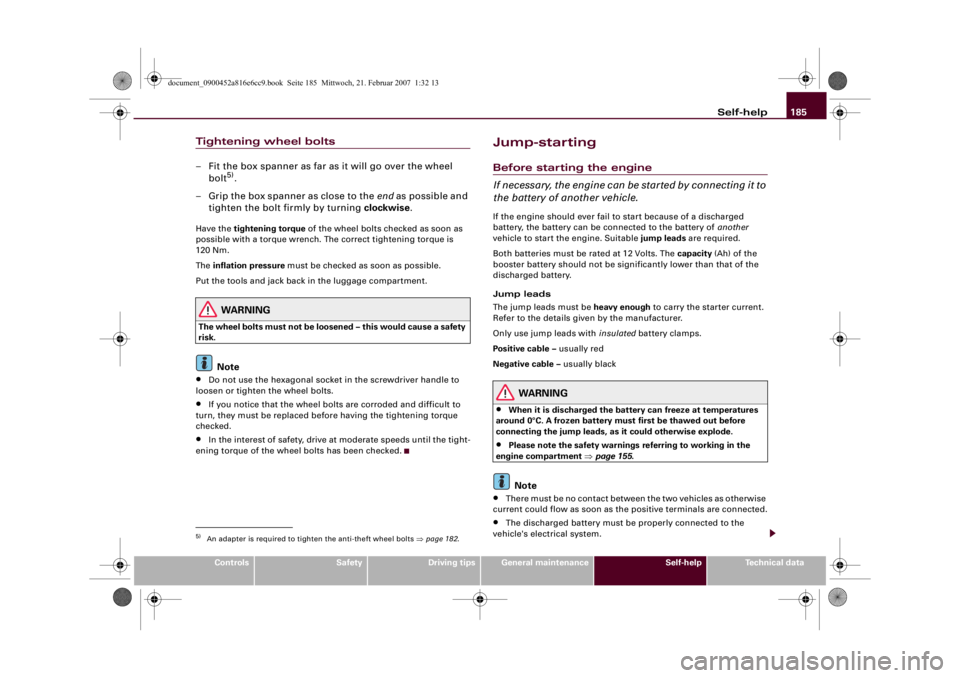

Taking off the wheel

–Using the hexagonal opening in the screwdriver handle

(provided in the vehicle's tool kit), unscrew the wheel bolt

nearest to the top and place the bolt on a clean surface.–Screw in the mounting pin (provided in the vehicle's tool

kit) by hand in place of the wheel bolt ⇒fig. 130.

– Then unscrew the other wheel bolts as described above.

– Take off the wheel ⇒. The mounting pin stays where

it is.

Putting on the wheel

– Put on the spare wheel, using the mounting pin to guide

it into place ⇒.

– Screw in the wheel bolts and tighten them lightly using

the hexagonal opening in the screwdriver handle.

– Then unscrew the mounting pin and tighten the

remaining wheel bolt lightly.

The wheel bolts should be clean and turn easily. Before putting on

the wheel, inspect the condition of the wheel and hub mounting

surfaces. These surfaces must be clean before mounting the wheel.

The hexagonal opening in the screwdriver handle makes it easier to

turn the wheel bolts when they are loose. The reversible screwdriver

blade should be removed when the tool is used for this purpose.

Note the direction of rotation when putting on a tyre with direc-

tional tread pattern ⇒page 182.

Caution

When removing/fitting the wheel the rim may hit and damage the

brake disc. For this reason, please take care and get a second person

to assist you.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen

or tighten the wheel bolts.

WARNING (continued)

Fig. 130 Changing a

wheel: Mounting pin in

wheel bolt hole nearest

to the top

document_0900452a816e6cc9.book Seite 184 Mittwoch, 21. Februar 2007 1:32 13

Page 187 of 210

Self-help185

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Tightening wheel bolts– Fit the box spanner as far as it will go over the wheel

bolt

5).

– Grip the box spanner as close to the end as possible and

tighten the bolt firmly by turning clockwise.

Have the tightening torque of the wheel bolts checked as soon as

possible with a torque wrench. The correct tightening torque is

120 Nm.

The inflation pressure must be checked as soon as possible.

Put the tools and jack back in the luggage compartment.

WARNING

The wheel bolts must not be loosened – this would cause a safety

risk.

Note

•

Do not use the hexagonal socket in the screwdriver handle to

loosen or tighten the wheel bolts.

•

If you notice that the wheel bolts are corroded and difficult to

turn, they must be replaced before having the tightening torque

checked.

•

In the interest of safety, drive at moderate speeds until the tight-

ening torque of the wheel bolts has been checked.

Jump-startingBefore starting the engine

If necessary, the engine can be started by connecting it to

the battery of another vehicle.If the engine should ever fail to start because of a discharged

battery, the battery can be connected to the battery of another

vehicle to start the engine. Suitable jump leads are required.

Both batteries must be rated at 12 Volts. The capacity (Ah) of the

booster battery should not be significantly lower than that of the

discharged battery.

Jump leads

The jump leads must be heavy enough to carry the starter current.

Refer to the details given by the manufacturer.

Only use jump leads with insulated battery clamps.

Positive cable – usually red

Negative cable – usually black

WARNING

•

When it is discharged the battery can freeze at temperatures

around 0°C. A frozen battery must first be thawed out before

connecting the jump leads, as it could otherwise explode.

•

Please note the safety warnings referring to working in the

engine compartment ⇒page 155.Note

•

There must be no contact between the two vehicles as otherwise

current could flow as soon as the positive terminals are connected.

•

The discharged battery must be properly connected to the

vehicle's electrical system.

5)An adapter is required to tighten the anti-theft wheel bolts ⇒page 182.

document_0900452a816e6cc9.book Seite 185 Mittwoch, 21. Februar 2007 1:32 13

Page 188 of 210

Self-help 186•

Switch off the car telephone if necessary. Details will be given in

the manufacturer's instructions for the car telephone.

Starting the engine

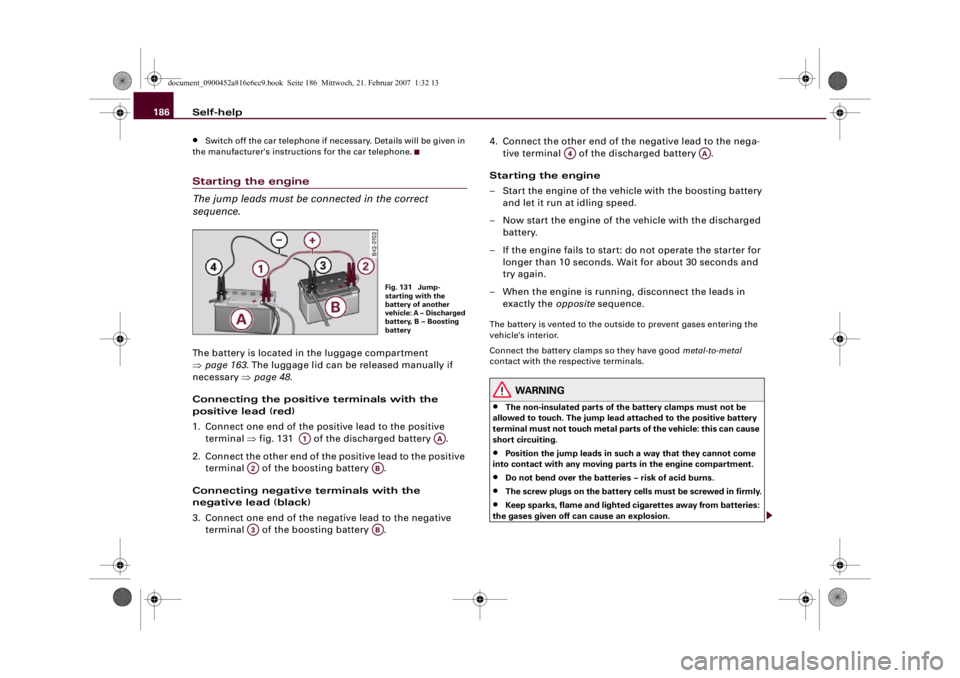

The jump leads must be connected in the correct

sequence.The battery is located in the luggage compartment

⇒page 163. The luggage lid can be released manually if

necessary ⇒page 48.

Connecting the positive terminals with the

positive lead (red)

1. Connect one end of the positive lead to the positive

terminal ⇒fig. 131 of the discharged battery .

2. Connect the other end of the positive lead to the positive

terminal of the boosting battery .

Connecting negative terminals with the

negative lead (black)

3. Connect one end of the negative lead to the negative

terminal of the boosting battery .4. Connect the other end of the negative lead to the nega-

tive terminal of the discharged battery .

Starting the engine

– Start the engine of the vehicle with the boosting battery

and let it run at idling speed.

– Now start the engine of the vehicle with the discharged

battery.

– If the engine fails to start: do not operate the starter for

longer than 10 seconds. Wait for about 30 seconds and

try again.

– When the engine is running, disconnect the leads in

exactly the opposite sequence.

The battery is vented to the outside to prevent gases entering the

vehicle's interior.

Connect the battery clamps so they have good metal-to-metal

contact with the respective terminals.

WARNING

•

The non-insulated parts of the battery clamps must not be

allowed to touch. The jump lead attached to the positive battery

terminal must not touch metal parts of the vehicle: this can cause

short circuiting.

•

Position the jump leads in such a way that they cannot come

into contact with any moving parts in the engine compartment.

•

Do not bend over the batteries – risk of acid burns.

•

The screw plugs on the battery cells must be screwed in firmly.

•

Keep sparks, flame and lighted cigarettes away from batteries:

the gases given off can cause an explosion.

Fig. 131 Jump-

starting with the

battery of another

vehicle: A – Discharged

battery, B – Boosting

battery

A1

AA

A2

AB

A3

AB

A4

AA

document_0900452a816e6cc9.book Seite 186 Mittwoch, 21. Februar 2007 1:32 13

Page 189 of 210

Self-help187

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Caution

Please note that the described method of connecting the leads is

meant for jump-starting your vehicle. If jump-starting another

vehicle, you should not connect the negative lead (–) to the negative

terminal of the discharged battery ⇒page 186, fig. 131 , but

directly to the engine block or a solid metal part bolted to the engine

block. If the battery of the other vehicle does not have a gas vent,

there is a risk that a mixture of oxygen and hydrogen gas can accu-

mulate and cause an explosion.Tow-starting and towing awayGeneral notes

Points to observe when tow-starting or towing awayIf you use a towrope:

Notes for the driver of the towing vehicle

– The towrope must be taut before driving off.

– Engage the clutch very gently when starting to move

(press the accelerator slowly if you have R tronic).

Notes for the driver of the towed vehicle

– The ignition should be switched on so that the turn

signals, horn, windscreen wipers and washers can be

used. Please ensure that the steering wheel is unlocked

when you switch on the ignition and that it moves freely.

– Put the gear lever in neutral or move the selector lever to

position N.– The brake servo and power steering only work when the

engine is running. Considerably more effort is required

on the brake pedal and steering wheel when the engine

is switched off.

– Ensure that the towrope remains taut at all times when

towing.

Towrope or towbar

It is easier and safer to tow a vehicle with a towbar. You should only

use a towrope if you do not have a towbar.

A towrope should be slightly elastic to reduce the loading on both

vehicles. It is advisable to use a towrope made of synthetic fibre or

similar material.

Attach the towrope or the towbar only to the towing anchorages

provided for this purpose ⇒page 188.

Driving technique

Towing requires some experience – especially when using a

towrope. Both drivers should be familiar with the technique required

for towing. Inexperienced drivers should not attempt to tow-start or

tow away another vehicle.

Do not pull too hard with the towing vehicle and take care to avoid

jerking the towrope. When towing on a loose surface there is always

a risk of overloading and damaging the anchorage points.

Caution

If there is no oil in the gearbox or no lubricant in the automatic

transmission the car may only be towed with the driven wheels

lifted clear of the road, or transported on a special car transporter

or trailer.

Note

•

Note the regulations concerning towing.

A4

document_0900452a816e6cc9.book Seite 187 Mittwoch, 21. Februar 2007 1:32 13

Page 190 of 210

Self-help 188•

The hazard warning lights of both vehicles must normally be

switched on. However, observe any regulations to the contrary.

•

Make sure that the towrope is not twisted, as otherwise the front

towline anchorage on your vehicle could work itself loose.

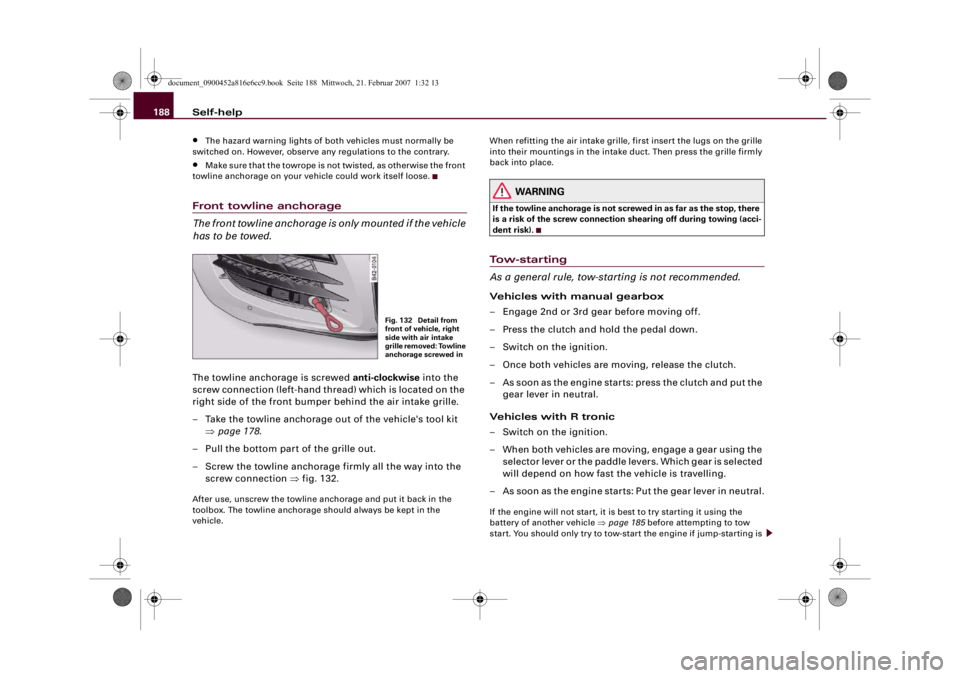

Front towline anchorage

The front towline anchorage is only mounted if the vehicle

has to be towed.The towline anchorage is screwed anti-clockwise into the

screw connection (left-hand thread) which is located on the

right side of the front bumper behind the air intake grille.

– Take the towline anchorage out of the vehicle's tool kit

⇒page 178.

– Pull the bottom part of the grille out.

– Screw the towline anchorage firmly all the way into the

screw connection ⇒fig. 132.After use, unscrew the towline anchorage and put it back in the

toolbox. The towline anchorage should always be kept in the

vehicle.When refitting the air intake grille, first insert the lugs on the grille

into their mountings in the intake duct. Then press the grille firmly

back into place.

WARNING

If the towline anchorage is not screwed in as far as the stop, there

is a risk of the screw connection shearing off during towing (acci-

dent risk).Tow-starting

As a general rule, tow-starting is not recommended.Vehicles with manual gearbox

– Engage 2nd or 3rd gear before moving off.

– Press the clutch and hold the pedal down.

– Switch on the ignition.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts: press the clutch and put the

gear lever in neutral.

Vehicles with R tronic

– Switch on the ignition.

– When both vehicles are moving, engage a gear using the

selector lever or the paddle levers. Which gear is selected

will depend on how fast the vehicle is travelling.

– As soon as the engine starts: Put the gear lever in neutral.If the engine will not start, it is best to try starting it using the

battery of another vehicle ⇒page 185 before attempting to tow

start. You should only try to tow-start the engine if jump-starting is

Fig. 132 Detail from

front of vehicle, right

side with air intake

grille removed: Towline

anchorage screwed in

document_0900452a816e6cc9.book Seite 188 Mittwoch, 21. Februar 2007 1:32 13