AUDI R8 SPYDER 2014 Owners Manual

Manufacturer: AUDI, Model Year: 2014, Model line: R8 SPYDER, Model: AUDI R8 SPYDER 2014Pages: 244, PDF Size: 61.06 MB

Page 211 of 244

you should contac t you r authorized Audi

dealer imme diate ly to have the problem co r

rected.

- Do not use comme rcially ava ila ble tire seal

ants. Otherw ise, the electrical components

of the tire pressure monitoring system w ill

no l onger wor k properly and the sensor for

t h e tire pressure mo nitoring system will

hav e to b e replaced by a qualified wor kshop .

Tires and wheels 209

•

•

Page 212 of 244

210 What do I do now?

What do I do now?

Trunk escape handle

Appl ies to vehicles: wit h tru nk escape hand le

In case of an emergency, the front lid can be

opened from the inside using the trunk es

cape handle .

.,. To

open the front lid pu ll the handle.

The trunk escape handle inside the luggage

compartment is made of fluorescent material

to g low in the dark.

A WARNING

The trunk escape handle is to be used only

in an emergency.

Vehicle tool kit

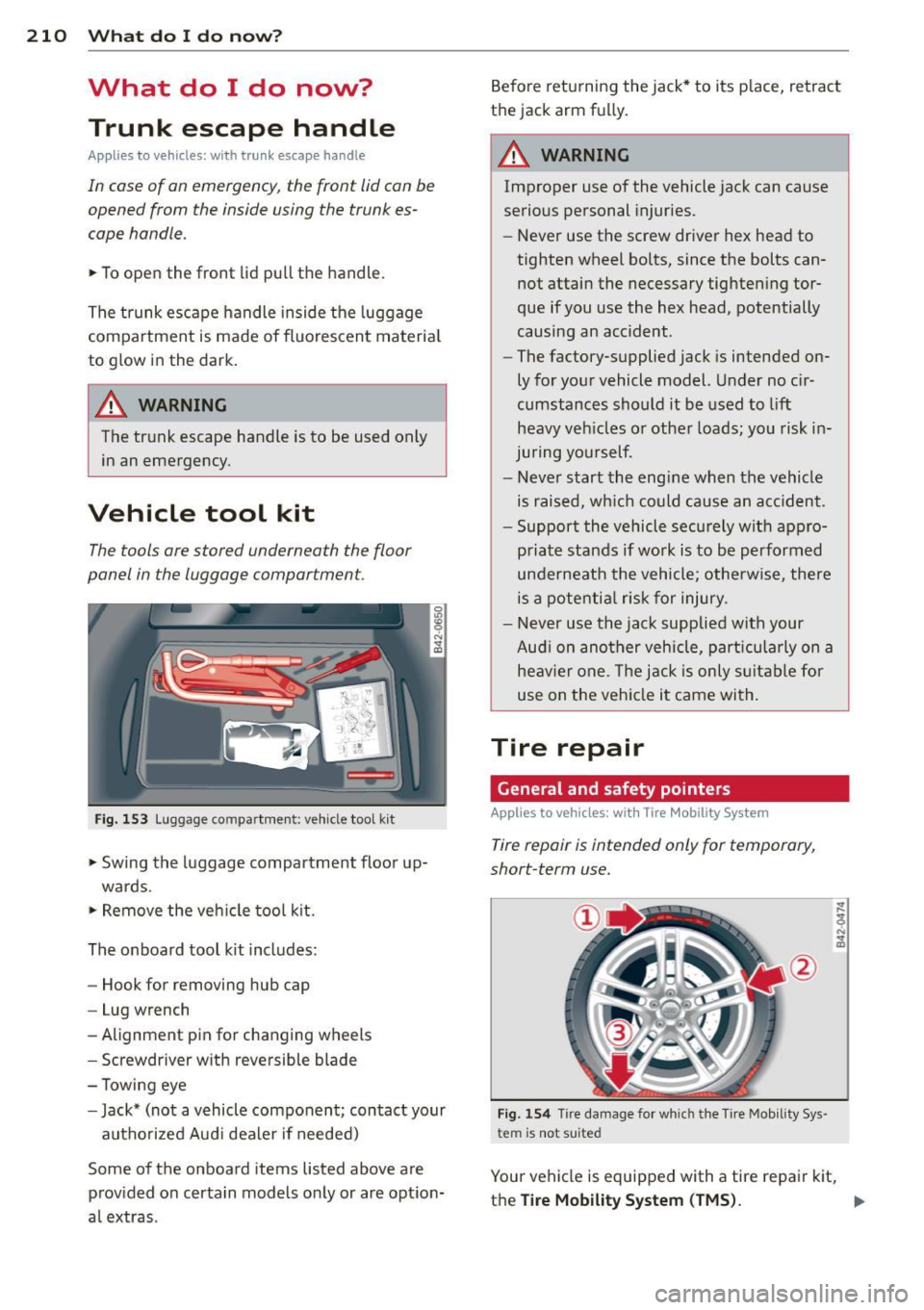

The tools are stored underneath the floor

panel in the luggage comportment.

Fig. 153 Luggage compartment: ve hicle tool k it

.,. Swing the luggage compartment floor up-

wards .

.,. Remove the vehicle tool kit.

The onboard tool kit includes:

- Hook for removing hub cap

- Lug wrench

- Alignment pin for changing wheels

- Screwdriver with reversible blade

- T owing eye

- Jack* (not a vehicle component; contact your

authorized Aud i dealer if needed)

Some of the on board items listed above are provided on certain models only or are option

a l extras. Before

returning the jack* to its place, retract

t h e jack arm fully.

A WARNING

-

Improper use of the vehicle jack can cause

serious personal injuries.

- Never use the screw driver hex head to

tighten wheel bolts, since the bolts can

not attain the necessary tightening tor

que if you use the hex head, potentially

causing an accident.

- The factory-supplied jack is intended on

ly for your vehicle model. Under no cir

cumstances should it be used to

lift

heavy veh icles or other loads; you risk in

juring yourself.

- Never start the engine when the vehicle

is raised, which could cause an acc ident.

- Support the vehicle securely with appro

priate stands if work is to be performed

underneath the vehicle; otherwise, there

is a potential risk for injury.

- Never use the jack supplied with your

Aud i on another vehicle, part icularly on a

heav ier one. The jack is only suitable for

use on the vehicle it came with.

Tire repair

General and safety pointers

Applies to veh icles: w it h Tire Mob ility System

Tire repair is intended only for temporary,

short-term use.

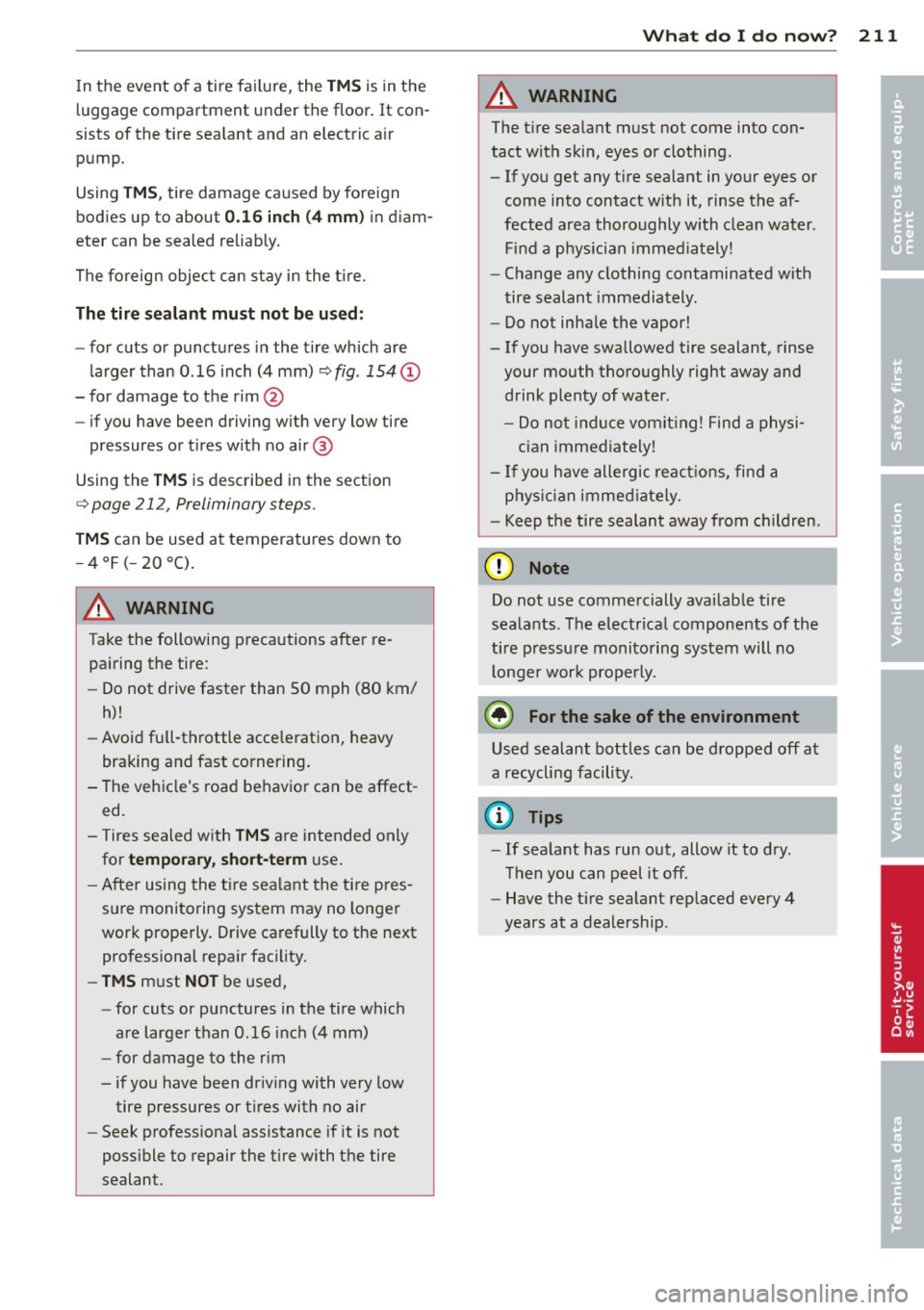

Fig . 154 Tire damage for wh ich the Tir e Mob ility Sys

te m is no t suited

Your vehicle is equipped with a tire repair kit,

the

Tire Mobility System (TMS). .,,.

Page 213 of 244

In the event of a tire fai lure, the TM S is in the

l uggage compartment under the floor . It con

sists of the tire sea lant and an electric a ir

pump.

Using

TM S, tire damage ca used by foreign

bodies up to about

0.1 6 inch (4 mm ) in diam

eter can be sealed reliab ly.

The foreign object can stay in the t ire.

The tir e sea lant must not be us ed :

- for cuts or punctu res in the tire which are

larger than 0.16 inch (4 mm)

r;;';> fig . 154 @

- for damage to the rim@

- if you have been driving w ith very low tire

pressures or tires with no air @

Using the

T M S is described in the section

¢ page 212, Preliminary steps.

TM S can be used at temperatures down to

-4 °F ( -20 °().

8_ WARNING

Take the following precautions after re

pairing the tire:

-

- Do not drive faster than 50 mph (80 km/

h)!

- Avoid full-throttle acce leration, heavy

braking and fast cornering.

- The vehicle's road behavior can be affect ed.

- Tires sealed with

TMS are intended only

for

tempora ry, short-te rm use .

- After using the t ire sea lant the ti re p res

sure monitoring system may no longer

work properly. Drive carefully to the next professional repair fac ility.

- TMS must NO T be used,

- for cuts or punctures in the tire which

are larger than 0.16 inch (4 mm)

- for damage to the rim

- if you have been dr iv ing with very low

tire pressures or tires with no air

- Seek profess ional assistance if it is not

poss ible to repair the tire with the tire

sealant.

What do I do now? 211

8_ WARNING

The tire sealant must not come into con

tact with skin, eyes or clothing.

- If you get any tire sealant in your eyes or

come into contact with it, rinse the af

fected area thoroughly with clean water .

Find a phys ician immed iately!

- Change any clothing contaminated wit h

tire sealant immediately.

- Do not inhale the vapor!

- If you have swallowed tire sealant, rinse your mouth thoroughly right away and drink plenty of water .

- Do not indu ce vomit ing! Find a physi

c ian immediately!

- I f you have allergic react ions, find a

phys ician immediately.

- Keep the tire sealant away from children.

(D Note

Do not use commercially available tire

sealants . The electr ical components of the

tire pressure monitoring system will no

l onge r work properly.

@ For the sake of the env ironment

Used sealant bottles can be dropped off at

a recycling facility .

(D Tips

-If sealant has run out, allow it to dry .

Then you can peel it off.

- Have the t ire sealant replaced every 4

years at a dealership .

• -

•

Page 214 of 244

212 What do I do now?

Preliminary steps

Applies to vehicles: with T ire Mobility System

Some preliminary steps are necessary for tire

repair .

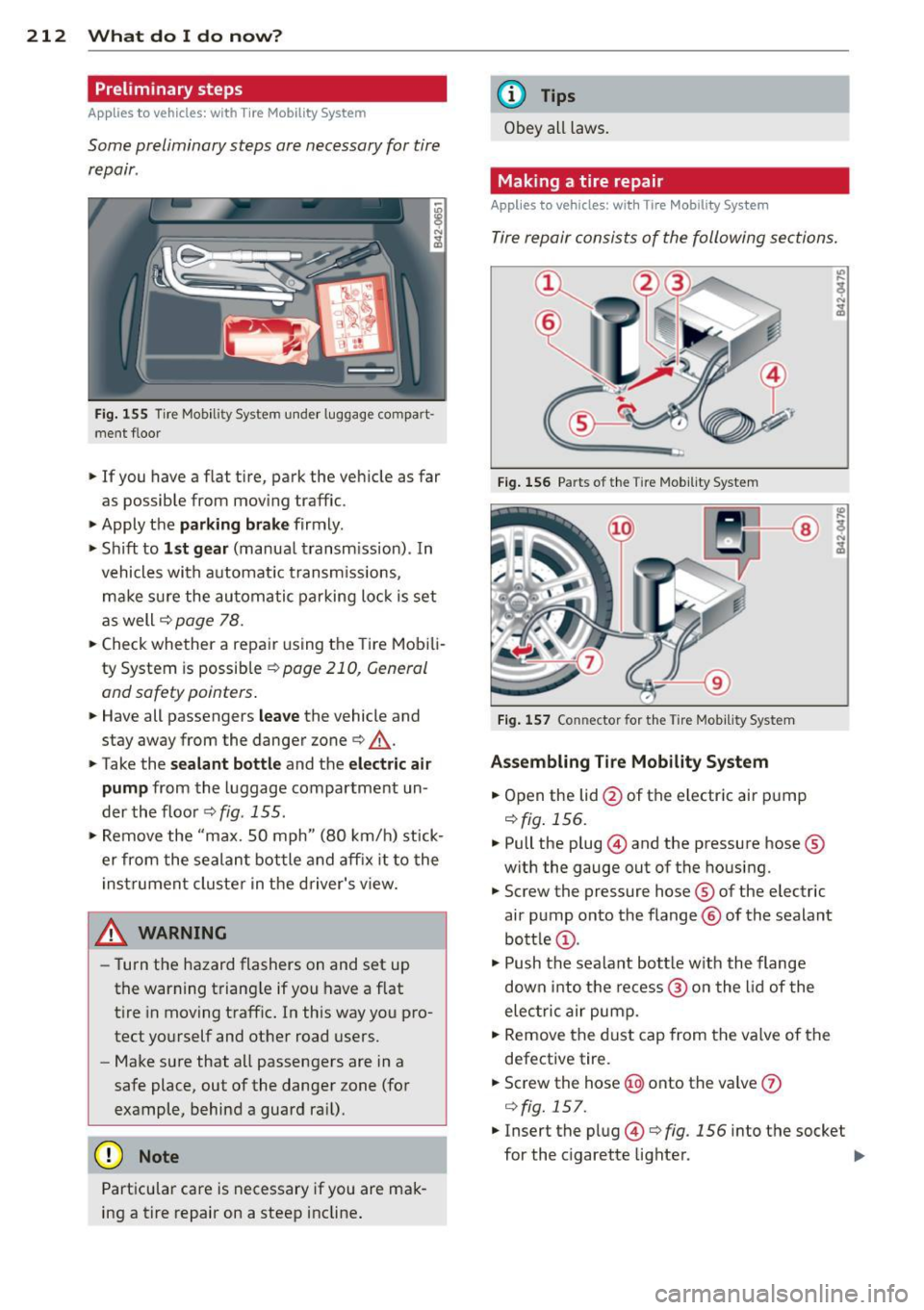

Fig. 155 Tire Mobili ty System under luggage co mpart

ment f loor

.,. If you have a flat tire, park the vehicle as far

as possible from mov ing traffic .

.,. Apply the

park ing brake firmly .

.,. Shift to

1st gear (manual transmission) . In

vehicles with a utomat ic transm iss ions,

make sure the automatic parking lock is set

as well

c::> page 78 .

.,. Check whether a repair using the Tire Mobili

ty System is possible

c::> page 210, General

and safety pointers .

.,. Have all passengers leave the vehicle and

stay away from the danger zone

c::> .&, .

.,. Take the sealant bottle and the electric air

pump from the luggage compartment un

der the floor

c::> fig. 155.

.,. Remove the "max. 50 mph" (80 km/h) stick

er from the sealant bottle and affix it to the

instrument cluster in the driver 's view.

A WARNING

- Turn the hazard flashers on and set up

the warning triangle if you have a flat

tire in moving traff ic. In this way you pro

tect you rs elf and other road users.

- Make sure that all passengers are in a

safe place, out of the danger zone (for

example, behind a guard ra il).

(D Note

Particular care is necessary if you are mak

ing a tire repair on a steep incline.

-

(D Tips

Obey all laws.

Making a tire repair

Applies to vehicles: with Tire Mobility System

Tire repair consists of the following sections.

Fig. 156 Parts of the Ti re Mobility System

Fig. 157 Conn ector for the Tire Mob i,lity System

Assembling Tire Mobility System

.,. Open the lid @of the electric air pump

c::> fig. 156 .

.,. Pull the plug© and the pressure hose ®

w ith the gauge out of the housing.

.,. Screw the pressure hose ® of the electric

air pump onto the flange @ of the sealant

bottle @.

.,. Push the sealant bott le w ith the flange

down into the recess @ on the lid of the

electric air pump.

.. Remove the dust cap from the valve of the

defective tire.

.. Screw the hose @onto the valve

(j)

c::>fig. 157.

.,. Insert the plug© c::> fig. 156 into the socket

for the cigarette lighter. .,,_

Page 215 of 244

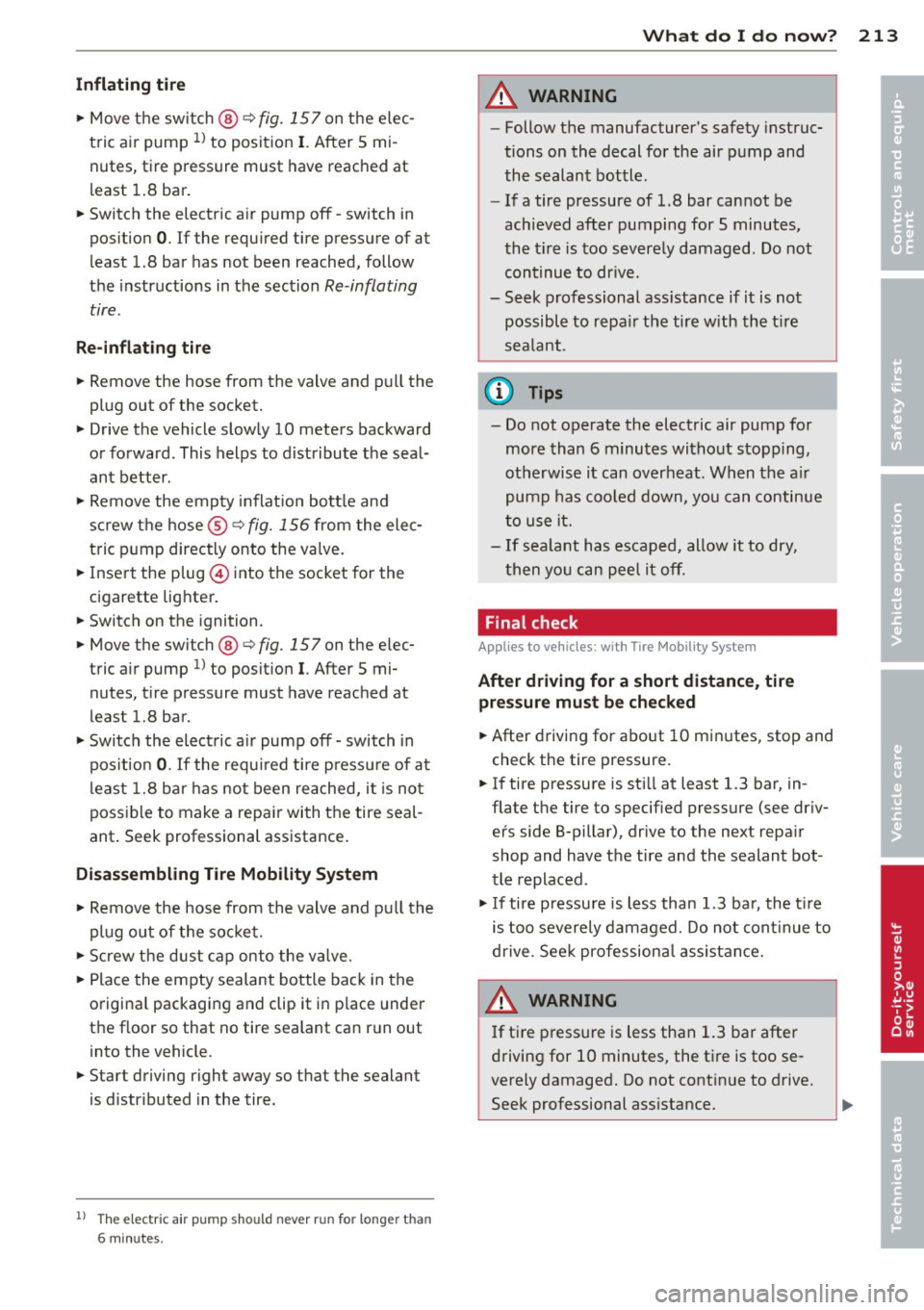

Inflating tire

"' Move the switch @¢ fig. 157 on the elec

tric air pump

ll to posit ion I. After 5 mi

nutes, tire pressure must have reached at

l east 1.8 bar .

"' Switch the electric a ir pump off - switch in

position

0 . If the required tire pressure of at

least 1.8 bar has not been reached, follow

the instructions in the section

Re -inflating

tire .

Re-infl ating tire

"' Remove the hose from the valve and pu ll the

plug out of the socket.

"' Drive the vehicle slowly 10 meters backward

or forward. This helps to distribute the seal

ant better.

"' Remove the empty inflat ion bottle and

sc rew the hose ®¢

fig. 156 from the elec

tric pump directly onto the va lve.

"' Insert the plug @ into the socket for the

cigarette lighter .

"' Switch on the ignition.

"' Move the switch @¢

fig. 157 on the elec

tric a ir pump

l) to posit ion I. After 5 mi

nutes, t ire pressure must have reached at

least 1.8 bar.

"' Switch the electric a ir pump off - switch in

pos ition

0 . If the requ ired t ire pressu re of at

l east 1.8 ba r has not been reached, it is not

possible to make a repair with the tire seal

ant . Seek professional assistance .

Disassembling Tire Mobility System

"'Remove the hose from the valve and pu ll the

plug out of the soc ket.

"' Screw the dust c ap onto the va lve.

"' Place the empty sealant bottle back in the

o riginal packaging and clip it in p lace under

the floor so that no tire sealant can run out into the vehicle.

"' Start driving right away so that the sealant

is d istributed in the tire.

l ) The e lectr ic a ir pu mp sho uld never r un for lo nge r th an

6 m in utes .

What do I do now? 213

A WARNING

-Follow the manufacturer's safety instruc

tions on the decal for the air pump and

the sealant bottle.

- If a tire pressure of 1.8 bar cannot be

achieved after pumping for 5 minutes,

the t ire is too severe ly damaged . Do not

continue to dr ive.

- Seek professional ass istance if it is not

possible to repa ir the tire w ith the t ire

sealant.

(D Tips

- Do not operate the electric air pump for

more than 6 minu tes witho ut stopping,

otherwise it can overheat . When the a ir

pump has coo led down, you can continue

to use it.

- I f sea lant has escaped, allow it to dry,

t hen yo u can peel it off.

Final check

App lies to vehicl es: wi th Tire Mobility Sy stem

Aft er driv ing for a short distance, tire

pre ssure must be chec ked

"' After driving for about 10 min utes, stop and

check the tire pressure.

"' If tire pressure is st ill at least 1.3 bar, in

flate the tire to specified pressure (see dr iv

er's side B-pillar), drive to the next repa ir

shop and have the tire and the sealant bot

tle replaced .

"'I f ti re pressu re is less than 1.3 ba r, the t ire

is too severely damaged. Do not con tinue to

drive . See k professiona l assist ance.

A WARNING

=

If t ire press ure is less than 1.3 bar after

driving for 10 minutes, the tire is too se

verely damaged. Do not cont in ue to drive.

Seek professional ass istance.

-

•

•

Page 216 of 244

214 What do I do now ?

@ Tips

After a tire repair, have the sealant bottle

rep laced at a dealership. This restores full

functionality to the Tire Mob ility System.

What should I be

aware of when

changing a tire?

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed the

right direction .

A unidirectiona l tire can be ident ified by ar

row s on the sidewall,

which point in the direc

tion of the rotation. You must follow the

specified direction of rotat ion. This is necessa

ry in order for these t ires to develop the ir op·

timum characteristics regarding grip, road noise, wear, and hydroplani ng.

Anti-theft wheel bolts

A special adapter is needed to turn the anti· theft wheel bolts.

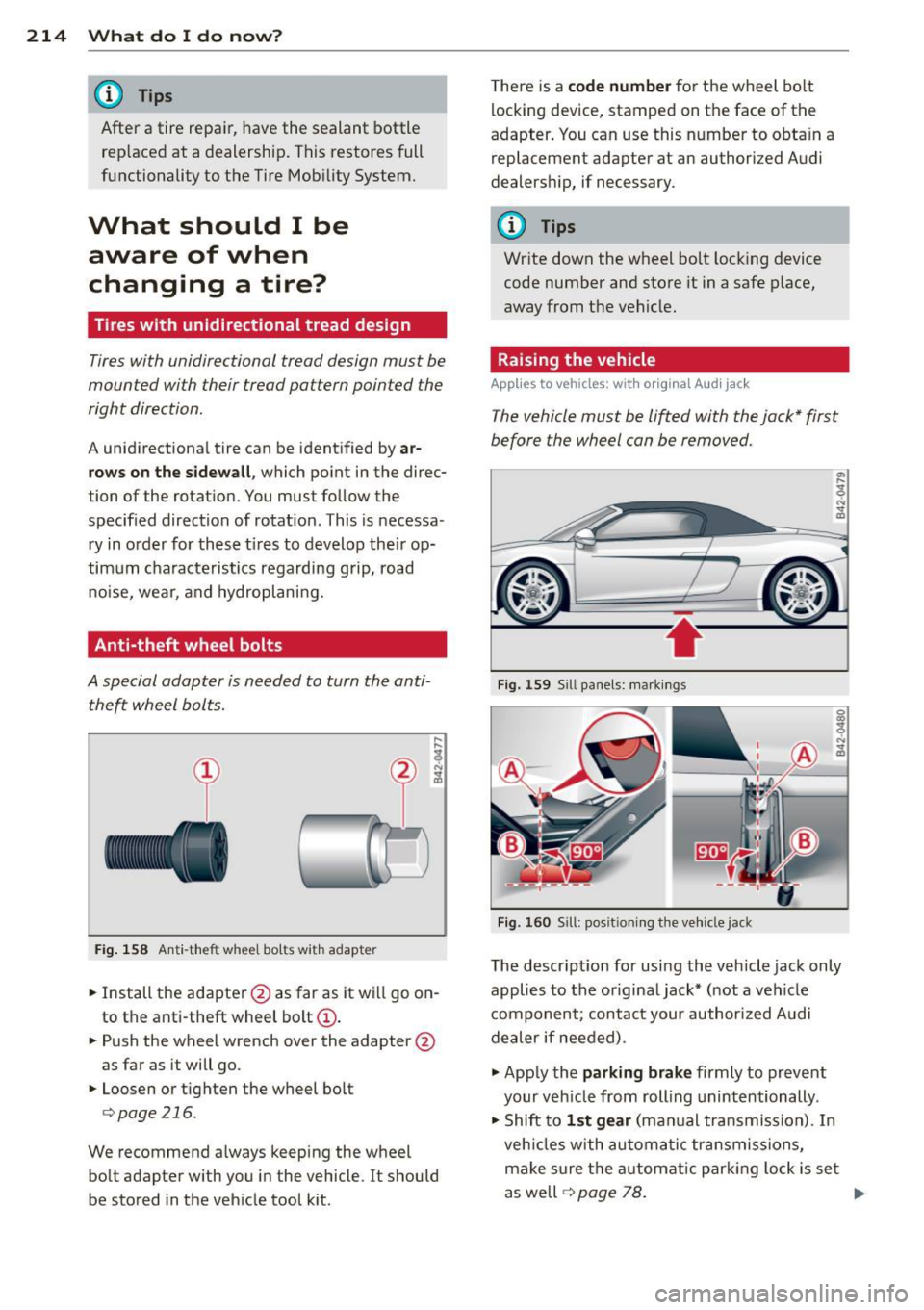

Fi g. 1 58 Anti-theft wheel bolts with adapter

., Install the adapter @as far as it wi ll go on

to the ant i-theft wheel bolt(!).

., Push the wheel wrench over the adapter @

as far as it wi ll go.

., Loosen or tighten the wheel bo lt

r=> page 216.

We recommend a lways keeping the wheel

bolt adapter w ith you i n the vehicle. It should

be stored in the veh icle tool k it. T

he re is a

c ode number for the wheel bo lt

locking device , stamped on the face of the

adapter . You can use this n umber to obta in a

replacement adapter at an authorized A udi

dealers hip, if necessary.

(0 Tips

Wr ite down the wheel bolt lock ing device

code number and store it in a safe place,

away from t he vehicle.

Raising the vehicle

Applies to vehicles: with orig inal Audi jack

The vehicle must be lifted with the jack* first

before the wheel can be removed.

•

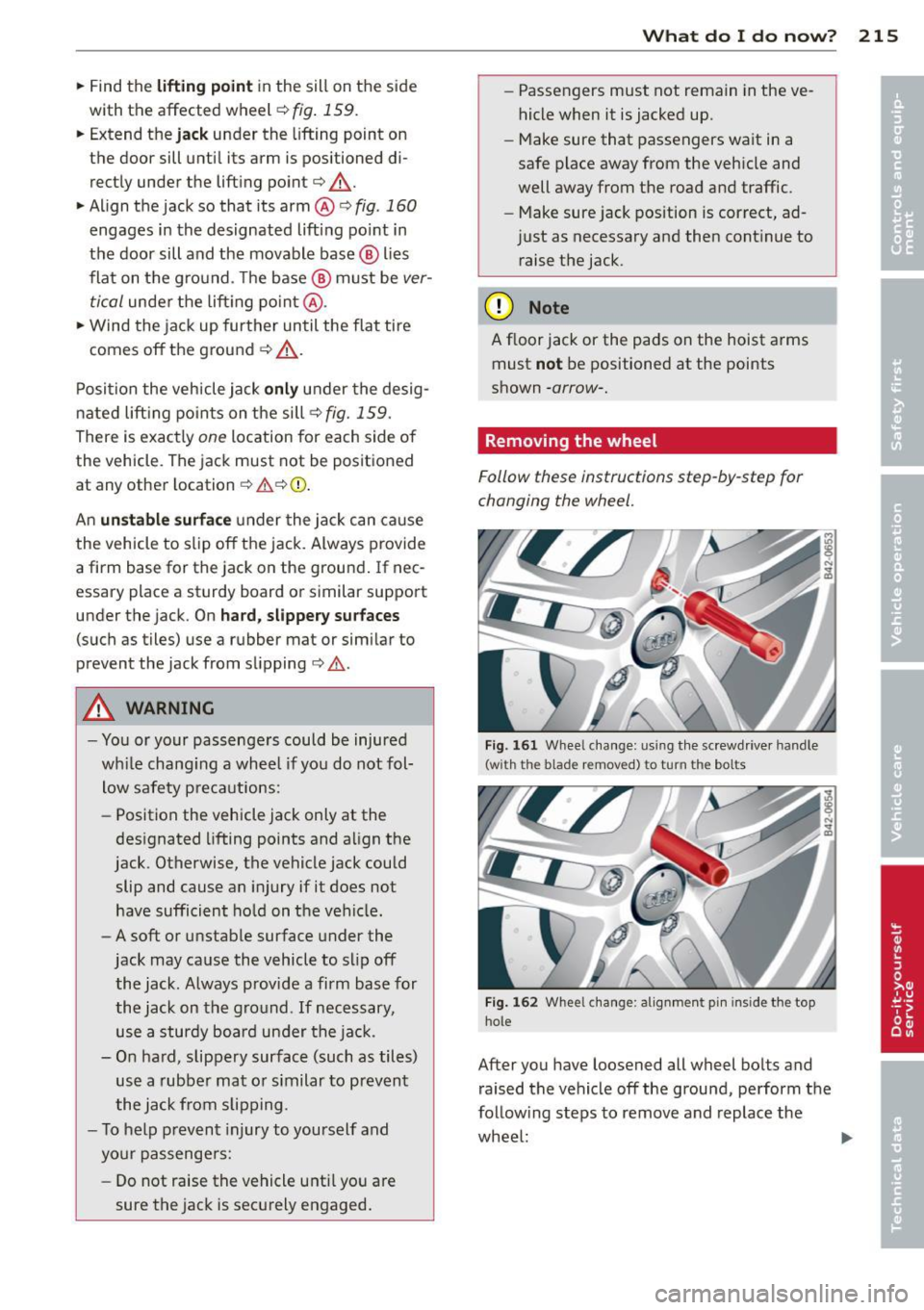

F ig. 159 Sill panels: ma rk in gs

Fi g. 16 0 Sill: pos it io nin g th e ve hicle jack

The descr ip ti on for using the vehicle jack only

applies to the origina l jack* (not a vehicle

component; contact your author ized A udi

dealer if nee ded) .

., App ly the

parking brake firmly to prevent

your veh icle from rolling unintentionally.

., Shift to

1st gear (manual transmission). In

veh icles with au toma tic tra nsmissions,

make sure t he au tomatic par king lock is se t

as well

r=> page 78 . ..,

Page 217 of 244

.. Find the lifting p oint in the sill on the side

with the affected wheel¢

fig. 159.

.. Extend the ja ck under the lifting point on

the doo r sill unti l its arm is positioned di

rectly under the lifting point¢ &_ .

.. Align the jack so that its arm @¢

fig. 160

engages in the designated lifting point in

the door sill and the movable base @ lies

flat on the ground. The base @ must be

ver

tical

under the lift ing po int @ .

.. Wind the jack up further until the flat tire

comes off the ground¢&_ .

Position the vehicle jack

onl y under the desig

nated lift ing po ints on the sill¢

fig. 159.

There is exactly one location for each side of

the vehicle. The jack must not be pos itioned

at any other location ¢ fri. ¢0 .

An

un sta bl e s urfa ce u nder the jack can cause

the vehicle to s lip off the jack . Always provide

a firm base for the jack on the ground . If nec

essary plac e a sturdy board or similar support

under the jack. On

ha rd, slippe ry surface s

(such as tiles) use a rubber mat or sim ilar to

prevent the jack from slipping¢&. .

A WARNING

-You or your passengers could be injured

wh ile chang ing a wheel if you do not fol

low safety p re ca utions:

- Position the vehicle jack only at the

designated lifting points and align the

jack . Otherwise, the vehicle jack could

slip and cause an injury if it does not

have sufficient ho ld on the vehicle.

- A soft or unstable surface under the

jack may cause the vehicle to slip off the jack. Always provide a firm base for

the jack on the ground . If necessary,

use a sturdy boa rd under the jack.

- On ha rd, slippery surface (such as tiles)

use a rubber mat o r similar to prevent

the jack from slipping .

- To help prevent injury to yourself and

your passenge rs:

- Do not raise the vehicle unti l yo u are

sure the jack is securely engaged .

What do I do now ? 215

-Passengers must not remain in the ve

hicle when it is jacked up .

- Make sure that passengers wait in a

safe place away from the veh icle and

well away from the road and traffic .

- Make sure jack position is correct, ad

just as necessary and then cont inue to

raise the jack .

(D Note

A floor jack or the pads on the hoist arms

must

not be positioned at the points

shown

-arrow -.

Removing the wheel

Follow these instructions step -by-step for

changing the wheel .

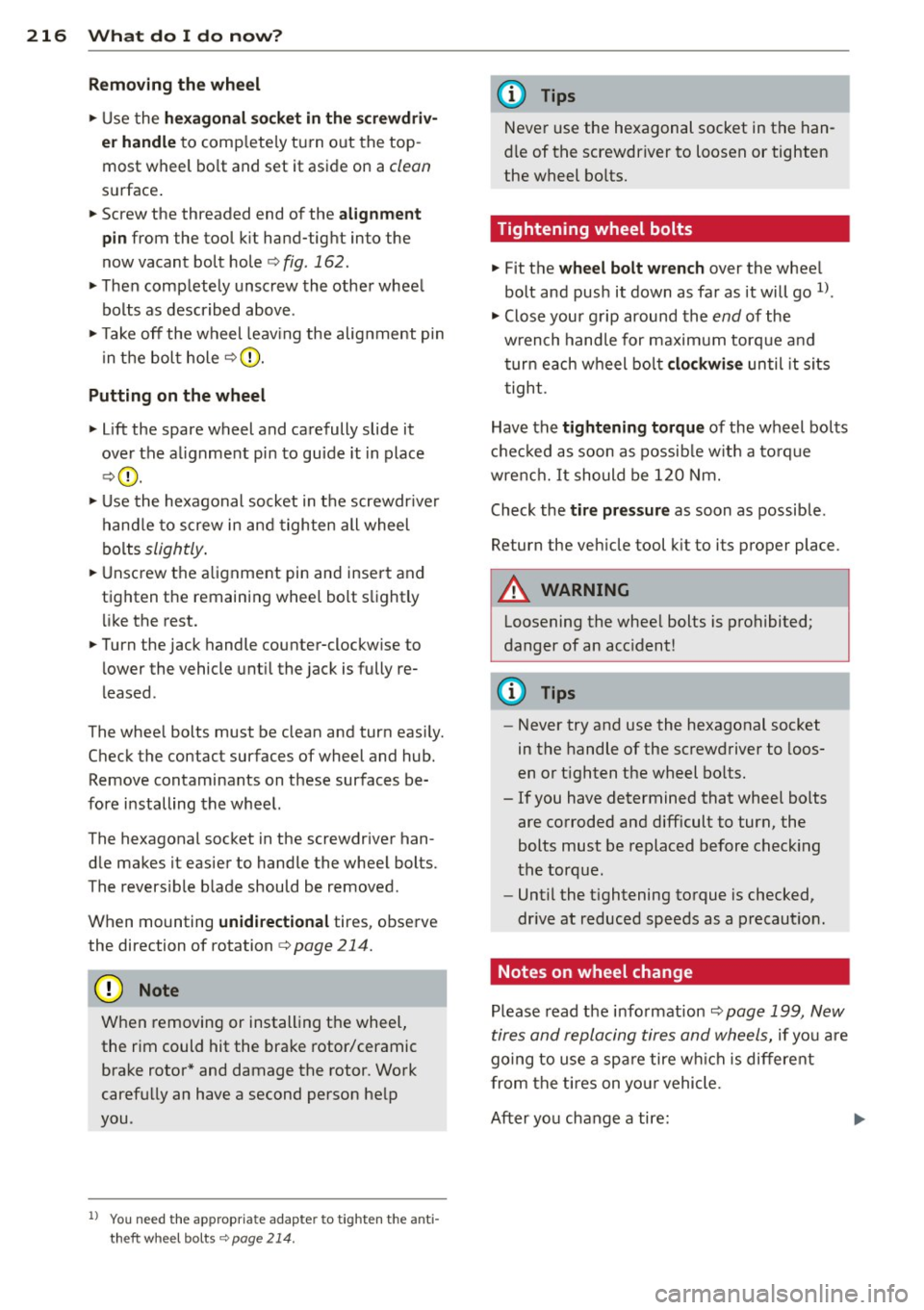

Fig . 1 61 W hee l change: us ing the sc rewdr iver hand le

(w it h th e blade r emov ed) to t urn th e bolts

F ig . 1 62 Whee l change: alignmen t pin inside the top

h ol e

After you have loosened all wheel bo lts and

raised the vehicle off the grou nd, perform the

follow ing steps to remove and replace the

whee l: ..,.

Page 218 of 244

216 What do I do now?

Removing the wheel

.. Use the hexagonal socket in the screwdriv

er handle

to comp letely turn out the top

most wheel bolt and set it aside on a

clean

sur face .

.. Screw the threaded end of the

alignment

pin

from the tool kit hand-tight into the

now vacant bolt hole

o fig. 162.

.. Then completely unscrew the other wheel

bolts as described above .

.. Take off the wheel leav ing the alignment pin

in the bolt hole

o(D .

Putting on the wheel

.. Lift the spare wheel and carefully slide it

over the alignment pin to guide it in place

o@.

.. Use the hexagonal socket in the screwdr iver

handle to screw in and tighten all wheel

bolts

slightly .

.. Unscrew the alignment pin and insert and

tighten the remaining whee l bolt slig htly

like the rest.

.. Turn the jack handle counter-clockw ise to

lower the vehicle until the jack is fully re

leased .

The wheel bolts must be clean and turn easily.

Check the contact surfaces of wheel and hub. Remove contaminants on these surfaces be

fore installing the wheel.

The hexagonal socket in the screwdriver han

dle makes it easier to handle the wheel bolts.

The reversible blade should be removed.

When mounting

unidirectional tires, observe

the direction of rotation

o page 214.

«I) Note

When removing or installing the wheel,

the rim could hit the brake rotor/ceramic

brake rotor* and damage the rotor. Work

carefully an have a second perso n he lp

you .

1l You need the appropriate adapte r to tigh ten the anti

theft whee l bo lts

c:> page 214.

(D Tips

Never use the hexagonal socket in the han

dle of the screwdriver to loosen or tighten

the wheel bo lts.

Tightening wheel bolts

.. Fit the wheel bolt wrench over the wheel

bolt and push it down as far as it will go

ll.

.. Close your grip around the end of the

w rench handle for maximum torque and

turn each wheel bolt

clockwise until it sits

tight .

Have the

tightening torque of the wheel bolts

checked as soon as possible with a to rque

wrench. It should be 120 Nm .

Check the

tire pressure as soon as possible.

Return the veh icle tool k it to its proper place.

A WARNING ..,___

Loosening the wheel bolts is prohibited;

danger of an acc ident!

(D Tips

- Never try and use the hexagonal socket

in the handle of the screwdriver to loos

en or t ighten the wheel bo lts.

- If you have determined that wheel bolts are corroded and difficult to turn, the

bolts must be replaced before check ing

the torque .

- Until the t ightening torque is checked,

dr ive at reduced speeds as a precaution.

Notes on wheel change

-

Please read the information o page 199, New

tires and replacing tires and wheels,

if you are

go ing to use a spa re tire wh ich is different

from the tires on your vehicle.

After you change a tire:

Page 219 of 244

-Che ck the tire p re ss ure on the spare imme

diatel y afte r mounting.

- Hav e the wheel b olt tightening torque

checked with a torque wrench a s soon a s

possib le by you r auth orized Audi dealer or

a qu alified ser vice sta tio n.

- With steel and allo y w heel rim s, the wheel

bolts are correctl y tight ened at a to rq ue of

90 ft lb (1 20 Nm ).

- If yo u notice while changin g a ti re th at the

wheel bolts are co rrod ed and diff icult to

turn , then they should be repl aced before

y ou check the t ighten ing to rqu e.

- Replace the flat t ire with a new one and

ha ve it installed on your vehicle as soon as

possib le . R emount th e wh eel co ver .

Until then, driv e with extra care and at re

d uced speeds.

A WARNING

- If you are going to equip your vehicle

with t ires or rims wh ich differ from those

w hich were factory installed, then be

sure to read the informat ion

~page 199,

New tires and replacing tires and

wheels.

- Always store the tools securely in lug

gage compa rtment. Otherw ise, in an ac

c ident o r sudden mane uver they could fly

f orward, causing inju ry to passengers in

the vehicle .

(D Note

Do not use commerc ia lly available t ire

sealants. Othe rwise, the elec trical compo

nents of the tire pressure monitoring sys

tem* will no longer work properly and the

sensor for the tire pressure monitoring

system wi ll have to be replaced by a qua li

fied workshop.

What do I do now? 217

Jump-starting

General

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

us ing a

pair of jump er cabl es to start the en

gine.

Both batteries must be rated at 12 volts . The

capacity (Ah) of the booster battery must not

be substantia lly less than the capac ity of the

discharged battery .

Jumper cables

Use only jumper cables of suff ic ient ly large

cro ss se ction to safely car ry the starter cur

rent . Refer to the manufacturer's specifica

tions .

Use only jumper cab les which have

insulated

term inal clamps and are properly marked for

dist inction:

plu s(+) cable : in most cases colored r ed

m inu s(-) cable :

in most cases colored black

A WARNING ~

Batteries contain e lectric ity, acid, and gas .

Any of these can cause very serious or fata l

injury. Follow the instructions below for

safe handling of your vehicle's battery.

-Always shield your eyes and avo id lean-

ing over the battery whenever poss ible.

- A discharged battery can a lready freeze

at temperatures just below 32 °F (0 °(). Before connect ing a jumper cable , the

frozen battery must be thawed com

pletely, othe rwise it could explode .

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

wate r immediately .

- Improper use of a booster battery to

start a vehicle may cause an explosion. •

•

Page 220 of 244

218 Wh at do I do now ?

-Vehicle batteries generate explos ive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any vehicle with

a low acid level in the battery.

- The voltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery. Use of batteries of different voltage or substant ially different "Ah" rating

may cause an explos ion and personal in

Jury.

- Never charge a frozen battery. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batteries of different voltage or

substant ially different capacity (Ah) rat

ing may cause an explosion and injury.

T he capacity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before yo u check anything in the engine

compartment, always read and heed all

WARNINGS ¢

page 172, Working in the

engine compartment.

(D Note

- Applying a higher vo ltage booster bat

tery wi ll ca use expensive damage to sen

sitive electronic components, s uch as

control units, relays, radio, etc.

- There m ust be no e lectrica l contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

positive(+) terminals are connected .

(0 Tips

-The discharged battery must be proper ly

connected to the vehicle's electrical sys

tem.

- Switch off any car phone, or follow the

car phone instructions for this situation.

Use of jumper cables

Make sure to connect the jumper cable

clamps in exactly the order described below!

F ig . 1 63 Luggage compartment: co nnectors for a

charge r and jump start cables

Fi g. 1 64 Jump start us ing the battery in a nother vehi

cle: A· Fema le socket, B • D isc harge

The battery is located in the luggage compart

ment¢

page 185. T he front lid can be opened

i n an emergency¢

page 34.

Do not connect the negative cable d irectly to

the negative term inal on the battery. Connect

it to a

jump st a rt pin instead ¢ fig. 163.

Connect the po sitive cable (red ) to the

positive terminal

1. Co nnect one end of the red jumper cable

¢

fig . 164 (!) to the positive terminal of

discharged battery @.

2 . Connect the other end of the red jumper

cable to the positive terminal @of the

booster battery @.

Connect the n egativ e cable (black ) to the

n egati ve terminal

3. Connect one end of the b lack jumper ca

ble @ to the negative terminal of the

booster battery @. .,.