AUDI RS7 SPORTBACK 2014 Owners Manual

Manufacturer: AUDI, Model Year: 2014, Model line: RS7 SPORTBACK, Model: AUDI RS7 SPORTBACK 2014Pages: 292, PDF Size: 73.56 MB

Page 251 of 292

installed without wheel sensors or with in

compatible wheel sensors.

- A whee l sensor or another component has

failed.

- Using snow cha ins can affect the function of

the system because of the shie lding effect

of the chains.

- Th e tire pressure monitoring system is not

available due to a malfunction .

- Transmitters with the same frequency, such

as headphones or remote -contro lled devi

ces, may cause a temporary system ma l

function due to the strong electromagnetic

field.

The

ffim indicator light turns off once the ti re

press ure monitoring system is avai lab le again.

If you cannot correct the malfunction and the

m i ndicator light stays on, drive to an au

thor ized Audi dealer or a qualified workshop

to have the ma lfunction corrected .

Tires and wheels 249

•

•

Page 252 of 292

250 What do I do now?

What do I do now?

Emergency warning

triangle

App lies to vehicles: with emerge ncy warning triangle

The warning triangle is located on the inside

of the trunk lid .

-

"' M ~ 0 6

~ ~

Fig. 203 Trunk lid: Warning triang le

.,. To open the cover, turn the locking mecha

nism and pull the cover downward .

" m

.,. Remove the warning triang le from its hold

er .

The rear lid is only designed to hold the warn

ing triangle offered by the original accessories

program. If you would like to retrofit your ve

hicle with a warning triangle, p lease contact

your authorized Audi dealer.

Vehicle tool kit

Vehicle tool kit and jack

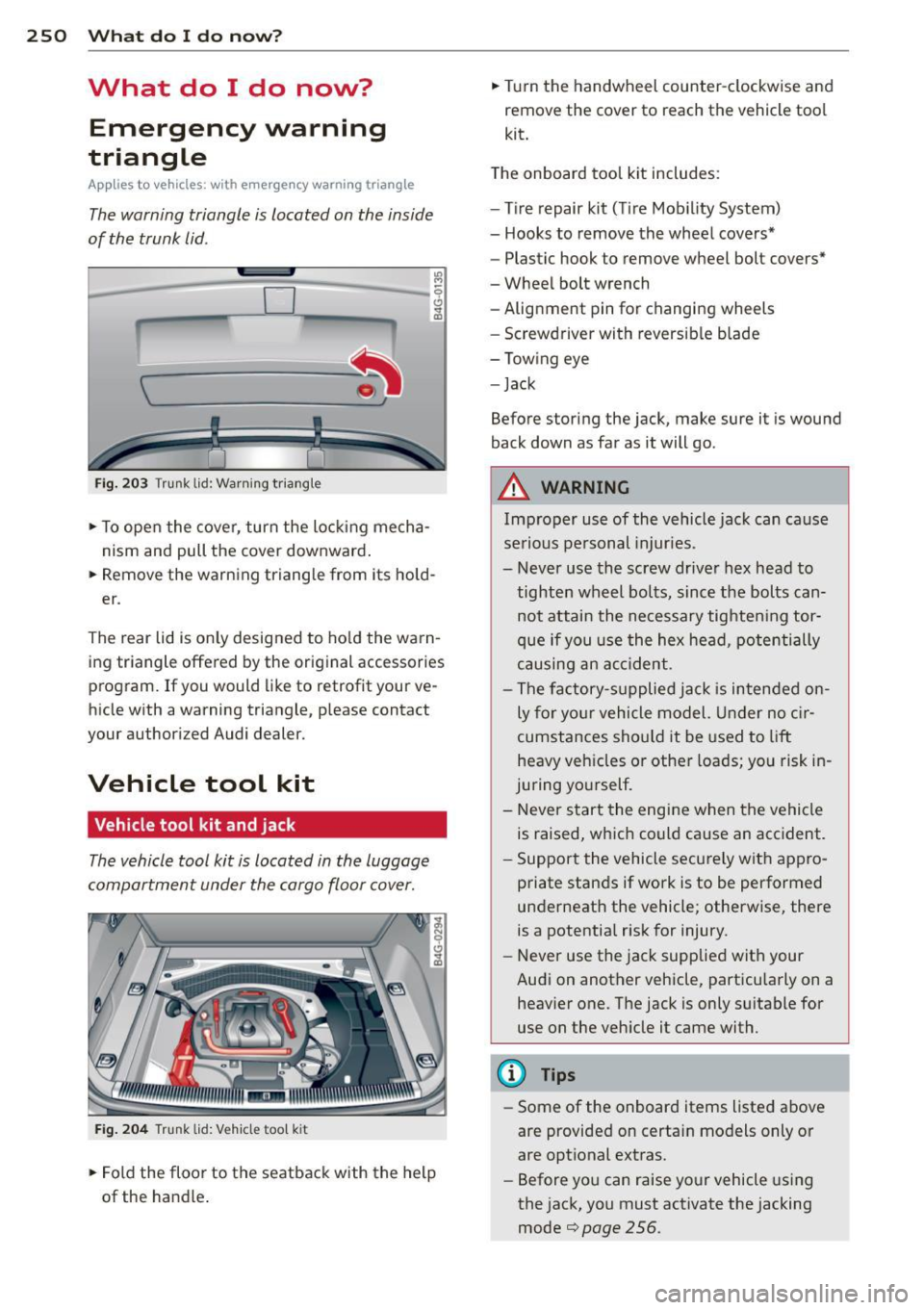

The vehicle tool kit is located in the luggage

compartment under the cargo floor cover.

Fig. 204 Trunk lid: V ehicl e too l kit

.,. Fold the floor to the seatback with the help

of the handle . .,.

Turn the handwheel counter-clockwise and

remove the cover to reach the veh icle tool

kit.

T he onboard tool kit includes :

- Tire repair kit (Tire Mobility System)

- Hooks to remove the wheel covers*

- Plastic hook to remove wheel bolt covers*

- Wheel bolt wrench

- Alignment pin for changing wheels

- Screwd river with reversible bla de

-Towing eye

-J ack

Before storing the jack, make sure it is wound

back down as far as it will go .

A WARNING

Improper use of the vehicle jack can cause

serious personal injuries.

- Never use the screw driver hex head to

tighten wheel bolts, since the bolts can

not attain the necessary tighten ing tor

que if you use the hex head, potentially

causing an accident .

- The factory-supplied jack is intended on

ly for your vehicle model. Under no cir

cumstances should it be used to lift

heavy veh icles or other loads; you risk in

juring yourself.

- Never start the engine when the vehicle

is raised, which could cause an acc ident.

- Support the vehicle securely with appro

priate stands if work is to be performed

underneath the vehicle; otherwise, there

is a potential risk for injury.

- Never use the jack supplied with your

Audi on another vehicle, particularly on a

heav ier one. The jack is only suitable for

use on the veh icle it came with.

@ Tips

- Some of the onboard items listed above

are provided on certain models only or

are optional extras .

- Before you can raise your vehicle using

the jack, you must activate the jacking

mode¢

page 256 .

Page 253 of 292

Tire repair

General and safety pointers

Tire repair is intended only for temporary,

short -term use .

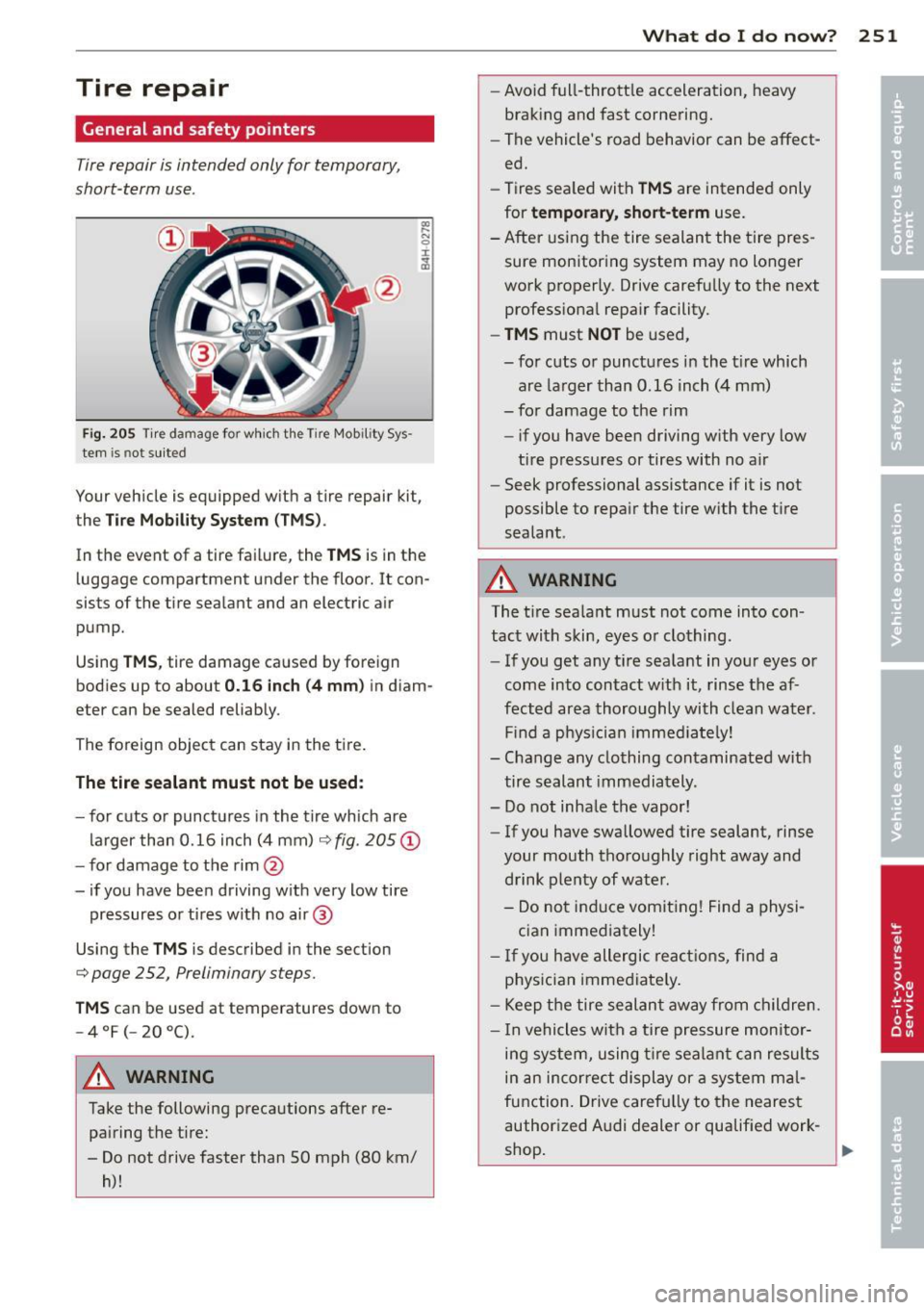

Fig. 205 Tire damage for w hich the Tire Mobil ity Sys ·

tern is not su ited

Your veh icle is equipped w ith a tire repair kit,

the

Ti re Mob ilit y Sys tem (TM S).

In the event of a tire fai lure, the TM S is in the

luggage compartment under the floor. It con

sists of the tire sealant and an electric air

pump.

Using

TMS , tire damage caused by foreign

bodies up to about

0.1 6 inch (4 mm ) in diam

eter can be sealed reliably.

The foreign object can stay in the tire .

The tire se alant must not be us ed :

- for c uts or punct ures in the tire which are

larger than 0.16 inch (4 mm)

¢ fig. 205 @

- for damage to the rim@

- if you have been driving with very low tire pressures or tires with no air @

Using the

TM S is described in the section

¢ page 252, Preliminary steps.

TM S can be used at temperatures down to

-4°F(-20°C) .

A WARNING

Take the following precautions after re

pairing the tire:

- Do not drive faster than

50 mph (80 km/

h)!

What do I d o now ? 251

-Avoid full-throttle acceleration, heavy

brak ing and fast cornering.

- The vehicle's road behavior can be affect

ed.

- Tires sea led with

T MS are intended only

for

t e mpo rary, sh or t-t erm use.

-After using the tire sealant the tire pres sure mon itoring system may no longer

work properly. Drive carefully to the next

professional repa ir facility.

- TMS must NOT be used,

- for cuts or punctu res in the t ire which

are larger than 0.16 inch (4 mm)

- for damage to the rim

- if you have been driving with very low

tire pressures or tires with no a ir

- Seek professional assistance if it is not

possible to repa ir the tire with the t ire

sealant .

A WARNING

The tire sea lant must not come into con

tact with skin, eyes o r clothing .

- If you get any tire sealant in your eyes or

come into contact w ith it, rinse the af

fected area thoroughly with clean water .

Find a phys ician immed iately!

- Change any clothing contaminated with

tire sealant immediately .

- Do not inha le the vapor!

- If you have swallowed tire sealant, rinse

your mouth thoroughly right away and

drink plenty of water .

- Do not induce vomiting! Find a physi

c ian immediately!

- I f you have allergic react ions, find a

physician immediately .

- Keep the tire sealant away from ch ildren .

- In vehicles with a tire pressure monitor-

ing system, using t ire sealant can results

in an incorrect display or a system mal

fu nction. Drive carefu lly to the neares t

authorized Audi dealer or qualified work-

shop . ..,.

Page 254 of 292

252 What do I do now?

(D Note

Do not use commerc ia lly available tire

sealants . The electrical components of the

tire pressure mon itoring system will no

longer work properly.

@ For the sake of the environment

Used sealant bottles can be dropped off at

a recycl ing facility.

@ Tips

- If sealant has run out, allow it to dry.

Then you can peel it off.

- Have the tire sealant replaced every 4

years at a dea lership.

Preliminary steps

Some preliminary steps ore necessary for tire

repair.

.,. If you have a fla t t ire, park the veh icle as far

as possible from moving traffic.

.,. Apply the

parking brake firmly .

.,. Move the

selector lever to the P position .

.,. Check whether a repair using the Tire Mobili

ty System is possible Q page 251, General

and safety pointers .

.,. Have all passengers leave the vehicle and

stay away from the danger zone

q ,& .

.,. Take the s ealant bottle and the electric air

pump

from the luggage compartment un

der the floor.

.,. Remove the "max . SO mph" (80 km/h) stick

er from the sealant bottle and aff ix it to the

instrument cluster in the driver's view .

A WARNING

-Turn the hazard flashers on and set up

the warning triangle* if you have a flat

tire in moving traffic. In this way you pro

tect you rs elf and other road users .

- Make sure that all passengers are in a

safe place, out of the danger zone (for

example, behind a guard ra il).

-

(D Note

Particular care is necessary if you are mak

ing a tire repa ir on a steep incl ine.

@ Tips

Obey all laws.

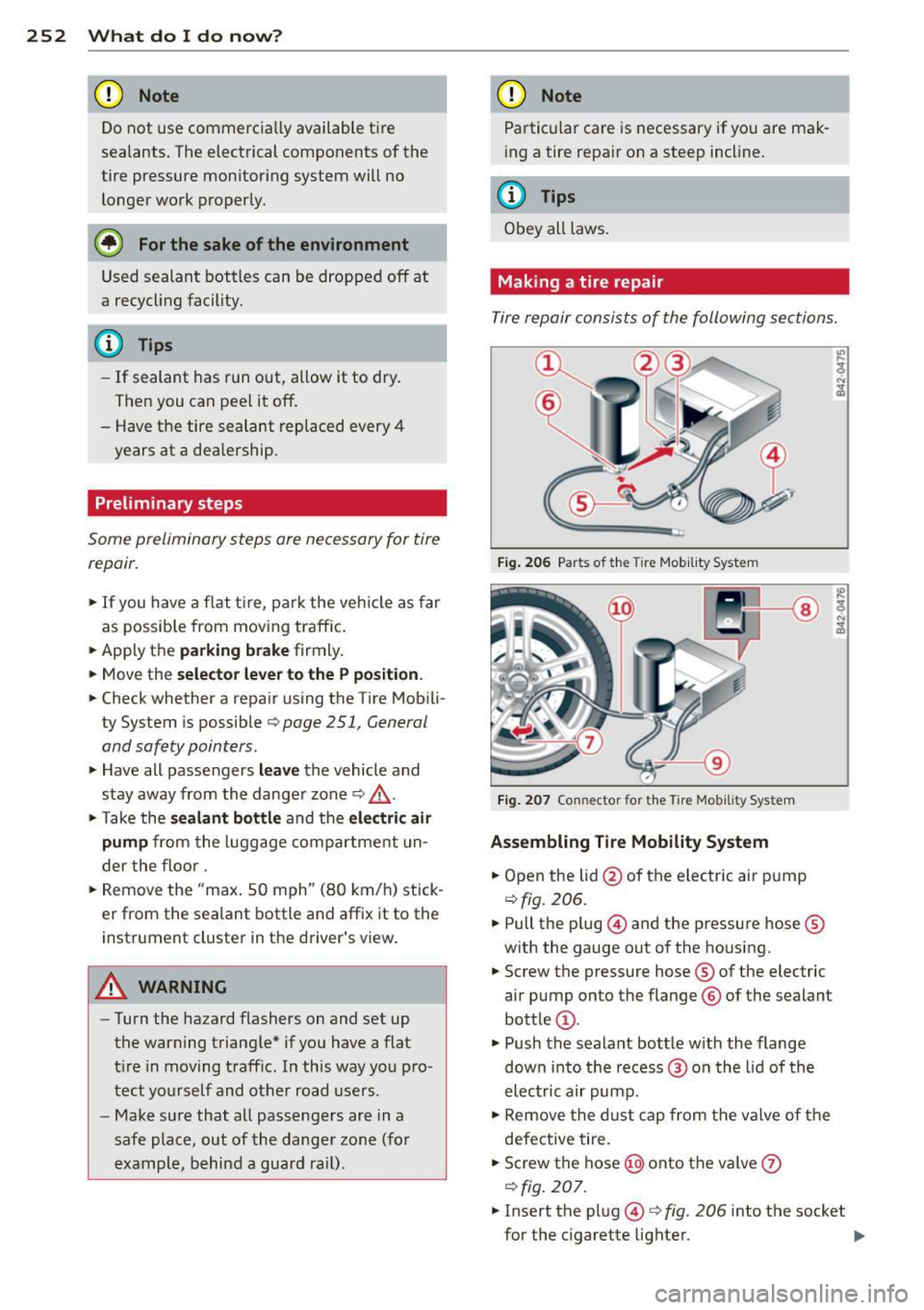

Making a tire repair

Tire repair consists of the following sections.

Fig. 206 Parts of t he Tire Mob ility System

Fig. 207 Co nn ector for the Tire Mobility Sys tem

Assembling Tire Mobility System

.,. Open the lid @of the electric air pump

qfig. 206.

.,. Pull the plug @and the pressure hose ®

with the gauge out of the housing .

.,. Screw the pressure hose ® of the electric

air pump onto the flange ® of the sealant

bottle @.

.,. Push the sealant bottle w ith the flange

down into the recess@ on the lid of the

electric air pump .

.,. Remove the d ust cap from the valve of the

defective tire .

.,. Screw the hose@) onto the valve

(J)

qfig. 207 .

.,. Insert the plug@¢ fig. 206 into the socket

for the cigarette lighter.

IJJ,

Page 255 of 292

~ Switch on the ignition.

Inflating tire

~ Move the sw itch @ c:> fig. 207 on t he e lec

t ric air pump

ll to posi tion I. After 5 mi

nutes, t ire press ure mus t have reac hed at

l east 1.8 ba r.

~ Switch the electric air pump off -switch in

position

0 . If the requi red tire p ressure of at

least 1.8 bar has not been reached, follow

the instructions in t he section

Re-inflating

tire.

Re -inflating tire

~ Remove the hose from the valve and p ull the

pl ug out of the soc ket .

~ Drive the vehicle s low ly 33 feet (10 meters)

backward or forward. Th is helps to distrib

ute the sealant better.

~ Remove the empty inflat ion bott le and

screw t he hose ®

c:> fig. 206 from the elec

t ric pump directly onto the va lve.

~ Inse rt the plug @ c:> fig. 206 into the so cket

f o r t he cig arette lighter.

~ Switch on the igni tion.

~ Move the sw itch @ c:>fig . 207 on the e lec

tric ai r pump

ll to positio n I. After 5 mi

nutes, t ire pressure must have reached at

least 1.8 bar.

~ Switch the electric a ir pump off - switch in

pos itio n

0. If the requ ired t ire pressu re of at

least 1.8 ba r has not been reached, it is not

poss ib le to make a repa ir with t he tire seal

an t. Seek profession al ass istance.

Disassembling Tire Mobility System

~ Remove the hose from the valve and pu ll the

plug out of the socket .

~ Screw the dust cap onto the va lve .

~ Pla ce the emp ty sealant bottle ba ck in the

o rigi nal packag ing and clip i t in place unde r

the floor so that no tire sealant can r un out

into the vehicle.

~ Place the elect ric a ir pump in the luggage

compartment fo r the time being .

l) The e lectr ic a ir pu m p sh oul d never r un for long er than

6 min utes.

What do I do now? 253

~ S tart driving rig ht away so tha t the sealant

is dist ributed in the tire .

A WARNING

- Follow the manufacturer 's sa fety instruc

tions on the decal for the air p ump and

the sealant bottle.

- If a tire pressure of 1.8 bar cannot be

achieved after pumping for S minutes,

the t ire is too severe ly damaged . Do not

con tinu e to dr ive .

- Seek pro fessional assistance if it is not

possible to repa ir the tire w ith the t ire

sealant.

(D Tips

- Do not operate the electric air pump for

more than 6 minutes witho ut stopping,

otherwise it can overheat . When the a ir

pump has coo led down, you can continue

to use it.

- If sea lant has escaped, allow it to dry,

t hen yo u can peel it off .

Final check

After driving for a short distance, tire pressure must be checked

~ A ft er driving for about 10 mi nutes, stop and

check the tire pressure.

~ If tire pressure is st ill at least 1.3 bar, in

flate the tire to specif ied p ress ure (see dr iv

er's side B-pillar), drive to the next repa ir

sh op and have t he tire and the sealant bot

tle replaced .

~ If tire pressu re is less than 1.3 bar, the tire

is too severely damaged. Do not cont inu e to

dr ive . See k professiona l as sistan ce.

A WARNING

If tir e press ure is less th an 1.3 bar a fter

d riving for 10 minutes, the t ire is too se

ve rely damage d. Do not cont in ue to drive .

Seek professional ass istance .

-

•

•

Page 256 of 292

254 What do I do now?

After a tire repa ir, have the sealant bottle

rep laced at a dealership. This restores full

functionality to the Tire Mob ility System.

Changing a wheel

Before changing a wheel

Observe the following precautions for your

own and your passenger's safety when chang

ing a wheel .

• After you experience a tire fa ilure, pull the

car well away from moving traffic and try to

reach

level g ro und before you stop¢ /.1..

• All passengers sho uld le ave the car a nd

move to a sa fe loca tion (fo r instance, beh ind

t h e guardrai l) ¢

/.1. .

• Engage the pa rking b rake to prevent your

vehicle from ro lling unintentionally ¢

/.1..

• Move selector leve r to position P ¢ &_ .

• Take the jack out of the luggage compart

ment

¢ page 250.

A WARNING

You or your passe ngers cou ld be injured

w hile c hanging a whee l if you do not fol

low t hese safety p re cau tions:

-If you have a flat t ire, move a safe dis

tan ce off the road. Tur n off the e ng in e,

tu rn the e mergen cy fla shers o n and use

other wa rning dev ices to alert o ther mo

torists.

- M ake su re th at passengers wai t in a safe

place away from the ve hicl e an d well

away from the road and traff ic.

- T o help p revent the veh icle from mov ing

s u dden ly and possibly slipping off the

jack, a lways fully set the parking bra ke

and bloc k the whee l diagona lly opp osite

the whee l being cha nged. When one

front whee l is lifted off the gro und, plac

ing the A utomat ic Transmiss io n in P

(Pa rk) will

not pre vent the vehicle from

moving. -

Before you change a wheel, be s ure t he

ground is level and firm. If necessary,

use a sturdy board under the jack.

- Always store the vehicle tool kit, the jack

and the rep laced tire in t he luggage com

partment

¢page 129.

(D Note

If you are changing the whee l on a steep

i ncl ine, use a roc k or similar object to

block the opposite whee l to prevent the

vehicle from moving.

(D Tips

- Before changing the wheel, you must ac

tivate the jacking mode, so that t he au

tomatic cont rols for the Adaptive Air

Suspension* do not ma ke it mo re d iff i

cult to lift the veh icle w it h the jack

¢page 256.

- Obey all laws.

Changing a wheel

When you change a wheel , follow these

quence described below step-by-step and in

exactly that order .

l. Activate the vehicle jack mode*

¢ page 256.

2. Remove the wheel bolt caps* . For more

details see also ¢

page 255, Wheels with

wheel bolt caps.

3. Loosen the wheel bolt s ¢page 255.

4. Loc ate the p roper moun ting point fo r the

j ack an d align the jack be low that poin t

¢page 256.

5. Raise the car with the jack¢ page 256.

6. Remove the wheel with the flat tire and

then insta ll the other whee[¢

page 258.

7. Tighte n all whee l bolts lightly .

8.

Lower the vehicle wi th the jack .

9 . Use the wheel bolt w rench and

firmly

t ig ht en al l w heel bo lt s¢ page 255.

10. Re place the wheel bolt caps* .

Page 257 of 292

11. Deactivate the vehicle jack mode* in the

MMI:

! CARI function button> (C ar)* sys

tem s

control button > Servicing & chec ks

> Air susp. : jack mo de> Off .

The vehicle jack mode* switches off automati

cally at speeds above 6 mph (10 km/h).

A WARNING

Always read and follow all WARNINGS and

information

c:> .&. in Raising the vehicle on

page 257

and c::> page 259.

After changing a wheel

A wheel change is not complete without the

doing the following .

.. Always store the vehicle tool kit, the jack*

and the replaced tire in the luggage com

partment

c::> page 129.

.. As soon as possible, have the tighten ing

torqu es

on all wheel bolts checked with a

torque wrench . The correct tightening tor

que is 90 ft lb (120 Nm) .

.. Have the flat tire

re pl ace d as soon as poss i

ble.

@ Tips

- If you notice that th e whee l bolts are

corroded and difficult to turn wh ile

changing a t ire, they should be replaced

before you check the tighten ing torque .

- Drive at reduced speed unt il you have the

tightening torq ues checked .

- After changing a wheel, the tire pressure

i n a ll four tires must be checked/cor rect

ed and the tire pressure mon itoring indi

cator must be stored in the MM I

c::>page248 .

What do I do now ? 255

Wheels with wheel bolt caps

Applies to vehicles: with wheel bolts with caps

The caps must be removed first from the

wheel bolts before the bolts can be un

screwed .

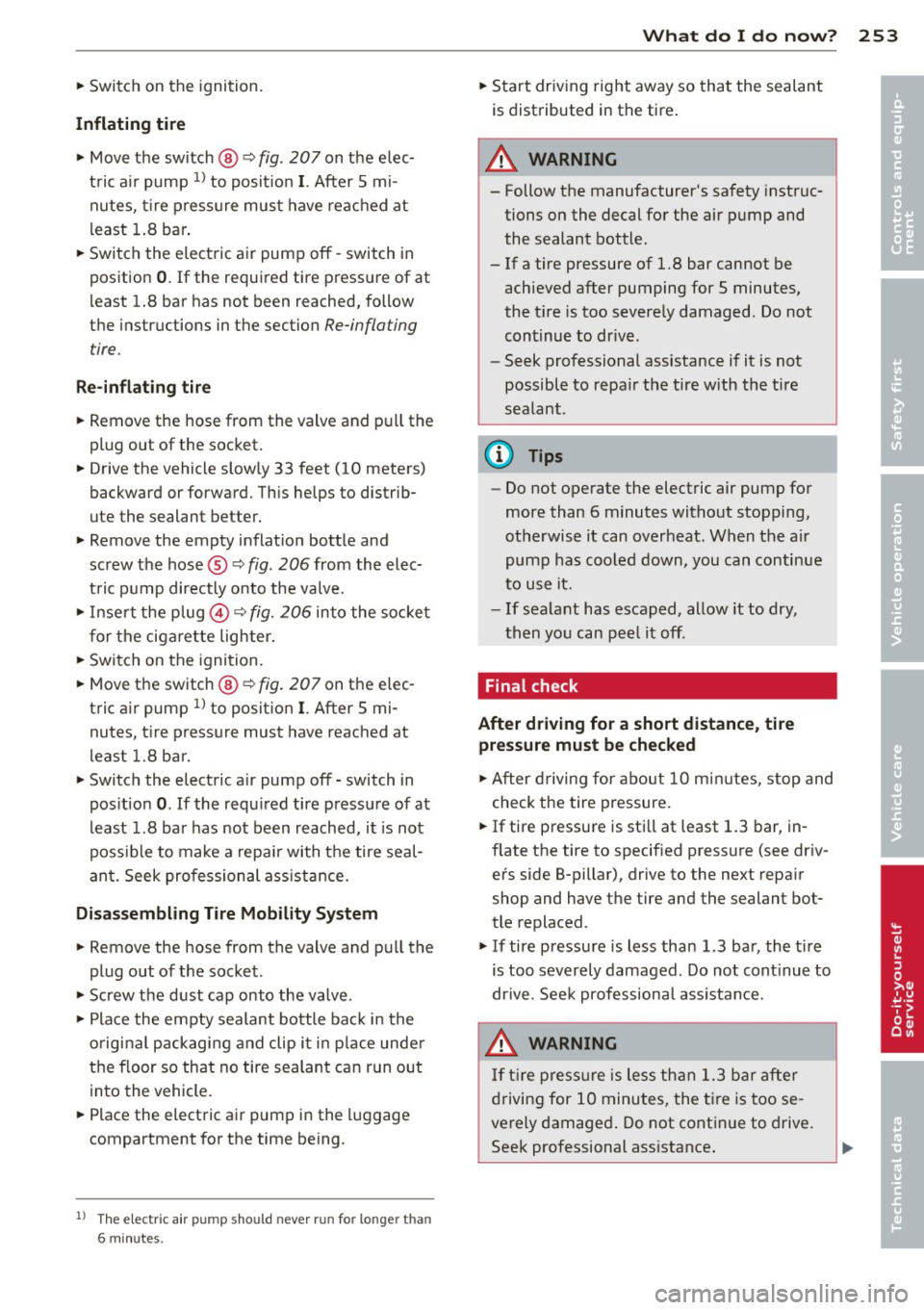

Fig. 208 C hanging a whee l: removi ng the wheel bo lt

caps

Removing

.. Push the pla stic clip (provided with the veh i

cle too l kit) over the wheel bo lt cap until the

inner retainers on the clip align w ith the

edge of the cove r.

.,. Remove the cap with the

plas tic clip (ve hicle

too l kit)

c::> fig. 208 .

Refitting

.,. Place the caps over the whee l bolts and

push them back on.

The caps are to protect and keep the wheel bolts clean.

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle.

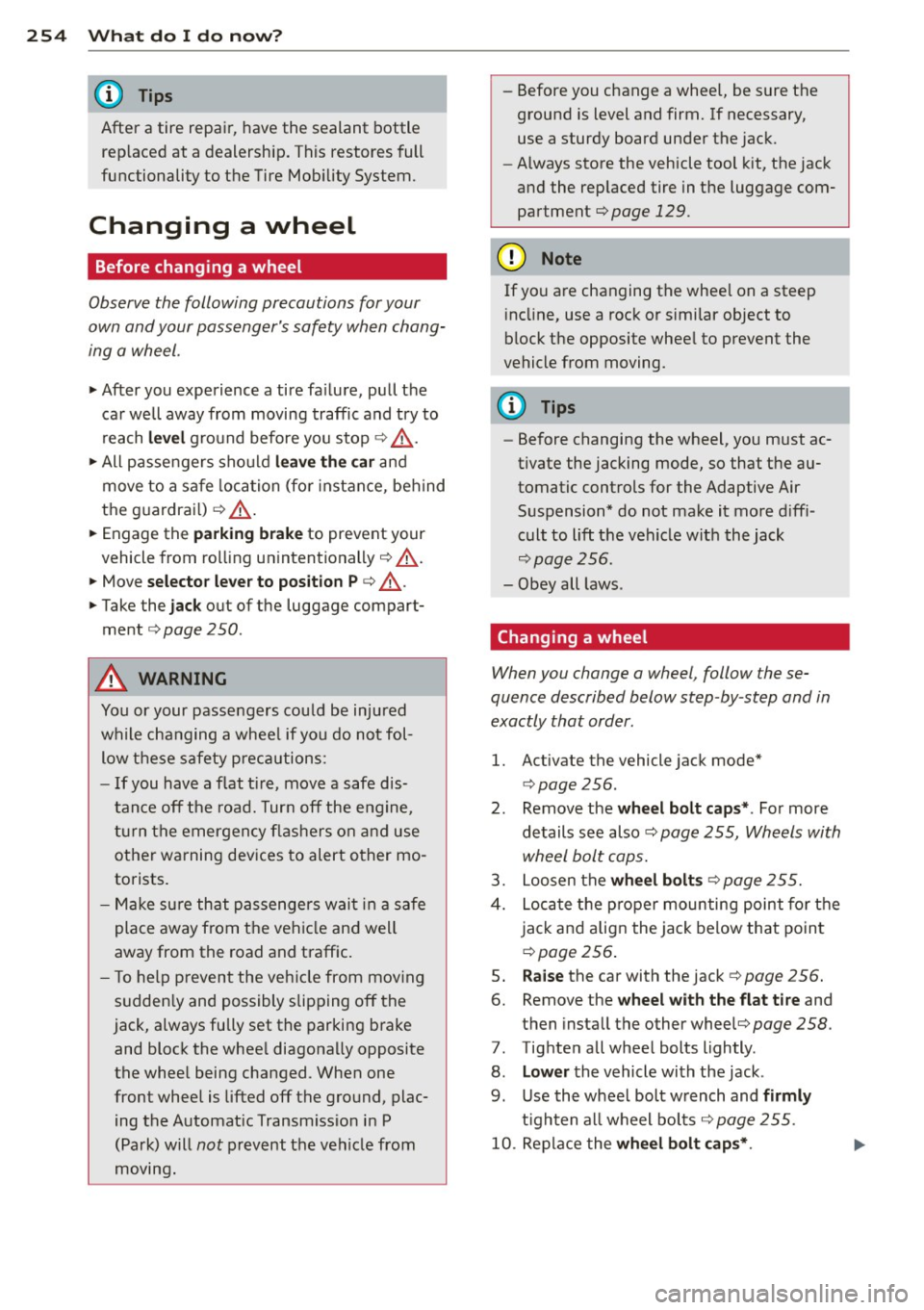

Fig. 209 Changing a wheel: loosening t he wheel bolts ..

Page 258 of 292

256 What do I do now?

Loosening

.,. Slide the wheel wrench onto the wheel bolt

as far as it will go.

.,. Take tight hold of the

end of the wrench

handle and turn the wheel bolts

counter

clockwise

about one single turn in the direc

t ion of arrow

c:;, fig. 209.

Tightening

.,. Slide the wheel wrench onto the wheel bolt

as far as it will go .

.,. Take tight hold of the

end of the wrench

hand le and turn each wheel bolt

clockwise

until it is seated.

_& WARNING

- Do not use force or hurry when changing

a wheel -you can cause the vehicle to slip

off the jack and cause serious personal injuries.

- Do not loosen the wheel bolts more than

one turn

before you raise the vehicle with

the jack. -You risk an injury.

@ Tips

- Never use the hexagonal socket in the

handle of the screwdriver to loosen or

tighten the wheel bolts.

- If a wheel bolt is very tight, you may find

it easier to loosen by carefully pushing

down on the end of the wheel bolt

wrench with

one foot only. As you do so,

hold on to the car to keep your balance

and take care not to slip.

Ra ising the vehicle

The vehicle must be lifted with the jack first

before the wheel can be removed .

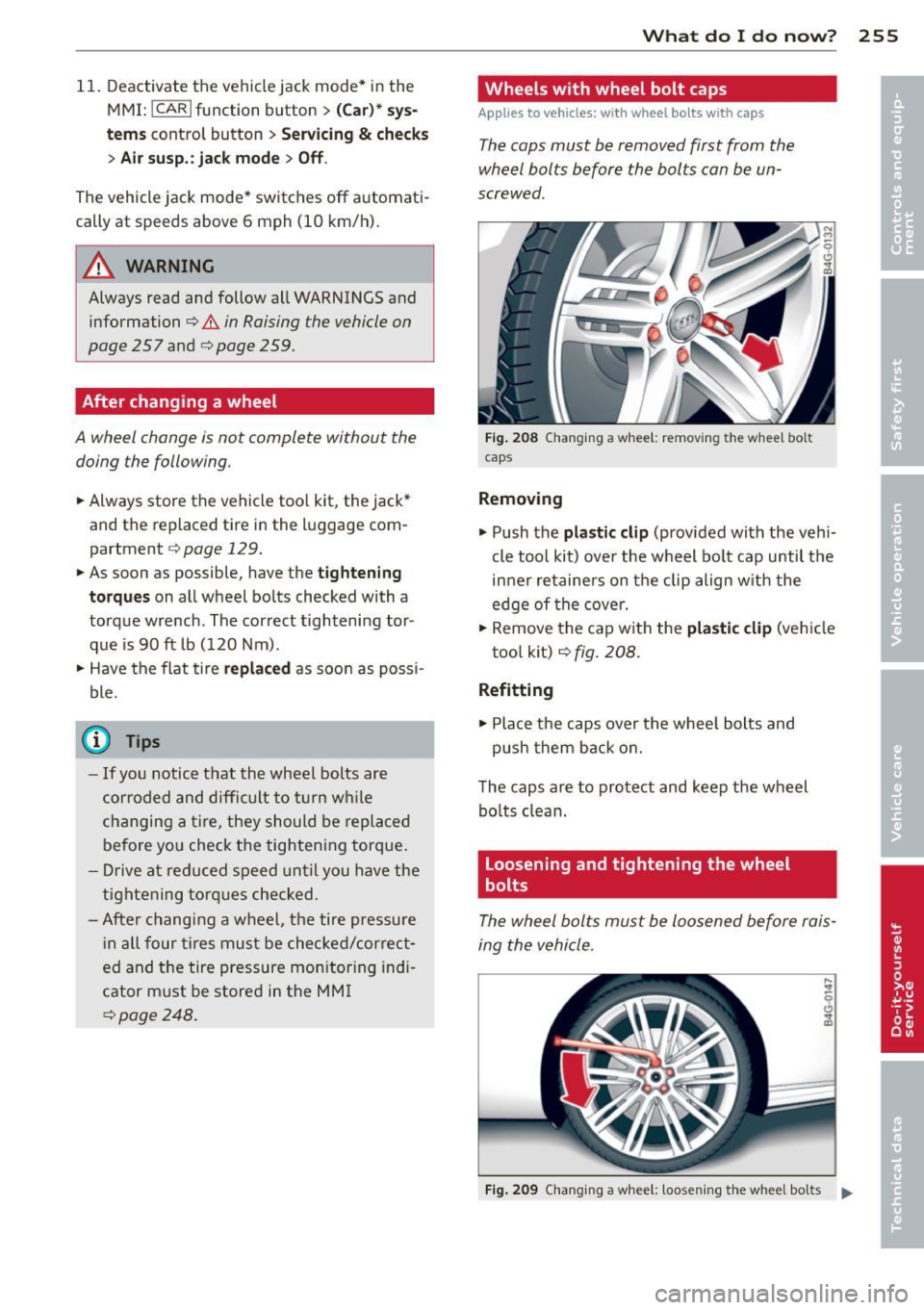

Fig. 210 Sill pane ls : markings

; q

--~~~~~-~

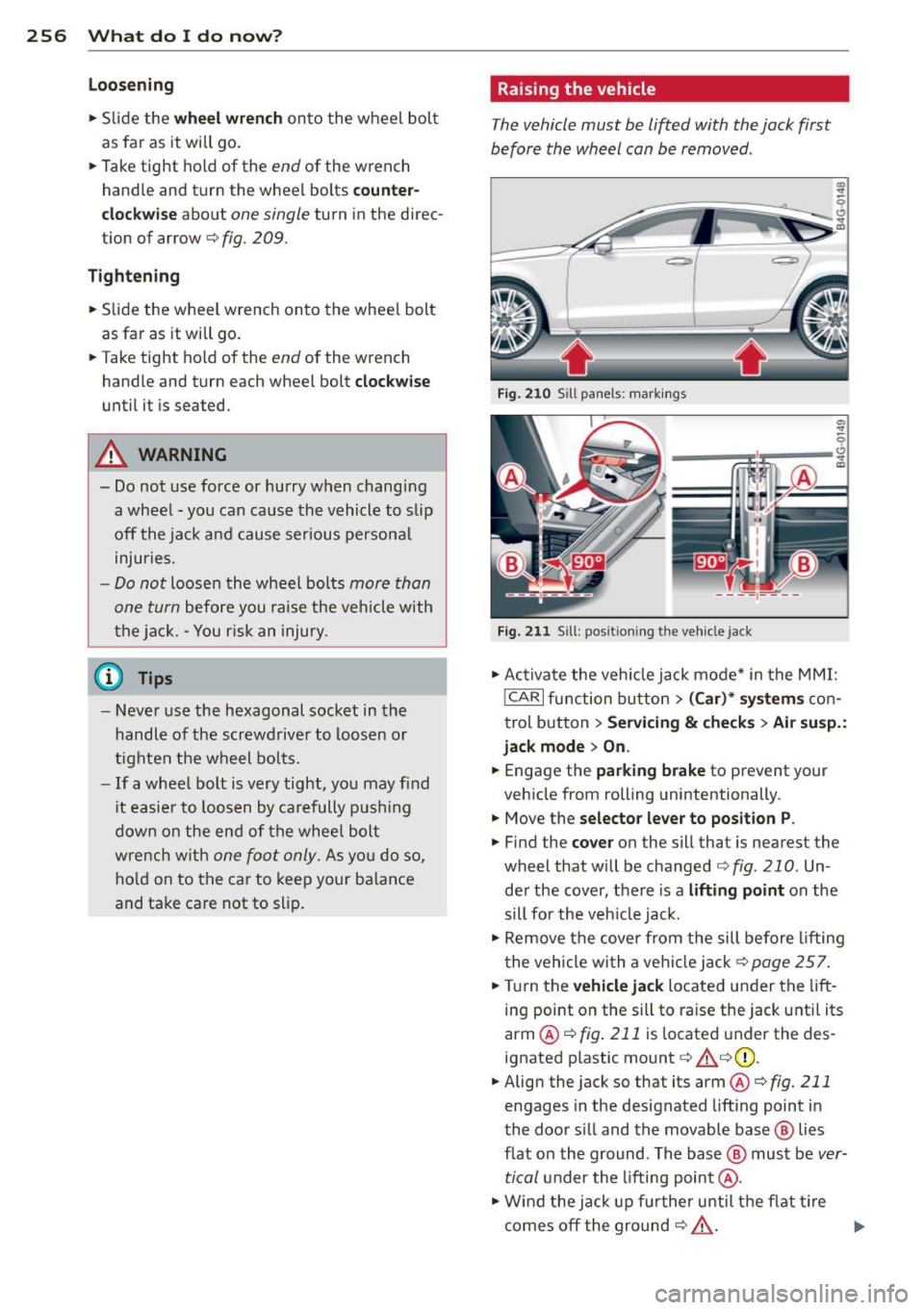

Fig. 211 Sill: posit ioning the Ve hicle jack

.,. Activate the vehicle jack mode* in the MMI:

!CARI function button> (Car)* systems con

trol button>

Servicing & checks> Air susp.:

jack mode

> On.

.,. Engage the parking brake to prevent your

vehicle from rolling unintentionally.

.,. Move the

selector lever to position P .

.,. Find the cover on the sill that is nearest the

wheel that will be changed

c:;, fig. 210 . Un

der the cover, there is a

lifting point on the

sill for the vehicle jack .

.,. Remove the cover from the sill before lifting

the vehicle with a vehicle jack

c:;, page 257 .

.,. Turn the vehicle jack located under the lift

ing point on the sill to raise the jack until its

arm @

c:;, fig. 211 is located under the des

ignated plastic mount

c:;, &c:;,(I) ,

.,. Align the jack so that its arm @ c:;, fig. 211

engages in the designated lifting point in

the door s ill and the movable base @ lies

flat on the ground . The base @ must be

ver

tical

under the lifting point @ .

.,. Wind the jack up further until the flat tire

comes off the ground

c:;, & . ..,.

Page 259 of 292

Position the vehicle jack o nl y under the desig

nated lifting points on the sill

¢ fig . 210.

There is exactly one location for each wheel.

The jack must not be positioned at any other

location¢ 8_¢Q) .

An

un sta bl e s urf a ce under the jack can cause

the vehicle to slip off the jack. Always provide

a firm base for the jack on the ground. If nec

essary place a sturdy board or s imilar support

u nder the jack . On

hard, slippery su rf ac es

(such as tiles) use a rubber mat or sim ila r to

prevent the jack from sli pping ¢&. .

A WARNING

-You or your passengers could be injured

wh ile chang ing a whee l if you do not fol

low these safety precautions:

- Position the vehicle jack only at the

des ignated lifting points and align the

jack . Otherwise, the vehicle jack could

slip and cause an injury if it does not

have sufficient ho ld on the vehi cle.

- A soft or unstab le surface under the

jack may cause the vehicle to slip off the jack. A lways provide a firm base for

the jack on the gro und. If necessary,

use a sturdy board under the jack.

- On ha rd, slippery surfa ce (such as tile s)

use a rubbe r mat o r similar to prevent

the jack from slipping.

- T o help prevent injury to yourself and

yo ur passenge rs:

- Do not raise the vehicle unti l you are

sure the jack is securely engaged.

- Passengers must not remain in the ve hicle when it is jacked up.

- Make sure that passengers wait in a

safe place away from the vehicle and

well away from the road and traffic .

- Make sure jack position is correct, ad just as necessary and then continue to ra ise the jack.

- Changes in temperature or load can af

fect the height of the vehicle.

What do I d o now ? 257

(D Note

Do not lift the vehicle by the sil l. Position

the veh icle jack only at the designated lift

i ng po ints on the sill. Otherwise, your vehi

cle will be damaged.

{!) Tips

The vehicle jack mode* switches off auto

matically at speeds above 6 mp h (10 km/

h).

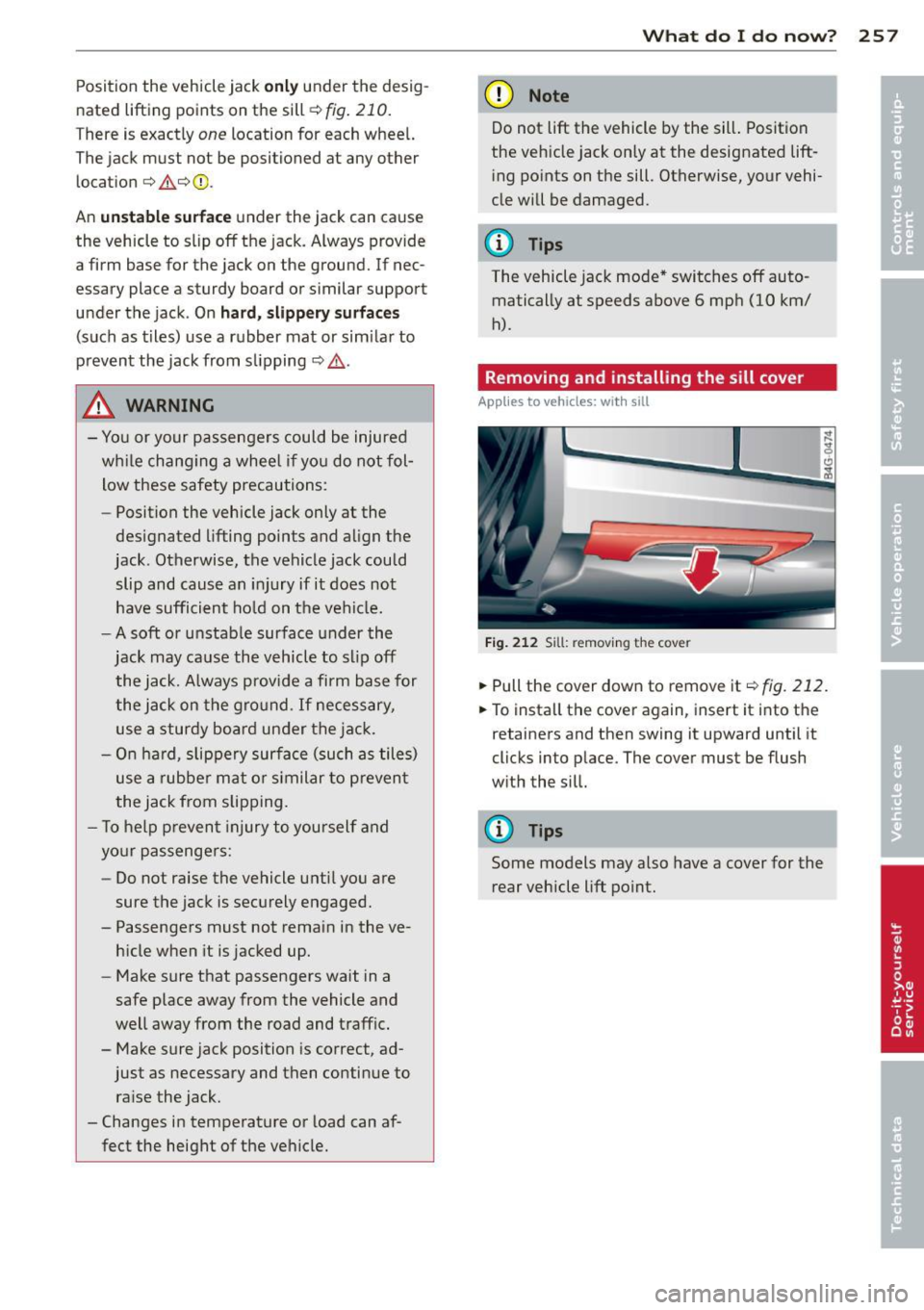

Removing and installing the sill cover

App lies to vehicles: with sill

Fi g. 212 Sill: remov ing the cove r

... Pull the cover down to remove it ~fig. 212.

... To insta ll the cover again, insert it into the

retainers and then swing it upward until it

clicks into p lace. The cover must be flush

w ith the sill.

(D Tips

Some models may also have a cover for the

rear vehicle lift point.

Page 260 of 292

2 58 What do I do now ?

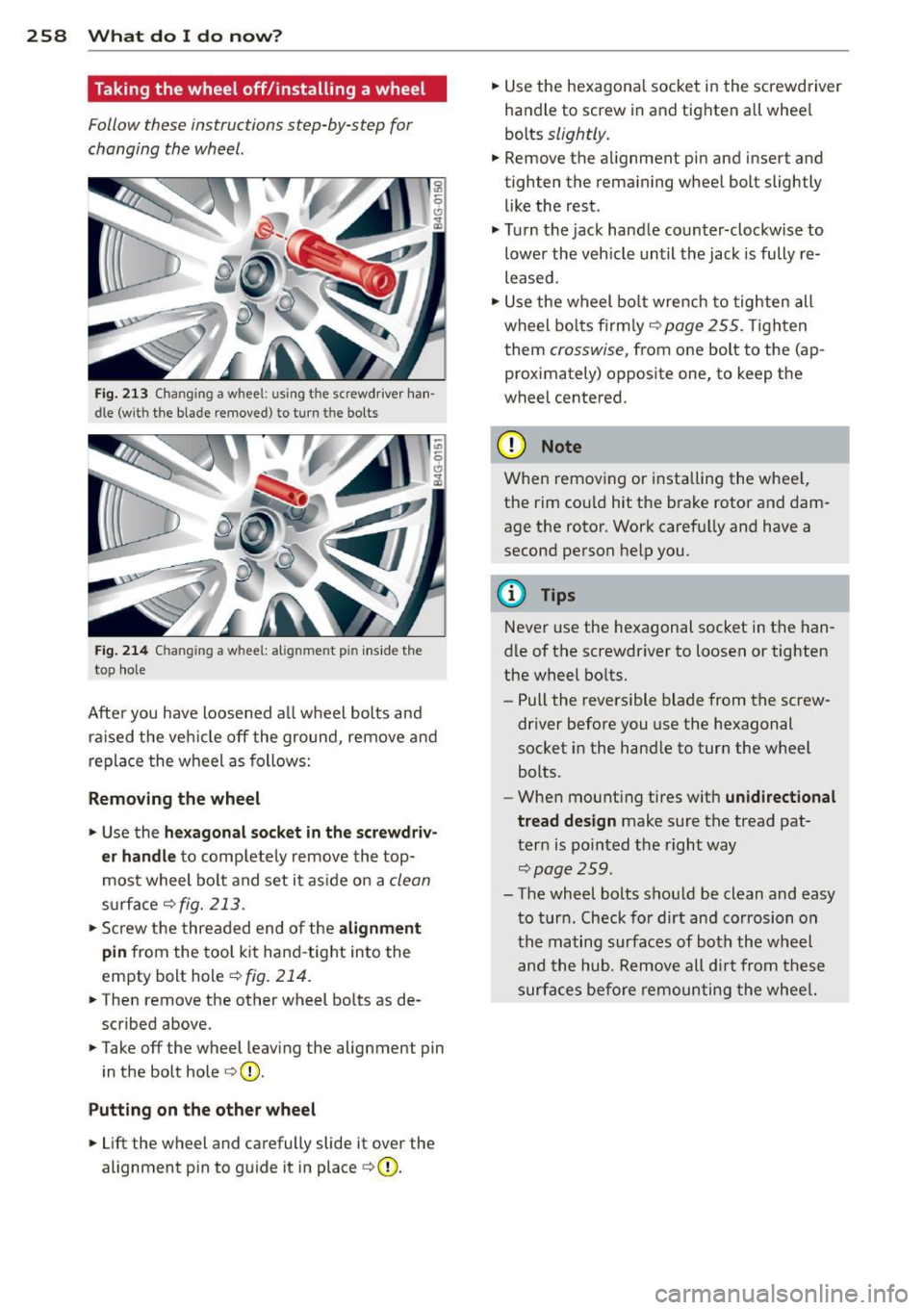

Taking the wheel off/installing a wheel

Follow these instructions step-by-step for

changing the wheel.

Fig. 213 Changing a whee l: u sing the screwdriver han

dle (w ith the blade removed } to turn t he bolts

Fig . 214 C hanging a w hee l: al ignm en t pi n inside the

top hole

Afte r you have loosened a ll wheel bolts and

raised the vehicle off the ground, remove and

replace the wheel as follows:

Removing the wheel

.. Use the hexagonal socket in the screwdriv

er handle

to comp letely remove the top

most wheel bolt and set it aside on a

clean

surface c:> fig. 213 .

.. Screw the threaded end of the alignment

pin

from the tool kit hand -tight into the

empty bolt hole

c:> fig. 214.

.. The n remove the other wheel bo lts as de

scribed above .

.. Take off the wheel leaving the alignment pin

in the bolt hole

c:> (D .

Putting on the other wheel

.. Lift the wheel and carefully slide it over the

alignment pin to guide it in place

c:>(D.

.. Use the hexagonal socket in the screwdriver

handle to screw in and tighten all whee l

bolts

slightly.

.. Remove the alignment pin and insert and

tighten the remaining wheel bolt slightly like the rest .

.. Turn the jack handle counter-clockwise to

lower the vehicle until the jack is fully re

leased .

.. Use the wheel bolt wrench to tighten all

wheel bolts fir m ly

c:> page 255 . Tighten

them

crosswise, from one bolt to the (ap

proximately) opposite one, to keep the

wheel centered.

(D Note

When remov ing or installing the wheel,

the rim cou ld hit the brake rotor and dam

age the rotor. Work carefu lly and have a

second person help you.

(D Tips

Never use the hexagonal socket in the han

d le of the screwdriver to loosen or tighten

the wheel bolts.

- Pull the reversible blade from the screw

driver before you use the hexagonal

socket in the handle to turn the wheel

bolts.

- When mounting tires w ith

unidirectional

tread design

make sure the tread pat

tern is pointed the right way

c:>page25 9.

-The wheel bolts should be clean and easy

to turn . Check for dirt and corrosion on

the mating surfaces of both the wheel

and the hub. Remove all dirt from these

surfaces before remounting the wheel.