torque AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 34 of 72

35

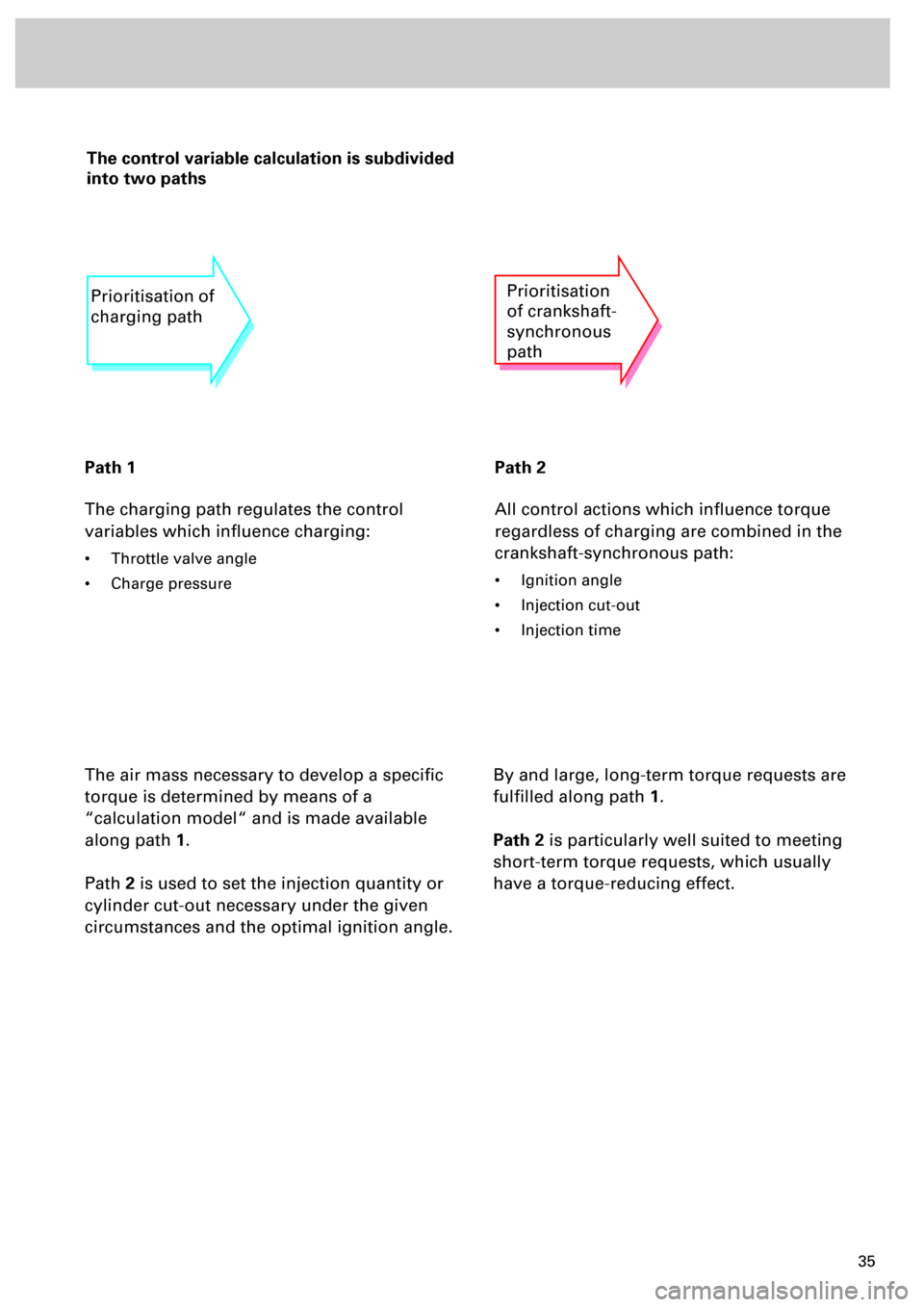

The control variable calculation is subdivided

into two paths

Path 1

The charging path regulates the control

variables which influence charging:

• Throttle valve angle

• Charge pressure

Path 2

All control actions which influence torque

regardless of charging are combined in the

crankshaft-synchronous path:

• Ignition angle

• Injection cut-out

• Injection time

The air mass necessary to develop a specific

torque is determined by means of a

“calculation model“ and is made available

along path

1

.

Path

2

is used to set the injection quantity or

cylinder cut-out necessary under the given

circumstances and the optimal ignition angle.

Prioritisation of

charging pathPrioritisation

of crankshaft-

synchronous

path

By and large, long-term torque requests are

fulfilled along path

1

.

Path 2

is particularly well suited to meeting

short-term torque requests, which usually

have a torque-reducing effect.

Page 36 of 72

37

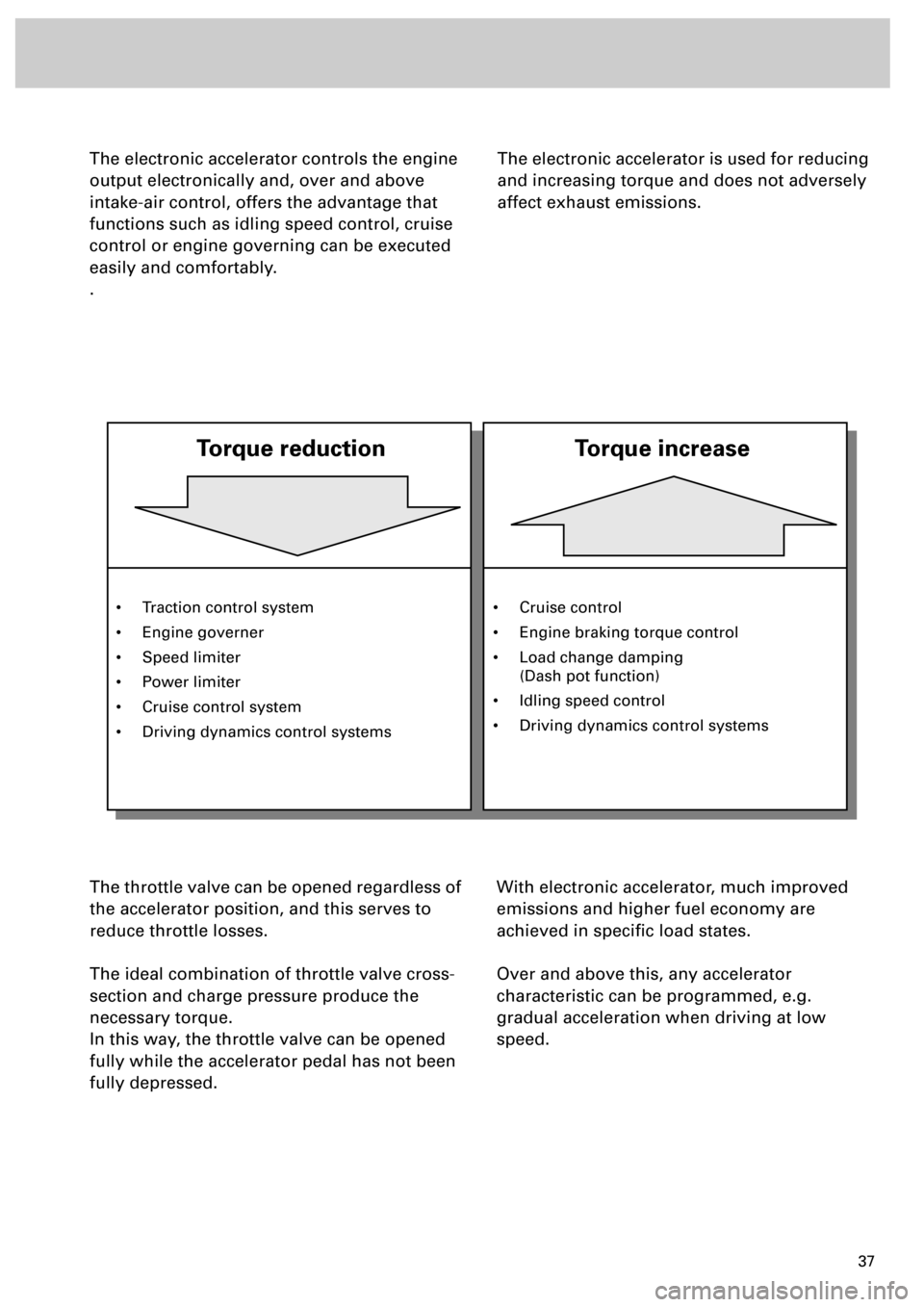

The electronic accelerator controls the engine

output electronically and, over and above

intake-air control, offers the advantage that

functions such as idling speed control, cruise

control or engine governing can be executed

easily and comfortably.

.

The throttle valve can be opened regardless of

the accelerator position, and this serves to

reduce throttle losses.

The ideal combination of throttle valve cross-

section and charge pressure produce the

necessary torque.

In this way, the throttle valve can be opened

fully while the accelerator pedal has not been

fully depressed.With electronic accelerator, much improved

emissions and higher fuel economy are

achieved in specific load states.

Over and above this, any accelerator

characteristic can be programmed, e.g.

gradual acceleration when driving at low

speed.

The electronic accelerator is used for reducing

and increasing torque and does not adversely

affect exhaust emissions.

• Traction control system

• Engine governer

• Speed limiter

• Power limiter

• Cruise control system

• Driving dynamics control systems

Torque reduction

Torque increase

• Cruise control

• Engine braking torque control

• Load change damping

(Dash pot function)

• Idling speed control

• Driving dynamics control systems

Page 38 of 72

39

Self-diagnosis/emergency

running

If a fault occurs in the accelerator position

sender or the wiring, two emergency running

programs can be run depending on fault type.

Emergency running program 1

If an accelerator position sender fails:

• Accelerator position limited to a defined value.

• If a full load is predefined, the power output is

increased slowly.

• In the case of implausible signals between G79

and G185, the lower value is used.

Prerequisite:

The idling speed position must be learnt once

by the intact sender.

• The signal supplied by brake light switch for

brake pedal switch F47 indicates the idling

speed.

• Comfort functions (CCS) are prohibited.

• The fault lamp for electric throttle control K132

comes on.

Emergency running program 2

If both accelerator position senders fail, driver

input recognition is not possible:

• The engine only runs at idling speed.

• The fault lamp for electric throttle control K132

comes on.

At idling speed, the accelerator

position senders G79 and G185 are

not diagnosed.

If the plug of the accelerator position

sender drops off, no fault is stored in

the control unit.

The fault lamp for electric throttle

control K132 does not come on.

The engine runs at idling speed and

does not respond to the accelerator

pedal.

Safety function:

For safety reasons, the throttle valve

is closed as far as a defined angular

position when both the accelerator

pedal and the brake pedal are

depressed.

If the brake is pressed first followed

by the accelerator pedal, the driver

input (torque request) is executed.

Page 39 of 72

40

SSP 198/28

Subsystems of the Motronic

The throttle valve control part comprises...

... throttle valve housing with throttle valve

... throttle valve drive G186 with reduction

gear

... angle senders for throttle valve drive

G187 and G188

Activated by the engine control unit, the

throttle valve drive controls the air-flow rate

necessary to develop the required torque.

Feedback on momentary throttle valve

position is provided by two potentiometers

G187 and G188.

For safety reasons, two angle senders

(redundancy) are used. They have opposite

impedance characteristics (see diagram).

If an angle sender fails, the second sender

maintains the electronic accelerator function

via an emergency running program.

Throttle valve housing

with throttle valve

Housing cover with electrical

connections

Throttle valve drive G186

(Electric throttle control)

Angle senders for throttle valve

drive G187 and G188

Resistance in

W

Angle senders G187 and G188 cannot

be replaced separately. The throttle

valve control part may not be opened.

Redundancy means: superfluous,

non-essential.

0 100%

SSP 198/27

G188

G187

Throttle valve opening in %

throttle valve control part J338 with throttle valve drive G186, angle

senders 1 G187 and 2 G188 for throttle valve drive

Page 42 of 72

43

Emergency running program 1

If an angle sender for throttle valve drive fails

or an implausible signal is received:

• Torque-increasing requests on engine, e.g. CCS,

EBC (engine braking control) are suppressed.

• The fault lamp for electrical throttle control K132

comes on.

Prerequisite:

An intact angle sender and plausible

air mass flow. The air mass flow is

indicated by the air mass meter and

the charge pressure sender G31.

Self-diagnosis/emergency running mode

If a fault occurs in the throttle valve control part or in the wiring, three emergency running

programs can be run, depending on fault type.

Emergency running program 2

If the throttle valve drive fails or malfunctions:

• The throttle valve drive is switched off and the

throttle valve goes into the emergency running

position. This results in considerable loss of

power, increased idling speed and possibly also

rough idling .

• Driver inputs are executed as far as possible via

the ignition angle and charge pressure. The

engine shows little response to the throttle.

• The fault lamp for electrical throttle control K132

comes on.

Prerequisite:

Emergency running program 2 is only

run if both angle senders for throttle

valve drive recognise the emergency

running position.

Emergency running program 3

If the throttle valve position is not clearly

recognisable and/or if the throttle valve is not

definitely known to be in the emergency

running position:

• The throttle valve drive is switched off and the

throttle valve goes into the emergency running

position. This results in considerable loss of

power, increased idling speed and possibly also

rough idling.

• The engine speed is limited to approx. 1200 rpm

by restricting the injection.

• The fault lamp for electric throttle control K132

comes on.

Repair work may not be performed on

the throttle valve control part J338! If

G186, G187 or G188 becomes faulty,

unit J338 must be replaced

completely and a

basic setting

performed.

Page 49 of 72

50

SSP 198/16

Sensors

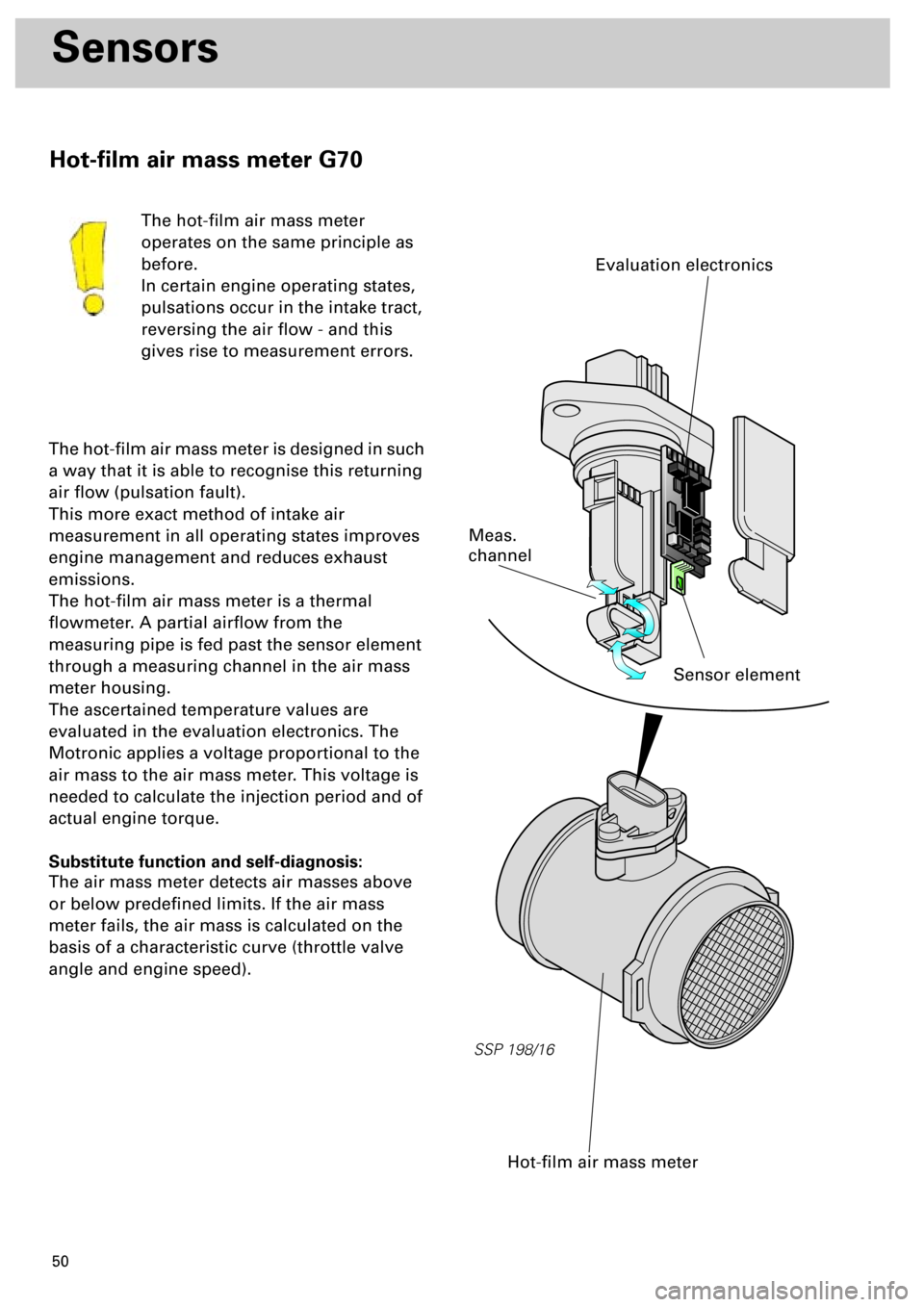

The hot-film air mass meter

operates on the same principle as

before.

In certain engine operating states,

pulsations occur in the intake tract,

reversing the air flow - and this

gives rise to measurement errors.

The hot-film air mass meter is designed in such

a way that it is able to recognise this returning

air flow (pulsation fault).

This more exact method of intake air

measurement in all operating states improves

engine management and reduces exhaust

emissions.

The hot-film air mass meter is a thermal

flowmeter. A partial airflow from the

measuring pipe is fed past the sensor element

through a measuring channel in the air mass

meter housing.

The ascertained temperature values are

evaluated in the evaluation electronics. The

Motronic applies a voltage proportional to the

air mass to the air mass meter. This voltage is

needed to calculate the injection period and of

actual engine torque.

Substitute function and self-diagnosis:

The air mass meter detects air masses above

or below predefined limits. If the air mass

meter fails, the air mass is calculated on the

basis of a characteristic curve (throttle valve

angle and engine speed).

Hot-film air mass meter

Sensor element

Meas.

channel

Evaluation electronics

Hot-film air mass meter G70

Page 66 of 72

67

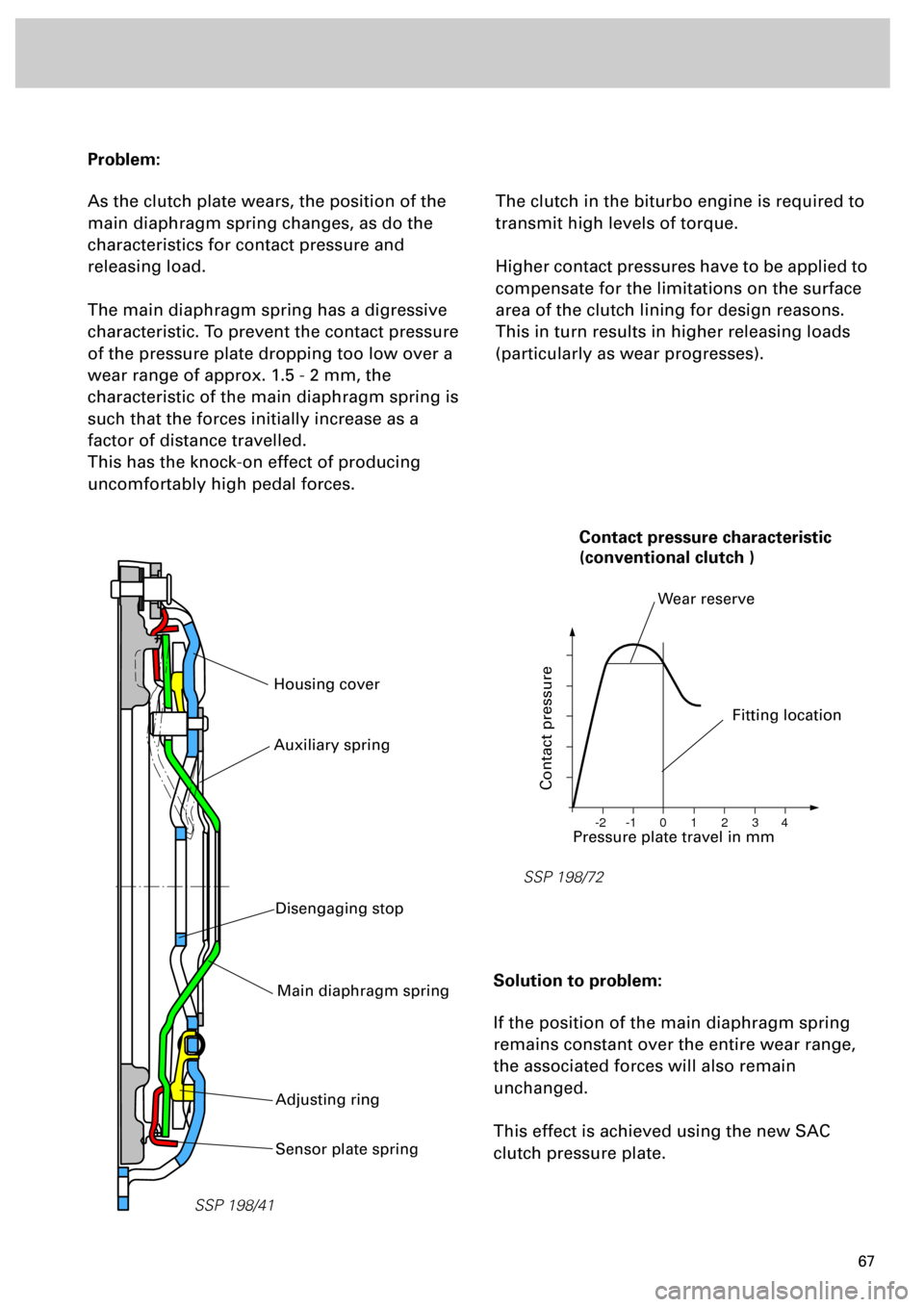

Problem:

As the clutch plate wears, the position of the

main diaphragm spring changes, as do the

characteristics for contact pressure and

releasing load.

The main diaphragm spring has a digressive

characteristic. To prevent the contact pressure

of the pressure plate dropping too low over a

wear range of approx. 1.5 - 2 mm, the

characteristic of the main diaphragm spring is

such that the forces initially increase as a

factor of distance travelled.

This has the knock-on effect of producing

uncomfortably high pedal forces.

The clutch in the biturbo engine is required to

transmit high levels of torque.

Higher contact pressures have to be applied to

compensate for the limitations on the surface

area of the clutch lining for design reasons.

This in turn results in higher releasing loads

(particularly as wear progresses).

Solution to problem:

If the position of the main diaphragm spring

remains constant over the entire wear range,

the associated forces will also remain

unchanged.

This effect is achieved using the new SAC

clutch pressure plate.

SSP 198/41

Housing cover

SSP 198/72

0 -1 -2 1 2 3 4

Pressure plate travel in mm

Contact pressure

Fitting location

Wear reserve

Contact pressure characteristic

(conventional clutch )

Sensor plate spring

Main diaphragm spring

Adjusting ring

Auxiliary spring

Disengaging stop