gearbox AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 3 of 72

3

This Self-study Programme provides you with information

regarding design and function.

The Self-study Programme is not a Workshop Manual!

Please refer to the Service Literature for all the relevant

maintenance and repair instructions.

Page

Engine .........................................................

Technical data, crankshaft, cylinder head,

camshaft timing, cooling circuit, engine

lubrication, overview of components, air ducting,

charging, exhaust system, pneumatically

controlled systems, charge pressure control, air

divert control in overrun, ACF system, crankcase

breather

4

Motronic ME 7.1 ..........................................

Subfunctions, system overview

31

Subsystems of the Motronic .....................

Torque-oriented engine management, torque-

oriented functional structure, Electronic throttle,

exhaust gas temperature control

33

Sensors .......................................................

Additional sensors of the Motronic

49

Auxiliary signals/interfaces ...................... 57

Functional diagram ..................................... 62

Self-diagnosis .............................................

Vehicle diagnosis, test and information system

VAS 5051, test box V.A.G 1598/31

64

Transmission ..............................................

Self-adjusting clutch, gearbox

66

Contents

Important!/Note!

New!

Page 33 of 72

34

Subsystems of the Motronic

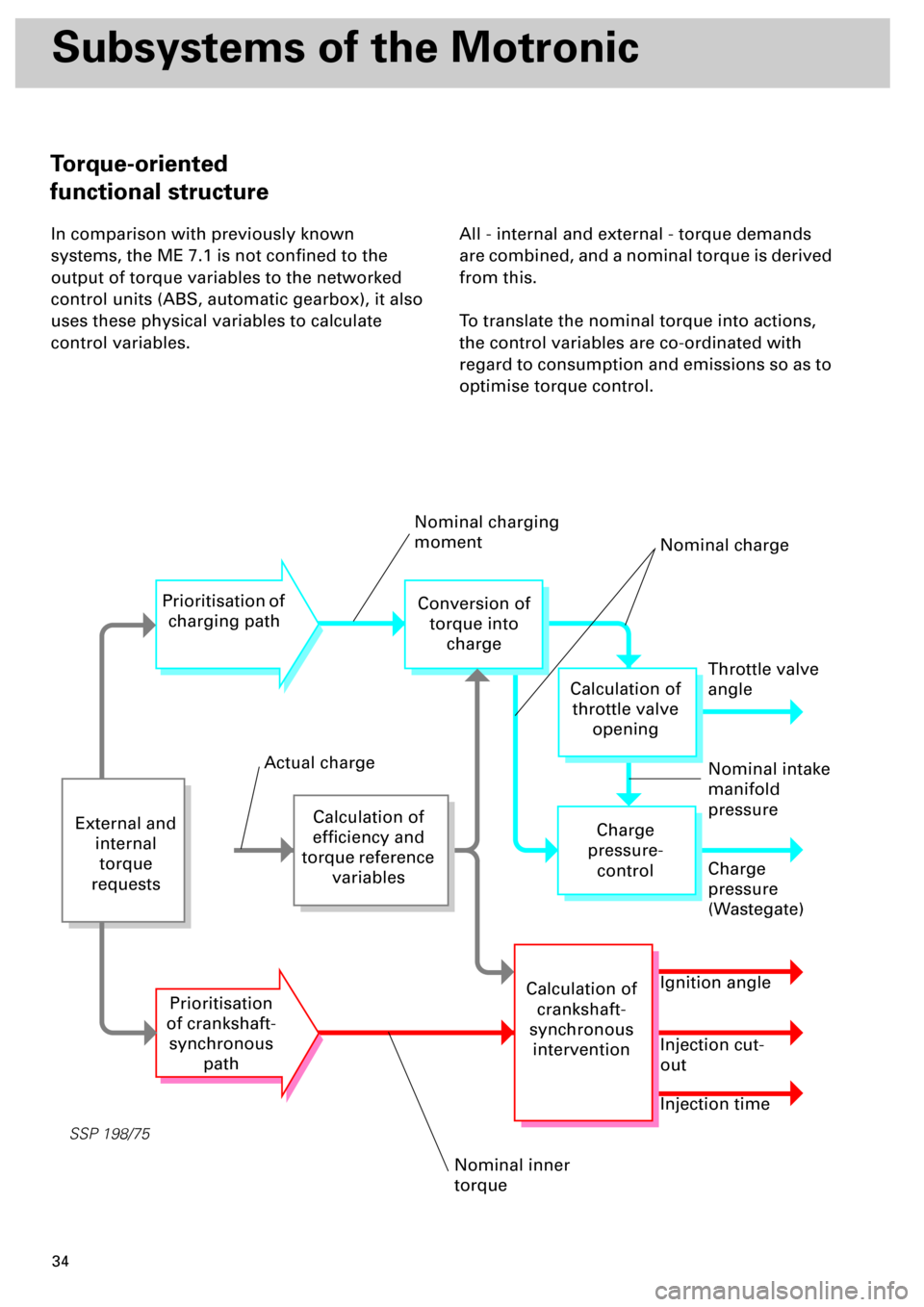

In comparison with previously known

systems, the ME 7.1 is not confined to the

output of torque variables to the networked

control units (ABS, automatic gearbox), it also

uses these physical variables to calculate

control variables.All - internal and external - torque demands

are combined, and a nominal torque is derived

from this.

To translate the nominal torque into actions,

the control variables are co-ordinated with

regard to consumption and emissions so as to

optimise torque control.

SSP 198/75

External and

internal

torque

requests

Calculation of

efficiency and

torque reference

variables

Prioritisation of

charging path

Prioritisation

of crankshaft-

synchronous

path

Conversion of

torque into

charge

Throttle valve

angle

Charge

pressure-

control

Calculation of

crankshaft-

synchronous

intervention

Calculation of

throttle valve

opening

Charge

pressure

(Wastegate)

Ignition angle

Injection cut-

out

Injection time

Nominal charging

moment

Nominal charge

Nominal intake

manifold

pressure

Nominal inner

torque

Actual charge

Torque-oriented

functional structure

Page 37 of 72

38

Subsystems of the Motronic

SSP 198/12

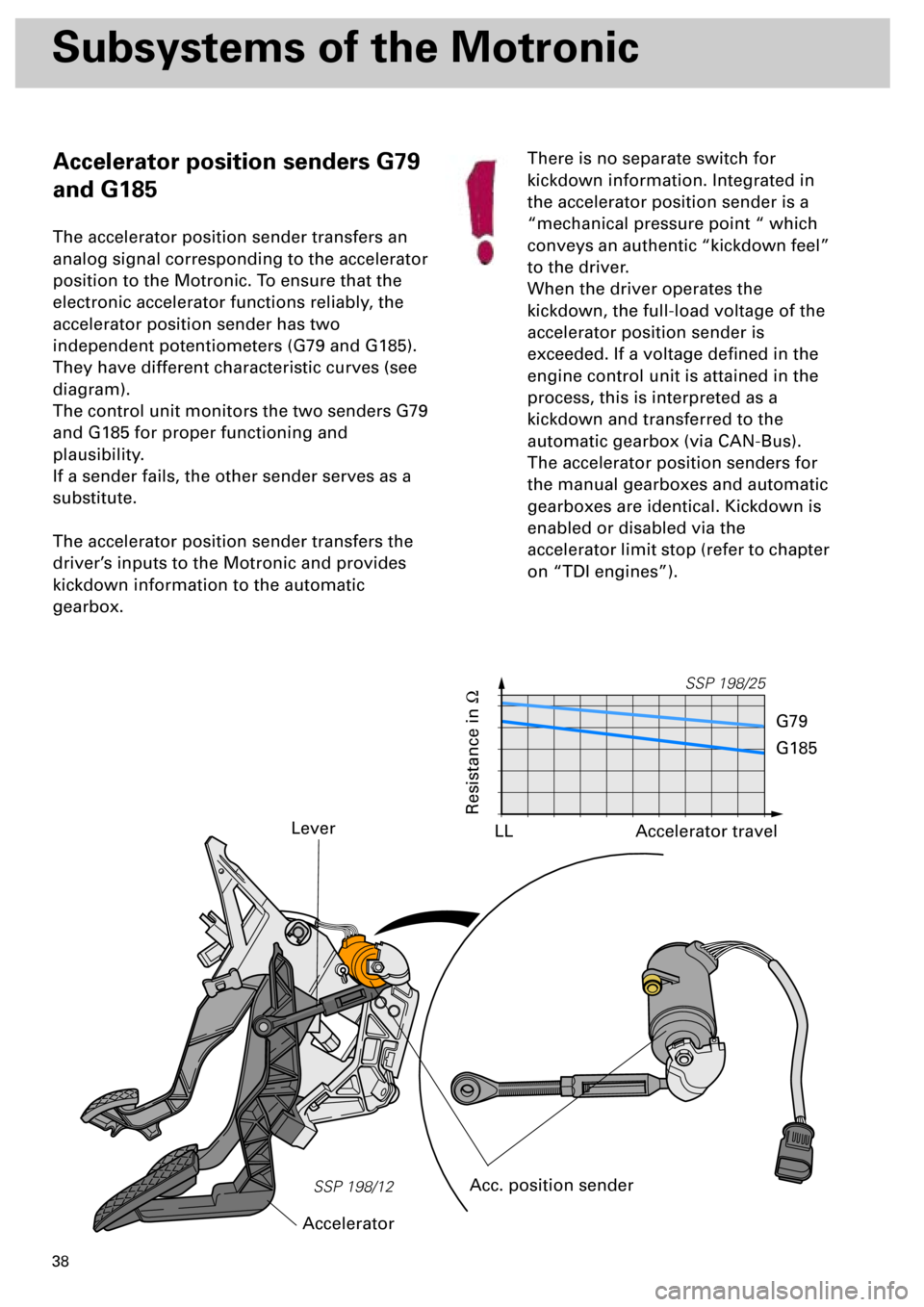

Accelerator position senders G79

and G185

The accelerator position sender transfers an

analog signal corresponding to the accelerator

position to the Motronic. To ensure that the

electronic accelerator functions reliably, the

accelerator position sender has two

independent potentiometers (G79 and G185).

They have different characteristic curves (see

diagram).

The control unit monitors the two senders G79

and G185 for proper functioning and

plausibility.

If a sender fails, the other sender serves as a

substitute.

The accelerator position sender transfers the

driver’s inputs to the Motronic and provides

kickdown information to the automatic

gearbox.

Lever

Acc. position sender

AcceleratorThere is no separate switch for

kickdown information. Integrated in

the accelerator position sender is a

“mechanical pressure point “ which

conveys an authentic “kickdown feel”

to the driver.

When the driver operates the

kickdown, the full-load voltage of the

accelerator position sender is

exceeded. If a voltage defined in the

engine control unit is attained in the

process, this is interpreted as a

kickdown and transferred to the

automatic gearbox (via CAN-Bus).

The accelerator position senders for

the manual gearboxes and automatic

gearboxes are identical. Kickdown is

enabled or disabled via the

accelerator limit stop (refer to chapter

on “TDI engines”).

SSP 198/25

Resistance in

W

Accelerator travel

G79

G185

LL

Page 44 of 72

45

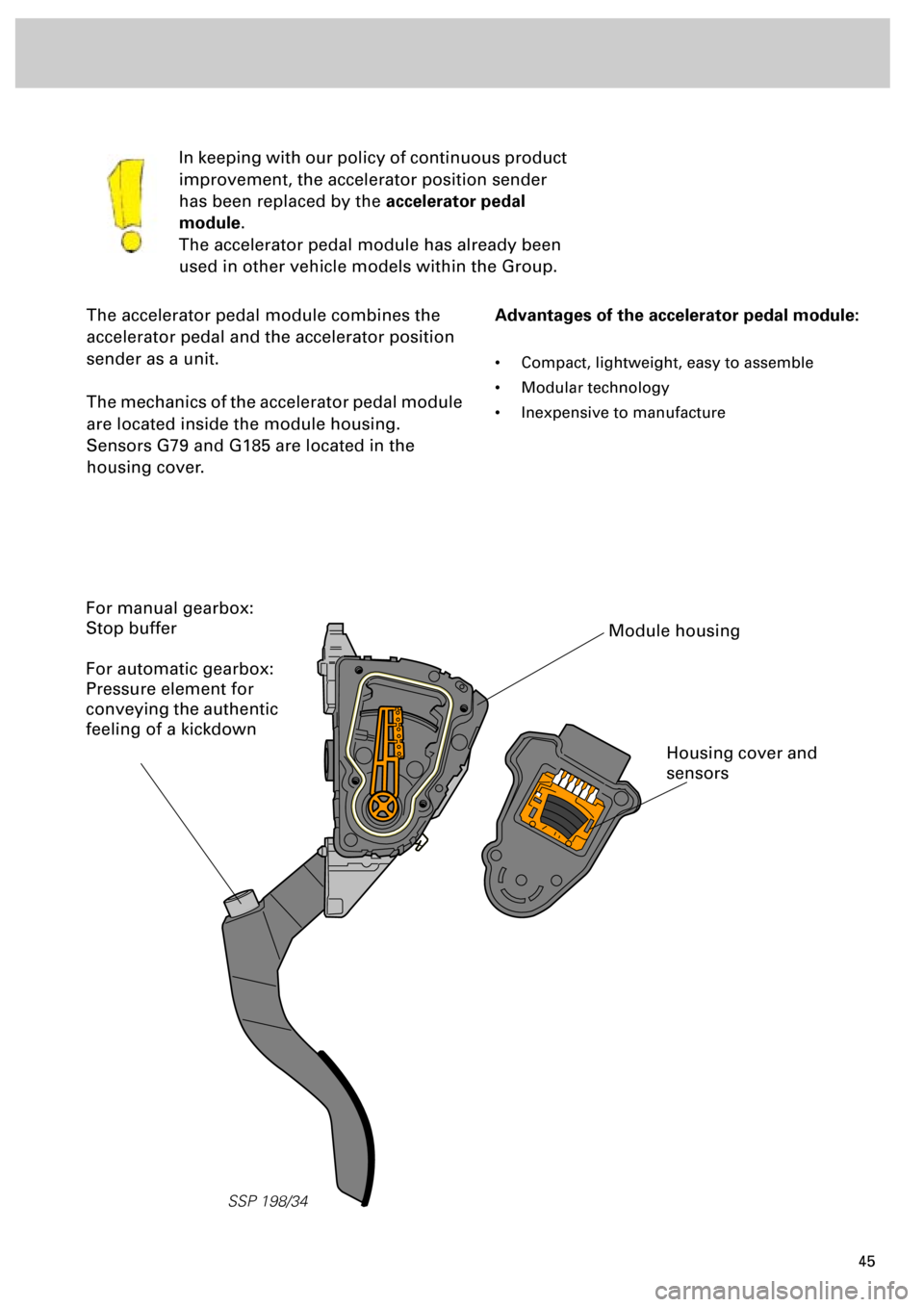

SSP 198/34

The accelerator pedal module combines the

accelerator pedal and the accelerator position

sender as a unit.

The mechanics of the accelerator pedal module

are located inside the module housing.

Sensors G79 and G185 are located in the

housing cover.In keeping with our policy of continuous product

improvement, the accelerator position sender

has been replaced by the

accelerator pedal

module

.

The accelerator pedal module has already been

used in other vehicle models within the Group.

Advantages of the accelerator pedal module:

• Compact, lightweight, easy to assemble

• Modular technology

• Inexpensive to manufacture

Module housing

Housing cover and

sensors

For manual gearbox:

Stop buffer

For automatic gearbox:

Pressure element for

conveying the authentic

feeling of a kickdown

Page 56 of 72

57

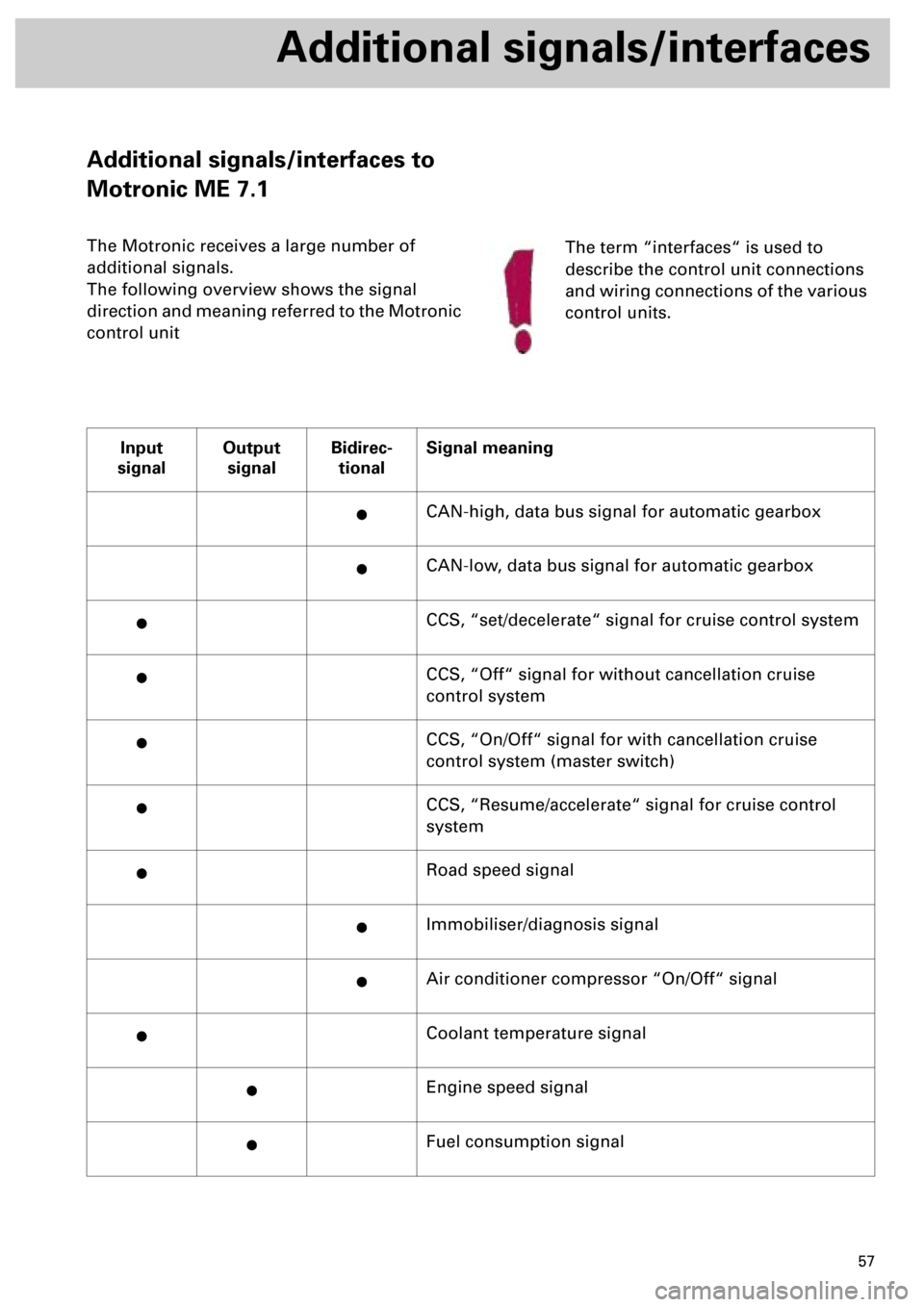

Additional signals/interfaces

Additional signals/interfaces to

Motronic ME 7.1

The Motronic receives a large number of

additional signals.

The following overview shows the signal

direction and meaning referred to the Motronic

control unit

Input

signalOutput

signalBidirec-

tionalSignal meaning

·CAN-high, data bus signal for automatic gearbox

·CAN-low, data bus signal for automatic gearbox

·CCS, “set/decelerate“ signal for cruise control system

·CCS, “Off“ signal for without cancellation cruise

control system

·CCS, “On/Off“ signal for with cancellation cruise

control system (master switch)

·CCS, “Resume/accelerate“ signal for cruise control

system

·Road speed signal

·Immobiliser/diagnosis signal

·Air conditioner compressor “On/Off“ signal

·Coolant temperature signal

·Engine speed signal

·Fuel consumption signal

The term “interfaces“ is used to

describe the control unit connections

and wiring connections of the various

control units.

Page 59 of 72

60

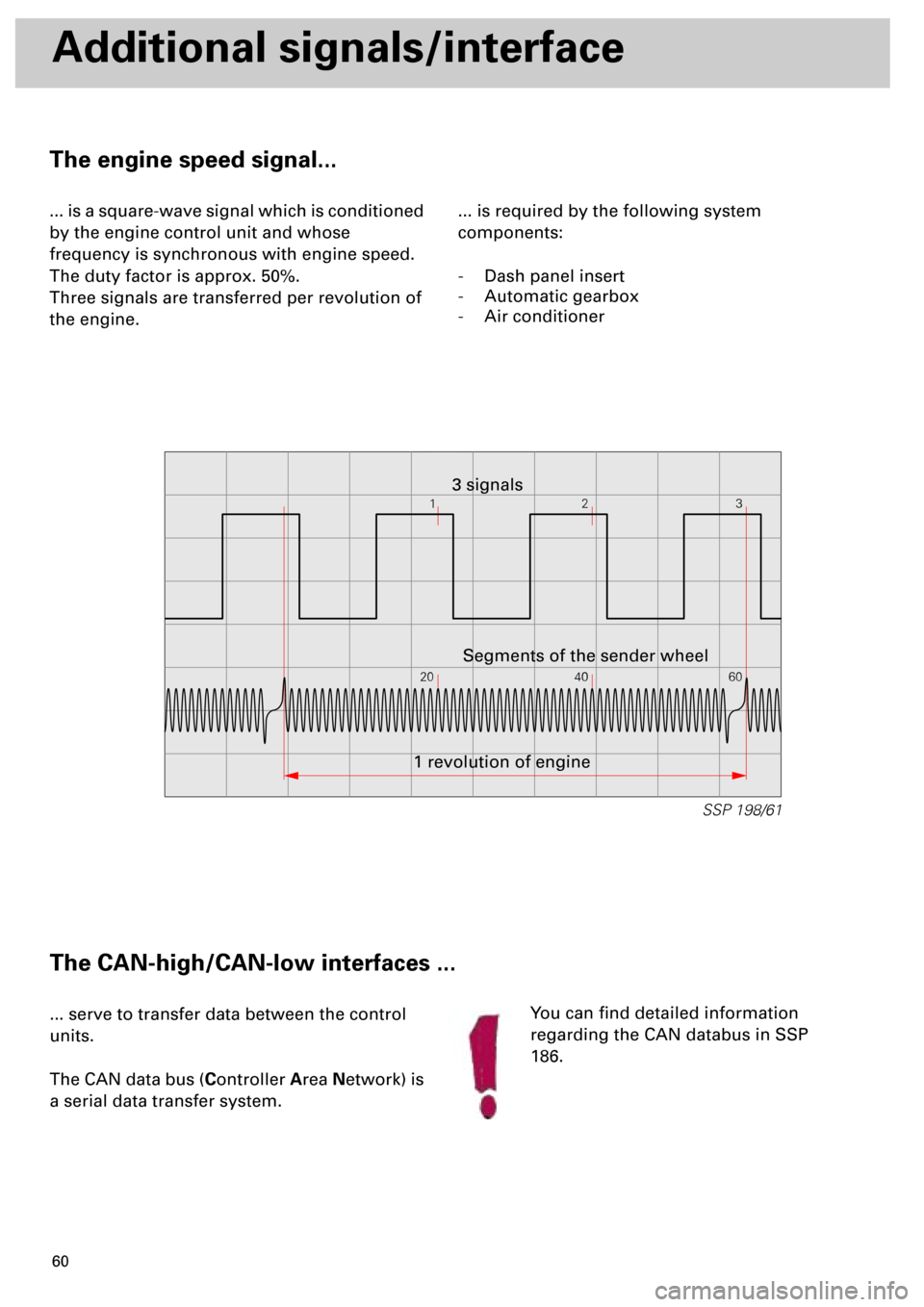

Additional signals/interface

The engine speed signal...

... is a square-wave signal which is conditioned

by the engine control unit and whose

frequency is synchronous with engine speed.

The duty factor is approx. 50%.

Three signals are transferred per revolution of

the engine.... is required by the following system

components:

- Dash panel insert

- Automatic gearbox

- Air conditioner

The CAN-high/CAN-low interfaces ...

... serve to transfer data between the control

units.

The CAN data bus (Controller Area Network) is

a serial data transfer system.You can find detailed information

regarding the CAN databus in SSP

186.

12

20 40 603

SSP 198/61

1 revolution of engineSegments of the sender wheel 3 signals

Page 61 of 72

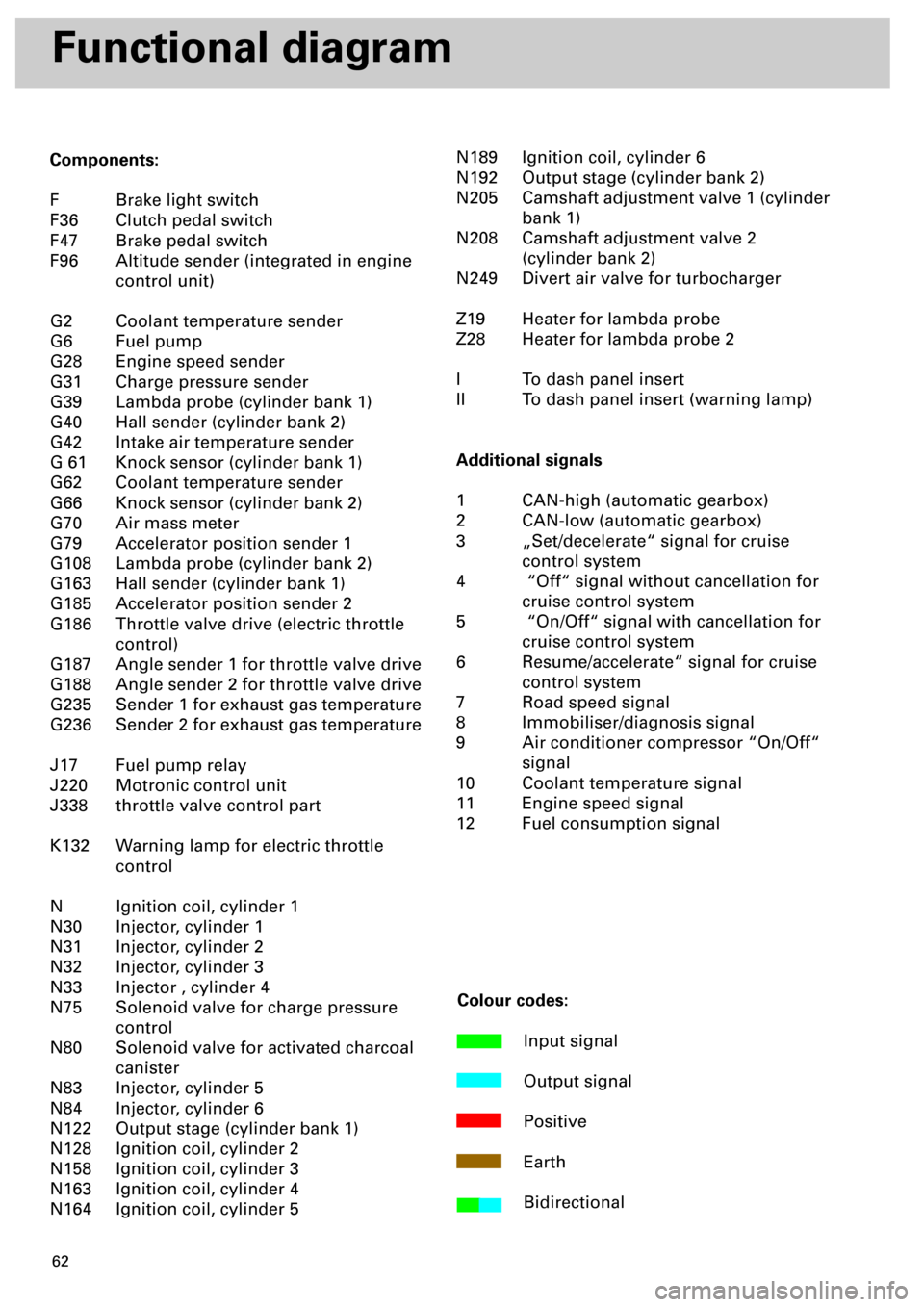

62

Functional diagram

Components:

F Brake light switch

F36 Clutch pedal switch

F47 Brake pedal switch

F96 Altitude sender (integrated in engine

control unit)

G2 Coolant temperature sender

G6 Fuel pump

G28 Engine speed sender

G31 Charge pressure sender

G39 Lambda probe (cylinder bank 1)

G40 Hall sender (cylinder bank 2)

G42 Intake air temperature sender

G 61 Knock sensor (cylinder bank 1)

G62 Coolant temperature sender

G66 Knock sensor (cylinder bank 2)

G70 Air mass meter

G79 Accelerator position sender 1

G108 Lambda probe (cylinder bank 2)

G163 Hall sender (cylinder bank 1)

G185 Accelerator position sender 2

G186 Throttle valve drive (electric throttle

control)

G187 Angle sender 1 for throttle valve drive

G188 Angle sender 2 for throttle valve drive

G235 Sender 1 for exhaust gas temperature

G236 Sender 2 for exhaust gas temperature

J17 Fuel pump relay

J220 Motronic control unit

J338 throttle valve control part

K132 Warning lamp for electric throttle

control

N Ignition coil, cylinder 1

N30 Injector, cylinder 1

N31 Injector, cylinder 2

N32 Injector, cylinder 3

N33 Injector , cylinder 4

N75 Solenoid valve for charge pressure

control

N80 Solenoid valve for activated charcoal

canister

N83 Injector, cylinder 5

N84 Injector, cylinder 6

N122 Output stage (cylinder bank 1)

N128 Ignition coil, cylinder 2

N158 Ignition coil, cylinder 3

N163 Ignition coil, cylinder 4

N164 Ignition coil, cylinder 5N189 Ignition coil, cylinder 6

N192 Output stage (cylinder bank 2)

N205 Camshaft adjustment valve 1 (cylinder

bank 1)

N208 Camshaft adjustment valve 2

(cylinder bank 2)

N249 Divert air valve for turbocharger

Z19 Heater for lambda probe

Z28 Heater for lambda probe 2

I To dash panel insert

II To dash panel insert (warning lamp)

Additional signals

1 CAN-high (automatic gearbox)

2 CAN-low (automatic gearbox)

3 „Set/decelerate“ signal for cruise

control system

4 “Off“ signal without cancellation for

cruise control system

5 “On/Off“ signal with cancellation for

cruise control system

6 Resume/accelerate“ signal for cruise

control system

7 Road speed signal

8 Immobiliser/diagnosis signal

9 Air conditioner compressor “On/Off“

signal

10 Coolant temperature signal

11 Engine speed signal

12 Fuel consumption signal

Colour codes:

Input signal

Output signal

Positive

Earth

Bidirectional

Page 70 of 72

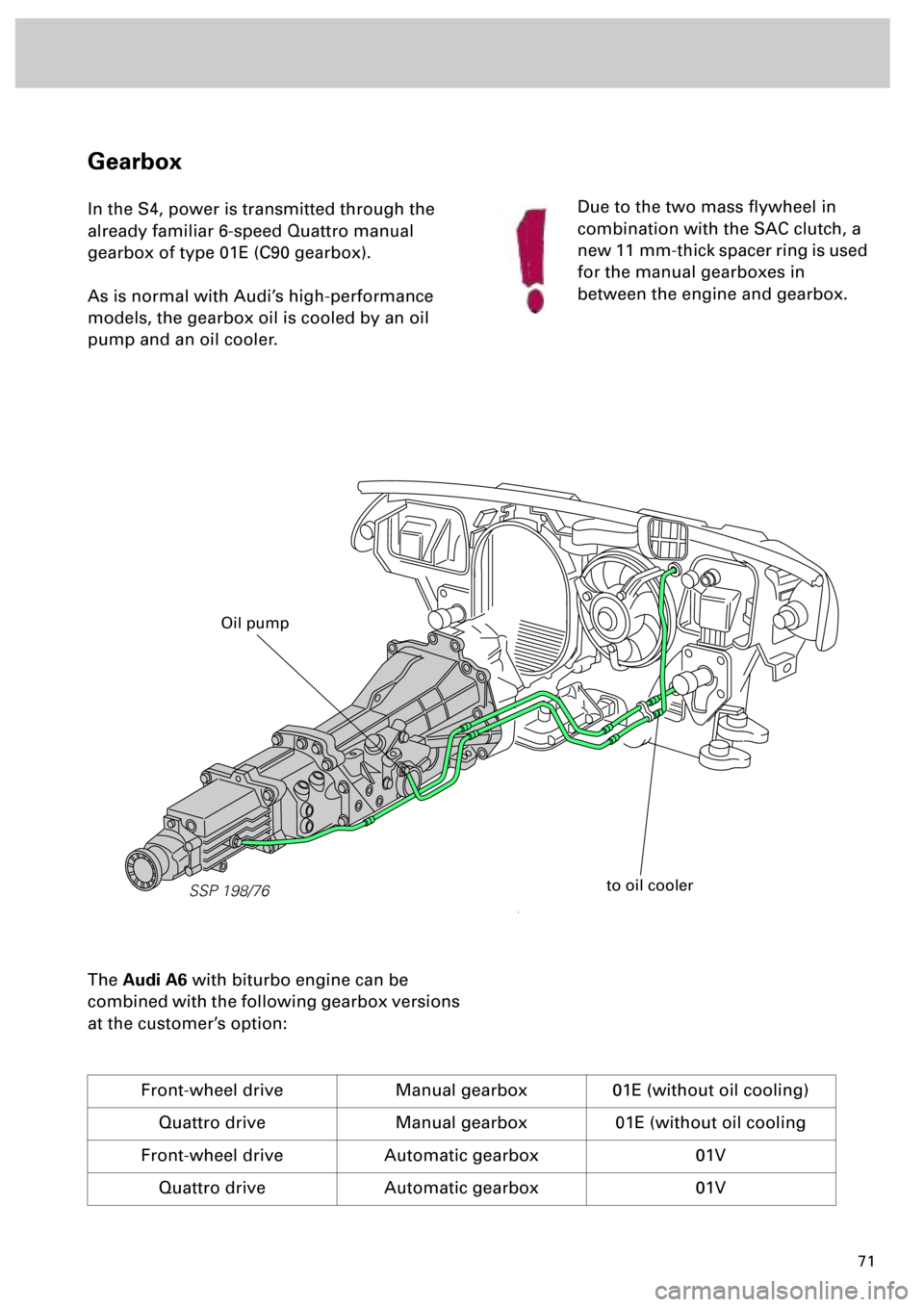

71

Gearbox

In the S4, power is transmitted through the

already familiar 6-speed Quattro manual

gearbox of type 01E (C90 gearbox).

As is normal with Audi’s high-performance

models, the gearbox oil is cooled by an oil

pump and an oil cooler.

The

Audi A6

with biturbo engine can be

combined with the following gearbox versions

at the customer’s option:

Front-wheel drive Manual gearbox 01E (without oil cooling)

Quattro drive Manual gearbox 01E (without oil cooling

Front-wheel drive Automatic gearbox 01V

Quattro drive Automatic gearbox 01V

Due to the two mass flywheel in

combination with the SAC clutch, a

new 11 mm-thick spacer ring is used

for the manual gearboxes in

between the engine and gearbox.

SSP 198/76

to oil cooler

Oil pump