Lambda AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 18 of 72

19

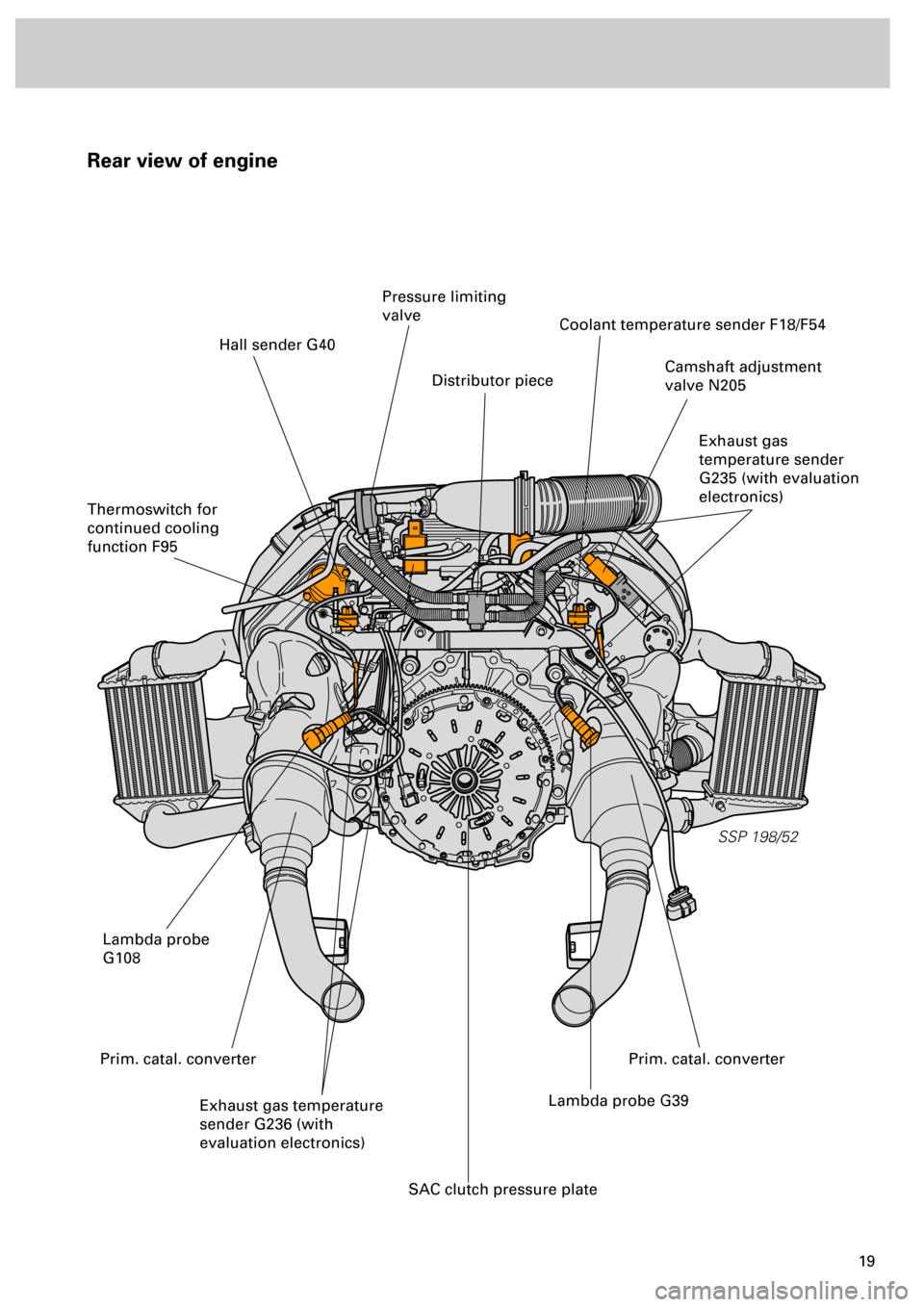

Rear view of engine

SSP 198/52

Hall sender G40

Thermoswitch for

continued cooling

function F95

Pressure limiting

valve

Distributor piece

Coolant temperature sender F18/F54

Camshaft adjustment

valve N205

Exhaust gas

temperature sender

G235 (with evaluation

electronics)

Lambda probe

G108

Exhaust gas temperature

sender G236 (with

evaluation electronics)Lambda probe G39

SAC clutch pressure plate

Prim. catal. converterPrim. catal. converter

Page 23 of 72

24

SSP 198/33

Engine

A new generation of probes is used

in this engine.

The “planar lambda probe“ is an

improvement on the finger-type

lambda probe (refer to chapter on

“Sensors”).

Advantage:

•

Short warm-up time

•

Less heating energy demand

•

Long service life

•

More stable control

characteristic

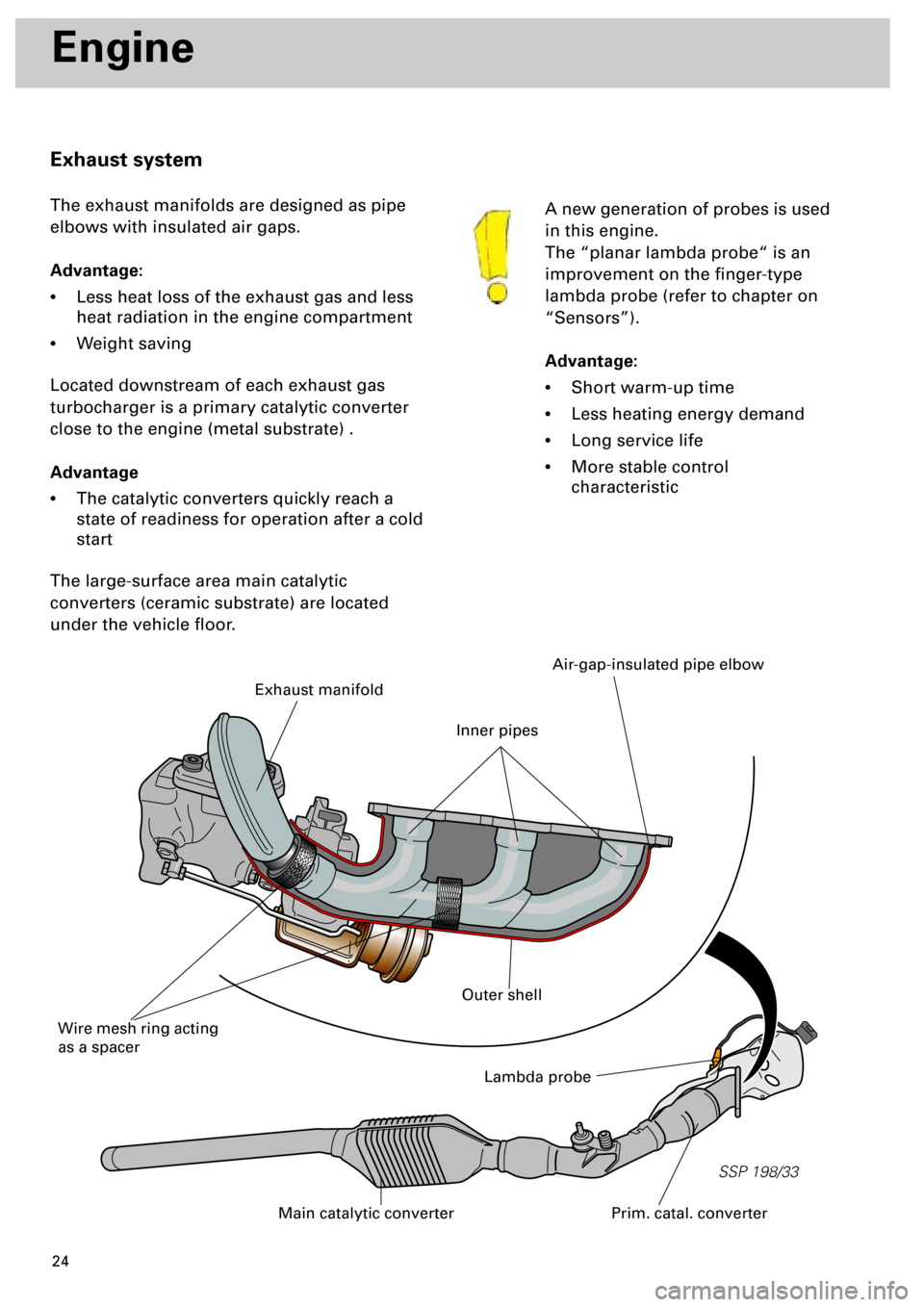

Exhaust system

The exhaust manifolds are designed as pipe

elbows with insulated air gaps.

Advantage:

•

Less heat loss of the exhaust gas and less

heat radiation in the engine compartment

•

Weight saving

Located downstream of each exhaust gas

turbocharger is a primary catalytic converter

close to the engine (metal substrate) .

Advantage

•

The catalytic converters quickly reach a

state of readiness for operation after a cold

start

The large-surface area main catalytic

converters (ceramic substrate) are located

under the vehicle floor.

Lambda probe

Prim. catal. converterMain catalytic converter

Exhaust manifold

Wire mesh ring acting

as a spacer

Air-gap-insulated pipe elbow

Outer shell

Inner pipes

Page 30 of 72

31

Motronic ME 7.1

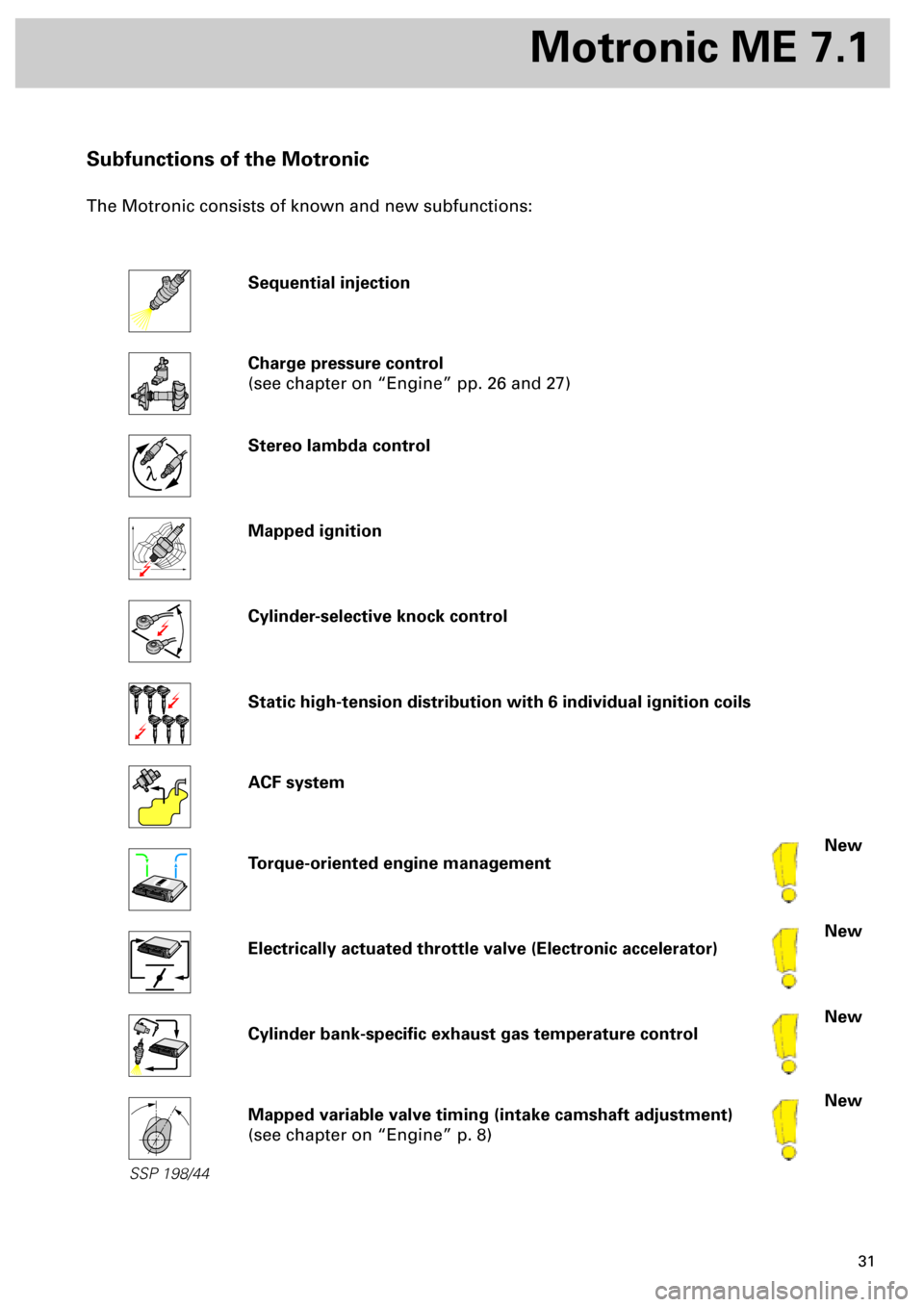

Subfunctions of the Motronic

The Motronic consists of known and new subfunctions:

Sequential injection

Charge pressure control

(see chapter on “Engine” pp. 26 and 27)

Stereo lambda control

Mapped ignition

Cylinder-selective knock control

Static high-tension distribution with 6 individual ignition coils

ACF system

Torque-oriented engine management

Electrically actuated throttle valve (Electronic accelerator)

Cylinder bank-specific exhaust gas temperature control

Mapped variable valve timing (intake camshaft adjustment)

(see chapter on “Engine” p. 8)

New

New

New

New

l

SSP 198/44

Page 31 of 72

32

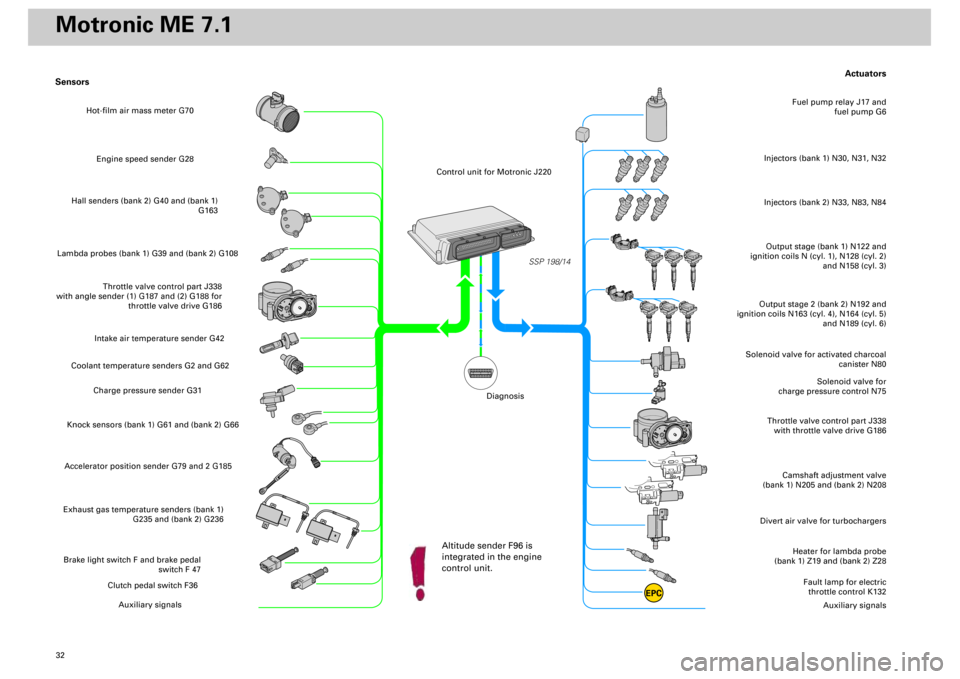

Actuators

Heater for lambda probe

(bank 1) Z19 and (bank 2) Z28

Divert air valve for turbochargers

Camshaft adjustment valve

(bank 1) N205 and (bank 2) N208

Throttle valve control part J338

with throttle valve drive G186

Solenoid valve for

charge pressure control N75

Solenoid valve for activated charcoal

canister N80

Output stage (bank 1) N122 and

ignition coils N (cyl. 1), N128 (cyl. 2)

and N158 (cyl. 3)Injectors (bank 1) N30, N31, N32

Fuel pump relay J17 and

fuel pump G6

Output stage 2 (bank 2) N192 and

ignition coils N163 (cyl. 4), N164 (cyl. 5)

and N189 (cyl. 6)

Fault lamp for electric

throttle control K132

Auxiliary signals

Sensors

Engine speed sender G28

Hall senders (bank 2) G40 and (bank 1)

G163

Lambda probes (bank 1) G39 and (bank 2) G108

Throttle valve control part J338

with angle sender (1) G187 and (2) G188 for

throttle valve drive G186

Intake air temperature sender G42

Coolant temperature senders G2 and G62

Charge pressure sender G31

Knock sensors (bank 1) G61 and (bank 2) G66Accelerator position sender G79 and 2 G185Exhaust gas temperature senders (bank 1)

G235 and (bank 2) G236Brake light switch F and brake pedal

switch F 47

Clutch pedal switch F36

Auxiliary signals

SSP 198/14

EPC

Injectors (bank 2) N33, N83, N84

Hot-film air mass meter G70

Control unit for Motronic J220

Altitude sender F96 is

integrated in the engine

control unit.

Diagnosis

Motronic ME 7.1

Page 45 of 72

46

SSP 198/26

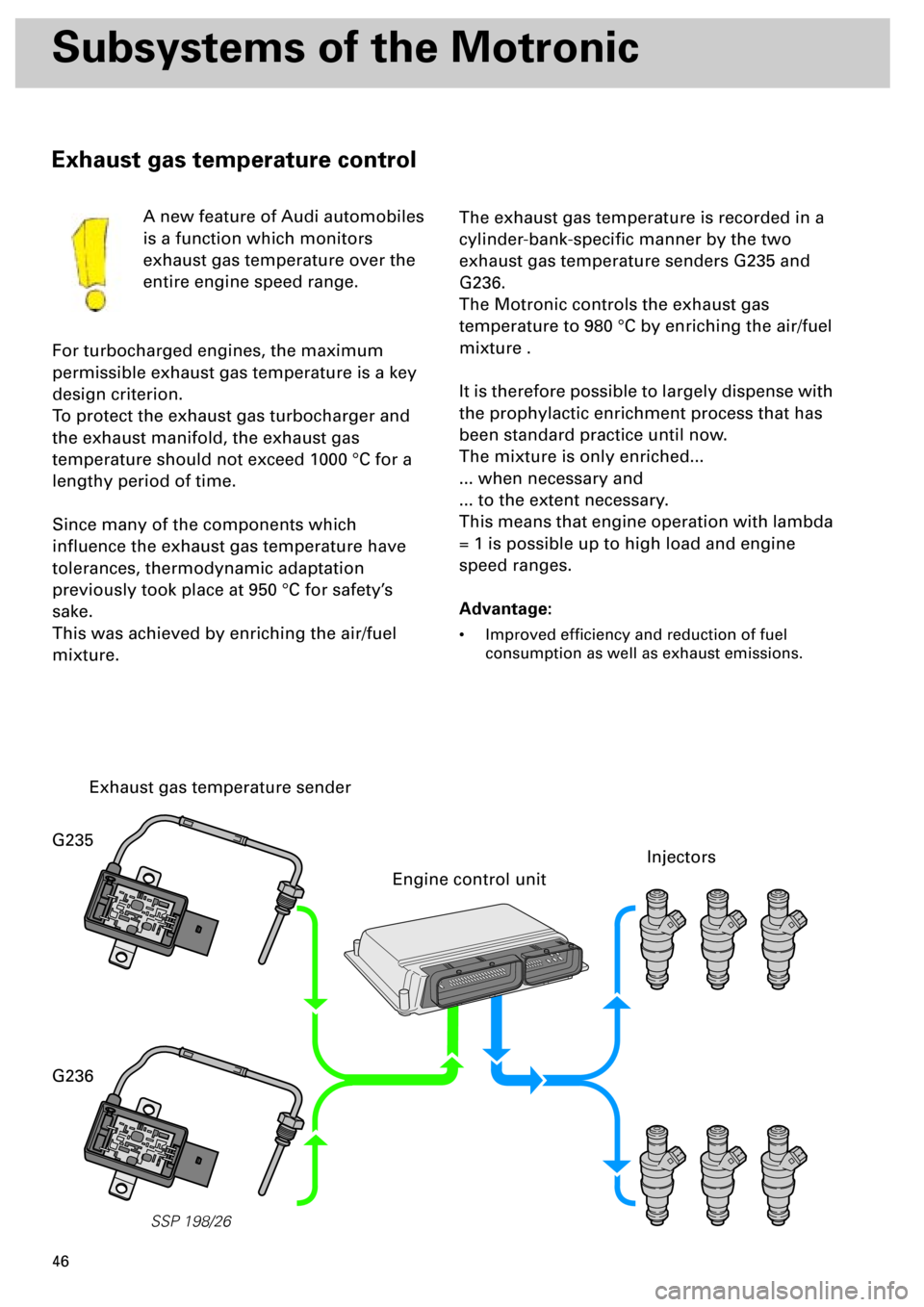

Subsystems of the Motronic

Exhaust gas temperature control

A new feature of Audi automobiles

is a function which monitors

exhaust gas temperature over the

entire engine speed range.

For turbocharged engines, the maximum

permissible exhaust gas temperature is a key

design criterion.

To protect the exhaust gas turbocharger and

the exhaust manifold, the exhaust gas

temperature should not exceed 1000 °C for a

lengthy period of time.

Since many of the components which

influence the exhaust gas temperature have

tolerances, thermodynamic adaptation

previously took place at 950 °C for safety’s

sake.

This was achieved by enriching the air/fuel

mixture.

The exhaust gas temperature is recorded in a

cylinder-bank-specific manner by the two

exhaust gas temperature senders G235 and

G236.

The Motronic controls the exhaust gas

temperature to 980 °C by enriching the air/fuel

mixture .

It is therefore possible to largely dispense with

the prophylactic enrichment process that has

been standard practice until now.

The mixture is only enriched...

... when necessary and

... to the extent necessary.

This means that engine operation with lambda

= 1 is possible up to high load and engine

speed ranges.

Advantage:

• Improved efficiency and reduction of fuel

consumption as well as exhaust emissions.

Exhaust gas temperature sender

Engine control unit

Injectors

G235

G236

Page 51 of 72

52

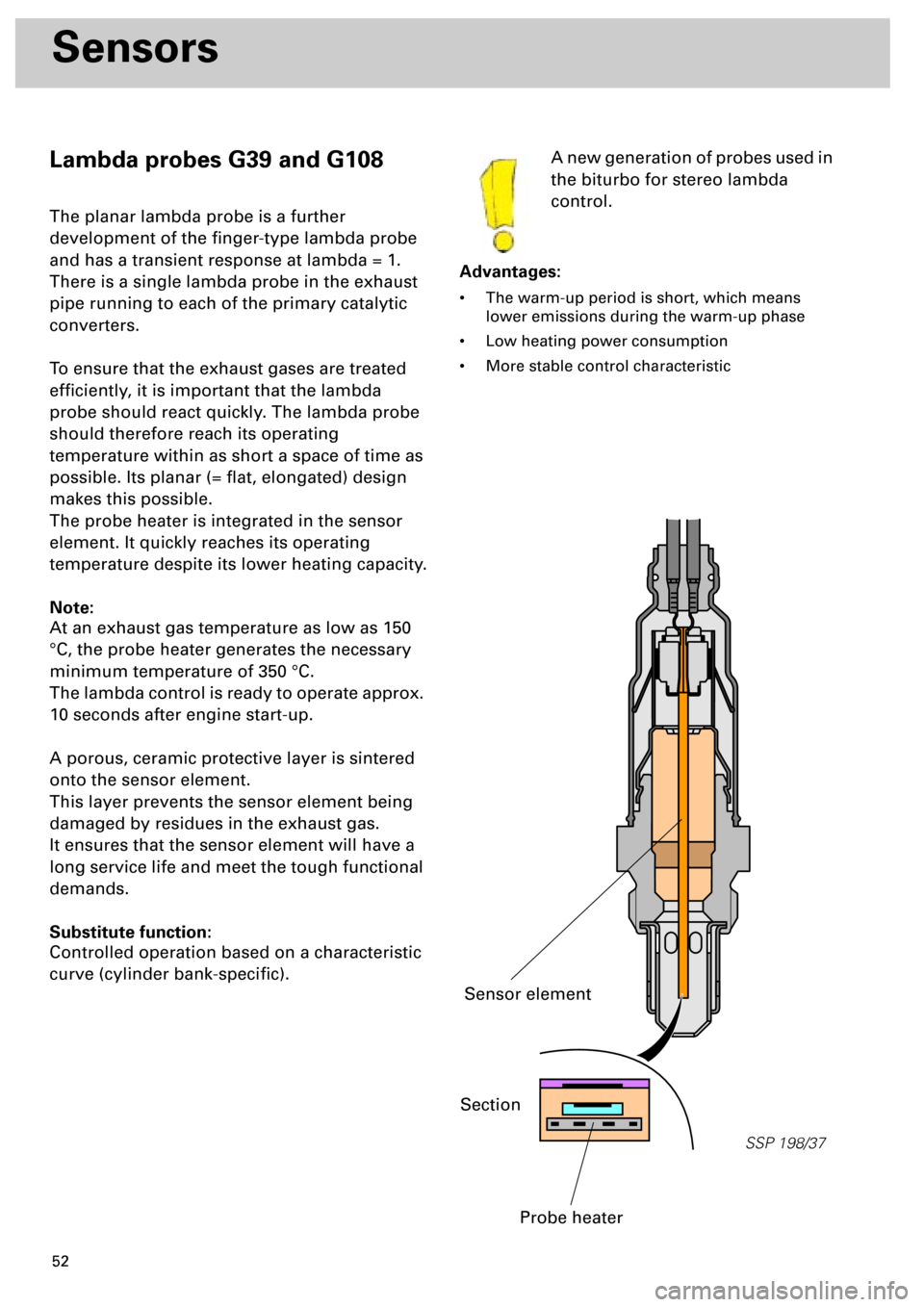

Sensors

Lambda probes G39 and G108

The planar lambda probe is a further

development of the finger-type lambda probe

and has a transient response at lambda = 1.

There is a single lambda probe in the exhaust

pipe running to each of the primary catalytic

converters.

To ensure that the exhaust gases are treated

efficiently, it is important that the lambda

probe should react quickly. The lambda probe

should therefore reach its operating

temperature within as short a space of time as

possible. Its planar (= flat, elongated) design

makes this possible.

The probe heater is integrated in the sensor

element. It quickly reaches its operating

temperature despite its lower heating capacity.

Note:

At an exhaust gas temperature as low as 150

°C, the probe heater generates the necessary

minimum temperature of 350 °C.

The lambda control is ready to operate approx.

10 seconds after engine start-up.

A porous, ceramic protective layer is sintered

onto the sensor element.

This layer prevents the sensor element being

damaged by residues in the exhaust gas.

It ensures that the sensor element will have a

long service life and meet the tough functional

demands.

Substitute function:

Controlled operation based on a characteristic

curve (cylinder bank-specific).A new generation of probes used in

the biturbo for stereo lambda

control.

Advantages:

• The warm-up period is short, which means

lower emissions during the warm-up phase

• Low heating power consumption

• More stable control characteristic

SSP 198/37

Section

Probe heater

Sensor element

Page 61 of 72

62

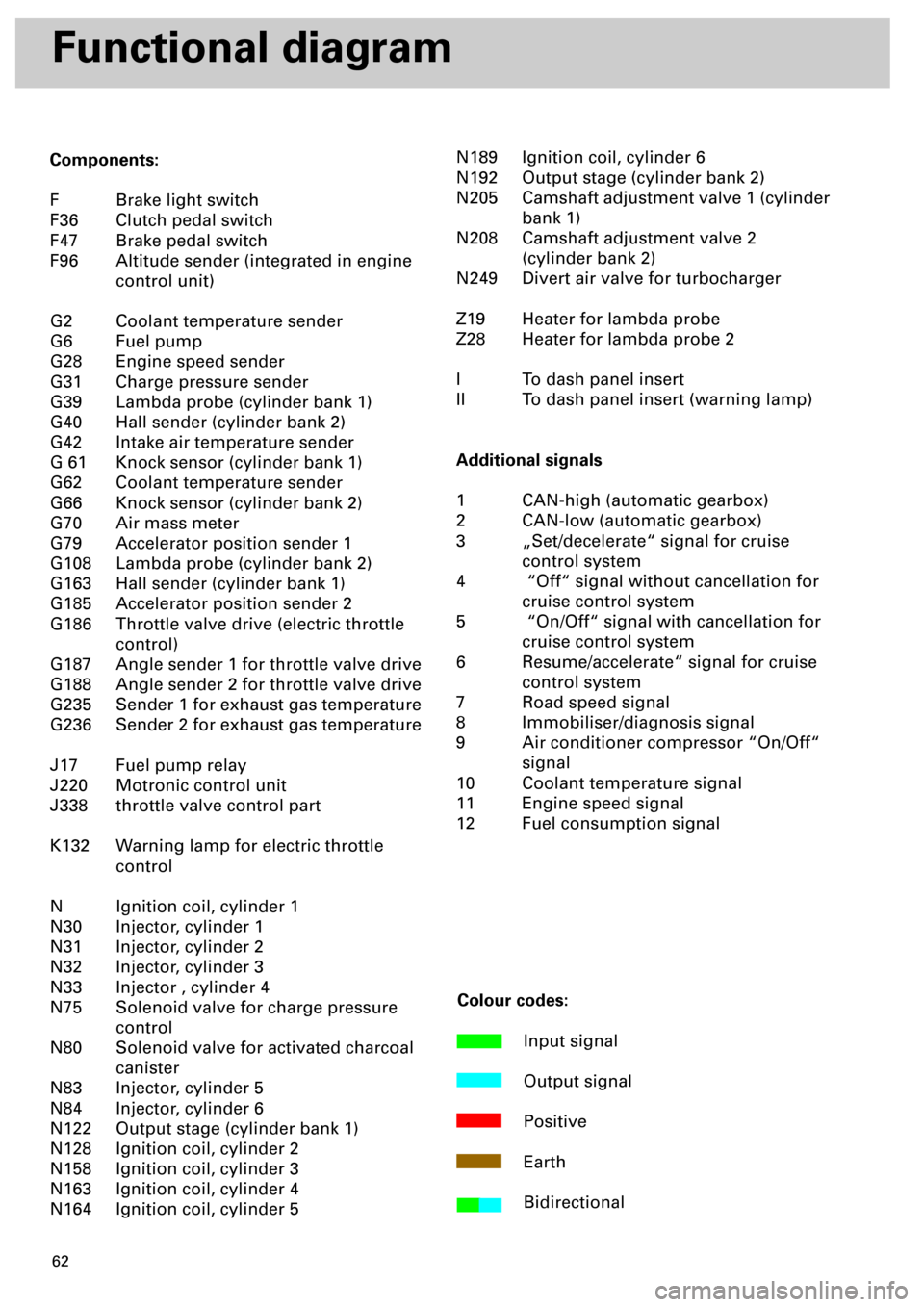

Functional diagram

Components:

F Brake light switch

F36 Clutch pedal switch

F47 Brake pedal switch

F96 Altitude sender (integrated in engine

control unit)

G2 Coolant temperature sender

G6 Fuel pump

G28 Engine speed sender

G31 Charge pressure sender

G39 Lambda probe (cylinder bank 1)

G40 Hall sender (cylinder bank 2)

G42 Intake air temperature sender

G 61 Knock sensor (cylinder bank 1)

G62 Coolant temperature sender

G66 Knock sensor (cylinder bank 2)

G70 Air mass meter

G79 Accelerator position sender 1

G108 Lambda probe (cylinder bank 2)

G163 Hall sender (cylinder bank 1)

G185 Accelerator position sender 2

G186 Throttle valve drive (electric throttle

control)

G187 Angle sender 1 for throttle valve drive

G188 Angle sender 2 for throttle valve drive

G235 Sender 1 for exhaust gas temperature

G236 Sender 2 for exhaust gas temperature

J17 Fuel pump relay

J220 Motronic control unit

J338 throttle valve control part

K132 Warning lamp for electric throttle

control

N Ignition coil, cylinder 1

N30 Injector, cylinder 1

N31 Injector, cylinder 2

N32 Injector, cylinder 3

N33 Injector , cylinder 4

N75 Solenoid valve for charge pressure

control

N80 Solenoid valve for activated charcoal

canister

N83 Injector, cylinder 5

N84 Injector, cylinder 6

N122 Output stage (cylinder bank 1)

N128 Ignition coil, cylinder 2

N158 Ignition coil, cylinder 3

N163 Ignition coil, cylinder 4

N164 Ignition coil, cylinder 5N189 Ignition coil, cylinder 6

N192 Output stage (cylinder bank 2)

N205 Camshaft adjustment valve 1 (cylinder

bank 1)

N208 Camshaft adjustment valve 2

(cylinder bank 2)

N249 Divert air valve for turbocharger

Z19 Heater for lambda probe

Z28 Heater for lambda probe 2

I To dash panel insert

II To dash panel insert (warning lamp)

Additional signals

1 CAN-high (automatic gearbox)

2 CAN-low (automatic gearbox)

3 „Set/decelerate“ signal for cruise

control system

4 “Off“ signal without cancellation for

cruise control system

5 “On/Off“ signal with cancellation for

cruise control system

6 Resume/accelerate“ signal for cruise

control system

7 Road speed signal

8 Immobiliser/diagnosis signal

9 Air conditioner compressor “On/Off“

signal

10 Coolant temperature signal

11 Engine speed signal

12 Fuel consumption signal

Colour codes:

Input signal

Output signal

Positive

Earth

Bidirectional