AUDI S6 2009 Owners Manual

Manufacturer: AUDI, Model Year: 2009, Model line: S6, Model: AUDI S6 2009Pages: 398, PDF Size: 43 MB

Page 361 of 398

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ ffllll

•

Conn ect POSITIVE (+ ) to PO SITIVE (+ ) (r ed )

- Open the red cover on the pos itive pole => page 358,

fig. 270.

1. Connect one end of the positive cable (red) on the

jump

start bolt=>

page 358, fig. 27 1 G) (Bolts under red cover

= "positive") of the vehicle to be started @.

2. Connect the other end to the positive terminal@ of the

booster battery ®·

Conn ect NEGATIVE (- ) to NEGATIVE (-) (black )

3. Connect one end to the negat ive termi nal 0 of t he

boos ter battery ®·

4 . Connect the other end of the negative cable (black) to the

jump sta rt bolt 0 (Bolts with hex head = "n egative") of

the vehicle to be s tarted @.

Startin g th e e ngin e

-Start the engine of the veh icle w ith the booster battery .

Run t he engine at a moderate speed .

- Start engine with discharged ve hicle battery in the usual

ma nner.

- If the engine fails to s tart: do not keep the star ter

cranking for longer than 10 seconds. Wait f or about

30 seconds and then try again.

- With engine running, remove jumper cables from both

vehicles in the exact reverse order.

- Close the red cover on the positive pole.

The battery is vented to the outside to prevent gases from entering

the vehic le interior . Make sure that the jumper clamps are well connected with their

metal parts in full contact with the battery

t erminals .

& WARNING

To avoid seriou s per sonal in jur y a nd d amage to the vehicle , heed

a ll wa rning s and in stru ction s o f th e jum per ca ble man ufa cturer . If

in doubt , call for ro ad serv ice.

• Jump er c able s must b e lo ng eno ugh so that the vehi cle s d o not

touch .

• When conne cting jumpe r cable s, ma ke sure th at the y cann ot

g et caught in an y mo ving p arts i n the engine comp art m ent .

• Before you che ck anyth ing in the en gin e com partm ent , a lwa ys

r ea d and h eed all W ARNIN GS~ pag e 293, "E ngine compa rtm ent ".

0 Note

Improper hook -up of jumper cables can ruin the generato r.

• Always connect POSITIVE(+) to POS ITIVE( +), and NEGATIVE( -) to

NEGATIVE( -) ground post of the battery manager control unit.

• Check that al l screw p lugs on the battery ce lls are screwed in

firm ly . If not, tighten plugs prior to connecting clamp on negative

battery termi nal.

• Please note that the procedure for connecting a jumper cab le as

described above applies specifical ly to the case of your vehicle

being jump started. When you are giving a jump start to another

vehicle, do

not connect the negative(-) cable to the negative (-1

terminal on the discharged battery©~

page 358, fig. 271. Instead,

securely connect the negative ( -1 cable to either a solid metal

component that is firmly bolted to the engine b lock or to the engine

block itself . If the battery that is being charged does not vent to the

outside, escap ing battery gas could ignite and exp lode! •

Do-it-yourself service

Page 362 of 398

lll'I...__E_ m _ e _r.;:g '-e_ n_ c-=y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

Emergency towing with commercial

tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by commercial tow truck

operators who know how to operate their equipment safely.

• Never tow your Audi, towing will cause damage to the engine

and transmission.

• Never wrap the safety chains or winch cables around the brake

lines.

• To prevent unnecessary damage, your Audi must be transported

with a flat bed truck.

• To load the vehicle on to the flat bed, use the towing loop found

in the vehicle tools and attach to the front or rear anchorage

~ page 360 and~ page 361.

& WARNING

A vehicle being towed is not safe for passengers. Never allow

anyone to ride in a vehicle being towed, for any reason. •

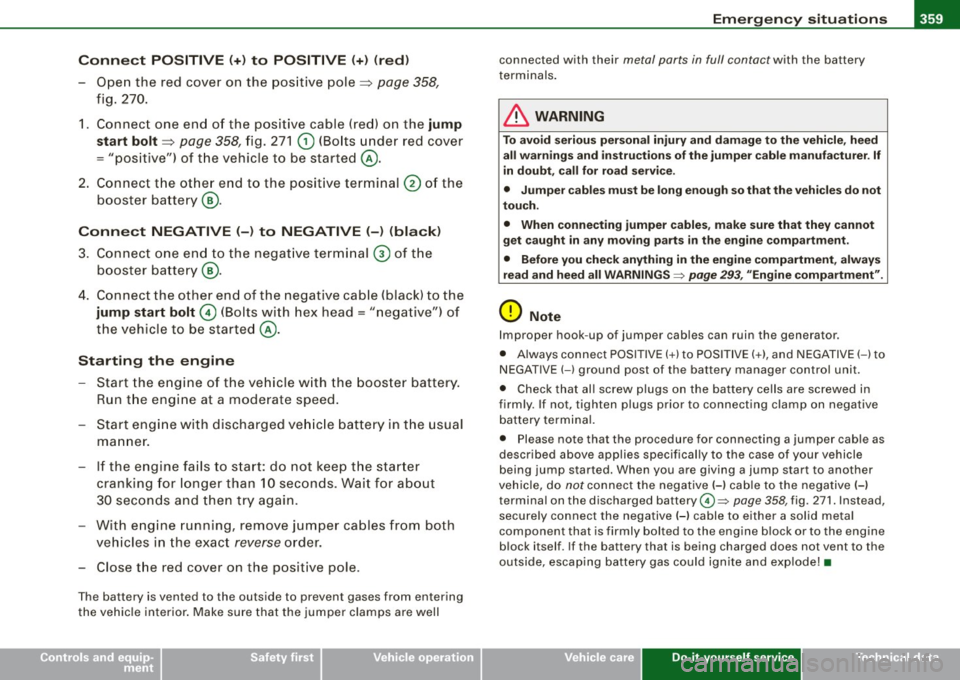

Front towing loop

Do not install the front towing loop until it is needed.

Fig. 272 Front

bumper: removing the

cover cap

Fig . 273 Front

bumper: screwing in

the towing loop

The towing loop fits into the threaded hole located on the

right side of the front bumper and covered by a small cover

when not in use.

- Remove the towing loop from the vehicle toolkit

=>

page 342.

- Press the cover in by applying short sharp pressure to the

bottom part to release it from the bumper => fig. 272.

- Screw the towing loop tightly into the threaded hole as

far as it will go=> fig. 273. ..,

Page 363 of 398

________________________________________________ E_ m_ e_r ,,::g c..e_ n _ c..::y;._ s_ i_t _u _a_ t_ i_o _n_ s _ ___._

When it is no longer needed, unscrew the towing loop and put it

back into the vehicle toolkit. Be sure to have the towing loop stored

in the vehicle at all times.

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

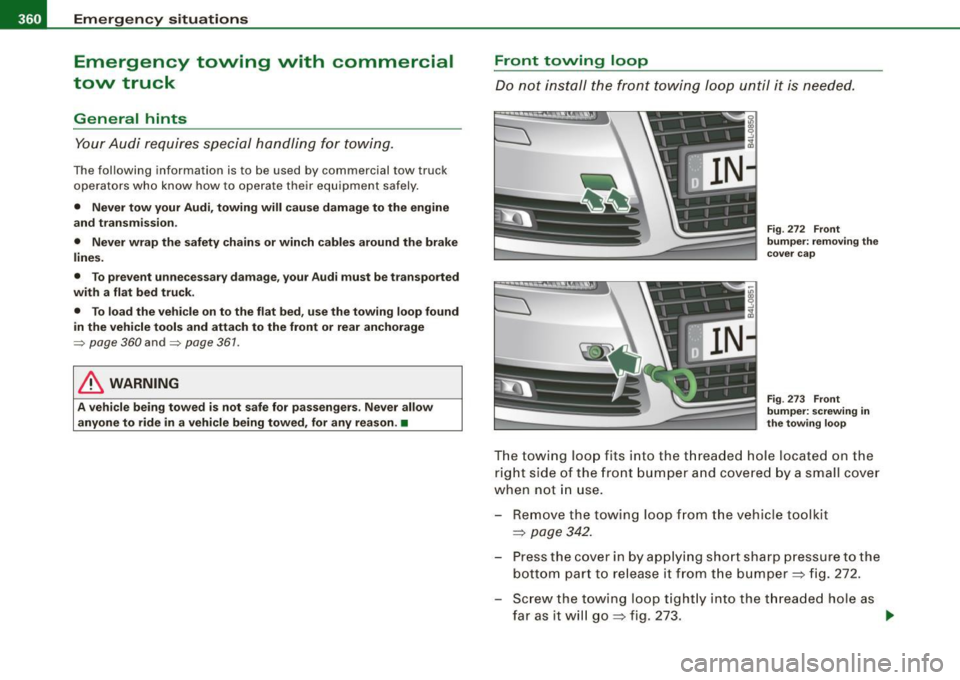

Rear towing loop

Do not install the rear towing loop until it is needed.

Fig. 274 Rear bumper:

screwing in the towing

loop

On the right side under the rear bumper there is a threaded

hole for the towing loop. The threaded hole is protected by

a cover.

- Remove the towing loop from the vehicle toolkit

=> page 342.

- Pull the protective cover out of the threaded hole

~ fig. 274 .

- Screw the towing loop tightly into the threaded hole as far as it will go .

When it is no longer needed, unscrew the towing loop and put it

back into the vehicle toolkit. Be sure to have the towing loop stored

in the vehicle at all times.

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

Loading the vehicle onto a f lat bed truck

Front hook up

Fig . 275 Vehicle on flat

bed truck

- Align the vehicle with the centerline of the car carrier

ramp.

- Attach the winch hook to the front towline eye previously

installed .

Rear hook up

-Align the vehicle with the centerline of the car carrier

ramp.

Vehicle care Do-it-yourself service irechnical data

Page 364 of 398

lll'I...__E_ m _ e _r.;:g '-e_ n_ c-=y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

- Attach the winch hook to the rear towline eye previously

installed.

[ i ) Tips

Check carefully to make sure the hook -up is secure before moving

the ca r up the flatbed t ruck ramp. •

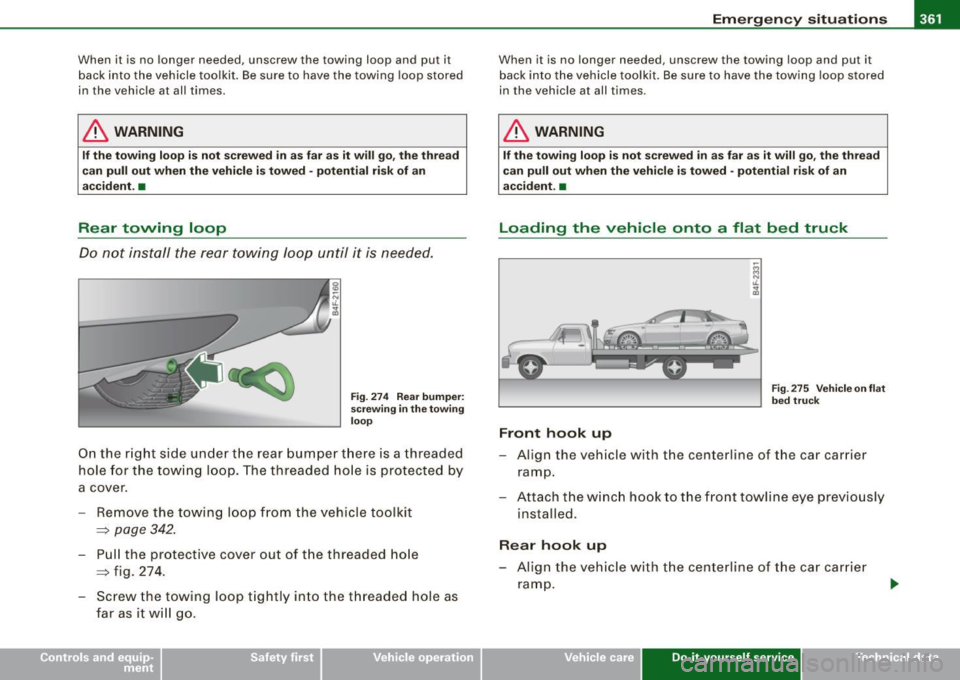

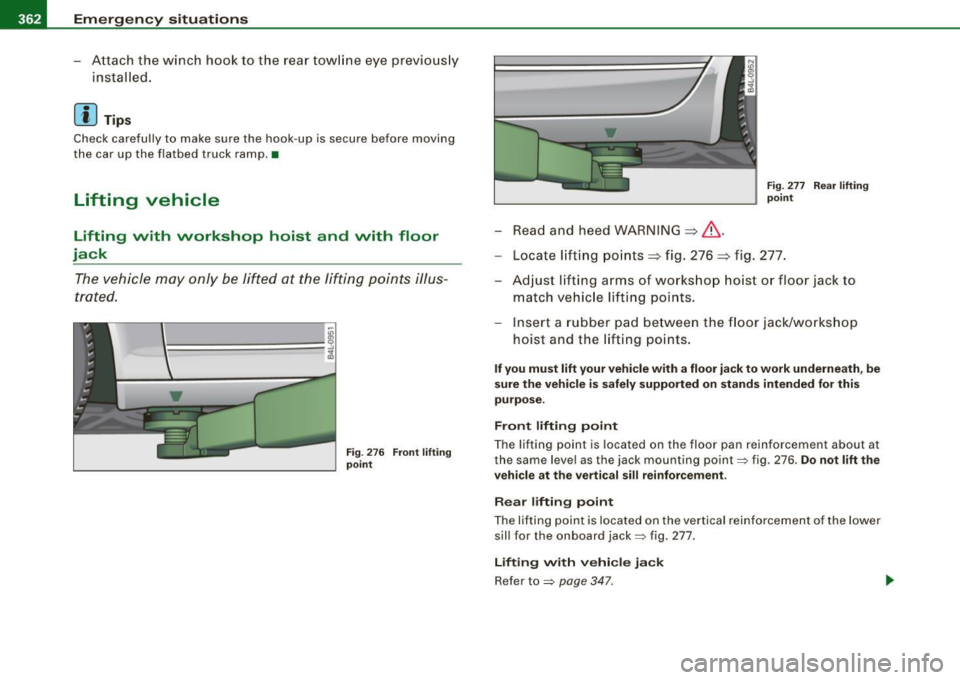

Lifting vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting points illus

trated.

~ ~

\ ======== ======= ~ ;,

Fig. 276 Front lifting

point

- Read and heed WARNING::::,& .

Fig. 277 Rear lifting

point

-Locate lifting points::::, fig. 276 ::::, fig. 277.

- Adjust lifting arms of workshop hoist or floor jack to

match vehicle lifting points.

- Insert a rubber pad between the floor jack/workshop

hoist and the lifting points.

If you must lift your vehicle with a floor jack to work underneath, be

sure the vehicle is safely supported on stands intended for this

purpose.

Front lifting point

The lifting point is located on the floor pan reinforcement about at

the same level as the jack mounting point:::::, fig. 276 .

Do not lift the

vehicle at the vertical sill reinforcement.

Rear lifting point

The lifting point is located on the vertical reinforcement of the lower

sill for the on board jack:::::, fig. 277.

Lifting with vehicle jack

Refer to :::::, page 347 .

Page 365 of 398

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ lllll

•

& WARNING

• To reduce the risk of serious injury and vehicle damage.

-Always lift the vehicle only at the special workshop hoist and

floor jack lift points illustrated

=> page 362, fig. 276 and

=> page 362, fig. 277.

- Failure to lift the vehicle at these points could cause the

vehicle to tilt or fall from a lift if there is a change in vehicle

weight distribution and balance. This might happen, for

example, when heavy components such as the engine block or

transmission are removed.

• When removing heavy components like these, anchor vehicle

to hoist or add corresponding weights to maintain the center of

gravity. Otherwise, the vehicle might tilt or slip off the hoist,

causing serious personal injury.

0 Note

• Be aware of the following points before lifting the vehicle:

- The vehicle should never be lifted or jacked up from under

neath the engine oil pan, the transmission housing, the front or

rear axle or the body side members . This could lead to serious

damage.

- To avoid damage to the underbody or chassis frame, a rubber

pad must be inserted between the floor jack and the lift points.

- Before driving over a workshop hoist, check that the vehicle

weight does not exceed the permissible lifting capacity of the hoist .

- Before driving over a workshop hoist, ensure that there is

sufficient clearance between the hoist and low parts of the

vehicle. •

Do-it-yourself service

Page 366 of 398

_,

Page 367 of 398

~

.> -

\\

o:i,

o.0. \'?> ...........

... ~ 'A

Page 368 of 398

111!1....__G_ e_ n_ e_r_a _ l_ i _n_ f_ o_ rm_ a _t_io _ n _______________________________________________ _

General information

Explanation of technical data

Some of the technical data listed in this manual requires

further explanation.

The technical data for your vehicle is listed in the charts starting on

~ page 369 . This section provides general information, notes and

restrictions which app ly to this data. •

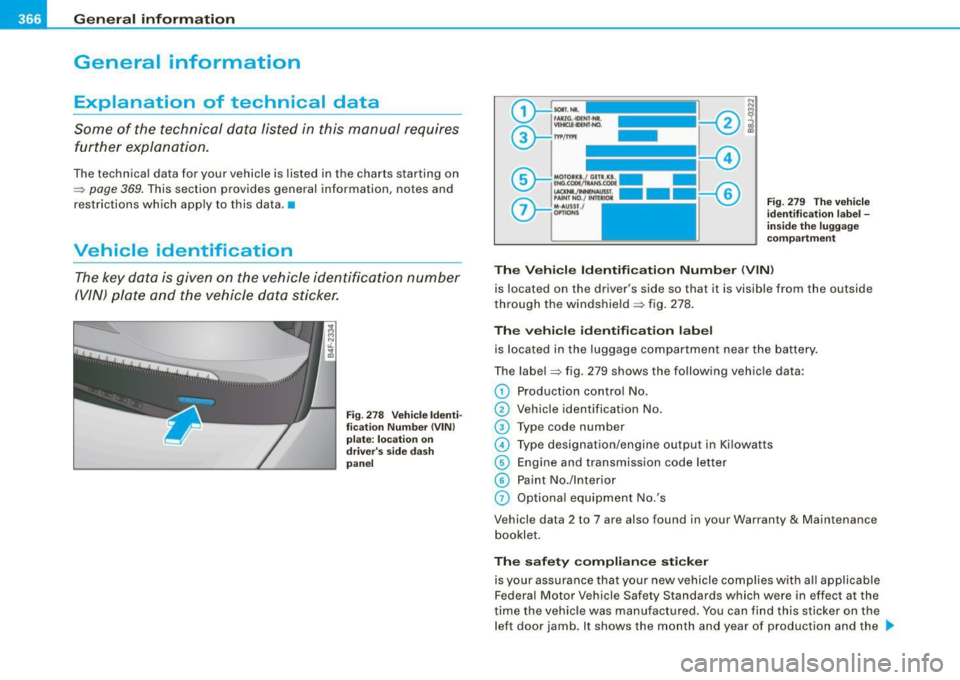

Vehicle identification

The key data is given on the vehicle identification number

(VIN) pla te and the vehicle data st icker.

F ig. 278 Ve hicl e Id enti

fi ca tion Number (V IN)

pl ate : lo cation on

d riv er 's s ide das h

pan el F

ig . 2 79 The vehi cle

i d e ntifi cat ion la be l -

i nside the lug gag e

com partm ent

The Vehicle Id enti fication Numb er (V IN)

is located on the driver's side so that it is visible from the outside

through the windshield ~ fig . 278.

Th e veh icle i de ntifi cat ion lab el

is located in the luggage compar tment near the battery.

The label~ fig. 279 shows the following vehic le data :

0 Production control No.

0 Vehicle identification No.

G) Type code number

© Type designation/engine output in Ki lowatts

@ Engine and transmission code letter

© Paint No./lnterior

0 Optiona l equipment No.'s

Vehicle data 2 to 7 are also found in your Warranty

& Maintenance

booklet.

Th e s afet y co mpli ance sti cker

is your assurance that your new vehicle complies with a ll app licable

Federa l Motor Vehicle Safety Standards which were in effect at the

time the vehicle was manu factured. You can find this sticker on the

left door jamb . It shows the month and year of production and the .._

Page 369 of 398

_________________________________________________ G_ e_ n_ e_r _a _l_ i_n _f_o _ r_ m_ a_ t _i _o _ n __ PII

vehicle identification number of your vehicle (perforation) as well as

the Gross Vehicle Weight Rating (GVWR) and the Gross Axle Weight

Rating (GAWRl.

The high voltage warning label is located on the lock carrier.

The spark ignition system complies with the Canadian standard ICES-002. •

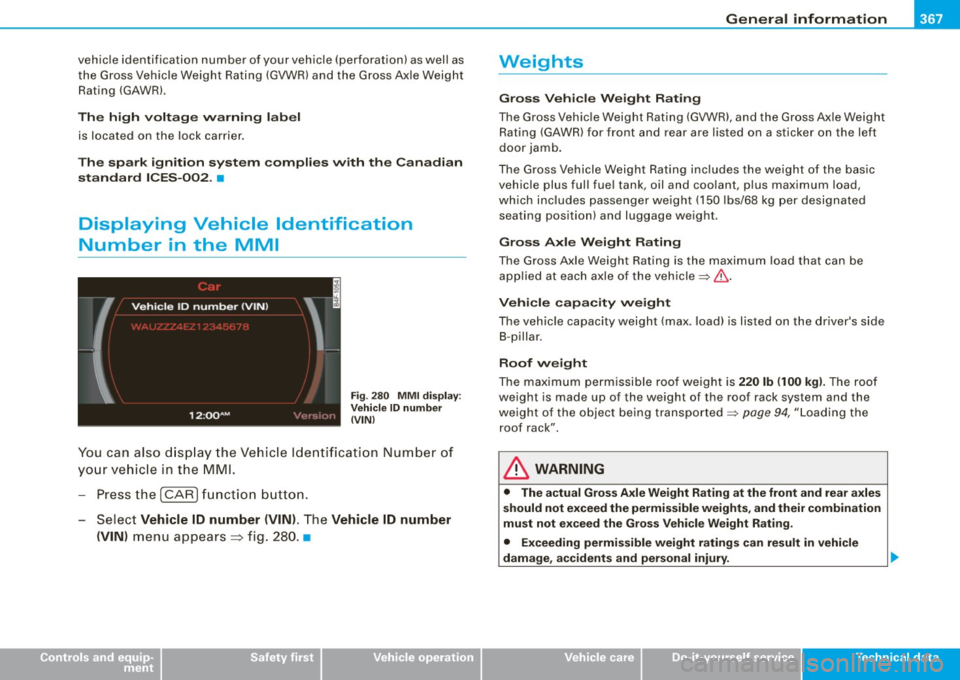

Displaying Vehicle Identification

Number in the MMI

Fig. 280 MMI display:

Vehicle ID number

(VIN)

You can also display the Vehicle Identification Number of

your vehicle in the MMI.

- Press the

(CARI function button.

- Select

Vehicle ID number (VIN). The Vehicle ID number

(VIN)

menu appears=> fig. 280. •

Controls and equip

ment Safety first Vehicle operation

Weights

Gross Vehicle Weight Rating

The Gross Vehicle Weight Rating (GVWR), and the Gross Axle Weight

Rating (GAWR) for front and rear are listed on a sticker on the left

door jamb.

The Gross Vehicle Weight Rating includes the weight of the basic

vehicle plus full fuel tank, oil and coolant, plus maximum load,

which includes passenger weight (150 lbs/68 kg per designated

seating position) and luggage weight .

Gross Axle Weight Rating

The Gross Axle Weight Rating is the maximum load that can be

applied at each axle of the vehicle~&.

Vehicle capacity weight

The vehicle capacity weight (max. load) is listed on the driver's side

8-pi Ila r.

Roof weight

The maximum permissible roof weight is 220 lb (100 kg). The roof

weight is made up of the weight of the roof rack system and the

weight of the object being transported

~ page 94, "Loading the

roof rack".

& WARNING

• The actual Gross Axle Weight Rating at the front and rear axles

should not exceed the permissible weights, and their combination

must not exceed the Gross Vehicle Weight Rating.

• Exceeding permissible weight ratings can result in vehicle

damage, accidents and personal injury.

Vehicle care Do-it-yourself service Tec hn ica l da ta

Page 370 of 398

___ G_ e_n_ e_ r_ a _l _i_n _f _o _ r_ m_ a_ t_ i_ o _ n ________________________________________________ _

0 Note

• The vehicle capacity weight figures apply when the load is

distributed evenly in the vehicle (passengers and luggage). When

transporting a heavy load in the luggage compartment, carry the

load as near to the rear axle as possible so that the vehicle's

handling is not impaired.

• Do not exceed the maximum permissible axle loads or the

maximum gross vehic le weight. Always remember that the vehic le's

handling will be affected by the extra load. Therefore, adjust your

speed accordingly .

• Always observe local regulations. •

Dimensions

The specifications refer to the basic model. Differences may occur

depending on the mode l type and options ordered, for example, tire

sizes.

0 Note

When driving up steep ramps, on rough roads, over curbs, etc. it is

important to remember that some parts of your vehicle, such as

spoilers or exhaust system components, may be close to the

ground. Be careful not to damage them. •