wheel bolts AUDI S6 2009 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2009, Model line: S6, Model: AUDI S6 2009Pages: 398, PDF Size: 43 MB

Page 333 of 398

Tires and wheels -________________ w-.

•

ture. For exam ple , t he numbers 2 208 mean that the tire was

pr od uce d in the 22nd w eek o f 20 08 . T he ot her num bers a re

marketing cod es that may or may not b e used by the tire manufac

tu rer. This inf or ma tion is use d to conta ct consum ers if a tir e defec t

requires a recall.

Audi Original tire

Ti res with the identification "AO" or "R O" hav e been specia lly

m atc h ed wi th you r A ud i. We re comm end u sing on ly these tire s

becaus e they meet the highest standards re garding safety and

dri ving c haracter istic s when used correctly . You r aut horized Audi

d ealer w ill glad ly prov ide you with mor e information .

Tire ply composition and materials used

The number of p li e s indicates the numb er of layers of rubber -coat ed

fabric i n the tir e . In genera l, the grea te r the number of pl ies, th e

mo re we ig ht a t ire can suppo rt. T ire ma nufactu rers also must ind i

cate the materia ls in the tire, which include steel, ny lon, polyester,

and oth ers .

Maximum Load Rating

This numb er ind icat es the maximum load in kil ograms and pou nds

th at ca n be ca rried by t he tire.

Tire qual ity grading for treadvvear , traction , and

temperature resistance

T read wear , traction and temperature grades::::;, page 332.

Maximum Permissible Inflation Pressure

This number is the greatest amount of air pressure that should ever

be put in the t ir e u nder nor mal d riving co nd it ion s.

& WARNING

• Using incorrect or unmatched tires and / or wheels or improper

tire and wheel combinations can lead to loss of control , collision

and serious personal injury .

& WARNING (continued )

• Always use tires, rims and wheel bolts that meet the specifica

tions of original factory -installed tires or other combinations that

have been spec ifically approved by the veh icle manufacturer .

• Tires age even if they are not being used and can fail suddenly,

especially at high speeds . Tires that are more than 6 years old can

only be used in an emergency and then with special care and at

lower speeds .

• Never mount used tires on your vehicle if you are not sure of

their "previous history." Old used tires may have been damaged

even though the damage cannot be seen that can lead to sudden

tire failure and loss of vehicle control.

• All four wheels must be fitted with radial tires of the same type ,

size (rolling circumference ) and the same tread pattern. Driving

with different tires reduces vehicle handling and can lead to a loss of control.

• If the spare tire is not the same as the tires that are mounted

on the vehicle - for example with winter tires - only use the spare

tire for a short period of time and drive with extra care . Refit the

normal road wheel as soon as safely possible.

• Never drive faster than the maximum speed for which the tires

on your vehicle are rated because tires that are driven faster than

their rated speed can fail suddenly.

• Overloading tires cause heat build -up, sudden tire failure ,

includ ing a blowout and sudden deflation and loss of control.

• Temperature grades apply to tires that are properly inflated and

not over or underinflated .

• For technical reasons it is not always possible to use wheels

from other vehicles -in some cases not even wheels from the

same vehicle model.

• If you install wheel trim discs on the vehicle wheels , make sure

that the air flow to the brakes is not blocked. Reduced airflow to

the brakes can them to overheat , increasing stopping distances

and causing a collision.

~

Vehicle care I t •

Page 337 of 398

Tires and wheels -_______________________ ..::...:..:..-=::.......:.:..;::..:....____;___

•

Wheel bolts

Wheel bolts must always be tightened to the correct

torque.

The design of wheel bolts is matched to the factory installed rims. If

different rims are fitted, the correct wheel bolts with the right length

and correctly shaped bolt heads must be used. This ensures that

wheels are fitted securely and that the brake system functions

correctly.

In certain circumstances, you may not use wheel bolts from a

different vehicle - even if it is the same model~

page 374.

& WARNING

Improperly tightened or maintained wheel bolts can become loose

causing loss of control, a collision and serious personal injury.

• Always keep the wheel bolts and the threads in the wheel hubs

clean so the wheel bolts can turn easily and be properly tightened.

• Never grease or oil the wheel bolts and the threads in the wheel

hubs. They can become loose while driving if greased or oiled,

even if tightened to the specified torque.

• Only use wheel bolts that belong to the rim being installed.

• Never use different wheels bolts on your vehicle.

• Always maintain the correct tightening torque for the wheel

bolts to reduce the risk of a wheel loss.

If the tightening torque of

the wheel bolts is too low, they can loosen and come out when the

vehicle is moving. If the tightening torque is too high, the wheel bolts and threads can be damaged and the wheel can become

loose.

0 Note

The specified torque for the wheel bolts is 90 ft lb (120 Nm) with a

tolerance of ± 7,4 ft lb(± 10 Nm). Torque wheel bolts diagonally.

After changing a wheel, the torque must be checked as soon as possible with a torque wrench

-preferably by an authorized Audi

dealer or qualified workshop. •

Low aspect ratio tires

Your Audi is factory-equipped with low aspect ratio tires. These tires

have been thoroughly tested and been selected specifically for your

model for their superb performance, road feel and handling under

a variety of driving conditions. Ask your authorized Audi dealer for

more details.

The low aspect ratio of these tires is indicated by a numeral of 55 or

less in the tire's size designation. The numeral represents the ratio

of the tire's sidewall height in relation to its tread width expressed

in percentage. Conventional tires have a height/width ratio of 60 or

more.

The performance of low-aspect-ratio tires is particularly sensitive to improper inflation pressure. It is therefore important that low

aspect ratio tires are inflated to the specified pressure and that the

inflation pressure is regularly checked and maintained. Tire pres

sures should be checked at least once a month and always before a

long trip~

page 323, "Checking tire pressure" .

What you can do to avoid tire and rim damage Low aspect ratio tires can be damaged more easily by impact with

potholes, curbs, gullies or ridges on the road, particularly if the tire

is underinflated.

In order to minimize the occurrence of impact damage to the tires

of your vehicle, we recommend that you observe the following

precautions:

• Always maintain recommended inflation pressures . Check your

tire pressure every 2,000 miles (3,000 km) and add air if necessary.

• Drive carefully on roads with potholes, deep gullies or ridges.

The impact from driving through or over such obstacles can

damage your tires. Impact with a curb may also cause damage to

your tires. ..,

Vehicle care

I t •

Page 345 of 398

What do I do now? 111111 _______________________________ ....:..:..:..:..:.:..:--=.:..::....:.....:.:...::..___;__ _ __,J

& WARNING !continued)

• Never start or run the engine while the vehicle is supported by

the jack.

• If you must work under the vehicle, always use safety stands

specifically designed for this purpose.

• Never use the hexagonal socket in the handle of the screw

driver to loosen or tighten the wheel bolts.

• Always make sure the spare tire and even a flat tire are secured

in place and not loose, otherwise they could fly forward, causing

personal injury to passengers in the vehicle in an accident or

sudden maneuver. •

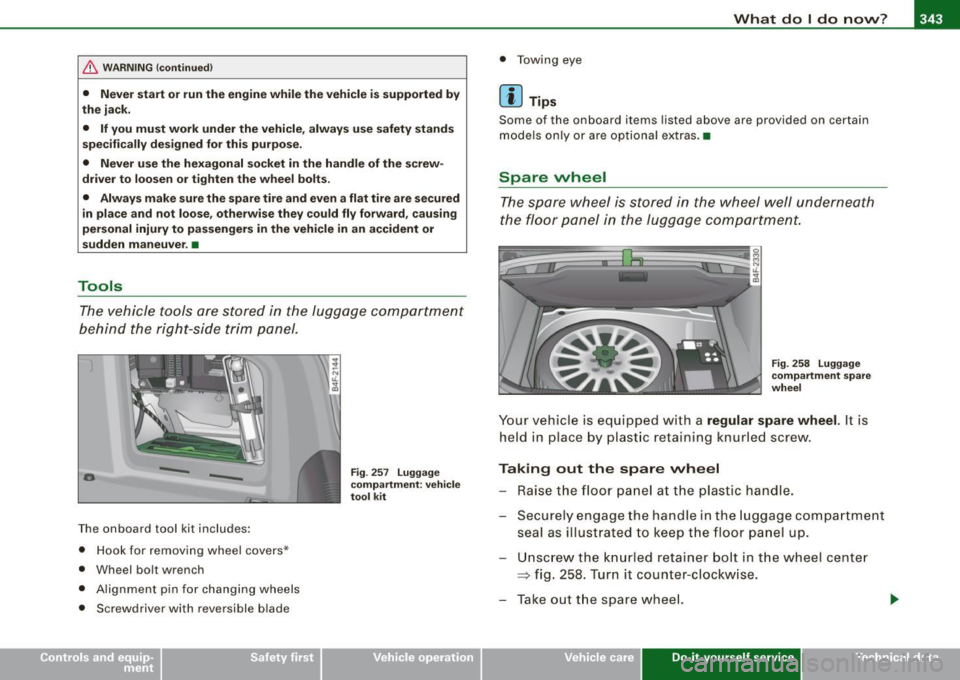

Tools

The vehicle tools are stored in the luggage compartment

behind the right-side trim panel.

-

-

The onboard tool kit includes:

• Hook for removing wheel covers *

• Wheel bolt wrench

• Alignment pin for changing wheels

• Screwdriver with reversible blade

Fig. 257 Luggage

compartment: vehicle

tool kit

• Towing eye

[ i] Tips

Some of the on board items listed above are provided on certain

models only or are optional extras.•

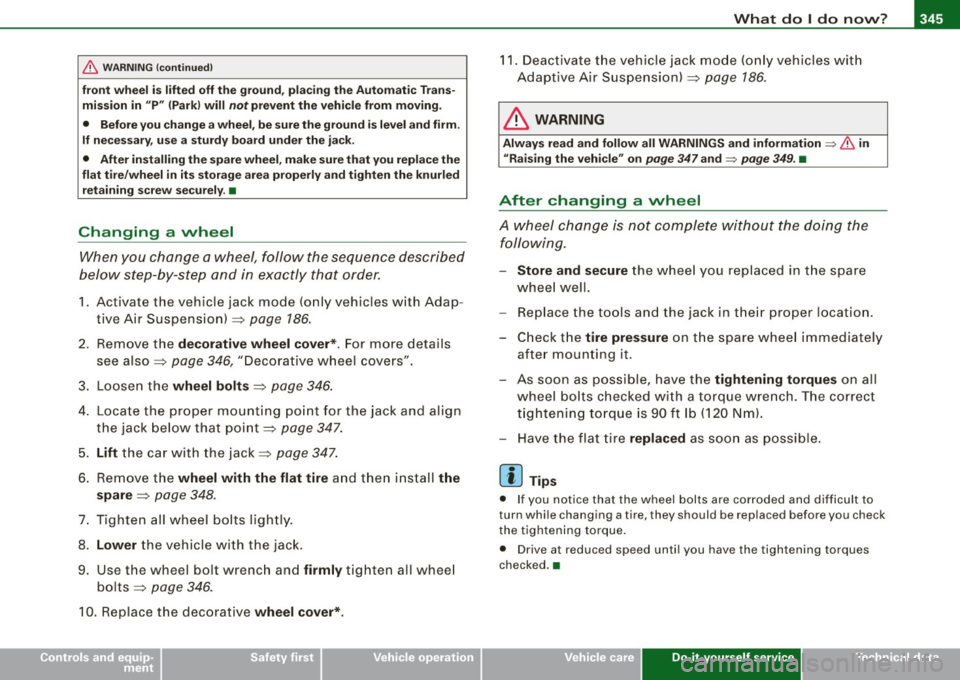

Spare wheel

The spare wheel is stored in the wheel well underneath

the floor panel in the luggage compartment.

Fig. 258 Luggage

compartment spare

wheel

Your vehicle is equipped with a regular spare wheel. It is

held in place by plastic retaining knurled screw.

Taking out the spare wheel

- Raise the floor panel at the plastic handle.

- Securely engage the handle in the luggage compartment

seal as illustrated to keep the floor panel up.

Unscrew the knurled retainer bolt in the wheel center

=> fig. 258. Turn it counter-clockwise.

- Take out the spare wheel.

Vehicle care Do-it-yourself service irechnical data

Page 347 of 398

_______________________________________________ W_ h_ a_t _ d_ o_ l _d _o_ n_ o _ w_ ? __ IIII

•

& WARNING (continued)

front wheel is lifted off the ground, placing the Automatic Trans

mission in "P" {Park) will

not prevent the vehicle from moving.

• Before you change a wheel , be sure the ground is level and firm.

If necessary, use a sturdy board under the jack.

• After installing the spare wheel, make sure that you replace the

flat tire/wheel in its storage area properly and tighten the knurled

retaining screw securely. •

Changing a vvheel

When you change a wheel, follow the sequence described

below step-by-step and in exactly that order.

1. Act ivate the vehicle jack mode (only vehicles with Adap

tive Air Suspension) ~

page 186.

2. Remove the decorative wheel cover*. For more details

see also ~

page 346, "Decorative wheel covers".

3. Loosen the

wheel bolts ~ page 346.

4. Locate the proper mounting point for the jack and align

the jack below that point~

page 347.

5. Lift the car with the jack~ page 347.

6. Remove the wheel with the flat tire and then install the

spare

~ page 348.

7. Tighten all wheel bolts lightly.

8.

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly tighten all wheel

bolts

~ page 346.

10. Replace the decorative wheel cover*.

11. Deactivate the veh icle jack mode (only vehicles with

Adaptive Air Suspension)~

page 186.

& WARNING

Always read and follow all WARNINGS and information => & in

"Raising the vehicle" on

page 347 and => page 349. •

After changing a vvheel

A wheel change is not complete without the doing the

following.

- Store and secure the wheel you replaced in the spare

wheel well.

- Replace the tools and the jack in their proper location.

-Check the tire pressure on the spare wheel immediately

after mounting it.

- As soon as possible, have the

tightening torques on all

wheel bolts checked with a torque wrench. The correct

tightening torque is 90 ft lb (120 Nm).

- Have the flat tire

replaced as soon as possible.

[ i] Tips

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Drive at reduced speed until you have the tightening torques

checked. a

Do-it-yourself service

Page 348 of 398

-L--____:W:...:....:. h.:..: a::.. t:....: d.:..:o:....:. l...: d::.. o ..:.... n:..:..:: o...:vv ...:...;. ? ____________________________________________ _

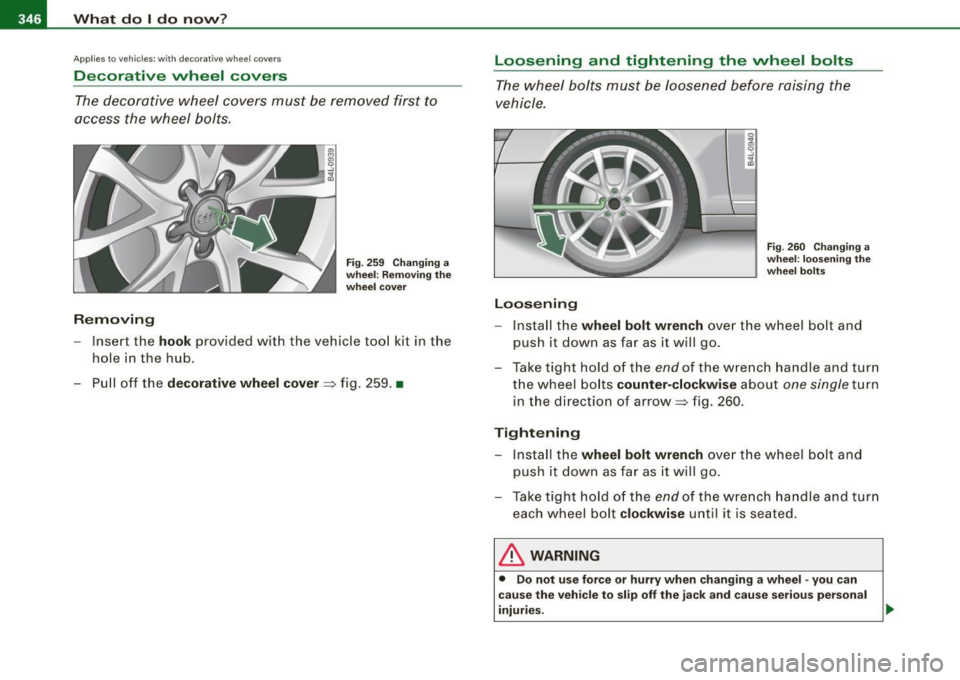

Applies to veh ic les : with decorative wheel covers

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts.

Removing

Fig. 259 Changing a

wheel: Removing the

wheel cover

- Insert the hook provided with the vehicle tool kit in the

hole in the hub.

- Pull off the decorative wheel cover=> fig. 259. •

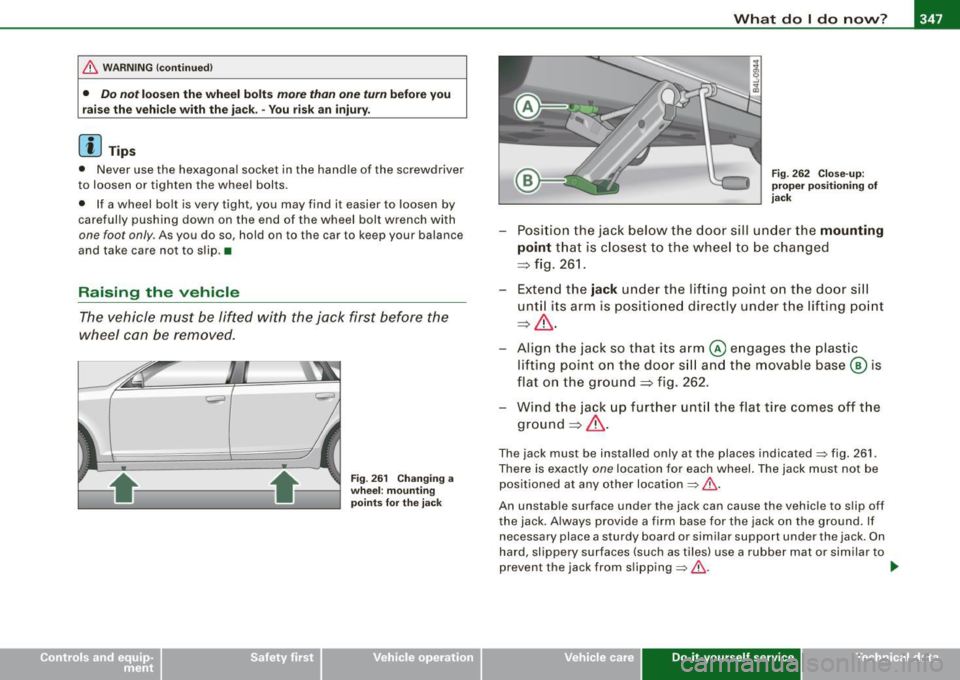

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle.

Loosening

Fig. 260 Changing a

wheel: loosening the

wheel bolts

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

the wheel bolts counter-clockwise about

one single turn

in the direction of arrow~ fig. 260.

Tightening

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

each wheel bolt clockwise until it is seated.

& WARNING

• Do not use force or hurry when changing a wheel · you can

cause the vehicle to slip off the jack and cause serious personal

injuries.

Page 349 of 398

_____________________________________________ W_ h_ a_t _d_ o_l _ d_o _ n_o_ w_ ? _ __._

& WARNING !continued)

• Do not loosen the wheel bolts more than one turn before you

raise the vehicle with the jack . - You risk an injury.

[ i J Tips

• Never use the hexagonal socket in the handle of the screwdriver

to loosen or tighten the wheel bolts .

• If a wheel bolt is very tight, you may find it easier to loosen by

carefully pushing down on the end of the wheel bolt wrench with

one foot only . As you do so, hold on to the car to keep your balance

and take care not to slip .•

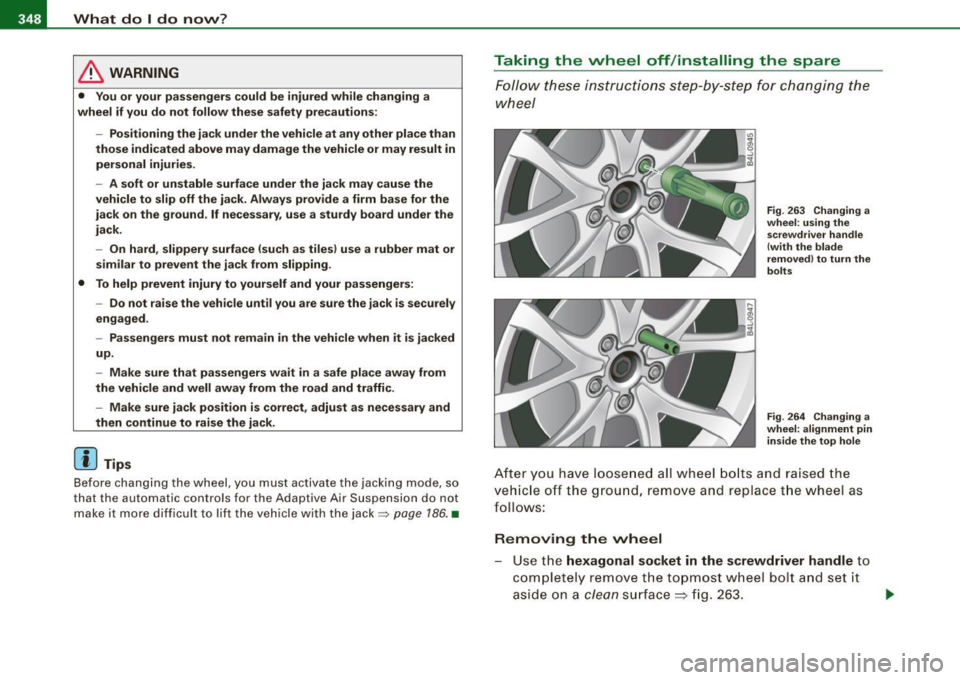

Rais ing the vehicle

The vehicle must be lifted with the jock first before the

wheel con be removed.

Fig. 261 Changing a

wheel: mounting

points for the jack Fig

. 262 Close-up:

proper positioning of

jack

- Position the jack below the door sill under the mounting

point

that is closest to the wheel to be changed

:::;, fig. 261 .

- Extend the

jack under the lifting point on the door sill

until its arm is positioned directly under the lifting point

:::;, & .

- Align t he jack so that its arm @ engages the plastic

lifting point on the door sill and the movable base@ is

flat on the ground :::;, fig. 262.

- Wind the jack up further until the flat tire comes off the

ground :::;,& .

The jack must be installed only at the places indicated=> fig. 261.

There is exactly

one locat ion for each wheel. The jack must not be

positioned at any other location

=> & .

An unstable surface under the jack can cause the vehicle to slip off

the jack . Always provide a firm base for the jack on the ground. If

necessary place a sturdy board or similar support under the jack. On

hard, slippery surfaces (such as tiles) use a rubber mat or similar to

prevent the jack from slipping=> &. .,_

Vehicle care Do-it-yourself service Technical data

Page 350 of 398

111!1...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? ______________________________________________ _

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow these safety precautions:

- Positioning the jack under the vehicle at any other place than

those indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack. Always provide a firm base for the

jack on the ground.

If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers: -Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait in a safe place away from

the vehicle and well away from the road and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack.

[ i ] Tips

Before changing the wheel, you must activate the jacking mode, so

that the automatic controls for the Adaptive Air Suspension do not

make it more difficult to lift the vehicle with the jack =>

page 186. •

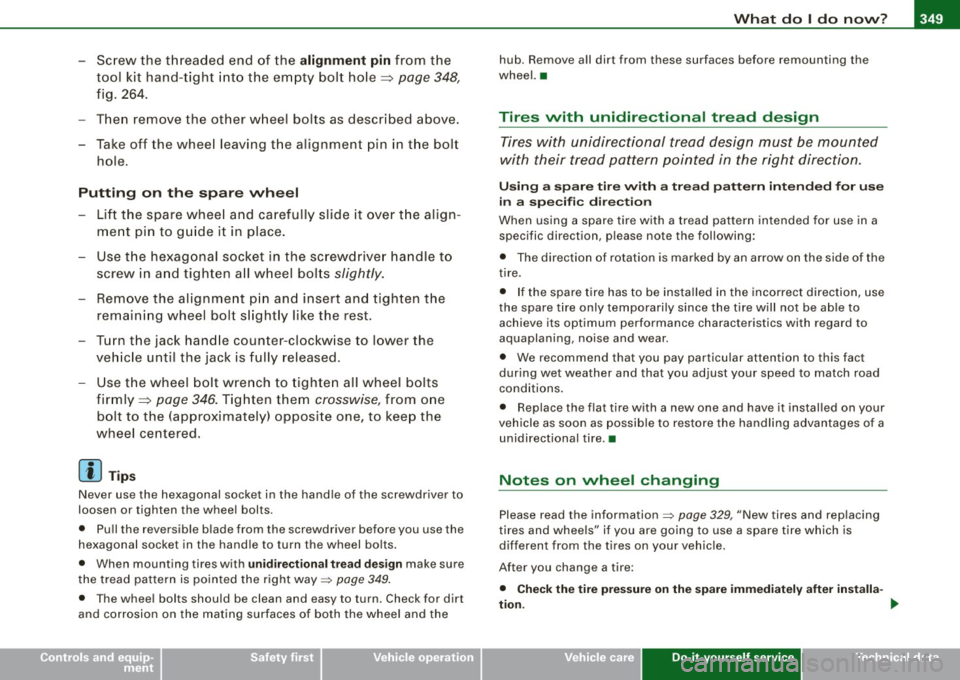

Taking the wheel off /installing the spare

Follow these instructions step-by-step for changing the

wheel

Fig . 263 Changing a

wheel: using the

screwdriver handle

(with the blade

removed) to turn the

bolts

Fig . 264 Changing a

wheel: alignment pin

inside the top hole

After you have loosened all wheel bolts and raised the

vehicle off the ground, remove and replace the wheel as

follows:

Removing the wheel Use the hexagonal socket in the screwdriver handle to

completely remove the topmost wheel bolt and set it

aside on a

clean surface ~ fig. 263. .,_

Page 351 of 398

_______________________________________________ W_ h_ a_t _ d_ o_ l _d _o_ n_ o _ w_ ? __ ffllll

•

- Screw the th readed end of the a lignment pin from the

tool k it hand-tight into the em pty bolt hole~ page 348,

fig. 264 .

- Then remove the other w heel bolts as described above.

- Take off the wheel leaving the al ignment pin in the bolt

hole.

Putting on the spar e wheel

- Lift the spare whee l and carefully slide it over t he align

ment pin to g uide it in place .

- Use the hexagonal socket in the screw drive r ha ndle t o

screw in a nd tighten a ll w heel bol ts slightly .

- Remove the alignment p in and insert and tighten the

remaini ng wheel bol t slightly like the rest.

- Turn the jack hand le counter -clockwise to lower the

ve hicle until the jack is fully released .

- Use the wheel bolt wrench to tighten all wheel bolts

firmly ~ page 346 . Tighten them crosswise, from one

bolt to the (approximately) opposite one, to keep the

wheel centered .

[ i J Tip s

Never use the hexagonal socke t in the hand le of the screwdriver to

loosen or tighten the wheel bolts .

• Pull the reversible blade from the screwdriver before you use the

hexagonal socket in the hand le to turn the wheel bo lts .

• When mounting tires with

unidire ctional tre ad de sign make sure

t he tread pattern is po inted the right way~

page 349.

• T he wh ee l bolts should b e clean and easy to turn . Check for dirt

and corrosion on the mating surfaces of both the wheel and the hub

. Remove all dirt from these surfaces before remounting the

wheel. •

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their tread pa ttern pointed in the right dire ction .

Using a spare tire with a tread patte rn intended f or use

in a s pec ific direc tio n

When using a spare tire with a t read pattern intended for use in a

specific direction, please note the following :

• The direction of rotation is marked by an arrow on the side of the

tire .

• I f the spare tire has to be insta lled in the incorrect direction, use

the spare t ire only temporarily since the tire will not be ab le to

achieve its optimum performance characteristics wi th regard to

aquaplaning , noise and wear.

• We recommend that you pay particular attention to this fact

dur ing wet weather and that you ad just your speed to match road

conditions .

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as p ossible to res tore the handling advantages of a

unidirectional tire. •

Notes on wheel changing

Please read the information~ page 329, "New tires and replacing

tires and whee ls" if you are going to use a spare tire which is

different from the tires on your vehic le.

Aft er you change a tire :

• Check the tire pre ssure on the spare im mediat ely a fter in stalla -

tion . _,,,

Do-it -yourself service

Page 352 of 398

11111.___W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? ______________________________________________ _

• Have the wheel bolt tightening torque checked with a torque

wrench as soon a s possible by your authorized Audi dealer or a

qualified service station .

• With steel and alloy wheel rims , the wheel bolts are correctly

tightened at a torque of 90

ft lb (1 20 Nm ).

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire , they should be repla ced before you check

the tightening torque .

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible . Remount the wheel cover.

Until then , drive with extra care and at redu ced speeds .

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed , then be sure to read

the information

=> page 329 , "New tires and replacing tires and

wheels" .

• Always make sure the damaged wheel or even a flat tire and

the jack and tool kit are properly secured in the luggage compart

ment and are not loose in the passenger compartment .

• In an accident or sudden maneuver they could fly forward ,

injur ing anyone in the vehicle .

• Always store damaged wheel , jack and tools securely in the

lugg age compartment . Otherwise , in an accident or sudden

maneuver they could fly forward, cau sing injury to passengers in

the vehi cle .

0 Note

Do not use commercially available ti re sealants . Otherwise, the elec

t rical components of the tire pressu re monitor ing sys tem* will no

longer work properly and the sensor for the tire pressure moni

to ring system wi ll hav e to be r eplace d by a qua lifi ed wo rkshop. •

Page 393 of 398

______________________________________________ A_ l_,_ p _h_ a_ b_e _t_i c_ a _ l _in _ d_e _ x __ _

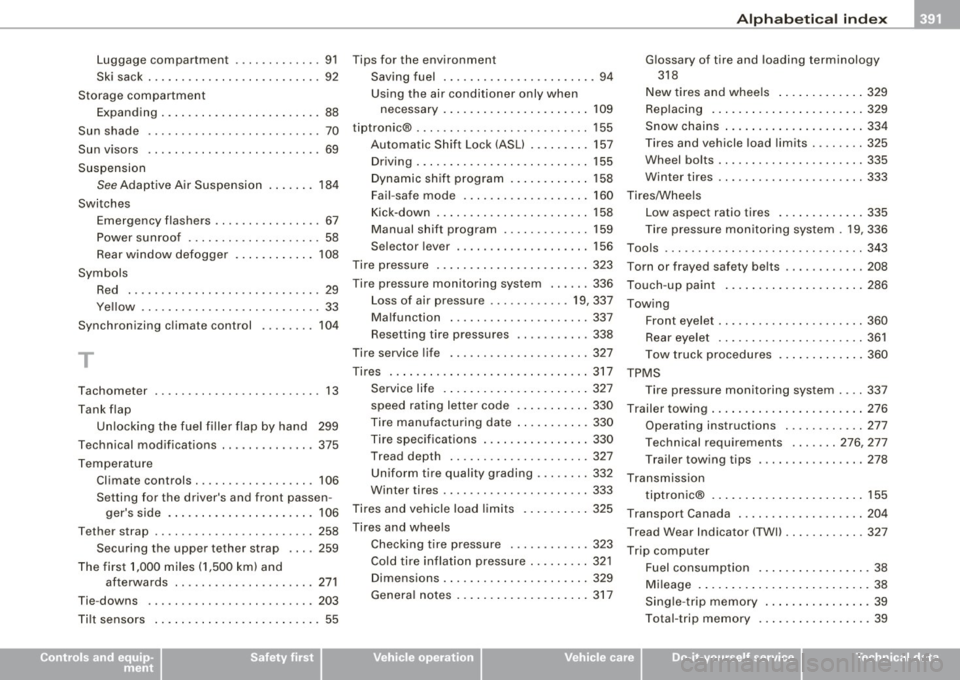

Luggage compartment ... ... . ..... . 91

Ski sack . .... .... .... .... ..... .. .. 92

Storage compartment

Expanding . ... ...... .. ... .. .... ...

88

Sun shade .. .... .... ... .... ... .... .. 70

Sun visors .. .... ... ... ..... ...... ... 69

Suspension

See Adaptive Air Suspension . .... .. 184

Switches

Emergency flashers .. .... .... .... ..

67

Power sunroof .... ... .... .... .... . 58

Rear window defogger ... ... . ... .. 108

Symbols

Red . ...... .. ..... ... ..... .. .....

29

Yellow .. .. ... ... .... .... ... .... .. 33

Synchronizing climate control . ... .... 104

T

Tachometer . .... .... .... ... .... .... . 13

Tank f lap

Unlocking the fuel filler flap by hand

299

Technical modifications ........ .... .. 375

Temperature

Climate controls .. .... .... ... .... .

106

Setting for the driver's and front pass en-

ger's side ... ...... .... ... .... ..

106

Tether strap ...... .... .. ....... ..... 258

Securing the upper te ther strap 259

The first 1,000 miles (1,500 km) and

afterwards .. .... ... .... .... ....

271

Tie -downs .. .... .... .... ... .... .... 203

Tilt sensors ..... .... .... ... .. .. ..... 55

Controls and equip ment Safety first

Tips for the environmen

t

Saving fuel ... ... .... ...... .......

94

Using the air conditioner only when

necessary .. ... ..... .... .... ... .

. . ® t1ptronic ... .... .... .... .... .... .. .

Au tomatic Shift Lock (ASU ... ..... .

109

155

157

Driving .. . ... ... ... .. .. .. ... . ... . 155

Dynamic shift program ...... ...... 158

Fail -safe mode .. ....... .... .... .. 160

Kick -down .... .. . ... .. ...... ..... 158

Manual shift program .. ... .... .... 159

S elector lever .... .... ...... ..... . 156

Tire pressure . ... ... .... ... .... .... . 323

Tire pressure monitoring syst em .. .... 336

Loss of air pressure ... .... ..... 19 ,337

Malfunction . .... .... ...... ...... 337

Resetting tire pressures .. .. .. .... . 338

Tire servic e lif e ........ ... .. .... .... 327

Tires .. .... . ... ... . ... .... .... .... . 317

Service life . .... . ... ..... .... .... 327

speed rating letter code ... .... .... 330

Tire manufacturing date .... . ... ... 330

Tire specificat ions ... ..... ... ... .. 330

Tread depth .. ... ..... ... .... .... 327

Uniform tir e quality grading ..... ... 332

Winter tires ......... ........ .... . 333

Tires and vehicle load limits ... ...... . 325

Tires and wheels

Checking tire pressure . ... .... ....

323

Cold tire inflation pressure .... .... . 321

Dimensions . .... ... .. ...... .. .... 329

General notes ... ...... ..... ..... . 317

Glossary of tire and loading terminology

318

New tires and wheels .... .... .... . 329

Replacing ... .. .. .... .... .... .. . . 329

Snow chains .. ... .... ... . ... ..... 334

Tires and v ehicle load limits . ...... . 325

Wh eel bolts .. ... ........ ... .. .... 335

Winter tires ... .... ... ... .... ... .. 333

Tires/Wheels

Low aspect ratio tires ... .. .... .. . .

335

Tire pressure monitoring sys tem . 19, 336

Tools ...... ... .. .... .... ...... .... . 343

Torn or frayed safety b elts .... ... .. .. . 208

Touch -up paint ... .. .... .... .... .. .. 286

Towing

Front eyelet .. .. .. .... .... .... ....

360

Rear eyelet ... .... ....... .. ...... 361

Tow truck procedures .. ...... .... . 360

TPMS

Tire pressure monitoring system ....

337

Trailer towing .... ... ... .. ....... ... . 276

Operating instructions . ... ... ... .. 277

Technical r equ irem ents ... .... 276 , 277

Trailer towing tips ....... ..... .... 278

Transmission

tiptronic® ... ... .... .... .... .....

155

Transport Canada ...... ........ .... . 204

Tread Wear Indicator (TWll .... ... .... . 327

Trip computer

Fuel consumption . ... ... .... ..... .

38

Mileage . ... .. .... .... .. .... .... .. 38

Single -trip memory .. .... . .... ... .. 39

Total -trip memory ...... .... ... .. .. 39

Vehicle operation Vehicle care Do-it-yourself service Technical data