AUDI TT 2012 Owners Manual

Manufacturer: AUDI, Model Year: 2012, Model line: TT, Model: AUDI TT 2012Pages: 132, PDF Size: 89.43 MB

Page 111 of 132

Downloaded from www.Manualslib.com manuals search engine -

Tiresandwheels21

Whenitisnotpossibletocontinuedriving,evenwithrun-flattires?

-IftheElectronicStabilization Program(ESPl

isnotworkingorkeepscoming on.

-IftheTirePressure MonitoringSystemdoes

notwork.

-Ifthetirehasbeen severelydamaged,ina

crash, for

example.Thetreadcanseparate

framadamagedtireasthewheelturns,and

hitpartsofthevehicle, suchasthefueltank

fillerneck,fuellinesorbrake lines.

-Donotcontinuedriving ifsevere vibration

occurs orif

thetirestartstosmokebecause

thetireisrunning hot.

-

Donotcontinue drivingifdamagetothe

tire,suchascracksinthesidewall,appears.

AWARNING1=Improperuseofrun-flattires cancause

vehidedamagethatcan leadtolossofve

hidecontrol, acrash andseriouspersonal

injury.

- Run-flat tirescanonly beused with

spe

cialrims.

- Run-flat tire5

mustalwaysbemonitored

withapraperlyprogrammedTire Pre

ssureMonitoringSystem.

-Alwaysinspectatirethathaslostairto

makesureitissafetodrive withthetire

intherun-flatmode.

-Never drivewithrun-flattiresthathave

beendamagedinacollision.

- Never drivewith

run-flattiresifheat

build-upcausesthetiretogiveoff

smoke.

- Never drivewith

run-flattiresifthevehi

deshakesorvibrates severely.

- Never drivewitharun-flat tire

thatde

velops sidewall cracksor

otherdamage

whileinuse.

-

Ifyouswitchbetweenstandardand run

flattires, anauthorizedAudidealeror

qualified

workshopmustreprogramthe

controlmodule.~

Reinforced sidewallsgivethetiresrun-flatca

pability iftire

pressureislost.

Run-flattires

Tips

BeforeresettingtheTPMS,thecurrent

pressuresofailfourtiresmustcorrespond

to

thespecified values.Adjustthetire

pressureandresetthepressureinthetire

pressure

monitoringsystemaccordingto

theload youarecarryingqpage202.

Introduction

ReturningtotheStartmenu

~Pressthe1Resetlbuttonlongerthan2sec

onds

toreturnfrom anymenuleveltothe

Startmenu.

Run-flattirescanbeidentifiedbytheletters

"RSC'onthetiresidewall.

Ifyou dochangethetiresonyourvehidefrom

normal

torun-flat tires,youmustbuythe

special rimsrequired forrun-flat tires,andthe

TirePressureMonitoringSystemmustbere

programmed

byanauthorizedAudidealeror

other qualified workshop.

Whatdorun-flattiresdo?

Thesespecial tireshave run-flat capabilities

thathelpkeep youmoving ifatireloses pres

sUreandgoesflat.Under favorable conditions

tires canbedriven

atleast30miles(50km),

but you

mustnotdrivefasterthan50mph

(80km/hlqpage 220,Driving withrun-flat

tires.

Run-flat

tireshelpkeep youmoving

ifatire

goes fiat.

Appliestovehicles:withRun-flattires

Werecommendthatrun-flattiresonly be

mounted on

vehidesthatwereoriginally

equipped with

thesespecialtiresatthefacto

ryandhave aTire Pressure Monitoring Sys

tem.

Fig.159Display: Tirepressure

Applies

tovehicles:withtirepressuremonitoringsystem

@Tips

BeforeresettingtheTPMS,thecurrent

pressuresofailfourtiresmustcorrespond

tothespecified

values.Adjustthetire

pressureandresetthepressureinthetire

pressuremonitoringsystemaccording to

theloadyouarecarryingqpage202.

Resettirepressuremonitoringsyst~(Step2)•

Enteringandconfirming

~Selectthemenu:Storenow

~PressthetResetlbutton@.

~Selectthemenu:Confim

~Pressthe1Resetlbutton@.

Storingtirepressures

~Turn ontheignition.

~Selectthemenu:>Adjusting*>Tirepres

su re

>Store.

Fig.160Display: Tirepressure'"-

!Resetlbutton@androckehwitch®

qpage218,fig.157functions:

~---®

Fig.158Display:Startmenu

Fig.

157Wiperlever:

Controlsforthemenu display

Ifthetire pressure isadjusted, wheelsarero

totedorchonged, theTPMSmustberesetin

themenudisplay.

AppUestavehicles:withtirepressuremonitoringsystem

Resettirepressuremonitoringsystem(Stepl)

Toopenthemenu

~Pressthe1Resetlbutton@untilthemenu

displayqfig.158appears

Enteringandconfirming

~Pressthe1Resetlbutton@.

ReturningtotheStartmenu

~Pressthe1Resetlbuttonlongerthan2sec

ondstoreturnframanymenuleveltothe

Startmenu.

Selectionsandsettings

~Presstherocker switch®toreachamenu

display. Theswitchisoperatedthesameas

thedisplay (up/downl.

!Resetlbutton@androckerswitch®

qfig.157functions:

Page 112 of 132

Downloaded from www.Manualslib.com manuals search engine 220Tiresandwheels

CDNote

Run-flat

tireshave specialcharacteristics

andrequirements,thatareverydifferent

fromconventionaltires. Run-flattiresre

quire special rims

forrun-flatuseandcan

notbeusedonconventionalwheelrims.

Tips

-

Ifyouarenotabletocontinuedriving

with

run-flattires,pleaseseekprofessio

nalassistance.

- PleasecontactyourauthorizedAudi

dealerorAudiofAmerica, Inc.ifyou

have

questionsabouttiresandrims.

Driving

withrun-flat tires

Appliestavehicles:withRun-flat tires

Handling characteristics changewhentire

pressure

islaw.

Driving ontireswithlowtirepressurechanges

theway avehiclehandles,particularLywhen

corneringandbraking. Thehandling charac

teristicsofrun-flattiresdonotseemto

changealotEvenwhendrivingonlow pres

sureorintherun-fLatmode.Neverthelessyou

muststilltakespecialprecautionswhenoper

atingavehicleonrun-flattireswhentire pres

sureisLoworthetirets) isflat:

~The Electronic Stabilization Program(ESP)

mustbeswitchedon.

~Neverdrivefasterthan50mph(80km/hl

q.&..

~Planaheadwhendrivingandanticipate

whatyouwilLhavetodoconsidering traffic

androadconditionsupahead.

~Acceleratecarefully.

~Avoidunnecessaryandsuddensteeringand

brakingmaneuvers.

~Reduceyourspeedinplentyoftimebefore

intersections,curvesandotherplaceswhere

youmay havetoreactquickly.

Please

see:qpage219,Whenitisnatpossi

bLeta continue driving,Evenwithrun-fLat

tires?

Handling characteristics changewhen

driving withlowairpressure orwithflattires evenwithspecial run-flat tires

A low

pressureorflatfront tireaffectsvehicle

handlingcharacteristicsbypullingthevehicle

slightlytothesidewherethetireismounted

andreducesbrakingperformance.

AlowpressureorfLatreartirealsoaffects

drivingcharacteristicsbypullingtotheside

wherethetireismountedandalso reduces

braking

performance.Theeffecton vehicle

handling

ismostnoticeablewhendriving

aroundcurves.

.&..WARNING

Changed vehiclehandlingcharacteristics

whendrivingintherun-flatmodecan

causelossofvehiclecontrol,acrash and

seriouspersonalinjury.

- Driving onspecial

run-flattiresinthe

run-flatmodewillchangevehicle han

dling

characteristicsduringbraking,

whencorneringandunderheavy acceler

ation.

-Never drivefasterthanthemaximum

ratedspeedof50mph(80km/hlwhen

driving

intherun-flatmode.

- Alwaysadjustvehiclespeedtotraffic,

road

andweathercond itionsanddrive

slowerthanthemaximumratedspeedif

necessaryweathera~roadconditions

aretakenintoaccount.

- Always obey

speedlimitsandothertraf

fic laws.

CDNote

We always

recommenddriving withEven

morecarewhenusingthesespecialtiresin

therun-flatmode.Always avoidsudden

maneuvers.

Replacing run-flattiresandrims

APpliestavehlcles:wlthRun-flattires

yourvehicLewasespeciaLLydesignedtause

speciaL run-fLat tires.

Voumayuseandcombineonlyapprovedrun

fIat tires

andspecialmatchingrimsthathave

been

designedforrun-flattires. Mounting

special

run-flattiresonstandardwheelswilL

not workandwillnotprovidetheadvantages

fotherun-faltfeature.Neverusespecialrun

flat tires on

standardwheelrims.

After driving withatire

intherun-flatmode,

always havethevehicleandaffectedtirets)

and rimes)

inspectedbyanauthorizedAudi

dealer. Tires

thathavebeendrivenintherun

flat

modemustbe replaced.

fbWARNING

Useofdamagedrun-flattiresandrims can

cause vehicle

damagethatcanLeadtoloss

ofvehiclecontrol,acrashandseriousper

sonal

injury.

- Always have

thevehicleandaffected

tirets)andrimes)inspectedbyanauthor

izedAudidealerafterdriving atireinthe

run-flatmode.

-Tiresthathavebeendrivenintherun

flatmodemustbereplaced.

Tiresandwheels

Page 113 of 132

Downloaded from www.Manualslib.com manuals search engine 222Whatdo1donow?

------

Whatdo1donow?223

-

Preliminarysteps

Fig.163TireMobility SystemunderluggagecompartmentRoor

@Forthesakeoftheenvironment

Usedsealantbottlescanbedroppedoffat

arecycling facility.

~Ifyouhave aflattire,parkthevehicleasfar

aspossiblefrommovingtraffie.

~Applytheparkingbrakefirmly.

~Shiftintolstgearonvehicleswithmanual

transmission,ormovetheselectorleverta

thePpositiononveh icleswithautomatic

transmission.

~CheckwhetherarepairusingtheTire Mobi

litYSystemispossiblec;.page222,General

andsafetypointers.

~Have allpassengersleavethevehicleand

stayawayfromthedangerzonec;.&'

~Takethesealantbottleandtheelectricair

pumpframtheluggagecompartmentun

derthefloorc;.fig.163.

CDNote

Donotusecommerciallyavailabletire

sealants.Theelectricalcomponentsofthe

tirepressuremonitoringsystemwillno

longerworkproperly.

IDTips

-Ifsealanthasrunout,allowittodry.

Then youcan

peelitoff.

- Have

thetiresealantreplacedevery 4

yearsatadealership.

Somepreliminarystepsorenecessary fortire

repair.

Appliestovehicles: withTireMobility System

8.WARNING

Thetiresealantmustnotcomeintocon

tactwithskin,eyesorclothing.

-Ifyougetanytiresealantinyoureyesor

comeintocontactwithit,rinsetheaf

fectedareathoroughlywithcleanwater.

Find aphysicianimmediately!

-Changeanyclothingcontaminatedwith

tiresealantimmediately.

-Donotinhalethevapor!

-Ifyouhaveswallowedtiresealant,rinse

yourmouththoroughlyrightawayand

drinkplentyofwater.

-Donotinducevomiting!Find aphysi

cian

immediately!

-Ifyou have allergicreactions,finda

physician

immediately.

-Keepthetiresealantawayfromchildren.

~WARNING

Takethefollowingprecautionsafterre

pairing

thetire:

_Donotdrivefasterthan50mph(80km/

hl!

_Avoidfull-throttleacceleration,heavy

braking

andfastcornering.

_Thevehicle'sroadbehaviorcanbeaffect

ed.

_TiressealedwithTMSareintendedonly

fortemporary,short-termuse.

_ After usingthetiresealantthetirepres

suremonitoringsystemmaynolonger

workpraperly.Drivecarefullytothenext

professionalrepairfacility.

-

TMSmustNOTbeused,

-forcutsorpuncturesinthetirewhich

arelargerthan0.16inch(4mm)

-fordamagetotherim

-ifyouhavebeendrivingwithverylow

tirepressuresortireswithno air

-5eekprafessionalassistanceifitisnot

possibletorepairthetirewiththetire

sealant.

Fig.162Tiredamagefor whichtheTire MobilitySystemisnotsuited

Your vehicleisequippedwithatirerepairkit,

theTireMobilitySystem(TMS)*.

In

theeventofatirefailure,theTMSisinthe

luggagecompartmentunderthefloor.ltcon

sistsofthetiresealantandanelectricair

pump.

UsingTMS,tiredamagecausedby foreign

bodiesuptoabout0.16inch(4mm)indiam

etercanbesealedreliably

The

foreignobjectcanstayinthetire.

Thetiresealantmustnotbeused:

Tirerepair isintendedonLyfortemporary,

short-termuse.

-Neverusethehexagonalsocketinthe

handleofthescrewdrivertoloosenor

tightenthewheelbolts.

Tirerepair

Generalandsafetypointers•

Appliestovehicles: withTireMobility System

UsingtheTMSisdescribedinthesection

c;.page223,Preliminarysteps.

TMScanbeusedattemperaturesdownto

- 4oF(-20oC).

-forcutsorpuncturesinthetirewhichare

largerthan0.16inch(4mm)c;.fig.162@

-fordamagetotherim@

-ifyou havebeendrivingwithvery lowtire

pressuresortireswithnoair@)

Whatdo1donow?

VehicLetoolkit

Theonboardtoolkitincludes:

.&.WARNING-=--Using abumperjacktoraisethevehicle

will

damagethebumpersystem.The

jackmay slip,causinginjury.

-Neversupportyourvehicleoncinder

blocks, bricksorotherÇlbjects.These

maynotbeabletosupporttheloadand

couldcauseinjurywhentheyfail.

-Neverstartorruntheenginewhilethe

vehicleissupportedbythejack.

-

Ifyoumustworkunderthevehicle, al

ways

usesafetystandsspecificallyde

signedforthispurpose.

Thetoots arestoredunderneaththefLoor

panetinthetuggagecompartment.

Fig.161Luggagecompartment:vehicle toolkit

~Swingtheluggagecompartmentfloorup

wards.

~Removethevehicletoolkit.

- Hook

forremovi ngwheelcovers*

-Plastic cliptoremovewheelboltcovers*

-Wheelboltwrench

-Alignmentpinforchangingwheels

-Screwdriverwithreversibleblade

-Replacementbit(reversible Torxbitfor

changinglamps)

-Openendedwrench10x13

-Towing eye

Note:

someoftheonboarditemslistedabove

areprovidedoncertainmodelsonlyorareop

tionalextras.

Page 114 of 132

Downloaded from www.Manualslib.com manuals search engine ~Removethe"max.50mph"(80km/hl

sticker fromthesealantbottleandaffix itto

theinstrumentclusterinthedriver's view.

AWARNING

-Turnthehazardflashersonandsetup

thewarning triangleifyou have aflat

tireinmoving traffie.Inthis way youpro

tectyourselfandotherroad users.

- Make

surethatallpassengersareina

safeplace,outofthedangerzone (for

example, behindaguard rail).

CDNote

Particular careisnecessary ifyouaremak

ing atire repair ona

steepincline.

((DTips

Obeyalllaws.

Makingatirerepair

Appliestavehicles:withTireMobilitySystem

Tire repoirconsistsofthefollowingsections.

Fig.164PartsoftheTireMobilitySystem

Fig. 16S Connector

fortheTire Mobility System

1)TheeleetricairpumpshouldneverrunforLonger than8minutes.

AssemblingTireMobilitySystem

~Openthelid0oftheelectric airpump

9fig.164.

~PuIItheplug@andthepressure hose®

withthegaugeoutofthehousing.

~Screwthepressurehose®oftheelectric

air

pumpentatheflange®ofthesealant

bottle@.

~Pushthesealantbottlewiththeflange

down into

therecess®onthelidofthe

electric airpump.

~Removethedustcap fromthevalveofthe

defective tire.

~Screwthehose@entathevalve0

9fig.165.

[email protected]

for

thecigarettelighter.

~Switch ontheignition.

Inflatingtire

~Movetheswitch®9fig.165ontheelec

tric air

pump1)toposition1.After 5mi

nutes,tire pressuremusthave reachedat

least1.8bar.

~Switchtheelectric airpumpoff-switchin

positiono.Iftherequired tirepressure ofat

least1.8barhasnotbeen reached, follow

theinstructionsinthesectionRe-infloting

tire.

Re-inflatingtire

~Removethehosefrol'fl-l:hevalve andpull

theplugoutofthesocket.'.

~Drivethevehicle slowly10metersback

ward orforward. Thishelps

todistribute the

sealantbetter.

~Removetheemptyinflationbottleand

screw

thehose®9fig.164fromtheelec

tric

pumpdirectlyantethevalve.

[email protected]

for

thecigarettelighter.

~Switch ontheignition. •

Movetheswitch®9fig.165ontheelec

tric air

pump1)toposition1.After 5mi

nutes, tirepressure

musthave reachedat

least1.8bar.

• Switch

theelectric airpumpoff-switchin

positionO.Iftherequired tirepressureofat

least1.8barhasnotbeenreached, itisnot

possibletomakearepair withthetireseal

ant. Seek professional

assistance.

DisassemblingTireMobilitySystem

~Removethehosefromthevalve andpull

theplugoutofthesocket.

• Screw

thedustcapontothevalve.

• Place

theemptysealantbottlebackinthe

original packaging andclipitinplaceunder

thefloor50thatnotiresealantcan runout

intothevehicle.

~Placetheelectric airpumpintheluggage

compartmentforthetimebeing.

~Startdrivingrightaway50thatthesealant

isdistributedinthetire.

WARNING

- Follow

themanufacturer'ssafetyinstruc

tions on

thedecal fortheairpumpand

thesealantbottle.

-Ifatire pressureof1.8barcannotbe

achieved

afterpumping for5minutes,

thetireistooseverelydamaged.Donot

continuetodrive.

- Seek professional

assistanceifitisnot

possibletorepairthetire withthetire

sealant.

Tips

-Donotoperatetheelectric airpumpfor

morethan8minuteswithoutstopping,

otherwise itcan overheat.Whentheair

pumphascooled down,youcancontinue

touseit.

-Ifsealanthasescaped, allowittodry,

thenyoucanpeel itoff.

1)The eLeetricairpumpshouLdnever runforLonger than8minutes.

Finalcheck

AppLiestavehicles:withTireMobilitySystem

Afterdrivingforashortdistance,tirepressuremustbechecked

~Afterdriving forabout10minutes,stop

andcheckthetirepressure.

~Iftirepressureisstillatleast1.3bar, in

fla

tethetiretospecified pressure(seedriv

efsside 8-pillar), drivetothenextrepair

shopandhavethetireandthesealantbot

tlereplaced.

~Iftire pressureislessthan1.3bar,thetire

is

tooseverelydamaged.Donotcontinueto

drive. Seekprofessional assistance.

AWARNING

Iftirepressureislessthan1.3barafter

driving for10minutes,thetireistoose

verelydamaged.Donotcontinuetodrive.

Seek professional

assistance.

IDTips

After atire repair, havethesealantbottle

replacedatadealership. Thisrestores full

functionality

totheTire Mobility System.

WhatshouLd1be

awareofwhen

changingatire?

Generalinformation

Thefollowing sectionswillprovide youwith

importantinformation onhowtochangea

tire using

thevehicletoolkit.

However, we

recommendthatyouhave a

qualified service

centerchangethetireand

perform allwork

associatedwith changing it.

Page 115 of 132

Downloaded from www.Manualslib.com manuals search engine 226Whatdo1donO\N?.--------------------------------------

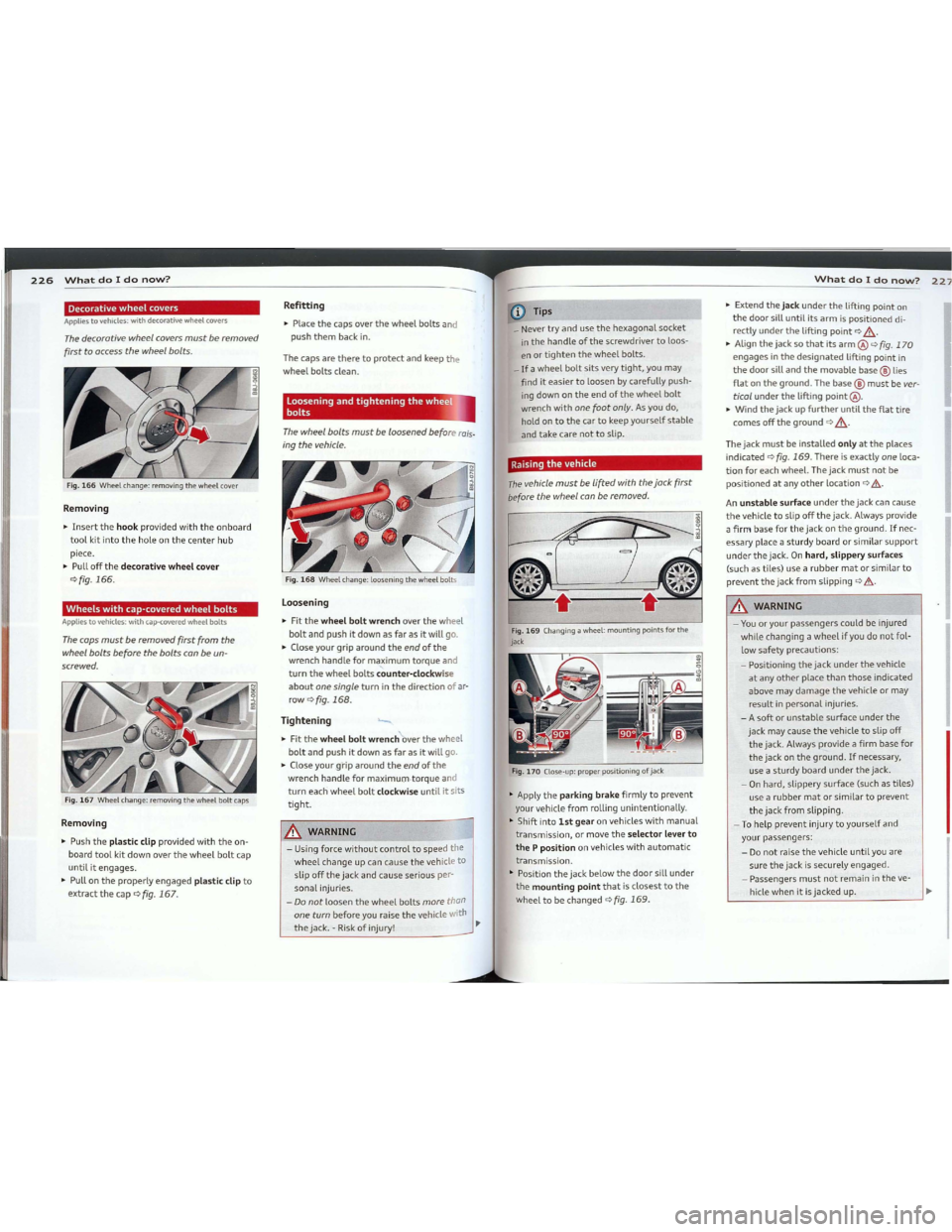

~Extendthejackundertheliftingpointon

thedoorsilluntil itsarmispositioneddi

rectlyundertheliftingpoint9A.

~Alignthejack50thatitsarm@~fig.170

engagesinthedesignatedliftingpointin

thedoorsillandthemovable base®lies

flatontheground.Thebase®mustbever

tical

undertheliftingpoint@.

~Windthejack upfurtheruntiltheflattire

comesofftheground~A.

AWARNING

-Vouoryourpassengerscould beinjured

while changing a

wheelifyoudonotfol

lowsafetyprecautions:

- Positioning

thejackunderthevehicle

atanyotherplacethanthoseindicated

above may

damagethevehicle ormay

resultinpersonalinjuries.

- A

softorunstablesurfaceunderthe

jack maycausethevehicletoslipoff

thejack. Always provide afirm basefor

thejackontheground.Ifnecessary,

use a

sturdyboardunderthejack.

-

Onhard, slipperysurface{suchastiles}

use a

rubbermatorsimilartoprevent

thejack from slipping.

-

Tohelppreventinjurytoyourself and

your

passengers:

-Donotraisethevehicle untilyouare

surethejackissecurelyengaged.

-Passengersmustnotremainintheve-

hicle when itisjacked up.~

Thejackmustbeinstalledonlyattheplaces

indicated

~fig.169.Thereisexactlyoneloca

tionfor each wheel. Thejackmustnotbe

positioned

atanyotherlocation~&..

Anunstablesurfaceunderthejack cancause

thevehicletoslipoffthejack. Always provide

a firm basefor

thejackontheground.Ifnec

essaryplace asturdyboard orsimilarsupport

underthejack.Onhard,slipperysurfaces

(suchastiles) usearubbermatorsimilarto

preventthejackfromslipping~&..

Fig.170Close-up: properpositioningofjack

iTips

_Nevertryandusethehexagonalsocket

inthehandleofthescrewdrivertoloos

en

ortightenthewheelbolts.

_If awheelboltsitsverytight,you may

find it

easiertoloosenbycarefully push

ing down

ontheendofthewheelbolt

wrench withonefootonly.Asyoudo,

hold

ontothecartokeepyourselfstable

andtakecarenottoslip.

Fig.169Changing awheel: mounting pointsforthejack

Raisingthevehicle

•Applytheparkingbrakefirmlytoprevent

yourvehicle fromrolling unintentionally.

•Shiftintolstgearonvehicles withmanual

transmission,ormovetheselectorleverto

thePpositiononvehicles withautomatie

transmission.

•Positionthejackbelowthedoorsillunder

themountingpointthatisc10sesttothe

wheeltobechanged~fig.169.

Thevehiclemustbeliftedwiththejockfirst

before

thewheel canberemoved.

The

wheel

boltsmustbeloosenedbeforerois

ingthevehicle.

Looseningandtighteningthewhee.!abolts•

Fig.168Wheel change: looseningthewheelbolts

Refitting

~Placethecapsoverthewheelbolts and

pushthembackin.

The

capsaretheretoprotectand keepthe

wheelboltsc1ean.

4.WARNING

-Using forcewithoutcontroltospeedthe

wheelchangeupcancausethevehicle to

slip off

thejack andcauseserious per

sonalinjuries.

-Donotloosenthewheelboltsmorethon

oneturnbeforeyouraisethevehicle with~thejack.-Riskofinjury!

Loosening

~FitthewheelboItwrenchoverthewheel

boltandpushitdownasfarasitwill go.

~Closeyourgrip aroundtheendofthe

wrenchhandleformaximumtorqueand

turnthewheelbolts counter-c1ockwise

aboutonesingleturninthedirectionofar

row~fig.168.

Tightening'-

~FitthewheelboItwrenchoverthewheel

boItandpushitdownasfarasitwill go.

~Close yourg·riparoundtheendofthe

wrenchhandleformaximum·torqueand

turneachwheelboltc10ckwise untilitsits

tight.

Fig.166Wheel change: removingthewheelcover

Wheelswithcap-coveredwheelboltsAppliestovehicles: withcap-covered wheelbolts

Fig.

167Wheel change: removingthewheelboltcaps

Removing

~Insertthehookprovided withtheonboard

toolkitintothehole onthecenterhub

piece.

~Pull offthedecorativewheelcoyer

~fig.166.

DecorativewheelcoversApplies tavehides: withdecorativewheel(avers

Thedecorative wheelcaversmustberemoved

firsttooccessthewheel bolts.

The caps

mustberemovedfirst fromthe

wheelboltsbeforetheboltscanbeun

screwed.

Removing

~Pushtheplasticclipprovided withtheon

boardtoolkitdown overthewheelboltcap

until it

engages.

~Pullontheproperlyengagedplasticclipto

extractthecap~fig.167.

Page 116 of 132

Downloaded from www.Manualslib.com manuals search engine Whatdo1donow?22!

Afteryouchangeatire:

Notesonwheelchange

andthehub. Remove alldirtfromthese

surfaces beforeremountingthewheel.

Aunidirectional tirecan be identified

byar

rows onthesidewall, whichpointinthedirec

tion

oftherotation.Youmustfollowthe

specified directionofrotation.Thisisnecessa

ryin·orderforthesetirestodeveloptheirop

timumcharacteristics regardinggrip,road

noise, wear,andhydroplaning.

Tireswith unidirectional treaddesignmustbe

mountedwiththeir tread pattern pointedthe

rightdirection.

sensorforthetirepressure monitoring

systemwillhavetobereplacedbyaquali

fied workshop.

Tireswithunidirectionaltreaddesign

-

JCDNote

.&.WARNING

-

Ifyou aregoingtoequip yourvehicle

with tires

orrims which differfromthose

whichwerefactory installed,thenbe

sure

toreadtheinformationqpage209,

New tires andreplacing tires

and

wheels.

-AlwaysstorethetooLssecurelyinLug

gagecompartment.Otherwise,inanac

cident or

suddenmaneuvertheycouldfly

forward, causing

injurytopassengersin

thevehicle.

Donotusecommercially availabletire

seaLants. Otherwise,

theelectrical compo

nentsofthetirepressure monitoring sys

temwillnolongerworkproperly andthe

Pleasereadtheinformationqpage209,New

tires andreplacing tiresandwheels,

ifyou are

going

touse aspare tirewhichisdifferent

fromthetiresonyour vehicle.

_ Check

thetirepressureonthespareimme

diatelyaftermounting.

- HavethewheelboIttighteningtorque

checkedwithatorquewrenchassoonas

possible byyourauthorizedAudidealeror

aqualified servicestation.

-Withsteelandalloywheelrims,thewheel

boltsarecorrectlytightenedatatorqueof

90ftlb(120Nm).

-

Ifyounoticewhitechangingatirethatthe

wheelboLtsarecorrodedanddifficultto

turn,then theyshouldbereplaced before

you check

thetighteningtorque.

-ReplacethefIattirewithanewoneand

have itinstalledonyourvehicleassoonas

possible.Remountthewheelcoyer.

Until

then,drivewithextracareandatre

duced

speeds.

CDNote

Whenremovingorinstallingthewheel,

therim could hitthebrakerotoranddam

agetherotor. Workcarefully andhave a

secondperson helpyou

iTips

Never usethehexagonalsocketinthehan

dle

ofthescrewdrivertoloosenortighten

thewheelbolts.

- Pull

thereversible bladefromthescrew

driver before youuse

thehexagonal

socketinthehandletoturnthewheel

bolts.

-

Whenmounting tireswith unidirectional

treaddesignmakesurethetreadpat

ternispointedtheright way

qpage229.

-The wheel boltsshould beclean andeasy

toturn.Checkfordirtandcorrosion on

thematingsurfacesofboththewheel

Puttingonthewheel

~Liftthesparewheelandcarefully slideit

over

thealignmentpintoguide itinplace

q(D.

~Usethehexagonalsocketinthescrewdriver

handletoscrewinandtightenallwheel

bolts

slightly.

~Unscrewthealignmentpin andinsertand

tightentheremainingwheelbolt slightly

like

therest.

~Turnthejack handle counter-clockwise to

lower

thevehicle untilthejackisfullyre

leased.

~Usethewheelboltwrenchtotightenall

wheelbolts firmlyqpage226.Tighten

themcrosswise,fromonebolttothe(ap

proximately)

oppositeone,tokeepthe

wheelcentered.

~Screwthethreadedendofthealignment

pin fromthetoolkithand-tightintothe

nowvacantbolt holeqfig.172.

~Then completely unscrewtheotherwheel

boltsasdescribed above.

~Takeoffthewheelleavingthealignment

pininthebolthole.

Taking

thewheeloff

Fig.171WheeL change: usingthescrewdriverhandLe(withthebLaderemoved)toturntheboLts

Fig.

172Wheel change: aLignment pininside thetophoLe

Removingthewheel

~Usethehexagonalsocketinthescrewdriv

erhandletocompletelyturnoutthetop

mostwheelboltandsetitaside onacleon

surfaceqfig.171.

Follow theseinstructions step-by-step for

changing

thewheel.

- Makesurethatpassengerswaitina

safeplace awayfromthevehicle and

well away from

theroadway andtraffie.

- Make

surejack positioniscorrect, ad

justasnecessary andthencontinueto

raisethejack.

After youhave loosened all

wheelboltsand

raised

thevehicle offtheground, performthe

followingstepstoremoveandreplacethe

wheel:

KDNote

Afloor jackorthepadsonthehoistarms

mustnotbepositionedatthepoints

shown

-arrows-.

Page 117 of 132

Downloaded from www.Manualslib.com manuals search engine 230Fusesandbulbs

Fusesandbulbs

Electricalfuses

Replacingfuses

Fusesthathaveblawn willhavemetalstrips

thathave burned thraugh.

Fig.173Endfaceofinstrumentpanel:removing cover

plate toaccessfuses

Fig.174Left sideofenginecompartment:fusecover

Fusecoverontheleftendfaceoftheinstrumentpanel

~Switchofftheignitionandtheelectrical

componentaffected.

~Carefully prythefusecoverofftheinstru

mentpanelusingtheignitionkeyora

screwdriver

qfig.173.

~Checkthefuselisting onthenextpagesto

findoutwhichfusebelongstothecompo

nentwhichhasfailedqpoge231,FuseLo

cation,InstrumentPonelleft.

~Removetheblownfusewiththeplastic clip

provided. Theclip

islocatedontheholderin

thefusebox.

~Replace ablownfuse(recognizablebythe

meltedmetalstripinside) withafuseofthe

someamperage.

~Firmlysnapthecover backontotheinstru

mentpanelface.

Fusecoverinenginecompartment

~Switchtheignitionandtheaffectedcon

sumeroff.

~Unlatchthefusecover,pushthetwoslides

forwardqfig.174.

~Findoutwhichfusebelongstotheequip

mentwhichstoppedworkingqpoge232,

Fuse location,

leftsideofengine comport

ment.

~Removetheplasticframitsretainerinthe

fuseboxcover(leftfaceendoftheinstru

mentpanel),place itonthefuseinquestion

andpull itout.

~Ifthefuseisburnedout(recognizableby

meltedstripsofmetal),replace itwith a

new

fuseofthesomerating.

~Replacethefusecover.

~Pushthetwoslidestotherearqfig.174.

Installthefusecover carefullytoprevent

waterfromentering.

Thevariouselectricalcircuitsareprotectedby

fuses.Thefusesareclusteredinacentralized

unit. The

unitislocatedbehindthefacepanel

attheendoftheinstrumentpanel.

Vouarewelladvisedtokeep asupplyofspare

fusesinyourvehicle. Fuseswiththepraper

ampereratingsareavaitableatyourauthor

ized Audi dealer.

.&.WARNING

DonotrepairfusesanCleverreplace a

blown

fusewithonethath'àsahigheramp

rating.This cancausedamagetotheelec

tricalsystemandafire.

CDNote

Ifa newfuseburnsoutagainaftershortly

have youhave installed it,have

theelectri

cal

systemcheckedbyyourauthorizedAu

didealer.

FuseLocation,InstrumentPanelleft

Fig.175Fuse carrier behindtheinstrumentpanelend

face, cover removed

50meoftheequipmentitemslistedareop

tional oronly available on

certainmodelcon

figurations.

Note

thatthefollowingtableis accurateat

thetimeofgoingtapressandissubjectta

change.Intheeventofdiscrepancies,thela

belontheinsideofthecoveralwaystakes

precedence.

Thepowerseatsarepratectedbycircuit

breakers, whichautomaticallyresetaftera

few

secondsaftertheoverloadhasbeenrem

edied.

No.

EquipmentAmps

Engine relay,fueltankcontrol

1unit,

Airbag Offlight,light10switch (switch illumination), di-

agnosticconnector

2ABS,ASR,ESP,brakelight5

switch

3

AF5headlight([eft) 5

Fusesandbulbs23

No.EquipmentAmps

Oillevelsensor(extendedmain-

tenanceinterval)(WIV),tire

pressuremonitoringsystem,

4switchforElectronic

Stability

S

Program (ESP),

AFSheadlights

(controlunit),A/Csystem(pres-

suresensor),backuplight

switch

Automaticheadlightrangecon-

Strol,AFSheadlight(right)15/10manualheadlightrangecon-

trol,halogenheadlights

ControlunitforCANdatatrans-

6fer(gateway),electromechani-5

calsteering,automatietrans-

.missionshiftgate

Acoustic ParkAssist,automatic

dipping interiorrearviewmir-

7 ror,

garagedooropener,heata-5

ble windshieldwashernozzles,

washerpump,winddeflector

relay (Roadster)

8 Haldex

clutch/Haldexclutch5/10(TT5)

Control

unitAudimagneticride 5

Airbag

controlunit5

11Mass airflowsensor,crankcaseSilOheating

12Doorcontrolunit(centrallock-10ingdriver/passenger)

13Diagnosticconnector10

14Rainsensor,automatictrans-5

missionshiftgate

15Rooflight(interiorlighting) 5

16AlCsystem(controlunit)10

17Tirepressuremonitoringsys-

5

tem(controlunit)

18Notused

19Notused

20Notused

21Fuelinjectors(gasoline engine)10

22Winddeflector(Roadster)30

23Horn20~

Page 118 of 132

Downloaded from www.Manualslib.com manuals search engine Foryoursafety, werecommendthatyou have

your authorized Audidealer replace burned

outbulbsforyau.

Fusesandbulbs2:

-Ifyoumustreplacethelight bulbs your

self, always

rememberthattheengine

compartmentofanyvehicleisahazard

ousareatowork in.Always readand

heed

aUWARNINGSqpage176,Engine

compartmentqA.

-Itisbesttoaskyourauthorized Audi

dealerwheneveryouneedtochangea

bulb.

-

Changing Xenon

lampsrequiresthespe-

cialtraining, instructions andequip-

ment.

-Only anauthorizedAudidealerorother

qualifiedworkshopshouldchangethe

bulbsingasdischargelamps.

&..WARNING

There are

partswithsharpedgesonthe

openingsandonthebulb holdersthatcan

causeserious cuts.

-

Ifyouareuncertainaboutwhattodo,

havetheworkperformedbyanauthor-

. ized Audidealerorotherqualified work-

shop. Serious

personalinjurymayresult

from improperlyperformedwork.

[ijjTips1

10

Amps

5

No.Equipment

11Feed(brake pedal)

Activated charcoal

filter/charge12pressurecontrolvalve

Replacinglightbulbs

Foryour safety, werecommendthatyouhave

your

authorizedAudidealerreplace anybulbs

for you, since your

dealerhasthepropertools,

thecorrectbulbs andtheexpertise.

Gasdischargelamps(Xenon lights)*:

Duetothehighelectricalvoltage,havethe

bulbs replacedbyaqualified technician.

Headlights withXenon lightcanbeidentified

bythehigh voltage sticker.

AWARNING

Contact withhigh-voltage

componentsof

theelectricalsystemandimproperre

placementofgasdischarge (Xenon)head

light

bulbscancauseseriouspersonalin

jury anddeath.

-Xenon bulbsarepressurized andcanex·

plode

whenbeingchanged.

BuLbs

Itisbecoming increasinglymoreandmore

difficulttoreplacevehiclelightbulbs sincein

manycases,otherpartsofthecarmustfirst

beremoved beforeyouareabletogettothe

bulb. Thisapplies especiaUytothelightbulbs

inthefrontofyourcarwhich youcanonly

reach

throughtheenginecompartment.

Sheetmetaland bulb holders canhavesharp

edgesthatcancauseserious cuts,andparts

mustbecorrectlytakenapartandthenprop

erly

putbacktogethertohelppreventbreak

age

ofpartsand longtermdamagefrom wa

terthatcanenterhousingsthathavenotbeen

properly resealed.

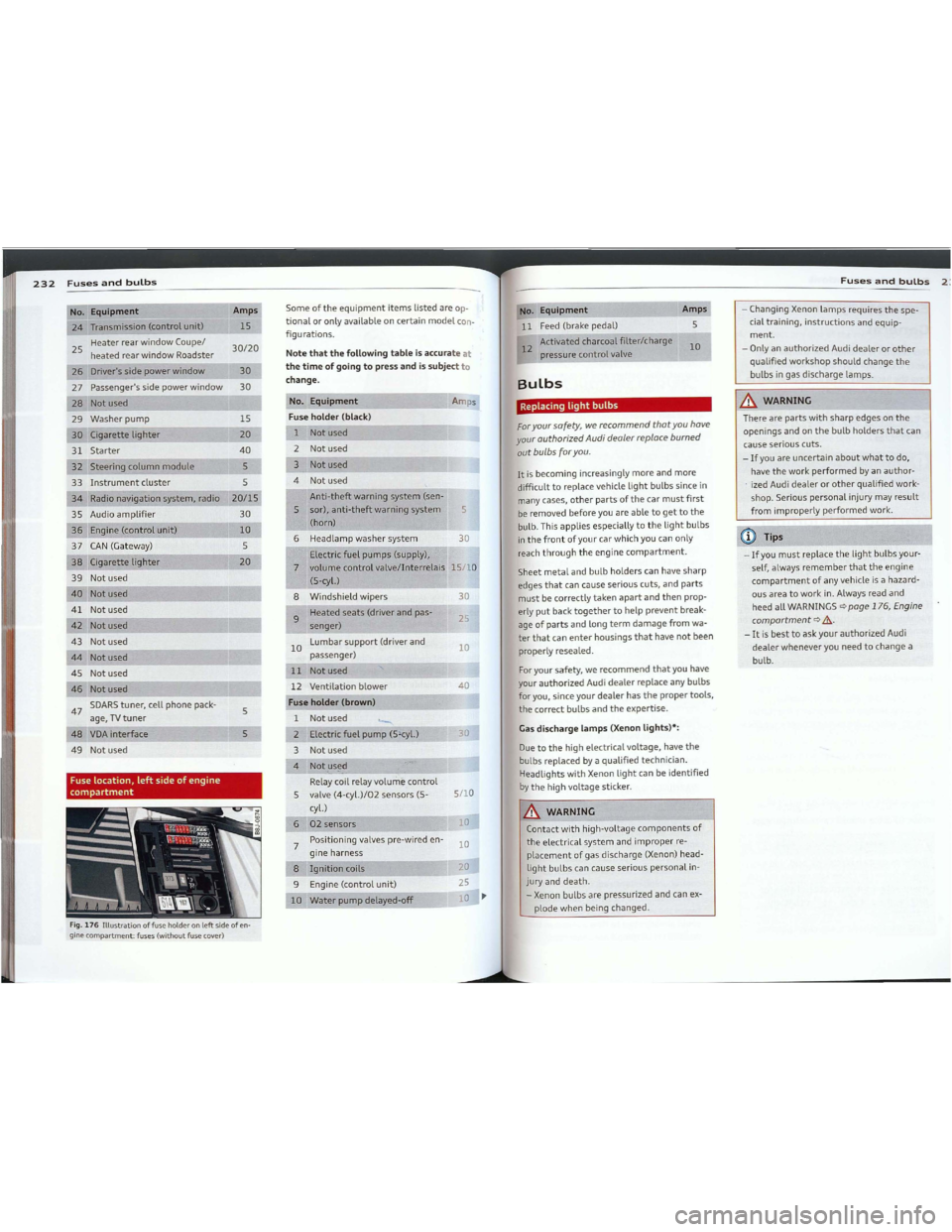

No.

EquipmentAmps

Fuseholder(black)

1 Not used

2 Not used

3 Not used

4 Not used

Anti-theft warning

system(sen-

Ssor),anti-theftwarningsystem5

(horn)

6

Headlampwashersystem30

Electricfuelpumps(supply),

7 volume

controlvalve/Interrelais15/10

(5-cyl.)

8 Windshield

wipers

30

9Heatedseats(driver

andpas-25senger)

10Lumbarsupport(driver and10passenger)

11Notused

12Ventilation blower40

Fuseholder(brown)

Notused'"-Electricfuelpump(s'cyl.)30

Notused

Relay coilrelay

volumecontrol

5valve

(4-cyl.}/02sensors(5-5/10

cyl.)

6

02sensors10

7 Positioning

valvespre-wired en-10gineharness

8Ignition

coils20

9Engine

(control unit)25

10Waterpumpdelayed-off10~

NotethatthefoUowingtableisaccurateat

thetimeofgoingtapressandissubjectta

change.

Someoftheequipmentitemslistedare op

tionaloronly available oncertainmodelcon

fig urations.

Fuselocation,leftsideofenginecompartment

232Fusesandbulbs

No.EquipmentAmps

24Transmission (controlunit)15

25HeaterrearwindowCoupe/30/20heatedrearwindow Roadster

26Driver'ssidepowerwindow30

27Passenger'ssidepower window30

28Notused

29Washerpump15

30Cigarettelighter20

31Starter40

32Steeringcolumnmodule5

33Instrumentcluster5

34Radionavigationsystem,radio20/1S

35Audio amplifier30

36

Engine (control unit)10

37CAN(Gateway)

5

38Cigarettelighter20

39Notused

40Not used

41Notused

42Notused

43Not used

44Notused

45Notused

46Notused

47SDARstuner, ceUphonepack-Sage,TVtuner

48VDAinterface5

49Notused

Fig.176Illustrationoffuse holder onleft sideofen

ginecompartment:fuses (without fusecaver)

Page 119 of 132

Downloaded from www.Manualslib.com manuals search engine 4.ConnectoneendoftheredjumpercabLe

onthejumpstartbolt(Dqfig.178

(Boltsunderredcaver="positive")ofthe

vehicletobestarted@.

S.Connecttheotherendoftheredjumper

cabLetathepositiveterminal@ofthe

boosterbattery@.

6.Connectoneendoftheblackjumperca

ble

tothenegativeterminaL@ofthe

boosterbattery@.

7. Connecttheotherendoftheblackjumper

cabletathenegativeterminal(boIt head)

@intheexternalstartingpoint@of

yourvehicle.

8.Routethejumpercables50thattheycan

natcatchinanyrotatingpartsintheen

gine

compartment.

Startingtheengine

9.Starttheengineofthevehicle providing

assistanceandallowittarunatidle.

la.Nowstarttheengineofthevehicle with

thedischargedbattery,waitfortwoto

threeminutesuntiltheengine"runs"

smoothly.

11.Iftheenginedoesnotstart:Stoptrying

afterlasecondsandthentryagainafter

about30seconds.

12.Inthevehiclethathasreceivedstartas

sistance,turnontheheaterblowerand

therearwindowheatingtoeliminateany

voltagepeakswhendisconnecting.Driv

inglightsmustbeswitchedoff!

13.Disconnectthecablewhiletheengineis

running exactly

inreverseordertothat

describedinqpage235,Connecting/dis

connecting

thejumpercable ..Whendo

ing sa,make

surethatthecablecannot

contactrotatingengineparts.

14.Closethecoveronthepositiveterminal.

Ernergencysituations

Thebatteryisventedtatheoutsidetaprevent

gasesfromenteringthevehicle interior. Make

surethatthejumperclampsarewellconnect

edwiththeirmetalpartsinfull contactwith

thebatteryterminaIs.~

Connecting/disconnectingthejumpercable.

Fig.177Engine compartment:Connectars forjumpercablesandcharger

Fig.178lumpstarting withthebatteryofanotherve

hicle:®discharged vehiclebattery.®boosterbattery

iTips

Thedischargedbatterymustbeproperly

connectedtathevehicle's eLectrical sys

tem.

Preparatorymeasures

1.Donotjumpstartafrozenbattery!Re

placesuch abattery!

2.

Otherwiseapplythehandbrakeandshift

into idlegearifyour vehiclehasmanual

transmission,andputtheseLector lever

into Pposition

ifyourvehiclehasauto

matietransmission.

3. Forbathvehicles switchoffalLconsumers

andtheignition.

The

proceduredescribedbelowforconnecting

jumpercabLesisintendedtoprovide

ajump

startforyourvehicle.

Makesuretoconnect thejumpercable

clamps

inexactly theorder described below!

Useofjumpercables

- Adischargedbatterycanalreadyfreeze

attemperaturesjustbelow32oF(0OC).

Beforeconnectingajumpercable,the

frozenbatterymustbethawedcom

pletely,otherwiseitcould explode.

-Donotallowbatteryacidtocontacteyes

orskin.Flush anycontactedareawith

waterimmediately.

-Improperuseofaboosterbatteryto

startavehicle maycauseanexplosion.

-Vehiclebatteriesgenerateexplosive gas

es. Keep sparks,

flameandlighted ciga

rettesawayfrombatteries.

-Donottrytojumpstartanyvehicle with

a low acid level

inthebattery.

- The

voltageoftheboosterbatterymust

also have a12-Volt rating.Thecapacity

(Ah)oftheboosterbatteryshouldnotbe

Lowerthanthatofthedischargedbat

tery. Use

ofbatteriesofdifferentvoltage

orsubstantialLydifferent"Ah"rating

may

causeanexplosionandpersonalin

jury.

-Neverchargeafrozenbattery. Gastrap

pedintheicemaycauseanexplosion.

-Neverchargeoruseabatterythathas

beenfrozen. Thebatterycasemayhave

beweakened.

-Useofbatteriesofdifferentvoltageor

substantiallydifferentcapacity(Ah)rat

ing may

causeanexpLosionandinjury.

The capacity

(Ah)'of1:heboosterbattery

shouldnotbelowerthànthatofthedis

chargedbattery.

-Before youcheckanythingintheengine

compartment,always readandheedaIL

WARNINGSqpage176,Enginecom

partment.

CDNotel

- Applying ahighervoltageboosterbat

terywillcauseexpensivedamagetasen

sitive eLectronic com

ponents,suchas

controlunits, relays, radio,etc.

-Theremustbenoelectricalcontactbe

tweenthevehiclesasotherwisecurrent

couldalreadystarttoflowassoonasthe

positive(+)terminaIsareconnected.~

Ifnecessary,theengine canbestartedby

connecting

ittothebatteryofanother vehi

cleo

Startingwithjumper

cables

CDNote

Vehicleswithanautomatictransmission

cannotbestartedbypushingortowing.

Iftheengineshouldfailtostartbecauseofa

dischargedorweakbattery,thebatterycanbe

connectedtothebatteryofanothervehicle,

using a

pairofjumpercablestostarttheen

gine.

Startingbypushingor

towing

Thischapterisintendedfortrainedemer

gencycrewsandworkingpersonnelwho

havethenecessarytoolsandequipmentto

performtheseoperations.

AWARNING

Batteriescontainelectricity, acid,andgas.

Anyofthesecancauseveryseriousorfatal

injury.Followtheinstructionsbelowfor

safehandlingofyourvehicle'sbattery.

-Alwaysshieldyoureyesandavoid lean

ing

overthebatterywheneverpossibLe.

plus(+)cableinmostcasescolored red

minus(-)cableinmostcasescoloredblack.

Emergencysituations

General

Useonlyjumpercableswhich haveinsulated

terminalclampsandareproperlymarkedfor

distinction:

]umpercables

Useonlyjumpercablesofsufficiently

largecrosssectiontosafelycarrythestarter

current.Refertothemanufacturer'sspecifica

tions.

234Ernergencysituations

Page 120 of 132

Downloaded from www.Manualslib.com manuals search engine 236Emergencysituations

AWARNING

Toavoidseriouspersonalinjuryanddam

agetothevehicle,heedallwarningsand

instructionsofthejumpercablemanufac

turer.Ifindoubt,callforroadservice.

-

]umpercablesmustbelongenough50

thatthevehiclesdonottouch.

-Whenconnectingjumpercables,make

surethattheycannotgetcaughtinany

moving

partsintheenginecompart

ment.

-Before youcheckanythingintheengine

compartment,always readandheedall

WARNINGS

qpage176,Enginecom

partment.

CDNote1

Improperhook-upofjumpercablescan ru

inthegenerator.

-AlwaysconnectPOSITIVE(+)toPOSI

TIVE(+),andNEGATIVE(-)toNEGATIVE

(-)groundpostofthebatterymanager

controlunit.

- Check

thatallscrewplugs onthebattery

cellsarescrewedinfirmly.Ifnot,tighten

plugs priortoconnectingclamponnega

tivebatteryterminal.

-Pleasenotethattheprocedureforcon

necting a

jumpercableasdescribed

above appUes specifically

tothecaseof

yourvehiclebeingjumpstarted.When

youaregivingajumpstarttoanotherve

hicle,

donotconnectthenegative(-)ca

ble

tothenegative(-)terminalonthe

[email protected],securely

connectthenegative(-)cabletoeithera

soUd

metalcomponentthatisfirmly

boltedtotheengineblockortotheen

gine block itself.

Ifthebatterythatisbe

ing

chargeddoesnotventtotheoutside,

escapingbatterygascould igniteandex

plode!

Emergencytowing

withcommerciaLtow

truck

Generalhints•

Your Audi requires specialhandling fortow

ing.

The followinginformationistobeusedby

commercialtowtruckoperatorswho know

how

tooperatetheirequipmentsafely.

- Never

towyourAudi,towingwillcause

damagetotheengineandtransmission.

-Neverwrapthesafetychainsorwinchca

blesaroundthebrakeUnes.

-

Topreventunnecessarydamage,yourAudi

mustbetransportedwitha carcarrier

(flatbedtruck).

-Toloadthevehicleontotheflatbed,use

thetowingloopfoundinthevehicletools

andattachtothefrontorrearanchorage

qpage237andqpage238.

AWARNING

A vehicle beingtowedisnotsafeforpas

sengers.Neverallowanyonetorideina

vehicle being

towed,for,anyreason.

Fronttowingloop(VersionA)

Donotinstallthefronttowing loopuntilitis

needed.

Fig.179Front bumper: removing thegrill

Fig.180Frontbumper: screwing inthetowingloop

The towline eyefitsintothethreadedholelo

catedontherightsideofthefrontbumper

behindthegrill.

~Removethescrewdriverandtowingloop

fromthevehicletoolkitqpage222.

~Insertthescrewdriverintotheslotas

shownandpresstowardthecenterofthe

vehicleqfig.179.Atthesametime,pull

thegrillforwardandout.

~Screwthetowing looptightlyintothe

threadedhaleasfarasitwillgoqfig.180.

When itisnolongerneeded,unscrewthe

towline eyeandputitbackintotheon-board

toolkit. Makesuretohavethetowlineeye

storedinthevehicleatalltimes.

Wheninstallingthegrillfortheairduct,be

Surethatthetabsonthegrillarefirstinsert

ed into

theirguidesonthevehicle. Thenpush

thegrillinto position.

Emergencysituations23~

AWARNING

Ifthetowing loopisnotscrewedinasfar

asitwill go,thethreadcanpulloutwhen

thevehicleistowed-potentialriskofan

accident.

Fronttowingloap(VersionB)

Donotinstallthefront towing loopuntilitis

needed.

Fig.181Rightfrontsection: removing theairintakegrille

Fig.182Rightfrontsectionwithplastic cover

Athreadedopeningwithleft-handthreadsis

locatedatthefrontrightofthebumperbe

hind

theairintakegrille. Thetowing loopis

installedinthisopening.

~Removethescrewdriverandthetowing

loop

framthevehicletoolkitqpage222.

~Reachthraughtheair intake grille,gripthe

horizontalfinsandpullitforwardtore

move.

~Usethescrewdrivertoprytheplastic coyer

offqfig.182.

~Installthetowing loopinthethreaded

openingandtightenituntilitstops

qpage237,fig.180.~