stop start AUDI TT 2013 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2013, Model line: TT, Model: AUDI TT 2013Pages: 262, PDF Size: 65.91 MB

Page 205 of 262

forget the spare tire. If the press ure in any tire

is too high when the tire is "cold," let air out

of the tire slowly with the edge of the t ire

gauge and keep checking the pressure until

you reach the pressure that is correct for the

load (passengers and luggage) and kind of

driving you plan to do .

If the pressure in any tire is too low, note the

d ifference between the pressure in the cold

tire and the pressure you need and add the a ir

that you need to reach the correct pressure for

the veh icle load (passengers and luggage) for

the tires on your veh icle as listed on the on

your ve hicle and in this manua l and the kind

of dr iving you p lan to do .

Never exce ed the ma ximum inflation pres

s ur e listed on t he tire s idewall for any re a

s on.

Remember that the vehicle manufacturer , not

the t ire manufacturer , determ ines the correct

tire pressure for the tires on your veh icle .

It is important to check the tire pressure when

the t ires a re cold .

- Read the req uired tire press ure from the tire

pressure label located on driver's s ide B-pil

l ar .

- Turn the valve stem cap counter-clockwise

to remove it from the tire valve .

- Place the air pressure ga uge on the valve.

- The tire pressures sho uld on ly be checked

and adjusted when the tires are cold . The

s light ly raised pressures of warm tires must

not be reduced.

- Adjust the tire pressure to the load you are

carrying.

- Re insta ll the va lve stem cap on the valve .

When should I check the tire pressure?

The correct tire pressure is espec ially impo r

tant at high speeds . The pressure sho uld

therefore be checked at least once a month

and a lways befo re starting a journey.

When should I adjust the tire pressures?

Adj ust the tire pressu re to the load you are

carry ing . After changi ng a wheel

or replacing

Tire s an d wheel s 203

whee ls yo u have to adjust the ti re p ressu res

o n all whee ls. In addition, yo u m ust then initi

a lize the new tire pressu res in the t ire pres

s u re monitoring system

Q page 214.

A WARNING

Incorrect tire pressures and/or underinfla

tion can lead sudden tire fa ilure, loss of

control, collision, serio us pe rsonal injury

or even death.

- When the warning symbol

[I] appears in

the instrument cluster, stop and inspect

the t ires.

- Inco rrect tire pressure and/or underinfla

tion can cause increased tire wea r and

can affect the handling of the vehicle and

stopping ability.

- Inco rrect tire pressures and/or underin

flation can a lso lead to sudden t ire fail

ure, including a blowou t and su dden de

flation, ca using loss of veh icle cont ro l.

- Th e drive r is responsi ble for the correc t

tire pressures for all tires on the veh icle.

The applicable pressure values a re locat

ed on a sticke r on the dr iver's side B-pil

lar.

- On ly when all tires on the vehicle are fil

led to the correct pressure, the t ire pres

sure mon itor ing system can work cor

rectly.

- The use of incorrect tire pressu re va lues

can lead to acc idents or other damage.

Therefore it is essential that the driver

observe the spec ified t ire pressure values

for the tires and the correct pressures for

the function of th e ti r e p ressu re monito r

ing system.

- Always inf late tires to the recommended

a nd correct t ire p ress ure before dr iv ing

off.

- Driving with unde rinflated tir es bend

mo re, letting t hem get too hot resulting

in tre ad separation, sudden tire f ailure

and loss of cont rol.

- Exces sive speed and/overloading can

cause he at bu ild- up, sudden tire failure

an d loss of cont rol. •

•

Page 217 of 262

remain continuous ly illuminated . This se

quence will continue upon subsequent vehicle

start-ups as long as the ma lfunction ex ists.

When the malfunct ion indicator is ill uminat

ed, the system may not be able to detect or

signa l low tire pressure as intended. TPMS

malfunct ions may occur for a variety of rea

sons, including the installat ion of replace

ment or alternate tires or wheels on the veh i

cle that prevent the TPMS from funct io ni ng

properly. Always check the TPMS malfunct ion

tellta le afte r replacing one or more t ires or

wheels on your veh icle to ensure that the re

p lacement or a lternate tires and wheels allow

the TPMS to continue to function properly.

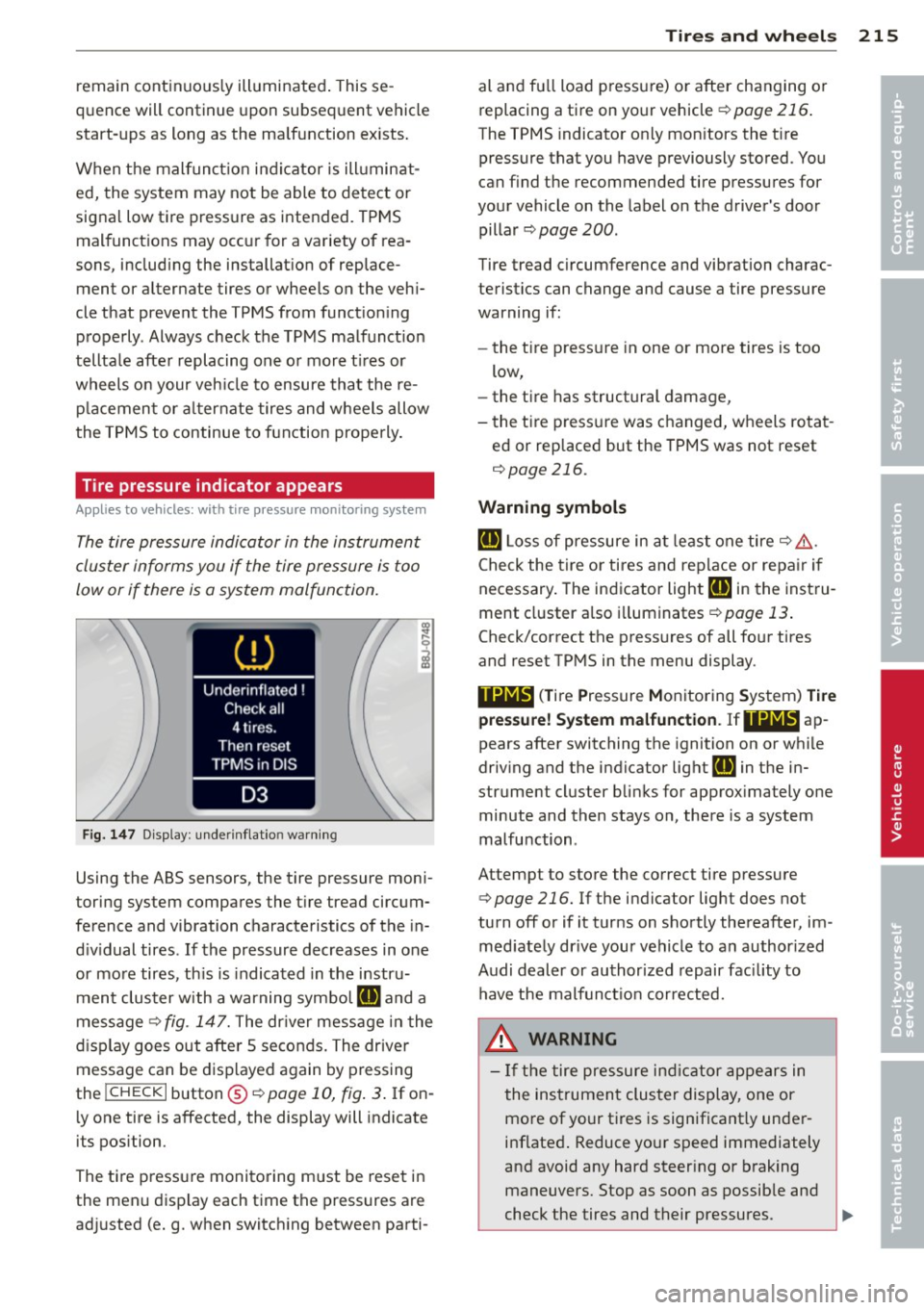

Tire pressure indicator appears

Applies to vehicles: with tire pressure monitoring system

The tire pressure indicator in the instrument

cluster informs you if the tire pressure is too

low or if there is a system malfunction.

F ig. 1 47 Disp lay : under infla tion warn ing

Using the ABS sensors, the tire pressure moni

toring system compares the t ire tread circum

fe rence and vibration characteristics of the in

d iv idual tires . If the pressure decreases in one

or mo re tires, th is is indicated in the instru

ment clus ter with a warning symbol

RE and a

message

'* fig. 147. The dr iver message in the

d isp lay goes out after 5 seconds. The driver

message can be d isplayed again by pressing

the

! CHECK I button @¢ page 10, fig . 3 . If on

ly one tire is affected, the display will indicate

its pos ition.

The ti re pressure monito ring m ust be reset in

the menu display each time the pressures are

ad justed (e.g. when switching between parti-

Tire s an d wheel s 215

al and fu ll load pressure) or after changing o r

replacing a tire on your vehicle '*

page 216.

The TPMS indicator on ly mon itors the t ire

pressure that you have previously stored . You

can f ind the recommended tire pressures for

your vehicle on the label on the driver's door

pillar ¢

page 200.

Tire tread circumference and vibration charac

teristics can change and cause a tire pressure

warning if:

- the t ire press ure in one or more tires is too

low,

- the tire has structural damage,

- the t ire press ure was changed, wheels rotat -

ed or rep laced but the TPMS was not reset

¢ page 216.

Warning symbo ls

RE L oss of pressure in a t least one tire ¢ ,&..

Check the tire or tires and rep lace or repa ir if

necessary . The indicator light

RE in the inst ru

ment cluster a lso i lluminates

¢ page 13 .

Check/correct the press ures of all four tires

and reset TPMS in the menu display .

Iii;~, (T ire Pressure Monitoring System) Ti re

pre ssure! System malfun ction .

Ifllilff' ap

pears after switching the ignition on or whi le

driv ing and the indicator light

RE in the in

strument cluster blinks for approx imately one

minute and then stays on, there is a system

malfunction .

Attempt to store the correct tire pressure '*

page 216. If the indicator light does not

turn off or if it turns on shortly thereafter, im

med iate ly dr ive your vehicle to a n author ized

Audi dealer or author ized repair fac ility to

have the malfunct io n cor rected.

.8, WARNING

-

- If the tire pressure ind ic a tor ap pears in

the ins trumen t cluster display, one or

more of your tires is significant ly under

inflated . Reduce yo ur speed immediately

and avoid any hard steer ing or braking

maneuvers. Stop as soon as possible and

check the tires and their pressures.

~

•

•

Page 218 of 262

216 Tires and wheels

Inflate the tire pressure to the proper

pressure as indicated on the vehicle's tire

pressure label¢

page 200. Driving on a

significantly under-inflated tire causes

the tire to overheat and can lead to tire

failure. Under-inflation also is likely to

impair the vehicle's handling and stop

ping ability .

- The driver is responsible for maintaining

the correct tire pressures. You must

check the tire pressures regularly.

- Under certain conditions (such as a spor

ty driving style, winter conditions or un

paved roads), the pressure monitor ind i

cator may be delayed.

- Ask your authorized Audi dealer if run

flat tires may be used on your vehicle .

Your vehicle registration becomes invalid

if you use these tires when not permit

ted. Damage to your veh icle or accidents

could also result.

- If you switch between standard and run

flat tires, an authorized Audi dealer or

qualified workshop must reprogram the

control module .

@ Tips

-The tire pressure monitoring system

stops working when there is an ESC/ABS

malfunction.

- Using snow chains may result in a system

malfunction .

- The tire pressure monitoring system on

your Audi was developed using t ires with

the "AO" or "RO" identification on the

tire sidewall ¢

page 207. We recom

mend using these tir es.

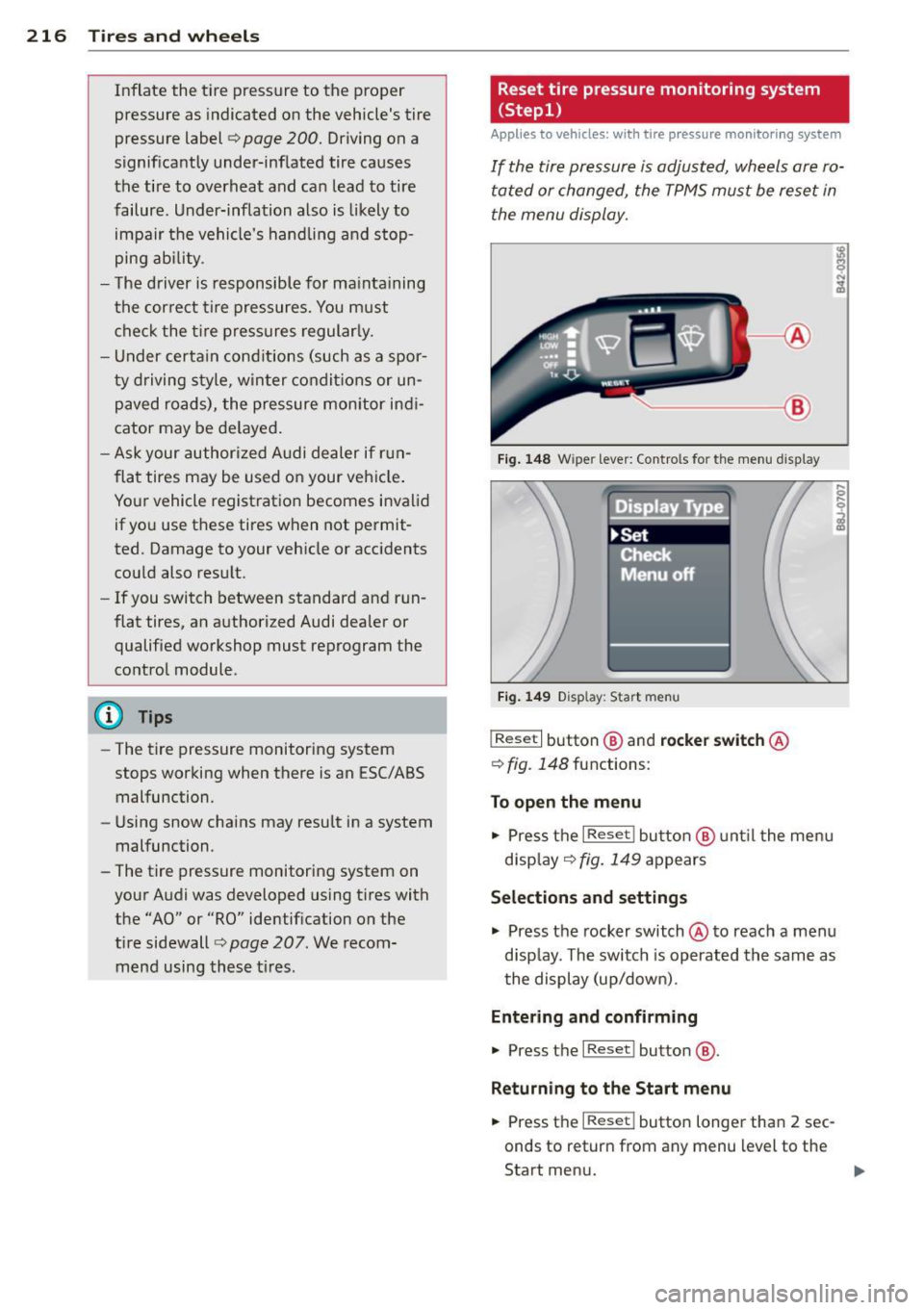

Reset tire pressure monitoring system

(Stepl)

Applies to veh icles: w ith tire pressure monitoring system

If the tire pressure is adjusted, wheels are ro

tated or changed, the TPMS must be reset in

the menu display.

----- ®

Fig. 148 Wipe r lever: Contro ls fo r the menu d isplay

Fig. 149 Disp lay: S ta rt m enu

I Rese t I button @ and rocker switch @

¢

fig. 148 functions:

To open the menu

" Press the I Reset ! button @ unt il the menu

disp lay

~fig. 149 appears

Selections and settings

" Press the rocker switch @ to reach a menu

disp lay. The switch is operated the same as

the display (up/down) .

Entering and confirming

" Press the I Reset I button @.

Returning to the Start menu

" Press the I Rese t I button longer than 2 sec

onds to return from any menu level to the

Start menu.

Page 225 of 262

~ Drive the vehicle slow ly 10 meters back

ward or forward. This helps to distribute the

sealant better .

~ Remove the empty inflation bott le and

screw the hose ®¢

fig. 155 from the elec

tric pump directly onto the valve.

~ Insert the plug©¢ fig. 155 into the socket

for the cigarette lighter.

~ Switc h on the igni tion.

~ Move the switch @¢ fig. 156 on the e lec

tric a ir pump

ll to posi tion I. After 5 mi

nutes, tire pressure must have reached at

least 1.8 bar.

~ Switch the electric a ir pump off - switch in

position

0 . If the requ ired tire pressure of at

least 1.8 bar has not been reached, it is not

poss ible to make a repa ir with the tire seal

ant. Seek professional ass istance.

Disassembling Tire Mobility System

~ Remove the hose from the valve and pu ll

the plug out of the socket.

~ Screw the dust cap onto the valve.

~ Place the empty sealant bottle back in the

original packag ing and clip it in place under

the floor so that no tire sealant can run out

into the vehicle.

~ Place the elect ric air pump in the luggage

compartment for the time being.

~ Start driving right away so that the sealant

is distributed in the tire.

A WARNING

-Follow the manufacturer's safety instruc

t ions on the deca l for the air pump and

the sealant bott le.

- If a t ire pressure of 1.8 bar cannot be

achieved after pump ing for 5 m inutes,

the tire is too severely damaged. Do not

continue to drive .

- Seek profess ional assistance if it is not

poss ible to repair the tire with the tire

sealant.

l ) The e lectr ic air pump s hould never r un for longer than

6 min utes.

What do I do now? 223

(D Tips

-Do not operate the electric air pump for

more than 6 minutes witho ut stopping,

otherwise it can overheat. When the a ir

pump has coo led down, you can continue

to use it.

- If sealant has escaped, allow it to dry,

then you can peel it off.

Final check

App lies to vehicles: wit h Tire Mobility System

After driving for a short distance, tire

pressure must be checked

~ After d riving for about 10 m inutes, stop

and check the tire pressure.

~ If tire pressure is still at leas t 1.3 bar, in

flate the tire to specified pressure (see driv

ers side B -pillar), drive to the next repair

shop and have the tire and the sealant bot

tle replaced.

~ If tire pressure is less than 1.3 bar, the t ire

is too severely damaged. Do not cont inue to

drive . Seek professional assistance.

A WARNING

If t ire pressure is less than 1.3 bar after

driving for 10 minutes, the tire is too se

ve rely damaged. Do not continue to drive.

Seek professional ass istance .

(D Tips

After a tire repair, have the sealant bottle

replaced at a dealership. This restores full

funct iona lity to the Tire Mobility System.

-

•

•

Page 235 of 262

@ Tips

The discharged battery must be properly

connected to the vehicle's electrical sys

tem.

Use of jumper cables

Make sure to connect the jumper coble

clomps in exactly the order described below!

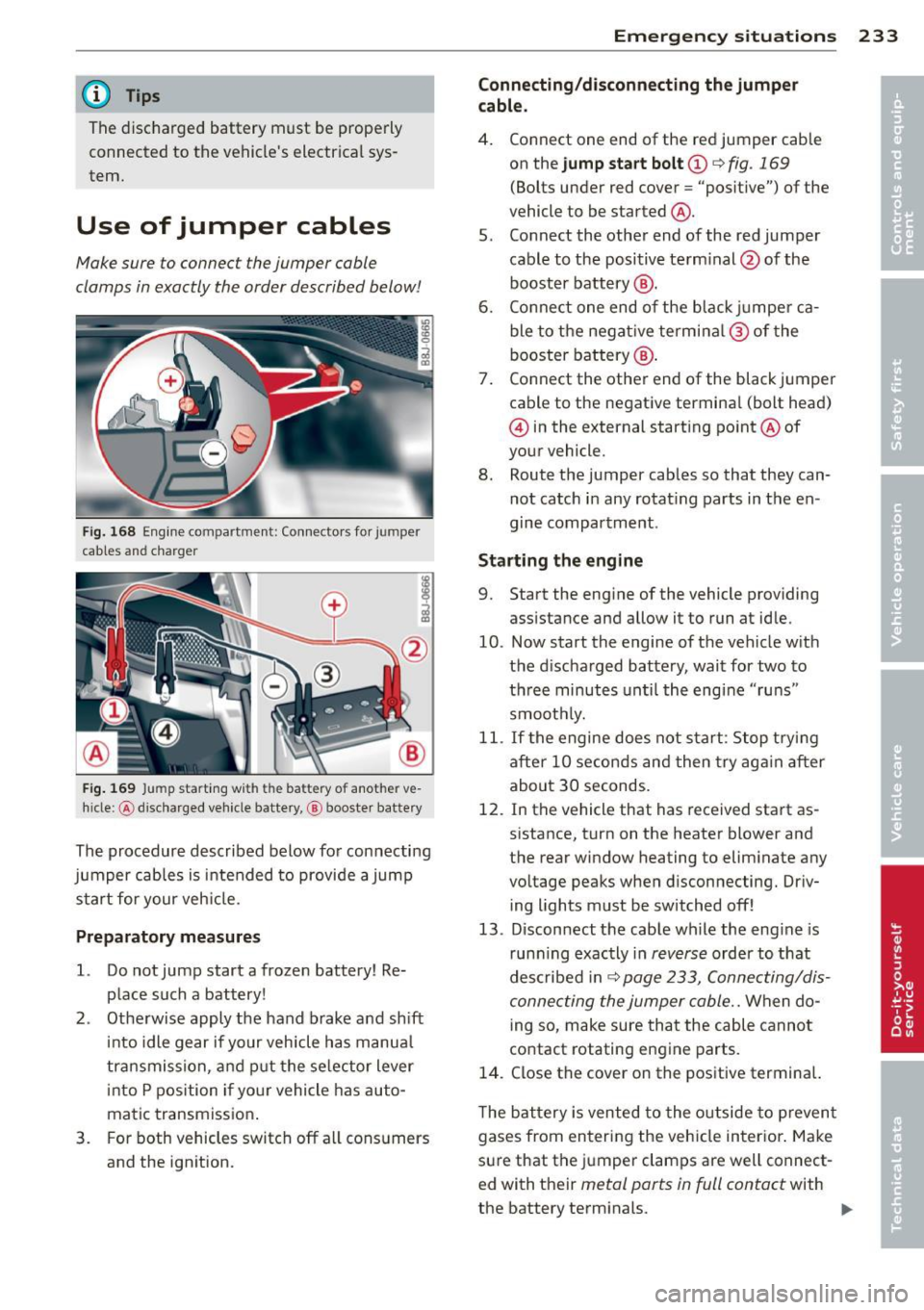

Fi g. 168 Engine compartment: Connecto rs for jumper

cables and charger

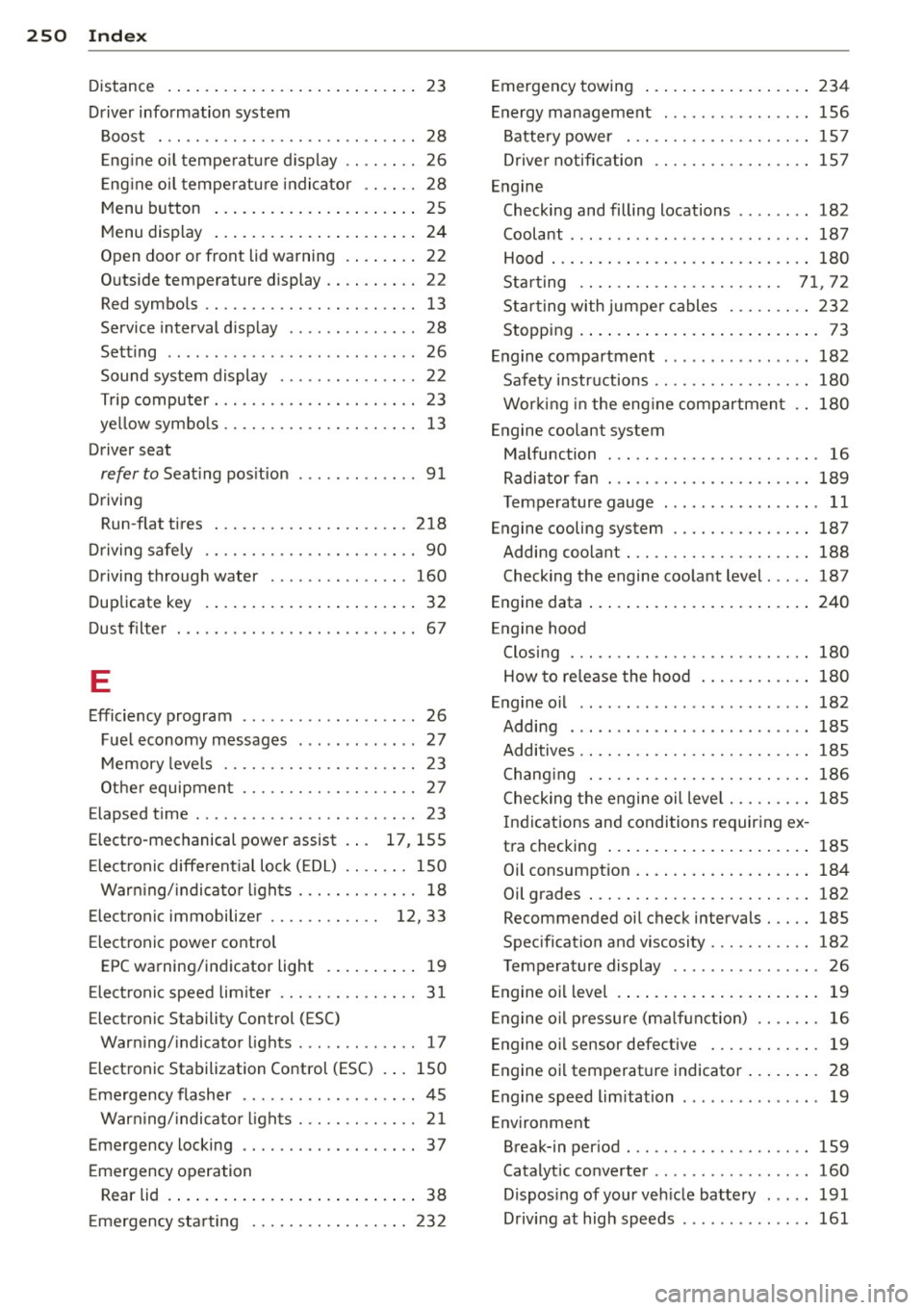

Fig. 169 Jump starting with the battery of another ve

h icle: @discharged veh icle batte ry, @ booste r battery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your veh icle.

Preparatory measures

1. Do not jump start a frozen battery! Re

place such a battery!

2 . Otherwise apply the hand brake and shift

in to idle gear if your veh icle has manua l

transmission , and put the selector lever

into P position if your vehicle has auto

matic transm ission.

3. For both vehicles switch off all consumers

and the ignition.

Emergency situations 233

Connecting/disconnecting the jumper

cable.

4. Connect one end of the red jumper cable

on the

jump start bolt (D c:> fig. 169

(Bolts under red cover= "positive") of the

vehicle to be started @.

5. Connect the other end of the red jumper

cable to the positive term inal @of the

booster battery @.

6. Connect one end of the black jumper ca

ble to the negative terminal@ of the

booster battery @.

7. Connect the other end of the black jumper

cable to the negative terminal (bolt head)

@ in the external starting point @of

your vehicle.

8. Route the jumper cables so that they can not catch in any rotat ing parts in the en

gine compartment .

Starting the engine

9. Start the engine of the vehicle providing

assistance and allow it to run at idle.

10. Now start the engine of the vehicle w ith

the d ischarged battery, wait for two to

three minutes until the engine "runs"

smoot hly.

11. If the engine does not start: Stop trying

after 10 seconds and then try again after

about 30 seconds.

12. In the vehicle that has received start as

s istance, turn on the heater blower and

the rear window heating to eliminate any

voltage peaks when disconnecting. Driv ing lights must be switched off!

13. Disconnect the cable while the eng ine is

running exactly in

reverse order to that

described inc:>

page 233, Connecting/dis

connecting the jumper coble ..

When do

ing so, make sure that the cable cannot

contact rotating engine parts.

14. C lose the cover on the positive terminal.

T he battery is vented to the outside to prevent

gases from entering the vehicle interior . Make

sure that the jumper clamps are well connect

ed with their

metal ports in full contact with

the battery term inals.

Page 252 of 262

250 Index

Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Driver information system Boost .......................... .. 28

E ng ine oi l tempe ratu re d isplay .. .. .... 26

Engine oil temperatu re indicator ...... 28

Menu button . . . . . . . . . . . . . . . . . . . . . . 25

Menu display . . . . . . . . . . . . . . . . . . . . . . 24

Open door or front lid warning . . . . . . . . 22

Outside temperature display .. .. .. .. . . 22

Red symbols ................. ...... 13

Service interval display ...... .. .. .. .. 28

Setting .. .. ... .... ...... ... ... .. .. 26

Sound system display . . . . . . . . . . . . . . . 22

Trip computer. . . . . . . . . . . . . . . . . . . . . . 23

ye llow symbo ls ......... .. .. .. .. .. .. 13

Driver seat

refer to Seat ing pos ition . ........ .. .. 91

Driving Run-flat tires . ........... .... .... . 218

Driving safely . . . . . . . . . . . . . . . . . . . . . . . 90

Driving through water ........ .. .. ... 160

Duplicate key .............. ... .... .. 32

Dust filter . ... .............. .. .. .. .. 67

E

Efficiency program . . . . . . . . . . . . . . . . . . . 26

Fuel economy messages ..... .. .. .... 27

Memory levels . . . . . . . . . . . . . . . . . . . . . 23

Other equipment ........... .. .. .. .. 27

Elapsed time . . . . . . . . . . . . . . . . . . . . . . . . 23

Electro-mechanical power assist . . . 17, 155

E lectronic diffe rent ial lock (EDL) .. .. ... 150

Warn ing/ indicator lights ....... .. .... 18

Electronic immobilizer . . . . . . . . . . . . 12, 33

Electronic power control EPC warning/indicator light . ..... .. .. 19

E lect ronic speed limiter . . . . . . . . . . . . . . . 31

Electronic Stability Control (ESC) Warning/indicator lights ..... .. .. .. . . 17

Electronic Stabilization Control (ESC) . .. 150

E mergency flasher . . . . . . . . . . . . . . . . . . . 45

Warn ing/ indicator l ights ... .... .... .. 21

Emergency locking ............. .... .. 37

Emergency operation

Rear lid . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

E mergency starting ........ .... ..... 232 Emergency towing

.............. .... 234

Energy management . ............ ... 156

Battery power ................ .... 157

Driver notification ............. .. .. 157

Engine Checking and filling locations .... .. .. 182

Coolant . .. ... ... .. .......... ... .. 187

Hood . .... .. .. .. ............. .. .. 180

Starting . . . . . . . . . . . . . . . . . . . . . . 71, 72

Starting with jumper cables ... .. .. .. 232

Stopping .. .... .. .. .............. .. 73

Engine compartment ......... ... .. .. 182

Safety instructions ... .......... .. .. 180

Working in the eng ine compartment 180

Engine coolant system Malfunction ..... ... ........... ... . 16

Radiator fan . .. .. ..... ..... ... .. .. 189

Temperature gauge ....... ..... .. .. . 11

Engine cooling system ........... .... 187

Adding coolant ................ .... 188

Checking the engine coolant level ..... 187

Engine data ..... .. ................ . 240

Engine hood

Closing . .. .. .. .. ............... .. 180

How to release the hood .......... .. 180

Engine oil ...... .. .. ..... ... ... .. .. 182

Adding . ...... .. .. ..... ... ... .. .. 185

Additives .. .. .. .. .. ... ........ .... 185

Changi ng ... .. .. ............. .. .. 186

Checking the engine oil leve l ..... .... 185

Indications and conditions requiring ex-

tra checking ..... ................ . 185

Oil consumption . ................. . 184

Oil grades . ................... .... 182

Recommended oil check intervals . .. .. 185

Specification and viscosity . ...... .. .. 182

Temperature display ........ ... .. .. . 26

Engine oil level .... ................ .. 19

Engine oil pressu re (ma lfunction) .... .. . 16

Engine oil sensor defective . . . . . . . . . . . . 19

Engine oil temperature indicator ........ 28

Engine speed limitation . ......... .. .. . 19

Environment Break-in period .................... 159

Catalytic converter ....... ...... .. .. 160

Dispos ing of your veh icle battery . . . . . 191

Driving at high speeds . ...... ... .. .. 161

Page 258 of 262

256 Index

------------------------------------

Starting on hills

H ill hold ass ist . ....... ... .. .. .... ..

74

Starti ng the eng ine . . . . . . . . . . . . . . 7 1, 7 2

Wha t should I do if the eng ine does no t

s ta rt? . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 2

Steel wheels ........... .... ... .. ... 169

St ee ring

refer to Ele ct ro -me chanic al power as -

s is t . . . . . . . . . . . . . . . . . . . . . . . . .

17, 155

Steer ing column

A dj usting . .... .. ..... ... .. .. .... ..

7 1

Lock ing the st eering . . . . . . . . . . . . . . . . 7 1

Steps fo r de termining co rrect load lim it . 205

Stopp ing the eng ine . . . . . . . . . . . . . . . . . . 73

Sto rage ..... ... .. ..... ... .. .. .... .. 64

Compartment in the front seats ... .. . . 64

Cup holde r . . . . . . . . . . . . . . . . . . . . . . . . 62

Glove compartment . . . . . . . . . . . . . . . . . 64

Storage compartment

E xpanding . . . . . . . . . . . . . . . . . . . . . . . .

59

S tron ic .... ........... ........ ... .. 80

Dr iving Notes . . . . . . . . . . . . . . . . . . . . . . 8 2

Eme rgency program .. .... .. .. .... .. 85

Emergency release . . . . . . . . . . . . . . . . . . 86

K ick -down . . . . . . . . . . . . . . . . . . . . . . . . . 85

Launch Con tro l Program ... .. .... .. . . 85

Selector leve r lock ..... ... .. .. .... .. 81

Selector lever pos it ions . . . . . . . . . . . . . . 80

Tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . . 84

T iptronic controls on t he steering wheel 84

Sun v isors .... .. .. ..... ... .. .. .... .. 4 6

Sw itches

E me rgency flasher . . . . . . . . . . . . . . . . . .

4 5

Symbo ls

Red symbols in the center d isp lay .. ....

13

Yellow symbols in the center d isp lay ... 13

also refer to War ning/Ind icator lights .. 12

T

Tachometer .. .......... ........ ... .. 10

Tank flap

Un lock ing the fue l fille r flap by hand ..

17 9

Tec hni cal mo difi cat ions . .. .. .. .. .... . 24 6

Temper ature ........... ........ ... .. 67

Temperature display

Engin e oi l ... .. .. ..... ... .. .. .... ..

26

Teth er anchors . . . . . . . . . . . . . . . . . . . . . 147

Tether st rap ...... ................ . 147

The first 1,000 miles (1,500 km) and afte r-

wards .. .... .. .. .. ...... ....... ....

159

T ie-downs . . . . . . . . . . . . . . . . . . . . . . 59, 97

T ighte ning whee l bo lts ... ........... . 224

Tips for the envi ronment

S aving fuel .. .. .. .... ... ... .. ..... .

62

Tire mob ility system ...... ....... .... 22 0

Tire pressure ........... ........... . 202

Tire p ressure mo nitor ing system ... .. .. 214

Loss of a ir pres sure ..... ..... .. .... 215

Malfun ction . .. .. .... ... ... ... .. .. 215

Rese tting tire press ures ...... .. 216,217

Tire repa ir k it ... .. .. .... .... ... .. .. 220

T ires .......... .................... 196

Rep lac ing . .. .. . .. ... ... ... .. ... .. 2 0 7

run-fl at ... .. .. .. ... .. ..... ... .... 2 17

Serv ice life .... .. ... .. ..... ... .. .. 2 06

speed ra ting lette r code ..... .... . .. 2 08

Ti re manufact uri ng date ..... ... .. .. 208

T ir e specifications ...... ....... .... 208

Tread dep th . .. .. .... ... ... .. ..... 206

Uniform tire quali ty grad ing . .... .... 210

Winter tires ..... ................ . 211

Tires/Wheels

Low aspect rat io ti res .. ... ... ... .. ..

2 13

Ti re mob ility sy stem ... .. ... ... .. .. 220

Ti re pressure moni toring system . .. .. 214

Tire repair kit .. ............ ....... 2 20

T ires and vehicle load limits .... ... .. .. 204

T ires and wheels

Checking t ire p ress ure . ... ... ... .. ..

2 02

Co ld tire infla tion press ure ... ... .... 200

Dimens ions . ..... .. ... ..... ... .. .. 2 07

Gen eral notes . . . . . . . . . . . . . . . . . . . . . 196

G lossary of tir e and loading t erm inolo-

gy ....... .... .. ...... ... ... .....

197

New tires and wheels .. ... ... ... .. .. 207

Replac ing ... .. .. ... .. ..... ..... .. 208

S now cha ins . .. ............ ....... 212

Tires and veh icle load limits ......... 204

Whee l bolts . .. .. ... .. ..... ... .. .. 2 13

Winter tires . .. .. .... ... ... ... .. .. 2 11

Tire service life .. .. ... .. ..... ..... .. 206

Too l kit . ... .... .. ... .. ..... .... . .. 220

To uch -u p pa int .. .. .... ... ... ... .. .. 168