warning AUDI TT COUPE 2014 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2014, Model line: TT COUPE, Model: AUDI TT COUPE 2014Pages: 284, PDF Size: 34.42 MB

Page 244 of 284

Downloaded from www.Manualslib.com manuals search engine Mobility

Tool kit/tyre repair kit/compressor

Fig. 223 Luggage compartment: Floor panel (closed)

The tools, tyre repair kit and compressor are stor

ed under the floor panel in the luggage compart

ment.

"' Press the plastic handle and Lift up the floor

panel.

"' Fold back the floor panel.

Before stowing the jack* again, wind down the

arm of the jack as far as it will go.

Tyre repair kit

Preparations

Applies to vehicles: with tyre repair kit

"' Please refer to the important safety notes

¢page 241.

"'Apply the parking brake.

"' Manual gearbox: Engage first gear.

"' Automatic gearbox: Move the selector lever to

position P.

"' Check whether a repair is possible using the

tyre repair kit¢ page 242.

Using the tyre repair kit

Applies to vehicles: with tyre repair kit

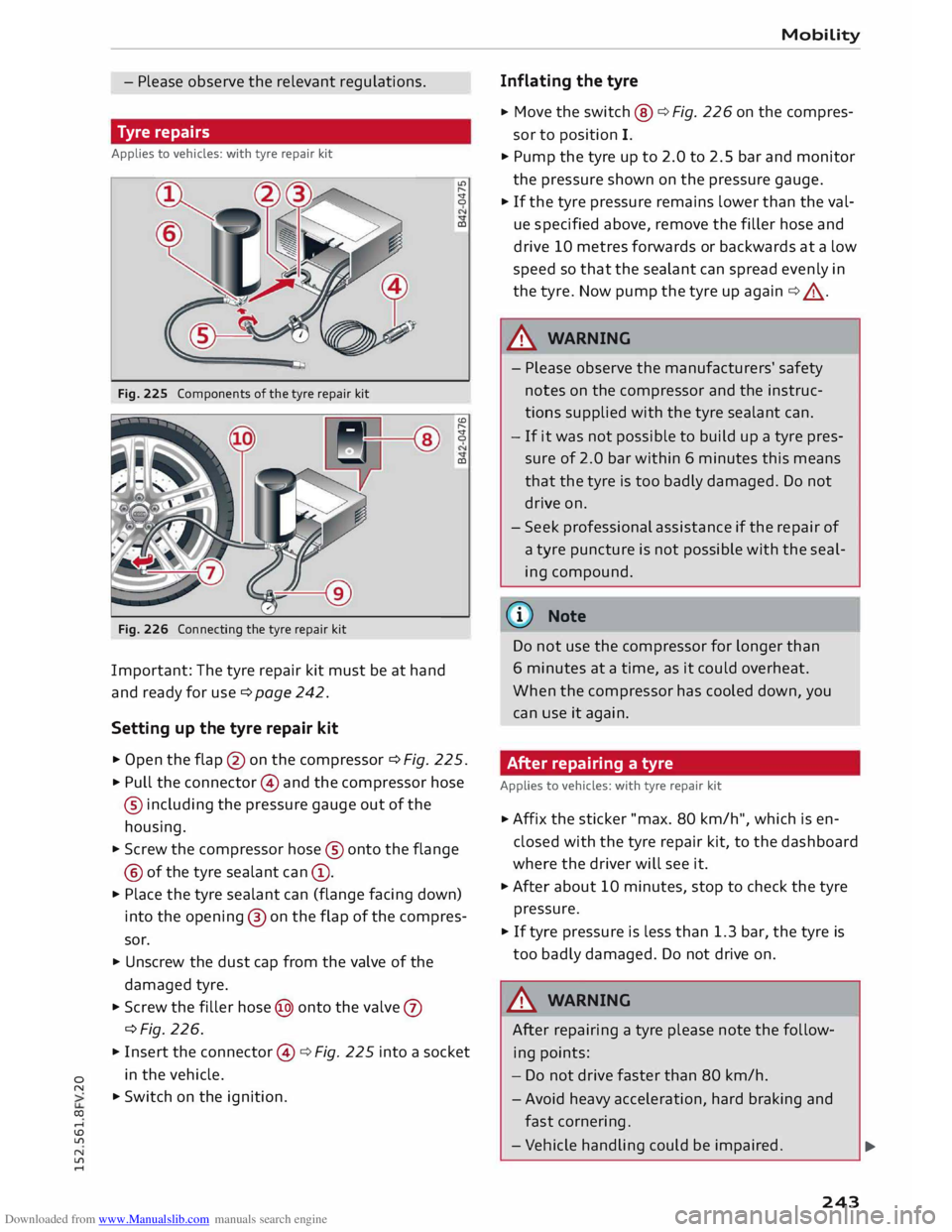

Fig. 224 Tyres: Irreparable tyre damage

242 Repaired

tyres are only suitable for temporary

use. Replace the damaged tyre as quickly as pos

sible ¢,&..

If the tyre was damaged by an object, such as a

nail, do not remove it from the tyre.

The tyre repair kit can be used at outside temper

atures down to - 20 °(.

The tyre repair kit must NOT be used:

- On cuts and punctures larger than 4 mm (D

¢Fig. 224

- If the wheel rim has been damaged @.

- if you have been driving with very low pressure

or a completely flat tyre@

.

In these cases, you should seek professional as

sistance.

A WARNING

- Pl ease note that the tyre repair kit is not

suitable for use in every situation and

should only be used as a temporary meas

ure.

- Do not allow the sealant to come into con

tact with your eyes, skin or clothing.

- If you do come into contact with the sealant

immediately rinse the eyes or skin affected

with clean water.

- Make sure you do not breathe in the fumes.

- If you accidentally swallow tyre sealant, im-

mediately rinse your mouth thoroughly and

drink a large amount of water. Do not in

duce vomiting. Immediately contact a doc

tor.

- Change clothing immediately if it becomes

soiled with the tyre sealant.

- If

any allergic reactions should occur get

medical help immediately.

- Keep the sealant away from children.

(©) Note

- If sealant should leak out, leave it to dry.

When it has dried, you can pull it off Like a

piece of foil.

- Observe the expiry date stated on the seal

ing compound can. Have the sealing com

pound exchanged by a qualified workshop.

Page 245 of 284

Downloaded from www.Manualslib.com manuals search engine 0

N

co

....

\D L/'l

N

L/'l

.... -

Please observe the relevant regulations.

Tyre repairs

Applies to vehicles: with tyre repair kit

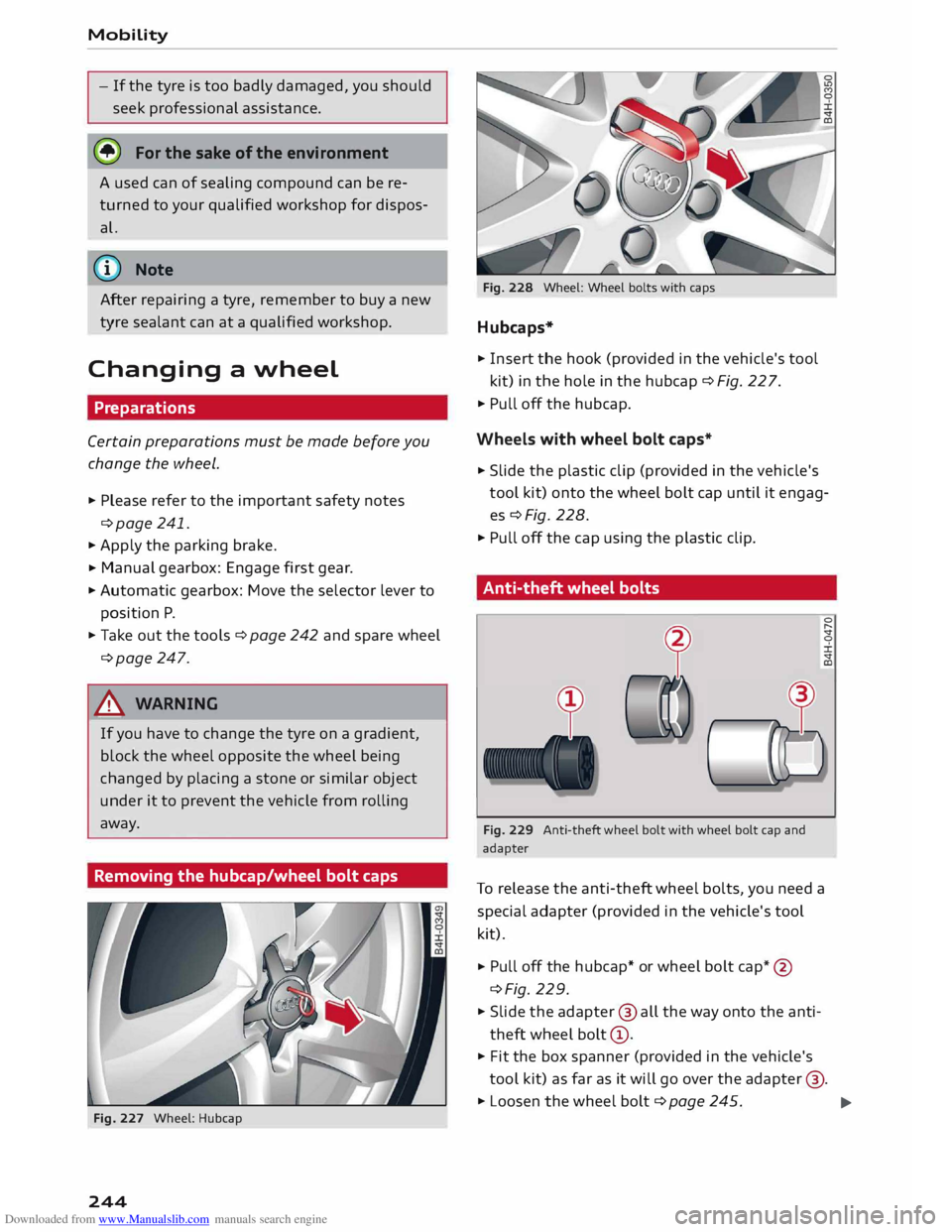

Fig. 225 Components of the tyre repair kit

Fig. 226 Connecting the tyre repair kit

Important: The tyre repair kit must be at hand

and ready for use¢ page 242.

Setting up the tyre repair kit LC'>

.....

'St

0

CD

'St

0

CD

.,. Open the flap @on the compressor ¢ Fig. 225.

.,. Pull the connector @ and the compressor hose

® including the pressure gauge out of the

housing.

.,. Screw the compressor hose® onto the flange

@ of the tyre sealant can (D.

.,. Place

the tyre sealant can (flange facing down)

into the opening ® on the flap of the compres

sor.

.,. Unscrew the dust cap from the valve of the

damaged tyre.

.,. Screw the filler hose@ onto the valve (J)

¢Fig. 226.

.,. Insert the connector @¢ Fig. 225 into a socket

in the vehicle.

.,. Switch on the ignition. Mobility

Inflating the tyre

.,. Move

the switch @¢ Fig. 226 on the compres

sor to position I.

.,. Pump the tyre up to 2.0 to 2.5 bar and monitor

the pressure shown on the pressure gauge.

.,. If the tyre pressure remains lower than the val

ue specified above, remove the filler hose and

drive 10 metres forwards or backwards at a low

speed so that the sealant can spread evenly in

the tyre. Now pump the tyre up again ¢_&..

A WARNING

- Please observe the manufacturers' safety

notes on the compressor and the instruc

tions supplied with the tyre sealant can.

- If it was not possible to build up a tyre pres

sure of 2.0 bar within 6 minutes this means

that the tyre is too badly damaged. Do not

drive on.

- Seek professional assistance if the repair of

a tyre puncture is not possible with the seal

ing compound.

(!)) Note

Do not use the compressor for longer than

6 minutes at a time, as it could overheat.

When the compressor has cooled down, you

can use it again.

After repairing a tyre

Applies to vehicles: with tyre repair kit

.,. Affix

the sticker "max. 80 km/h", which is en

closed with the tyre repair kit, to the dashboard

where the driver will see it.

.,. After about 10 minutes, stop to check the tyre

pressure.

.,. If tyre pressure is less than 1.3 bar, the tyre is

too badly damaged. Do not drive on .

A WARNING

After repairing a tyre please note the follow

ing points:

- Do not drive faster than 80 km/h.

- Avoid heavy acceleration, hard braking and

fast cornering .

- Vehicle handling could be impaired.

.,..

243

Page 246 of 284

Downloaded from www.Manualslib.com manuals search engine Mobility

- If the tyre is too badly damaged, you should

seek professional assistance.

(f!j} For the sake of the environment

A used can of sealing compound can be re

turned to your qualified workshop for dispos

al.

ij) Note

After repairing a tyre, remember to buy a new

tyre sealant can at a qualified workshop.

Changing a wheel

Preparations

Certain preparations must be made before you

change the wheel.

� Please refer to the important safety notes

¢page 241.

� Apply the parking brake.

� Manual

gearbox: Engage first gear.

� Automatic gearbox: Move the selector lever to

position P.

� Take out the tools ¢ page 242 and spare wheel

¢page 247.

A WARNING

If you have to change the tyre on a gradient,

block the wheel opposite the wheel being

changed by placing a stone or similar object

under it to prevent the vehicle from rolling

away.

Removing the hubcap/wheel bolt caps

Fig. 227 Wheel: Hubcap

244 Fig.

228 Wheel: Wheel bolts with caps

Hubcaps*

� Insert the hook (provided in the vehicle's tool

kit) in the hole in the hubcap ¢ Fig. 22 7.

� Pull off the hubcap.

Wheels with wheel bolt caps*

� Slide

the plastic clip (provided in the vehicle's

tool kit) onto the wheel bolt cap until it engag

es¢ Fig. 228.

� Pull off the cap using the plastic clip.

Anti-theft wheel bolts

Fig. 229 Anti-theft wheel bolt with wheel bolt cap and

adapter

To release the anti-theft wheel bolts, you need a

special adapter (provided in the vehicle's tool

kit).

� Pull

off the hubcap* or wheel bolt cap*@

¢Fig. 229.

� Slide the adapter @ all the way onto the anti

theft wheel bolt@.

� Fit

the box spanner (provided in the vehicle's

tool kit) as far as it will go over the adapter @.

� Loosen the wheel bolt ¢page 245.

..,.

Page 247 of 284

Downloaded from www.Manualslib.com manuals search engine 0

N

co

,-j

\D L/'l

N

L/'l

,-j �

Note

Note the code number of the anti-theft wheel

bolt and keep it in a safe place -not in your

vehicle. If you need a replacement adapter,

give the code number to your Audi dealer.

Loosening the wheel bolts

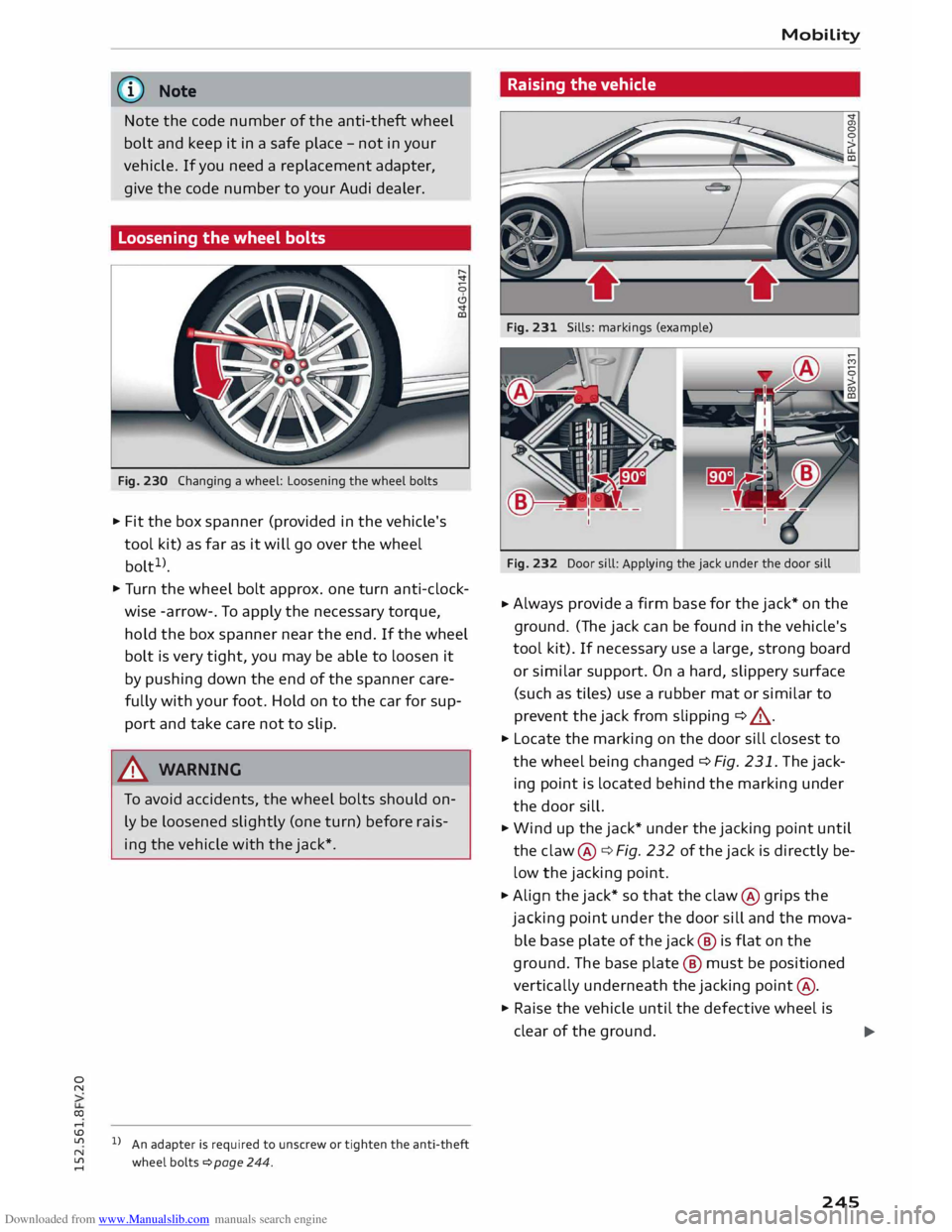

Fig. 230 Changing a wheel: Loosening the wheel bolts

.,. Fit the box spanner (provided in the vehicle's

tool kit) as far as it will go over the wheel

bolt 1

>.

.,. Turn the wheel bolt approx. one turn anti-clock

wise -arrow-. To apply the necessary torque,

hold the box spanner near the end. If the wheel

bolt is very tight, you may be able to loosen it

by pushing down the end of the spanner care

fully with your foot. Hold on to the car for sup

port and take care not to slip.

.&_ WARNING

To avoid accidents, the wheel bolts should on

ly be loosened slightly (one turn) before rais

ing the vehicle with the jack*.

l l

An adapter is required to unscrew or tighten the anti-theft

wheel bolts � page 244. Mobility

Raising the vehicle

Fig. 231 Sills: markings (example)

Fig. 232 Door sill: Applying the jack under the door sill

.,. Always

provide a firm base for the jack* on the

ground. (The jack can be found in the vehicle's

tool kit). If necessary use a large, strong board

or similar support. On a hard, slippery surface

(such as tiles) use a rubber mat or similar to

prevent the jack from slipping ¢ ,,&.

.,. Locate the marking on the door sill closest to

the wheel being changed ¢ Fig. 231. The jack

ing point is located behind the marking under

the door sill.

.,. Wind up the jack* under the jacking point until

the claw @¢ Fig. 232 of the jack is directly be

low the jacking point .

.,. Align the jack* so that the claw @ grips the

jacking point under the door sill and the mova

ble base plate of the jack @ is flat on the

ground. The base plate @ must be positioned

vertically underneath the jacking point@ .

.,. Raise the vehicle until the defective wheel is

clear of the ground.

.,.

245

Page 248 of 284

Downloaded from www.Manualslib.com manuals search engine Mobility

.&_ WARNING

- Make sure the jack* is stable. If the ground

underneath the jack* is slippery or soft, the

jack can slip or sink in -risk of injury!

- Use only the jack* supplied with your vehicle

to raise the vehicle. If you use a jack from a

different vehicle, your vehicle may slip off

the jack -risk of injury!

- Apply the jack* only at the jacking points Lo

cated behind the markings on the door sill

and align it properly. Otherwise there is a

risk of injury since the jack* can slip off sud

denly if it is not properly engaged.

- The height of the parked vehicle can change

as a result of variations in Loading.

- Never start the engine when the vehicle is

on the jack -risk of accident!

- If work has to be done under the vehicle, en

sure that it is safely supported on suitable

stands -risk of injury!

CD CAUTION

The vehicle must not be lifted up on its sills.

Only apply the jack* at the jacking points Loca

ted behind the markings on the door sill. Oth

erwise your vehicle could be damaged.

Taking off/ putting on the wheel

Fig. 233 Wheel: Hexagonal socket for turning wheel bolts

246 Fig.

234 Wheel: Mounting pin in wheel bolt hole nearest

to the top

Taking off the wheel

... Using the hexagonal socket in the screwdriver

handle {provided in the vehicle's tool kit), un

screw the top wheel bolt and place it on a clean

surface ¢ Fig. 233.

... Screw in the mounting pin (provided in the ve

hicle's tool kit) by hand in place of the wheel

bolt¢ Fig. 234.

.,. Then unscrew the other wheel bolts .

.,. Take off the wheel ¢(D

. The mounting pin

stays where it is.

Putting on the wheel

When putting on a tyre with directional tread

pattern, refer to ¢ page 247.

.,. Put on the wheel, using the mounting pin to

guide it into place ¢(D

.

.,. Screw in the wheel bolts and tighten them

lightly using the hexagonal socket .

... Then unscrew the mounting pin and tighten the

remaining wheel bolt lightly .

... Carefully lower the car with the jack* .

.,. Tighten the wheel bolts in diagonal sequence

with the box spanner.

The wheel bolts should be clean and turn easily.

Before putting on the wheel, inspect the condi

tion of the wheel and hub mounting surfaces.

These surfaces must be clean before mounting

the wheel.

.&_ WARNING

Do not use the hexagonal socket in the screw-

driver handle to tighten the wheel bolts. It is ..,.

Page 250 of 284

Downloaded from www.Manualslib.com manuals search engine Mobility

Snow chains

For technical reasons, snow chains must not be

used on the compact temporary spare wheel.

Sheu ld you have a puncture on one of the front

wheels when using snow chains, fit the compact

temporary spare wheel in place of one of the rear

wheels. You can then attach the snow chains to

the wheel taken from the rear and use this wheel

to replace the punctured front wheel.

A WARNING

- The tyre pressure must be checked as soon

as possible after fitting the spare wheel-an

incorrectly inflated tyre can increase the risk

of accident. You can find the tyre pressures

here ¢ page 233, Fig. 220.

- Do not drive faster than 80 km/h when the

compact temporary spare wheel is fitted -

higher speeds can cause an accident.

- Avoid heavy acceleration, hard braking and

fast cornering when the compact temporary

spare wheel is fitted -risk of accident!

- Never use two or more compact spare tyres

at the same time -risk of accident!

- No other type of tyre (normal summer or

winter tyres) may be fitted on the compact

temporary spare wheel.

]ump-starting Before starting the engine

If necessary, the engine can be started by con

necting it to the battery of another vehicle.

If the engine fails to start because of a dis

charged battery, the battery can be connected to

the battery of another vehicle to start the engine.

Suitable jump Leads are required.

Both batteries must be rated at 12 Volts. The ca

pacity (Ah) of the booster battery should not be

significantly lower than that of the discharged

battery.

Jump Leads

The jump Leads must be heavy enough to carry

the starter current. Refer to the details given by

the manufacturer.

248 Only

use jump leads with insulated battery

clamps.

Positive cable -usually red.

Negative cable -usually black.

A WARNING

- When it is discharged the battery can freeze

at temperatures around 0°

(. A frozen bat

tery must first be thawed out before con

necting the jump leads, as it could other

wise explode.

- Note the safety warnings referring to work

ing in the engine compartment ¢ page 220.

(© Note

- There must be no contact between the two

vehicles as otherwise current could flow as

soon as the positive terminals are connec

ted and the boosting battery could be dis

charged.

- The disch arged battery must be properly

connected to the vehicle's electrical system.

- Switch off the car telephone if necessary.

Details will be given in the manufacturer's

instructions for the car telephone.

Page 251 of 284

Downloaded from www.Manualslib.com manuals search engine N

....

Lfl

N

Lfl

.... Starting

the engine

The jump leads must be connected in the correct

sequence.

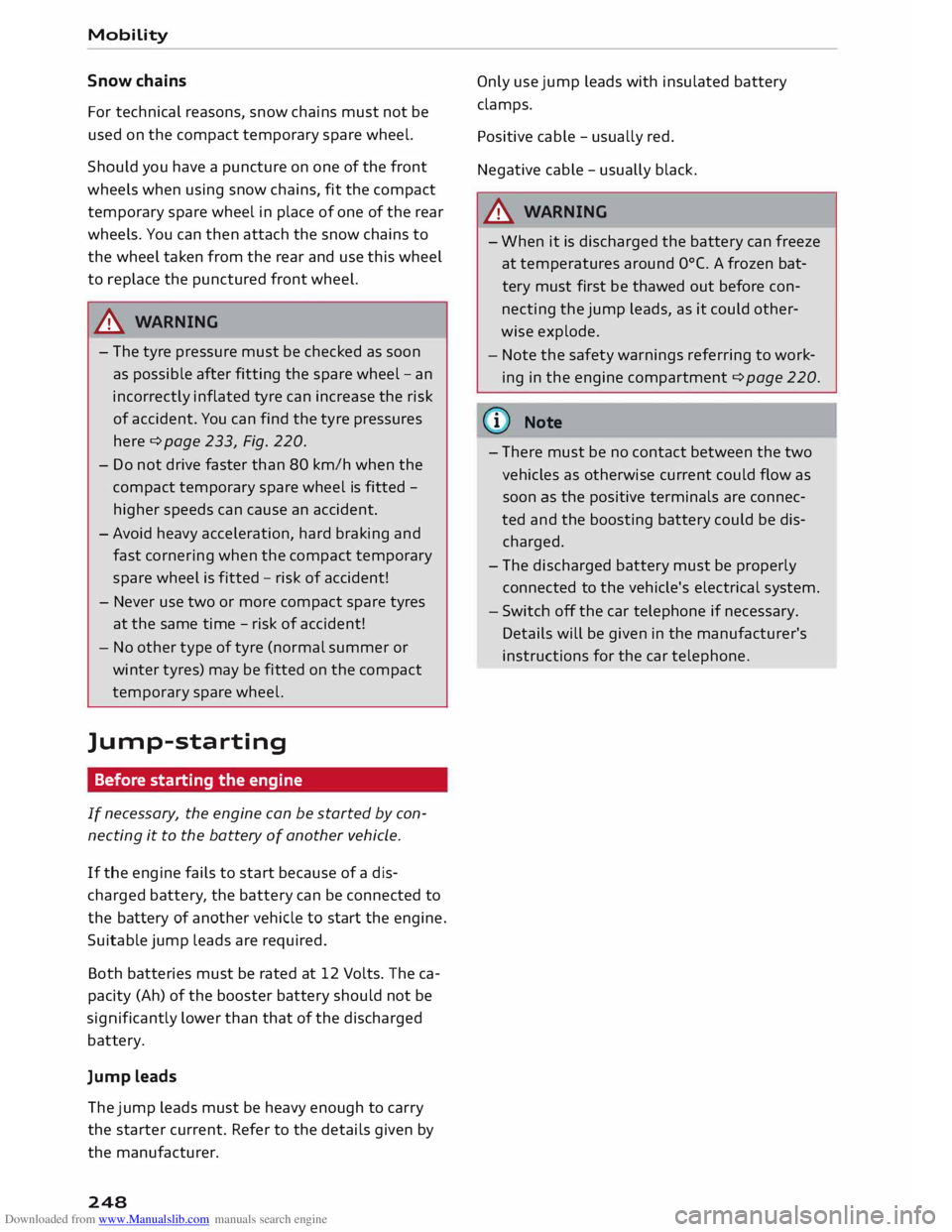

Fig. 237 Engine compartment: Terminals for jump leads

and battery charger

Fig. 238 Jump-starting with the battery of another vehi

cle: A -Discharged battery, B -Boosting battery

Please note that the described method of con

necting the leads is meant for jump-starting your

vehicle.

Preparations

1. Do not attempt to jump-start a vehicle with a

battery which has been frozen. If a battery

has frozen it must be replaced.

2. Apply the handbrake and move the gear lever

to neutral (manual gearbox) or move these

lector Lever to P (automatic gearbox).

3. Switch off all electrical equipment and the ig-

nition on both vehicles.

Connecting and disconnecting the jump

leads

4.

5. Before

jump-starting the vehicle you must

open the cap on the positive terminal.

Connect one end of the red jump lead to the

positive terminal (!) ¢Fig. 238 ofthejump

start connection @ in your vehicle. Mobility

6. Connect

the other end of the red jump lead

to the positive terminal @ofthe boosting

battery @.

7. Connect one end of the black lead to the neg

ative terminal@ of the boosting [email protected] the other end of the black jump lead

to the negative terminal (bolt head) © of the

jump-start connection@ in your vehicle.

9.

Position the jump leads in such a way that

they cannot come into contact with any mov

ing parts in the engine compartment.

Starting the engine

10. Start the engine of the vehicle with the

boosting battery and let it run at idling

speed.

11. Start the engine of the car with the dis

charged battery and wait two or three mi

nutes until the engine is running smoothly.

12. If the engine fails to start: do not operate the

starter for longer than 10 seconds. Wait for

about 30 seconds and try again.

13. Switch

on the blower and the rear window

heating on the vehicle which has been jump

started in order to offset excessive voltage

which may occur when disconnecting the

leads. The headlights must be switched off!

14. When the engines are running, disconnect

the leads in exactly the opposite sequence to

that described on¢ page 249, Connecting

and disconnecting the jump leads. Make sure

that the leads cannot come into contact with

any moving parts in the engine compart

ment.

15. Close the cap on the positive terminal.

16. Switch off the blower and the rear window

heating again.

_& WARNING

- The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the

vehicle: this can cause short circuiting.

- Do not lean over the batteries -risk of acid

burns!

- The screw plugs on the battery cells must be

screwed in firmly.

.,..

249

Page 253 of 284

Downloaded from www.Manualslib.com manuals search engine 0

N

co

....

\D U'l ,&.

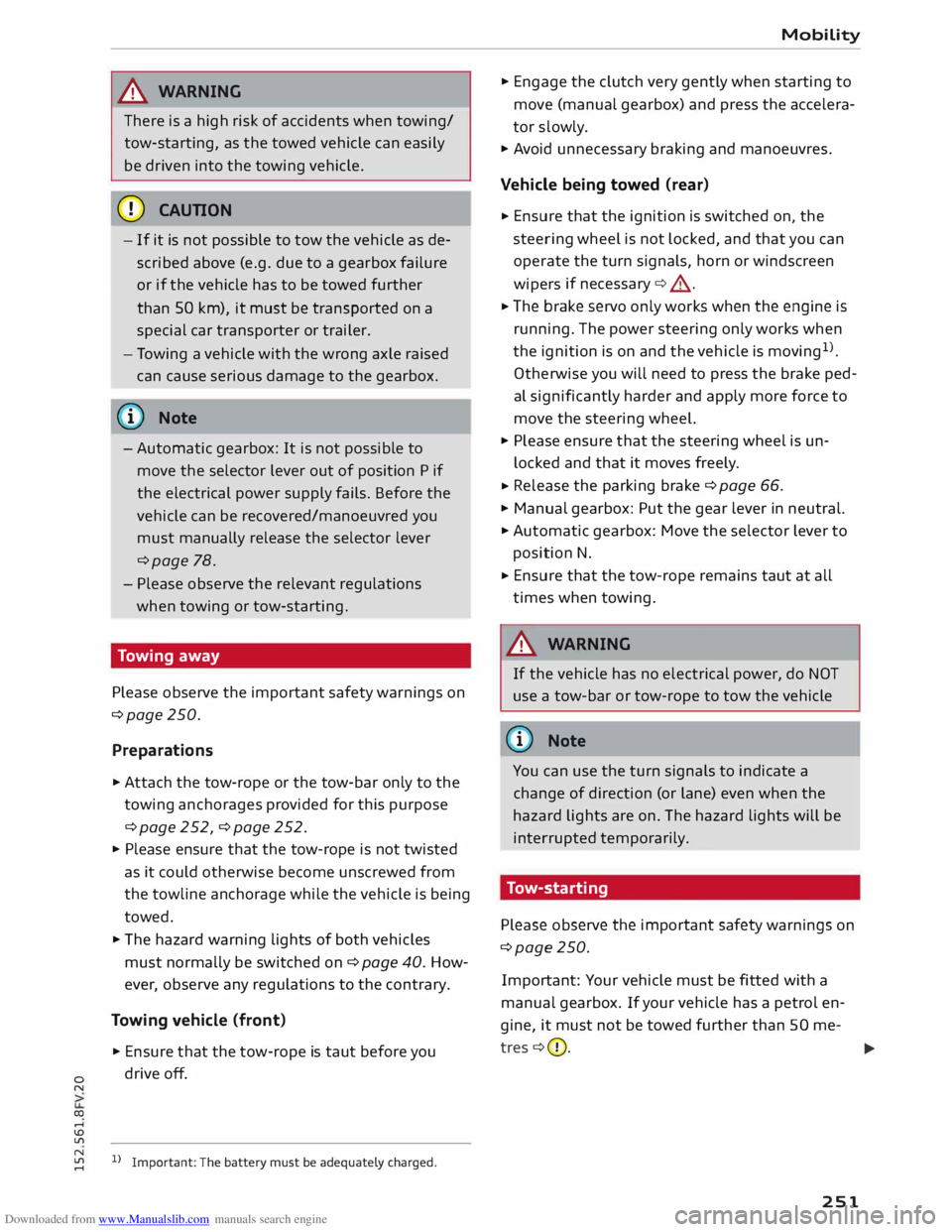

WARNING

There is a high risk of accidents when towing/

tow-starting, as the towed vehicle can easily

be driven into the towing vehicle.

CD CAUTION

- If it is not possible to tow the vehicle as de

scribed above (e.g. due to a gearbox failure

or if the vehicle has to be towed further

than 50 km), it must be transported on a

special car transporter or trailer.

- To wing a vehicle with the wrong axle raised

can cause serious damage to the gearbox.

@ Note

- Automatic gearbox: It is not possible to

move the selector lever out of position P if

the electrical power supply fails. Before the

vehicle can be recovered/manoeuvred you

must manually release the selector lever

¢page 78.

- Please observe the relevant regulations

when towing or tow-starting.

Towing away

Please observe the important safety warnings on

¢page 250.

Preparations

.. Attach the tow-rope or the tow-bar only to the

towing anchorages provided for this purpose

¢page 252, ¢page 252.

.. Please ensure that the tow-rope is not twisted

as it could otherwise become unscrewed from

the towline anchorage while the vehicle is being

towed.

.. The hazard warning lights of both vehicles

must normally be switched on ¢ page 40. How

ever, observe any regulations to the contrary.

Towing vehicle (front)

.. Ensure that the tow-rope is taut before you

drive off.

N

� l

l

Important: The battery must be adequately charged. Mobility

.. Engage the clutch very gently when starting to

move (manual gearbox) and press the accelera

tor slowly.

.. Avoid unnecessary braking and manoeuvres.

Vehicle being towed (rear)

.. Ensure

that the ignition is switched on, the

steering wheel is not locked, and that you can

operate the turn signals, horn or windscreen

wipers if

necessary ¢,& .

.. The

brake servo only works when the engine is

running. The power steering only works when

the ignition is on and the vehicle is moving 1

).

Otherwise you will need to press the brake ped

al significantly harder and apply more force to

move the steering wheel.

.. Please ensure that the steering wheel is un-

locked and that it moves freely.

.. Release

the parking brake ¢page 66.

.. Manual gearbox: Put the gear lever in neutral.

.. Automatic gearbox: Move the selector lever to

position N.

.. Ensure

that the tow-rope remains taut at all

times when towing.

,&. WARNING

If the vehicle has no electrical power, do NOT

use a tow-bar or tow-rope to tow the vehicle

@ Note

You can use the turn signals to indicate a

change of direction (or lane) even when the

hazard lights are on. The hazard lights will be

interrupted temporarily .

Tow-starting

Please observe the important safety warnings on

¢page 250.

Important: Your vehicle must be fitted with a

manual gearbox. If your vehicle has a petrol en

gine, it must not be towed further than SO me-

tres ¢(D.

.,.

251

Page 254 of 284

Downloaded from www.Manualslib.com manuals search engine Mobility

..

Attach the tow-rope or the tow-bar only to the

towing anchorages provided for this purpose

¢page 252, ¢page 252 .

.. Engage second or third gear before moving off.

.. Press the clutch and hold the pedal down .

.. Switch

on the ignition.

.. Once both vehicles are moving, release the

clutch.

"'As soon as the engine starts, press the clutch

pedal and put the gear lever in neutral.

CD CAUTION

When tow-starting the vehicle, do not tow it

further than SO metres; otherwise the cata

lytic converter could be damaged.

Front towline anchorage

The front towline anchorage is only mounted if

the vehicle has to be towed.

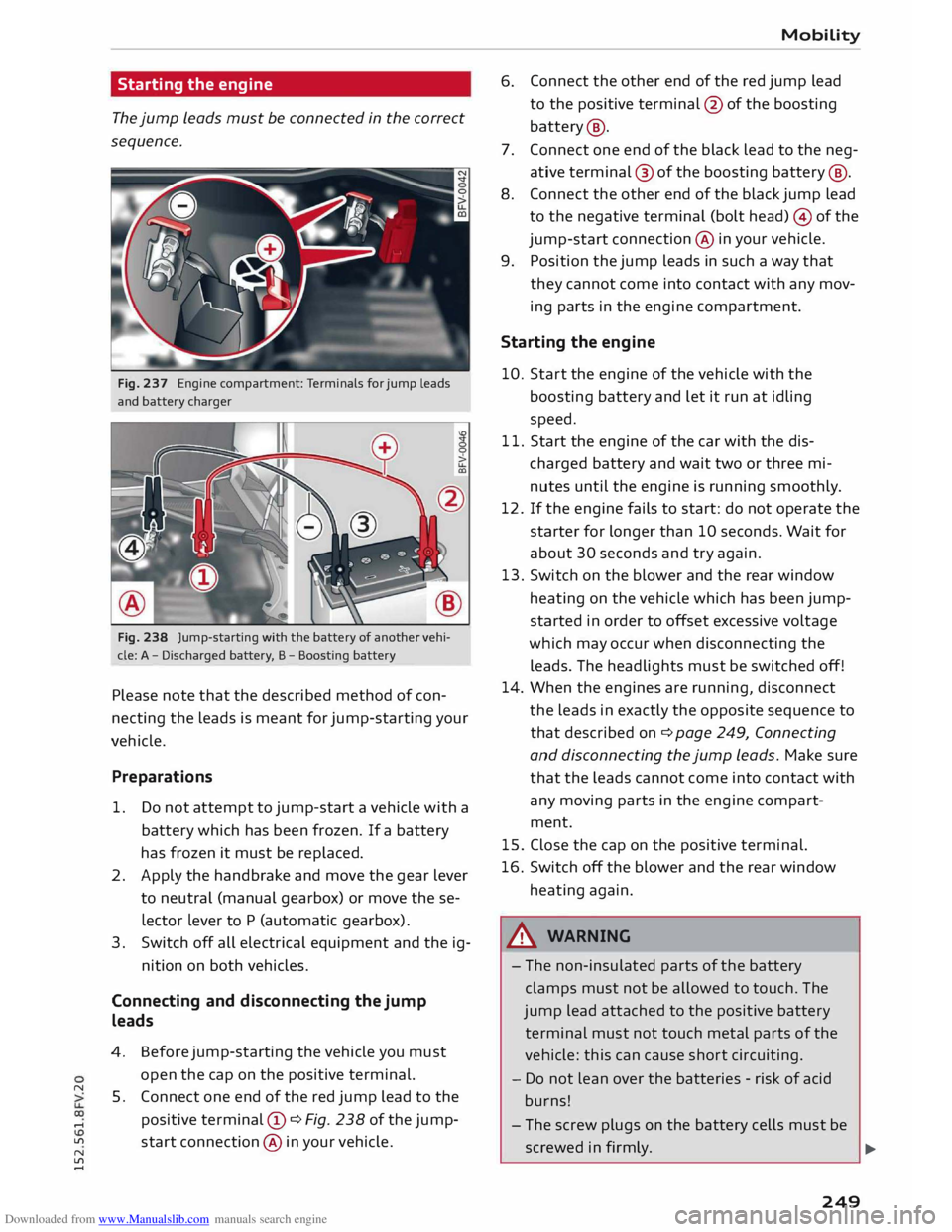

Fig. 239 Front bumper: Cover cap

Fig. 240 Front bumper: Fitting the towline anchorage

The screw connection for the towline anchorage

is located behind a cover cap on the right side of

the front bumper.

.. Take the towline anchorage out of the vehicle's

tool kit ¢ page 242.

252 ..

To detach the cover cap from the bumper press

the top left part of the cap inwards ¢ Fig. 239.

.. Screw the towline anchorage into the screw

connection as far as it will go¢ Fig. 240 and

tighten it with the box spanner .

.. Put

the towline anchorage back in the tool kit

after use .

A WARNING

If the towline anchorage is not screwed in as

far as the stop, there is a risk of the screw

connection shearing off during towing -risk of

accident!

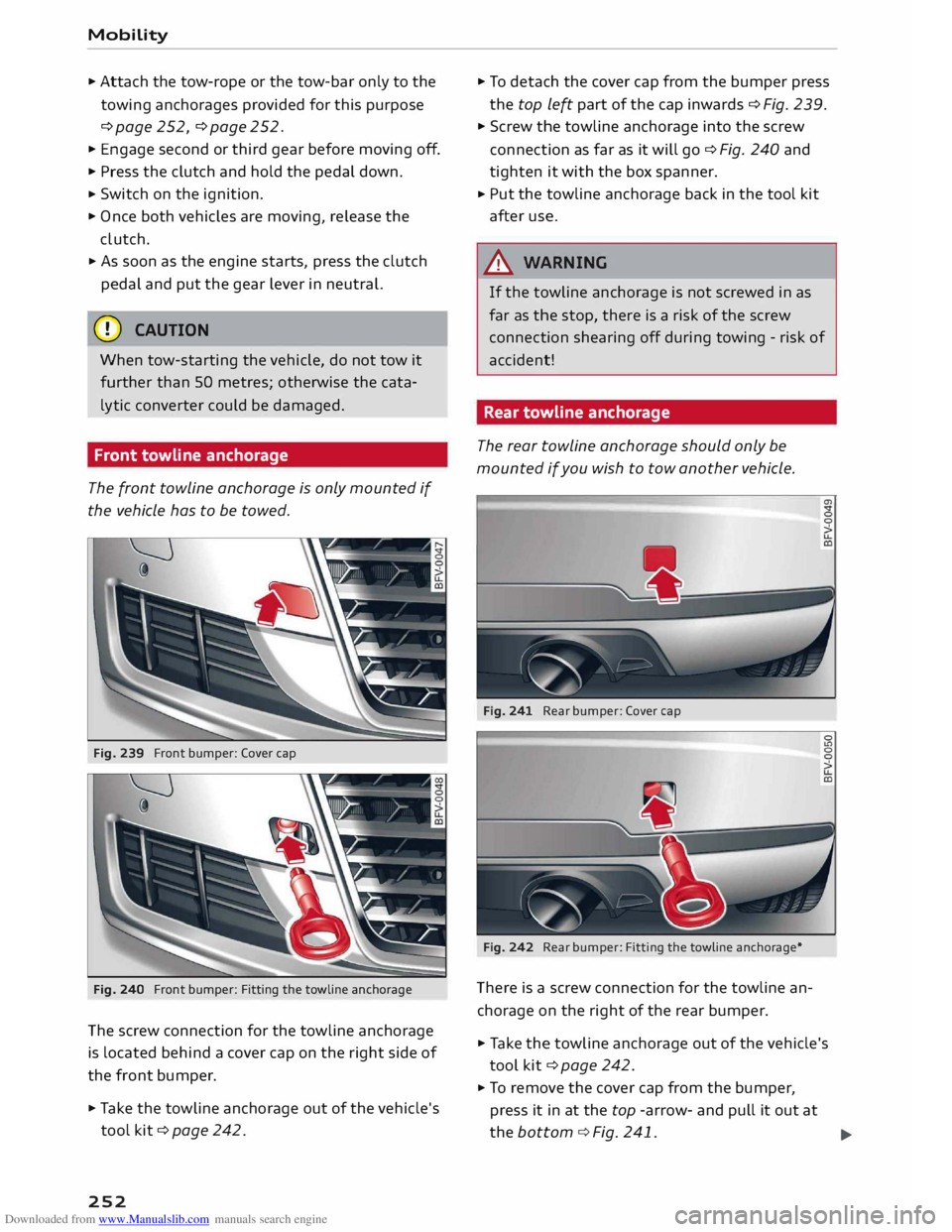

Rear towline anchorage

The rear towline anchorage should only be

mounted if you wish to tow another vehicle.

Fig. 241 Rear bumper: Cover cap

Fig. 242 Rear bumper: Fitting the towline anchorage*

There is a screw connection for the towline an

chorage on the right of the rear bumper. a,

.. Take the towline anchorage out of the vehicle's

tool kit ¢ page 242.

"'To remove the cover cap from the bumper,

press it in at the top -arrow- and pull it out at

the bottom ¢ Fig. 241.

..,.

Page 255 of 284

Downloaded from www.Manualslib.com manuals search engine 0

N

co

....

\D U'l

N

U'l

.... ...

Screw the towline anchorage into the screw

connection as far as it will go¢ Fig. 242 and

tighten it with the box spanner .

... Put the towline anchorage back in the tool kit

after use.

A WARNING

If the towline anchorage is not screwed in as

far as the stop, there is a risk of the screw

connection shearing off during towing -risk of

accident! Mobility

253