bolt pattern AUDI TT ROADSTER 2017 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2017, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2017Pages: 314, PDF Size: 76.54 MB

Page 279 of 314

CD

CD

.... N

" N .... 0 r--. V, co

-To reduce the risk of injury, support the ve

hicle securely with suitable stands if work is

to be performed underneath the vehicle.

- To help prevent injury to yourself and your

passengers:

- Do not raise the vehicle until you are sure

the jack is securely engaged .

- Passengers must not remain in the vehicle

when it is jacked up.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

- Make sure jack position is correct, adjust

as necessary and then continue to raise

the jack.

- If work has to be done under the vehicle,

ensure that it is safely supported on suita

ble stands -risk of injury!

- Never start the engine when the vehicle is

on the jack -risk of accident!

(D Note

Do not lift the vehicle by the sill . Position the

vehicle jack* only at the designated mounting points on the side sill. Otherwise, your vehicle

will be damaged.

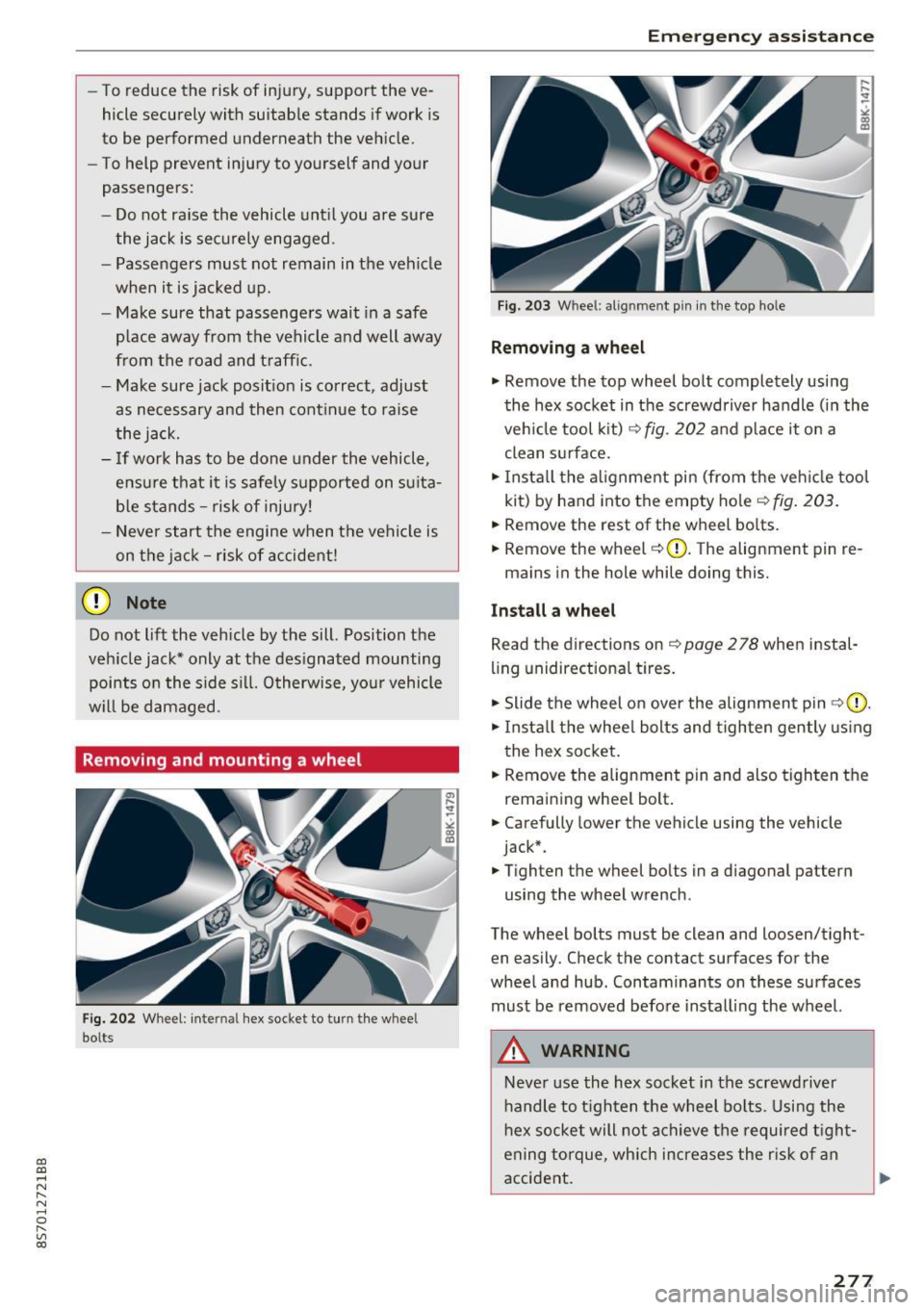

Removing and mounting a wheel

Fig. 202 Wheel : internal hex socket to turn the wheel

bolts

Emergency assistance

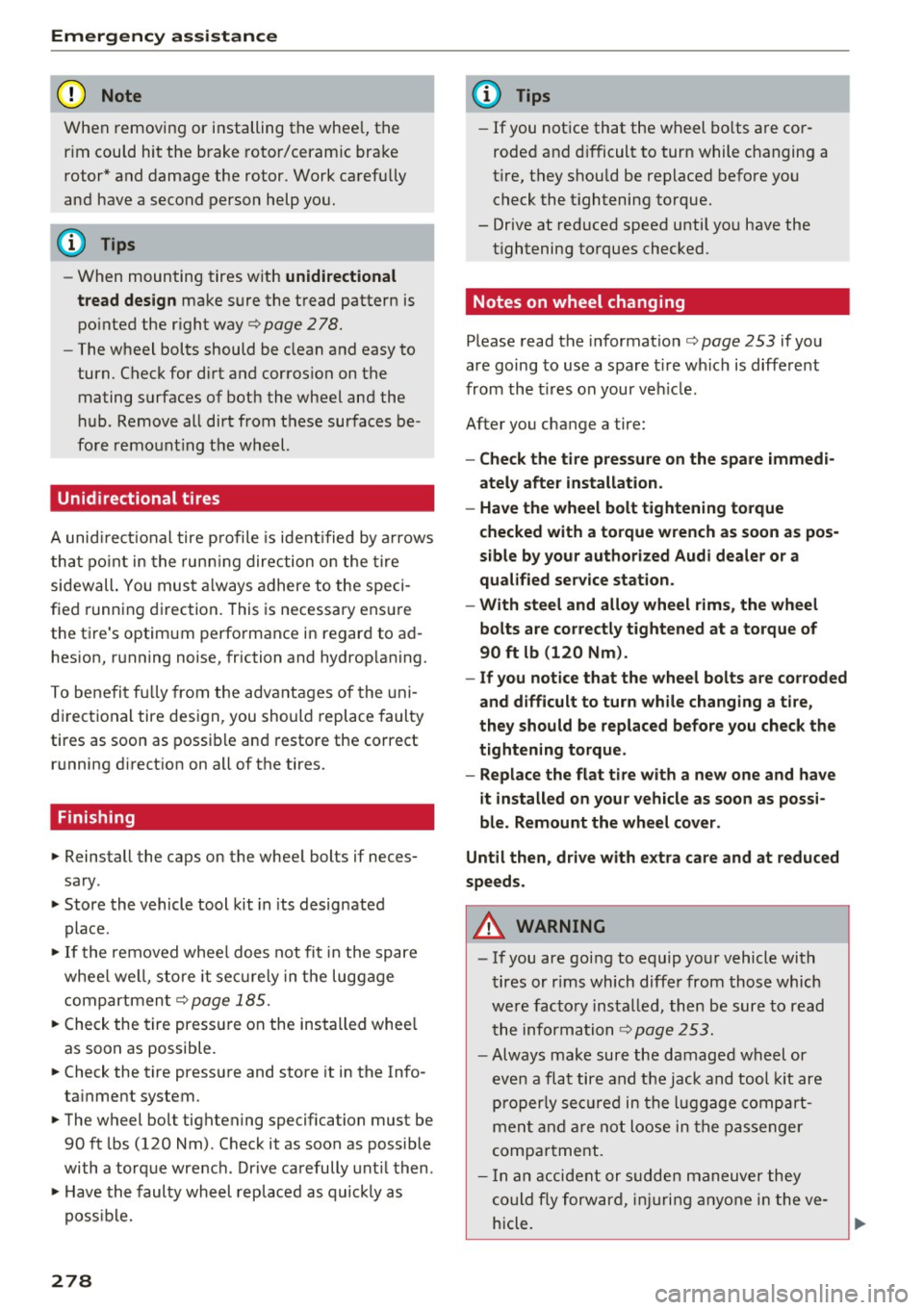

Fig. 203 W hee l: alignment pin in the top ho le

Removing a wheel

.,. Remove the top wheel bolt completely using

the hex socket in the screwdriver handle (in the

vehicle tool kit)

c::> fig. 202 and place it on a

clean surface.

.,. Install the alignment pin (from the vehicle tool

kit) by hand into the empty hole

c::>fig. 203 .

.,. Remove the rest of the wheel bolts.

.,. Remove the wheel

c::>0. The alignment pin re-

mains in the hole while doing this.

Install a wheel

Read the directions on c::> page 2 78 when instal

ling unidirectional tires.

.,. Slide the wheel on over the alignment pin

c::>(D.

.,. Install the wheel bolts and tighten gently using

the hex socket.

.,. Remove the alignment pin and also tighten the

remai ning wheel bolt .

.,. Carefully lower the vehicle using the vehicle

jack* .

.,. Tighten the wheel bolts in a diagonal pattern

using the wheel wrench .

The wheel bolts must be clean and loosen/tight

en easily. Check the contact surfaces for the

wheel and hub . Contaminants on these surfaces

must be removed before installing the wheel.

A WARNING

-

Never use the hex socket in the screwdriver

handle to tighten the wheel bolts . Using the

hex socket will not achieve the required tight

ening torque, which increases the risk of an

accident .

277

Page 280 of 314

Emergency assistance

CJ) Note

When removing or installing the whee l, the

r im could hit the brake rotor/ceramic bra ke

rotor* and damage the rotor. Work ca refu lly

and have a second person help yo u.

@ Tips

-W hen mounting tires w ith unidirectional

tread design

ma ke s ure the t read pattern is

po inted the r ight way

¢ page 278 .

- The wheel bolts should be clean and easy to

turn. Check for d irt and cor ros ion on the

mating s urfaces of both th e wheel and the

h ub. Remove all dirt from t hese surfaces be

fo re re mount ing th e wheel.

Unidirectional tires

A unid irec tional tire p rofile is ident ified by a rrows

th at poin t in the run nin g dir e cti on o n the tire

sidewall. You mus t always a dhere to the speci

fied running d irec tion. This is necessary ens ure

the t ire's optim um perfo rmance in regar d to a d

hes ion, r unning noise, fr iction and hydrop la ning.

T o be nefi t fu lly fro m the adv ant ages of the uni

d irect ional tire des ign, you sho uld replace faulty

tires as soon as possi ble an d restore the correct

r u nning di rect io n on all of the tires.

Finishing

.,. Reinstall the caps on the whee l bolts if neces

sary .

.,. Store the vehicle tool kit in its designated

place .

.,. If the re m oved whee l does not fi t in the sp are

whee l we ll, store it se cur ely in t he luggage

com partmen t

¢page 18 5.

.,. Check the tire press ure on the ins talled whee l

as soon as possible.

.,. Check the tire press ure and store it in the Info

ta inment system.

.,. The w heel bo lt tightening specification must be

90 ft lbs (120 Nm) . Check it as soon as poss ible

with a torq ue wrenc h. Drive ca refully unt il then .

.,. Have th e faulty wheel rep laced as quic kly as

poss ib le.

278

(D Tips

- If you not ice that t he w heel bo lts a re cor

rode d and difficult to tur n while changing a

t ir e, t hey s hou ld be replaced befo re yo u

check the t ightening torque.

- Drive at red uce d speed unti l yo u have the

t ightening to rques checked.

· Notes on wheel changing

Please read t he informat ion¢ page 253 if yo u

are going to use a spa re t ire wh ic h is diffe re nt

fro m the t ires on your ve hicle.

After you change a tire:

- Check the tire pressure on the spa re immedi

ately after installation.

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as pos

sible by your authorized Audi dealer or a

qualified service station .

- With steel and alloy wheel rims, the wheel

bolts are cor rectly tightened at a torque of

90 ft lb (120 Nm) .

-If you notice that the wheel bolts are corroded

and difficult to turn while changing a tire,

they should be replaced before you check the

tightening torque .

- Replace the flat tire with a new one and have

it installed on your vehicle as soon as possi

ble. Remount the wheel cover .

Until then, dr ive with e xtra care and at reduced

speeds.

A WARNING

- If you are going to equip yo ur vehicle wi th

t ires or r ims which diffe r from those which

we re fac to ry insta lled , th en be su re to read

t he informa tion

¢ page 253 .

-Always make sure the damage d w heel or

ev en a fla t tire and the jack and to ol kit ar e

p ro p erl y se cured in t he lug gage co mpart

me nt an d ar e no t lo o se in the pas senge r

co mp artme nt.

- I n an ac cident or su dde n man euver they

co uld fl y forw ard , injur ing an yone i n t he ve

hicle.