engine coolant BMW 3 SERIES 1985 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1985, Model line: 3 SERIES, Model: BMW 3 SERIES 1985 E30Pages: 228, PDF Size: 7.04 MB

Page 62 of 228

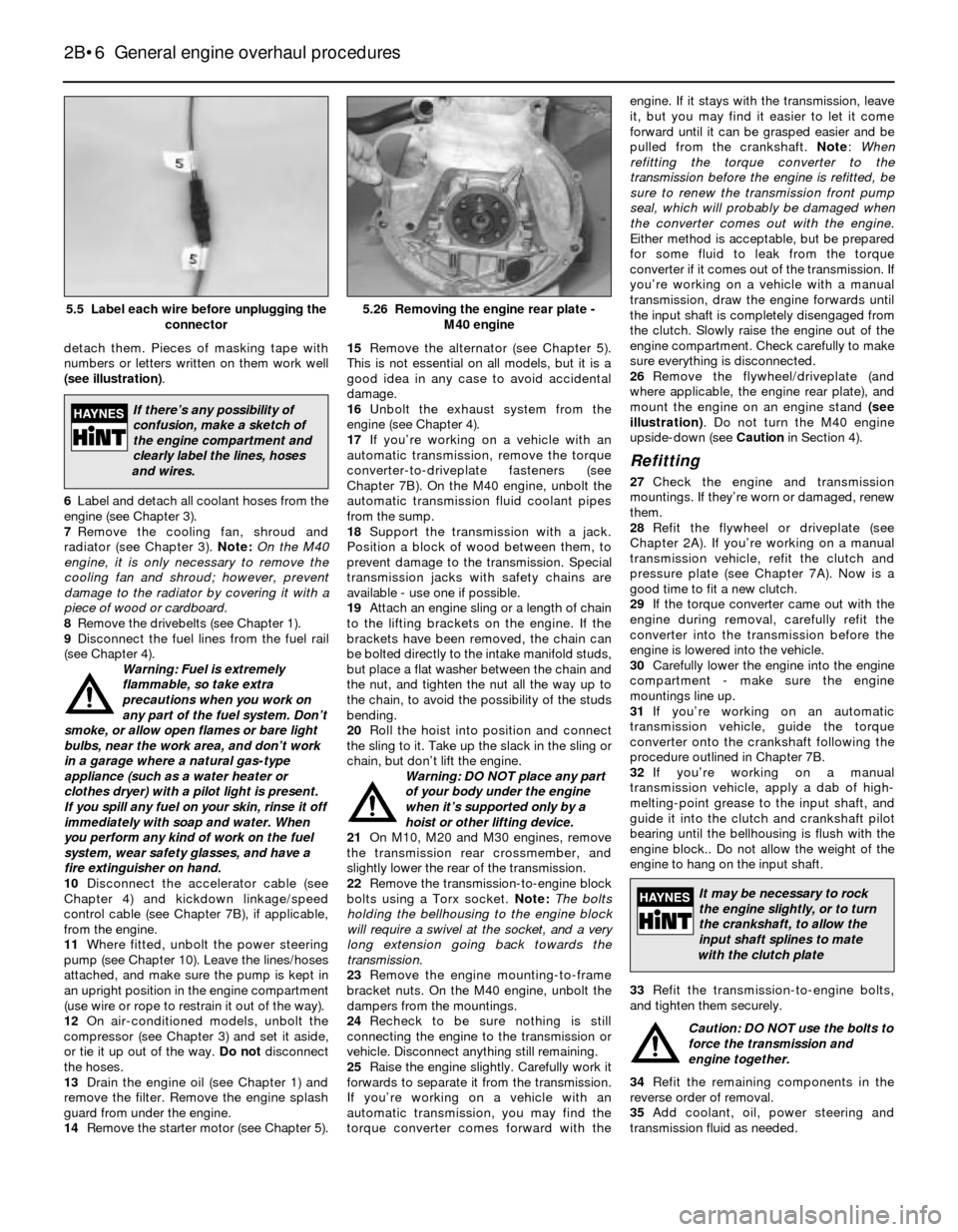

detach them. Pieces of masking tape with

numbers or letters written on them work well

(see illustration).

6Label and detach all coolant hoses from the

engine (see Chapter 3).

7Remove the cooling fan, shroud and

radiator (see Chapter 3). Note:On the M40

engine, it is only necessary to remove the

cooling fan and shroud; however, prevent

damage to the radiator by covering it with a

piece of wood or cardboard.

8Remove the drivebelts (see Chapter 1).

9Disconnect the fuel lines from the fuel rail

(see Chapter 4).

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area, and don’t work

in a garage where a natural gas-type

appliance (such as a water heater or

clothes dryer) with a pilot light is present.

If you spill any fuel on your skin, rinse it off

immediately with soap and water. When

you perform any kind of work on the fuel

system, wear safety glasses, and have a

fire extinguisher on hand.

10Disconnect the accelerator cable (see

Chapter 4) and kickdown linkage/speed

control cable (see Chapter 7B), if applicable,

from the engine.

11Where fitted, unbolt the power steering

pump (see Chapter 10). Leave the lines/hoses

attached, and make sure the pump is kept in

an upright position in the engine compartment

(use wire or rope to restrain it out of the way).

12On air-conditioned models, unbolt the

compressor (see Chapter 3) and set it aside,

or tie it up out of the way. Do not disconnect

the hoses.

13Drain the engine oil (see Chapter 1) and

remove the filter. Remove the engine splash

guard from under the engine.

14Remove the starter motor (see Chapter 5).15Remove the alternator (see Chapter 5).

This is not essential on all models, but it is a

good idea in any case to avoid accidental

damage.

16Unbolt the exhaust system from the

engine (see Chapter 4).

17If you’re working on a vehicle with an

automatic transmission, remove the torque

converter-to-driveplate fasteners (see

Chapter 7B). On the M40 engine, unbolt the

automatic transmission fluid coolant pipes

from the sump.

18Support the transmission with a jack.

Position a block of wood between them, to

prevent damage to the transmission. Special

transmission jacks with safety chains are

available - use one if possible.

19Attach an engine sling or a length of chain

to the lifting brackets on the engine. If the

brackets have been removed, the chain can

be bolted directly to the intake manifold studs,

but place a flat washer between the chain and

the nut, and tighten the nut all the way up to

the chain, to avoid the possibility of the studs

bending.

20Roll the hoist into position and connect

the sling to it. Take up the slack in the sling or

chain, but don’t lift the engine.

Warning: DO NOT place any part

of your body under the engine

when it’s supported only by a

hoist or other lifting device.

21On M10, M20 and M30 engines, remove

the transmission rear crossmember, and

slightly lower the rear of the transmission.

22Remove the transmission-to-engine block

bolts using a Torx socket. Note:The bolts

holding the bellhousing to the engine block

will require a swivel at the socket, and a very

long extension going back towards the

transmission.

23Remove the engine mounting-to-frame

bracket nuts. On the M40 engine, unbolt the

dampers from the mountings.

24Recheck to be sure nothing is still

connecting the engine to the transmission or

vehicle. Disconnect anything still remaining.

25Raise the engine slightly. Carefully work it

forwards to separate it from the transmission.

If you’re working on a vehicle with an

automatic transmission, you may find the

torque converter comes forward with theengine. If it stays with the transmission, leave

it, but you may find it easier to let it come

forward until it can be grasped easier and be

pulled from the crankshaft. Note:When

refitting the torque converter to the

transmission before the engine is refitted, be

sure to renew the transmission front pump

seal, which will probably be damaged when

the converter comes out with the engine.

Either method is acceptable, but be prepared

for some fluid to leak from the torque

converter if it comes out of the transmission. If

you’re working on a vehicle with a manual

transmission, draw the engine forwards until

the input shaft is completely disengaged from

the clutch. Slowly raise the engine out of the

engine compartment. Check carefully to make

sure everything is disconnected.

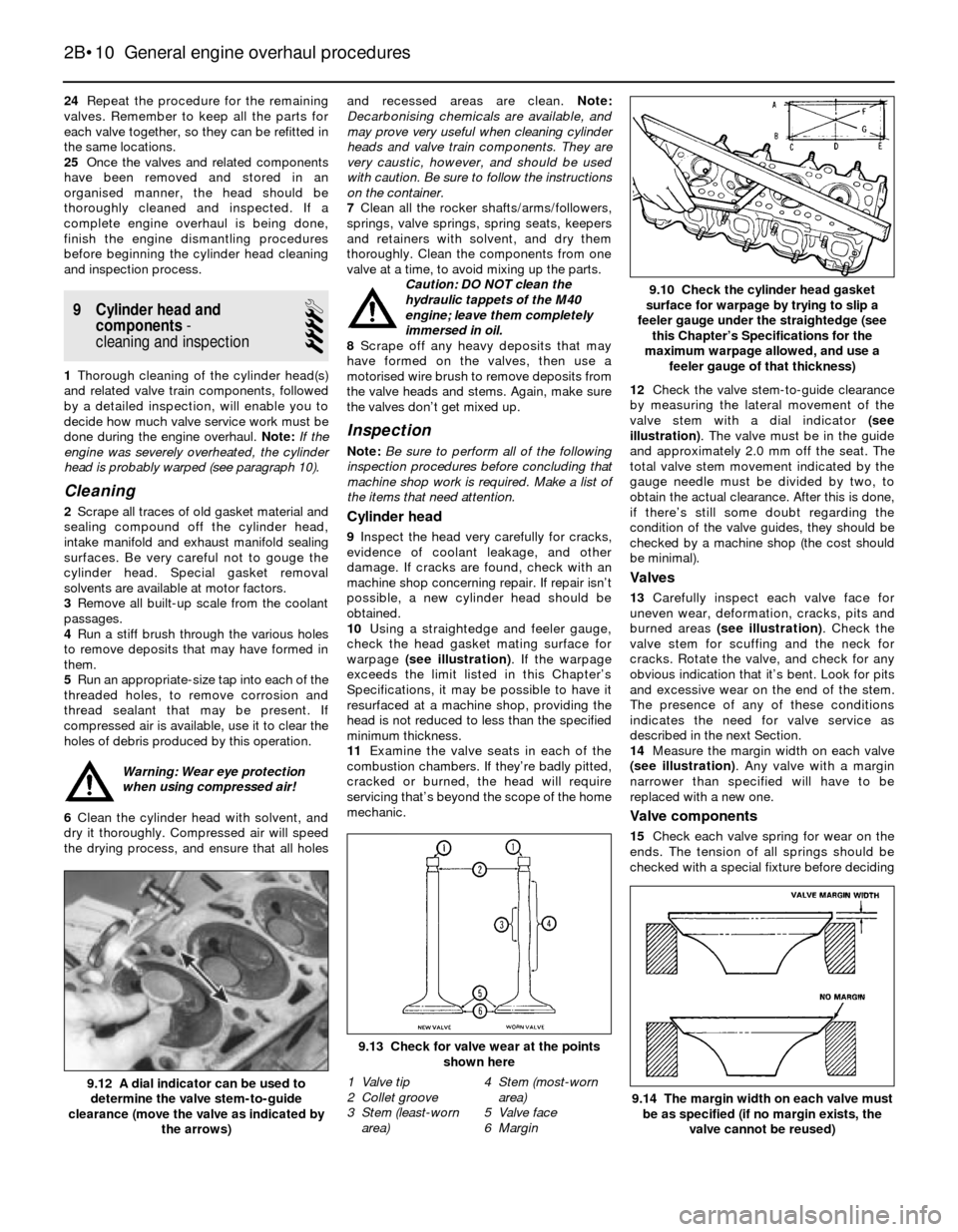

26Remove the flywheel/driveplate (and

where applicable, the engine rear plate), and

mount the engine on an engine stand (see

illustration). Do not turn the M40 engine

upside-down (see Cautionin Section 4).

Refitting

27Check the engine and transmission

mountings. If they’re worn or damaged, renew

them.

28Refit the flywheel or driveplate (see

Chapter 2A). If you’re working on a manual

transmission vehicle, refit the clutch and

pressure plate (see Chapter 7A). Now is a

good time to fit a new clutch.

29If the torque converter came out with the

engine during removal, carefully refit the

converter into the transmission before the

engine is lowered into the vehicle.

30Carefully lower the engine into the engine

compartment - make sure the engine

mountings line up.

31If you’re working on an automatic

transmission vehicle, guide the torque

converter onto the crankshaft following the

procedure outlined in Chapter 7B.

32If you’re working on a manual

transmission vehicle, apply a dab of high-

melting-point grease to the input shaft, and

guide it into the clutch and crankshaft pilot

bearing until the bellhousing is flush with the

engine block.. Do not allow the weight of the

engine to hang on the input shaft.

33Refit the transmission-to-engine bolts,

and tighten them securely.

Caution: DO NOT use the bolts to

force the transmission and

engine together.

34Refit the remaining components in the

reverse order of removal.

35Add coolant, oil, power steering and

transmission fluid as needed.

2B•6 General engine overhaul procedures

5.26 Removing the engine rear plate -

M40 engine5.5 Label each wire before unplugging the

connector

If there’s any possibility of

confusion, make a sketch of

the engine compartment and

clearly label the lines, hoses

and wires.

It may be necessary to rock

the engine slightly, or to turn

the crankshaft, to allow the

input shaft splines to mate

with the clutch plate

Page 66 of 228

24Repeat the procedure for the remaining

valves. Remember to keep all the parts for

each valve together, so they can be refitted in

the same locations.

25Once the valves and related components

have been removed and stored in an

organised manner, the head should be

thoroughly cleaned and inspected. If a

complete engine overhaul is being done,

finish the engine dismantling procedures

before beginning the cylinder head cleaning

and inspection process.

9 Cylinder head and

components-

cleaning and inspection

4

1Thorough cleaning of the cylinder head(s)

and related valve train components, followed

by a detailed inspection, will enable you to

decide how much valve service work must be

done during the engine overhaul. Note: If the

engine was severely overheated, the cylinder

head is probably warped (see paragraph 10).

Cleaning

2Scrape all traces of old gasket material and

sealing compound off the cylinder head,

intake manifold and exhaust manifold sealing

surfaces. Be very careful not to gouge the

cylinder head. Special gasket removal

solvents are available at motor factors.

3Remove all built-up scale from the coolant

passages.

4Run a stiff brush through the various holes

to remove deposits that may have formed in

them.

5Run an appropriate-size tap into each of the

threaded holes, to remove corrosion and

thread sealant that may be present. If

compressed air is available, use it to clear the

holes of debris produced by this operation.

Warning: Wear eye protection

when using compressed air!

6Clean the cylinder head with solvent, and

dry it thoroughly. Compressed air will speed

the drying process, and ensure that all holesand recessed areas are clean. Note:

Decarbonising chemicals are available, and

may prove very useful when cleaning cylinder

heads and valve train components. They are

very caustic, however, and should be used

with caution. Be sure to follow the instructions

on the container.

7Clean all the rocker shafts/arms/followers,

springs, valve springs, spring seats, keepers

and retainers with solvent, and dry them

thoroughly. Clean the components from one

valve at a time, to avoid mixing up the parts.

Caution: DO NOT clean the

hydraulic tappets of the M40

engine; leave them completely

immersed in oil.

8Scrape off any heavy deposits that may

have formed on the valves, then use a

motorised wire brush to remove deposits from

the valve heads and stems. Again, make sure

the valves don’t get mixed up.

Inspection

Note: Be sure to perform all of the following

inspection procedures before concluding that

machine shop work is required. Make a list of

the items that need attention.

Cylinder head

9Inspect the head very carefully for cracks,

evidence of coolant leakage, and other

damage. If cracks are found, check with an

machine shop concerning repair. If repair isn’t

possible, a new cylinder head should be

obtained.

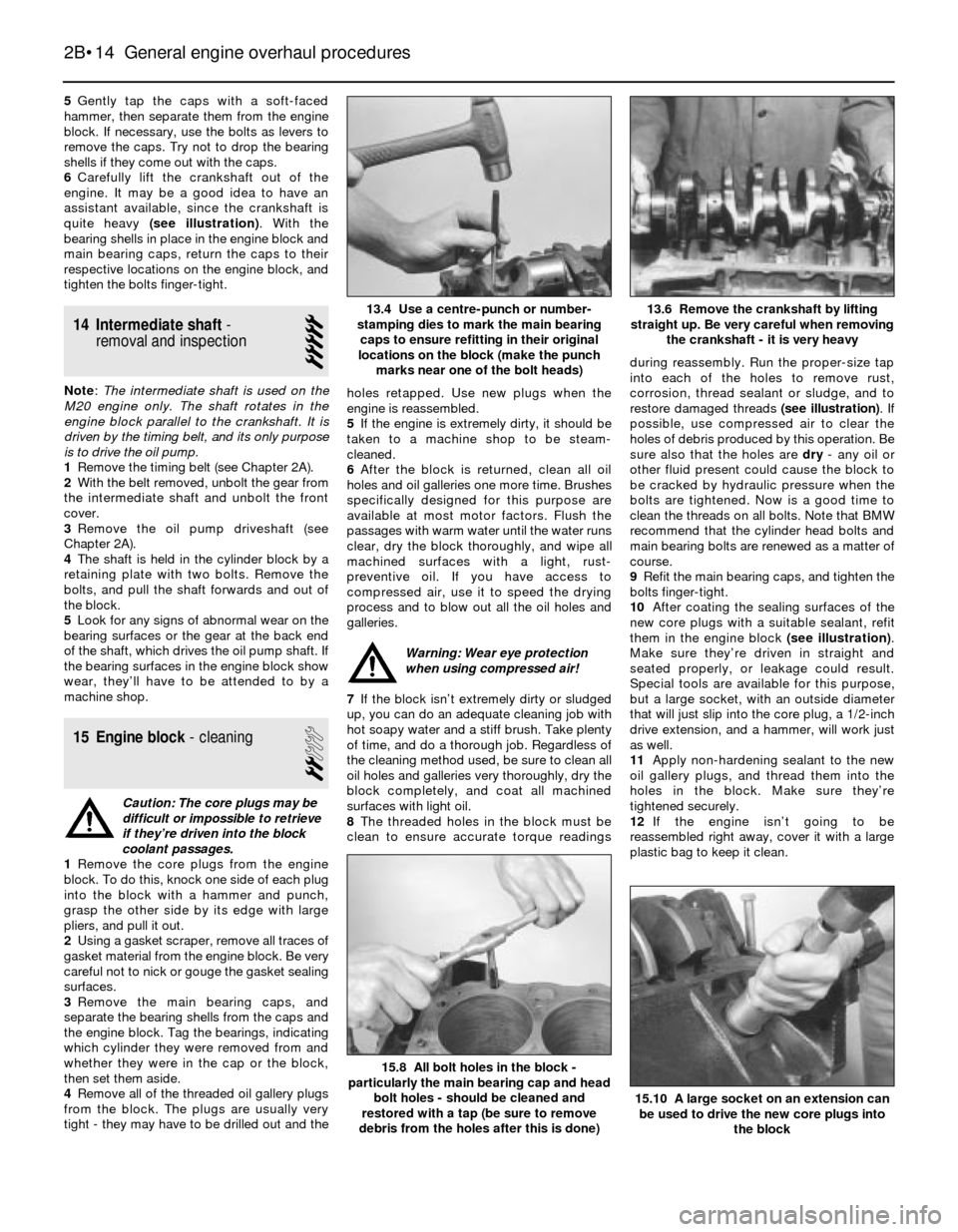

10Using a straightedge and feeler gauge,

check the head gasket mating surface for

warpage (see illustration). If the warpage

exceeds the limit listed in this Chapter’s

Specifications, it may be possible to have it

resurfaced at a machine shop, providing the

head is not reduced to less than the specified

minimum thickness.

11Examine the valve seats in each of the

combustion chambers. If they’re badly pitted,

cracked or burned, the head will require

servicing that’s beyond the scope of the home

mechanic.12Check the valve stem-to-guide clearance

by measuring the lateral movement of the

valve stem with a dial indicator (see

illustration). The valve must be in the guide

and approximately 2.0 mm off the seat. The

total valve stem movement indicated by the

gauge needle must be divided by two, to

obtain the actual clearance. After this is done,

if there’s still some doubt regarding the

condition of the valve guides, they should be

checked by a machine shop (the cost should

be minimal).

Valves

13Carefully inspect each valve face for

uneven wear, deformation, cracks, pits and

burned areas (see illustration). Check the

valve stem for scuffing and the neck for

cracks. Rotate the valve, and check for any

obvious indication that it’s bent. Look for pits

and excessive wear on the end of the stem.

The presence of any of these conditions

indicates the need for valve service as

described in the next Section.

14Measure the margin width on each valve

(see illustration). Any valve with a margin

narrower than specified will have to be

replaced with a new one.

Valve components

15Check each valve spring for wear on the

ends. The tension of all springs should be

checked with a special fixture before deciding

2B•10 General engine overhaul procedures

9.14 The margin width on each valve must

be as specified (if no margin exists, the

valve cannot be reused)

9.13 Check for valve wear at the points

shown here

9.12 A dial indicator can be used to

determine the valve stem-to-guide

clearance (move the valve as indicated by

the arrows)

9.10 Check the cylinder head gasket

surface for warpage by trying to slip a

feeler gauge under the straightedge (see

this Chapter’s Specifications for the

maximum warpage allowed, and use a

feeler gauge of that thickness)

1 Valve tip

2 Collet groove

3 Stem (least-worn

area)4 Stem (most-worn

area)

5 Valve face

6 Margin

Page 70 of 228

5Gently tap the caps with a soft-faced

hammer, then separate them from the engine

block. If necessary, use the bolts as levers to

remove the caps. Try not to drop the bearing

shells if they come out with the caps.

6Carefully lift the crankshaft out of the

engine. It may be a good idea to have an

assistant available, since the crankshaft is

quite heavy (see illustration). With the

bearing shells in place in the engine block and

main bearing caps, return the caps to their

respective locations on the engine block, and

tighten the bolts finger-tight.

14 Intermediate shaft-

removal and inspection

5

Note:The intermediate shaft is used on the

M20 engine only. The shaft rotates in the

engine block parallel to the crankshaft. It is

driven by the timing belt, and its only purpose

is to drive the oil pump.

1Remove the timing belt (see Chapter 2A).

2With the belt removed, unbolt the gear from

the intermediate shaft and unbolt the front

cover.

3Remove the oil pump driveshaft (see

Chapter 2A).

4The shaft is held in the cylinder block by a

retaining plate with two bolts. Remove the

bolts, and pull the shaft forwards and out of

the block.

5Look for any signs of abnormal wear on the

bearing surfaces or the gear at the back end

of the shaft, which drives the oil pump shaft. If

the bearing surfaces in the engine block show

wear, they’ll have to be attended to by a

machine shop.

15 Engine block- cleaning

2

Caution: The core plugs may be

difficult or impossible to retrieve

if they’re driven into the block

coolant passages.

1Remove the core plugs from the engine

block. To do this, knock one side of each plug

into the block with a hammer and punch,

grasp the other side by its edge with large

pliers, and pull it out.

2Using a gasket scraper, remove all traces of

gasket material from the engine block. Be very

careful not to nick or gouge the gasket sealing

surfaces.

3Remove the main bearing caps, and

separate the bearing shells from the caps and

the engine block. Tag the bearings, indicating

which cylinder they were removed from and

whether they were in the cap or the block,

then set them aside.

4Remove all of the threaded oil gallery plugs

from the block. The plugs are usually very

tight - they may have to be drilled out and theholes retapped. Use new plugs when the

engine is reassembled.

5If the engine is extremely dirty, it should be

taken to a machine shop to be steam-

cleaned.

6After the block is returned, clean all oil

holes and oil galleries one more time. Brushes

specifically designed for this purpose are

available at most motor factors. Flush the

passages with warm water until the water runs

clear, dry the block thoroughly, and wipe all

machined surfaces with a light, rust-

preventive oil. If you have access to

compressed air, use it to speed the drying

process and to blow out all the oil holes and

galleries.

Warning: Wear eye protection

when using compressed air!

7If the block isn’t extremely dirty or sludged

up, you can do an adequate cleaning job with

hot soapy water and a stiff brush. Take plenty

of time, and do a thorough job. Regardless of

the cleaning method used, be sure to clean all

oil holes and galleries very thoroughly, dry the

block completely, and coat all machined

surfaces with light oil.

8The threaded holes in the block must be

clean to ensure accurate torque readingsduring reassembly. Run the proper-size tap

into each of the holes to remove rust,

corrosion, thread sealant or sludge, and to

restore damaged threads (see illustration). If

possible, use compressed air to clear the

holes of debris produced by this operation. Be

sure also that the holes are dry- any oil or

other fluid present could cause the block to

be cracked by hydraulic pressure when the

bolts are tightened. Now is a good time to

clean the threads on all bolts. Note that BMW

recommend that the cylinder head bolts and

main bearing bolts are renewed as a matter of

course.

9Refit the main bearing caps, and tighten the

bolts finger-tight.

10After coating the sealing surfaces of the

new core plugs with a suitable sealant, refit

them in the engine block (see illustration).

Make sure they’re driven in straight and

seated properly, or leakage could result.

Special tools are available for this purpose,

but a large socket, with an outside diameter

that will just slip into the core plug, a 1/2-inch

drive extension, and a hammer, will work just

as well.

11Apply non-hardening sealant to the new

oil gallery plugs, and thread them into the

holes in the block. Make sure they’re

tightened securely.

12If the engine isn’t going to be

reassembled right away, cover it with a large

plastic bag to keep it clean.

2B•14 General engine overhaul procedures

15.10 A large socket on an extension can

be used to drive the new core plugs into

the block

15.8 All bolt holes in the block -

particularly the main bearing cap and head

bolt holes - should be cleaned and

restored with a tap (be sure to remove

debris from the holes after this is done)

13.6 Remove the crankshaft by lifting

straight up. Be very careful when removing

the crankshaft - it is very heavy13.4 Use a centre-punch or number-

stamping dies to mark the main bearing

caps to ensure refitting in their original

locations on the block (make the punch

marks near one of the bolt heads)

Page 72 of 228

7Wipe the oil out of the cylinder, and repeat

the procedure for the remaining cylinders.

8After the honing job is complete, chamfer

the top edges of the cylinder bores with a

small file, so the rings won’t catch when the

pistons are refitted. Be very careful not to nick

the cylinder walls with the end of the file.

9The entire engine block must be washed

again very thoroughly with warm, soapy

water, to remove all traces of the abrasive grit

produced during the honing operation. Note:

The bores can be considered clean when a

lint-free white cloth - dampened with clean

engine oil - used to wipe them out doesn’t

pick up any more honing residue, which will

show up as grey areas on the cloth.Be sure to

run a brush through all oil holes and galleries,

and flush them with running water.

10After rinsing, dry the block, and apply a

coat of light rust-preventive oil to all machined

surfaces. Wrap the block in a plastic bag to

keep it clean, and set it aside until

reassembly.

18 Pistons/connecting rods-

inspection

3

1Before the inspection process can be

carried out, the piston/connecting rod

assemblies must be cleaned and the original

piston rings removed from the pistons.Note:

Always use new piston rings when the engine

is reassembled.

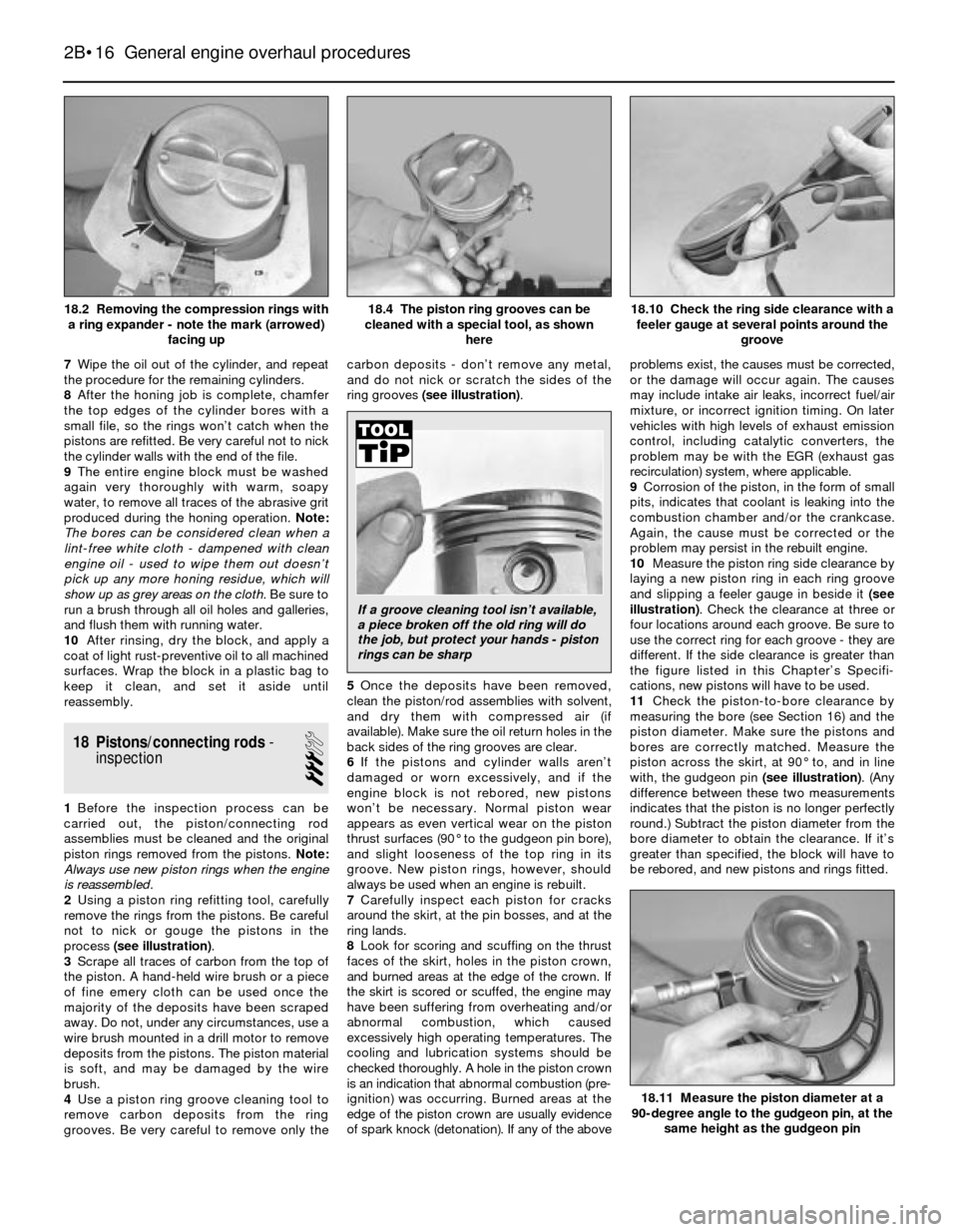

2Using a piston ring refitting tool, carefully

remove the rings from the pistons. Be careful

not to nick or gouge the pistons in the

process (see illustration).

3Scrape all traces of carbon from the top of

the piston. A hand-held wire brush or a piece

of fine emery cloth can be used once the

majority of the deposits have been scraped

away. Do not, under any circumstances, use a

wire brush mounted in a drill motor to remove

deposits from the pistons. The piston material

is soft, and may be damaged by the wire

brush.

4Use a piston ring groove cleaning tool to

remove carbon deposits from the ring

grooves. Be very careful to remove only thecarbon deposits - don’t remove any metal,

and do not nick or scratch the sides of the

ring grooves (see illustration).

5Once the deposits have been removed,

clean the piston/rod assemblies with solvent,

and dry them with compressed air (if

available). Make sure the oil return holes in the

back sides of the ring grooves are clear.

6If the pistons and cylinder walls aren’t

damaged or worn excessively, and if the

engine block is not rebored, new pistons

won’t be necessary. Normal piston wear

appears as even vertical wear on the piston

thrust surfaces (90° to the gudgeon pin bore),

and slight looseness of the top ring in its

groove. New piston rings, however, should

always be used when an engine is rebuilt.

7Carefully inspect each piston for cracks

around the skirt, at the pin bosses, and at the

ring lands.

8Look for scoring and scuffing on the thrust

faces of the skirt, holes in the piston crown,

and burned areas at the edge of the crown. If

the skirt is scored or scuffed, the engine may

have been suffering from overheating and/or

abnormal combustion, which caused

excessively high operating temperatures. The

cooling and lubrication systems should be

checked thoroughly. A hole in the piston crown

is an indication that abnormal combustion (pre-

ignition) was occurring. Burned areas at the

edge of the piston crown are usually evidence

of spark knock (detonation). If any of the aboveproblems exist, the causes must be corrected,

or the damage will occur again. The causes

may include intake air leaks, incorrect fuel/air

mixture, or incorrect ignition timing. On later

vehicles with high levels of exhaust emission

control, including catalytic converters, the

problem may be with the EGR (exhaust gas

recirculation) system, where applicable.

9Corrosion of the piston, in the form of small

pits, indicates that coolant is leaking into the

combustion chamber and/or the crankcase.

Again, the cause must be corrected or the

problem may persist in the rebuilt engine.

10Measure the piston ring side clearance by

laying a new piston ring in each ring groove

and slipping a feeler gauge in beside it(see

illustration). Check the clearance at three or

four locations around each groove. Be sure to

use the correct ring for each groove - they are

different. If the side clearance is greater than

the figure listed in this Chapter’s Specifi-

cations, new pistons will have to be used.

11Check the piston-to-bore clearance by

measuring the bore (see Section 16) and the

piston diameter. Make sure the pistons and

bores are correctly matched. Measure the

piston across the skirt, at 90° to, and in line

with, the gudgeon pin (see illustration). (Any

difference between these two measurements

indicates that the piston is no longer perfectly

round.) Subtract the piston diameter from the

bore diameter to obtain the clearance. If it’s

greater than specified, the block will have to

be rebored, and new pistons and rings fitted.

2B•16 General engine overhaul procedures

18.11 Measure the piston diameter at a

90-degree angle to the gudgeon pin, at the

same height as the gudgeon pin

18.10 Check the ring side clearance with a

feeler gauge at several points around the

groove18.4 The piston ring grooves can be

cleaned with a special tool, as shown

here18.2 Removing the compression rings with

a ring expander - note the mark (arrowed)

facing up

If a groove cleaning tool isn’t available,

a piece broken off the old ring will do

the job, but protect your hands - piston

rings can be sharp

Page 78 of 228

the bearing - use your fingernail or the edge of

a credit card.

20Make sure the bearing faces are perfectly

clean, then apply a uniform layer of

molybdenum disulphide (“moly”) grease or

engine assembly oil to both of them. You’ll

have to push the piston into the cylinder to

expose the face of the bearing shell in the

connecting rod - be sure to slip the protective

hoses over the rod bolts first, where

applicable.

21Slide the connecting rod back into place

on the journal, and remove the protective

hoses from the rod cap bolts. Refit the rod

cap, and tighten the nuts/bolts to the

specified torque.

22Repeat the entire procedure for the

remaining pistons/connecting rods.

23The important points to remember are:

a) Keep the back sides of the bearing shells

and the insides of the connecting rods

and caps perfectly clean when

assembling them.

b) Make sure you have the correct

piston/rod assembly for each cylinder.

c) The notch or mark on the piston must

face the front of the engine.

d) Lubricate the cylinder walls with clean oil.

e) Lubricate the bearing faces when refitting

the rod caps after the oil clearance has

been checked.

24After all the piston/connecting rod

assemblies have been properly fitted, rotate

the crankshaft a number of times by hand to

check for any obvious binding.25Check the connecting rod side play (see

Section 13).

26Compare the measured side play to the

Specifications to make sure it’s correct. If it

was correct before dismantling, and the

original crankshaft and rods were refitted, it

should still be right. If new rods or a new

crankshaft were fitted, the side play may be

incorrect. If so, the rods will have to be

removed and taken to a machine shop for

attention.

27 Initial start-up and running-

in after overhaul

1

Warning:Have a fire extinguisher

handy when starting the engine

for the first time.

1Once the engine has been refitted in the

vehicle, double-check the engine oil and

coolant levels.

2With the spark plugs removed and the

ignition system disabled (see Section 3), crank

the engine until oil pressure registers on the

gauge, or until the oil pressure warning light

goes out.

3Refit the spark plugs, connect the HT leads,

and restore the ignition system functions (see

Section 3).

4Start the engine. It may take a few

moments for the fuel system to build uppressure, but the engine should start without

a great deal of effort. Note: If backfiring

occurs through the throttle body or

carburettor, check the valve timing (check that

the timing chain/belt has been correctly fitted),

the firing order (check the fitted order of the

spark plug HT leads), and the ignition timing.

5After the engine starts, it should be allowed

to warm up to normal operating temperature.

While the engine is warming up, make a

thorough check for fuel, oil and coolant leaks.

6Shut the engine off and recheck the engine

oil and coolant levels.

7Drive the vehicle to an area with minimum

traffic, accelerate at full throttle from 30 to

50 mph, then lift off the throttle completely,

and allow the vehicle to slow to 30 mph with

the throttle closed. Repeat the procedure

10 or 12 times. This will load the piston rings,

and cause them to seat properly against the

cylinder walls. Check again for oil and coolant

leaks.

8Drive the vehicle gently for the first

500 miles (no sustained high speeds) and

keep a constant check on the oil level. It is not

unusual for an engine to use oil during the

running-in period.

9At approximately 500 to 600 miles, change

the oil and filter.

10For the next few hundred miles, drive the

vehicle normally - don’t nurse it, but don’t

abuse it, either.

11After 2000 miles, change the oil and filter

again. The engine may now be considered to

be fully run-in.

2B•22 General engine overhaul procedures

Page 79 of 228

3General

Coolant capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Thermostat rating

Opening temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80°C (176°F)

Fully open at . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100°C (212°F)

Cooling fan thermo-switch - switching temperatures

Low-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91°C (196°F)

High-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99°C (210°F)

Torque wrench settingsNm

Mechanical cooling fan clutch-to-water pump securing

nut (left-hand thread) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Mechanical cooling fan-to-clutch bolts . . . . . . . . . . . . . . . . . . . . . . . . . 10

Water pump bolts

Small bolts (M6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Large bolts (M8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Thermostat housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3

Cooling, heating and air conditioning systems

Air conditioner receiver-drier - removal and refitting . . . . . . . . . . . . 16

Air conditioning blower motor (E28/”old-shape” 5-series

models) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air conditioning compressor - removal and refitting . . . . . . . . . . . . . 13

Air conditioning condenser - removal and refitting . . . . . . . . . . . . . . 15

Air conditioning system - precautions and maintenance . . . . . . . . . 12

Antifreeze - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Coolant level check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Coolant temperature sender unit - check and renewal . . . . . . . . . . . 8

Cooling system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Cooling system servicing (draining, flushing and refilling)See Chapter 1Engine cooling fan(s) and clutch - check, removal and refitting . . . . 5

Evaporator matrix - removal and refitting . . . . . . . . . . . . . . . . . . . . . 17

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Heater and air conditioner control assembly - removal and refitting 10

Heater and air conditioning blower motor - removal,testing and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Heater matrix - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 11

Radiator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Thermostat - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water pump - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 7

3•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

1 General information

Engine cooling system

All vehicles covered by this manual employ

a pressurised engine cooling system, with

thermostatically-controlled coolant circulation.

An impeller-type water pump mounted on

the front of the block pumps coolant through

the engine. The coolant flows around each

cylinder, and towards the rear of the engine.

Cast-in coolant passages direct coolantaround the intake and exhaust ports, near the

spark plug areas, and in close proximity to the

exhaust valve guides.

A wax-pellet-type thermostat is located in-

line in the bottom hose on M10 engines, in a

housing near the front of the engine on M20

and M30 engines, or behind an elbow under

the timing belt upper cover (on the front of the

cylinder head) on M40 engines. During warm-

up, the closed thermostat prevents coolant

from circulating through the radiator. As the

engine nears normal operating temperature,

the thermostat opens and allows hot coolant

to travel through the radiator, where it’s

cooled before returning to the engine.The pressure in the system raises the

boiling point of the coolant, and increases the

cooling efficiency of the radiator. The cooling

system is sealed by a pressure-type cap. If

the system pressure exceeds the cap

pressure relief value, the excess pressure in

the system forces the spring-loaded valve

inside the cap off its seat, and allows the

coolant to escape through the overflow tube.

The pressure cap on four-cylinder models is

on the top of the radiator; on six-cylinder models,

it’s on top of a translucent plastic expansion

tank. The cap pressure rating is moulded into the

top of the cap. The pressure rating is either

1.0 bar (14 psi) or 1.2 bars (17 psi).

Page 80 of 228

Warning: Do not remove the

pressure cap from the radiator or

expansion tank until the engine

has cooled completely and

there’s no pressure remaining in the

cooling system. Removing the cap from a

hot engine risks personal injury by

scalding.

Heating system

The heating system consists of a blower fan

and heater matrix located in the heater box,

with hoses connecting the heater matrix to the

engine cooling system, and the heater/air

conditioning control head on the dashboard.

Hot engine coolant is circulated through the

heater matrix passages all the time the engine

is running. Switching the heater on opens a

flap door to direct air through the heater

matrix, and the warmed air enters the

passenger compartment. A fan switch on the

control head activates the blower motor,

which forces more air through the heater

matrix, giving additional heater output for

demisting, etc.

Air conditioning system

The air conditioning system consists of a

condenser mounted in front of the radiator, an

evaporator mounted adjacent to the heater

matrix, a compressor mounted on the engine,

a filter-drier (receiver-drier) which contains a

high-pressure relief valve, and the plumbing

connecting all of the above components.

A blower fan forces the warmer air of the

passenger compartment through the

evaporator matrix (a radiator-in-reverse),

transferring the heat from the air to the

refrigerant. The liquid refrigerant boils off into

low-pressure vapour, taking the heat with it

when it leaves the evaporator.

Note: Refer to the precautions at the start

of Section 12 concerning the potential

dangers associated with the air conditioning

system.

2 Antifreeze-

general information

Warning: Do not allow antifreeze

to come in contact with your skin

or painted surfaces of the

vehicle. Rinse off spills

immediately with plenty of water. If

consumed, antifreeze can be fatal;

children and pets are attracted by its

sweet taste, so wipe up garage floor and

drip pan coolant spills immediately. Keep

antifreeze containers covered, and repair

leaks in your cooling system as soon as

they are noticed.

The cooling system should be filled with a

60/40% water/ethylene-glycol-based anti-

freeze solution, which will prevent freezing

down to approximately -27°C (-17°F). The

antifreeze also raises the boiling point of thecoolant, and (if of good quality) provides

protection against corrosion.

The cooling system should be drained,

flushed and refilled at the specified intervals

(see Chapter 1). Old or contaminated

antifreeze solutions are likely to cause

damage, and encourage the formation of rust

and scale in the system. Use distilled water

with the antifreeze, if available, or clean

rainwater. Tap water will do, but not if the

water in your area is at all “hard”.

Before adding antifreeze, check all hose

connections, because antifreeze tends to

search out and leak through very minute

openings. Engines don’t normally consume

coolant, so if the level goes down, find the

cause and correct it.

The antifreeze mixture should be

maintained at its correct proportions; adding

too much antifreeze reduces the efficiency of

the cooling system. If necessary, consult the

mixture ratio chart on the antifreeze container

before adding coolant. Hydrometers are

available at most car accessory shops to test

the coolant. Use antifreeze which meets the

vehicle manufacturer’s specifications.

3 Thermostat-

check and renewal

1

Warning: Do not remove the

radiator cap, drain the coolant, or

renew the thermostat until the

engine has cooled completely.

Check

1Before assuming the thermostat is to blame

for a cooling system problem, check the

coolant level, drivebelt tension (see Chapter 1)

and temperature gauge (or warning light)

operation.

2If the engine seems to be taking a long time

to warm up (based on heater output or

temperature gauge operation), the thermostat

is probably stuck open. Renew the

thermostat.

3If the engine runs hot, use your hand to

check the temperature of the upper radiator

hose. If the hose isn’t hot, but the engine is,

the thermostat is probably stuck closed,preventing the coolant inside the engine from

circulating to the radiator. Renew the

thermostat.

Caution: Don’t drive the vehicle

without a thermostat. The engine

will be very slow to warm-up in

cold conditions, resulting in poor

fuel economy and driveability. A new

thermostat is normally an inexpensive

component anyway.

4If the upper radiator hose is hot, it means

that the coolant is flowing and the thermostat

is at least partly open. Consult the “Fault

finding” Section at the rear of this manual for

cooling system diagnosis.

Renewal

All models

5Disconnect the negative cable from the

battery.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

6Drain the cooling system (see Chapter 1). If

the coolant is relatively new or in good

condition, save it and re-use it.

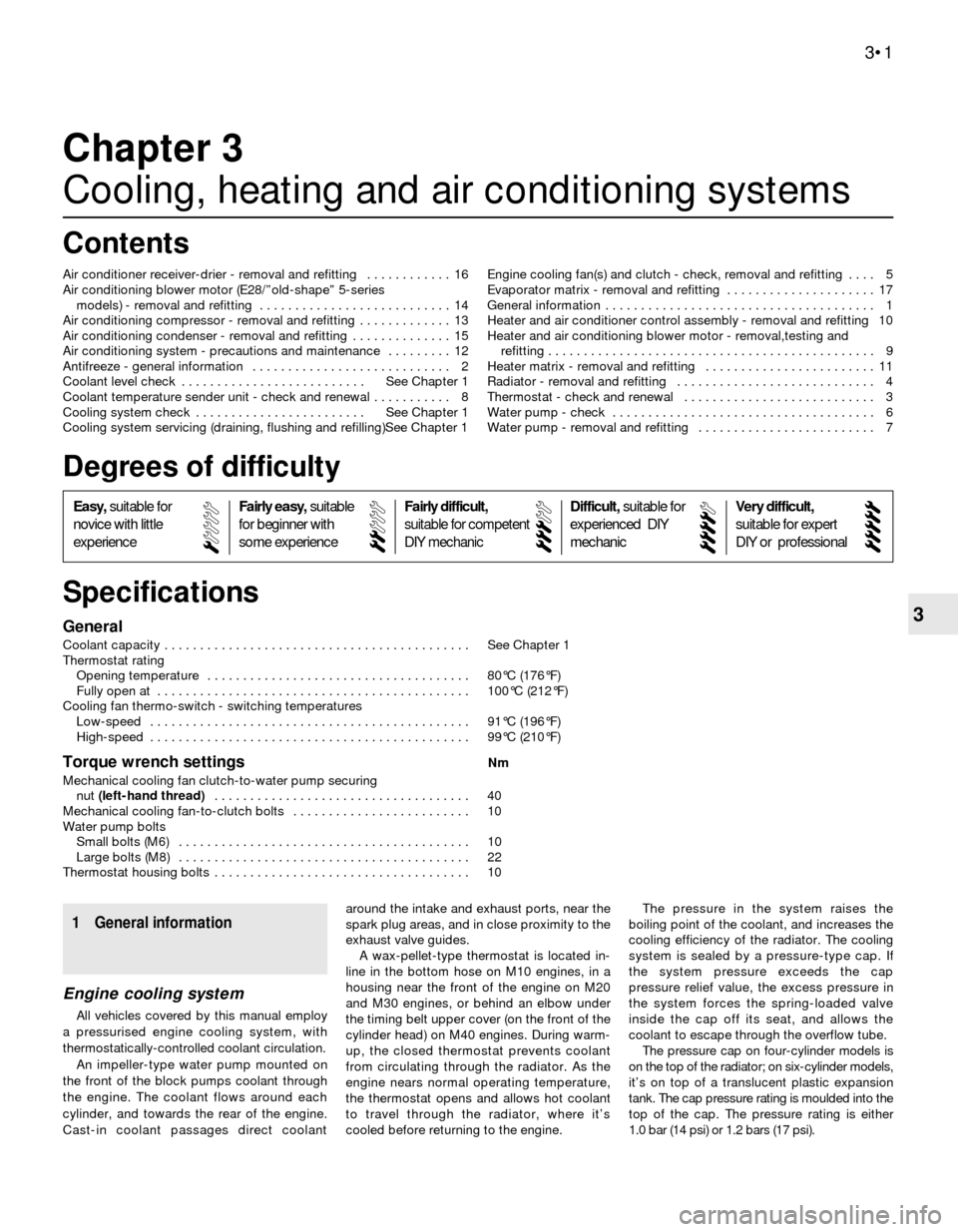

M10 engines

7The thermostat is located in the bottom

hose. First remove the cooling fan.

8Note the fitted position of the thermostat,

then unscrew the hose clamps and withdraw

the thermostat from the hose connections

(see illustration).

9Refit the thermostat-to-hose connections,

and tighten the hose clamps.

10Refit the cooling fan.

M20 and M30 engines

11Loosen the hose clamp (see illustration),

then detach the hose(s) from the thermostat

cover.

3•2 Cooling, heating and air conditioning systems

3.11 On M20 and M30 engine models,

loosen the hose clamp (A) and disconnect

the hose from the thermostat housing

cover - note that the coolant temperature

sender unit (barely visible behind the fuel

pressure regulator) is located at the top of

the thermostat housing (B)

3.8 On the M10 (four-cylinder) engine, the

thermostat (arrowed) is connected in-line

in the radiator hose

Page 81 of 228

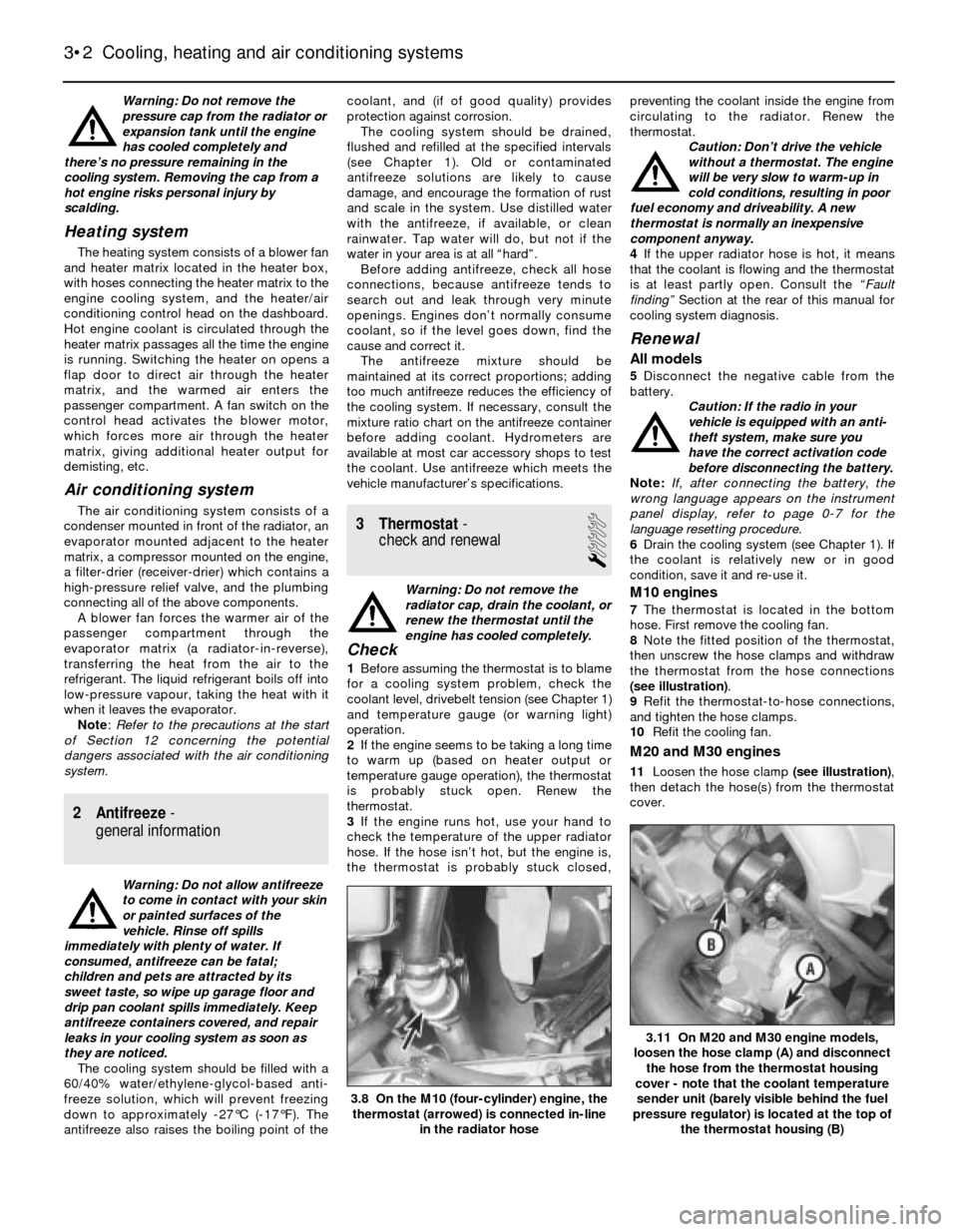

12If the outer surface of the fitting that

mates with the hose is deteriorated (corroded,

pitted, etc.), it may be damaged further by

hose removal. If it is, a new thermostat

housing cover will be required.

13Remove the bolts and detach the housing

cover. If the cover is stuck, tap it with a soft-

faced hammer to jar it loose. Be prepared for

some coolant to spill as the gasket seal is

broken.

14Note how it’s fitted, then remove the

thermostat.

15Stuff a rag into the engine opening, then

remove all traces of old gasket material (if the

gasket is paper type). Otherwise, remove the

rubber O-ring (see illustration)and sealant

from the housing and cover with a gasket

scraper. Remove the rag from the opening

and clean the gasket mating surfaces.

16Fit the new thermostat and gasket in the

housing. Make sure the correct end faces out

- the spring end is normally directed towards

the engine.

17Refit the cover and bolts. Tighten the

bolts to the torque listed in this Chapter’s

Specifications.

M40 engines

18Remove the cooling fan and timing belt

upper cover.

19Unscrew the hose clamp and detach thebottom hose from the elbow on the front of

the cylinder head.

20Unbolt the elbow from the cylinder head.

Note the fitted position of the thermostat, then

remove it (see illustrations). Remove the

rubber O-ring; a new one will be needed for

reassembly.

21Locate the thermostat in the cylinder head

in the same position as noted during removal

(arrow pointing upwards).

22Press a new O-ring in the groove, and

locate the elbow on the cylinder head. Tighten

the bolts.

23Connect the bottom hose to the elbow,

and tighten the hose clamp.

24Refit the upper timing belt cover and

cooling fan.

All models

25Refill the cooling system (see Chapter 1).

26Connect the battery negative cable.

27Start the engine and allow it to reach

normal operating temperature, then check for

leaks and proper thermostat operation (as

described earlier in this Section).

4 Radiator-

removal and refitting

1

Warning: Wait until the engine is

completely cool before beginning

this procedure.Note: If the radiator is being removed because

it is leaking, note that minor leaks can often be

repaired without removing the radiator, using

a radiator sealant.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

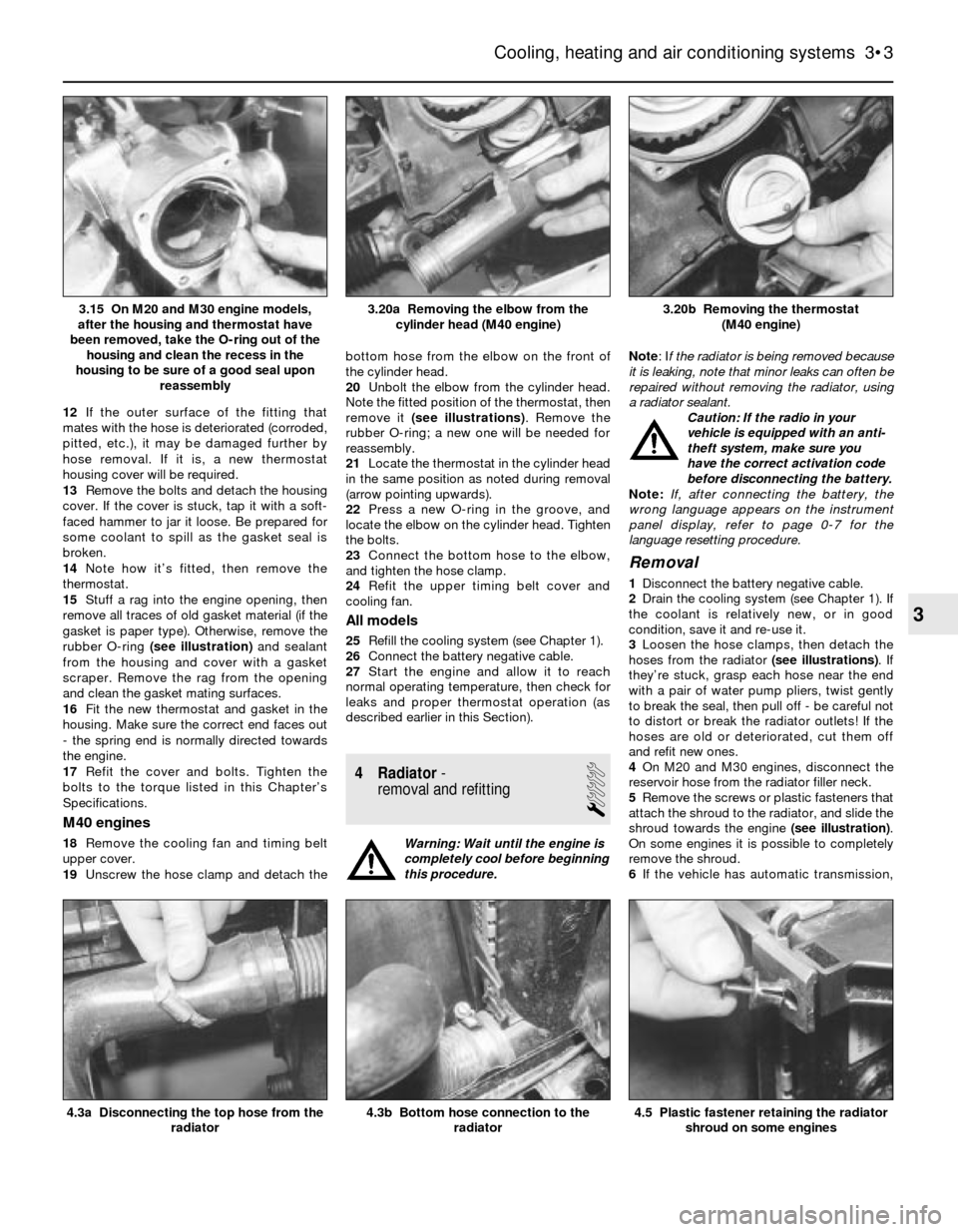

Removal

1Disconnect the battery negative cable.

2Drain the cooling system (see Chapter 1). If

the coolant is relatively new, or in good

condition, save it and re-use it.

3Loosen the hose clamps, then detach the

hoses from the radiator (see illustrations). If

they’re stuck, grasp each hose near the end

with a pair of water pump pliers, twist gently

to break the seal, then pull off - be careful not

to distort or break the radiator outlets! If the

hoses are old or deteriorated, cut them off

and refit new ones.

4On M20 and M30 engines, disconnect the

reservoir hose from the radiator filler neck.

5Remove the screws or plastic fasteners that

attach the shroud to the radiator, and slide the

shroud towards the engine (see illustration).

On some engines it is possible to completely

remove the shroud.

6If the vehicle has automatic transmission,

Cooling, heating and air conditioning systems 3•3

3.20b Removing the thermostat

(M40 engine)3.20a Removing the elbow from the

cylinder head (M40 engine)3.15 On M20 and M30 engine models,

after the housing and thermostat have

been removed, take the O-ring out of the

housing and clean the recess in the

housing to be sure of a good seal upon

reassembly

4.5 Plastic fastener retaining the radiator

shroud on some engines4.3b Bottom hose connection to the

radiator4.3a Disconnecting the top hose from the

radiator

3

Page 82 of 228

disconnect the fluid cooler lines from the

radiator. Use a drip tray to catch spilled fluid.

Plug the fluid cooler lines and fittings.

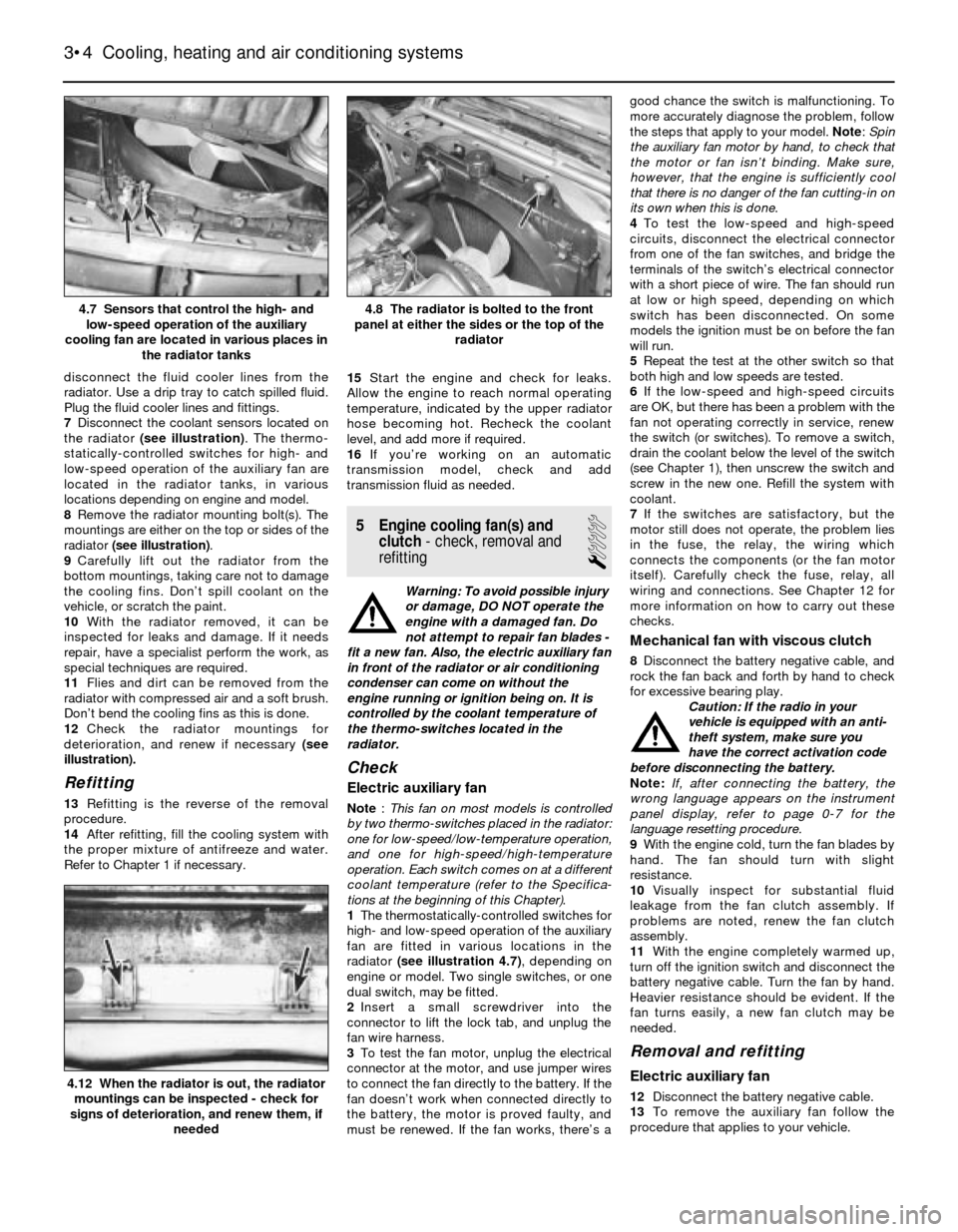

7Disconnect the coolant sensors located on

the radiator (see illustration). The thermo-

statically-controlled switches for high- and

low-speed operation of the auxiliary fan are

located in the radiator tanks, in various

locations depending on engine and model.

8Remove the radiator mounting bolt(s). The

mountings are either on the top or sides of the

radiator (see illustration).

9Carefully lift out the radiator from the

bottom mountings, taking care not to damage

the cooling fins. Don’t spill coolant on the

vehicle, or scratch the paint.

10With the radiator removed, it can be

inspected for leaks and damage. If it needs

repair, have a specialist perform the work, as

special techniques are required.

11Flies and dirt can be removed from the

radiator with compressed air and a soft brush.

Don’t bend the cooling fins as this is done.

12Check the radiator mountings for

deterioration, and renew if necessary (see

illustration).

Refitting

13Refitting is the reverse of the removal

procedure.

14After refitting, fill the cooling system with

the proper mixture of antifreeze and water.

Refer to Chapter 1 if necessary.15Start the engine and check for leaks.

Allow the engine to reach normal operating

temperature, indicated by the upper radiator

hose becoming hot. Recheck the coolant

level, and add more if required.

16If you’re working on an automatic

transmission model, check and add

transmission fluid as needed.

5 Engine cooling fan(s) and

clutch- check, removal and

refitting

1

Warning: To avoid possible injury

or damage, DO NOT operate the

engine with a damaged fan. Do

not attempt to repair fan blades -

fit a new fan. Also, the electric auxiliary fan

in front of the radiator or air conditioning

condenser can come on without the

engine running or ignition being on. It is

controlled by the coolant temperature of

the thermo-switches located in the

radiator.

Check

Electric auxiliary fan

Note: This fan on most models is controlled

by two thermo-switches placed in the radiator:

one for low-speed/low-temperature operation,

and one for high-speed/high-temperature

operation. Each switch comes on at a different

coolant temperature (refer to the Specifica-

tions at the beginning of this Chapter).

1The thermostatically-controlled switches for

high- and low-speed operation of the auxiliary

fan are fitted in various locations in the

radiator (see illustration 4.7), depending on

engine or model. Two single switches, or one

dual switch, may be fitted.

2Insert a small screwdriver into the

connector to lift the lock tab, and unplug the

fan wire harness.

3To test the fan motor, unplug the electrical

connector at the motor, and use jumper wires

to connect the fan directly to the battery. If the

fan doesn’t work when connected directly to

the battery, the motor is proved faulty, and

must be renewed. If the fan works, there’s agood chance the switch is malfunctioning. To

more accurately diagnose the problem, follow

the steps that apply to your model. Note: Spin

the auxiliary fan motor by hand, to check that

the motor or fan isn’t binding. Make sure,

however, that the engine is sufficiently cool

that there is no danger of the fan cutting-in on

its own when this is done.

4To test the low-speed and high-speed

circuits, disconnect the electrical connector

from one of the fan switches, and bridge the

terminals of the switch’s electrical connector

with a short piece of wire. The fan should run

at low or high speed, depending on which

switch has been disconnected. On some

models the ignition must be on before the fan

will run.

5Repeat the test at the other switch so that

both high and low speeds are tested.

6If the low-speed and high-speed circuits

are OK, but there has been a problem with the

fan not operating correctly in service, renew

the switch (or switches). To remove a switch,

drain the coolant below the level of the switch

(see Chapter 1), then unscrew the switch and

screw in the new one. Refill the system with

coolant.

7If the switches are satisfactory, but the

motor still does not operate, the problem lies

in the fuse, the relay, the wiring which

connects the components (or the fan motor

itself). Carefully check the fuse, relay, all

wiring and connections. See Chapter 12 for

more information on how to carry out these

checks.

Mechanical fan with viscous clutch

8Disconnect the battery negative cable, and

rock the fan back and forth by hand to check

for excessive bearing play.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

9With the engine cold, turn the fan blades by

hand. The fan should turn with slight

resistance.

10Visually inspect for substantial fluid

leakage from the fan clutch assembly. If

problems are noted, renew the fan clutch

assembly.

11With the engine completely warmed up,

turn off the ignition switch and disconnect the

battery negative cable. Turn the fan by hand.

Heavier resistance should be evident. If the

fan turns easily, a new fan clutch may be

needed.

Removal and refitting

Electric auxiliary fan

12Disconnect the battery negative cable.

13To remove the auxiliary fan follow the

procedure that applies to your vehicle.

3•4 Cooling, heating and air conditioning systems

4.12 When the radiator is out, the radiator

mountings can be inspected - check for

signs of deterioration, and renew them, if

needed

4.8 The radiator is bolted to the front

panel at either the sides or the top of the

radiator4.7 Sensors that control the high- and

low-speed operation of the auxiliary

cooling fan are located in various places in

the radiator tanks

Page 83 of 228

3-Series models

14Remove the radiator grille assembly (see

Chapter 11).

15Unbolt and remove the fan bracket and

shroud assembly from the radiator (see

Section 5).

16Remove the radiator (see Section 4).

17Unbolt the air conditioning condenser

mounting bolts, where applicable. Do not

remove the condenser or disconnect any

refrigerant lines from the condenser.

18Carefully pull the condenser back towards

the engine, slightly, to gain access to lift the

auxiliary fan.

19Disconnect the fan motor electrical

connection and remove the auxiliary fan.

20Refitting is the reverse of removal.

5-Series models

21Remove the screws and trim panel in front

of the radiator.

22Unbolt the fan assembly from the

condenser mounting points.

23Disconnect the fan electrical connector.

24Remove the fan and housing from the car,

being careful not to damage the air

conditioning condenser (when applicable)

while removing the fan.

25Refitting is the reverse of removal.

Mechanical fan with viscous clutch

26Disconnect the battery negative cable.

Remove the fan shroud mounting screws or

plastic fasteners, and detach the shroud (see

Section 4).

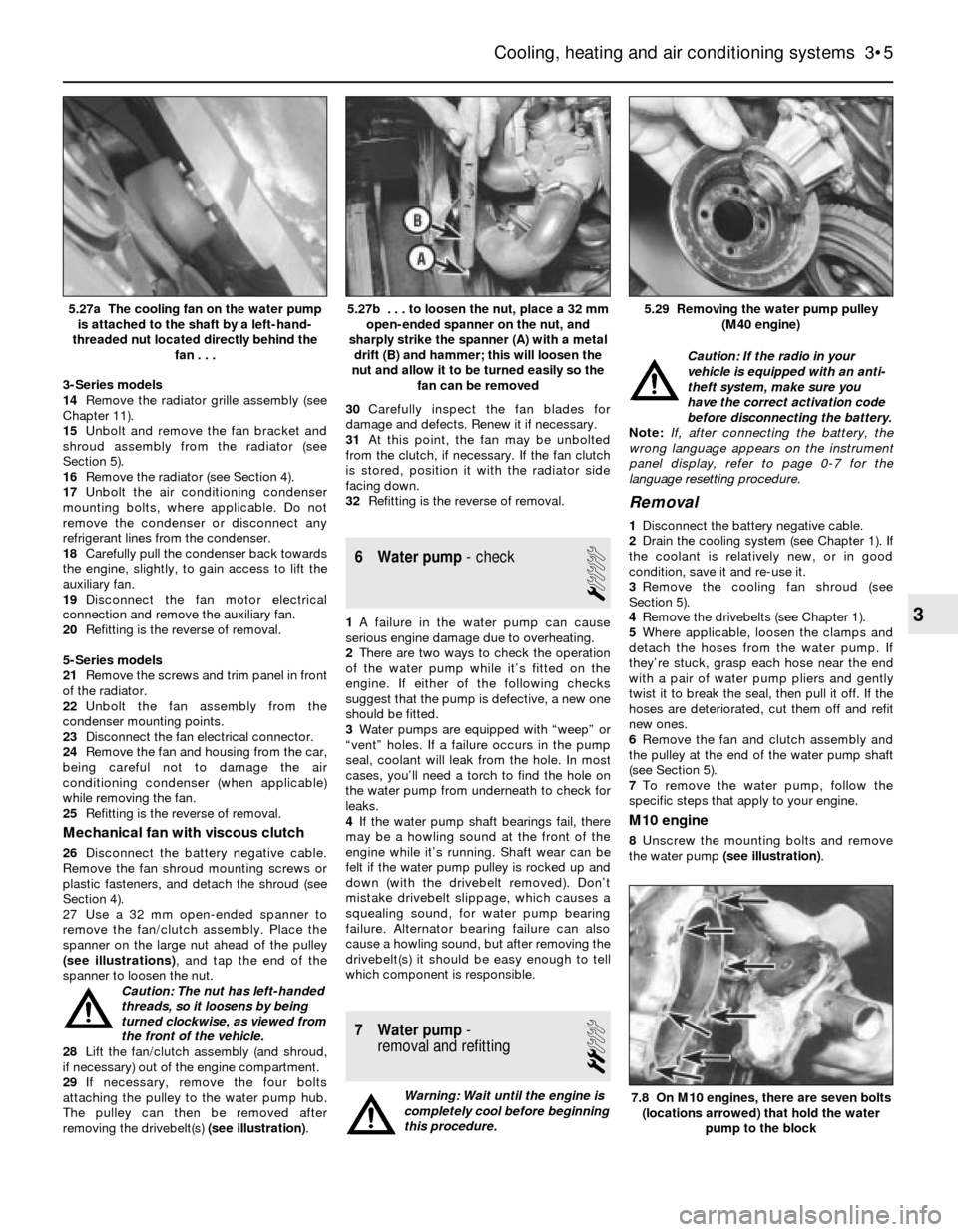

27 Use a 32 mm open-ended spanner to

remove the fan/clutch assembly. Place the

spanner on the large nut ahead of the pulley

(see illustrations), and tap the end of the

spanner to loosen the nut.

Caution: The nut has left-handed

threads, so it loosens by being

turned clockwise, as viewed from

the front of the vehicle.

28Lift the fan/clutch assembly (and shroud,

if necessary) out of the engine compartment.

29If necessary, remove the four bolts

attaching the pulley to the water pump hub.

The pulley can then be removed after

removing the drivebelt(s) (see illustration).30Carefully inspect the fan blades for

damage and defects. Renew it if necessary.

31At this point, the fan may be unbolted

from the clutch, if necessary. If the fan clutch

is stored, position it with the radiator side

facing down.

32Refitting is the reverse of removal.

6 Water pump- check

1

1A failure in the water pump can cause

serious engine damage due to overheating.

2There are two ways to check the operation

of the water pump while it’s fitted on the

engine. If either of the following checks

suggest that the pump is defective, a new one

should be fitted.

3Water pumps are equipped with “weep” or

“vent” holes. If a failure occurs in the pump

seal, coolant will leak from the hole. In most

cases, you’ll need a torch to find the hole on

the water pump from underneath to check for

leaks.

4If the water pump shaft bearings fail, there

may be a howling sound at the front of the

engine while it’s running. Shaft wear can be

felt if the water pump pulley is rocked up and

down (with the drivebelt removed). Don’t

mistake drivebelt slippage, which causes a

squealing sound, for water pump bearing

failure. Alternator bearing failure can also

cause a howling sound, but after removing the

drivebelt(s) it should be easy enough to tell

which component is responsible.

7 Water pump-

removal and refitting

2

Warning: Wait until the engine is

completely cool before beginning

this procedure.Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Drain the cooling system (see Chapter 1). If

the coolant is relatively new, or in good

condition, save it and re-use it.

3Remove the cooling fan shroud (see

Section 5).

4Remove the drivebelts (see Chapter 1).

5Where applicable, loosen the clamps and

detach the hoses from the water pump. If

they’re stuck, grasp each hose near the end

with a pair of water pump pliers and gently

twist it to break the seal, then pull it off. If the

hoses are deteriorated, cut them off and refit

new ones.

6Remove the fan and clutch assembly and

the pulley at the end of the water pump shaft

(see Section 5).

7To remove the water pump, follow the

specific steps that apply to your engine.

M10 engine

8Unscrew the mounting bolts and remove

the water pump (see illustration).

Cooling, heating and air conditioning systems 3•5

5.29 Removing the water pump pulley

(M40 engine)5.27b . . . to loosen the nut, place a 32 mm

open-ended spanner on the nut, and

sharply strike the spanner (A) with a metal

drift (B) and hammer; this will loosen the

nut and allow it to be turned easily so the

fan can be removed5.27a The cooling fan on the water pump

is attached to the shaft by a left-hand-

threaded nut located directly behind the

fan . . .

7.8 On M10 engines, there are seven bolts

(locations arrowed) that hold the water

pump to the block

3