Diff BMW 3 SERIES 1988 E30 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1988, Model line: 3 SERIES, Model: BMW 3 SERIES 1988 E30Pages: 228, PDF Size: 7.04 MB

Page 89 of 228

4

Carburettor (Solex 2B4)

Main jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X90

Air correction jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Venturi diameter

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 mm

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 mm

Idle/air jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50/120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40/125

Float needle valve diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Choke gap (pulldown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 to 5.5 mm

Throttle positioner spring preload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.0 to 24.0 mm

Float level

Stage 1 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.0 to 29.0 mm

Stage 2 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.0 to 31.0 mm

Chapter 4 Fuel and exhaust systems

Accelerator cable - check, adjustment and renewal . . . . . . . . . . . . . 9

Air cleaner assembly - removal and refitting . . . . . . . . . . . . . . . . . . . 8

Air filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Airflow meter - check, removal and refitting . . . . . . . . . . . . . . . . . . . 16

Carburettor - cleaning and adjustment . . . . . . . . . . . . . . . . . . . . . . . 12

Carburettor - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Carburettor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cold start injector and thermotime switch -

checkand renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Engine idle speed check and adjustment . . . . . . . . . See Chapter 1

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exhaust system servicing - general information . . . . . . . . . . . . . . . . 22

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel injection system - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fuel injection system - depressurising . . . . . . . . . . . . . . . . . . . . . . . 2Fuel injection system - fault finding . . . . . . . . . . . . See end of Chapter

Fuel injection - general information . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel injection systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fuel injectors - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fuel lines and fittings - repair and renewal . . . . . . . . . . . . . . . . . . . . 5

Fuel pressure regulator - check and renewal . . . . . . . . . . . . . . . . . . 18

Fuel pump, transfer pump and fuel level sender unit -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel pump/fuel pressure - check . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel system check . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel tank - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fuel tank cleaning and repair - general information . . . . . . . . . . . . . 7

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Idle air stabiliser valve - check, adjustment and renewal . . . . . . . . . 21

Throttle body - check, removal and refitting . . . . . . . . . . . . . . . . . . . 17

4•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 91 of 228

information on removing and refitting the

intake manifold, refer to Chapter 2A.

The throttle valve inside the throttle body or

carburettor is actuated by the accelerator

cable. When you depress the accelerator

pedal, the throttle plate opens and airflow

through the intake system increases.

On fuel injection systems, a flap inside the

airflow meter opens wider as the airflow

increases. A throttle position switch attached

to the pivot shaft of the flap detects the angle

of the flap (how much it’s open) and converts

this to a voltage signal, which it sends to the

computer.

Fuel system

On carburettor models, the fuel pump

supplies fuel under pressure to the

carburettor. A needle valve in the float

chamber maintains the fuel at a constant

level. A fuel return system channels excess

fuel back to the fuel tank.

On fuel injection models, an electric fuel

pump supplies fuel under constant pressure

to the fuel rail, which distributes fuel to the

injectors. The electric fuel pump is located

inside the fuel tank on later models, or beside

the fuel tank on early models. Early models

also have a transfer pump located in the fuel

tank. The transfer pump acts as an aid to the

larger main pump for delivering the necessary

pressure. A fuel pressure regulator controls

the pressure in the fuel system. The fuel

system also has a fuel pulsation damper

located near the fuel filter. The damper

reduces the pressure pulsations caused by

fuel pump operation, and the opening and

closing of the injectors. The amount of fuel

injected into the intake ports is precisely

controlled by an Electronic Control Unit (ECU

or computer). Some later 5-Series models

have a fuel cooler in the return line.

Electronic control system (fuel

injection system)

Besides altering the injector opening

duration as described above, the electronic

control unit performs a number of other tasks

related to fuel and emissions control. It

accomplishes these tasks by using data

relayed to it by a wide array of information

sensors located throughout the enginecompartment, comparing this information to

its stored map, and altering engine operation

by controlling a number of different actuators.

Since special equipment is required, most

fault diagnosis and repair of the electronic

control system is beyond the scope of the

home mechanic. Additional information and

testing procedures for the emissions system

components (oxygen sensor, coolant

temperature sensor, EVAP system, etc.) is

contained in Chapter 6.

2 Fuel injection system-

depressurising

1

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke or allow open flames or bare light

bulbs near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

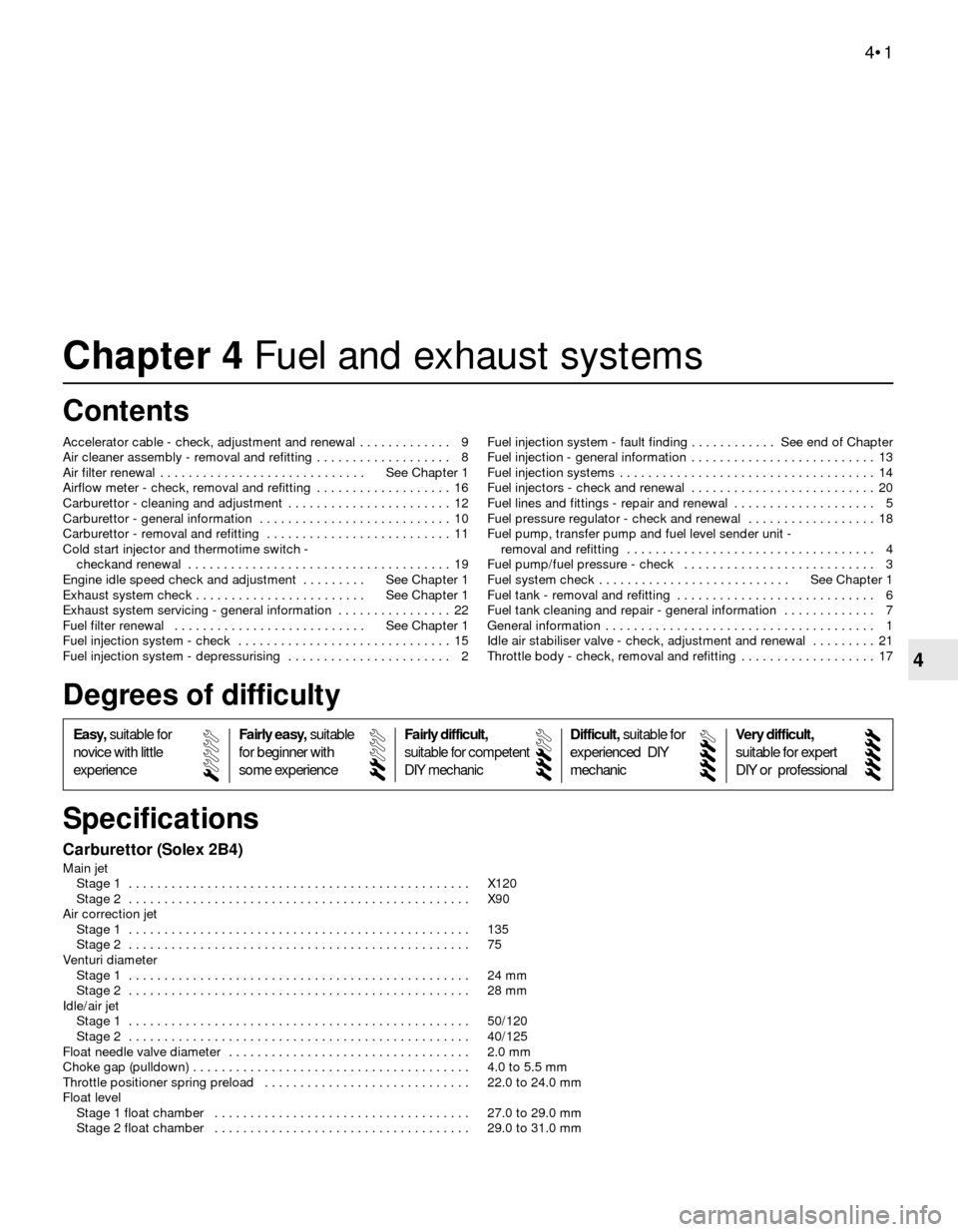

1Remove the fuel pump fuse from the main

fuse panel (see illustrations). Note:Consult

your owner’s handbook for the exact location

of the fuel pump fuse, if the information is not

stamped onto the fusebox cover.

2Start the engine, and wait for it to stall.

Switch off the ignition.

3Remove the fuel filler cap to relieve the fuel

tank pressure.

4The fuel system is now depressurised.

Note:Place a rag around fuel lines before

disconnecting, to prevent any residual fuel

from spilling onto the engine(see

illustration).

5Disconnect the battery negative cable

before working on any part of the system.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3 Fuel pump/fuel pressure-

check

3

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

Carburettor engines

1To test the fuel pump, it will be necessary to

connect a suitable pressure gauge between

the fuel pump outlet, and the carburettor

supply pipe. For this particular test, the fuel

return valve, which is normally connected in

the fuel line from the fuel pump to the

carburettor, mustbe bypassed.

2With the engine running at idle speed, the

pump pressure should be between 0.1 and

0.3 bars.

3Should a pressure gauge not be available, a

simpler (but less accurate) method of testing

the fuel pump is as follows.

4Disconnect the outlet hose from the fuel

pump.

5Disconnect the LT lead from the coil, to

prevent the engine firing, then turn the engine

over on the starter. Well-defined spurts of fuel

should be ejected from the outlet hose.

Fuel injection engines

Note 1:The electric fuel pump is located

inside the fuel tank on later models, or beside

the fuel tank on early models. Early models are

also equipped with a transfer pump located in

the fuel tank. The transfer pump feeds the

main pump, but can’t generate the high

pressure required by the system.

Note 2:The fuel pump relay on Motronic

systems is activated by an earth signal from

the Motronic control unit (ECU). The fuel

pump operates for a few seconds when the

ignition is first switched on, and then

continues to operate only when the engine is

actually running.

Fuel and exhaust systems 4•3

2.4 Be sure to place a rag under and

around any fuel line when disconnecting2.1b Removing the fuel pump fuse on

5-Series models2.1a Removing the fuel pump fuse on

3-Series models

4

Page 101 of 228

9Remove the screws securing the throttle

housing to the main body (see illustration).

10Prise out the intermediate throttle link. If

this proves difficult, unscrew the nut and

disconnect the lever from the primary throttle

spindle, taking care not to disturb the return

spring (see illustration).

11Separate the throttle housing from the

main body, and remove the gasket (see

illustrations).

12With the cover inverted, tap out the float

pivot pins, remove the floats, and lift out the

two needle valves - keeping all the

components identified side for side (see

illustrations).

13Unscrew the bypass fuel jet from the

secondary float chamber, then similarly

remove the jets from the cover - keeping them

all identified for location (see illustrations).

14Clean all the components, and blow all

the internal channels clear using low air

pressure.

15Reassembly is a reversal of dismantling,

but note the following points:

a) Fit the new gaskets and seals supplied in

the repair kit.

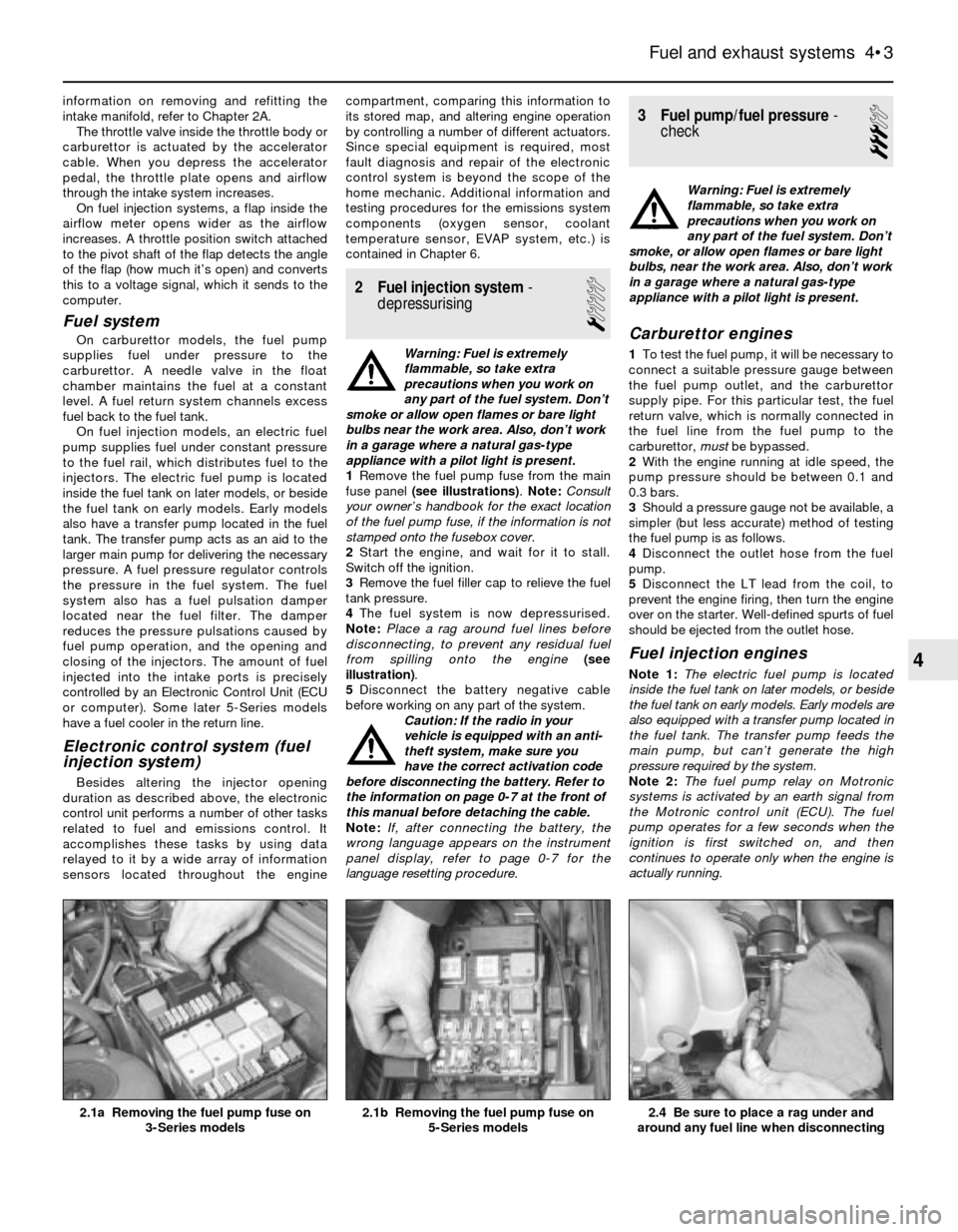

b) Before refitting the cover, check that the

choke linkage arm is correctly located in

the lever (see illustration).

c) Check and if necessary adjust the float

settings. Invert the cover, and check thedistance from the contact face (without

gasket) to the top of the float, making sure

that the needle valve spring-tensioned

ball is not depressed (see illustration).

Note that the dimension is different for

the primary and secondary floats (see

Specifications). If adjustment is

necessary, bend the float arm as required.

d) Make sure that the seal is fitted to the top

of the accelerator pump (see

illustration).

Adjustment

Note:Idle speed and mixture adjustments are

covered in Chapter 1.

Automatic choke (2B4)16Check that the automatic choke cover

and housing alignment marks are clearly

visible; if not, make new marks.

17Remove the three screws and withdraw

the metal ring (see illustration).

18Remove the plastic cover, at the same

time disengaging the bi-metal spring from the

control lever (see illustration).

19Fit a rubber band to the bottom of the

control lever. Push the pulldown lever to the

right and use a 4.2 mm diameter drill to check

the distance between the lower edge of the

choke valve and the wall of the carburettor(see illustration). Alternatively apply vacuum

to the pulldown unit to move the lever.

20If adjustment is necessary, turn the screw

on the end of the pulldown unit (see

illustration).

21Refit the cover in reverse order, making

sure that the alignment marks are in line.

Throttle positioner (2B4)

22With the throttle in the idle position, check

that the length of the spring on the throttle

positioner is 23.0 ± 1.0 mm. If not, adjust the

nut as required.

23With no vacuum applied (engine stopped)

check that the control travel, measured

between the stop screw and lever, is 5.0 ±

0.5 mm. If necessary, loosen the locknut and

turn the diaphragm rod as required. Tighten

the locknut on completion.

Fuel and exhaust systems 4•13

12.15b To check the float level, measure

the distance between the contact face and

the top of the float12.15a Choke linkage arm located in the

automatic choke lever

12.20 If adjustment is necessary, turn the

screw (arrowed) on the end of the

pulldown unit

12.19 Fit a rubber band (2) to the bottom

of the control lever, then push the

pulldown lever to the right, and use a

4.2 mm diameter drill (1) to check the

distance between the lower edge of the

choke valve and the wall of the carburettor

12.17 Remove the three screws and

withdraw the metal ring

12.15c Accelerator pump seal (arrowed)

12.18 Remove the automatic choke cover,

at the same time disengaging the bi-metal

spring from the control lever

4

Page 103 of 228

8Check the fuel system pressure (see

Section 3).

9If these checks do not locate the problem,

take the vehicle to a BMW dealer, who will be

able to read the fault codes stored in the ECU,

using special equipment.

16 Airflow meter- check,

removal and refitting

2

Check (L-Jetronic systems)

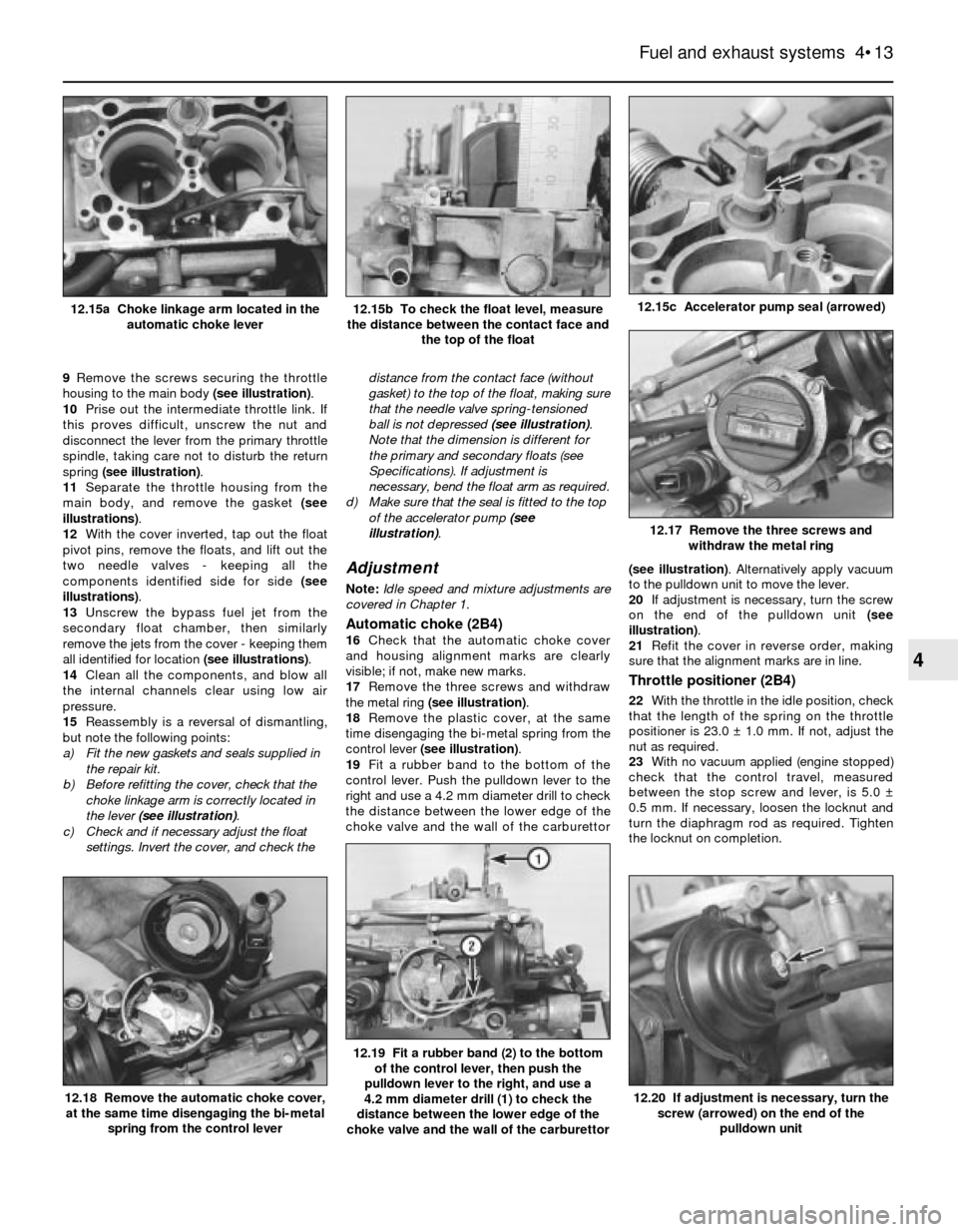

1Remove the duct from the intake end of the

airflow meter. Carefully open and close the

sensor flap (see illustration), and check for

binding. The flap can bend during a backfire,

and cause incorrect resistance readings. The

flap will bind and stick in a partially-open

position, causing the engine to run rich, and

stall when it returns to idle.

2Disconnect the electrical connector from

the airflow meter.

3Using an ohmmeter, check the resistancebetween terminals 7 and 8 (see illustration).

The resistance should increase steadily

(without any “flat spots”) as the sensor flap is

slowly moved from the fully-closed position to

the fully-open position.

4Also, check the intake air temperature

sensor (inside the airflow meter). Using an

ohmmeter, probe terminals 8 and 9 (see

illustration 16.3)and check for the proper

resistance. The resistance should be 2200 to

2700 ohms at 20º C.

5If the resistance readings are correct, check

the wiring harness (see Chapter 12). Plug in

the connector to the airflow meter. Ensure

that the ignition is switched off. Disconnect

the electrical connector from the ECU (located

under the right-hand side of the facia) and

probe terminals 7 and 8 (see illustration)with

an ohmmeter. Carefully move the door of the

airflow meter, and observe the change in

resistance as it moves from closed to fully-

open. The test results should be the same as

paragraph 3. If there are any differences in the

test results, there may be a shorted-out or

broken wire in the harness.

Check (Motronic systems)

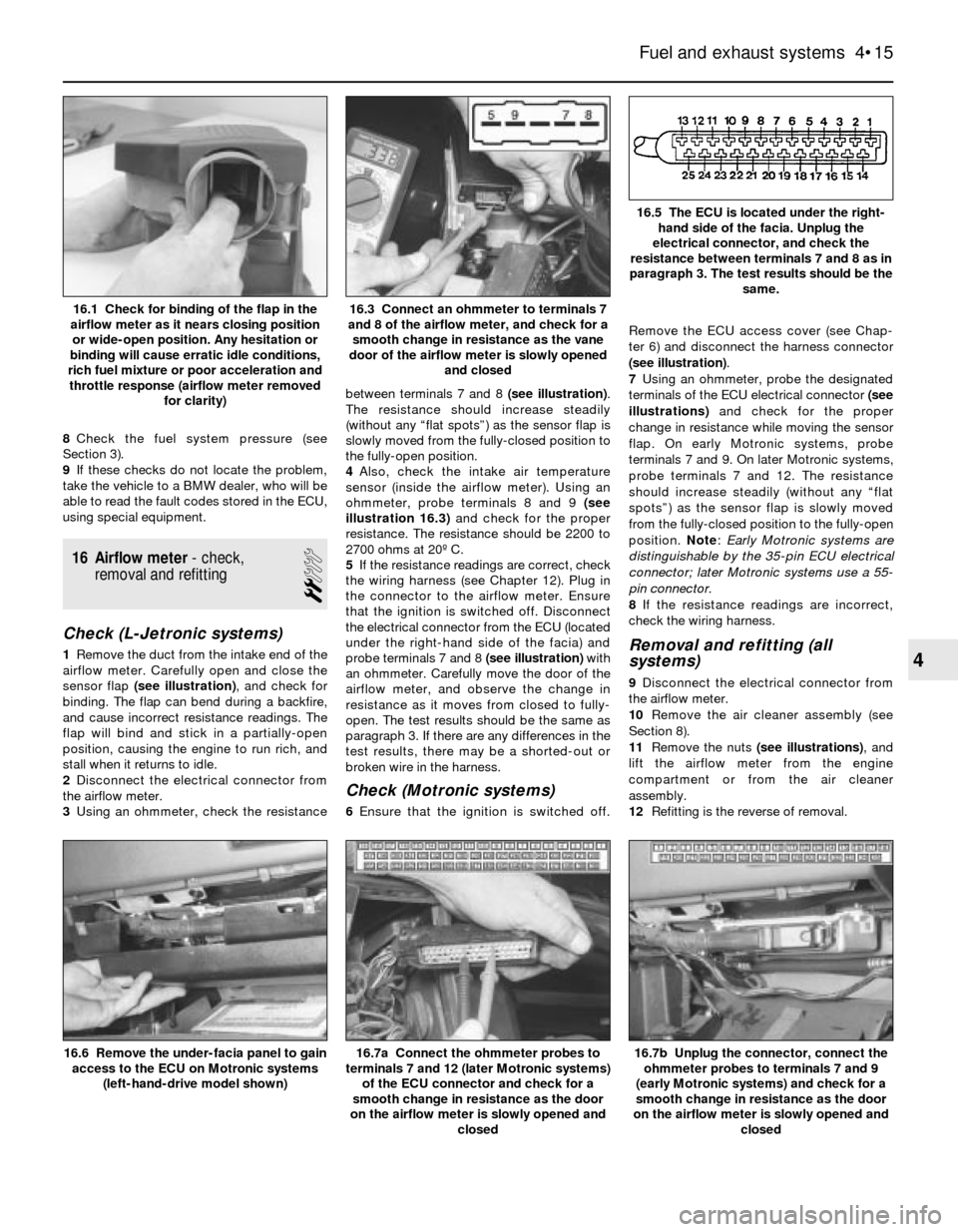

6Ensure that the ignition is switched off.Remove the ECU access cover (see Chap-

ter 6) and disconnect the harness connector

(see illustration).

7Using an ohmmeter, probe the designated

terminals of the ECU electrical connector (see

illustrations)and check for the proper

change in resistance while moving the sensor

flap. On early Motronic systems, probe

terminals 7 and 9. On later Motronic systems,

probe terminals 7 and 12. The resistance

should increase steadily (without any “flat

spots”) as the sensor flap is slowly moved

from the fully-closed position to the fully-open

position. Note: Early Motronic systems are

distinguishable by the 35-pin ECU electrical

connector; later Motronic systems use a 55-

pin connector.

8If the resistance readings are incorrect,

check the wiring harness.

Removal and refitting (all

systems)

9Disconnect the electrical connector from

the airflow meter.

10Remove the air cleaner assembly (see

Section 8).

11Remove the nuts (see illustrations), and

lift the airflow meter from the engine

compartment or from the air cleaner

assembly.

12Refitting is the reverse of removal.

Fuel and exhaust systems 4•15

16.5 The ECU is located under the right-

hand side of the facia. Unplug the

electrical connector, and check the

resistance between terminals 7 and 8 as in

paragraph 3. The test results should be the

same.

16.3 Connect an ohmmeter to terminals 7

and 8 of the airflow meter, and check for a

smooth change in resistance as the vane

door of the airflow meter is slowly opened

and closed16.1 Check for binding of the flap in the

airflow meter as it nears closing position

or wide-open position. Any hesitation or

binding will cause erratic idle conditions,

rich fuel mixture or poor acceleration and

throttle response (airflow meter removed

for clarity)

16.7b Unplug the connector, connect the

ohmmeter probes to terminals 7 and 9

(early Motronic systems) and check for a

smooth change in resistance as the door

on the airflow meter is slowly opened and

closed16.7a Connect the ohmmeter probes to

terminals 7 and 12 (later Motronic systems)

of the ECU connector and check for a

smooth change in resistance as the door

on the airflow meter is slowly opened and

closed16.6 Remove the under-facia panel to gain

access to the ECU on Motronic systems

(left-hand-drive model shown)

4

Page 109 of 228

Fuel injection system - fault finding

L-Jetronic fuel injection system

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch faulty Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump inoperative Check fuel pump fuse and fuel pump relay (see Sections 3 and 4)

Airflow meter flap (door) binding or stuck

in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3). Test fuel pressure regulator (Section 18)

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or

wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Incorrect ignition timing Check ignition timing (see Chapter 5). Check vacuum advance system

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating continuously Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pump(s). Renew if necessary (see Section 3)

Insufficient residual fuel pressure Test residual fuel pressure. Renew fuel pump or fuel accumulator as necessary

(see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as required (see Chapter 4)

Coolant temperature sensor faulty or

wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (warm weather) Check fuel pressure (see Section 3)

EVAP system faulty (where applicable) Check EVAP system (see Chapter 6, Section 6)

Incorrect ignition timing Check ignition timing (see Chapter 5). Check vacuum advance system

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged or faulty Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Vacuum advance system faulty Check vacuum advance system and electronic vacuum advance relay

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Motronic fuel injection system

Note:With this system, when faults occur, the ECU stores a fault code in its memory. These codes can only be read by a BMW dealer, as

specialised equipment is required. It may save time to have at least the initial fault diagnosis carried out by a dealer.

Lack of power

Probable cause Corrective action

Coolant temperature sensor faulty, Test coolant temperature sensor and wiring. Repair wiring or renew sensor if

or wire to sensor broken faulty (see Chapter 6)

Fuel pressure incorrect Check fuel pressure from main pump and transfer pump, as applicable (see Section 3)

Throttle plate not opening fully Check accelerator cable adjustment to make sure throttle is opening fully. Adjust cable if

necessary (see Section 9)

Fuel and exhaust systems 4•21

4

Page 110 of 228

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch

faulty (early Motronic system only) Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump not running Check fuel pump fuse and fuel pump relay (see Sections 2 and 3)

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or Test coolant temperature sensor (see Chapter 6, Section 4)

wiring problem

TPS (throttle position sensor) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Crankshaft position signal missing Faulty position sensor or flywheel, or reference pin missing (see Chapter 5)

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating

continuously (early Motronic system only) Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pressure (see Section 3)

Insufficient residual fuel pressure Test fuel system hold pressure (see Section 3)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as necessary

Coolant temperature sensor faulty

or wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (in warm weather) Check fuel pressure (see Section 3)

EVAP system faulty Check EVAP system (see Chapter 6, Section 6)

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Oxygen sensor faulty (where applicable) Check the oxygen sensor (see Chapter 6, Section 4)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or Inspect the airflow meter for damage (see Section 16)

stuck in open position

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6)

Engine idles too fast

Probable cause Corrective action

Accelerator pedal, cable or throttle valve binding Check for worn or broken components, kinked cable, or other damage. Renew faulty

components

Air leaking past throttle valve Inspect throttle valve, and adjust or renew as required

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Poor fuel economy

Probable cause Corrective action

Cold start injector leaking

(early Motronic system only) Test and, if necessary, renew cold start injector (see Section 19)

Oxygen sensor faulty (where applicable) Test the oxygen sensor (see Chapter 6, Section 4))

Sticking handbrake/binding brakes Check the handbrake/braking system (see Chapter 9)

Tyre pressures low Check tyre pressures (Chapter 1)

4•22 Fuel and exhaust systems

Page 111 of 228

5GeneralApplication

Models with carburettor or L-Jetronic fuel injection . . . . . . . . . . . . . . Transistorised Coil Ignition (TCI) system

Models with Motronic fuel injection . . . . . . . . . . . . . . . . . . . . . . . . . . Ignition functions controlled by Motronic system

Ignition coil

Primary resistance

TCI system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.82 ohms

Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 ohms

Secondary resistance

TCI system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8250 ohms

Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5000 to 6000 ohms

Distributor(models with TCI system)

Air gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 mm to 0.7 mm

Pick-up coil/impulse generator resistance . . . . . . . . . . . . . . . . . . . . . . . 900 to 1200 ohms

Ignition timing(models with TCI system)

(Vacuum line disconnected at distributor)

316 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25º BTDC at 2500 rpm (2900 rpm from 9/83)

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30º BTDC at 3000 rpm

320i with M20/B20 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23º BTDC at 5000 ±50 rpm

518 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25º BTDC at 2900 ±50 rpm

518i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30º BTDC at 3000 ±50 rpm

525i with M30/B25 engine (except distributor

237 302 033) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22º BTDC at 1800 ±50 rpm

525i with M30/B25 engine (distributor 237 302 033) . . . . . . . . . . . . . . . 22º BTDC at 2150 ±50 rpm

528i with M30/B28 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22º BTDC at 2150 ±50 rpm

Chapter 5 Engine electrical systems

Air gap (TCI system) – check and adjustment . . . . . . . . . . . . . . . . . . 11

Alternator – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Alternator brushes – check and renewal . . . . . . . . . . . . . . . . . . . . . . 17

Battery – emergency jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery cables – check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery check and maintenance . . . . . . . . . . . . . . . . See Chapter 1

Charging system – check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Charging system – general information and precautions . . . . . . . . . 13

Distributor – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drivebelt check, adjustment and renewal . . . . . . . . . See Chapter 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ignition coil – check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Ignition sensors (Motronic system) – check and renewal . . . . . . . . . 12

Ignition system – check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ignition system – general information and precautions . . . . . . . . . . 5

Ignition timing (TCI system) – check and adjustment . . . . . . . . . . . . 7

Impulse generator and ignition control unit – check and

renewal (TCI system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spark plug HT lead check and renewal . . . . . . . . . . . See Chapter 1

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Starter motor – in-vehicle check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starter motor – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 20

Starter solenoid – removal and refitting . . . . . . . . . . . . . . . . . . . . . . 21

Starting system – general information and precautions . . . . . . . . . . 18

Voltage regulator – renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 113 of 228

5 Ignition system- general

information and precautions

The ignition system includes the ignition

switch, the battery, the distributor, the primary

(low-voltage/low-tension or LT) and

secondary (high-voltage/high-tension or HT)

wiring circuits, the spark plugs and the spark

plug leads. Models fitted with a carburettor or

L-Jetronic fuel injection are equipped with a

Transistorised Coil Ignition (TCI) system.

Models fitted with the Motronic fuel injection

system have the ignition system incorporated

within the Motronic system (Digital Motor

Electronics or DME).

Transistorised Coil Ignition (TCI)

system

This system is has four major components;

the impulse generator, the ignition control

unit, the coil, and the spark plugs. The

impulse generator provides a timing signal for

the ignition system. Equivalent to cam-

actuated breaker points in a standard

distributor, the impulse generator creates an

A/C voltage signal every time the trigger

wheel tabs pass the impulse generator tabs.

When the ignition control unit (capacitive

discharge unit) receives the voltage signal, it

triggers a spark discharge from the coil by

interrupting the primary coil circuit. The

ignition dwell (coil charging time) is adjusted

by the ignition control unit for the most

intense spark. Note: The air gap (distance

between the impulse generator and trigger

wheel tabs) can be adjusted (see Section 11).

Ignition timing is mechanically adjusted

(see Section 7). A centrifugal advance unit

that consists of spring-loaded rotating

weights advances ignition timing as engine

speed increases. The vacuum advance

adjusts ignition timing to compensate for

changes in engine load.

Motronic ignition system

This system, also known as Digital Motor

Electronics (DME), incorporates all ignition

and fuel injection functions into one central

control unit or ECU (computer). The ignition

timing is based on inputs the ECU receives for

engine load, engine speed, coolant

temperature and intake air temperature. The

only function the distributor performs is the

distribution of the high voltage signal to the

individual spark plugs. The distributor is

attached directly to the cylinder head. There is

no mechanical spark advance system used on

these systems.

Ignition timing is electronically-controlled,

and is not adjustable on Motronic systems.

During starting, a crankshaft position sensor

(reference sensor) relays the crankshaft

position to the ECU, and an initial baseline

ignition point is determined. Once the engineis running, the ignition timing is continually

changing, based on the various input signals

to the ECU. Engine speed is signalled by a

speed sensor. Early Motronic systems have

the position reference sensor and the speed

sensor mounted on the bellhousing over the

flywheel on the left-hand side. Later Motronic

systems have a single sensor (pulse sensor)

mounted over the crankshaft pulley. This

sensor functions as a speed sensor as well as

a position reference sensor. Refer to Sec-

tion 12 for checking and renewing the ignition

sensors. Note: Some models are equipped

with a TDC sensor mounted on the front of the

engine. This sensor is strictly for the BMW

service test unit, and it is not part of the

Motronic ignition system.

Precautions

Certain precautions must be observed

when working on a transistorised ignition

system.

a) Do not disconnect the battery cables

when the engine is running

b) Make sure the ignition control unit (TCI

ignition system) is always well earthed

(see Section 10).

c) Keep water away from the distributor and

HT leads.

d) If a tachometer is to be connected to the

engine, always connect the tachometer

positive (+) lead to the ignition coil

negative terminal (-) and never to the

distributor.

e) Do not allow the coil terminals to be

earthed, as the impulse generator or coil

could be damaged.

f) Do not leave the ignition switch on for

more than ten minutes with the engine

off, or if the engine will not start.

6 Ignition system- check

2

Warning: Because of the high

voltage generated by the ignition

system, extreme care should be

taken whenever an operation is

performed involving ignition components.

This not only includes the impulse

generator (electronic ignition), coil,

distributor and spark plug HT leads, but

related components such as spark plug

connectors, tachometer and other test

equipment.

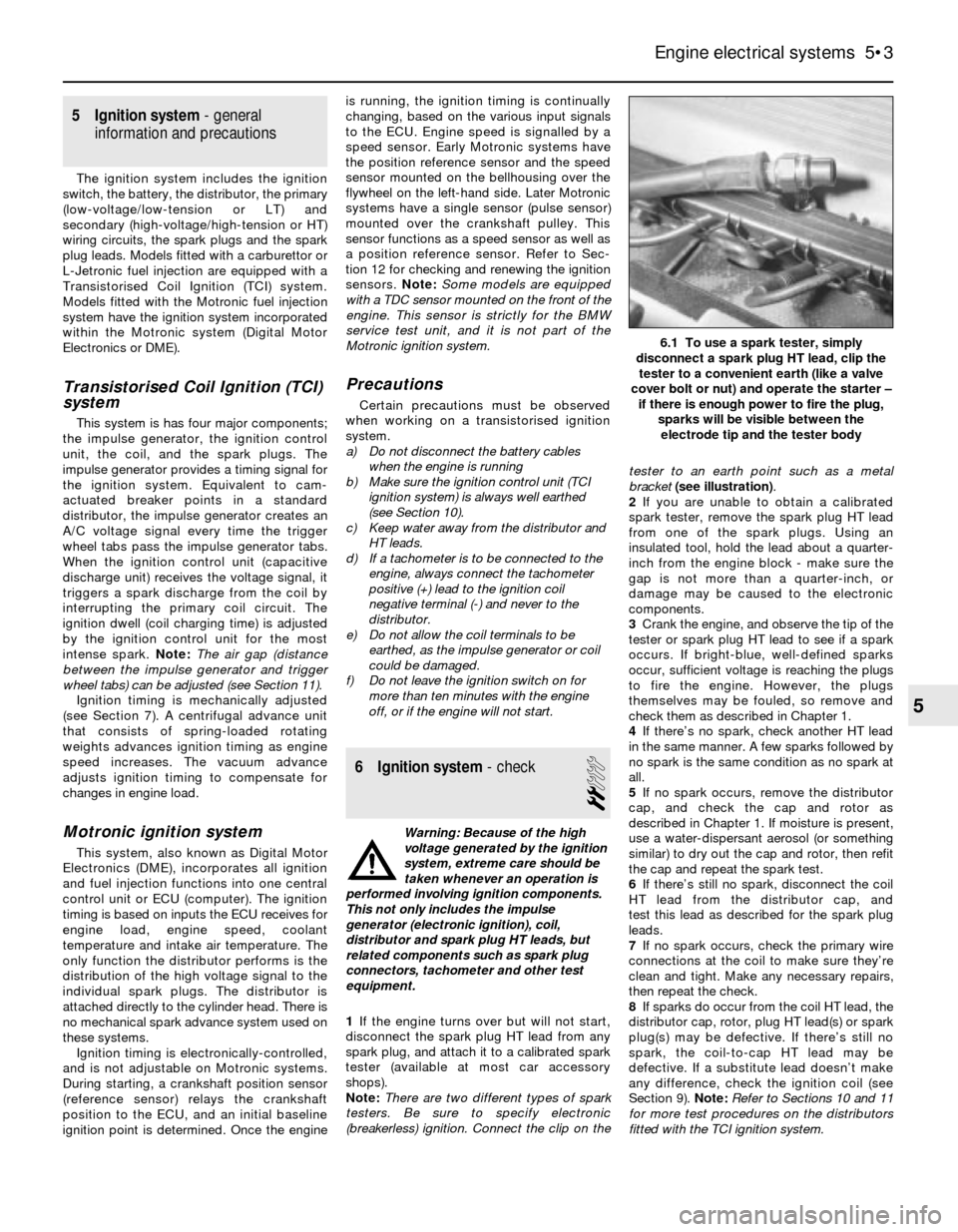

1If the engine turns over but will not start,

disconnect the spark plug HT lead from any

spark plug, and attach it to a calibrated spark

tester (available at most car accessory

shops).

Note:There are two different types of spark

testers. Be sure to specify electronic

(breakerless) ignition. Connect the clip on thetester to an earth point such as a metal

bracket (see illustration).

2If you are unable to obtain a calibrated

spark tester, remove the spark plug HT lead

from one of the spark plugs. Using an

insulated tool, hold the lead about a quarter-

inch from the engine block - make sure the

gap is not more than a quarter-inch, or

damage may be caused to the electronic

components.

3Crank the engine, and observe the tip of the

tester or spark plug HT lead to see if a spark

occurs. If bright-blue, well-defined sparks

occur, sufficient voltage is reaching the plugs

to fire the engine. However, the plugs

themselves may be fouled, so remove and

check them as described in Chapter 1.

4If there’s no spark, check another HT lead

in the same manner. A few sparks followed by

no spark is the same condition as no spark at

all.

5If no spark occurs, remove the distributor

cap, and check the cap and rotor as

described in Chapter 1. If moisture is present,

use a water-dispersant aerosol (or something

similar) to dry out the cap and rotor, then refit

the cap and repeat the spark test.

6If there’s still no spark, disconnect the coil

HT lead from the distributor cap, and

test this lead as described for the spark plug

leads.

7If no spark occurs, check the primary wire

connections at the coil to make sure they’re

clean and tight. Make any necessary repairs,

then repeat the check.

8If sparks do occur from the coil HT lead, the

distributor cap, rotor, plug HT lead(s) or spark

plug(s) may be defective. If there’s still no

spark, the coil-to-cap HT lead may be

defective. If a substitute lead doesn’t make

any difference, check the ignition coil (see

Section 9). Note:Refer to Sections 10 and 11

for more test procedures on the distributors

fitted with the TCI ignition system.

Engine electrical systems 5•3

6.1 To use a spark tester, simply

disconnect a spark plug HT lead, clip the

tester to a convenient earth (like a valve

cover bolt or nut) and operate the starter –

if there is enough power to fire the plug,

sparks will be visible between the

electrode tip and the tester body

5

Page 114 of 228

7 Ignition timing (TCI system)-

check and adjustment

4

Warning: Keep hands, equipment

and wires well clear of the

viscous cooling fan during

adjustment of the ignition timing.

Note:This Section describes the procedure

for checking and adjusting the ignition timing

on engines fitted with the TCI system. On

engines fitted with the Motronic engine

management system, the ignition timing is

controlled by the electronic control unit, and

no adjustment is possible. The timing can be

checked using the following procedure, but no

ignition timing values were available at the

time of writing. If the timing is thought to be

incorrect, refer to a BMW dealer.

1Some special tools are required for this

procedure (see illustration). The engine must

be at normal operating temperature, and the

air conditioning (where fitted) must be

switched off. Make sure the idle speed is

correct.

2Apply the handbrake, and chock the wheels

to prevent movement of the vehicle. The

transmission must be in neutral (manual) or

Park (automatic).

3The timing marks are located on the engine

flywheel (viewed through the timing checkhole in the bellhousing) and/or on the vibration

damper on the front of the engine.

4Where applicable, disconnect the vacuum

hose from the distributor vacuum advance

unit.

5Connect a tachometer and timing light

according to the equipment manufacturer’s

instructions (an inductive pick-up timing light

is preferred). Generally, the power leads for

the timing light are attached to the battery

terminals, and the pick-up lead is attached to

the No 1 spark plug HT lead. The No 1 spark

plug is the one at the front of the engine.

Caution: If an inductive pick-up

timing light isn’t available, don’t

puncture the spark plug HT lead

to attach the timing light pick-up

lead. Instead, use an adapter between the

spark plug and HT lead. If the insulation on

the HT lead is damaged, the secondary

voltage will jump to earth at the damaged

point, and the engine will misfire.

Note:On some models, a TDC transmitter is

fitted for checking the ignition system.

However, a special BMW tester must be

connected to the diagnostic socket to use it,

so unless the special tester is available, a

conventional timing light should be used. The

ignition timing mark may be on the vibration

damper, but if not, normally the TDC mark will

be. If the timing light is of the adjustable delay

type, then the ignition timing may be

determined by zeroing the adjustment, then

turning the adjustment until the TDC marks are

aligned, and then reading off the amount of

advance from the timing light. If a standard

timing light is being used, make a mark on the

vibration damper in accordance with the

specified advance, using the following formula

to calculate the distance from the TDC mark

to the timing mark:

Distance = 2Pr x advance

360

where P = 3.142

r = radius of vibration damper

advance = specified advance

BTDC in degrees

6With the ignition off, loosen the distributor

clamp nut just enough to allow the distributor

to pivot without any slipping.7Make sure the timing light wires are routed

away from the drivebelts and fan, then start

the engine.

8Raise the engine rpm to the specified

speed, and then point the flashing timing light

at the timing marks - be very careful of moving

engine components.

9The mark on the flywheel or vibration

damper will appear stationary. If it’s aligned

with the specified point on the bellhousing or

engine front cover, the ignition timing is

correct (see illustrations).

10If the marks aren’t aligned, adjustment is

required. Turn the distributor very slowly until

the marks are aligned, taking care not to

touch the HT leads.

11Tighten the nut on the distributor clamp,

and recheck the timing.

12Switch off the engine, and remove the

timing light and tachometer. Reconnect the

vacuum hose where applicable.

8 Distributor-

removal and refitting

4

TCI system

Removal

1After carefully marking them for position,

remove the coil HT lead and spark plug HT

leads from the distributor cap (see Chapter 1).

2Remove No 1 spark plug (the one nearest

you when you are standing in front of the

engine).

3Manually rotate the engine to Top Dead

Centre (TDC) on the compression stroke for

No 1 piston (see Chapter 2A)

4Carefully mark the vacuum hoses, if more

than one is present on your distributor.

5Disconnect the vacuum hose(s).

6Disconnect the primary circuit wires from

the distributor.

7Mark the relationship of the rotor tip to the

distributor housing (see illustration). Also

mark the relationship of the distributor

housing to the engine.

5•4 Engine electrical systems

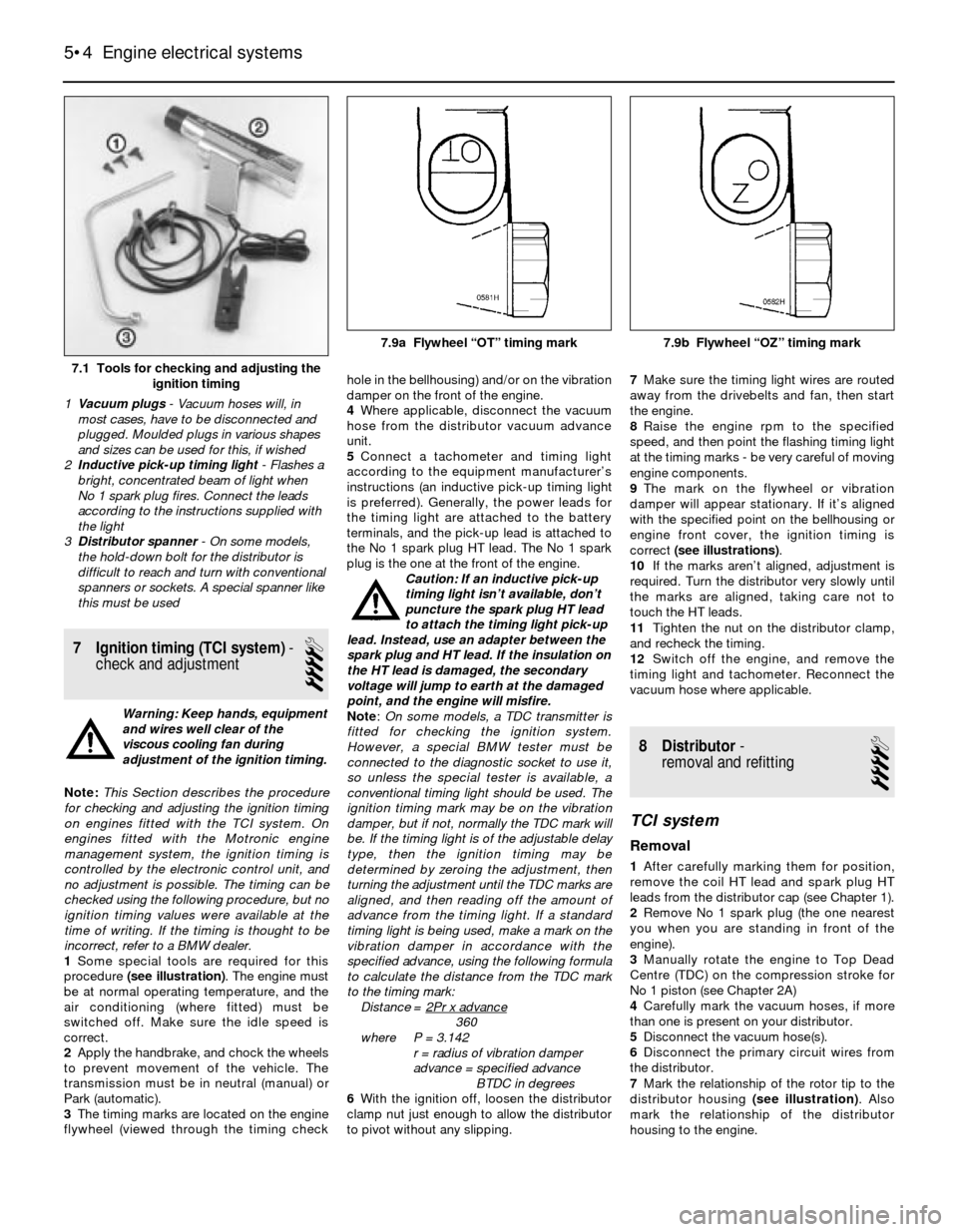

7.1 Tools for checking and adjusting the

ignition timing

1Vacuum plugs- Vacuum hoses will, in

most cases, have to be disconnected and

plugged. Moulded plugs in various shapes

and sizes can be used for this, if wished

2Inductive pick-up timing light- Flashes a

bright, concentrated beam of light when

No 1 spark plug fires. Connect the leads

according to the instructions supplied with

the light

3Distributor spanner - On some models,

the hold-down bolt for the distributor is

difficult to reach and turn with conventional

spanners or sockets. A special spanner like

this must be used

7.9a Flywheel “OT” timing mark 7.9b Flywheel “OZ” timing mark

Page 115 of 228

8Remove the hold-down nut or bolt and

clamp.

9Remove the distributor. Note:Do not rotate

the engine with the distributor out.

Refitting

10Before refitting the distributor, make

certain No 1 piston is still at TDC on the

compression stroke.

11Insert the distributor into the engine, with

the adjusting clamp centred over the hold-

down hole. Make allowance for the gear to

turn as the distributor is inserted.

12Refit the hold-down nut or bolt. The marks

previously made on the distributor housing,

and on the rotor and engine, should line up

before the nut or bolt is tightened.

13Refit the distributor cap.

14Connect the wiring for the distributor.

15Reconnect the spark plug HT leads.

16Reconnect the vacuum hoses as

previously marked.

17Check the ignition timing (see Section 7).

Motronic system

Removal

18Remove the cover from the distributor

(see illustration)and remove the distributor

cap (see Chapter 1).

19Using a small Allen key, remove the three

screws from the rotor (see illustration).

20Remove the rotor.

Refitting

21Refitting is the reverse of removal.

9 Ignition coil -

check and renewal

2

Caution: Do not earth the coil, as

the coil and/or impulse generator

could be damaged.

Note:On models equipped with the Motronic

system, a faulty ECU can cause the ignition

coil to become damaged. Be sure to test the

ignition coil if the engine will not start and an

ECU fault is suspected.

1Mark the wires and terminals for position,

then remove the primary circuit wires and the

HT lead from the coil.2Remove the coil assembly from its

mounting, then clean the outer casing and

check it for cracks and other damage.

3Inspect the coil primary terminals and the

coil tower terminal for corrosion. Clean them

with a wire brush if any corrosion is found.

4Check the coil primary resistance by

attaching an ohmmeter to the primary

terminals (see illustrations). Compare the

measured resistance to the Specifications

listed in this Chapter.

5Check the coil secondary resistance by

connecting one of the ohmmeter leads to one

of the primary terminals, and the other

ohmmeter lead to the coil high-tension

terminal (see illustrations). On TCI systems,

Engine electrical systems 5•5

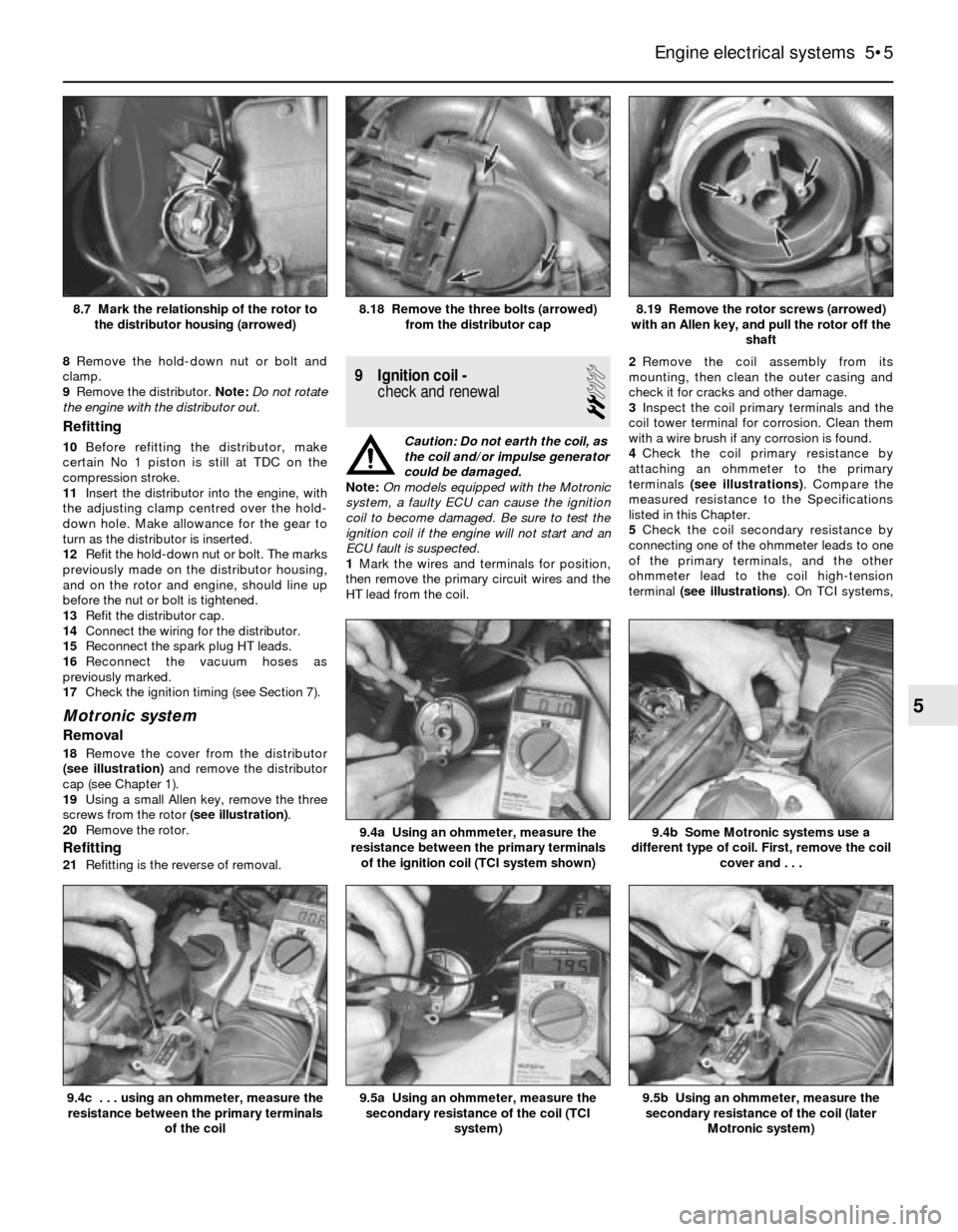

8.19 Remove the rotor screws (arrowed)

with an Allen key, and pull the rotor off the

shaft8.18 Remove the three bolts (arrowed)

from the distributor cap8.7 Mark the relationship of the rotor to

the distributor housing (arrowed)

9.5b Using an ohmmeter, measure the

secondary resistance of the coil (later

Motronic system)9.5a Using an ohmmeter, measure the

secondary resistance of the coil (TCI

system)

9.4b Some Motronic systems use a

different type of coil. First, remove the coil

cover and . . .9.4a Using an ohmmeter, measure the

resistance between the primary terminals

of the ignition coil (TCI system shown)

9.4c . . . using an ohmmeter, measure the

resistance between the primary terminals

of the coil

5