tow BMW 525i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 525i, Model: BMW 525i 1999 E39Pages: 1002

Page 11 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-1

010 General

General ........................... .01 0.2

How to Use this Manual ............ .01 0.2

Warnings. cautions and notes ........... .0l 0.3

Getting Started .................... .0i 0.5

Safety ............................. .O1 0.5

Lifting the car ........................ .O1 0.5

Raising car ......................... .O1 0.5

Working under car .................... .O1 0.6

Advice for the Beginner ............ .O1 0.7

Planning ahead ...................... .O1 0.7

Workshop practices ................... .O1 0.7

Non-reusable fasteners ................ .O1 0.7

Tightening fasteners .................. .O1 0.8

Gaskets and seals .................... .O1 0.9

Electrical testing .................... .O1 0.10

Wire repairs ........................ .O1 0.10

Buying Parts ..................... .01 0.11

Genuine BMW parts ................. .O1 0.11

Non-returnable parts ................. .O1 0.11

Information you need to know .......... .0l 0.12

Service ........................... 01 0-1 3

TOOIS ............................. 010-13

Basic tool requirements ............... 01 0-1 4

Jack stands ......................... 01 0-1 6

Oil change equipment ................. 01 0-1 6

Torque wrench ...................... 01 0-17

Digital multimeter .................... 010-17

BMW special tools ................... 01 0-1 8

Emergencies ...................... 01 0-1 8

Changing a tire ...................... 01 0-1 8

Jump starting ....................... 01 0-1 9

Indicator and warning lights ............ 01 0-1 9

Towing ............................ 010-20

Spare parts kit ...................... 010-21

Page 22 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-1 2

1 General

Information you need to know

Model

When ordering parts it is important that you know the correct

model designation for your car. Models covered in this E39

manual are the

525i,5281,530i, 540i in Sedan and Station

Wagon body styles.

Model year

This is not necessarily the same as date of manufacture or

date of sale.

A 1999 model may have been manufactured in

late 1998, and perhaps not sold until early 2000. It is still a

1999 model. Model years covered by this manual are 1997 to

2002.

Date of manufacture

This information is necessary when ordering replacement

parts or determining if any of the warranty recalls are applica-

ble to your car. The label on the driver's door below the door

latch will specify the month and year that the car was built.

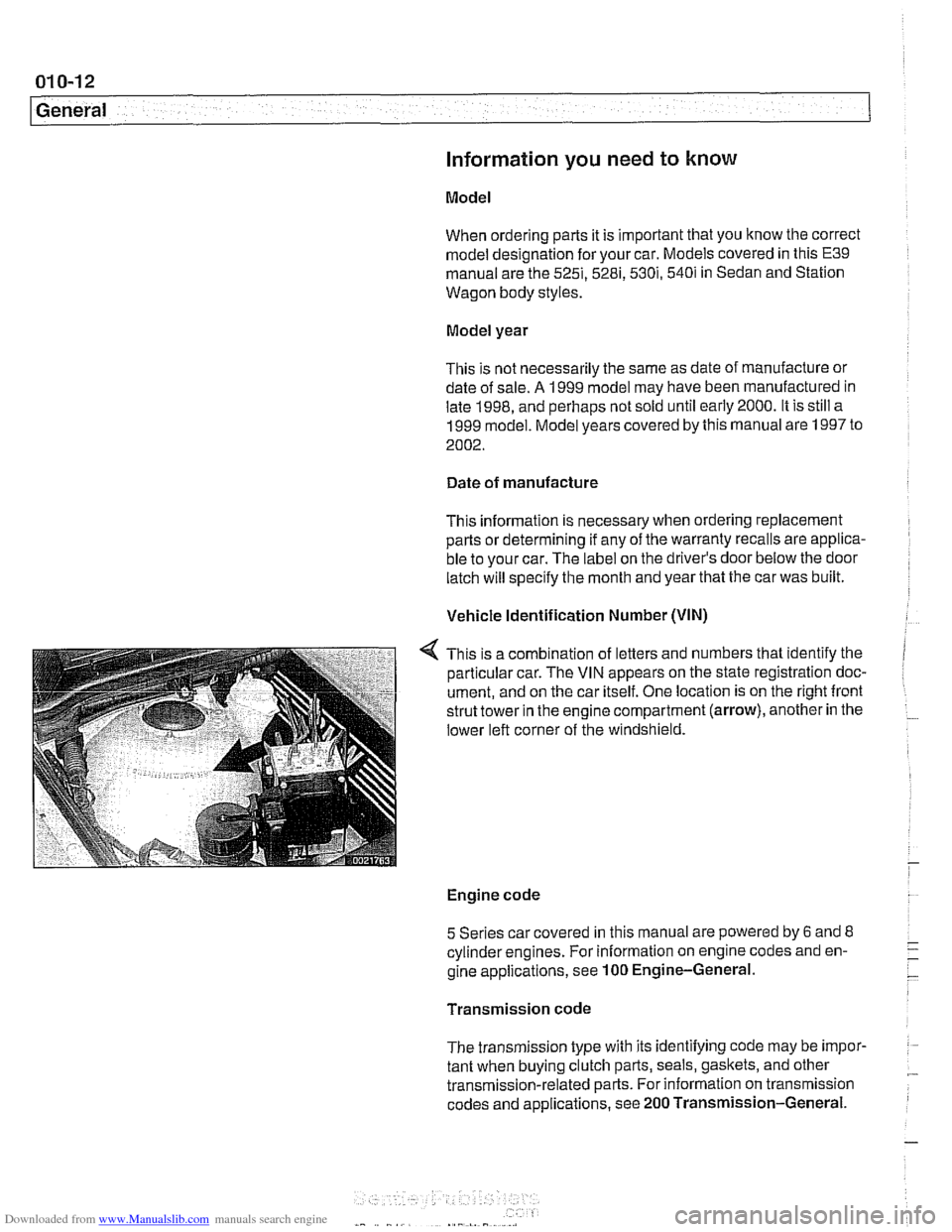

Vehicle

Identification Number (VIN)

This is a combination of letters and numbers that identify the

particular car. The VIN appears on the state registration doc-

ument, and on the car itself. One location is on the right front

strut tower in the engine compartment (arrow), another in the

lower left corner of the windshield.

Engine code

5 Series car covered in this manual are powered by

6 and 8 - cylinderengines. For information on engine codes and en- -. -

gine applications, see 100 Engine-General. -

Transmission code

The transmission type with its identifying code may be

impor- :

tant when buying clutch parts, seals, gaskets, and other .- transmission-related parts. For information on transmission

codes and applications, see 200 Transmission-General.

Page 30 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-20

General

more information on the Check Engine Light and the on-

board diagnostic system.

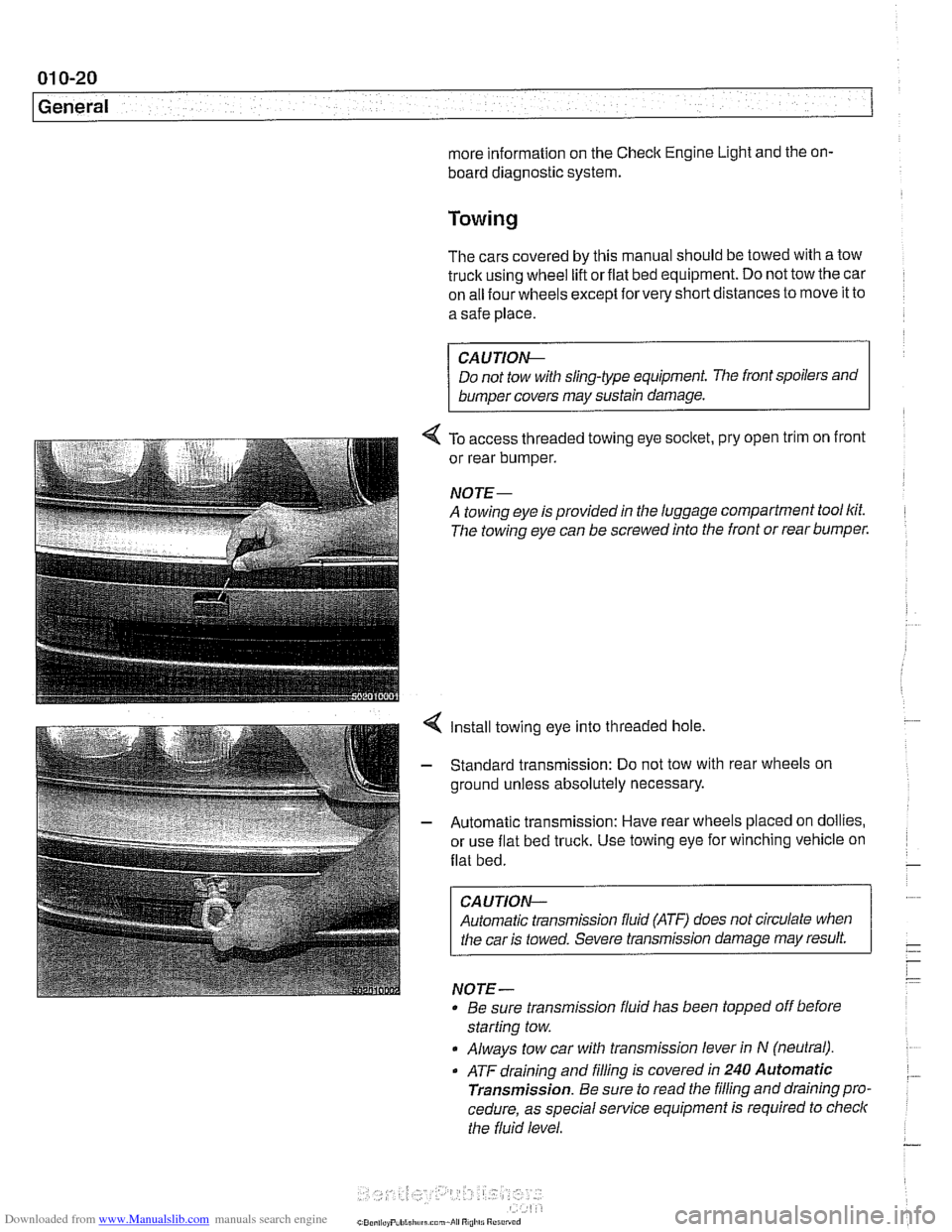

Towing

The cars covered by this manual should be towed with a tow

truck using wheel lift or flat bed equipment. Do not tow the car

on all four wheels except

forvery short distances to move it to

a safe place.

CA U JION-

Do not tow with sling-type equipment The front spoilers and

b~m~er covers may sustain damage.

4 To access threaded towing eye socltet, pry open trim on front

or rear bumper.

NOJE-

A towing eye is provided in the luggage compartment tool lcit.

The towing eye can be screwed into the front or rear bumper.

4 Install towing eye into threaded hole.

- Standard transmission: Do not tow with rear wheels on

ground unless absolutely necessary.

- Automatic transmission: Have rear wheels placed on dollies,

or use flat bed truck. Use towing eye for winching vehicle on

flat bed.

CAUTION-

Automatic transmission fluid (ATF) does not circulate when

I the car is towed. Severe transmission damage may result.

NOTE-

Be sure transrnission fluid has been topped off before

starting tow.

Always tow car with transrnission lever in

N (neutral).

. ATF draining and filling is covered in 240 Automatic

Transmission.

Be sure to read the filling and draining pro.

cedure, as special service equipment is required to

checlc

the fluid level.

Page 63 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

BODY AND INTERIOR MAINTENANCE

Body and hinges, lubricating

Door locksand loclccylinderscan be lubricated with an oil that

contains graphite.

Body and doorhinges, hood latch and doorcheclc rods should

be lubricated with

SAE 30 or SAE 40 engine oil. Lubricate

seat runners with multipurposegrease. Do not apply any oil to

rubber parts.

If door weather-strips are sticking, lubricate

them with silicone spray or talcum powder. The hood release

cable should be lubricated as well.

The use of winter

lock deicer sprays should be lkept to an

absolute minimum, as the alcohol in the deicer will wash the

grease out of the lock assemblies and may cause locks to

corrode internally or to become difficult to operate.

Exterior washing

The longer dirt is left on the paint, the greater the risk of dam-

aging theglossy finish,

eitherby scratching or by thechemical

effect dirt particles may have on the painted surface.

Do not wash the car in direct sunlight. If the engine hood is

warm, allow it to cool. Beads of water not only leave spots

when dried rapidly by the sun or heat from theengine, but also

can act as small magnifying glasses and burn spots into the

finish. Wash the car with a mixture of lukewarm water and a

car wash product. Rinse using plenty of clear water. Wipe the

body dry with a sofl cloth towel or chamois to prevent

water-spotting.

Interior care

Dirt spots can usually be removed with lultewarm soapy water

or a dry foam cleaner. Use spot remover for grease and oil

spots. Do not pour the liquid directly on the carpet or fabric,

but dampen a clean cloth and rub carefully, starting at the

edge of the spot and working inward. Do not use gasoline,

naphtha, or other flammable substances.

Leather upholstery and trim

Leather upholstery and trim should be periodically cleaned

using a slightly damp cotton or wool cloth. The idea is to get

rid of the dirt in the creases and pores that can cause brittle-

ness and premature aging. On heavily soiled areas, use a

mild detergent (such as

wooliteQ) or other specially formulat-

ed leather cleaners. Dry the trim and upholstery completely

Page 85 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and Installation

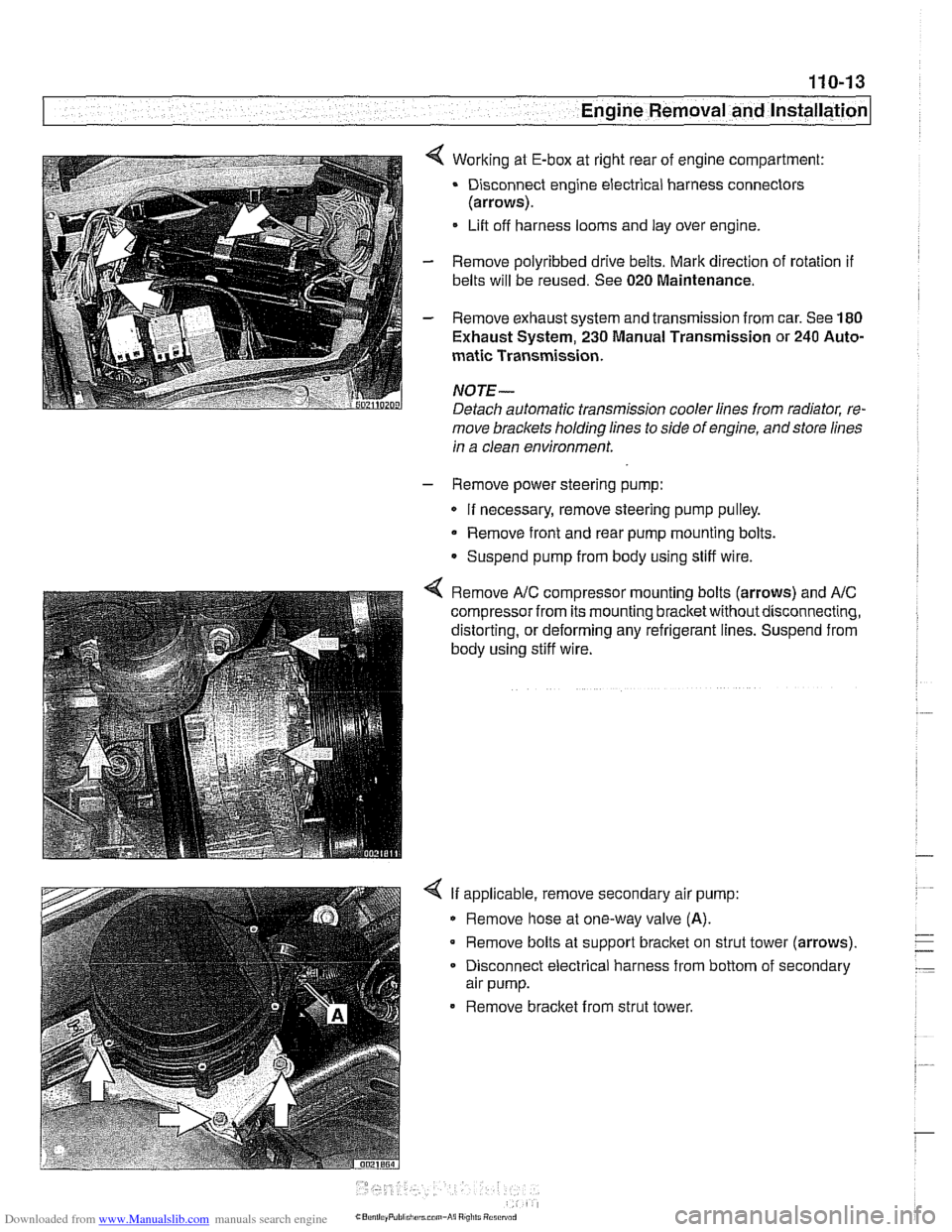

4 Working at E-box at right rear of engine compartment:

Disconnect engine electrical harness connectors

(arrows).

Lift off harness looms and lay over engine.

- Remove polyribbed drive belts. Mark direction of rotation if

belts will be reused. See 020 Maintenance.

- Remove exhaust system and transmission from car. See 180

Exhaust System, 230 Manual Transmission or 240 Auto-

matic Transmission.

NOJE-

Detach automatic transmission cooler lines from radiator, re-

move brackets holding lines to side of engine, andstore lines

in a clean environment.

- Remove power steering pump:

If necessary, remove steering pump pulley.

Remove front and rear pump mounting bolts.

Suspend pump from body using stiff wire.

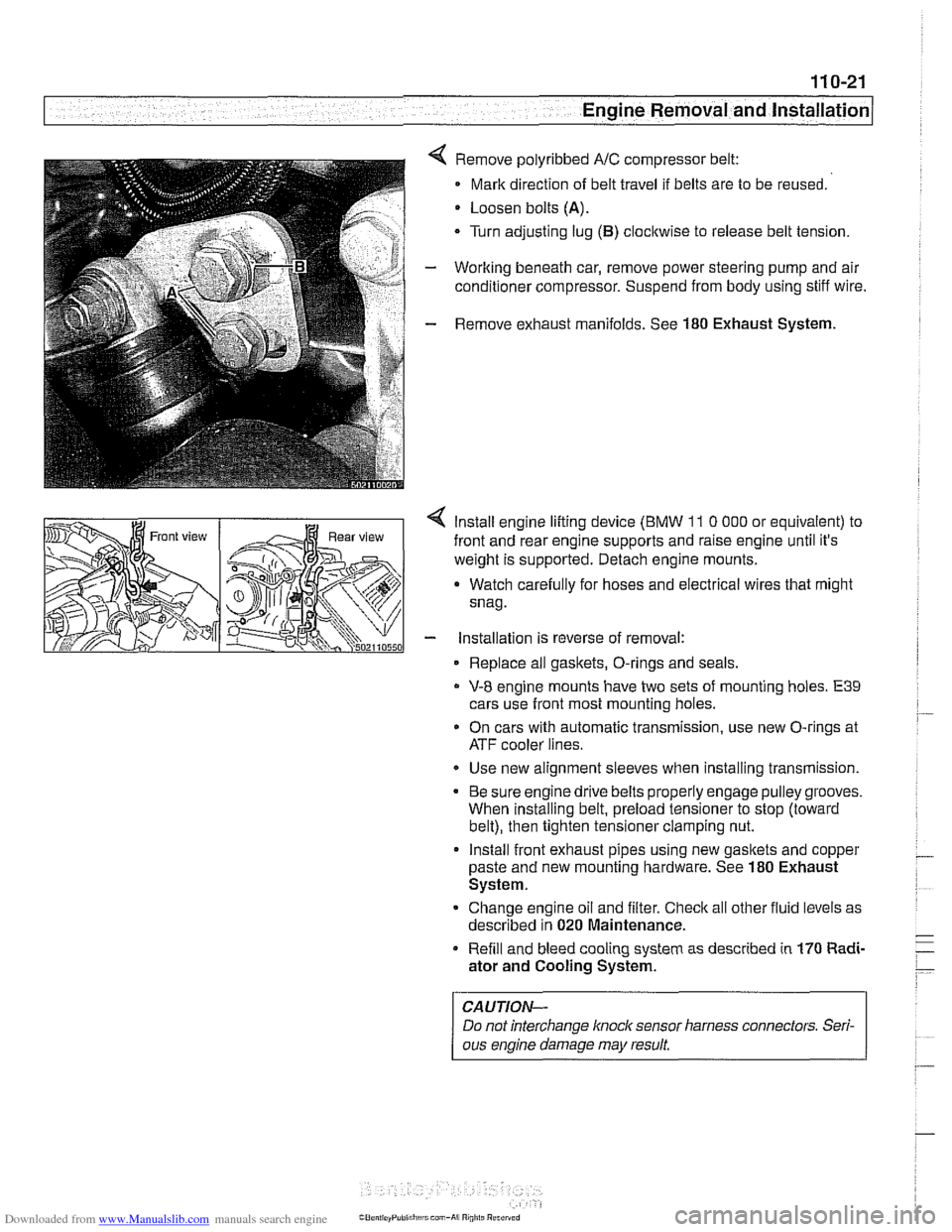

4 Remove A/C compressor mounting bolts (arrows) and AIC

compressor from its mounting bracketwithoutdisconnecting,

distorting, or deforming any refrigerant lines. Suspend from

body using stiff wire.

4 If applicable, remove secondary air pump:

Remove hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

- Disconnect electrical harness from bottom of secondary

air pump.

Remove bracket from strut tower.

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 118 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

Cylinder Head Removal and Installation

- Working at side of intake manifold near left strut tower, dis-

connect intake manifold resonance valve electrical harness

connector.

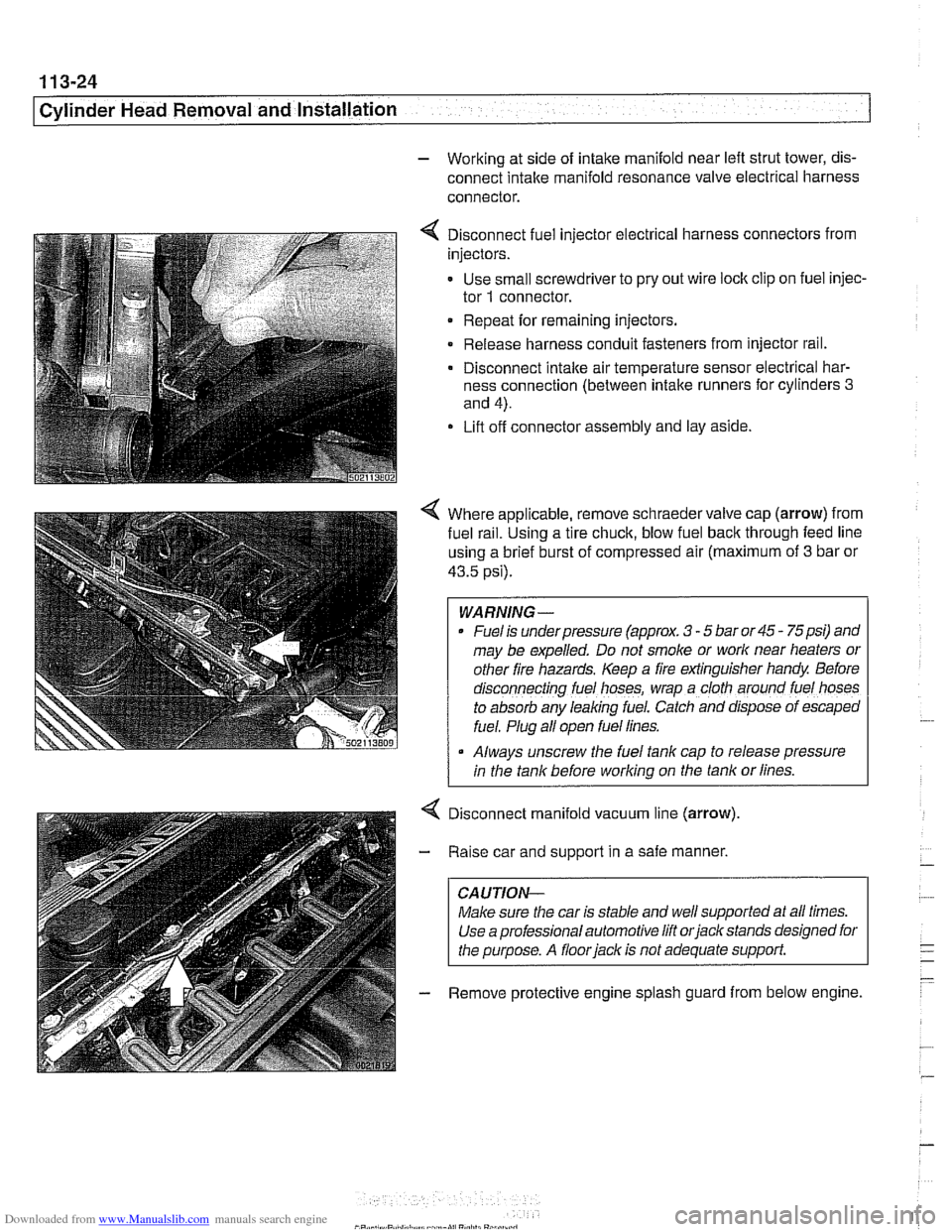

4 Disconnect fuel injector electrical harness connectors from

injectors.

- Use small screwdriver to pry out wire lock clip on fuel injec-

tor

1 connector.

Repeat for remaining injectors.

Release harness conduit fasteners from injector rail.

- Disconnect intake air temperature sensor electrical har-

ness connection (between intake runners for cylinders

3

and 4).

Lift off connector assembly and lay aside.

4 Where applicable, remove schraeder valve cap (arrow) from

fuel

ra~l. Using a tire chuck, blow fuel back through feed line

using a brief burst of compressed air (maximum of

3 bar or

43.5 psi).

WARNING-

Fuel is underpressure (approx. 3 - 5 bar or 45 - 75psi) and

may be expelled. Do not smoke or

work near heaters or

other fire hazards. Keep a fire extinguisher handy Before

d~sconnecting fuel hoses, wrap a cloth around fuel hoses

to absorb any leaking fuel. Catch and

dfspose of escaped

fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

I in the tank before working on the tank or lines.

Disconnect manifold vacuum line (arrow)

Raise car and support in a safe manner,

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A

floorjack is not adequate support.

Remove protective engine splash guard from below engine.

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

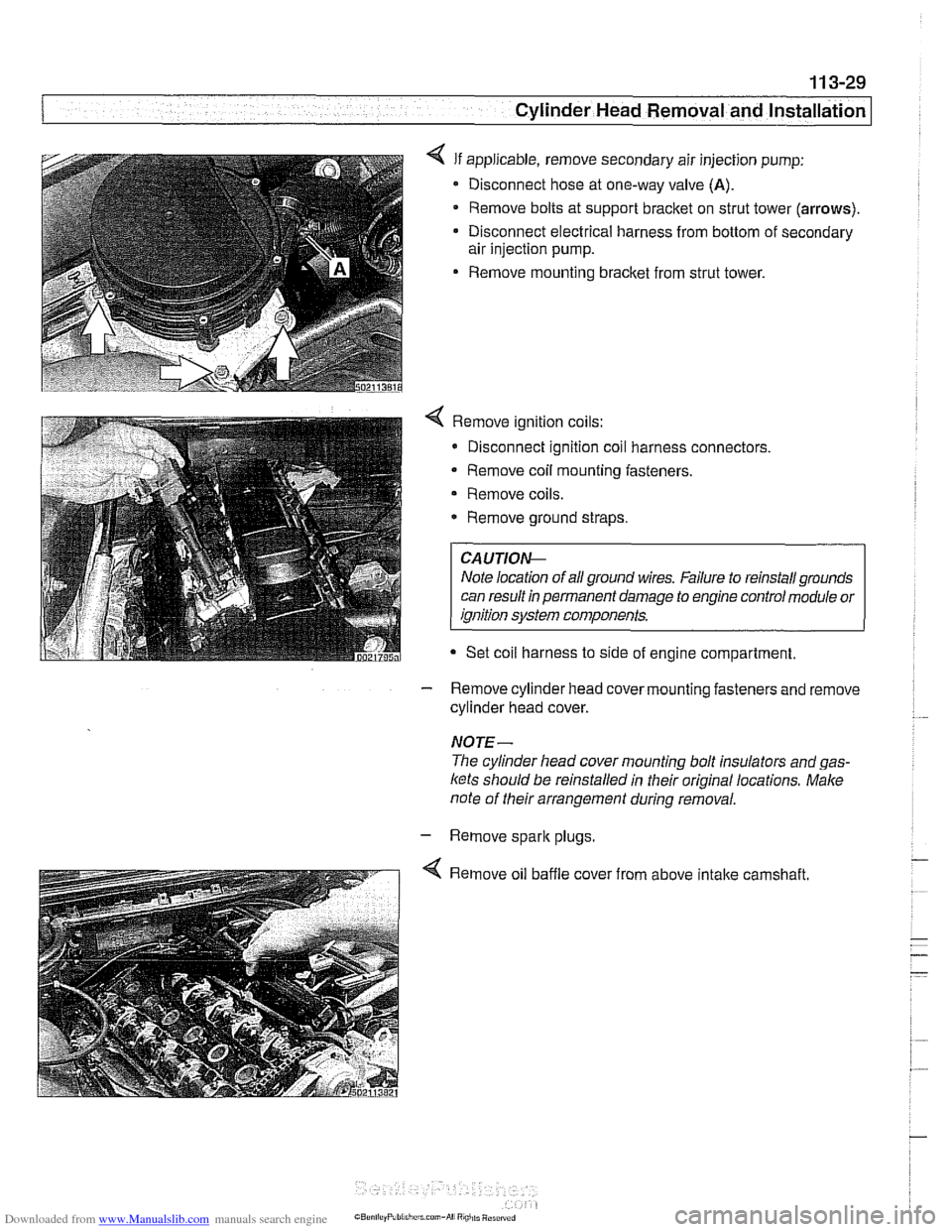

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.

Page 124 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and installation - - .- - - - -

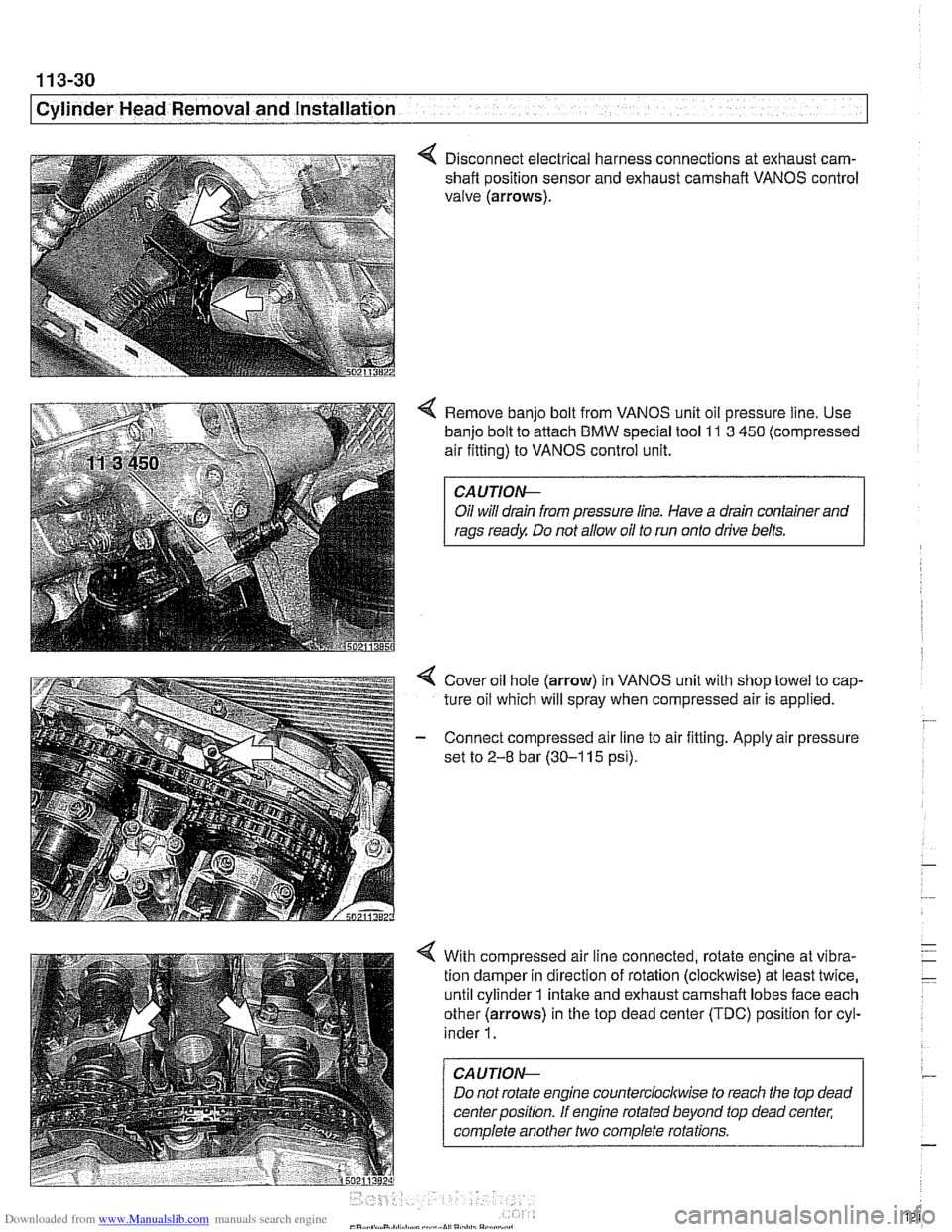

4 Disconnect electrical harness connections at exhaust cam-

shaft position sensor and exhaust camshaft VANOS control

valve (arrows).

4 Remove banjo bolt from VANOS unit oil pressure line. Use

banjo bolt to attach

BMW special tool 11 3 450 (compressed

air fitting) to VANOS control unit.

CAUTIOI\C

Oil will drain from pressure line. Have a drain container and

rags ready Do not allow oil to run onto drive belts.

4 Cover oil hole (arrow) in VANOS unit with shop towel to cap-

ture oil which will spray when compressed air is applied.

- Connect compressed air line to air fitting. Apply air pressure

set to

2-8 bar (30-1 15 psi).

4 With compressed air line connected, rotate engine at vibra-

tion damper in direction of rotation (clockwise) at least twice,

until cylinder 1 intake and exhaust camshaft lobes face each

other (arrows) in the top dead center (TDC) position for cyl-

inder

1.

CAUTION--

Do not rotate engine counterclocltwise to reach the top dead

center position. If engine rotated beyond top dead center;

complete another two complete rotations.

Page 127 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

-- .- Cylinder ~ead~ernoval and Installation I - -.

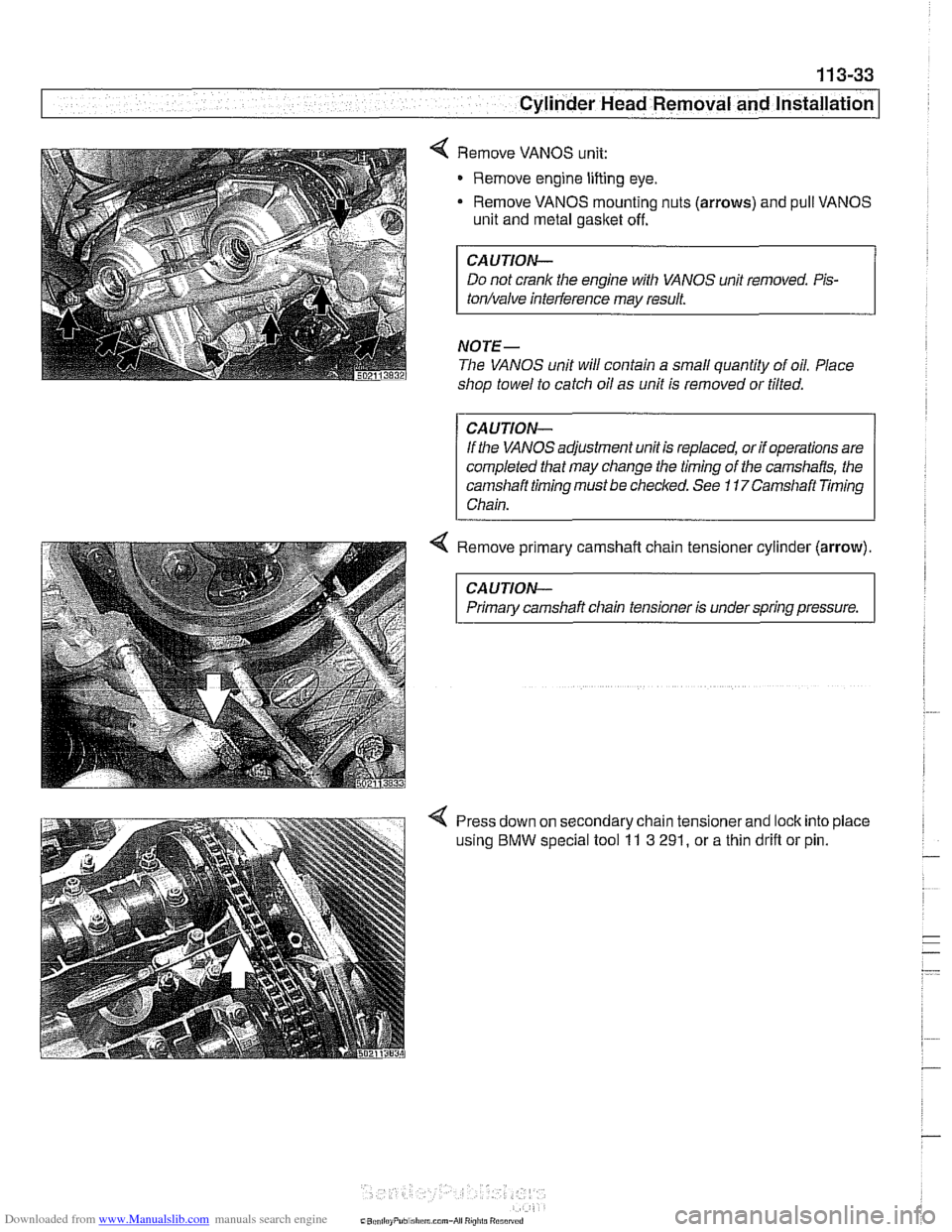

Remove VANOS unit:

Remove engine lifting eye.

- Remove VANOS mounting nuts (arrows) and pull VANOS

unit and metal gasket off.

CAUTION-

Do not crank the engine with VANOS unit removed. Pis-

tonhalve inteiference may result.

NOTE-

The VANOS unit will contain a small quantity of oil. Place

shop towel to catch oil as unit is removed or tilted.

CAUTION-

If the VANOS adjustment unit is replaced, or if operations are

completed that may change the timing of

the camshafts, the

camshaft timing must be checked. See

11 7Camshaft Timing

Chain.

4 Remove primary camshaft chain tensioner cylinder (arrow).

CAUTION-

Primary camshaft chain tensioner is under spring pressure.

Press down on secondary chain tensionerand lock into place

using

BMW special tool 11 3 291, or a thin drifl or pin.