brake sensor BMW 525i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 525i, Model: BMW 525i 2000 E39Pages: 1002

Page 33 of 1002

Downloaded from www.Manualslib.com manuals search engine

020 Maintenance

General ........................... .02 0.2

Special tools ........................ .02 0.2

Service Interval Indicator (Sll) ........... .02 0.3

Service Interval Indicator (Sll), resetting ... .02 0.3

Inspection I, Inspection 11 ............... .02 0.5

Maintenance Tables ................ .02 0.6

Fluid and Lubricant Specifications .. .02 0.9

Fluids and lubricants ................. .02 0.10

Engine Oil Service ................ .02 0.1 I

Engine oil. checking level ............. .02 0.12

Engine oil and filter. changing .......... .02 0-13

Engine Compartment Maintenance . .02 0.14

Accelerator and linkage ............... .02 0.14

Air filter. replacing ................... .02 0.1 4

Cooling system service ............... .02 0.15

Engine drive belt service .............. .02 0.16

Idlespeed .......................... 020-19

Catalytic converter and oxygen sensors .. .02 0.19

Power steering fluid, checking level ..... .02 0.20

Spark plugs ........................ .02 0.20

Spark plugs, replacing ................ .02 0.21

Interior ventilation microfilter, replacing ... .02 0.22

Other Mechanical Maintenance ..... .02 0.22

Battery, checking. cleaning. and replacing .02 0-22

Brake fluid. replacing ................. .02 0-24

Brake pad 1 rotor wear. checking ........ .02 0.24

Brake system, inspecting ............. .02 0.25

Parking brake. checking ............... 020-25

Clutch fluid. checking ................. 020-26

Differential oil level. checking ........... 020-26

Drive axle joint (CV joint) boots. inspecting 020-27

Exhaust system. inspecting ............ 020-27

Fuel filter. replacing .................. 020-27

Fuel tank and fuel lines. inspecting ...... 020-28

Suspension. front. inspecting ........... 020-29

Suspension. rear. inspecting ........... 020-29

Tires. checking inflation pressure ........ 020-29

Tires. rotating ....................... 020-29

Transmission service. automatic ........ 020-29

Transmission service. manual .......... 020-30

Transmission fluid. checking and filling

(manual transmission)

................ 020-30

Wheels. aligning ..................... 020-30

Body and Interior Maintenance ..... 020-31

Body and hinges. lubricating ........... 020-31

Exterior washing ..................... 020-31

Interior care ........................ 020-31

Leather upholstery and trim ............ 020-31

Polishing ........................... 020-32

Seat belts .......................... 020-32

Special cleaning ..................... 020-32

Washing chassis ..................... 020-32

Waxing ............................ 020-32

Windshield wiper blade maintenance ..... 020-33

Page 41 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

Maintenance

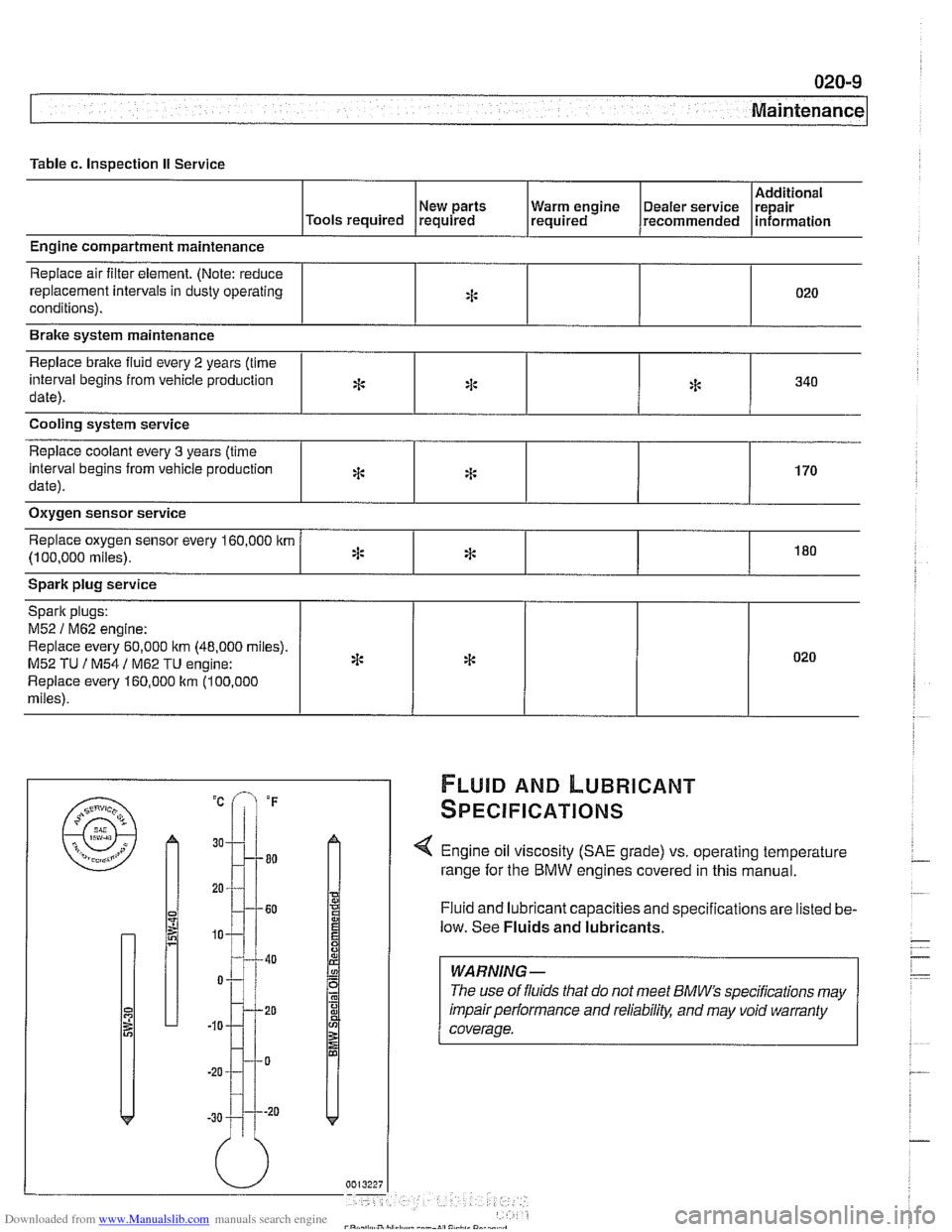

Table c. Inspection II Service

Additional

New parts Warm engine Dealer service repair

Tools required required required recommended information

Engine compartment maintenance

Replace air filter element. (Note: reduce

replacement intervals in dusty operating

conditions).

Replace brake

fluid every 2 years (time

interval begins from vehicle production

date).

Cooling system service

Spark plug service

Brake

system maintenance

:j:

*

Replace coolant every 3 years (time

interval begins from vehicle production

date).

Replace oxygen sensor every 160,000

itm

(1 00,000 miles).

020

FLUID AND LUBRICANT

SPECIFICATIONS

:I:

Oxygen sensor service

*

x:

Spark plugs:

M52

1 M62 engine:

Replace every 60,000 itm (48.000 miles).

M52

TU I M54 1 M62 TU engine:

Replace every 160,000

ltm (100.000

miles).

< Engine oil viscosity (SAE grade) vs. operating temperature

range for the BMW engines covered in this manual.

Fluid and lubricant capacities and specifications are listed be-

low. See

Fluids and lubricants.

:I:

*

*

*

WARNING -

The use of fluids that do not meet BMW" specifications may

impair performance and

reliabilitl: and may void warranty

coverage.

340

170

180

* 020

Page 90 of 1002

Downloaded from www.Manualslib.com manuals search engine

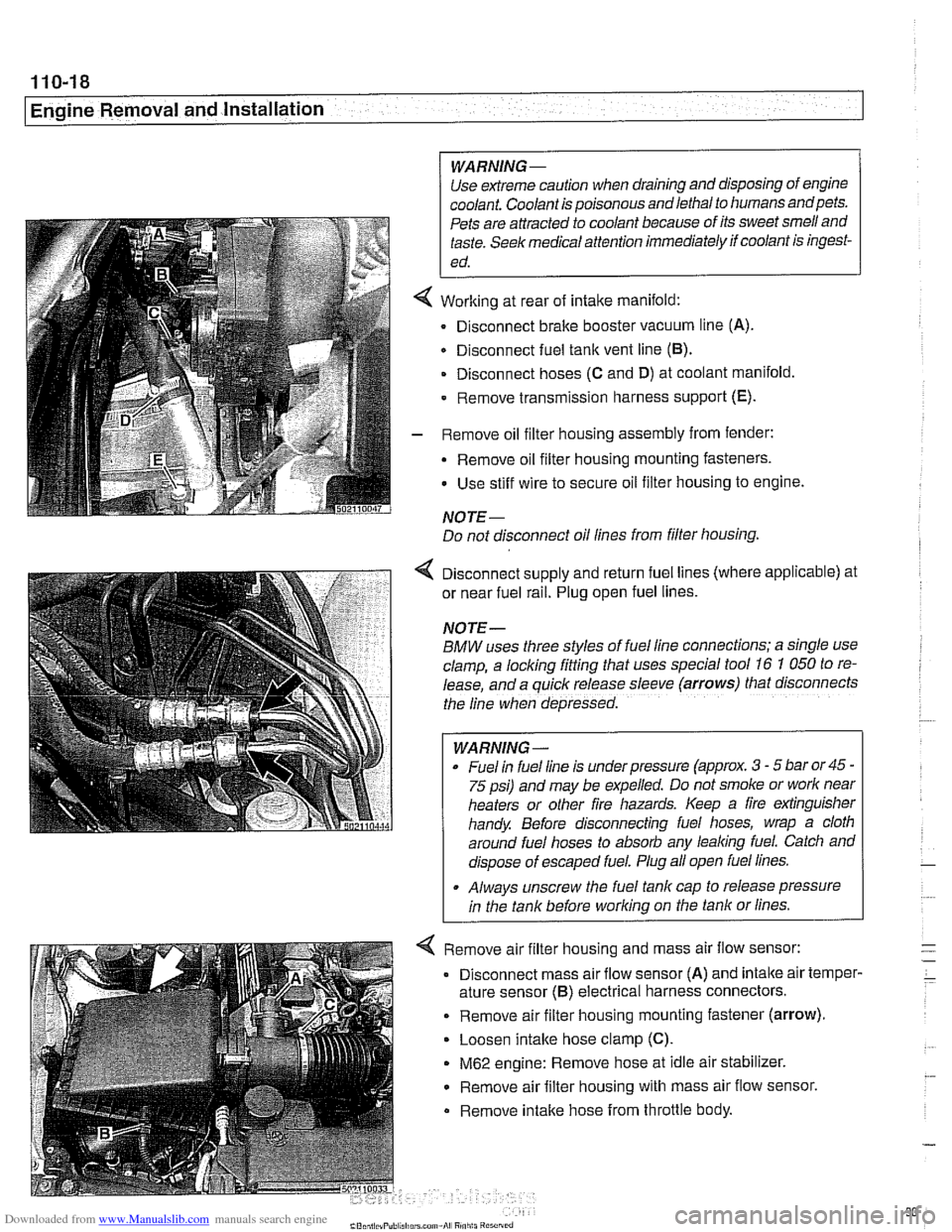

I Engine Removal and Installation

WARNING -

Use extreme caution when draining and disposing of engine

coolant. Coolant is poisonous andlethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste. Seek medical attention immediately if coolant is ingest-

---

Working at rear of intake manifold:

Disconnect brake booster vacuum line (A).

Disconnect fuel tank vent line

(6).

Disconnect hoses (C and D) at coolant manifold

- Remove transmission harness support (E).

- Remove oil filter housing assembly from fender:

- Remove oil filter housing mounting fasteners.

Use stiff wire to secure oil filter housing to engine.

NOTE-

Do not disconnect oil lines from filter housing.

4 Disconnect supply and return fuel lines (where applicable) at

or near fuel rail. Plug open fuel lines.

NOTE-

BMW uses three styles of fuel line connections; a slngle use

clamp, a locking fitting that uses special tool

16 7 050 to re-

lease, and a

quiclc release sleeve (arrows) that disconnects

the line when depressed.

WARNING-

Fuel In fuel line is under pressure (approx. 3 - 5 bar or45 -

75 psi) and may be expelled. Do not smoke or worlc near

heaters or other fire hazards. Keep a fire extinguisher

handy. Before disconnecting fuel hoses, wrap a cloth

around fuel hoses to absorb any lealcing fuel. Catch and

dispose of escaped fuel. Plug all open fuel lines.

. Always unscrew the fuel tank cap to release pressure

in the tank before worlcing on the tank or lines.

< Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor (A) and

intalte air temper-

ature sensor

(6) electrical harness connectors.

. Remove air filter housing mounting fastener (arrow).

Loosen intake hose clamp (C).

M62 engine: Remove hose at idle air stabilizer.

Remove air filter housing with mass air flow sensor.

Remove intalte hose from throttle body.

Page 454 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

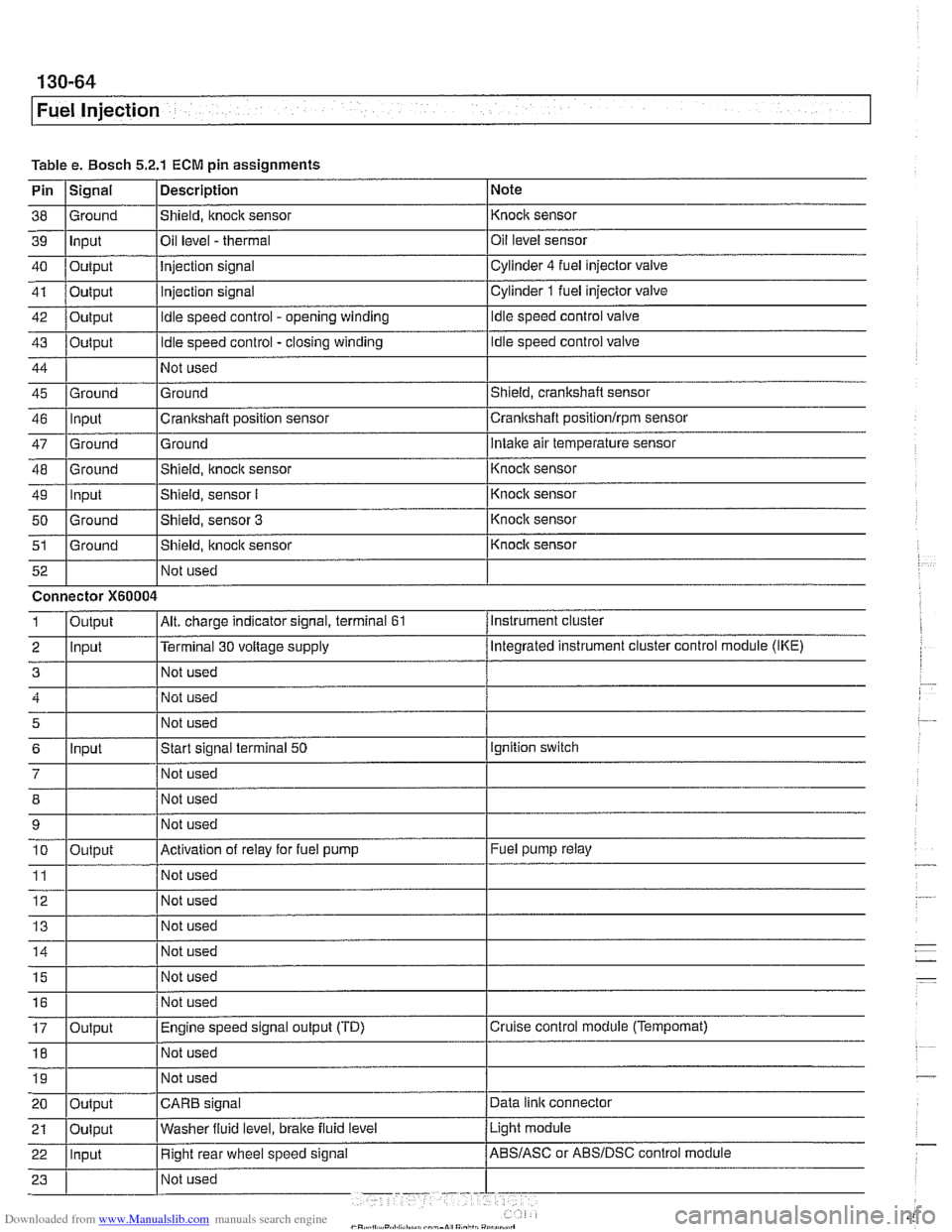

Fuel Injection

Table e. Bosch 5.2.1 ECM pin assignments

Pin

I~iqnal 1 Description 1 Note

I I I

46 llnput ICrankshaft position sensor Icrankshaft positionlrpm sensor

38

39

40

41

42

43

44

45 Ground Input

Output

Output

Output

Output

Ground

47

48

49

50

51

Not used

I Not used

52

Shield, knock sensor

Oil level

- thermal

Injection signal

injection signal

Idle speed control - opening winding

Idle speed control - closing winding

Not used

Ground

Ground

-- Ground Input

Ground

Ground Not used Knock sensor

Oil level sensor

Cylinder

4 fuel injector

valve

Cylinder

1 fuel injector valve

Idle speed control valve

Idle speed control valve

Shield, crankshaft sensor

5

6

7

12 Not used

Ground

Intake air temperature sensor

Connector

X60004

8

9 10

11

14 1 1 Not used I

Shield, knock sensor

Shield, sensor

I

Shield, sensor 3

Shield, itnock sensor

Input

- Knoclc sensor

Knock sensor

Knock sensor

Knock sensor

Instrument cluster

Output

2 llnput l~erminal 30 voltage supply /Megrated instrument cluster control module (IKE)

Alt. charge indicator signal, terminal 61 1

Not used

Start signal terminal

50

Not used

15

16

17

18

Output

Ignition switch

Not used

Not used

Activation of relay for fuel pump

Not used

19

Fuel pump relay

Output Not used

I I I 20 loutput ICARB signal /Data link connector

Not

used

Not used

Engine speed signal output (TD)

Not used

Light module

21

Cruise control module (Tempomat)

22 llnput I Right rear wheel speed signal /ABS/ASC or ABSIDSC control module

Oulput

Washer

fluid level,

brake fluid level

Page 469 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

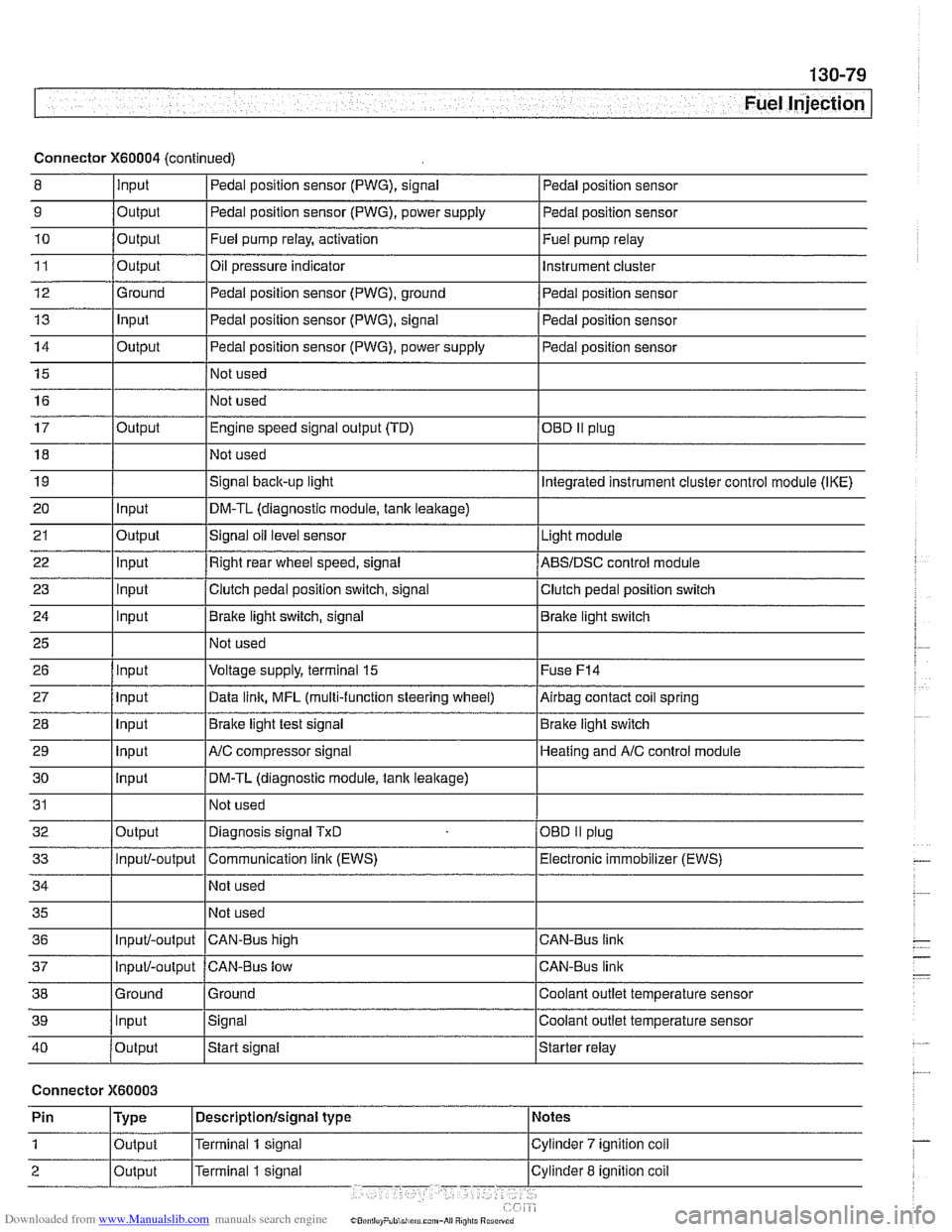

Connector X60004 (continued)

8 10

11

12

13

14

15

16

9

Output 0

Input

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

39

llnput lsignal l~oolant outlet temperature sensor

Output

Output

Ground

Input

Output

I I - I

40 /output Istart signal Istarter relay

Pedal position sensor (PWG), signal

Output Input

Output

input

Input

Input

Input

Input

Input

input

Input

Output

Input/-output

Input/-output

37

Connector X60003

Pedal position sensor

Fuel pump relay, activation

Oil pressure indicator Pedal position sensor (PWG), ground

Pedal position sensor (PWG), signal

Pedal position sensor (PWG), power supply

Not used

Not used Fuel

pump relay

Instrument cluster

Pedal position sensor

Pedal position sensor

Pedal position sensor

Engine speed signal output (TD)

Not used

Signal

back-up light

DM-TL (diagnostic module,

tank leakage)

Signal oil level sensor

Right rear wheel speed, signal

Clutch pedal position switch, signal

Brake light switch, signal

Not used

Voltage supply, terminal

15

Data link, MFL (multi-function steering wheel)

Brake light test signal

AJC compressor signal

DM-TL (diagnostic module, tank

leakage)

Not used

Diagnosis signal

TxD

Communication link (EWS)

Not used

Not used

CAN-BUS hiqh

38 1 Ground l~round I Coolant outlet temperature sensor

OED II plug

Integrated instrument cluster control module (IKE)

Light module

ABSIDSC control module

Clutch pedal position switch

Brake light switch

Fuse

F14

Airbag contact coil spring

Brake light switch

Heating and

A/C control module

OBD

II plug

Electronic immobilizer (EWS)

CAN-Bus link

CAN-Bus link

Input/-output CAN-Bus low

Page 630 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 0

/Suspension, Steering and Brakes - General

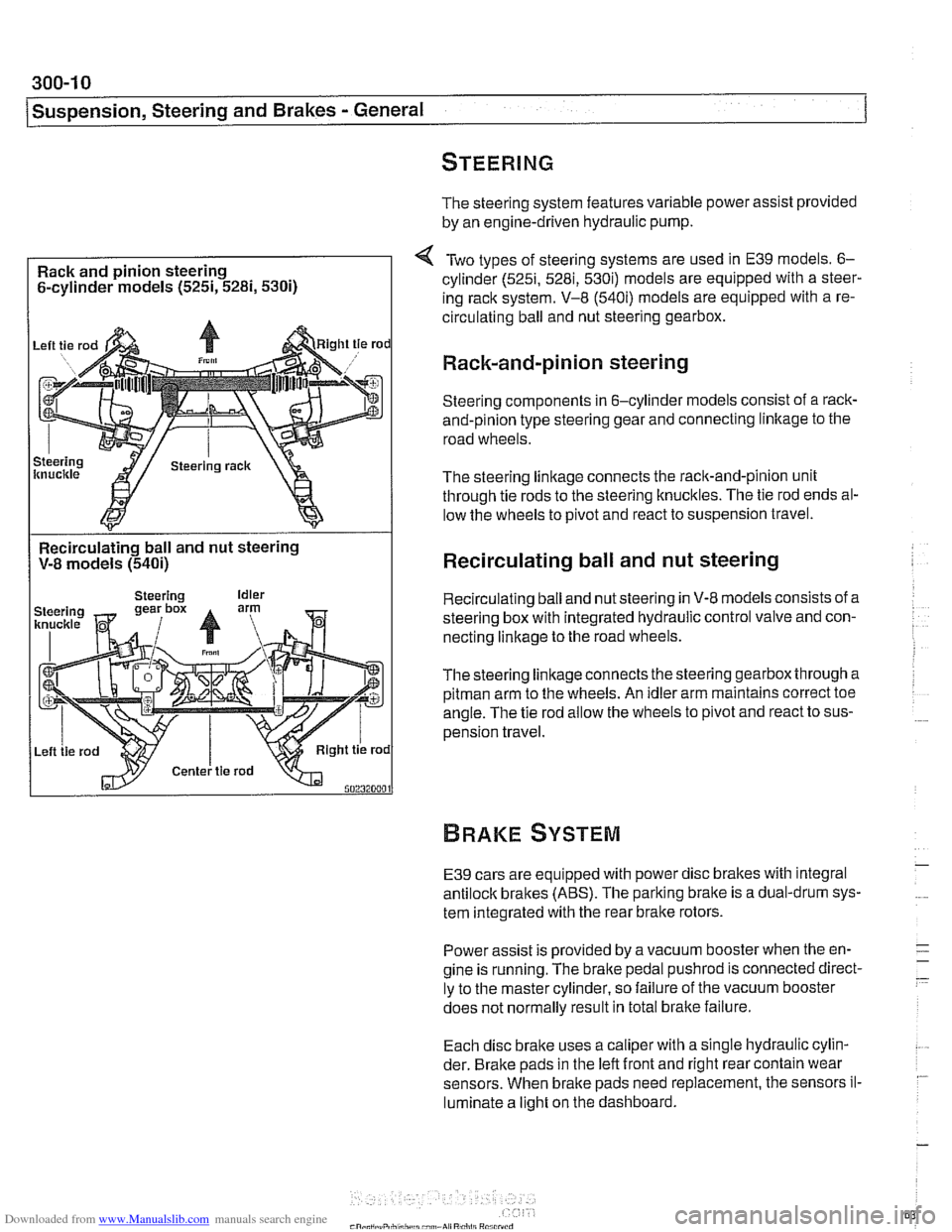

The steering system features variable power assist provided

by an engine-driven hydraulic pump.

Rack and pinion steering

6-cylinder models

(525i, 5281, 5300

Two types of steering systems are used in E39 models. 6-

cylinder (525i, 5281, 530i) models are equipped with a steer-

ing rack system. V-8

(540i) models are equipped with a re-

circulating ball and nut steering gearbox.

Rack-and-pinion steering

Steering components in 6-cylinder models consist of a rack-

and-pinion type steering gear and connecting linltage to the

road wheels.

The steering linkage connects the rack-and-pinion unit

through tie rods to the steering knucltles. The tie rod ends al-

low the wheels to pivot and react to suspension travel.

Recirculating ball and nut steering

V-8 models

(540i)

I

Recirculating ball and nut steering

Recirculating ball and nut steering in V-8 models consists of a

steering box with integrated hydraulic control valve and con-

necting linkage to the road wheels.

Thesteering linkageconnects the steering gearbox through a

pitman arm to the wheels. An idler arm maintains correct toe

angle. The tie rod allow the wheels to pivot and react to sus-

pension travel.

E39 cars are equipped with power disc brakes with integral

antilock brakes (ABS). The parking bralte is a dual-drum sys-

tem integrated with the rear brake rotors.

Power assist is provided by a vacuum booster when the en-

gine is running. The brake pedal

pushrod is connected direct-

ly to the master cylinder, so failure of the vacuum booster

does not normally result in total

bralte failure.

Each disc bralte uses a caliper with a single hydraulic cylin-

der. Brake pads in the left front and right rear contain wear

sensors. When brake pads need replacement, the sensors il-

luminate a light on the dashboard.

Page 632 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 2

I Sus~ension, Steerincl and Brakes - General

E39 electronic brake and stability control

systems application table

(528i, 54bi) Traction (ASC) I Hydraulic unit in right rear of engine compartment 1

Identifiers

Year (model)

I No precharge pump 1

Manuf. up to 911998 l~utomatic Stability Control plus I Electronic control module next to glove compartment

System

Precharge pump in

lefl front of engine compartment, below

steering fluid reservoir

Separate rotational rate (yaw) and lateral acceleration sensors

I I

Combined rotational rate (yaw) and lateral acceleration sensors

Electronic control

module next to glove compartment

Hydraulic unit in right rear of engine compartment

Manuf. up to 911999

(540i optional)

I I

ABS system

Dynamic Stability Control (Bosch

DSC

Ill v. 5.3)

The electronically controlled

ABS maintains vehicle stability

and control during emergency braking by preventing wheel

lock-up.

ABS provides optimum deceleration and stability dur-

ing adverse conditions. It automatically adjusts brake system

hydraulic pressure at each wheel to prevent wheel lock-up.

Control

moduleihydraulic unit

in right rear of engine compartment

No precharge pump

Manuf. from

911999

(all models)

Automatic Stability Control (ASC)

Dynamic Stability Control (Boscli

DSC Ill v. 5.7)

NOJE-

ASC (Automatic Stability Control) may also be referred to as

ASCiT (Automatic Stability ControkTraction).

ASC works in conjunction with ABS and the engine manage-

ment system to enhance vehicle control. The main function of

the

ASC system is to maintain the contact between the tires

and the road surface under all driving conditions. This is

achieved through exact application and management of brak-

ing and drivetrain forces.

The

ASC system improves traction by electronically applying

the rear brakes when the rear drive wheels are spinning at a

faster rate than the front wheels. The combined

ABSIASC

control module, operating through the ABS hydraulic control

unit, modulates braking force at the rear wheels.

In addition,

ASC overrides the throttle opening to reduce en-

gine torque and maintain vehicle traction. Because the throt-

tle is controlled electronically, the driver cannot increase

engine power output during

ASC intervention regardless of

how far the accelerator pedal is pushed.

Page 633 of 1002

Downloaded from www.Manualslib.com manuals search engine

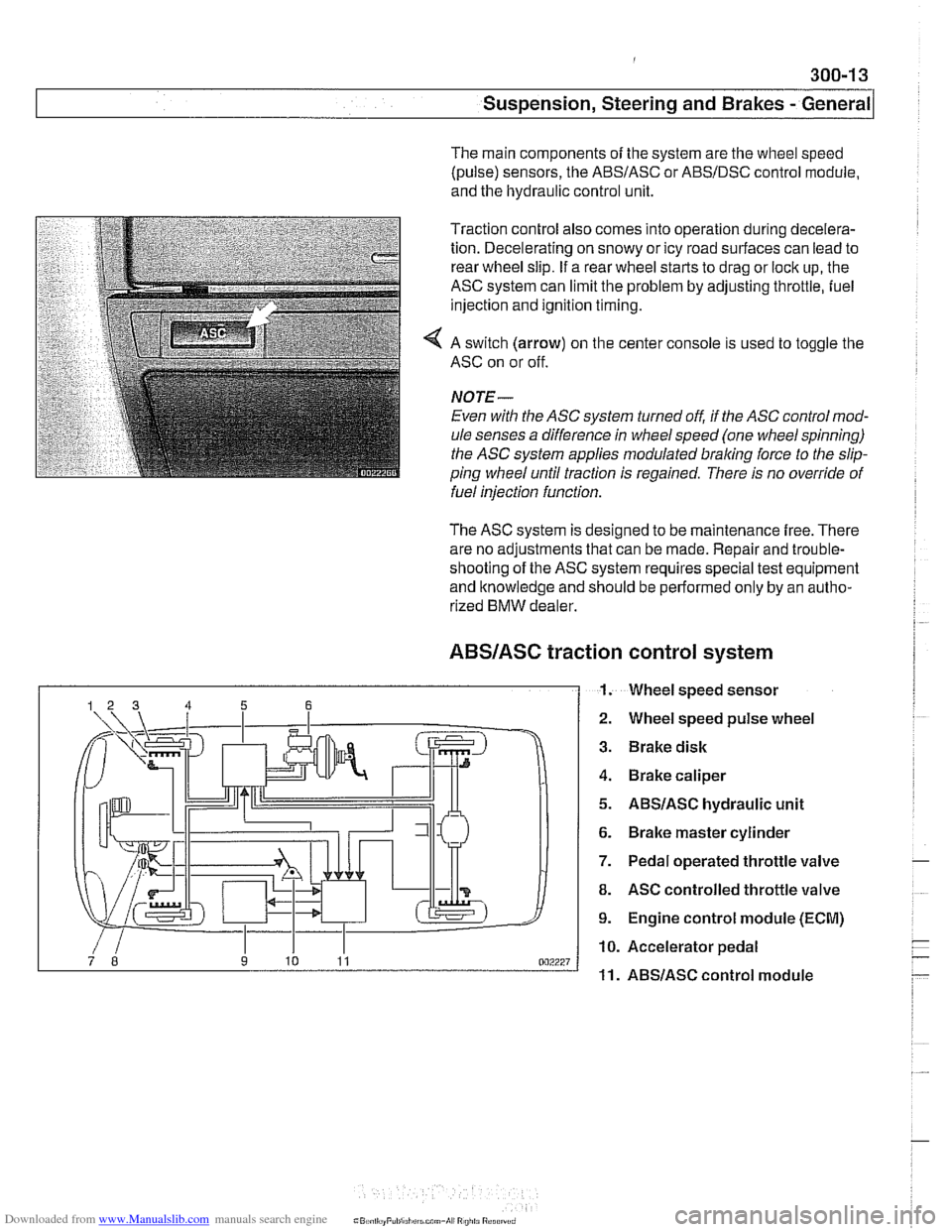

Suspension, Steering and Brakes - ~enerail

The main components of the system are the wheel speed

(pulse) sensors, the

ABSIASC or ABSIDSC control module,

and the hydraulic control unit.

Traction control also comes into operation during decelera-

tion. Decelerating on snowy or icy road surfaces can lead to

rear wheel slip. If a rear wheel starts to drag or lock up, the

ASC system can limit the problem by adjusting throttle, fuel

injection and ignition timing.

4 A switch (arrow) on the center console is used to toggle the

ASC on or off.

NOJE-

Even with the ASC system turned off, if the ASC control mod-

ule senses a difference in wheel speed (one wheel spinning)

the

ASC system applies modulated braling force to the slip-

ping wheel until traction is regained. There is no override of

fuelinjection function.

The ASC system is designed to be maintenance free. There

are no adjustments that can be made. Repair and trouble-

shooting of the ASC system requires special test equipment

and knowledge and should be performed only by an autho-

rized

BMW dealer.

ABSIASC traction

I 1.

control system

Wheel speed sensor

Wheel speed pulse wheel

Brake disk

Brake caliper

ABSIASC hydraulic unit

Brake master cylinder

Pedal operated throttle valve

ASC controlled throttle valve

Engine control module (ECM)

Accelerator pedal

ABSlASC control module

Page 641 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-5

Front ~uspensionl

Front strut assembly, removing and

installing

- Raise car and remove front wheel.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension

parts.

- Unbolt bralte caliper assembly, lkeeping bralte hose connect-

ed. Secure brake caliper to body with wire. Do not let it hang

from brake hose. See

340 Brakes.

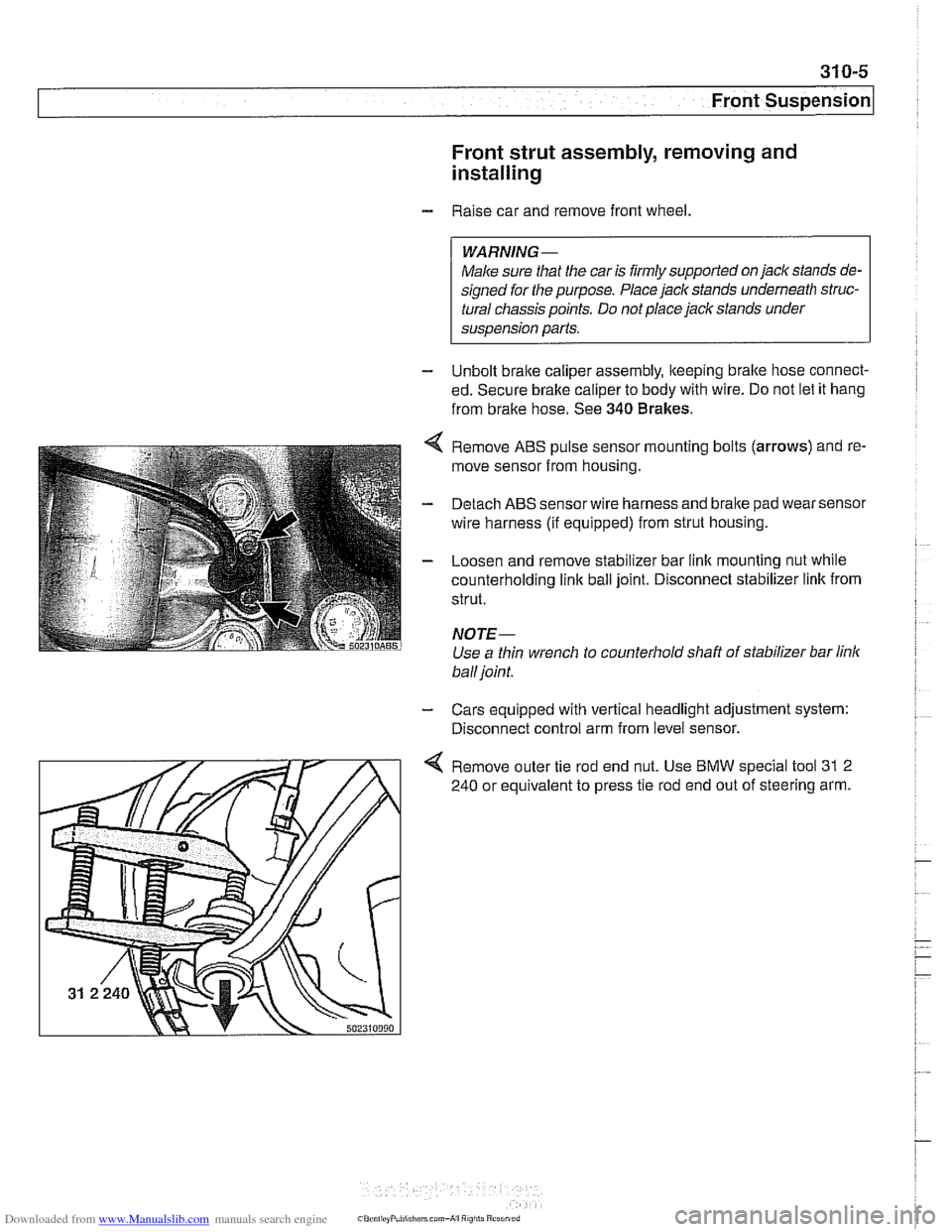

Remove ABS pulse sensor mounting bolts (arrows) and re-

move sensor from housing.

Detach ABS sensor wire harness and bralte pad wear sensor

wire harness (if equipped) from strut housing.

Loosen and remove stabilizer bar link mounting nut while

counterholding

link ball joint. Disconnect stabilizer link from

strut.

NOTE-

Use a thin wrench to counterhold shaft of stabilizer bar link

ball joint.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

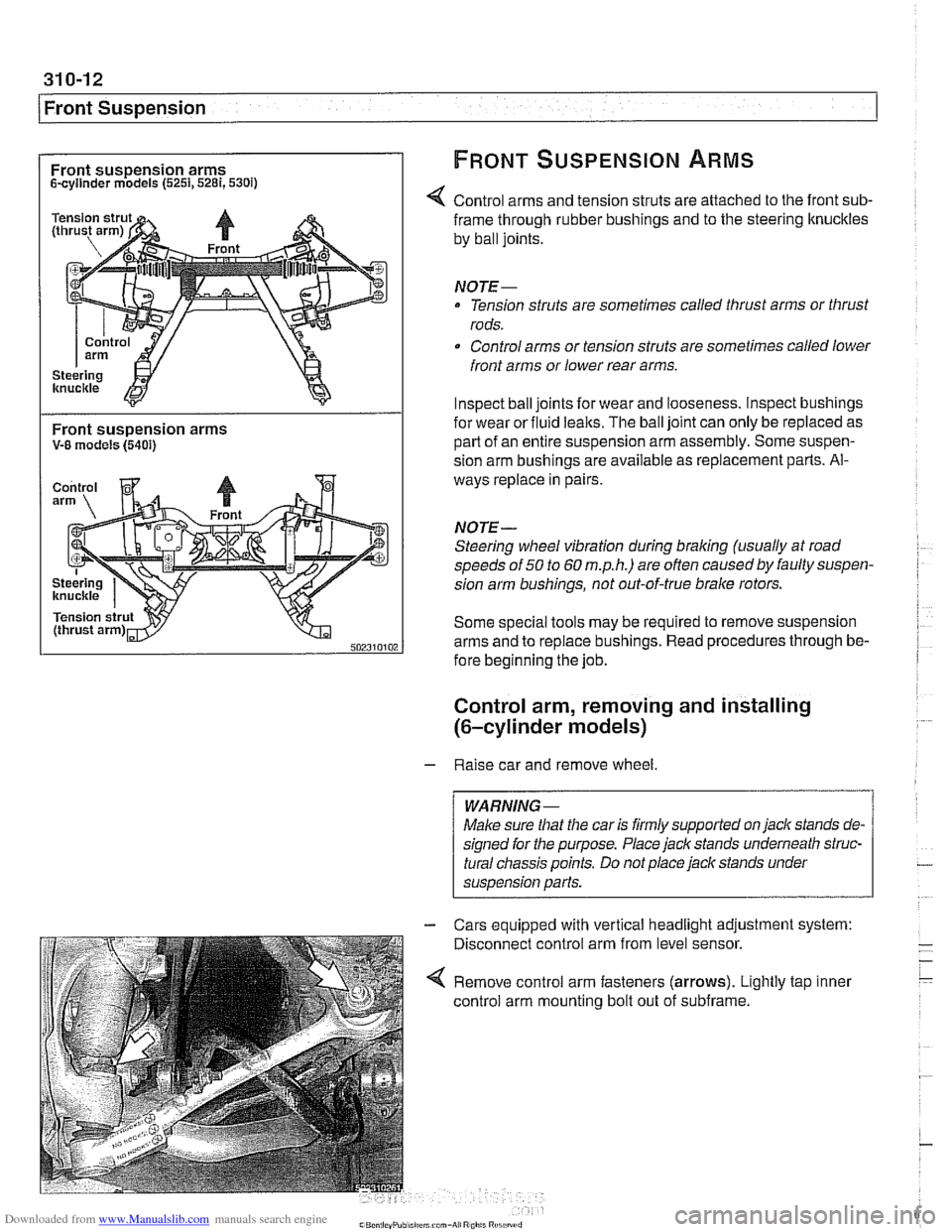

4 Remove outer tie rod end nut. Use BMW special tool 31 2

240 or equivalent to press tie rod end out of steering arm.

Page 648 of 1002

Downloaded from www.Manualslib.com manuals search engine

/~ront Susaension

Front suspension arms FRONT SUSPENSION ARMS

Scyllnder models (5251,5281,530i)

Control arms and tension struts are attached to the front sub-

Front suspension arms V-8 models (5401)

frame through rubber bushings and to the steering ltnuckles

by ball joints.

NOTE-

Tension struts are sometimes called thrust arms or thrust

rods.

Control arms or tension struts are sometimes called lower

front arms or lower rear arms.

Inspect ball joints for wear and looseness. lnspect bushings

for wear or fluid

lealts. The ball joint can only be replaced as

part of an entire suspension arm assembly. Some suspen-

sion arm

bushinas are available as re~lacement Darts. Al-

ways replace in pairs

NOTE-

Steering wheel vibration during braking (usually at road

speeds of

50 to 60 m.p.h.) are often causedby faulty suspen-

sion arm bushings, not out-of-true brake rotors.

Some special tools may be required to remove suspension

arms and to replace bushings. Read procedures through be-

fore beginning the job.

Control arm, removing and installing

(6-cylinder models)

- Raise car and remove wheel

Male sure

that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension

parfs.

Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

Remove control arm fasteners (arrows). Lightly tap inner

control arm mounting bolt out of subframe.