20 pin BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 562 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Clutch

- lnstall flywheel lock, special tool 11 2 170 (6 cylinder model)

or

11 2 070 (V-8 model).

- lnstall SAC pressure plate on dowel pins at flywheel. lnstall

clutch mounting bolts and tighten each one turn at a time until

pressure plate is fully seated. Torque to specification.

Tightening torques

Clutch to flywheel

- M8 (8.8 grade)

M8 (10.9 grade) 24

Nm (18

ft-ib)

34

Nm (25 ft-lb)

- Slip out clutch centering tool using large bolt.

- Remove flywheel locking tool.

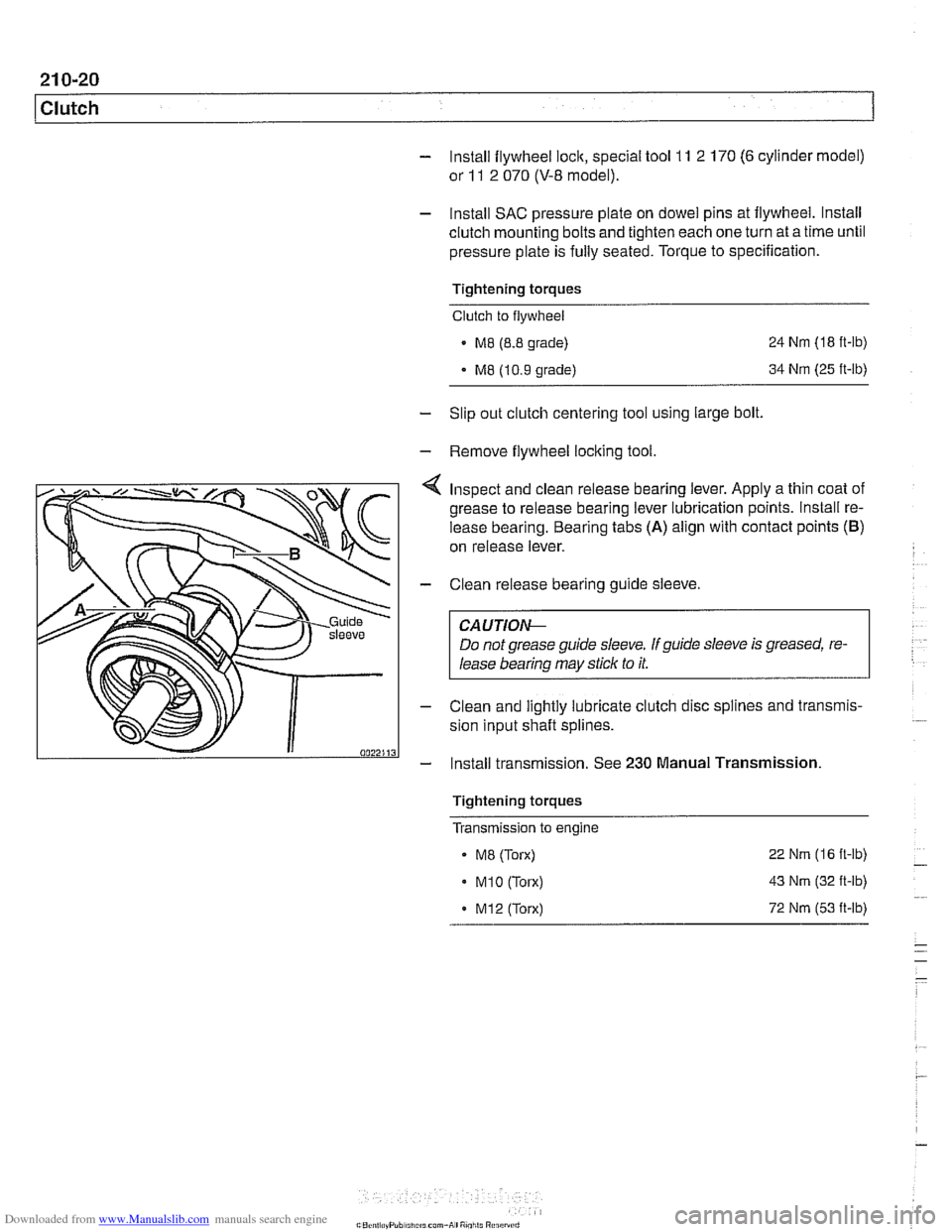

Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. lnstall re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

- Clean release bearing guide sleeve.

CA U TIOG

Do not grease guide sleeve. If guide sleeve is greased, re-

lease bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- Install transmission. See 230 Manual Transmission

Tightening torques

Transmission to engine

- ME (Torx)

. M1O (Torx)

. M12 (Torx) 22

Nm (16 ft-lb)

43

Nm (32 ft-lb)

72

Nm (53 it-lb)

Page 572 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission Selector shaft seal, replacing

(transmission installed)

- Put transmission into second gear.

- Raise and safely support vehicle.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floorjack is not adequate support

- 6-speed transmission: Remove rear engine splash shield

- Remove exhaust system and heat shields. See 180 Exhaust

System.

- Support transmission with transmission jack.

- Disconnect driveshaft at transmission and tie to side. See

260 Driveshaft.

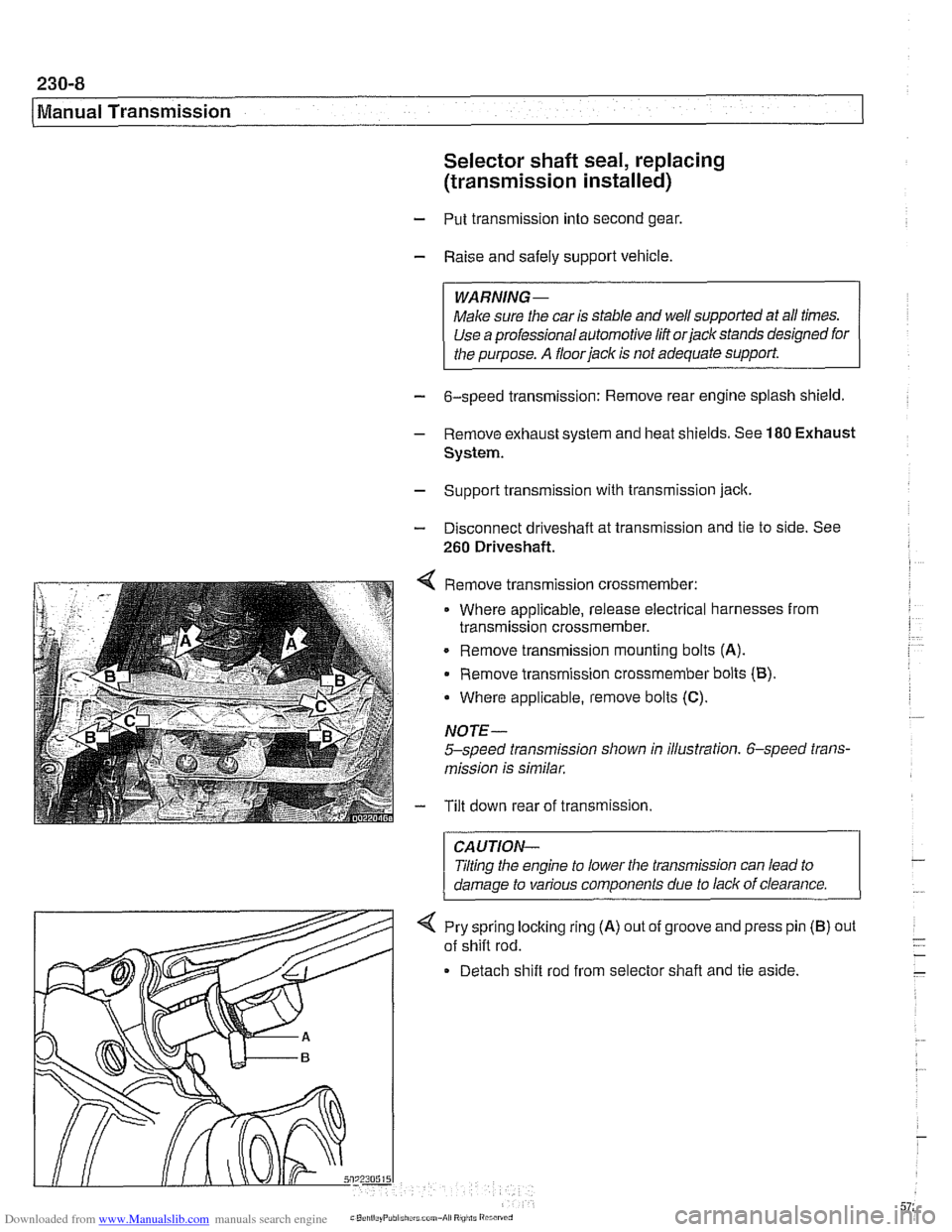

4 Remove transmission crossmember:

Where applicable, release electrical harnesses from

transmission crossmember.

. Remove transmission mounting bolts (A).

Remove transmission crossmember bolts (B).

Where applicable, remove bolts

(C).

NOTE-

5-speed transmission shown in illustration. 6-speed trans-

mission is similar.

- Tilt down rear of transmission.

CAUTION-

Jilting the engine to lower the transmission can lead to

damaae to various components due to lack of clearance.

-

4 Pry sprlng locking rlng (A) out of groove and press pin

of

sh~fl rod.

Detach

sh~ft rod from selector shafl and tie as~de.

(B) out

Page 573 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-9

Manual ~ransmissionl

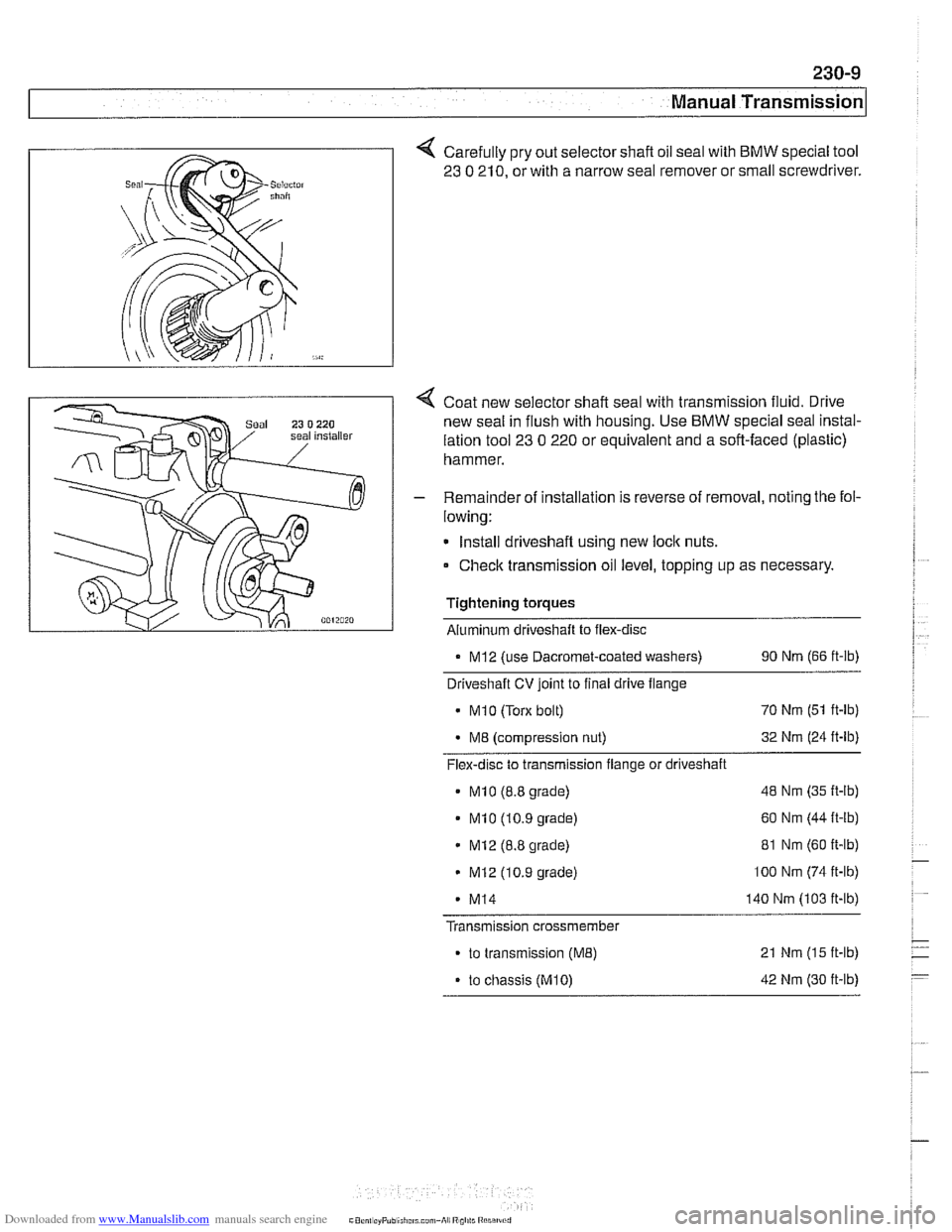

Carefully pry out selector shaft oil seal with BMW special tool

23

0 210, or with a narrow seal remover or small screwdriver.

Coat new selector shaft seal with transmission fluid. Drive

new seal in flush with housing. Use

BMW special seal instal-

lation tool

23 0 220 or equivalent and a soft-faced (plastic)

hammer.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new

loclc nuts.

Check transmission oil level, topping up as necessary.

Tightening torques Aluminum driveshaft to flex-disc

. MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft CV joint to final drive flange

MI 0 (Torx bolt) 70

Nm (51 ft-lb)

M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI0 (10.9 grade) 60

Nm (44 it-lb)

MI2 (8.8 grade) 81

Nm (60 ft-lb)

MI2 (10.9 grade) lo0 Nm (74 ft-lb)

- MI4 140 Nm (103 ft-lb)

Transmission crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

Page 575 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 1

Manual ~ransmissionl

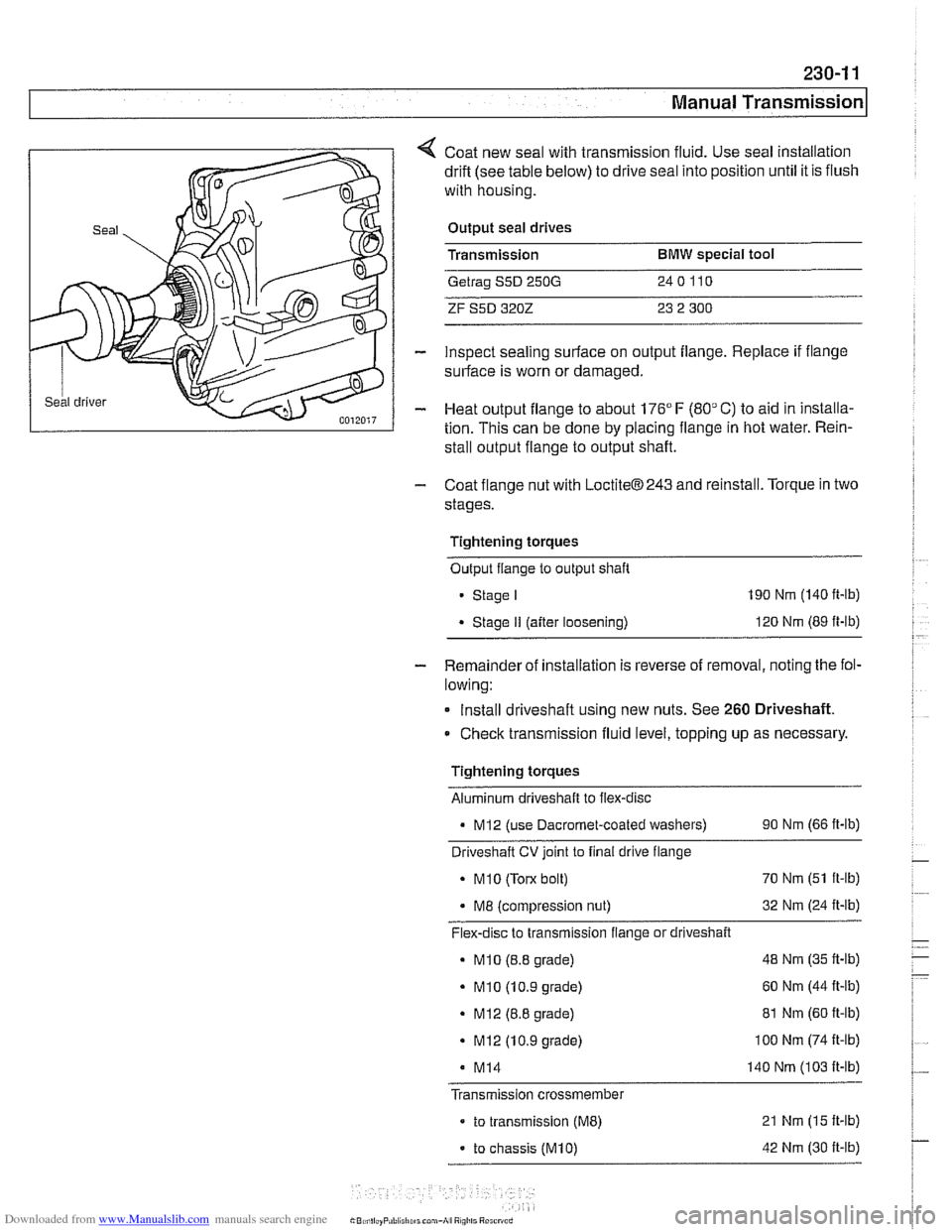

Coat new seal with transmission fluid. Use seal installation

drift (see table below) to drive seal into position until it is flush

with housing.

Output seal drives

Transmission

BMW special tool

Getrag S5D 250G 240110

ZF S5D 3202 23 2 300

inspect sealing surface on output flange. Replace if flange

surface is worn or damaged.

Heat output flange to about 176"

F (80" C) to aid in installa-

tion. This can be done by placing flange in hot water. Rein-

stall output flange to output shaft.

- Coat flange nut with LoctiteB243 and reinstall. Torque in two

stages.

Tightening torques Output flange to output shaft

Stage I 190 Nm (140 ft-lb)

Stage II (after loosening) 120

Nm (89 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Check transmission fluid level, topping up as necessary

Tightening torques Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

. MI0 (Torx bolt) 70

Nm (51 ft-lb)

. M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

- MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60

Nm (44 It-lb)

. MI2 (8.8 grade) 81 Nm (60 ft-lb)

. MI2 (10.9 grade) I00 Nm (74 It-lb)

M14 140 Nm (103 It-lb)

Transmission crossmember

- to transmission (ME) 21 Nm (15 It-lb)

- to chassis (M10) 42 Nm (30 It-lb)

Page 578 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-14

I Manual Transmission

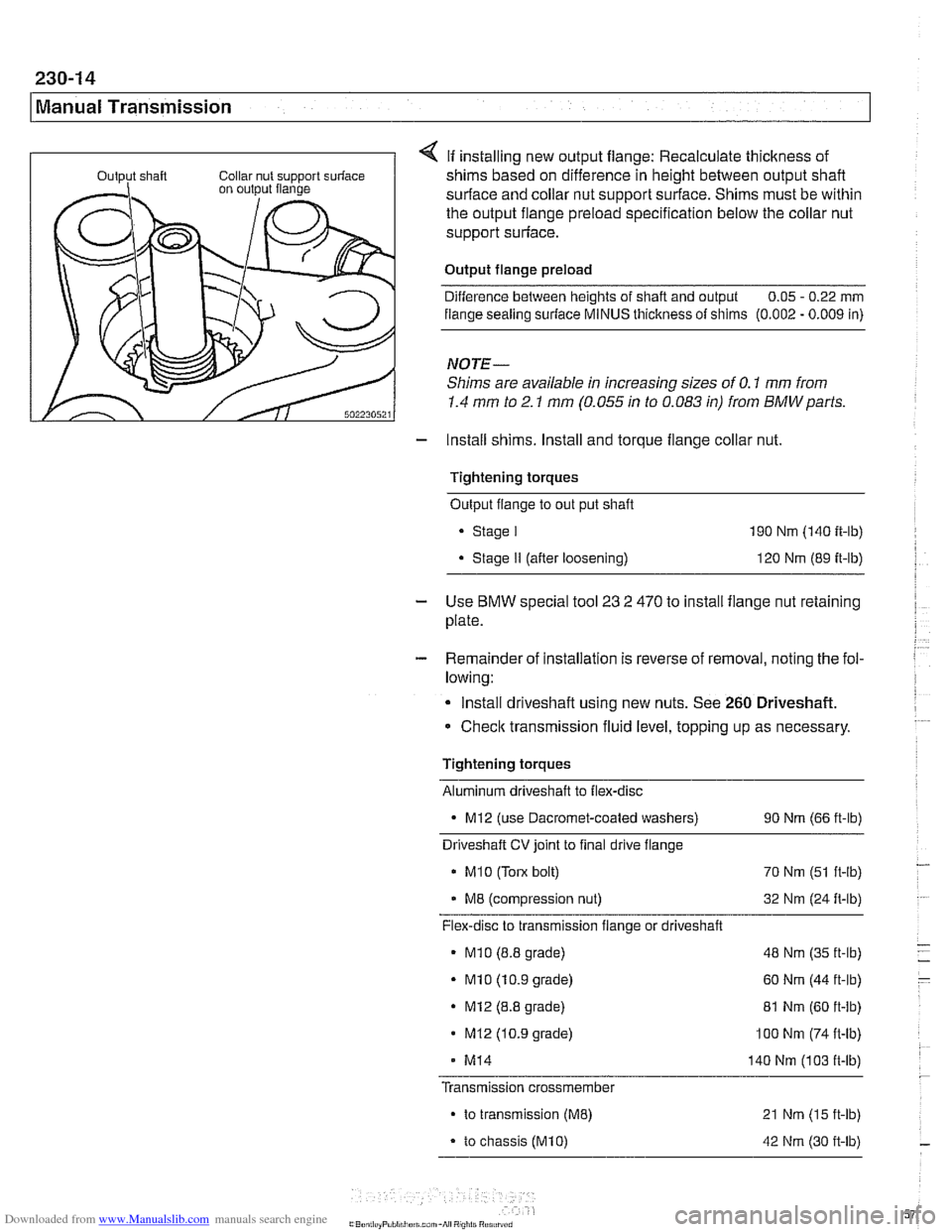

If installing new output flange: Recalculate thickness of

shims based on difference in height between output shaft

surface and collar nut support surface. Shims must be within

the output flange preload specification below the collar nut

support surface.

Output flange preload Difference between heights of shaft and output 0.05

- 0.22 mm

flange sealing

suriace MINUS thickness of shims (0.002 - 0.009 in)

NOTE-

Shims are available in increasing sizes of 0.1 mm from

1.4 mm to 2.1 mm (0.055 in to 0.083 in) from BMWparts.

- Install shims. Install and torque flange collar nut.

Tightening torques Output flange to out put shaft

. Stage I 190 Nm (140 ft-lb)

. Stage II (after loosening) 120 Nm (89 it-lb)

- Use BMW special tool 23 2 470 to install flange nut retaining

plate.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Checlc transmission fluid level, topping up as necessary.

Tightening torques

Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

MI0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

* MI0 (8.8 grade) 48 Nm (35 ft-lb)

- MI0 (10.9 grade) 60 Nm (44 ft-lb)

. MI2 (8.8 grade)

81 Nm (60 ft-lb)

MI2 (10.9 grade) 100 Nm (74 ft-lb)

- MI4 140 Nm (1 03 ft-lb)

Transmission

crossmembe~

to transmission (ME)

to chassis (M10)

21 Nm (15 ft-lb)

42 Nm (30 it-lb)

Page 583 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission

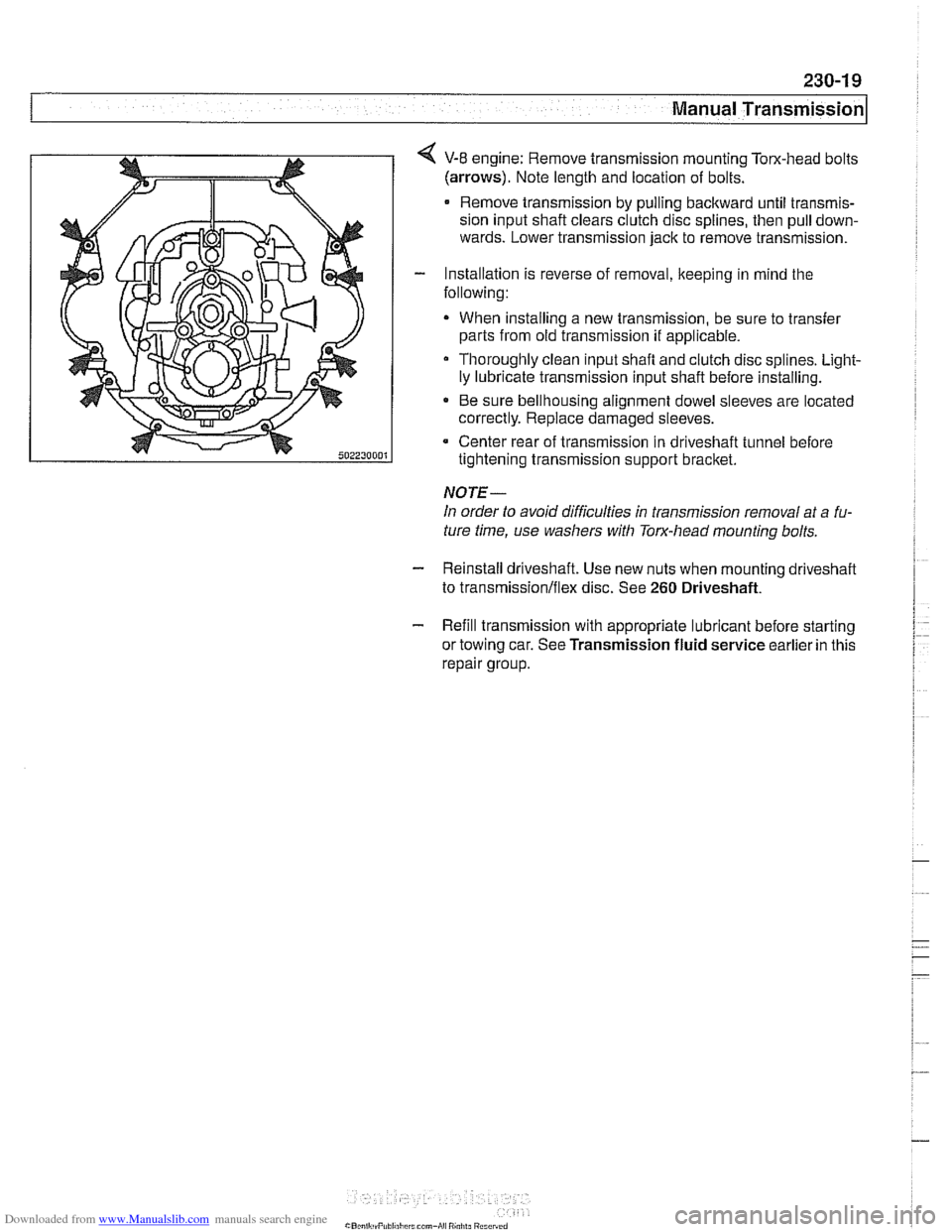

4 V-8 engine: Remove transmission mounting Tom-head bolts

(arrows). Note length and location of bolts.

Remove transmission by pulling backward until transmis-

sion input shaft clears clutch disc splines, then pull down-

wards. Lower transmission jack to remove transmission.

- Installation is reverse of removal, keeping in mind the

following:

When installing a new transmission, be sure to transfer

parts from old transmission

if applicable.

Thoroughly clean input shafl and clutch disc splines. Light-

ly lubricate transmission input shaft before installing.

* Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Center rear of transmission in driveshaft tunnel before

tightening transmission support bracket.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

- Reinstall driveshaft. Use new nuts when mounting driveshaff

to transmission/flex disc. See 260 Driveshaft.

- Refill transmission with appropriate lubricant before starting

or towing car. See Transmission fluid service earlier in this

repair group.

Page 595 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic ~ransmissionl

II I

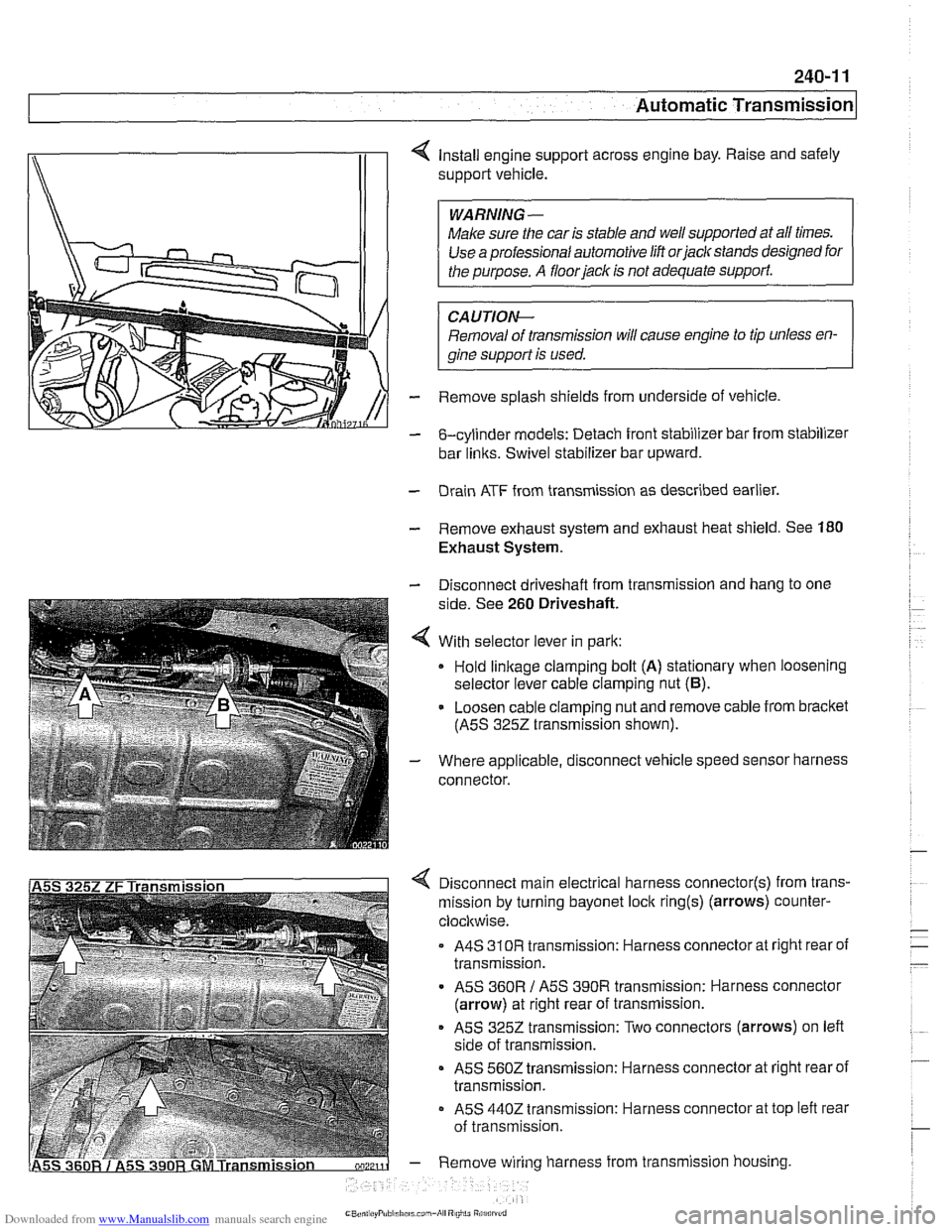

4 Install engine support across engine bay. Raise and safely

support vehicle.

Make sure the car is stable and

we1 supported at all times.

Use a professional automotive lift

orjaclc stands designed for

CAUTIOI\C

Removal of transmission will cause engine to tip unless en-

gine support is used.

- Remove splash shields from underside of vehicle.

- &cylinder models: Detach front stabilizer bar from stabilizer

bar

links. Swivel stabilizer bar upward.

- Drain ATF from transmission as described earlier.

- Remove exhaust system and exhaust heat shield. See 180

Exhaust System.

- Disconnect driveshaft from transmission and hang to one

side. See

260 Driveshaft.

4 With selector lever in park:

Hold

linkage clamping bolt (A) stationary when loosening

selector lever cable clamping nut

(6).

- Loosen cable clamping nut and remove cable from bracket

(ASS

3252 transmission shown).

- Where applicable, disconnect vehicle speed sensor harness

connector.

4 Disconnect main electrical harness connector(s) from trans-

mission by turning bayonet lock

ring(s) (arrows) counter-

clocltwise.

A4S

310R transmission: Harness connector at right rear of

transmission.

ASS

360R / ASS 390R transmission: Harness connector

(arrow) at right rear of transmission.

ASS 3252 transmission: Two connectors (arrows) on left

side of transmission.

ASS 5602 transmission: Harness connector at right rear of

transmission.

- ASS 4402 transmission: Harness connector at top left rear

of transmission.

- Remove wiring harness from transmission housing

Page 596 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

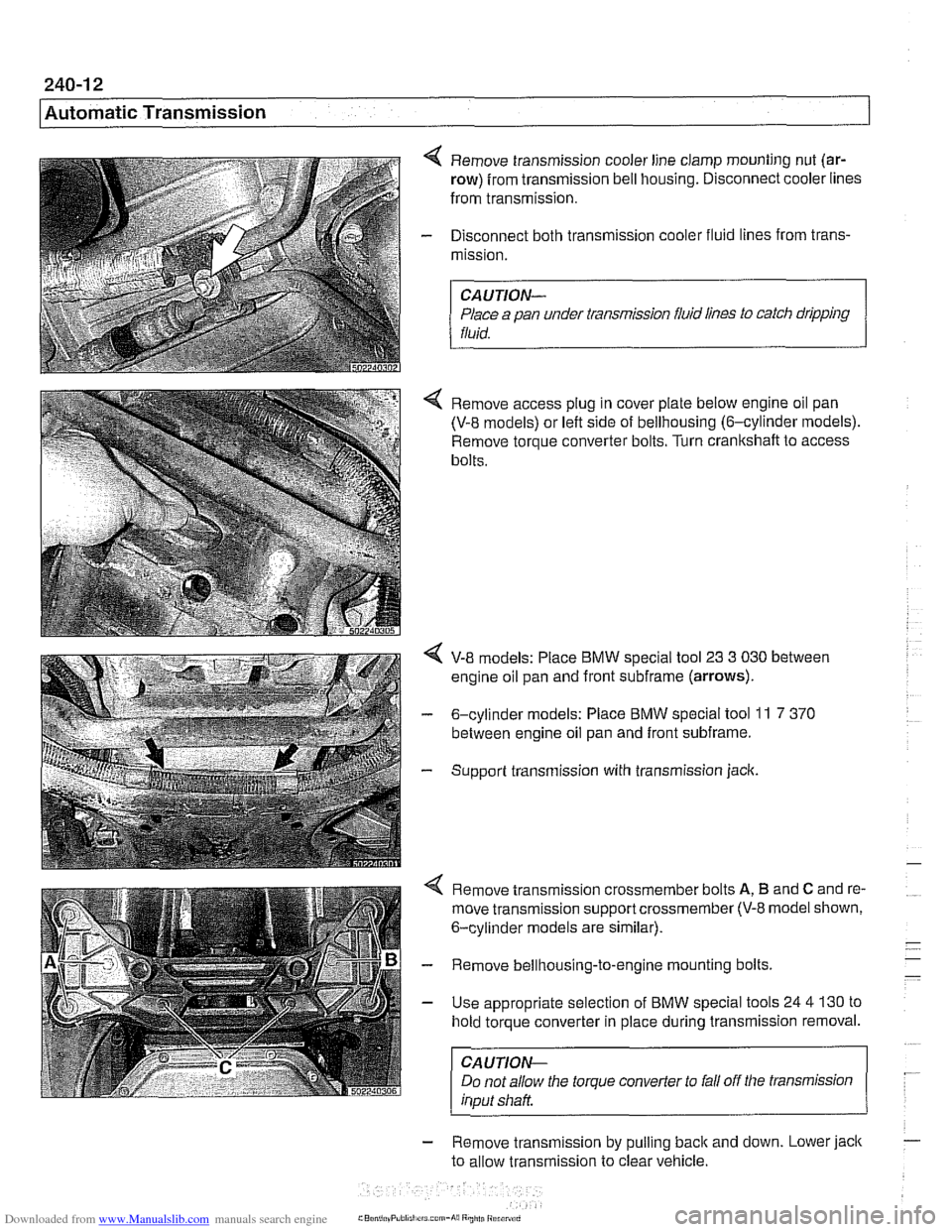

4 Remove transmission cooler line clamp mounting nut (ar-

row) from transmission bell housing. Disconnect cooler lines

from transmission.

- Disconnect both transmission cooler fluid lines from trans-

mission.

CAUTION-

Place a pan under transmission fluid lines to catch dripping

fluid.

4 Remove access plug in cover plate below engine oil pan

(V-8 models) or left side of bellhousing (6-cylinder models).

Remove torque converter bolts. Turn

cranltshaft to access

bolts.

V-8 models: Place BMW special tool 23 3 030 between

engine oil pan and front

subframe (arrows).

- 6-cylinder models: Place BMW special tool 11 7 370

between engine oil pan and front subframe.

- Support transmission with transmission jack.

4 Remove transmission crossmember bolts A, B and C and re-

move transmission support crossmember

(V-8 model shown,

6-cylinder models are similar).

- Remove bellhousing-to-engine mounting bolts.

- Use appropriate selection of BMW special tools 24 4 130 to

hold torque converter in place during transmission removal.

CAUTION-

Do not allow the torque converter to fall off the transmission

input shaft

- Remove transmlsslon by pull~ng back and down. Lower jack

to allow transmiss~on to clear vehicle.

rrs corn-hi8 Rniiti Riranrd

Page 600 of 1002

Downloaded from www.Manualslib.com manuals search engine

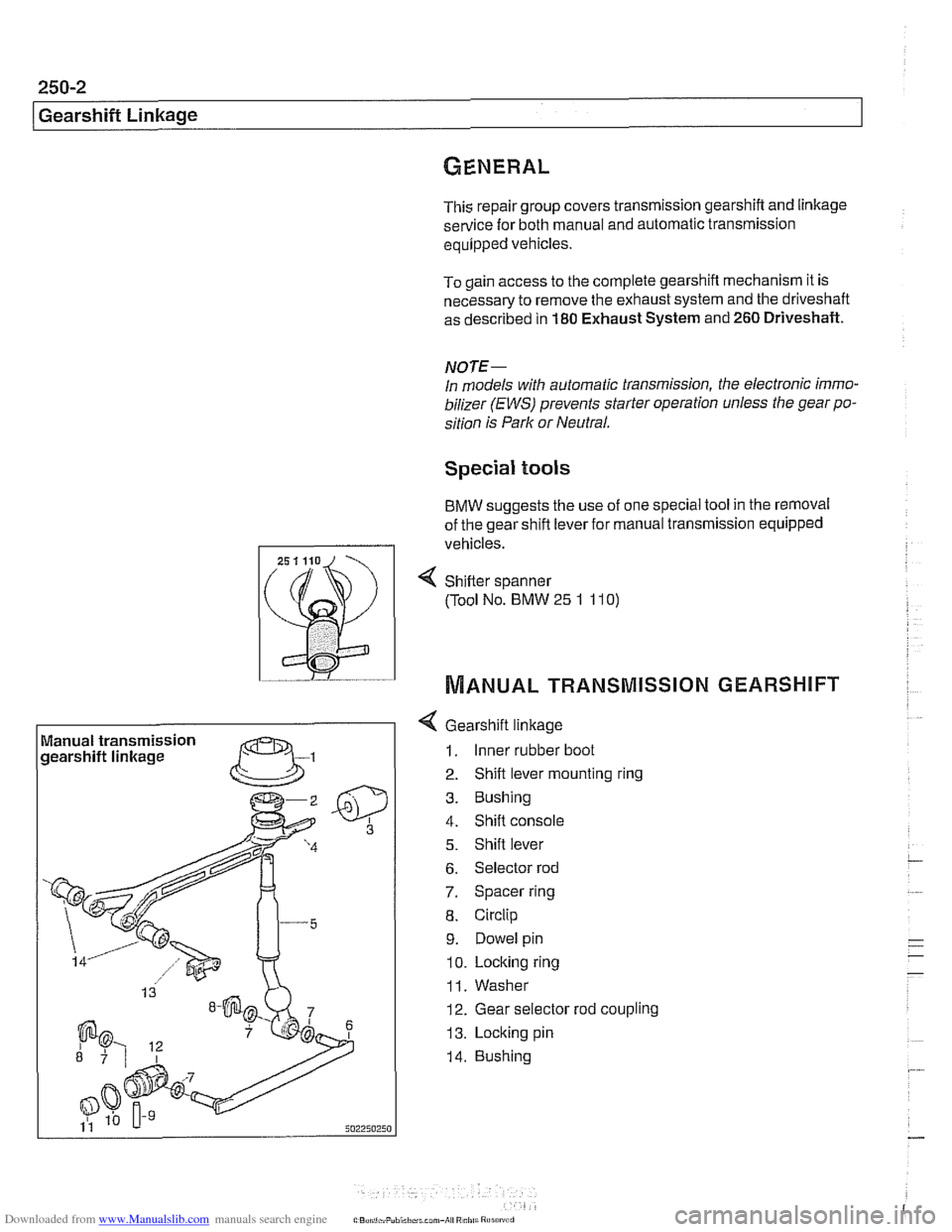

250-2

I Gearshift Linkage

This repair group covers transmission gearshift and linkage service for both manual and automatic transmission

equipped vehicles.

To gain access to the complete gearshift mechanism it is

necessary to remove the exhaust system and the driveshaft

as described in

180 Exhaust System and 260 Driveshaft.

NOTE-

In models with automatic transmission, the electronic immo-

bilizer

(EWS) prevents starter operation unless the gear po-

sition is Park or Neutral.

Special tools

BMW suggests the use of one special tool in the removal

of the gear shift lever for manual transmission equipped

I I vehicles.

Manual transmission

gearshift linkage

--

4 Gearshift linkage

1. Inner rubber boot

2. Shift lever mounting ring

3. Bushing

4. Shift console

5. Shift lever

6. Selector rod

7. Spacer ring

8. Circlip

9. Dowel pin

10. Locking ring

11. Washer

12. Gear selector rod coupling

13. Locking pin

14. Bushing

4 Sh~fter spanner

(Tool No. BMW

25 1 11 0)

MANUAL TRANSMISSION GEARSHIFT

Page 603 of 1002

Downloaded from www.Manualslib.com manuals search engine

Gearshift Linkage

- Connect selector rod to shift lever. Lift transmission, install

crossmember and tighten crossmember bolts.

Install driveshaft and heat shield. See

260 Driveshaft.

Reinstall exhaust system. See 180 Exhaust System.

. Lower vehicle. Install shift boot. Push shift ltnob on lever.

Tightening torque

Driveshaft

CV joint to final drive flange

. MI0 (Tom bolt)

70 Nm (51 ft-lb)

. M8 (compression nut) 32 Nm (24 ft-lb) - Driveshaft clamping sleeve

- MI0 ribbed nuts

80 Nm (59 ft-lb)

MI0 compressed nuts 64 Nm (47 ft-lb)

Flex-disc to driveshaft or transmission flange

MlO (8.8 grade) 48

Nm (35 ft-lb)

. MI0 (10.9 grade) 60

Nm (44 ft-lb)

- MI2 (10.9 grade) 100 Nm (74 ft-ib)

MI4 140 Nm (103 fi-lb)

Transmission crossmember

. to transmission 21 Nm (15 ft-lb)

. to chassis 42 Nm (30 ft-lb)