Front BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 614 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.- .

/ Driveshaft Driveshaft, removing

CAUTION-

. Be sure the wheels are off the ground before removing the

driveshak Set the parl(ing brake before removing the

driveshaft.

Once the driveshaft has been removed, the vehicle can

roll regardless of whether the transmission is in gear or

not.

The driveshaft is mounted to the transmission and final

drive

with self-locliing nuts. These nuts are designed to

be used only once and should be replaced during reas-

sembly.

Remove complete exhaust system. See

180 Exhaust

System.

- Remove exhaust heat shields.

- Support transmission with transmission jack.

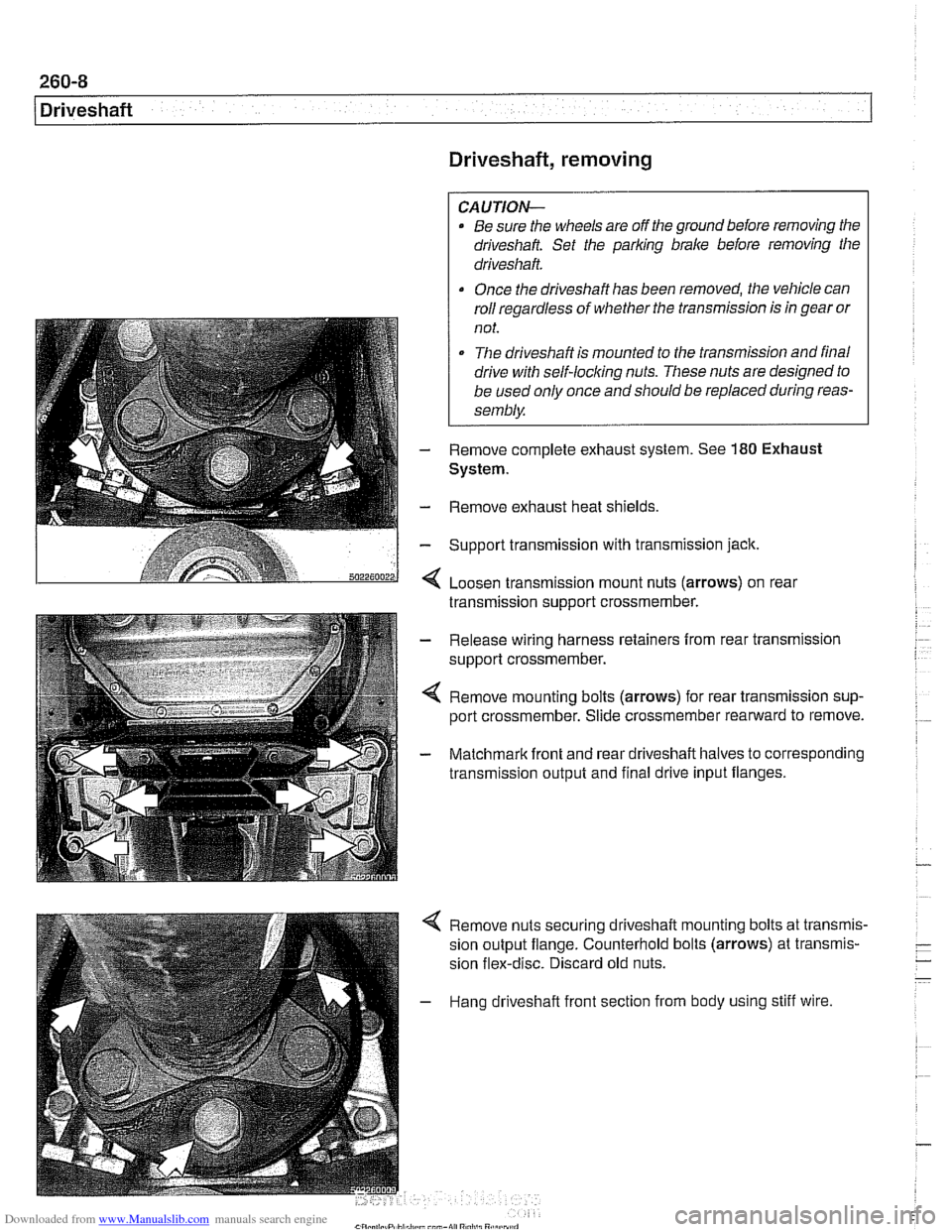

< Loosen transmission mount nuts (arrows) on real

transmission support crossmember.

- Release wiring harness retainers from rear transmission

support crossmember.

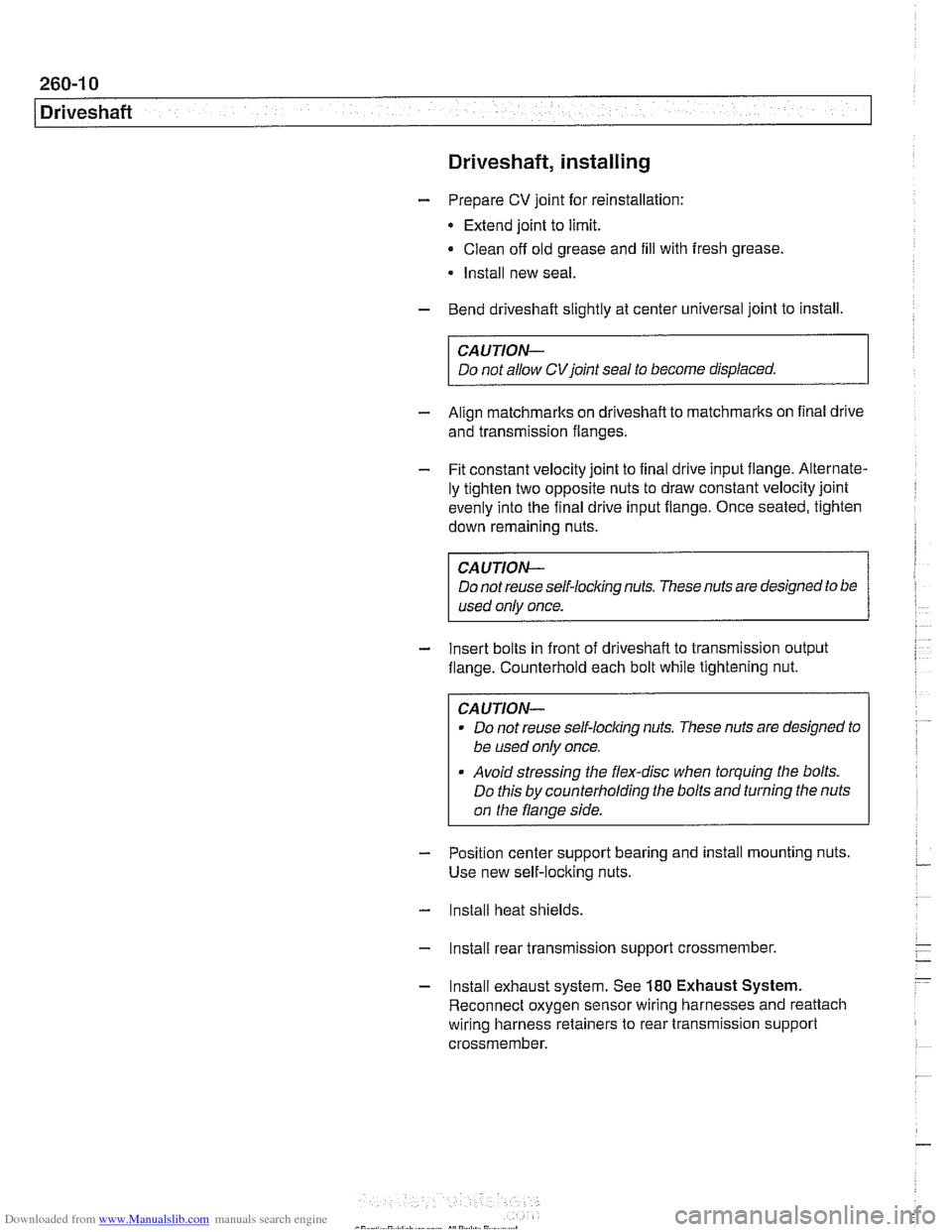

< Remove mounting bolts (arrows) for rear transmission sup-

port crossmember. Slide crossmember rearward to remove.

- Matchmark front and rear driveshaft halves to corresponding

transmission output and final drive input flanges.

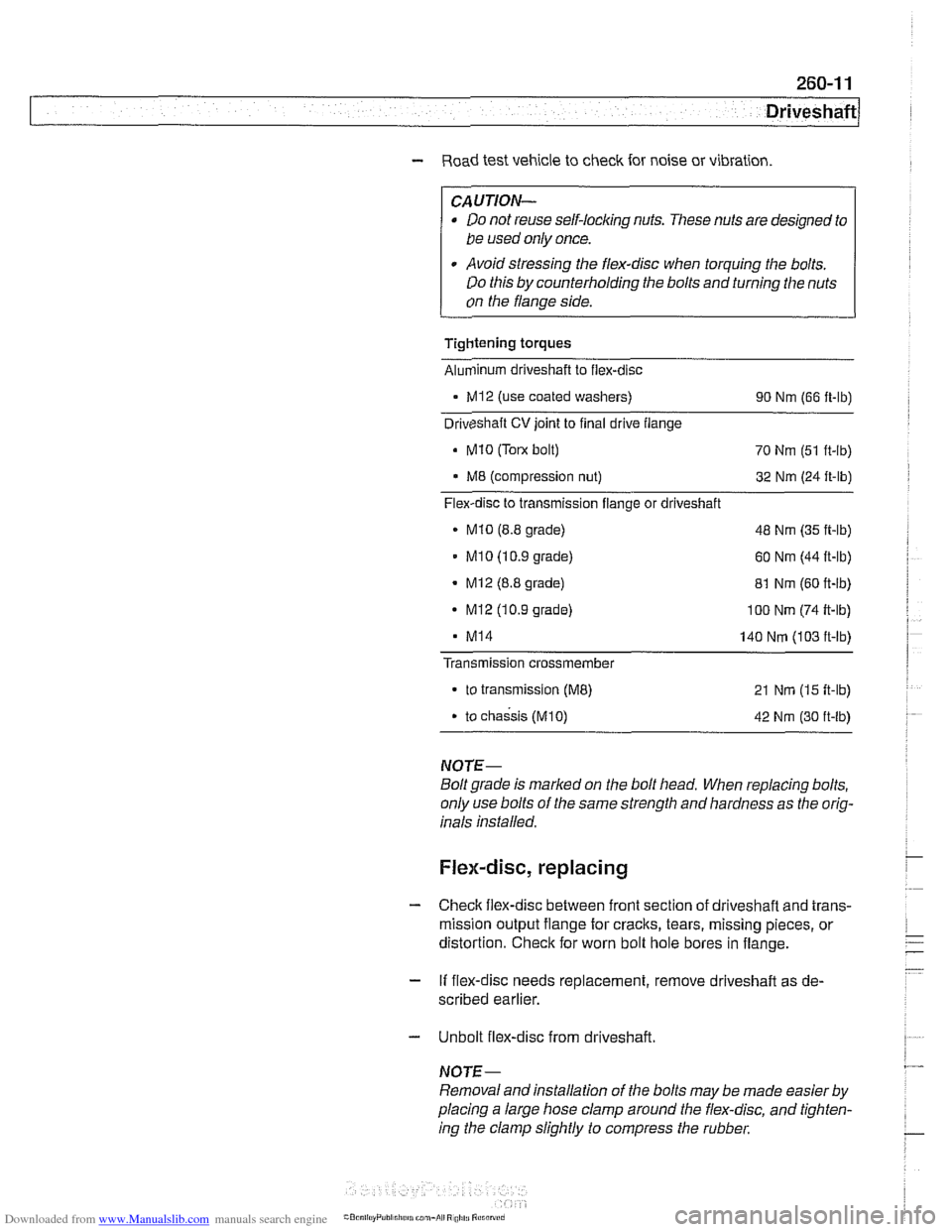

4 Remove nuts securing driveshaft mounting bolts at transmis-

sion output flange. Counterhold bolts (arrows) at transmis-

sion flex-disc. Discard old nuts.

- Hang driveshaft front section from body using stiff wire.

Page 616 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 0

/ Driveshaft

Driveshaft, installing

- Prepare CV joint for reinstallation:

Extend joint to limit.

Clean off old grease and fill with fresh grease

Install new seal.

- Bend driveshaft slightly at center universal joint to install

CAUTION-

Do not allow CVjoint seal to become displaced.

- Align matchmarlts on driveshaft to matchmarks on final drive

and transmission flanges.

- Fit constant velocity joint to final drive input flange. Alternate-

ly tighten two opposite nuts to draw constant velocity joint

evenly into the final drive input flange. Once seated, tighten

down remaining nuts.

I CAUTION-

I Do not reuse self-locking nuts. These nuts are designed to be /

I used onlv once. 1

- Insert bolts in front of driveshafl to transmission output

flange. Counterhold each bolt while tightening nut.

CAUTION-

. Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

- Position center support bearing and install mounting nuts.

Use new self-locking nuts.

- Install heat shields.

- Install rear transmission support crossmember.

- Install exhaust system. See 180 Exhaust System.

Reconnect oxygen sensor wiring harnesses and reattach

wiring harness retainers to rear transmission support

crossrnernber.

Page 617 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft

- Road test vehicle to check for noise or vibration

CAUTION-

Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

Tightening torques

Alunlinum driveshaft to flex-disc

- MI2 (use coated washers)

90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

Mi0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI 0 (1 0.9 grade) 60 Nm (44 ft-lb)

- Mi2 (8.8 grade)

81 Nm (60 ft-lb)

- MI2 (10.9 grade) I00 Nm (74 ft-lb)

MI4 140 Nm (103 ft-lb)

Transmission

crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

NOTE-

Boltgrade is marked on the bolt head. When replacing bolts,

only use bolts of the same strength and hardness as the orig-

inals installed.

Flex-disc, replacing

- Checlc flex-disc between front section of driveshafl and trans-

mission output flange for craclts, tears, missing pieces, or

distortion. Check for worn bolt hole bores in flange.

- If flex-disc needs replacement, remove driveshafl as de-

scribed earlier.

- Unbolt flex-disc from driveshaft.

NOTE-

Removal andinstallation of the bolts may be made easier by

placing a large hose clamp around the flex-disc, and tighten-

ing the clamp slightly to compress the rubber.

Page 618 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 2

1 Driveshaft

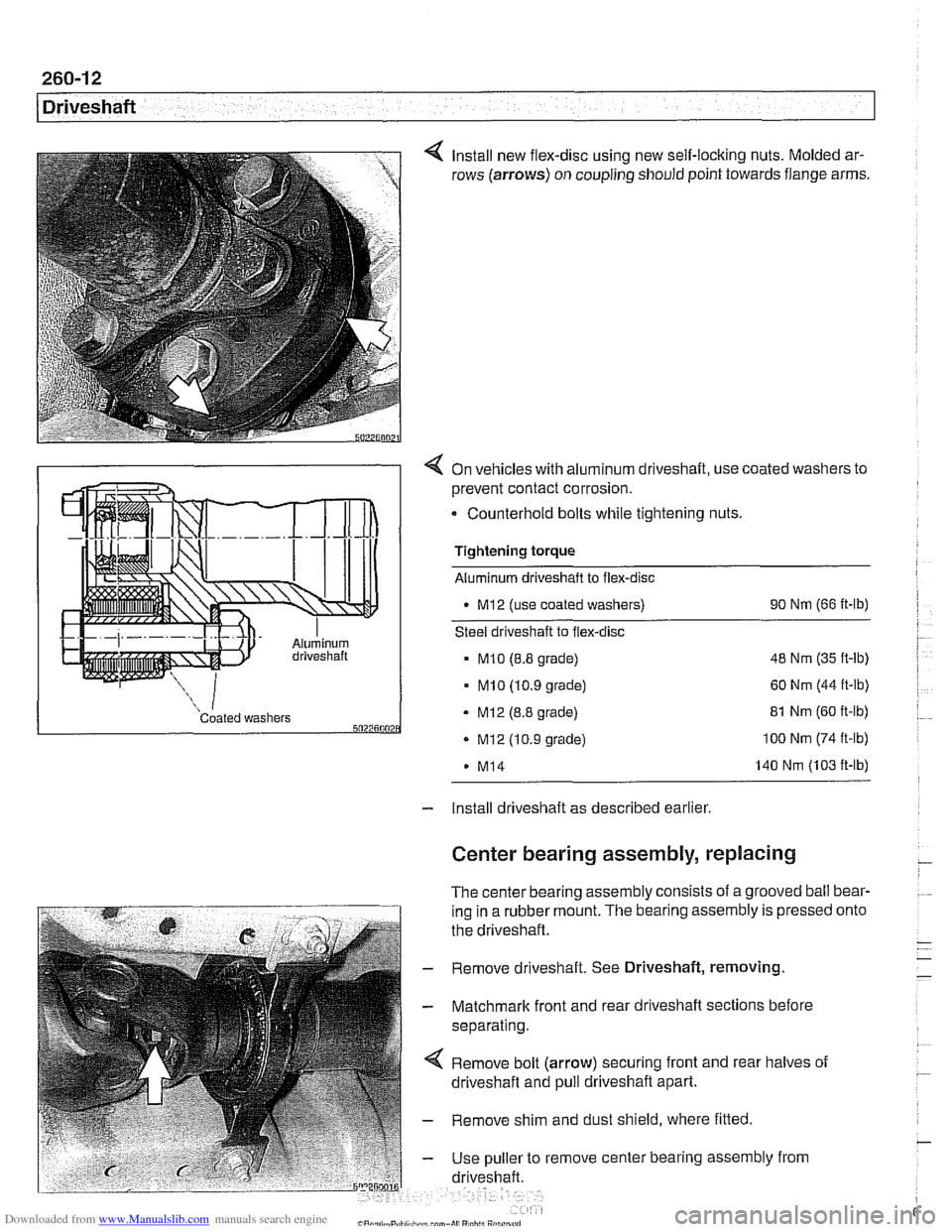

Install new flex-disc using new self-locking nuts. Molded ar-

rows (arrows) on coupling should point towards flange arms.

4 On vehicles with aluminum driveshaft, use coated washers to

prevent contact corrosion.

- Counterhold bolts while tightening nuts.

Tightening torque

Aluminum driveshaft to flex-disc

M12 (use coated washers) 90

Nm (66 ft-lb)

Steel driveshaft to flex-disc

MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60 Nm (44 ft-lb)

Coated washers - MI2 (8.8 grade) 5027500 . Mi2 (10.9 grade)

M14 81

Nm (60 ft-lb) 100 Nm (74 ft-lb)

140 Nm (103 ft-lb)

- Install driveshaft as described earlier

Center bearing assembly, replacing

The center bearing assembly consists of a grooved ball bear-

ing in a rubber mount. The bearing assembly is pressed

the driveshaft.

- Remove driveshaft. See Driveshaft, removing

- Matchmark front and rear driveshaft sections before

separating.

Remove bolt (arrow) securing front and rear halves of

driveshaft and pull driveshaft apart.

- Remove shim and dust shield, where fitted

- Use puller to remove center bearing assembly from

driveshaft. onto

Page 619 of 1002

Downloaded from www.Manualslib.com manuals search engine

- On installation, drive new center bearing firmly to stop.

Reassemble driveshaft using matchmarks made prior to

disassembly.

- Clean threads and install bolt securing driveshaft halves.

Use thread locking compound

LoctiteO or equivalent.

Tightening torque Driveshaft front half to rear half

(use thread locking compound) 97

Nm (72 fl-lb)

- Install driveshaft as described earlier.

Front centering guide, replacing

The front centering guide centers the driveshafl in relation to

the transmission. The guide is press-fit into a cavity in the

front of the driveshafl and slides onto the transmission output

shaft.

No specifications are given

forwear of the guide, but general-

ly the guide should fit snugly on the transmission output shafl.

NOTE-

Some driveshafts have a dust cap installed on the end of the

driveshaft, over the centering guide. The dust cap may be-

come bent or distorted when the driveshaft is removed or

in-

stalled. Damage to the dust cap should not affect the

centering guide and should not be mistaken for guide wear.

- Remove driveshafl as described earlier

- Pack cavity behind centering guide with heavy grease until

grease is flush with bottom edge of guide.

- Insert 14 mm (approximately 9/16 in.) diameter mandrel or

metal rod into guide. Strike guide with hammer to force cen-

tering guide out.

NOTE-

Tlie mandrel should fit snugly in the centering guide so that

the grease cannot escape around the sides of the mandrel.

- Remove old grease from driveshaft, lubricate new centering

guide with molybdenum disulfide grease

(MolykoteO, Long-

term8 2 or equivalent) and drive it into driveshaft.

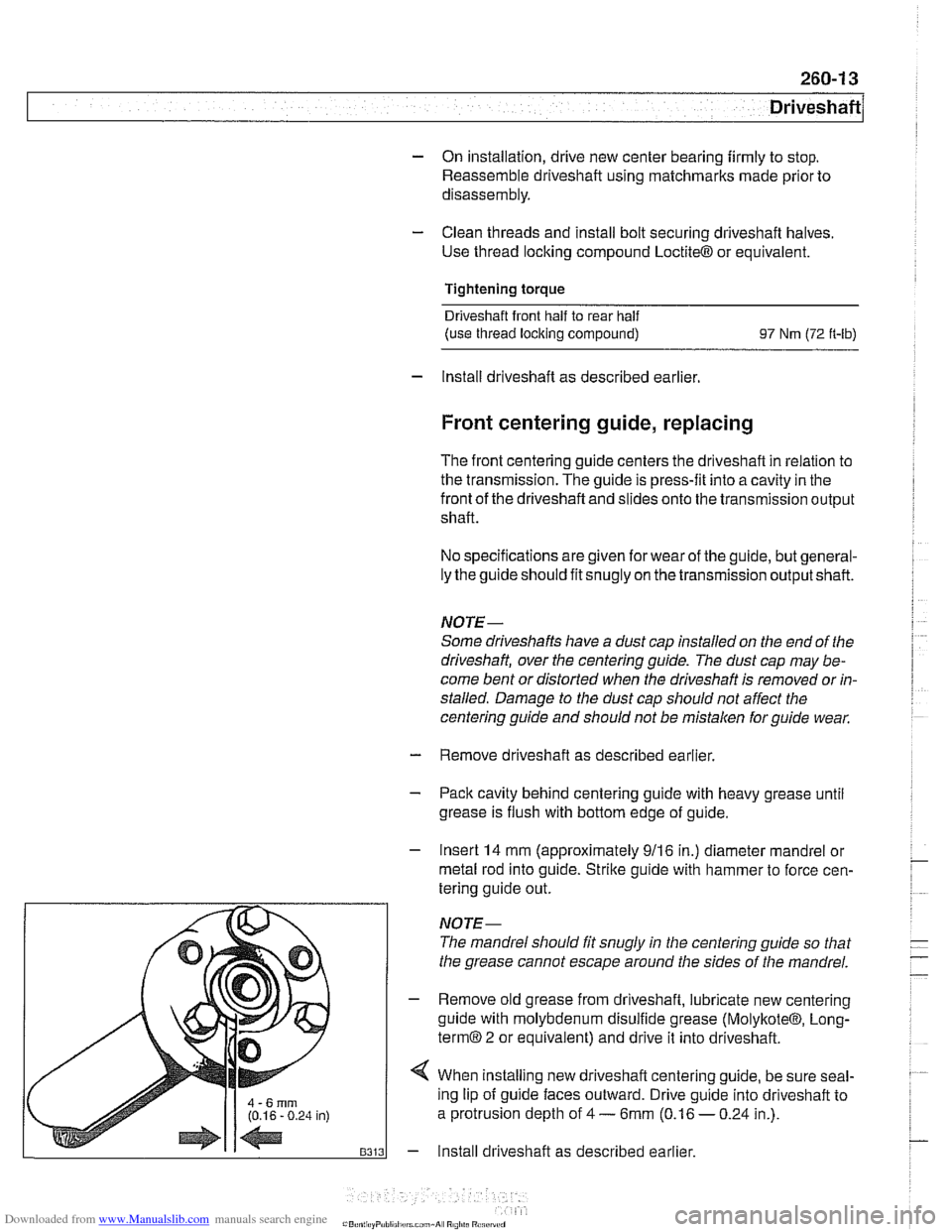

4 When installing new driveshafl centering guide, be sure seal-

ing lip of guide faces outward. Drive guide into driveshaft to

a protrusion depth of

4 - 6mm (0.16 - 0.24 in.).

- Install driveshaft as described earlier.

Page 621 of 1002

Downloaded from www.Manualslib.com manuals search engine

300 Suspension. Steering and Brakes .

Genera8

General ........................... .30 0.2

Aluminum suspension components

...... .30 0.2

Front Suspension ................. .30 0.2

Front suspension 6-cylinder models

(525i.5281. 530i) ..................... .30 0.3

Front suspension V-8 models (540i) ...... .30 0.4

Rear Suspension .................. .30 0.5

Sedan models

....................... .30 0.5

Rear suspension sedan models ........ .30 0.6

Sport Wagon models ................. .30 0.6

Rear suspension Sport Wagon

(with coil springs)

.................... .30 0.7

Rear suspension Sport Wagon

(EHC with air springs)

................. .30 0.8

EHC operational diagram .............. .30 0.9

Steering ......................... .30 0.10

Rack-and-pinion steering ............. .30 0.10

Recirculating ball and nut steering ...... .30 0.10

..................... Brake System 300-10

Wheels and Tires ................. 300-1 1

............... Rim and tire sizes table 300-1 1

Electronic Brake and Stability

.................. Control Systems 300-1 1

E39 electronic brake and stability

........ control systems application table 300-12

........................ ABS system 300-1 2

Automatic Stability Control (ASC)

....... 300-12

ABSIASC traction control system ....... 300-13

Dynamic Stability Control (DSC)

........ 300-14

Ride Height ....................... 300-14

......... Front ride height specifications 300-1 5

......... Rear ride height specifications 300-16

Page 622 of 1002

Downloaded from www.Manualslib.com manuals search engine

[~us~ension, Steering and Brakes - General

This section of the manual covers front and rear suspension,

braking and steering systems, and contains wheel, tire and

wheel alignment information and specifications. Also covered

here are the integrated braking and suspension systems in-

cluding

antilock braking (ABS), traction control (ASCIDSC),

and electronic height control (EHC).

Vehicle ride height information is at the end of this repair

group. Alignment information is in

320 Steering and Wheel

Alignment.

Aluminum suspension components

In order to reduce vehicle weight, aluminum suspension com-

ponents are used in some models. A test with a magnet will

easily reveal the metal used. If working with aluminum com-

ponents, be sure to read and follow the cautions below.

CAUTION-

* Due to the chemical and corrosion characteristics of alumi-

num, do not bring into contact with battery acid.

Do not use wire brushes with brass or iron bristles.

Only use brushes with stainless steel bristles.

Do not expose to flying sparks from

grinding/cutting op-

erations.

Do not subject to steel welding splashes.

Do not expose to temperatures over

80°C (176"F),

even for short periods. Temperatures in painting facili-

ties are not a problem.

The E39 front suspension subframe is used as a rigid mount-

ing platform for the front suspension arms, stabilizer bar and

steering gear.

The suspension arms, known as the lower control arms and

the tension struts (thrust arms), are connected to the

sub-

frame through rubber bushings. The arms are connected to

the steering

knucltles in a double pivot configuration.

Each front strut assembly includes a tubular strut and a coil

spring. The upper strut mount includes a bearing. The lower

end of each strut housing is fitted to the steering knuckle. The

integral wheel bearing and hub are bolted to the steering

Iknucltle.

6-cylinder and V-8 models use different steering systems and

other front suspension components.

Page 623 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-3

Suspension, Steering and Brakes - General

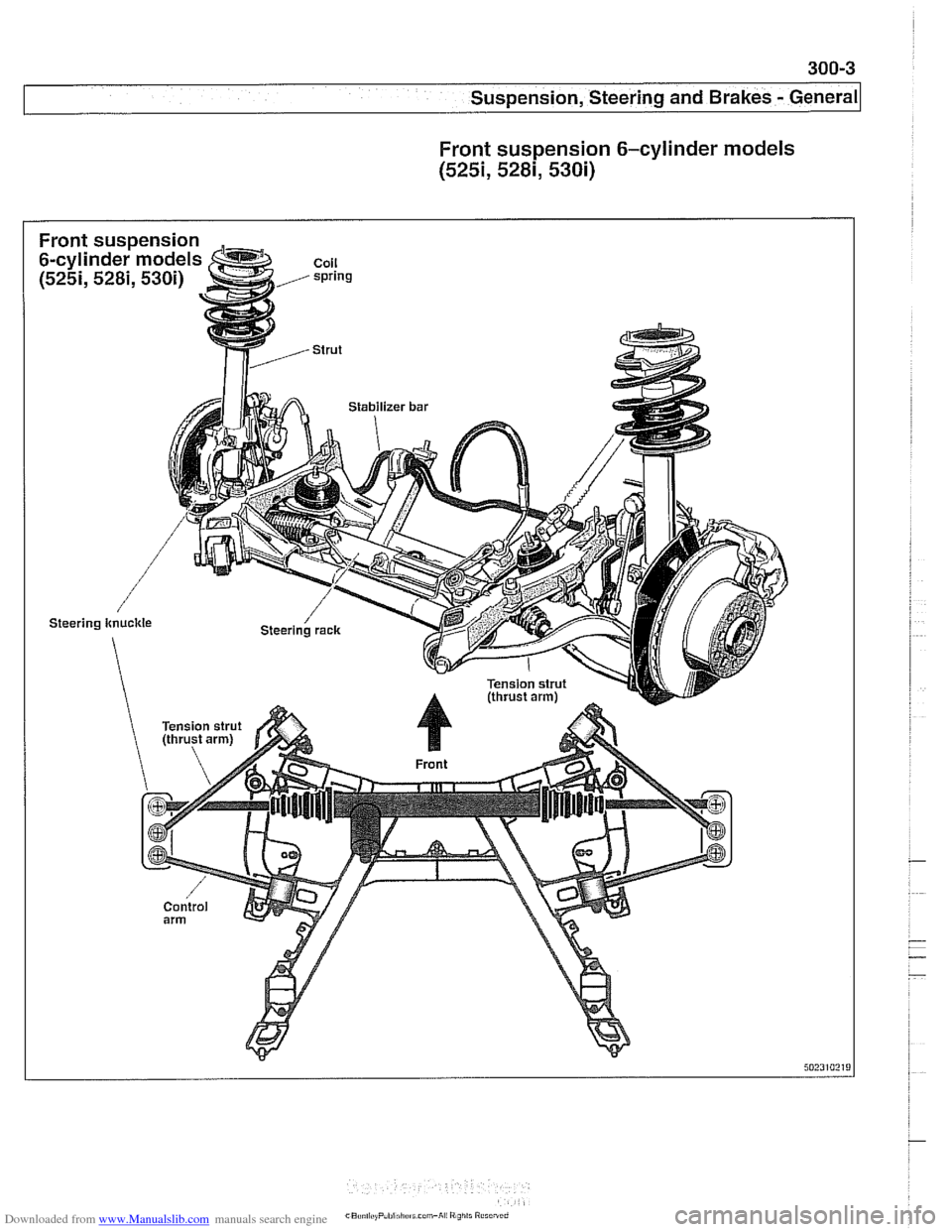

Front suspension 6-cylinder models

(5251, 5281, 530i)

Page 624 of 1002

Downloaded from www.Manualslib.com manuals search engine

Suspension, Steering and Brakes - General

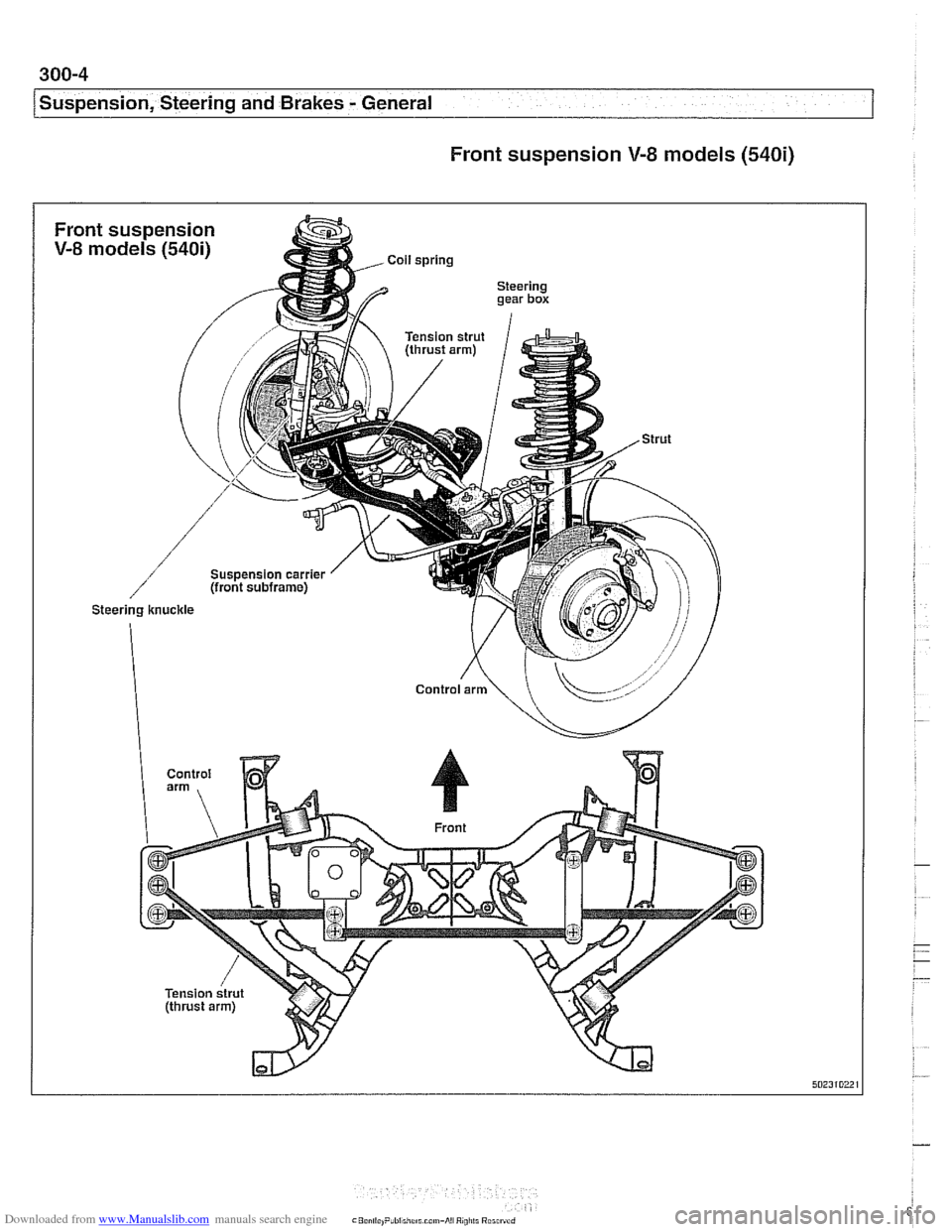

Front suspension V-8 models (540i)

Page 625 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-5

Suspension, Steering and Brakes - ~enerall

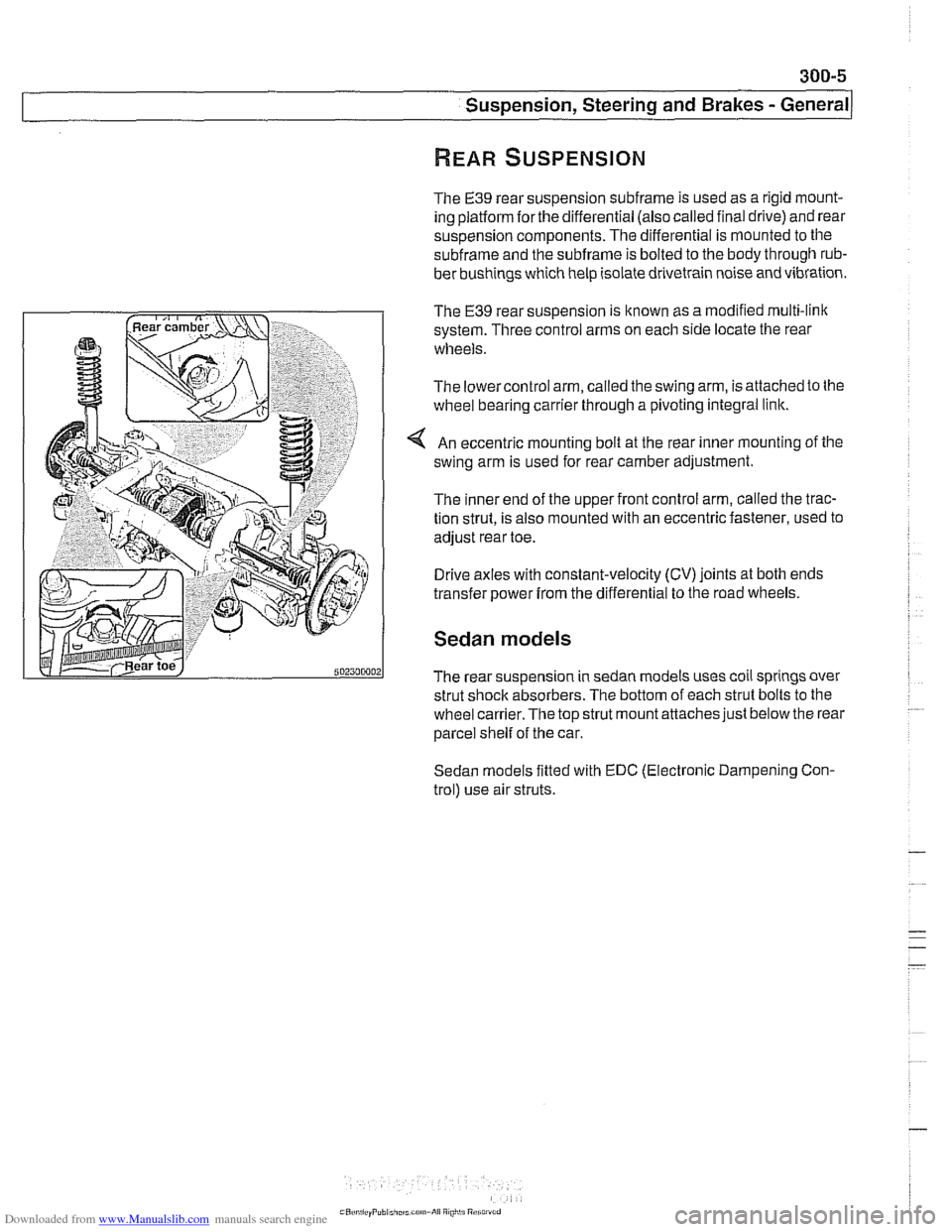

The E39 rear suspension subframe is used as a rigid mount-

ing platform

forthe differential (also called final drive) and rear

suspension components. The differential is mounted to the

subframe and the subframe is bolted to the body through rub-

ber bushings which help isolate drivetrain noise and vibration.

The

€39 rear suspension is known as a modified multi-link

system. Three control arms on each side locate the rear

wheels.

The lowercontrol arm, called the swing arm, is attached to the

wheel bearing carrier through a pivoting integral link.

An eccentric mounting bolt at the rear inner mounting of the

swing arm is used for rear camber adjustment.

The inner end of the upper front control arm, called the trac-

tion strut, is also mounted with an eccentric fastener, used to

adjust rear toe.

Drive axles with constant-velocity (CV) joints at both ends

transfer power

from the differential to the road wheels.

Sedan models

The rear suspension in sedan models uses coil springs over

strut shock absorbers. The bottom of each strut bolts to the

wheel

carrier.The top strut mount attaches just below the rear

parcel shelf of the car.

Sedan models fitted with EDC (Electronic Dampening Con-

trol) use air struts.