300 BMW 525i 2001 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 669 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~li~nrnentl

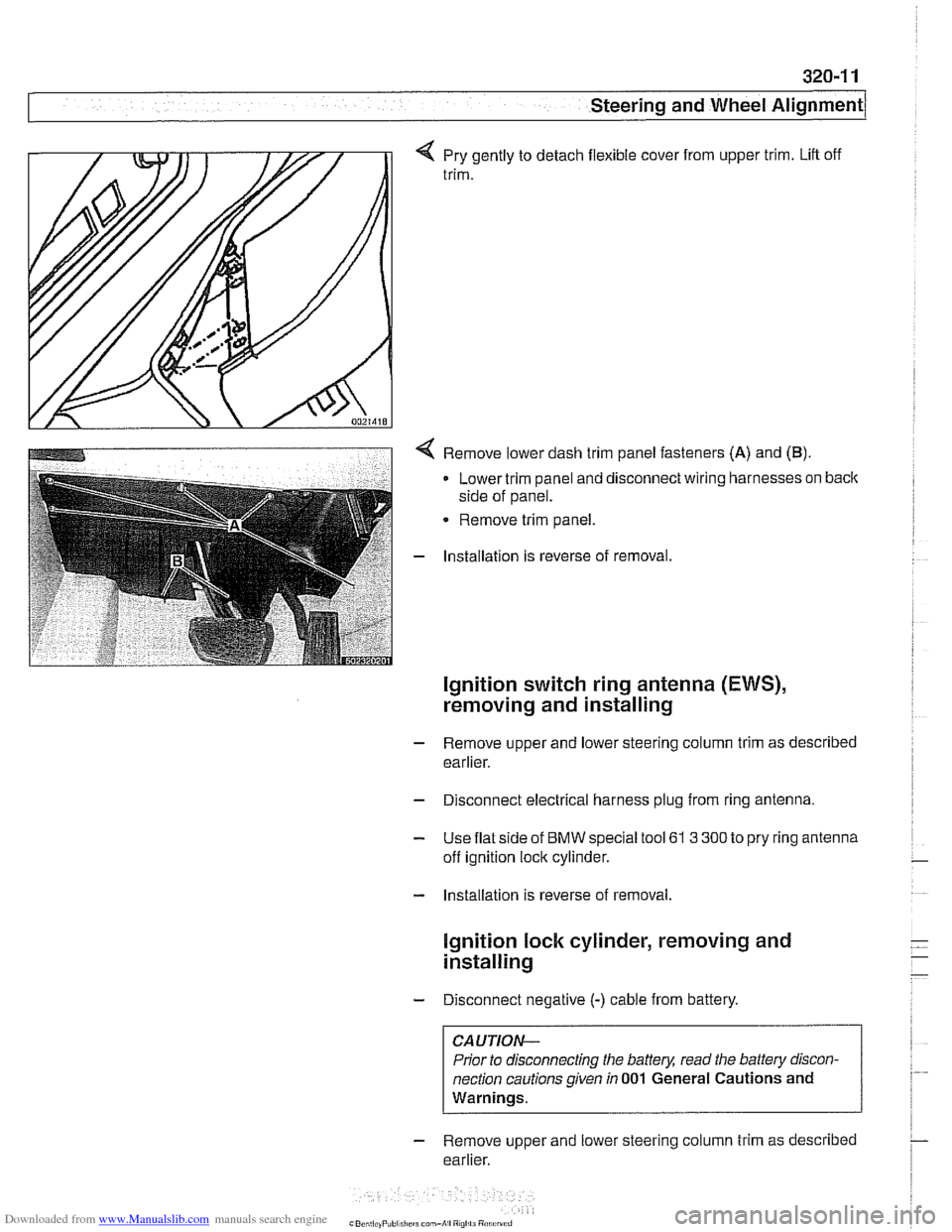

q Pry gently to detach flexible cover from upper trim. Lift off

trim.

< Remove lower dash trim panel fasteners (A) and (B).

Lower trim panel and disconnect wiring harnesses on back

side of panel.

Remove trim panel.

- Installation is reverse of removal.

Ignition switch ring antenna (EWS),

removing and installing

- Remove upper and lower steering column trim as described

earlier.

- Disconnect electrical harness plug from ring antenna.

- Use flat side of BMW special tool 61 3 300 to pry ring antenna

off ignition lock cylinder.

- Installation is reverse of removal.

lgnition lock cylinder, removing and

installing

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

- Remove upper and lower steering column trim as described

earlier.

Page 693 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

- Tighten nut while counterholding adjusting bolt,

- Tighten nut only after car has been lowered to ground and

suspension has settled.

Preparing for alignment

- The following conditions are necessary prior to wheel align-

ment:

Correct wheels and tires are installed, in good condition,

and are at the correct inflation pressures.

All steering and suspension parts and bushings are un-

damaged and show no signs of abnormal wear. Wheel

bearings are in good condition.

Ride height is in accordance with specifications. See

300

Suspension, Steering and Brakes-General.

Car is in normal loaded position. See below.

* Cars with air suspension: Remove air suspension power

fuse.

Normal loaded position

Each front seat

68 Kg (I50 lb)

Center of rear seat

Trunlc

Fuel tank

68 Kg (150 lb)

21 Kg (46 lb)

Full

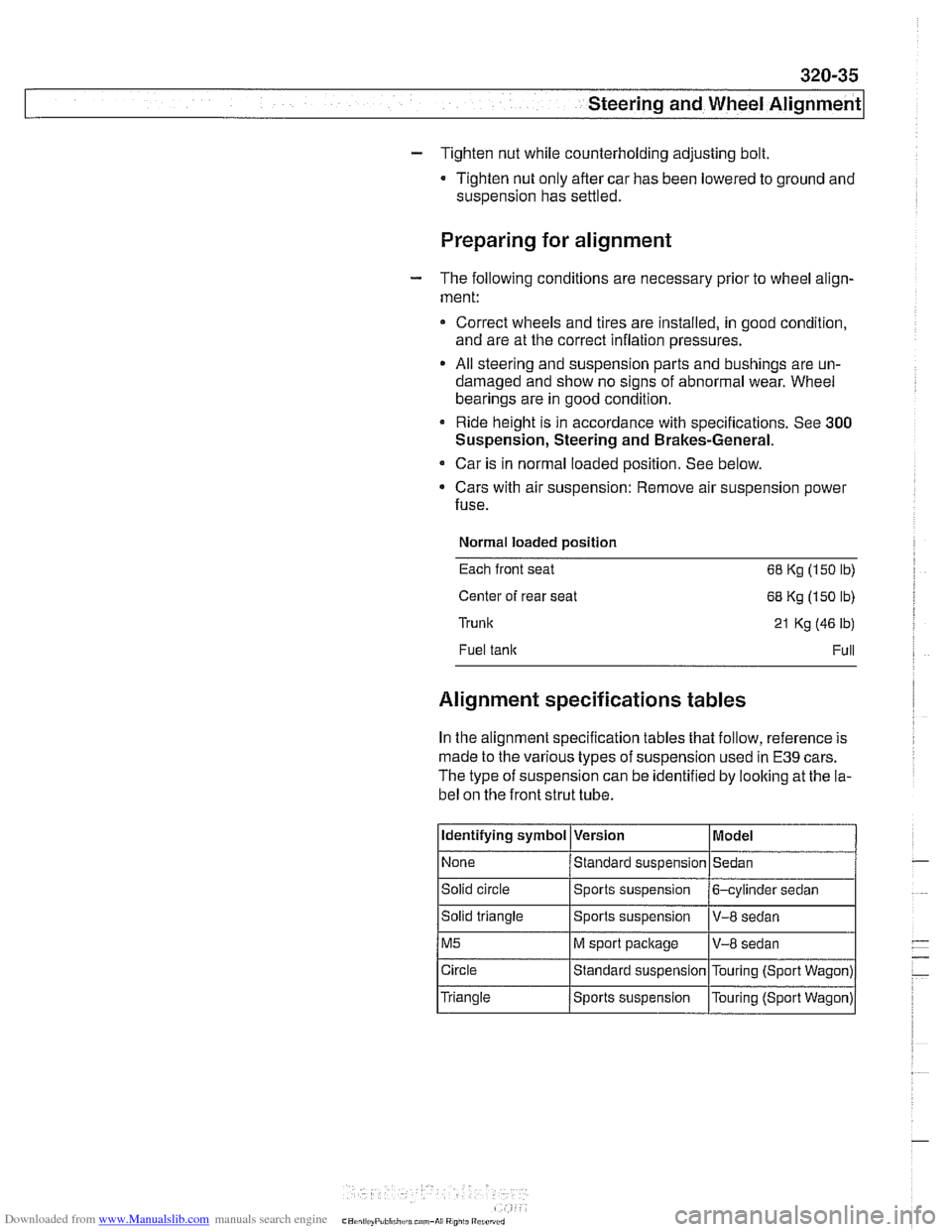

Alignment specifications tables

In the alignment specification tables that follow, reference is

made to the various types of suspension used in

E39 cars.

The type of suspension can be identified by loolting at the la-

bel on the front strut tube.

Identifying symbol

None

Solid circle

Solid triangle

M5

Circle

Triangle Version

Standard suspension

Sports

suspension

Sports suspension

M sport package

Standard suspension

Sports suspension Model

Sedan

6-cylinder sedan

V-8 sedan

V-8 sedan

Touring (Sport Wagon)

Touring (Sport Wagon)

Page 698 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-2

I Rear Suspension

This repair group covers removal and replacement of E39

rear suspension components. A general description of sus-

pension systems and ride height specifications can be found

in 300 Suspension, Steering and Brakes - General.

CAUTIOI\C

Some E39 models are equipped with aluminum suspen-

sion components. The following cautions apply:

Due to the chemical and corrosion characteristics of

aluminum, do not bring into contact with battery acid.

- Do not clean with wire brushes with brass or iron bris-

tles. Only use brushes with stainless steel bristles.

Do not expose to flying

sparl~s from grinding/cutting op-

erations.

* Do not subject to steel welding splashes.

0 Do not expose to temperatures over 80°C (176°F).

even for shortperlods. Temperatures in painting facili-

ties are not a problem.

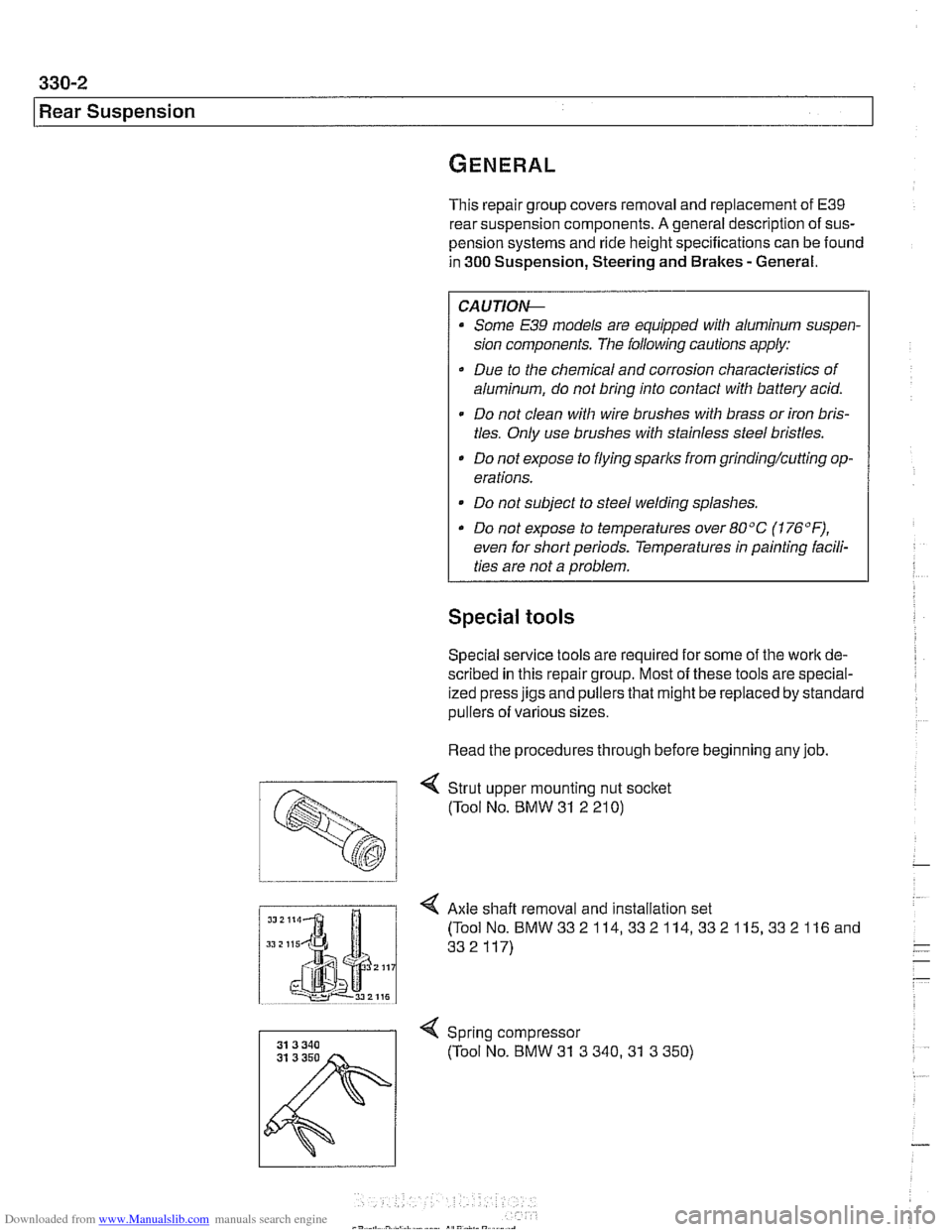

Special tools

Special service tools are required for some of the work de-

scribed in this repair group. Most of these tools are special-

ized press jigs and pullers that might be replaced by standard

pullers of various sizes.

Read the procedures through before beginning any job.

< Strut upper mounting nut socket

(Tool No. BMW

31 2 21 0)

I Axle shaft removal and installation set

Spring compressor (Tool No. BMW

31 3 340.31 3 350)

Page 705 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

C. -- -- - -- Rear ~us~ensionl

Depending on year and model applications, the Sport Wagon

rear suspension may be equipped with:

Conventional shock absorbers and coil springs

Electronic height control (EHC) system which incorporates

air springs

NOTE-

. Suspension and EHC troubleshooting is covered in 300

Suspension, Steering and Brakes-General.

EHC system repairs, other than air spring replacement,

are covered in Electronic height control

(EHC) compo-

nent replacement.

Replace shock absorbers and springs in pairs only.

Rear shock absorber, removing and

installing

- Raise car and remove rear wheels,

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jack stands under

suspension parts.

CAUTION-

If working on a vehicle with compressedairshock absorbers,

disable air supply pump by disconnecting electrical plug be-

fore performing any repairs. Pump is located beneath a cover

under the spare tire in the floor of the cargo compartment.

- Support swing arm from below

CAUTIOG

The shock absorber prevents the drive axle and wlieel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the shock absorber

mounting fasteners prevents damage to the

brake hose,

parking

brake cable and drive axle CVjoints.

- Working in cargo compartment, remove carpet. Remove tri-

angular upper shock mount covers located beside spare tire

well.

- If applicable: Detach air supply line from shock absorber.

Plug ports and lines to keep out dirt.

Page 724 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-28

Rear Suspension

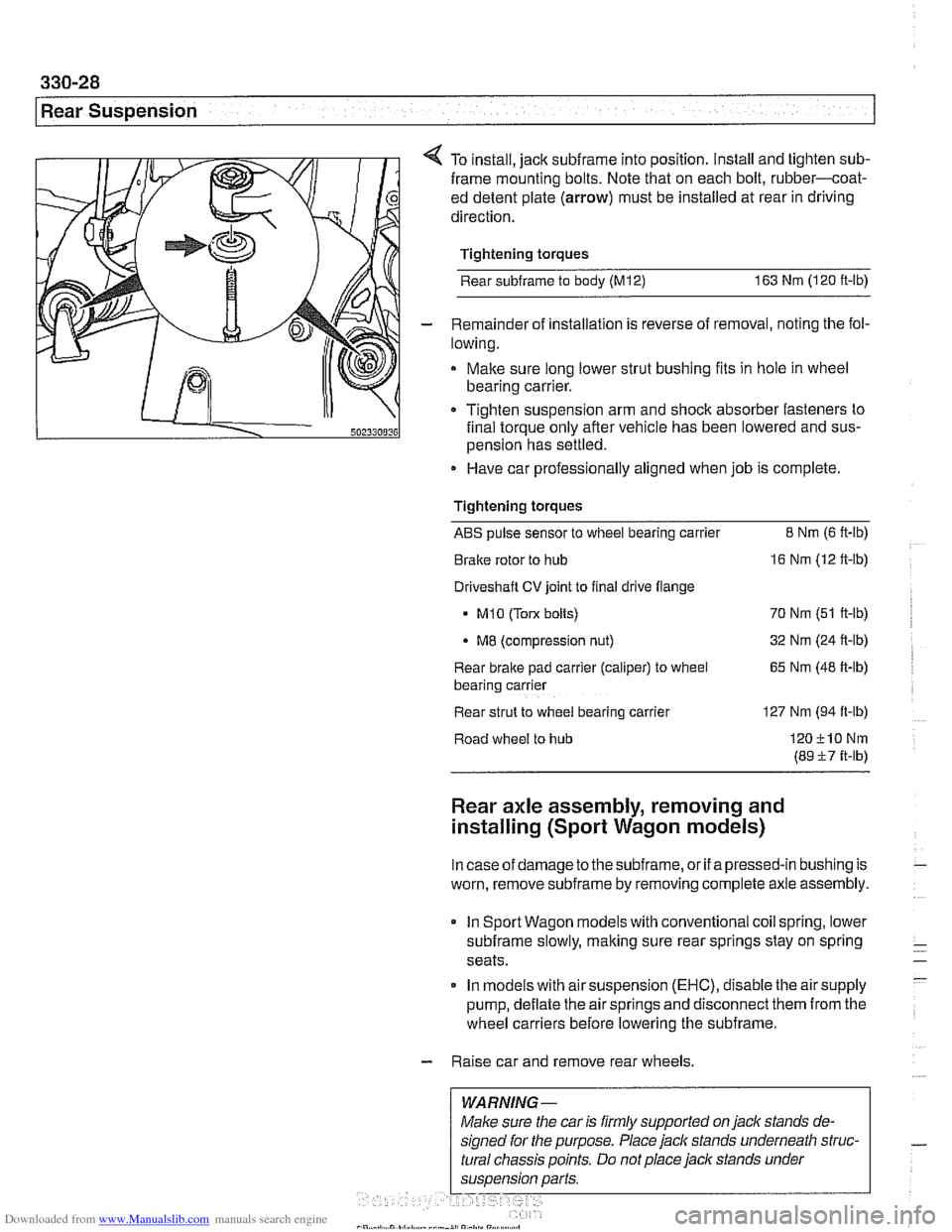

4 To install, jack subframe into position. Install and tighten sub-

frame mounting bolts. Note that on each bolt, rubber-coat-

ed detent plate

(arrow) must be installed at rear in driving

direction.

Tightening torques

Rear

subframe to body (M12) 163 Nm (120 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Make sure long lower strut bushing fits in hole in wheel

bearing carrier.

111 0 Tighten suspension arm and shoclc absorber fasteners to

502330036 final torque only afler vehicle has been lowered and sus-

pension has settled.

Have car professionally aligned when job is complete

Tightening torques

ABS pulse sensor to wheel bearing carrier 8 Nrn (6 ft-lb)

Brake rotor to hub

16 Nm (12 ft-lb)

Driveshaft

CV joint to final drive flange

- MI0 (Tow bolts) 70 Nm (51 ft-lb)

MB (compression nut) 32

Nm (24 ft-lb)

Rear brake pad

carrler (caliper) to wheel 65 Nm (48 ft-lb)

bear~ng carrler

Rear strut to

wheel bearlng carrler 127 Nm (94 ft-lb)

Road wheel to hub

120210Nrn

(89 57 ft-lb)

Rear axle assembly, removing and

installing (Sport Wagon models)

Incaseof damage to thesubframe, or if apressed-in bushing is

worn, remove

subframe by removing complete axle assembly.

In Sport Wagon models with conventional coil spring, lower

subframe slowly, making sure rear springs stay on spring

seats.

In models with air suspension

(EHC), disable the air supply

pump, deflate the air springs and disconnect them from the

wheel carriers before lowering the subframe.

- Raise car and remove rear wheels.

WARNING-

Page 731 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-35

Rear Suspension

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Always use new self-loclting nuts.

Make sure all threaded bolts, nuts and mating suriaces are

clean.

Make sure long lower strut bushing fits in hole in wheel

bearing carrier.

Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Stake axle collar nut after tightening.

Tightening torques

ABS pulse sensor to wheel bearing carrier

8 Nm (6 ft-lb)

Brake rotor to hub 16 Nm (12 ft-lb)

Rear brake pad carrier (caliper) to wheel 65

Nm (48

ft-lb)

bearing carrier

Rear axle shaft to hub

(M27) 300 Nm (221 ft-lb)

Rear strut to wheel bearing carrier 127

Nrn (94 ft-lb)

Road wheel to hub

120+10 Nm

(89

i7 ft-lb)

Swing arm to wheel bearing carrier 256

Nrn (189 ft-lb)

Upper front control arm (traction strut) to 65 Nrn

(48

ft-lb)

wheel carrier

Upper rear control arm to wheel carrier 142

Nrn (105

ft-lb)

Rear wheel bearing carrier, removing and

installing (Sport Wagon models)

- Raise rear end of car and remove wheel.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

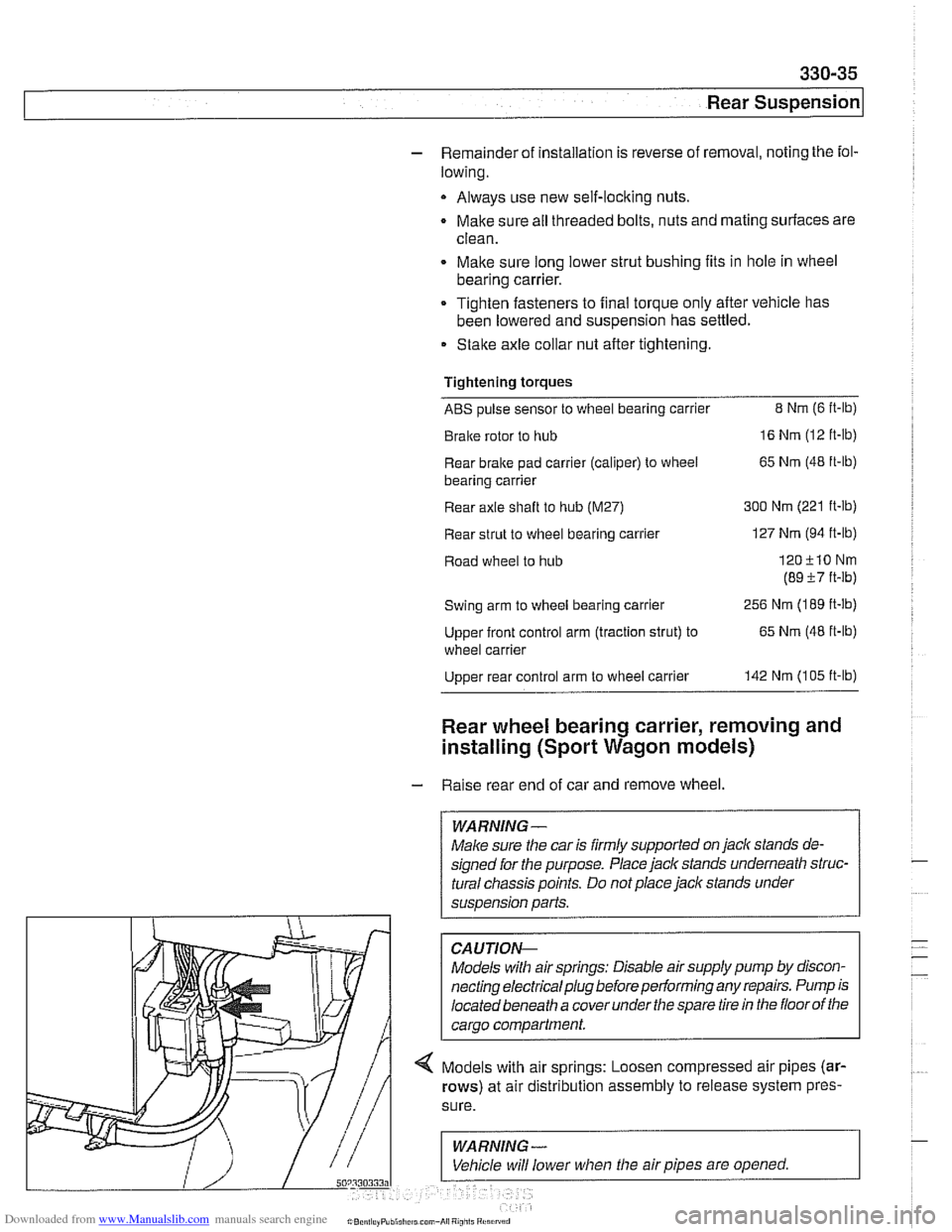

Models

with air springs: Disable air supply pump by discon-

necting electricalplug

beforepedormingany repairs. Pump is

located beneath a cover under the spare tire in the floor of the

cargo compartment.

-- 4 Models with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres-

Page 735 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-39

I Rear suspension1

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Models with coil springs: Fit spring correctly in lower spring

seat.

* Models with air suspension: Fit eccentric lug at bottom of

air spring in recess of wheel carrier spring seat.

Always use new self-locking nuts.

- Make sure all threaded bolts, nuts and mating surfaces are

clean.

a Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Stake axle collar nut afler tightening.

Tightening torques

ABS pulse sensor to wheel bearing 8 Nm (6

ft-lb)

carrier

Air spring to wheel bearing carrier 20 Nm (15 ft-lb)

Brake rotor to hub 16 Nm (12

it-lb)

Rear axle shaft to hub (M27) 300 Nm (221 ft-lb)

Rear brake pad carrier (caliper) to wheel 65 Nm (48 ft-lb)

bearing carrier

Road wheel to hub

120ilONm

(89 k7 ft-lb)

Swing arm to wheel bearing carrier 256 Nm (189 it-lb)

Upperfrontcontrol arm (traction strut) to 65 Nm (48 ft-lb)

wheel carrier

Upper rear control arm to wheel carrier 142 Nm (105 ft-lb)

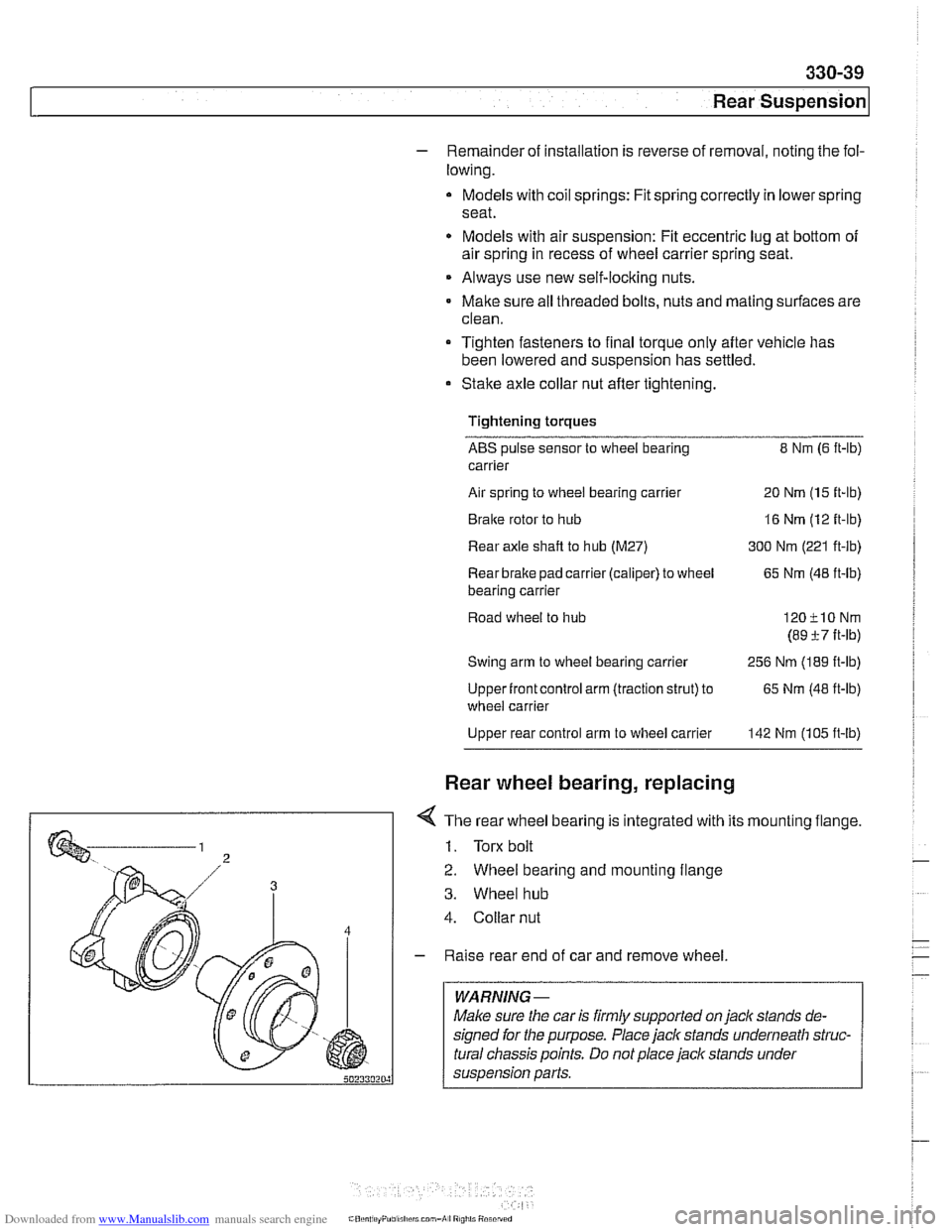

Rear wheel bearing, replacing

< The rear wheel bearing is integrated with its mounting flange.

1. Torx bolt

2. Wheel bearing and mounting flange

3. Wheel hub

4. Collar nut

- Raise rear end of car and remove wheel.

WARNING -

Make sure the car is firmly supported on jaclc stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

Page 738 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-42

/Rear Suspension

- Install ABS sensor and road wheel.

- Lower car to ground. With an assistant applying brakes, use

new axle collar nut to tighten to final torque. Stake nut.

- Remainder of installation is reverse of removal

Tightening torques ABS pulse sensor to wheel bearing carrier

8 Nm (6 ft-lb)

Brake disc to hub

16 Nm

Rear

brake pad carrier (caliper) to wheel

65 Nm (48 ft-lb)

bearing carrier

Rear axle shaft to hub

(M27) 300 Nrn (221 ft-lb)

Road wheel to hub 120F10 Nm

(89 ?7 ft-lb)

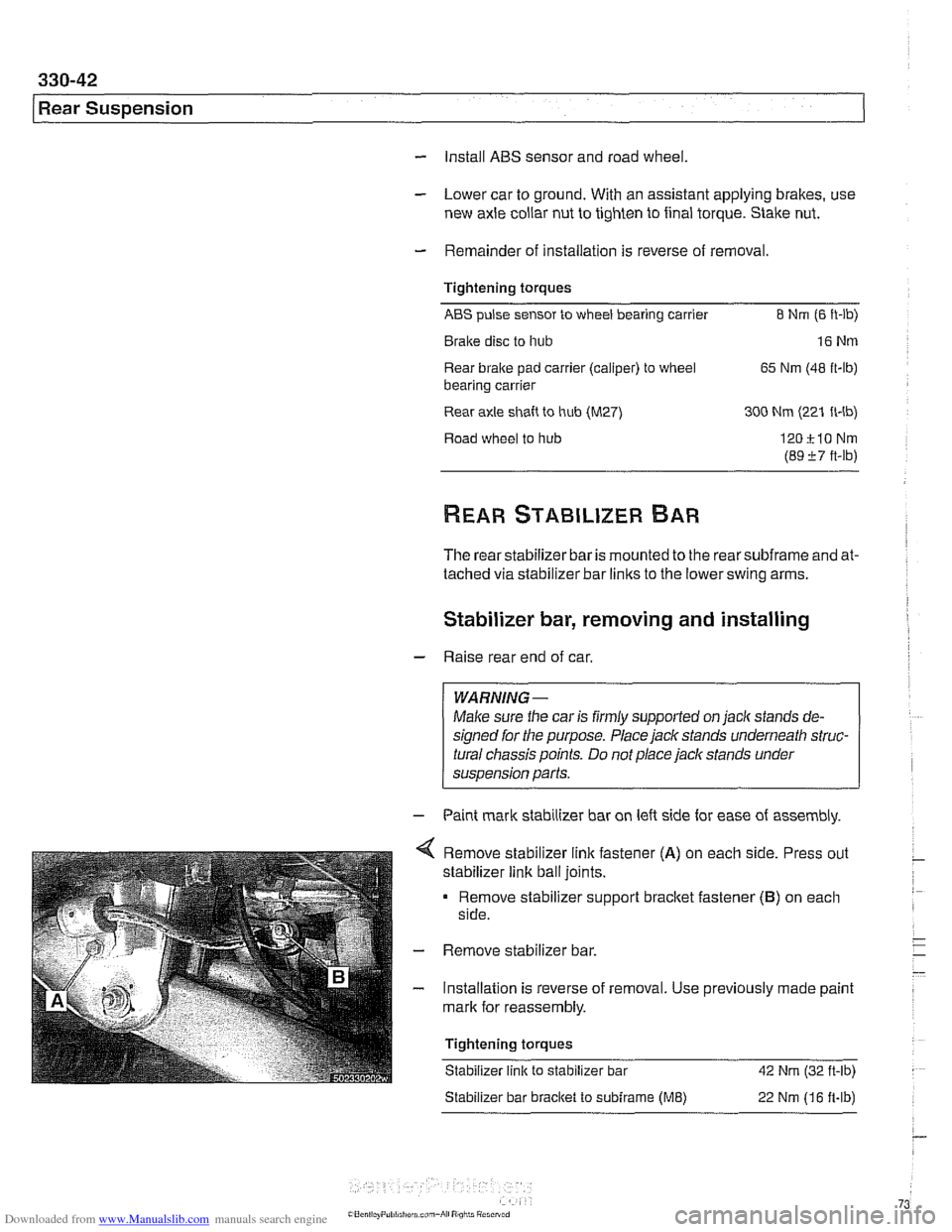

The rearstabilizer bar is mounted to the rear

subframe and at-

tached via stabilizer bar

linlts to the lower swing arms.

Stabilizer bar, removing and installing

- Raise rear end of car.

WARNING -

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension parts.

- Paint mark stabilizer bar on left side for ease of assembly.

Remove stabilizer link fastener

(A) on each side. Press out

stabilizer link ball joints.

Remove stabilizer support bracket fastener

(B) on each

side.

Remove stabilizer bar.

Installation is reverse of removal. Use previously made paint

mark for reassembly.

Tightening torques Stabilizer link to stabilizer bar

42 Nm (32 ft-lb)

Stabilizer bar bracket to sublrame (ME) 22 Nm (1 6 fi-lb)

Page 740 of 1002

Downloaded from www.Manualslib.com manuals search engine

---

Rear Suspension

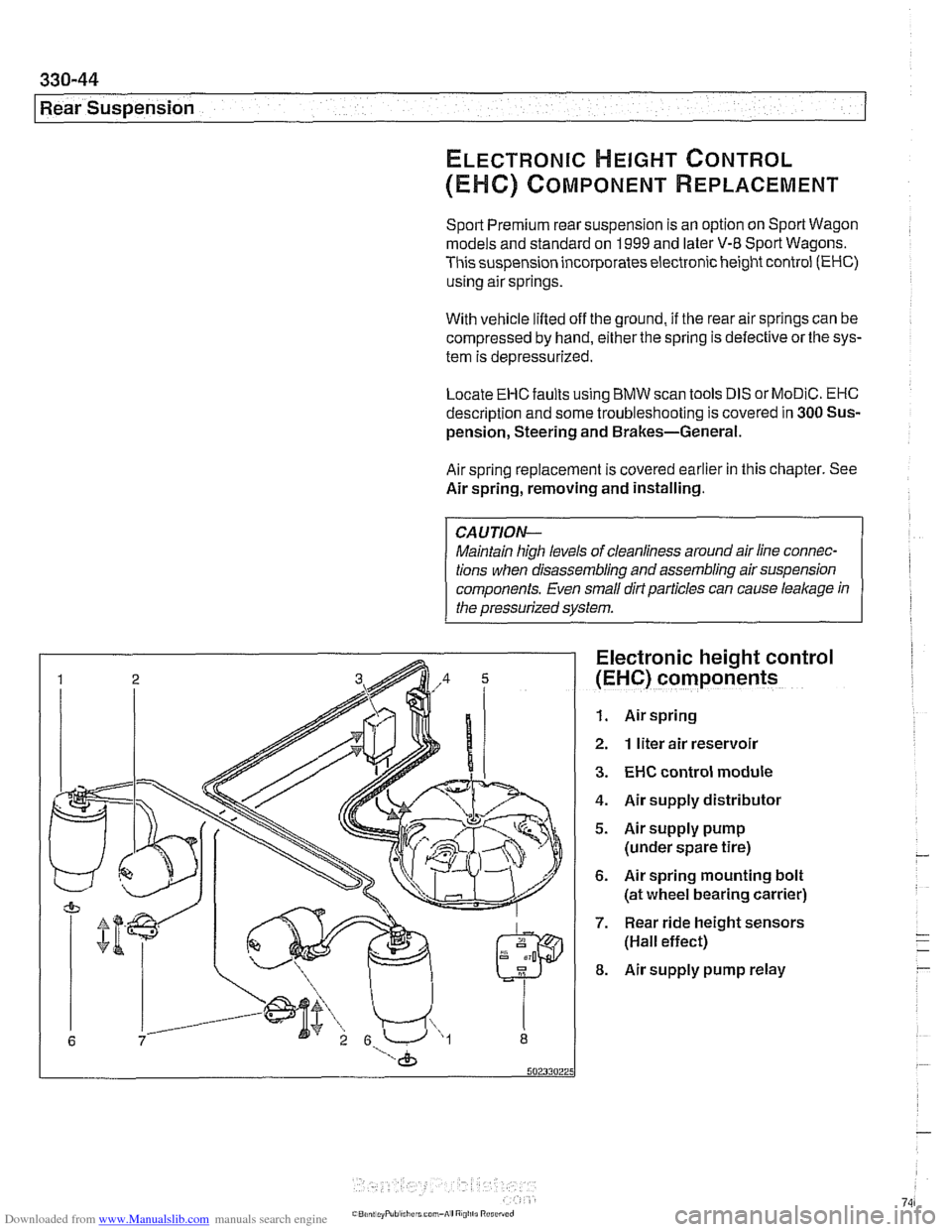

ELECTRONIC HEIGHT CONTROL

(EHC) COMPONENT REPLACEMENT

Sport Premium rear suspension is an option on Sport Wagon

models and standard on

1999 and later V-8 Sport Wagons.

This suspension incorporates electronic height control

(EHC)

using air springs.

With vehicle lifted off the ground,

if the rear air springs can be

compressed by hand, either the spring is defective or the sys-

tem is depressurized.

Locate

EHC faults using BMW scan tools DIS or MoDiC. EHC

description and some troubleshooting is covered in 300 Sus-

pension, Steering and Brakes-General.

Air spring replacement is covered earlier in this chapter. See

Air spring, removing and installing.

CAUTION-

Maintain high levels of cleanliness around air line connec-

tions when disassembling and assembling air suspension

components. Even

small dirt particles can cause leakage in

the pressurized system.

Electronic height control

(EHC) components

1. Air spring

2. 1 liter air reservoir

3. EHC control module

4. Air supply distributor

5. Airsupply pump

(under spare tire)

6. Air spring mounting bolt

(at wheel bearing carrier)

7. Rear ride height sensors

(Hall effect)

8. Air supply pump relay

Page 753 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-9

Final Drive

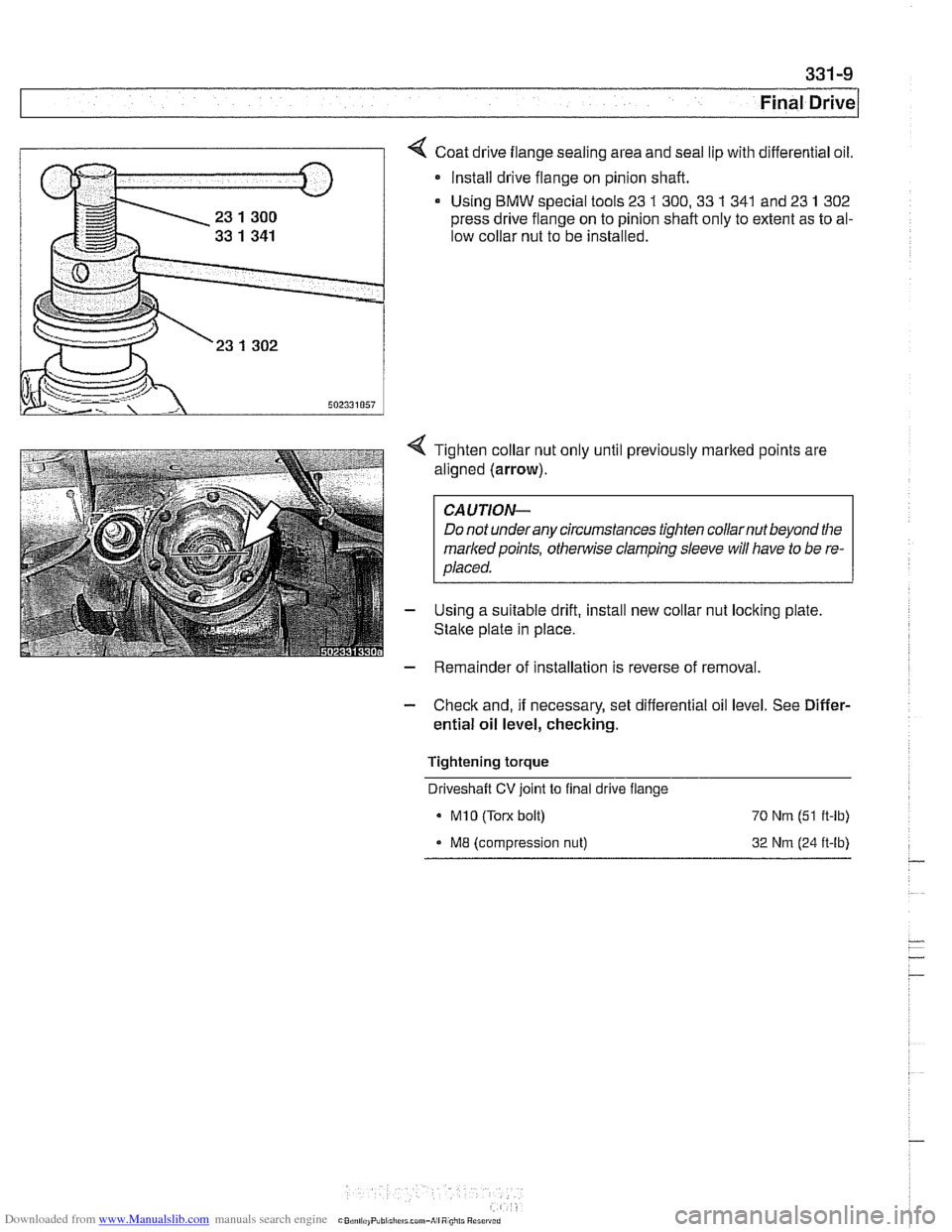

Coat drive flange sealing area and seal lip with differential oil.

* Install drive flange on pinion shaft.

Using

BMW special tools 23 1 300,33 1 341 and 23 1 302

press drive flange on to pinion shaft only to extent as to al-

low collar nut to be installed.

4 Tighten collar nut only until previously marked points are

aligned (arrow).

CAUTION-

Do not underany circumstances tighten collarnut beyond the

markedpoints,

othe~lise clamping sleeve will have to be re-

placed.

- Using a suitable drift, install new collar nut locking plate

Stalte plate in place.

- Remainder of installation is reverse of removal.

- Check and, if necessary, set differential oil level. See Differ-

ential oil level, checking.

Tightening torque Driveshaft

CV joint to final drive flange

MI0 (Torx bolt) 70 Nrn (51 ft-lb)

ME (compression nut) 32 Nrn (24 ft-lb)