300 BMW 525i 2001 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 567 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Manual ~ransmissionl

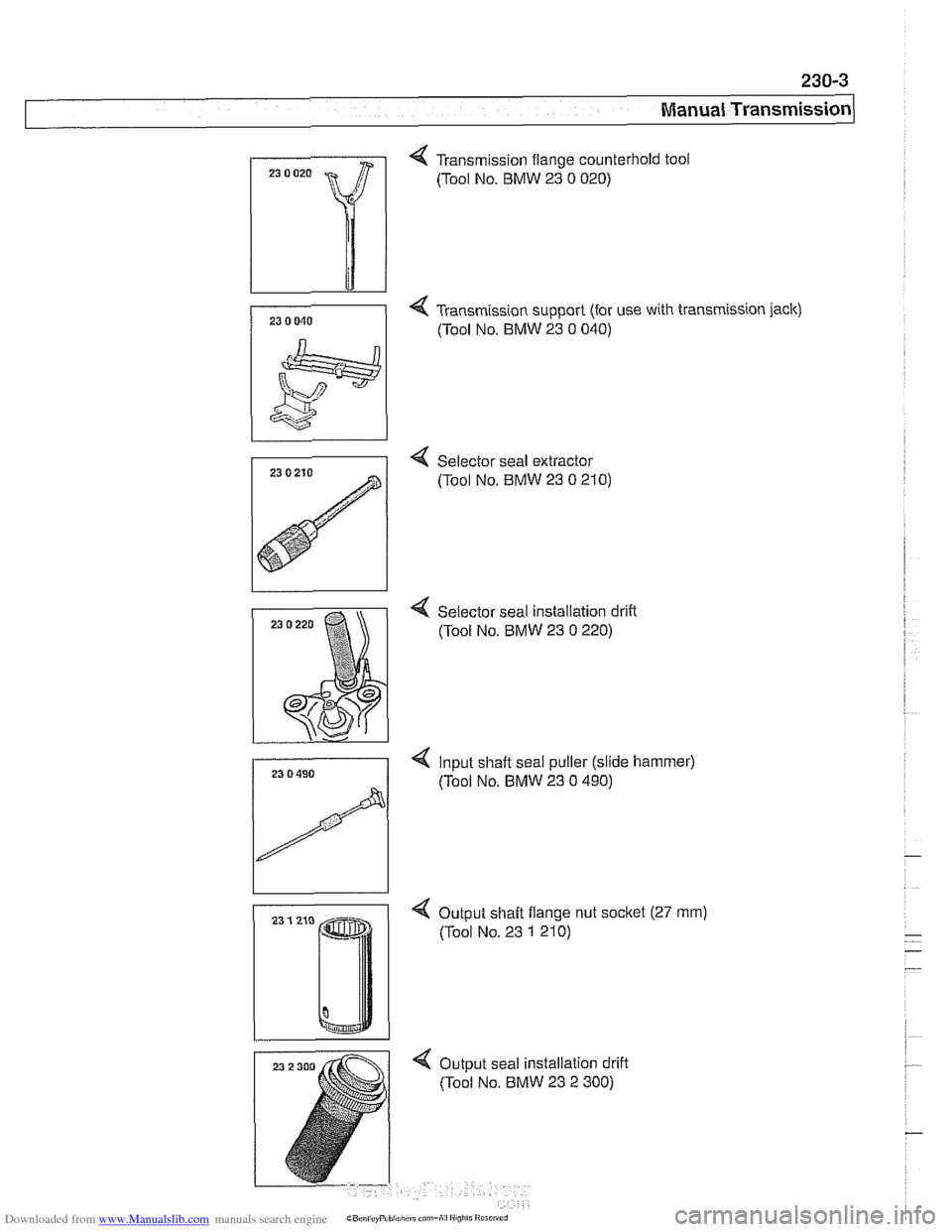

4 Transmission flange counterhold tool

(Tool No. BMW 23 0 020)

4 Transmission support (for use with transmission jack)

(Tool No. BMW 23

0 040)

Selector seal extractor

(Tool No. BMW 23

0 210)

4 Selector seal installation drifl

(Tool No. BMW 23

0 220)

4 Input shaft seal puller (slide hammer)

(Tool No. BMW 23

0 490)

4 Output shaft flange nut socltet (27 mm)

(Tool No. 23

1 210)

4 Output seal installation drift

(Tool No.

BMW 23 2 300)

EBlislltliPubiilir~ti corn-ill R~l1l. Rriniurd

Page 575 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 1

Manual ~ransmissionl

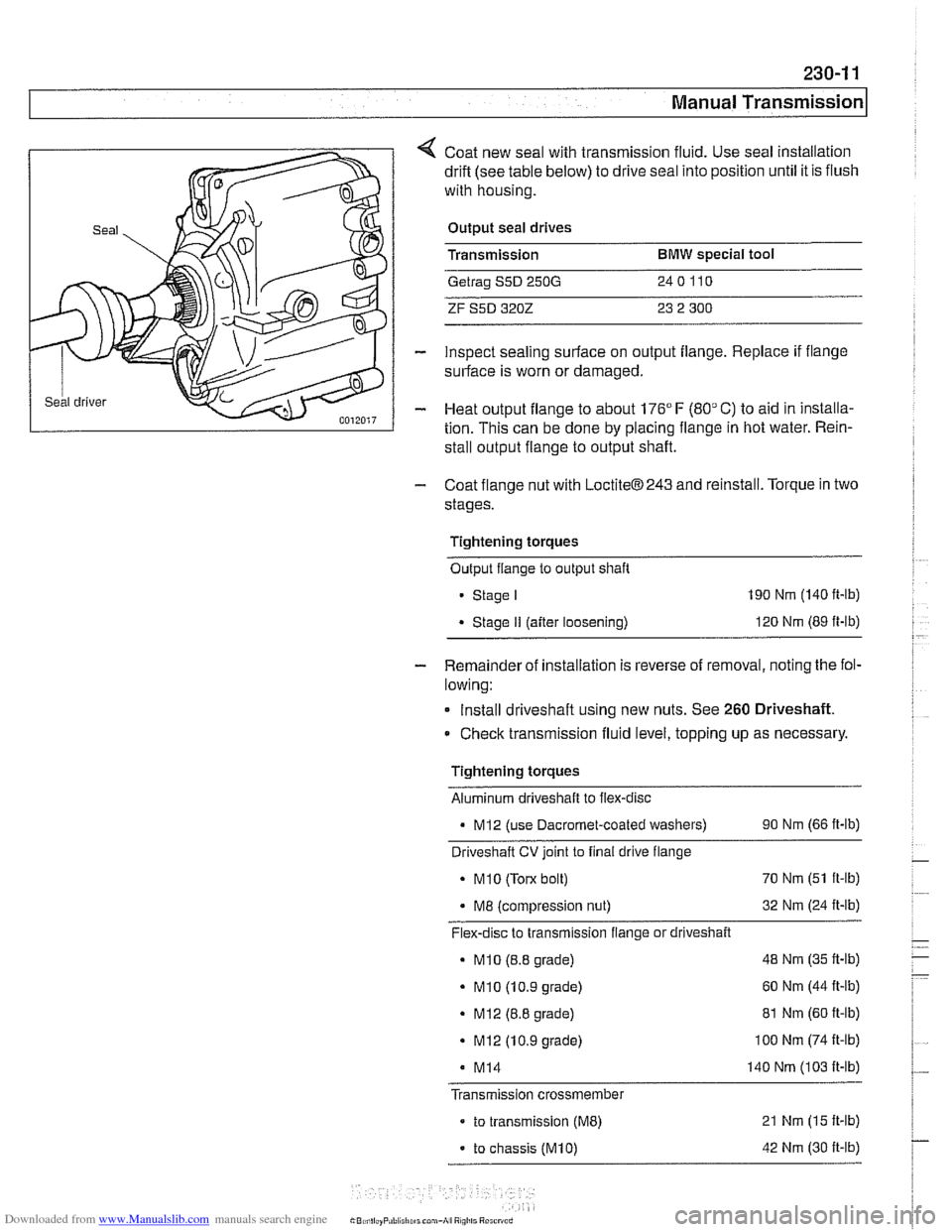

Coat new seal with transmission fluid. Use seal installation

drift (see table below) to drive seal into position until it is flush

with housing.

Output seal drives

Transmission

BMW special tool

Getrag S5D 250G 240110

ZF S5D 3202 23 2 300

inspect sealing surface on output flange. Replace if flange

surface is worn or damaged.

Heat output flange to about 176"

F (80" C) to aid in installa-

tion. This can be done by placing flange in hot water. Rein-

stall output flange to output shaft.

- Coat flange nut with LoctiteB243 and reinstall. Torque in two

stages.

Tightening torques Output flange to output shaft

Stage I 190 Nm (140 ft-lb)

Stage II (after loosening) 120

Nm (89 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Check transmission fluid level, topping up as necessary

Tightening torques Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

. MI0 (Torx bolt) 70

Nm (51 ft-lb)

. M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

- MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60

Nm (44 It-lb)

. MI2 (8.8 grade) 81 Nm (60 ft-lb)

. MI2 (10.9 grade) I00 Nm (74 It-lb)

M14 140 Nm (103 It-lb)

Transmission crossmember

- to transmission (ME) 21 Nm (15 It-lb)

- to chassis (M10) 42 Nm (30 It-lb)

Page 587 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-3

Automatic Transmission

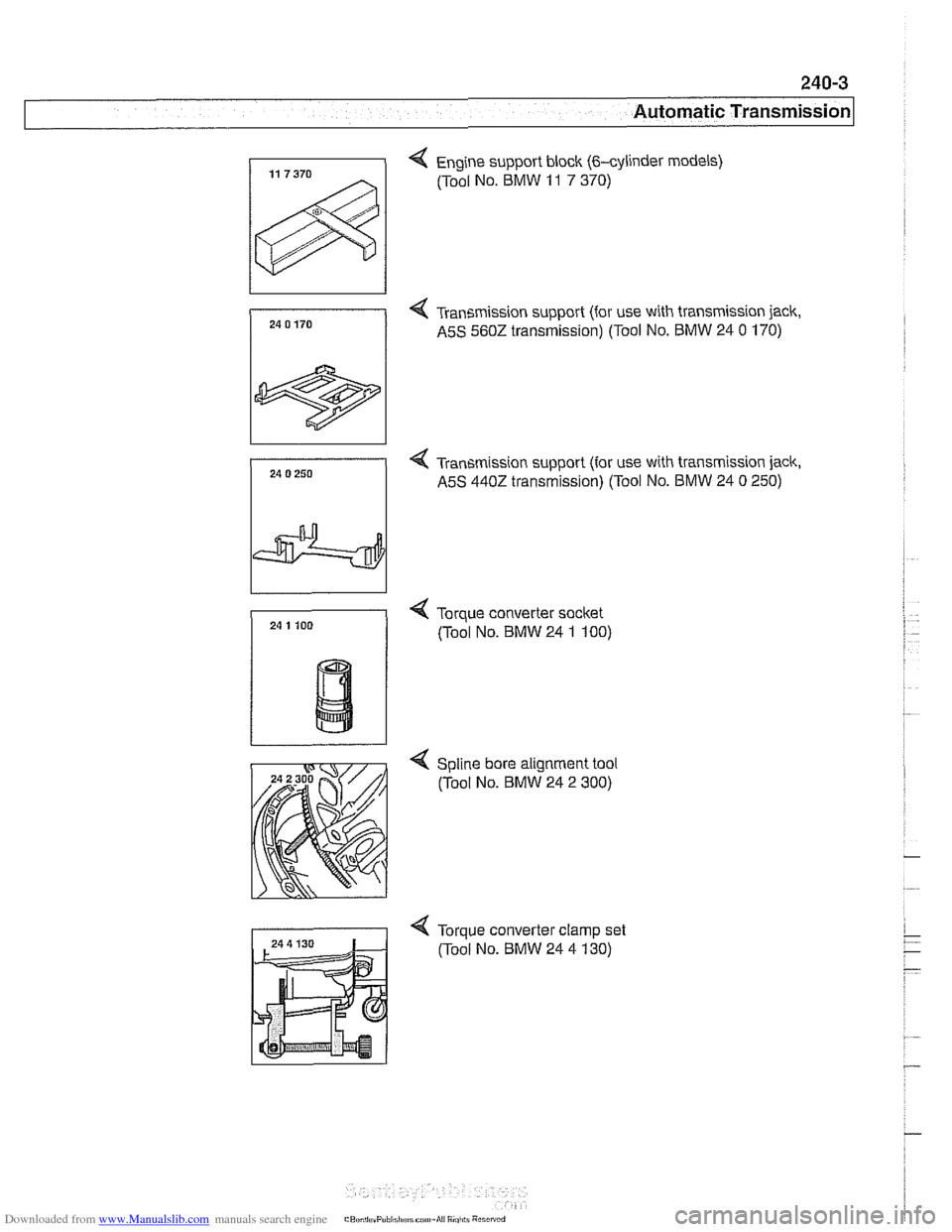

4 Engine support block (&cylinder models)

(Tool No. BMW

11 7 370)

4 Tran5mission support (for use with transmission jack,

A5S 560Z transmission) (Tool No. BMW 24

0 170)

4 Transmission support (for use with transmission jack,

A5S

4402 transmission) (Tool No. BMW 24 0 250)

4 Torque converter socket

(Tool No. BMW 24 1 100)

< Spline bore alignment tool

(Tool No.

BMW 24 2 300)

Page 597 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 3

Automatic ~ransmissionl

- Blow out oil cooler lines with low-pressure compressed air

and flush cooler with clean ATF twice before reattaching lines

to transmission.

CA UTIOG

Wear safety glasses when worling with compressed air:

@ Do not reuse ATF used for flushing.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Reinstall driveshafl using new nuts.

Install new sealing washers on transmission cooling line

banjo bolts.

Install new O-rings on transmission cooler lines, where

applicable.

Inspect engine drive plate (flywheel) for cracks or elongat-

ed holes. Replace

if necessary.

Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Checlc to be sure torque converter is seated correctly in

transmission during final installation.

Use

BMW special tool 24 2 300 to align three mounting

tabs on torque converter with indentations on drive plate

(flywheel).

Fill transmission with clean ATF until oil level is even with

fill hole. Then check fluid level as described earlier.

Adjust gearshift mechanism. See

250 Gearshift Linkage.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

Page 621 of 1002

Downloaded from www.Manualslib.com manuals search engine

300 Suspension. Steering and Brakes .

Genera8

General ........................... .30 0.2

Aluminum suspension components

...... .30 0.2

Front Suspension ................. .30 0.2

Front suspension 6-cylinder models

(525i.5281. 530i) ..................... .30 0.3

Front suspension V-8 models (540i) ...... .30 0.4

Rear Suspension .................. .30 0.5

Sedan models

....................... .30 0.5

Rear suspension sedan models ........ .30 0.6

Sport Wagon models ................. .30 0.6

Rear suspension Sport Wagon

(with coil springs)

.................... .30 0.7

Rear suspension Sport Wagon

(EHC with air springs)

................. .30 0.8

EHC operational diagram .............. .30 0.9

Steering ......................... .30 0.10

Rack-and-pinion steering ............. .30 0.10

Recirculating ball and nut steering ...... .30 0.10

..................... Brake System 300-10

Wheels and Tires ................. 300-1 1

............... Rim and tire sizes table 300-1 1

Electronic Brake and Stability

.................. Control Systems 300-1 1

E39 electronic brake and stability

........ control systems application table 300-12

........................ ABS system 300-1 2

Automatic Stability Control (ASC)

....... 300-12

ABSIASC traction control system ....... 300-13

Dynamic Stability Control (DSC)

........ 300-14

Ride Height ....................... 300-14

......... Front ride height specifications 300-1 5

......... Rear ride height specifications 300-16

Page 623 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-3

Suspension, Steering and Brakes - General

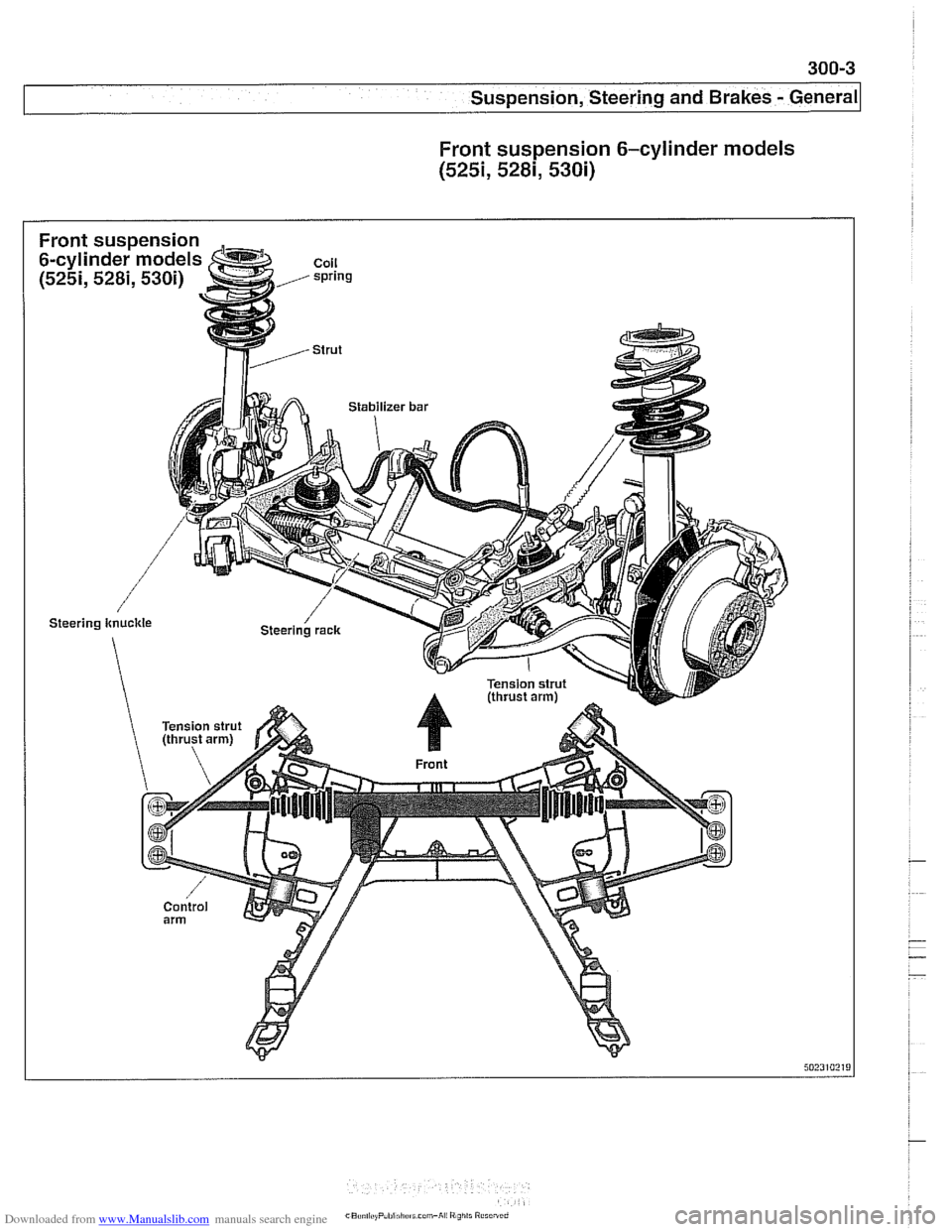

Front suspension 6-cylinder models

(5251, 5281, 530i)

Page 625 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-5

Suspension, Steering and Brakes - ~enerall

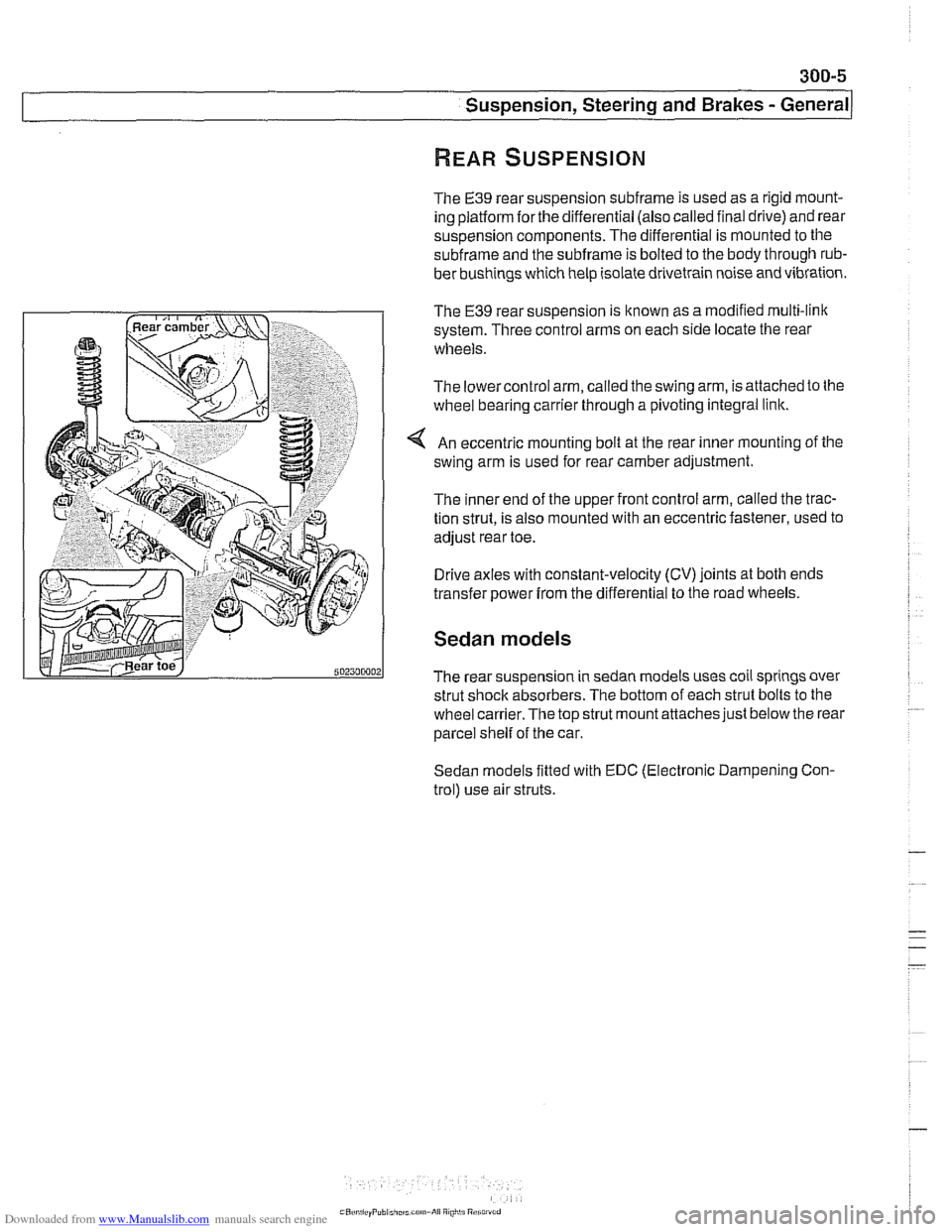

The E39 rear suspension subframe is used as a rigid mount-

ing platform

forthe differential (also called final drive) and rear

suspension components. The differential is mounted to the

subframe and the subframe is bolted to the body through rub-

ber bushings which help isolate drivetrain noise and vibration.

The

€39 rear suspension is known as a modified multi-link

system. Three control arms on each side locate the rear

wheels.

The lowercontrol arm, called the swing arm, is attached to the

wheel bearing carrier through a pivoting integral link.

An eccentric mounting bolt at the rear inner mounting of the

swing arm is used for rear camber adjustment.

The inner end of the upper front control arm, called the trac-

tion strut, is also mounted with an eccentric fastener, used to

adjust rear toe.

Drive axles with constant-velocity (CV) joints at both ends

transfer power

from the differential to the road wheels.

Sedan models

The rear suspension in sedan models uses coil springs over

strut shock absorbers. The bottom of each strut bolts to the

wheel

carrier.The top strut mount attaches just below the rear

parcel shelf of the car.

Sedan models fitted with EDC (Electronic Dampening Con-

trol) use air struts.

Page 626 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-6

/Suspension, Steering and Brakes - General

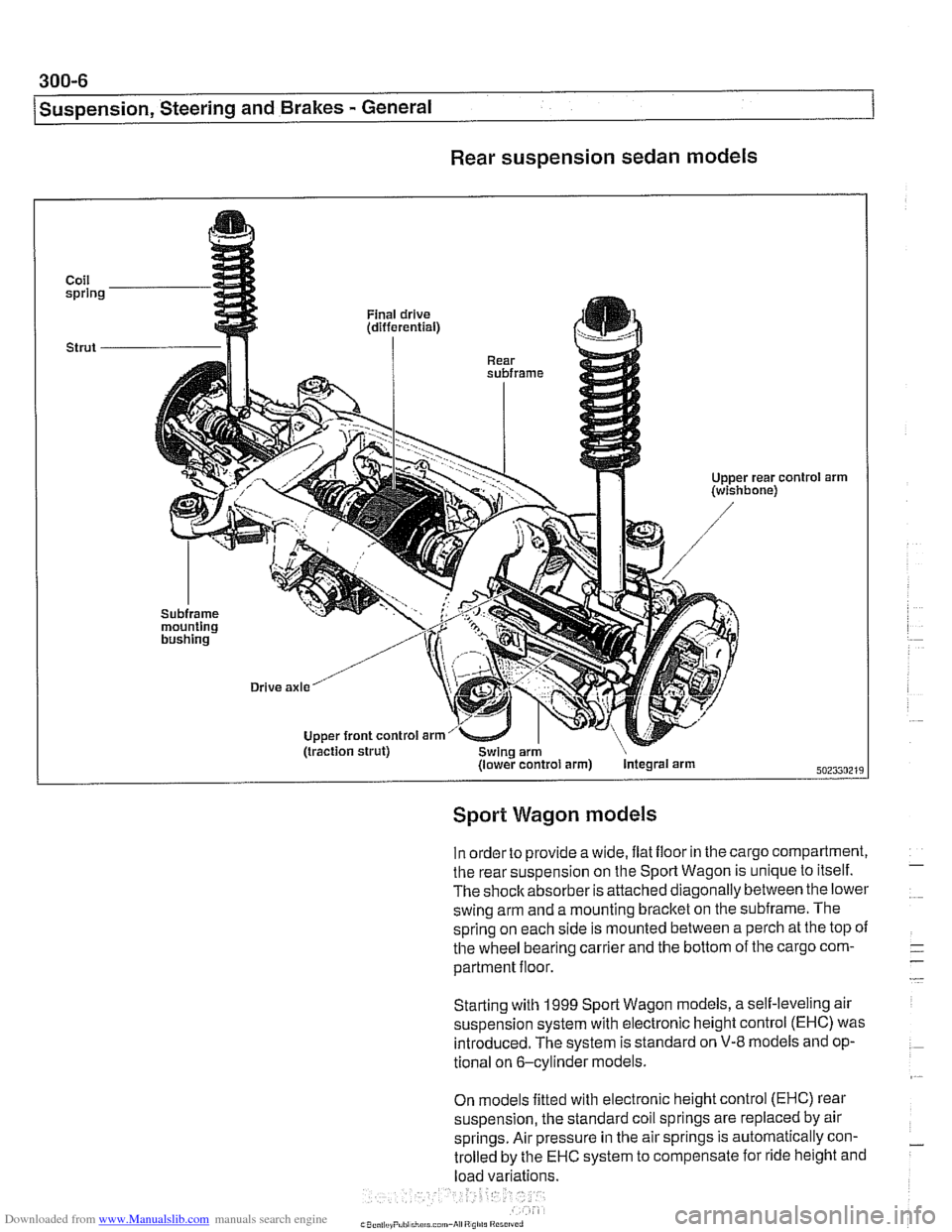

Rear suspension sedan models

Coil spring

Strut

-

'01 arm

Sport Wagon models

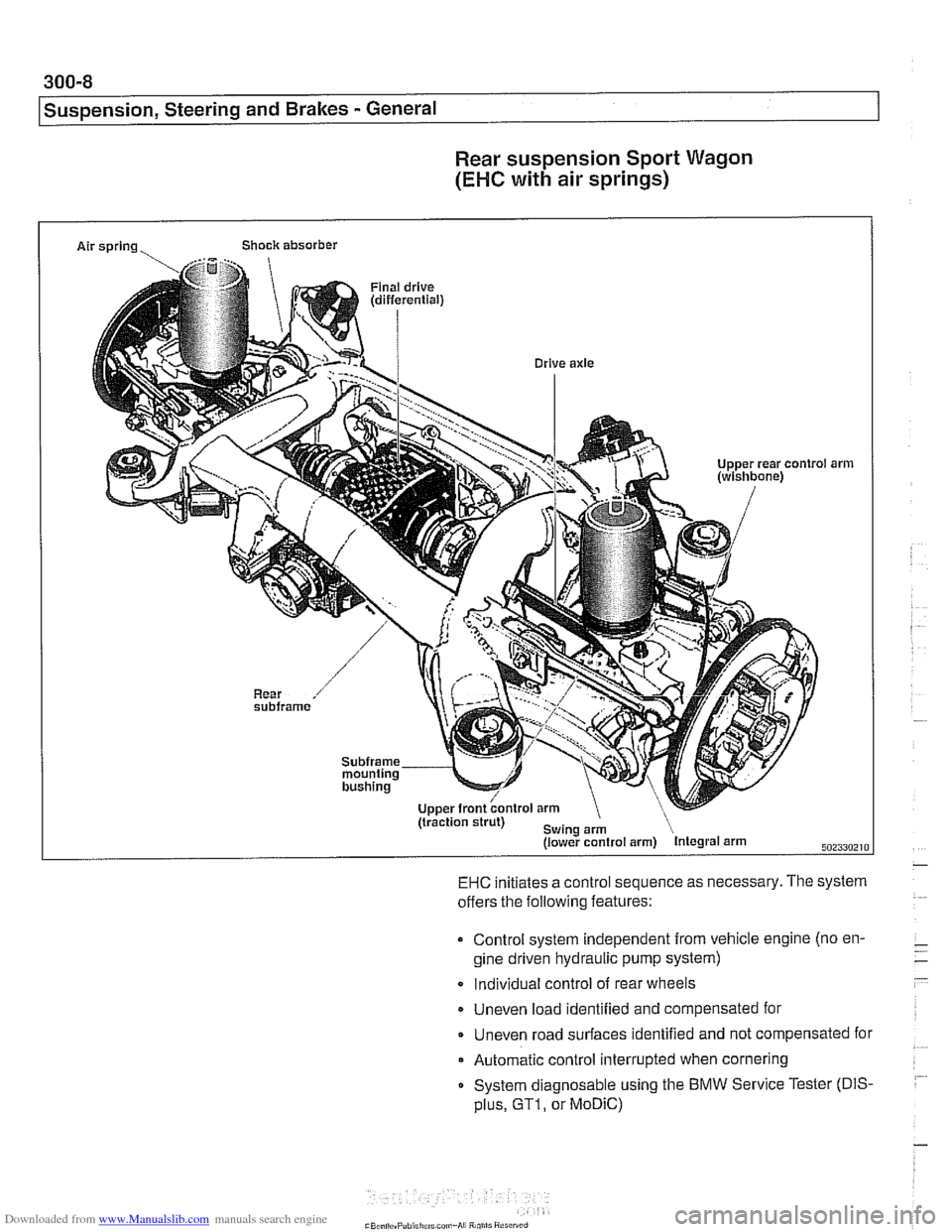

In order to provide a wide, ilat iloor in the cargo compartment,

the rear suspension on the Sport Wagon is unique to itself.

The shoclcabsorber is attached diagonally between the lower

swing arm and a mounting bracket on the subframe. The

spring on each side is mounted between a perch at the top

oi

the wheel bearing carrier and the bottom of the cargo com-

partment floor.

Starting with

1999 Sporl Wagon models, a self-leveling air

suspension system with electronic height control (EHC) was introduced. The system is standard on

V-8 models and op-

tional on 6-cylinder models.

On models fitted with electronic height control (EHC) rear

suspension, the standard coil springs are replaced by air

springs. Air pressure in the air springs is automatically con-

trolled by the

EHC system to compensate for ride height and

load variations.

Page 628 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-8

Suspension, Steering and Brakes - General

Rear suspension Sport Wagon

(EHC with air springs)

Air sprIn9 Shock absorber I

(tiaction strut) arA

(lower control arm) Integral arm 502330210

EHC initiates a control sequence as necessary. The system

offers the following features:

Control system independent from vehicle engine (no en-

gine driven hydraulic pump system)

Individual control of rear wheels

Uneven load identified and compensated for

Uneven road surfaces identified and not compensated for

Automatic control interrupted when cornering

System diagnosable using the

BMW Service Tester (DIS-

plus, GTI, or MoDiC)

Page 629 of 1002

Downloaded from www.Manualslib.com manuals search engine

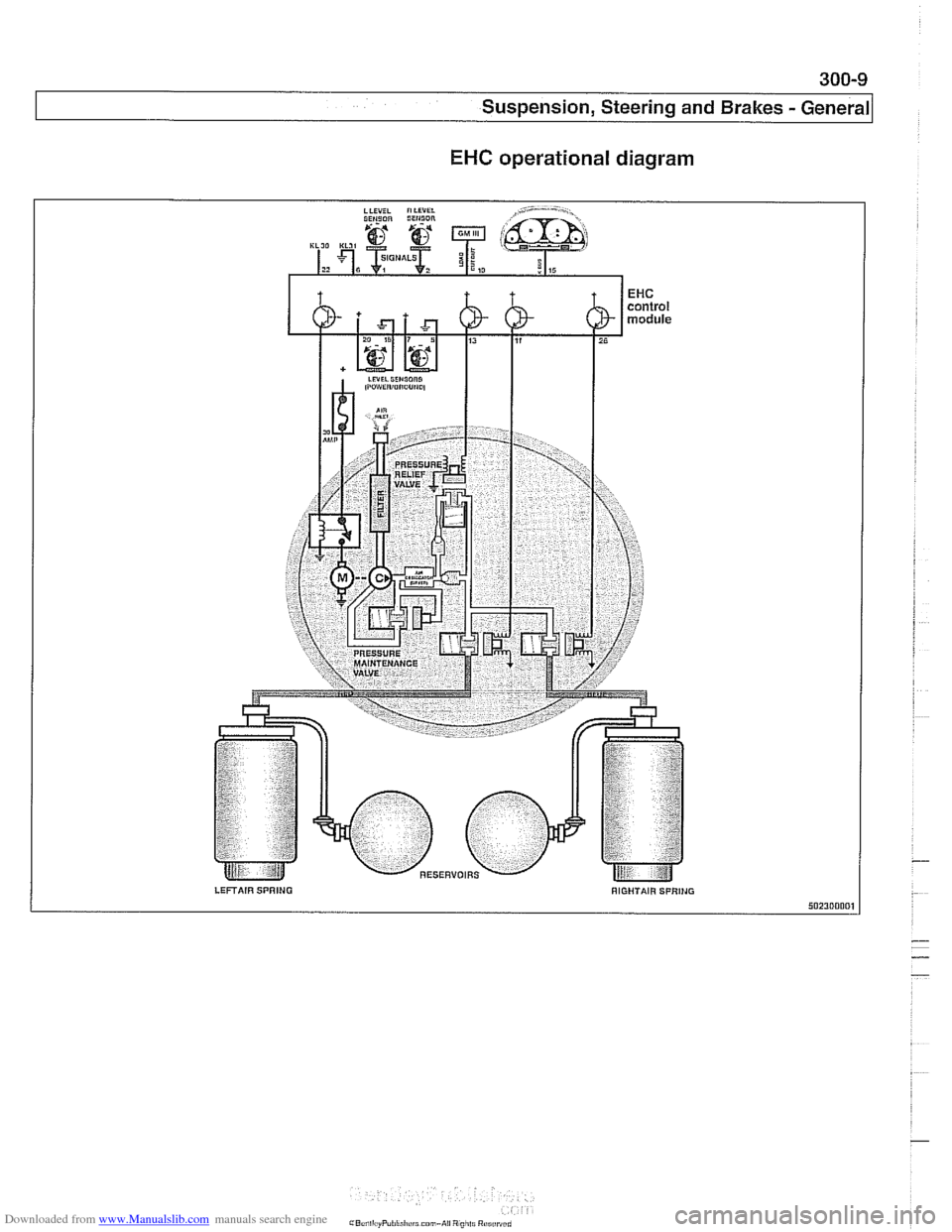

EHC operational diagram

LEFTAIR SPRING RIGHTAIR SPRlNG 50230000,

-

-

-