Alternator BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 48 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 6

Maintenance

loose, hose is damaged, or connection is dirty or corroded.

Dried coolant has achalky appearance. Hoses should be firm

and springy. Replace any hose that is cracked, has become

soft and limp, or has been contaminated by oil.

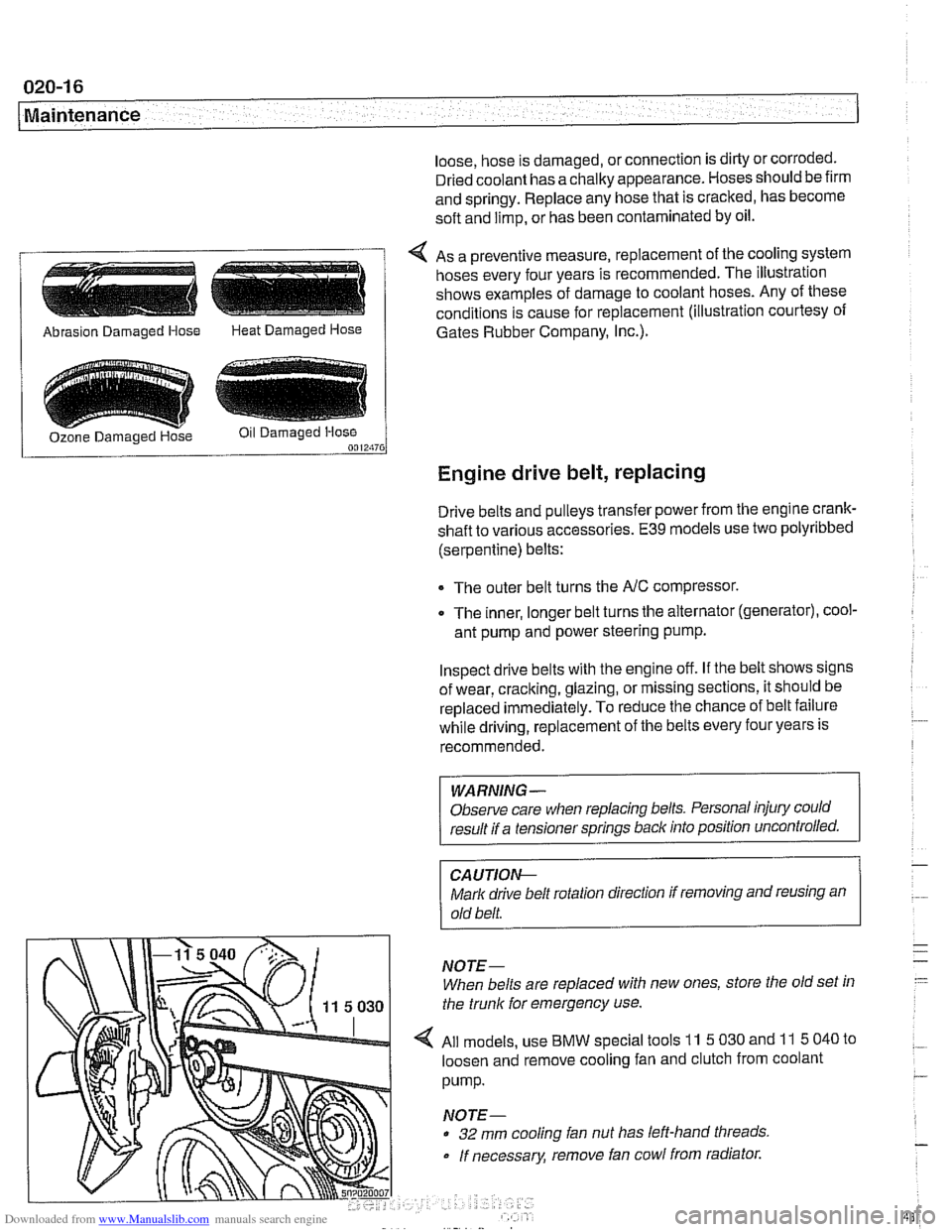

4 As a preventive measure, replacement of the cooling system

hoses every four years is recommended. The illustration

shows examples of damage to coolant hoses. Any of these

conditions is cause for replacement (illustration courtesy of

/ Abrasion Damaged Hose Heat Damaged Hose 1 Gates Rubber Company, I~c.).

Engine drive belt, replacing

Drive belts and pulleys transfer power from the engine crank-

shaft to various accessories.

E39 models use two polyribbed

(serpentine) belts:

The outer belt turns the

NC compressor.

0 The inner, longer belt turns the alternator (generator), cool-

ant pump and power steering pump.

Inspect drive belts with the engine off. If the belt shows signs

of wear, cracking, glazing, or missing sections, it should be

replaced

immediately. To reduce the chance of belt failure

while driving, replacement of the belts every four years is

recommended.

WARNING -

Observe care when replacing belts. Personal injury could

result if a tensioner springs back into position uncontrolled.

CA UTIOI\C

Mark drive belt rotation direction if removing and reusing an

old belt.

NOTE-

When belts are replaced with new ones, store the old set in

the trunk for emergency use.

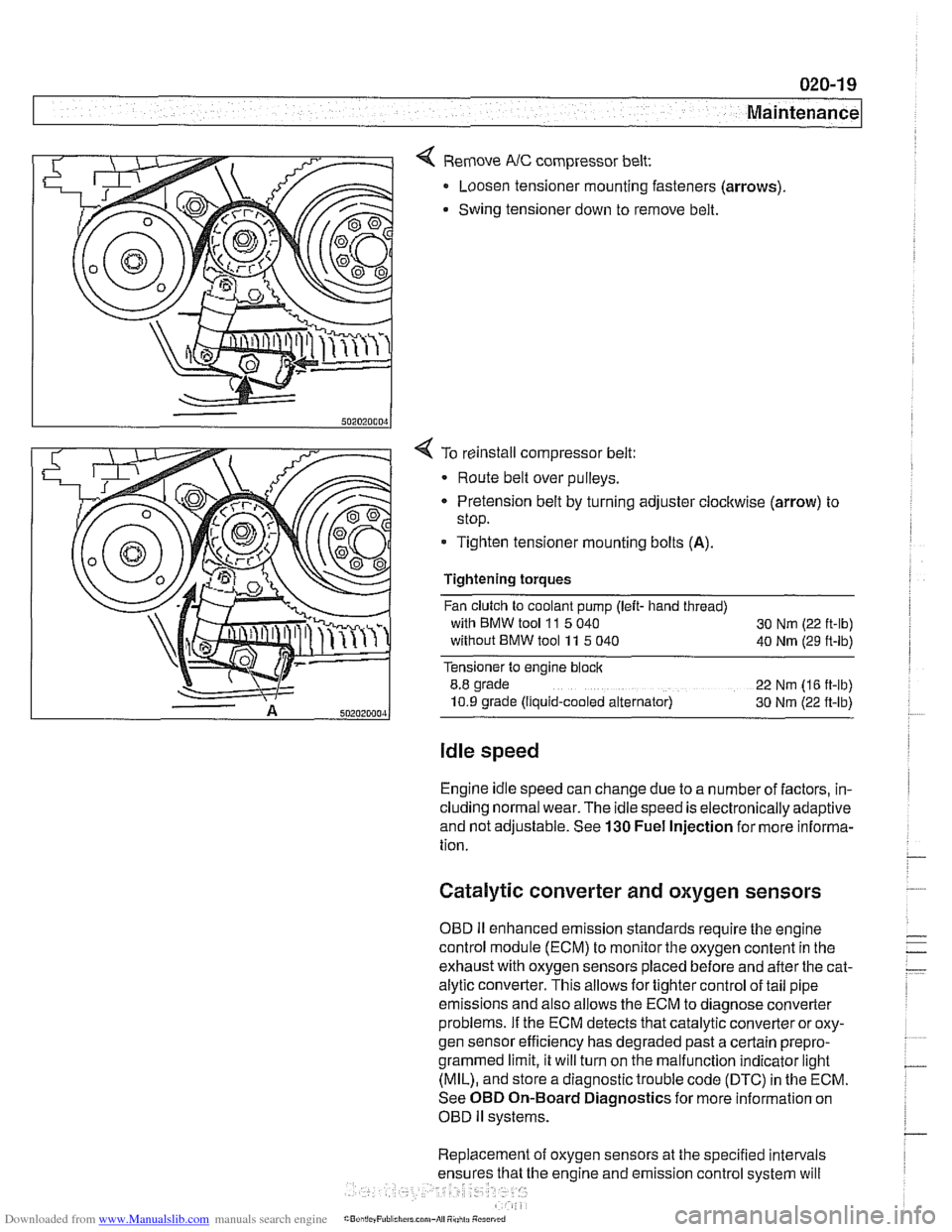

All models, use

BMW special tools 11 5 030 and 11 5 040 to

loosen and remove cooling fan and clutch from coolant

pump.

NOTE-

32 mm cooling fan nut has left-hand threads

If necessary, remove fan cowl from radiator.

Page 51 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

< Remove NC compressor belt:

Loosen tensioner mounting fasteners (arrows)

Swing tensioner down to remove belt.

4 To reinstall compressor belt:

Route belt over pulleys.

* Pretension belt by turning adjuster clockwise (arrow) to

stop.

- Tighten tensioner mounting bolts (A).

Tightening torques

Fan clutch to coolant pump (left- hand thread)

with BMW tool

11 5 040

30 Nm (22 ft-lb)

without BMW tool 11 5 040

40 Nm (29 ft-lb)

Tensioner to engine block

8.8 grade

22 Nm (16 ft-lb)

10.9 grade (Ilquid-cooled alternator) 30 Nm (22 ft-lb)

Idle speed

Engine idle speed can change due to a number of factors, in-

cluding normal wear. The idle speed is electronically adaptive

and not adjustable. See

130 Fuel Injection for more informa-

tion.

Catalytic converter and oxygen sensors

OBD II enhanced emission standards require the engine

control module (ECM) to monitor the oxygen content in the

exhaust with oxygen sensors placed before and after the cat-

alytic converter. This allows for tighter control of tail pipe

emissions and also allows the ECM to diagnose converter

problems. If the ECM detects that catalytic converter or oxy-

gen sensor efficiency has degraded past a certain

prepro-

grammed limit, it will turn on the malfunction indicator light

(MIL), and store a diagnostic trouble code (DTC) in the ECM.

See OBD On-Board Diagnostics for more information on

OBD

ll systems.

Replacement of oxygen sensors at the specified intervals

he engine and emission control system will

Page 56 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-24

Maintenance

tions. In general, replacement batteries should always be

rated equal or higher than the original battery.

The battery is held in place by a single hand screw and plate.

A secure battery hold-down is important in order to prevent

vibrations and road shoclt from damaging the battery.

CAUTION-

Prior to disconnecting the baitem read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

NOTE-

Always disconnect the negative (-) cable first, and connect

it last. While changing the battery, clean away any corro-

sion in or around the battery tray

More battery and charging system information is in 121

Battery, Alternator, Starter.

Brake fluid, replacing

Brake fluid absorbs moisture easily, and moisture in the fluid

affects bralte performance and reliability. This is why

BMW

strictly recommends replacing the bralte fluid every two

years. When replacing or adding bralte fluid, use only new

fluid from previously unopened containers. Do not use brake

fluid that has been bled from the system, even

if it is brand

new. Use only DOT

4 brake fluid.

NOTE-

See 340 Brakes for brake fluid flushing procedures.

Brake pad 1 rotor wear, checking

Disc brakes are fitted at all four wheels. Although the brakes

are equipped with a brake pad warning system, the system

only monitors one wheel per axle. Pad thickness should be

checked whenever wheels are off or brake

worlt is being

done.

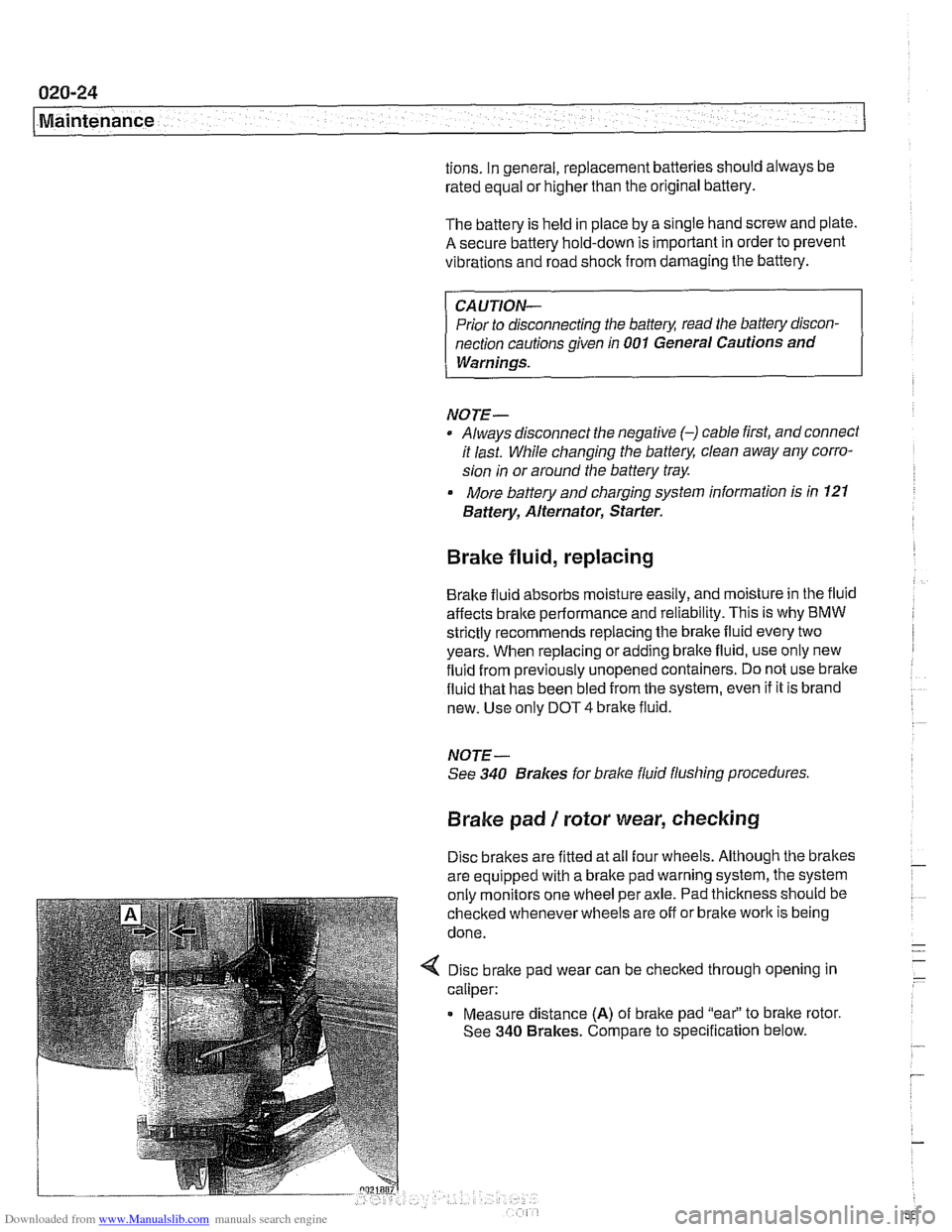

4 Disc brake pad wear can be checked through opening in

caliper:

Measure distance

(A) of brake pad "eai' to bralte rotor.

See

340 Brakes. Compare to specification below.

Page 70 of 1002

Downloaded from www.Manualslib.com manuals search engine

100-4

I Engine-General

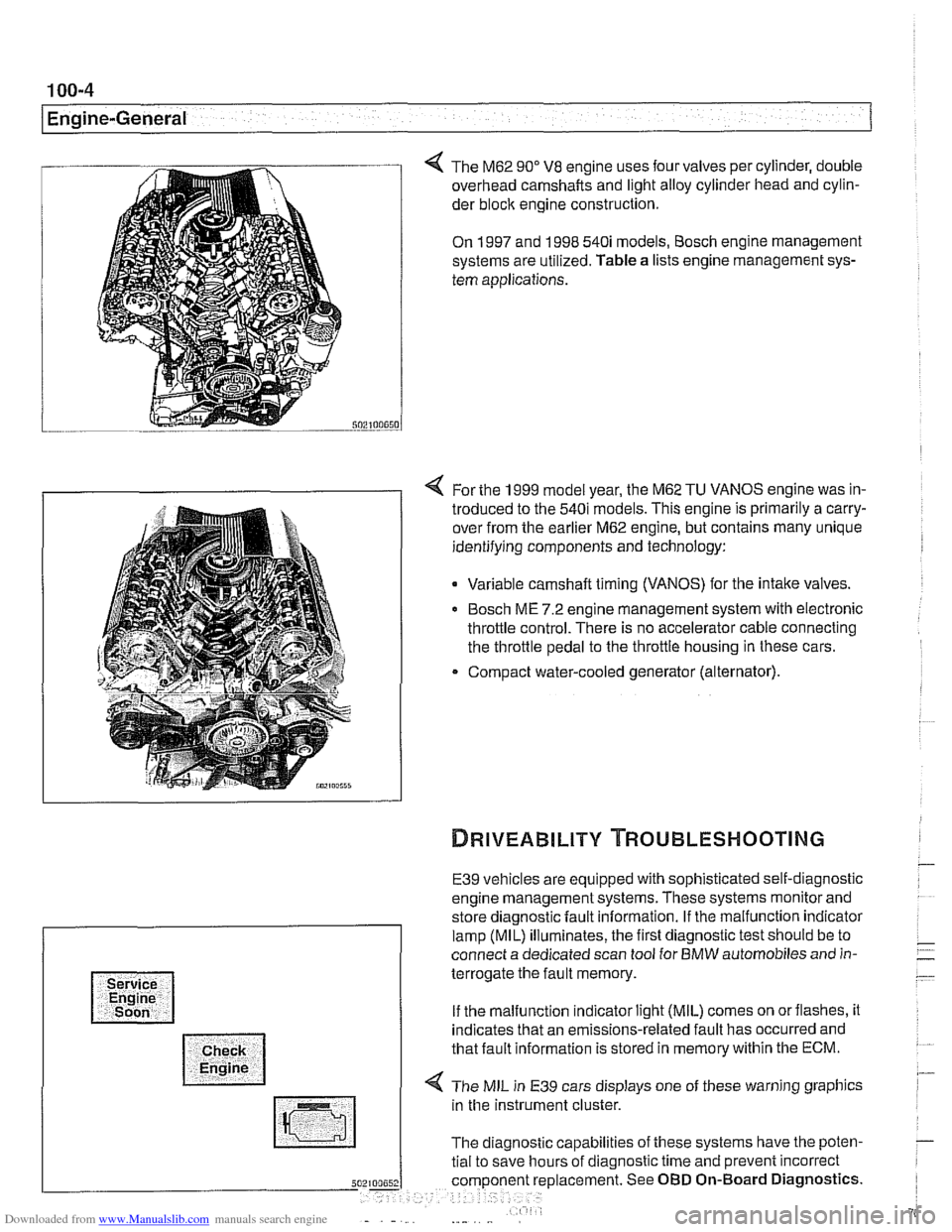

The M62 90" V8 engine uses four valves per cylinder, double

overhead camshafts and light alloy cylinder head and cylin-

der

bloclc engine construction.

On 1997 and 1998 540i models, Bosch engine management

systems are utilized. Table a lists engine management sys-

tem applications.

4 For the 1999 model year, the M62 TU VANOS engine was in-

troduced to the 540i models. This engine is primarily a carry-

over from the earlier M62 engine, but contains many unique

identifying components and technology:

Variable camshaft timing (VANOS) for the intake valves.

Bosch ME 7.2 engine management system with electronic

throttle control. There is no accelerator cable connecting

the throttle pedal to the throttle housing in these cars.

Compact water-cooled generator (alternator).

E39 vehicles are equipped with sophisticated self-diagnostic

engine management systems. These systems monitor and

store diagnostic fault information. If the malfunction indicator

lamp (MIL) illuminates, the first diagnostic test should be to

connect a dedicated scan tool for BMW automobiles and in-

terrogate the fault memory.

If the malfunction indicator light (MIL) comes on orflashes, it

indicates that an emissions-related fault has occurred and

that fault information is stored in memory within the ECM.

4 The MIL in E39 cars displays one of these warning graphics

in the instrument cluster.

The diagnostic capabilities of these systems have the poten-

tial to save hours of diagnostic time and prevent incorrect

5 placement. See OBD On-Board Diagnostics.

Page 71 of 1002

Downloaded from www.Manualslib.com manuals search engine

Two common causes of driveability problems are incorrect

system voltage and bad grounds.

System voltage

Digital motor electronics (DME) requires that the system (bat-

tery) voltage be maintained within a narrow range of DC volt-

age.

DC voltage levels beyond or below the operating range,

or any

AIC voltage in the electrical system can cause havoc.

When troubleshooting an illuminated MIL, make sure the bat-

tery is fully charged and capable of delivering all its power to

the electrical system. An undercharged battery can amplify

AIC alternator output ripple.

To

make a quick check of the battery charge, measure the

voltage across the battery terminals with all cables attached

and the ignition off.

Afully charged battery will measure 12.6

volts or slightly more, compared to 12.1 5 volts for a battery

with a 25% charge.

The DME system operates at low voltage and current levels,

making it sensitive to small increases in resistance. The elec-

trical system is routinely subjected to corrosion, vibration and

wear, so faults or corrosion in the wiring harness and connec-

tors are not uncommon. Check the battery terminals

forcorro-

sion or loose cable connections. See 121 Battery, Starter,

Alternator for additional information.

If a battery cable connection has no

v~sible faults but is still

suspect, measure the voltage drop across the connection. A

large drop indicates excessive resistance, meaning that the

connection is corroded, dirty, or damaged. Clean or repairthe

connection and retest.

NOTE-

For instructions on conducting a voltage drop test and other

general electrical troubleshooting information, see

600 Elec-

trical System-General.

Visually inspect all wiring, connectors, switches and fuses in

the system. Loose or damaged connectors can cause inter-

mittent problems, especially the small terminals in the ECM

connectors. Disconnect the wiring harness connectors to

check for corrosion, and use electrical cleaning spray to re-

move contaminants.

Main grounds

Good grounds are critical to proper DME operation. If a

ground connection has no visible faults but is still suspect.

measure the voltage drop across the connection. A large volt-

age drop means high resistance. Clean or repair the connec-

tion and retest.

LBuntr.yP~sbhnllcn.can#-AII A,~iltl Rcsrwsd

Page 74 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Engine Removal and Installation

Engine removal and installation are covered in this repail

group.

See 100 Engine-General for engine identification details

and engine codes.

Transmission removal is required for all models before the

engine can be removed. This is best accomplished with the

car raised on an automotive lift. For additional procedures re-

quired during engine removal, refer to the following repair

groups:

020 Maintenance

0 121 Battery, Alternator, Starter

170 Radiator and Cooling System

180 Exhaust System

4 230 Manual Transmission

0 240 Automatic Transmission

410 Fenders, Engine Hood

Special tools

Some special tools are required for engine removal and in-

stallation. Be sure to have the necessary equipment on hand

before starting the job.

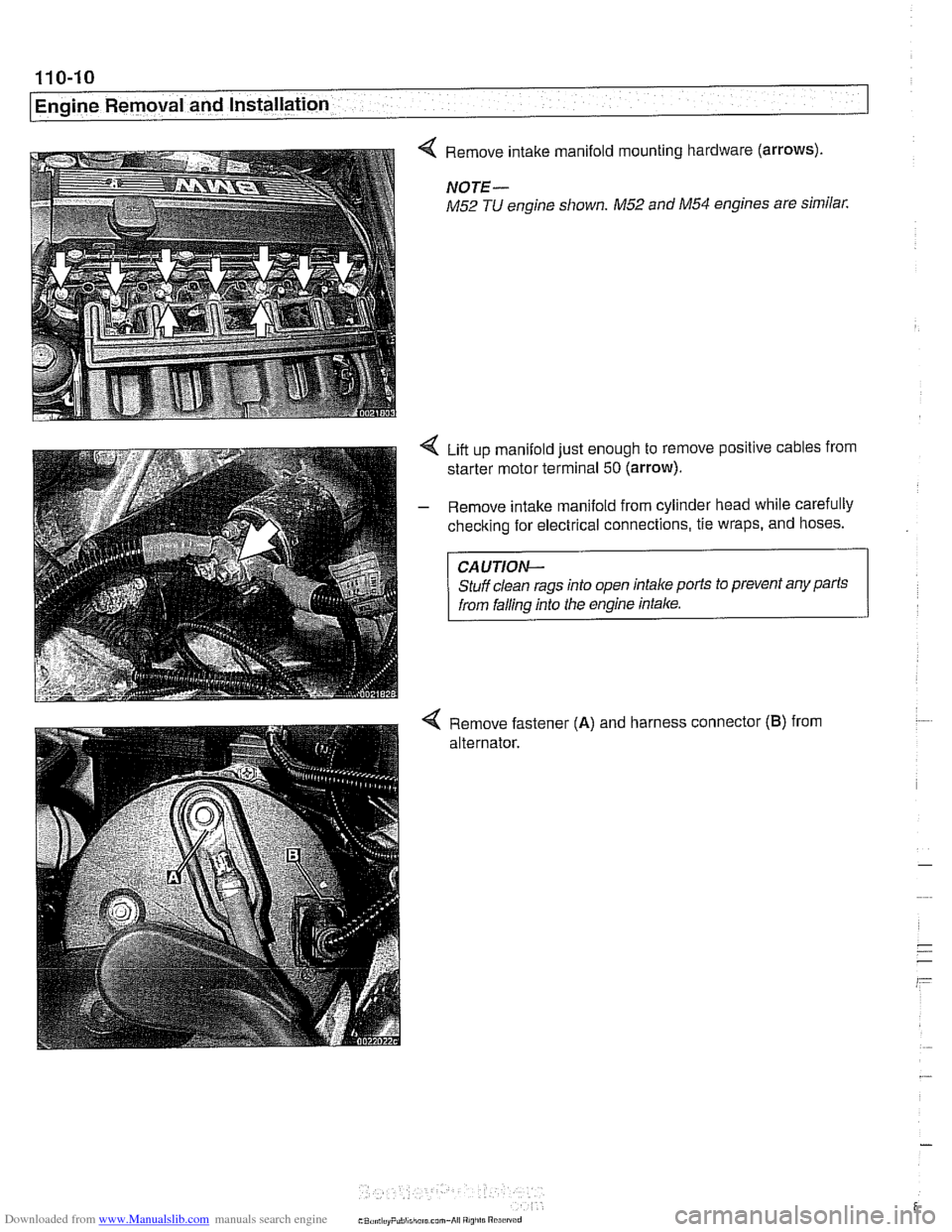

Engine lifting tool

(Tool No. BMW

11 0 000)

4 Cooling fan counterhold tool

(Tool No. BMW

11 5 030)

< Cool~ng fan wrench

(Tool No. BMW

11 5 040)

Page 82 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

-6val and Installation -

< Remove intake manifold mounting hardware (arrows).

NOTE-

M52 TU engine shown. M52 and M54 engines are similar.

Liit up manifold just enough to remove positive cables from

starter motor terminal

50 (arrow).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections, tie wraps, and hoses.

CAUTION-

Stuff clean rags into open intake ports to prevent any parts

from falling into the engine intake.

4 Remove fastener (A) and harness connector (B) from

alternator.

Page 83 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and installatid

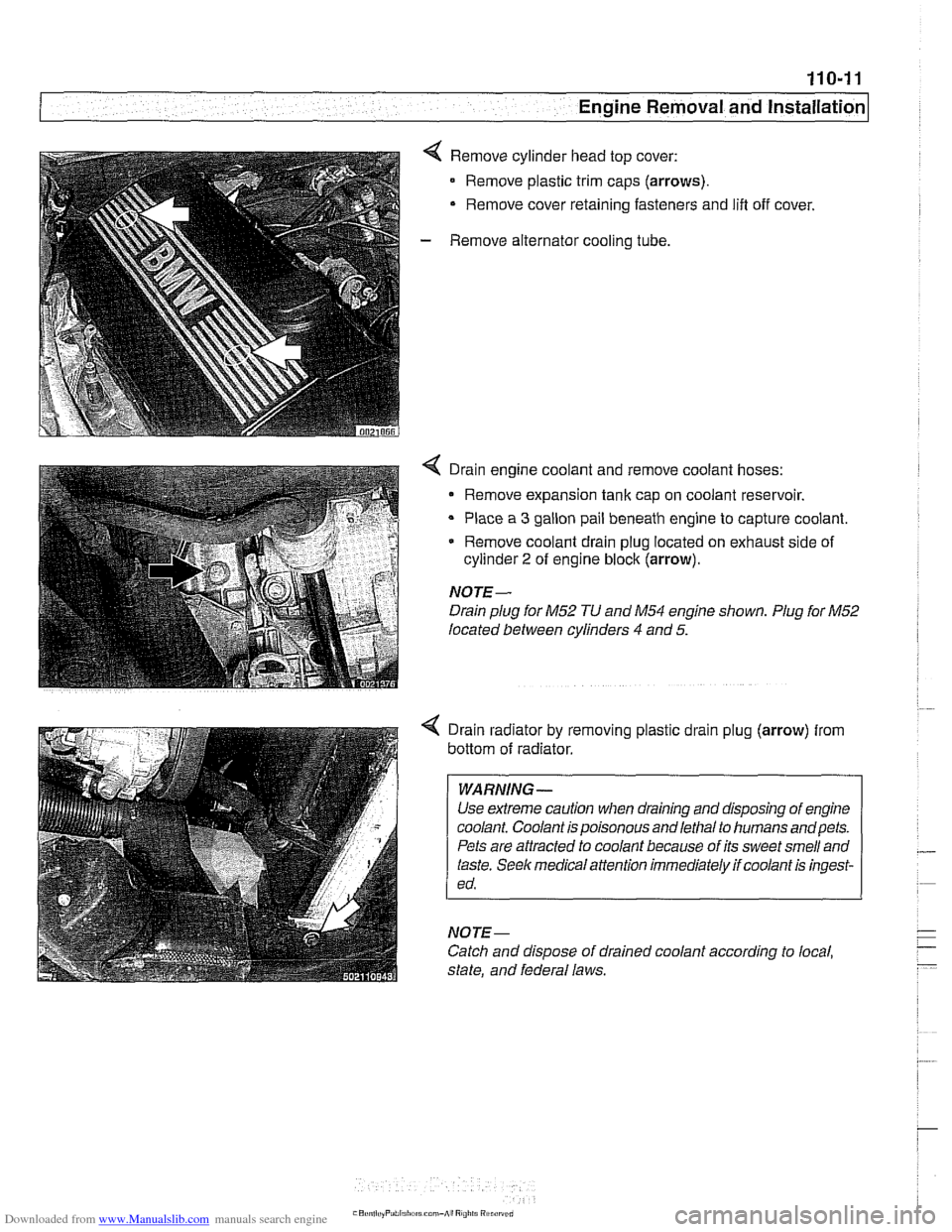

4 Remove cylinder head top cover:

Remove plastic trim caps

(arrows).

Remove cover retaining fasteners and lifl off cover.

- Remove alternator cooling tube.

4 Drain engine coolant and remove coolant hoses:

* Remove expansion tank cap on coolant reservoir.

Place a

3 gallon pail beneath engine to capture coolant,

* Remove coolant drain plug located on exhaust side of

cylinder

2 of engine block (arrow).

NOTE-

Drain plug for M52 TU and M54 engine shown. Plug for M52

located between cylinders 4 and 5.

Drain radiator by removing plastic drain plug (arrow) from

bottom of radiator.

WARNING-

Use extreme caution when draining and disposing of engine

coolant Coolant is poisonous andlethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste. Seek medical attention immediately if coolant is ingest-

ed.

NOTE-

Catch and dispose of drained coolant according to local,

state, and federal laws.

Page 92 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 0-20

Engine Removal and Installation

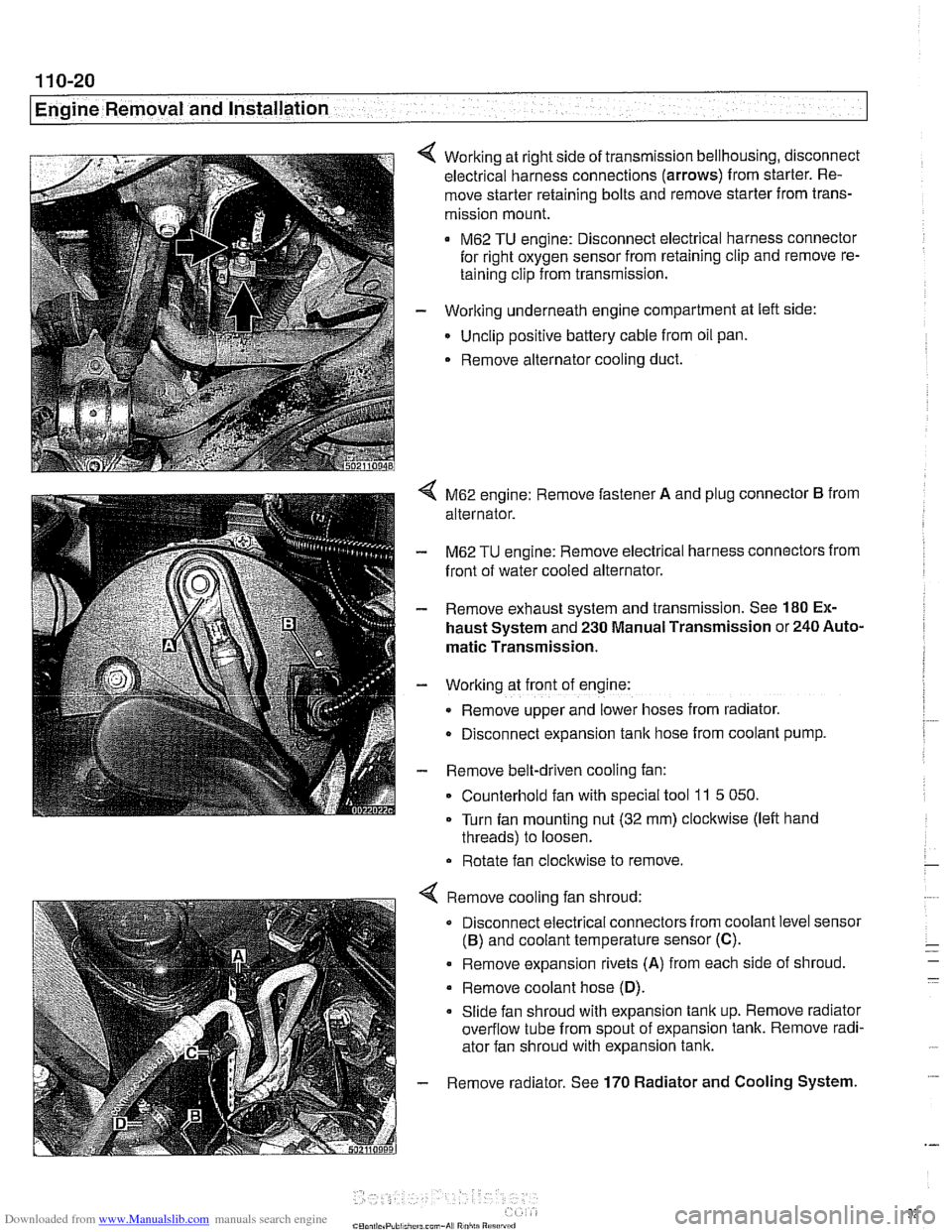

Working at right side of transmission bellhousing, disconnect

electrical harness connections (arrows) from starter. Re-

move starter retaining bolts and remove starter from trans-

mission mount.

M62 TU engine: Disconnect electrical harness connector

for right oxygen sensor from retaining clip and remove re-

taining clip from transmission.

- Working underneath engine compartment at left side:

Unclip positive battery cable from oil pan.

. Remove alternator cooling duct.

4 M62 engine: Remove fastener A and plug connector B from

alternator.

- M62 TU engine: Remove electrical harness connectors from

front of water cooled alternator.

- Remove exhaust system and transmission. See 180 Ex-

haust System and 230 Manual Transmission or 240 Auto-

matic Transmission.

- Working at front of engine:

Remove upper and lower hoses from radiator.

D~sconnect expansion tank hose from coolant pump.

- Remove belt-driven cooling fan:

Counterhold fan with special tool

11 5 050.

Turn fan mounting nut (32 mm) clockwise (left hand

threads) to loosen.

Rotate fan clockwise to remove.

Remove cooling fan shroud:

Disconnect electrical connectors from coolant level sensor

(B) and coolant temperature sensor (C).

. Remove expansion rivets (A) from each side of shroud

Remove coolant hose

(D).

Slide fan shroud with expansion tank up. Remove radiator

overflow tube from spout of expansion tank. Remove radi-

ator fan shroud with expansion tank.

Remove radiator. See

170 Radiator and Cooling System.