Car engin BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 358 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

ignition System

Disabling ignition system

The ignition system operates in a lethal voltage range and

should be disabled any time engine service or repair work is

being done that requires the ignition to be switched on.

The engine management system can be disabled by remov-

ing the DME main relay. The relay is located in the electronics

box (E-box) in the left rear of the engine

compartment, be.

neath the interior microfilter housing.

CAUTION- Relay locations may

vary. Use care when identifying relays.

See

610 Electrical Component Locations.

Checking for spark

CAUTION-

If

a spark test is done incorrecth damage to the Engine Con-

trol Module

(ECM) or the ignition coils may result.

NOTE-

Spark plug replacement is covered in 020 Maintenance.

Check~ng for spark is d~fflcult on englnes wlth d~str~butorless

ignition systems.

Try removing the spark plugs and inspecting for differences between them.

A poor-firing plug may be wet with fuel and/or ~. - ~

black and sooty, but not always. If a coil is not operating, the

engine management system will electrically disable the fuel

injector to that cylinder. The key is to look for differences be-

tween cylinders.

Ignition coil assembly, testing and

replacing

C4 UTION-

Use a digital multimeter for the following tests. I

- Remove plastic engine cover from top of valve cover by pry-

ing off bolt covers and removing cover mounting bolts.

- Raise car slowly while constantly checking position of jack

and car.

- Disconnect harness connector from coil. Connect multimeter

between terminal 15

(+) in connector and ground.

4 Terminal identification are typically molded into connector. In

photo, terminals are from left to right: 1,

4a, 15.

Page 360 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 2

ignition System

Crankshaftspeedsensor

Crankshaft speed sensor, replacing (M52, M52 TU and

M54 engines)

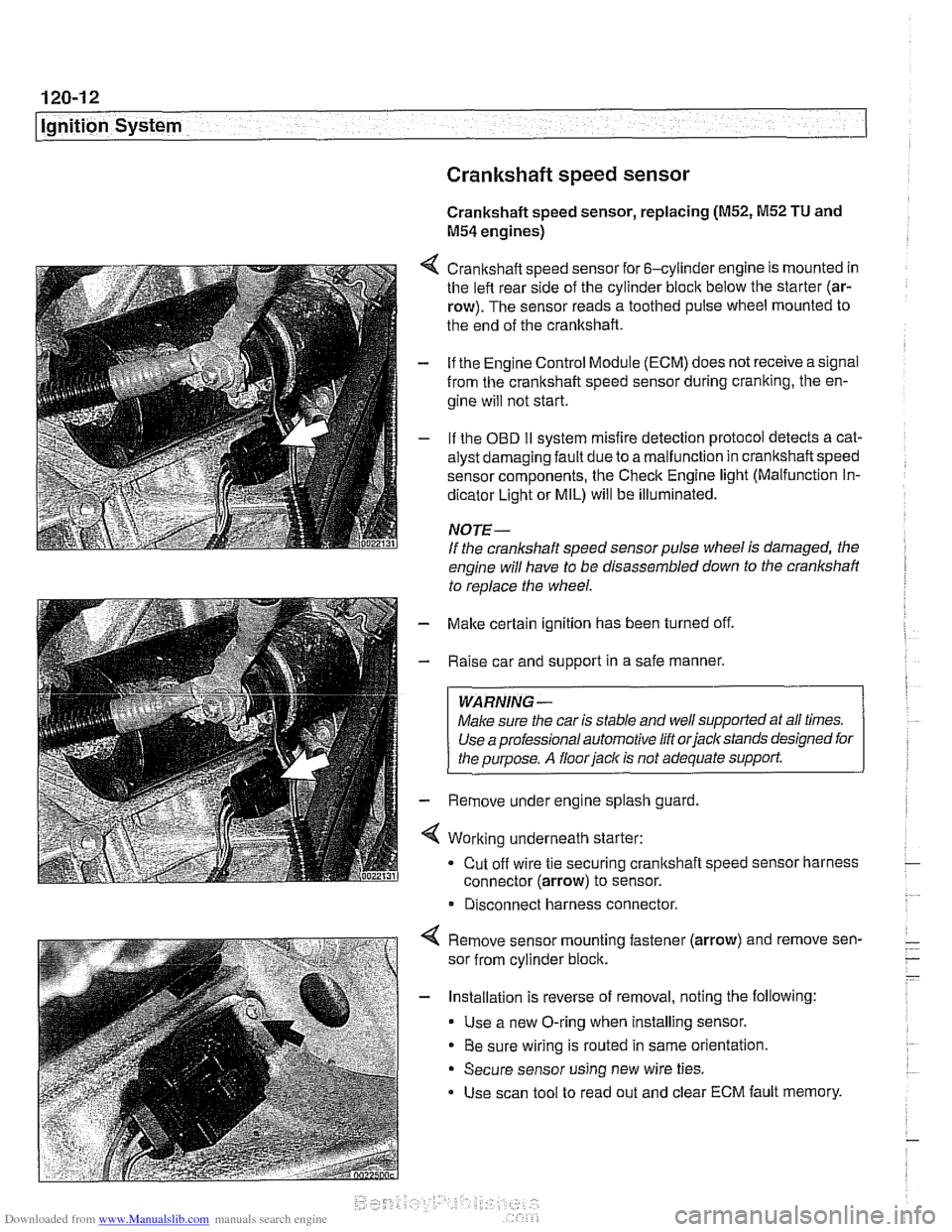

4 Crankshaft speed sensor for 6-cylinder engine is mounted in

the left rear side of the cylinder block below the starter (ar-

row). The sensor reads a toothed pulse wheel mounted to

the end of the crankshaft.

- if the Engine Control Module (ECM) does not receive a signal

from the crankshaft speed sensor during cranking, the en-

gine will not start.

- If the OBD II svstem misfire detection ~rotocol detects a cat- - - ~~

alysr oarnagin; faLlt oJe to a ma I-nclion in crandshafi speeo

sensor components. Ine Check Engine

lignr (Malfuncrion In-

dicator Light or MIL) will be illuminated.

NOTE-

If the crankshaft speed sensor pulse wheel is damaged, the

engine will have to be disassembled down to the crankshaft

to

reolace the wheel.

- Make certain ignition has been turned off.

- Raise car and support in a safe manner.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

the ouroose.

A floor iaclc is not adequate support.

- Remove under engine splash guard

4 Working underneath starter:

Cut off wire tie securing crankshaft speed sensor harness

connector (arrow) to sensor.

* Disconnect harness connector.

4 Remove sensor mounting fastener (arrow) and remove sen-

sor from cylinder block.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

Be sure wiring is routed in same orientation.

Secure sensor using new wire ties.

Use scan tool to read out and clear ECM fault memory.

Page 361 of 1002

Downloaded from www.Manualslib.com manuals search engine

ignition System

Crankshaft speed sensor, replacing (M62 and M62TU

engines)

The crankshaft speed sensor reads a toothed pulse wheel

mounted on the flywheel.

If the Engine Control Module(ECM)

does not receive an impulse signal from the crankshaft speed

sensor during

cranking, the engine will not start. If the OBD II

system misfire detection protocol detects a catalyst damag-

ing fault due to a malfunction in the crankshaft speed sensor

components, the Check Engine light (Malfunction

Indicator

Light or MIL) will be Illuminated.

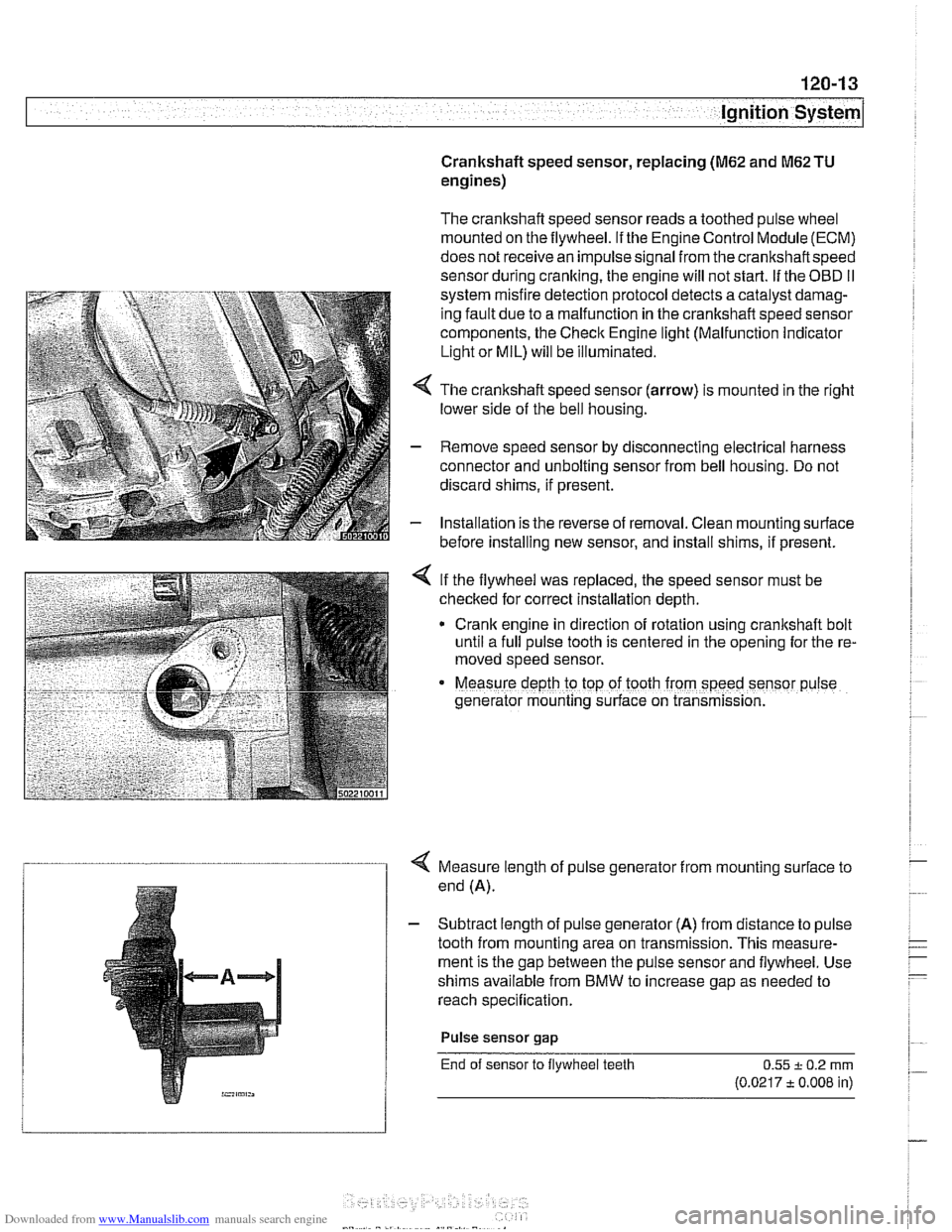

4 The crankshaft speed sensor (arrow) is mounted in the right

lower side of the bell housing.

- Remove speed sensor by disconnecting electrical harness

connector and unbolting sensor from bell housing. Do not

discard shims, if present.

- Installation is the reverse of removal. Clean mounting surface

before installing new sensor, and install shims, if present.

< If the flywheel was replaced, the speed sensor must be

checked for correct installation depth.

* Crank engine in direction of rotation using crankshaft bolt

until a full pulse tooth is centered in the opening for the re-

moved speed sensor.

Measure depth ro top of tooth from speed sensor p~lse

generator mounting s~rface on transmission.

4 Measure length of pulse generator from mounting surface to

end (A).

- Subtract length of pulse generator (A) from distance to pulse

tooth from mounting area on transmission. This measure-

ment is the gap between the pulse sensor and flywheel. Use

shims available from BMW to increase gap as needed to

reach specification.

Pulse sensor

gap

End of sensor to flywheel teeth 0.55 + 0.2 rnrn

(0.0217 t 0.008 in)

Page 368 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Battery, Starter, Alternator

This section covers the battery, alternator, starter and associ-

ated components of the electrical system.

Troubleshooting information

forthese components isfound in

Table a. Battery, alternator and starter troubleshooting.

For additional electrical troubleshooting information, see

600 Electrical System-General.

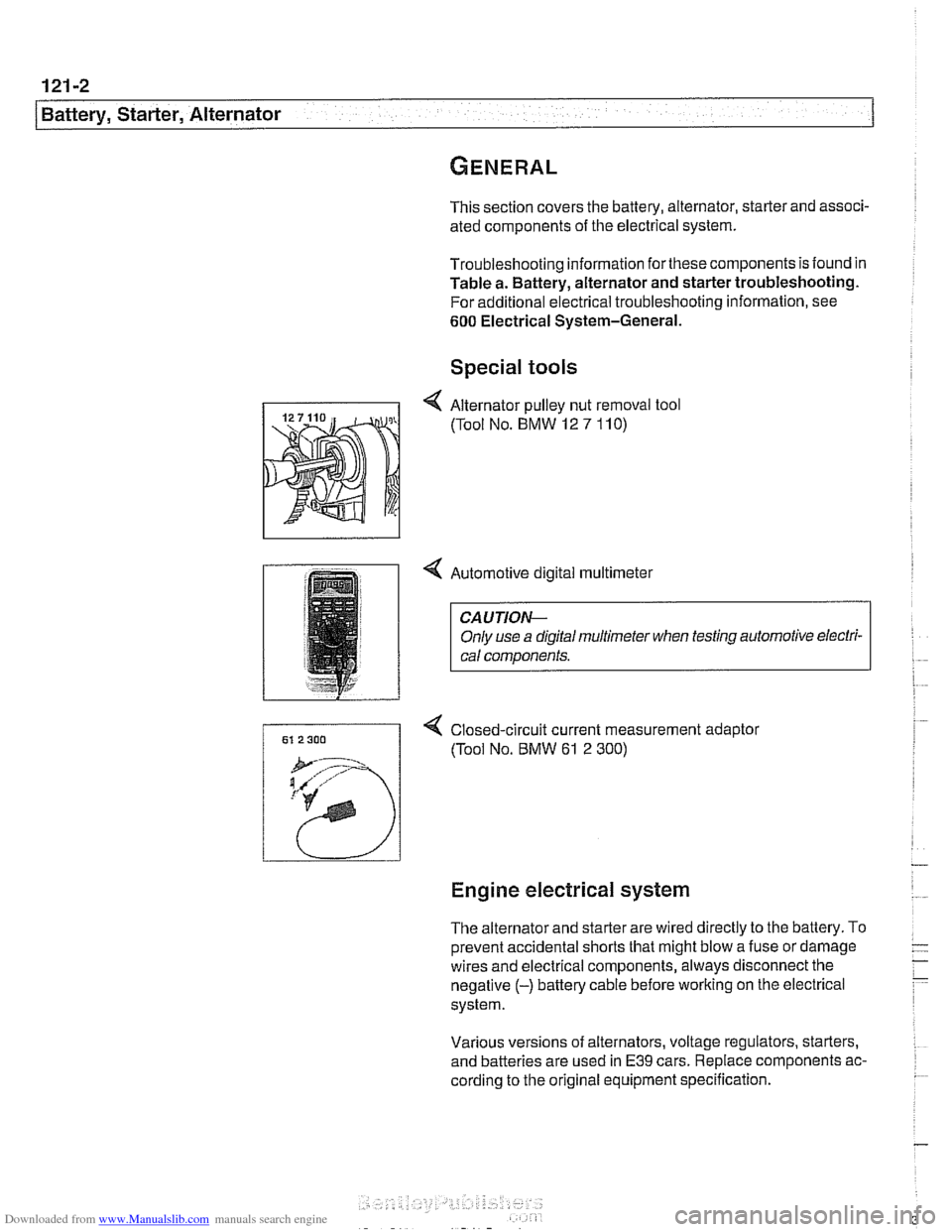

Special tools

4 Automotive digital multimeter

CAUTION-

Only use a digital multirneter when testing automotive electri- I) cal components.

4 Closed-circuit current measurement adaptor

(Tool No.

BMW 61 2 300)

Engine electrical system

The alternator and starter are wired directly to the battery. To

prevent accidental shorts that might blow a fuse or damage

wires and electrical components, always disconnect the

negative

(-) battery cable before working on the electrical

system.

Various versions of alternators, voltage regulators, starters,

and batteries are used in

E39 cars. Replace components ac-

cording to the original equipment specification.

Page 373 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

WARNING-

Always wear protective goggles and clothing when perform-

ing a load test.

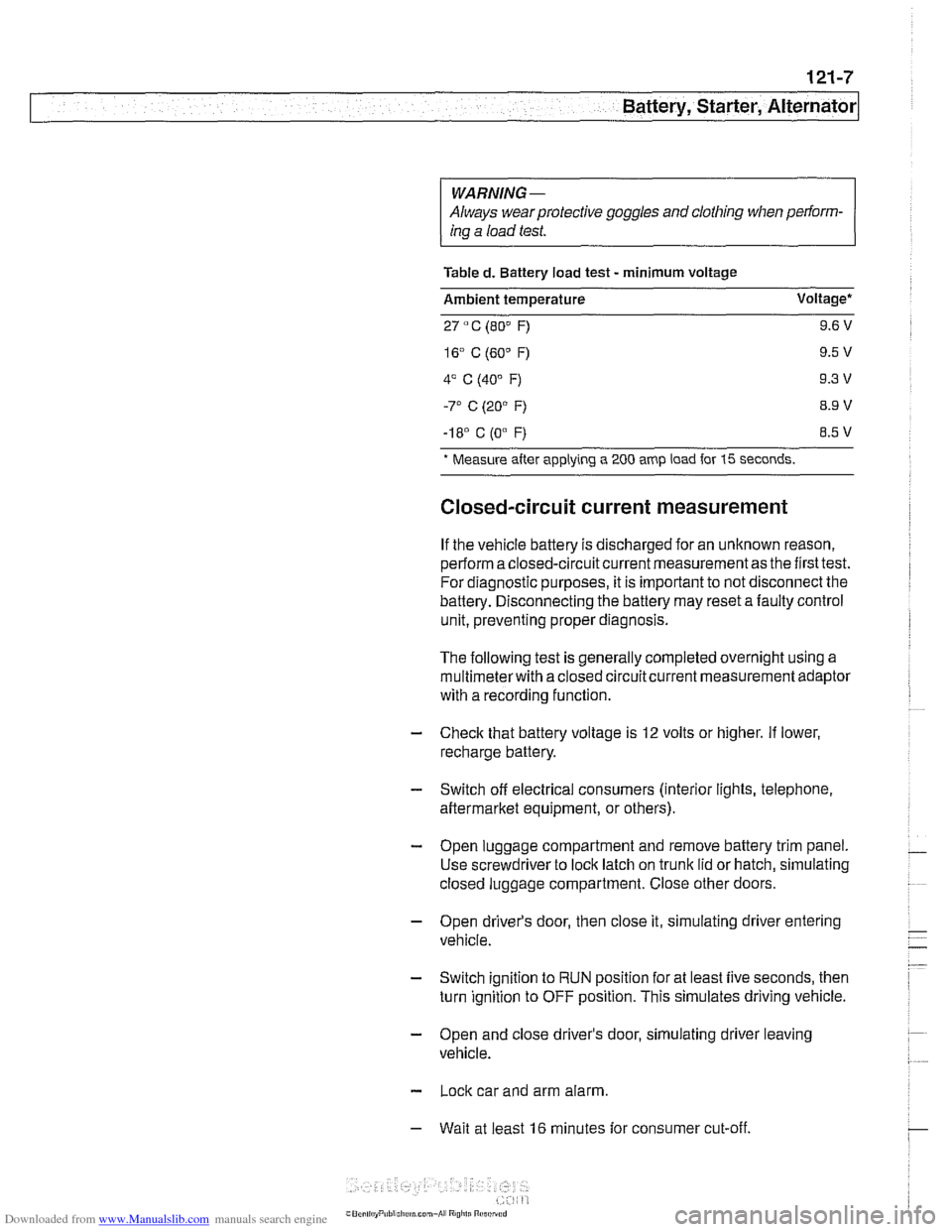

Table

d. Battery load test - minimum voltage

Ambient temperature Voltage*

27

" C (80" F) 9.6 V

-I 8' C (0"

F) 8.5 V

* Measure

after applying a 200 amp load for 15 seconds.

Closed-circuit current measurement

If the vehicle battery is discharged for an unknown reason,

perform a closed-circuit current measurement as the first test.

For diagnostic purposes, it is important to not disconnect the

battery. Disconnecting the battery may reset a faulty control

unit, preventing proper diagnosis.

The following test is generally completed overnight using a

multimeterwith a closed circuitcurrent measurement adaptor

with a recording function

- Check that battery voltage is 12 volts or higher. If lower,

recharge battery.

- Switch off electrical consumers (interior lights, telephone,

aftermarket equipment, or others).

- Open luggage compartment and remove battery trim panel.

Use screwdriver to lock latch on trunk lid or hatch, simulating

closed luggage compartment. Close other doors.

- Open driver's door, then close it, simulating driver entering

vehicle.

- Switch ignition to RUN position for at least five seconds, then

turn ignition to OFF position. This simulates driving vehicle.

- Open and close driver's door, simulating driver leaving

vehicle.

- Lock car and arm alarm.

- Wait at least 16 minutes for consumer cut-off.

Page 374 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-8

/Battery, Starter, Alternator

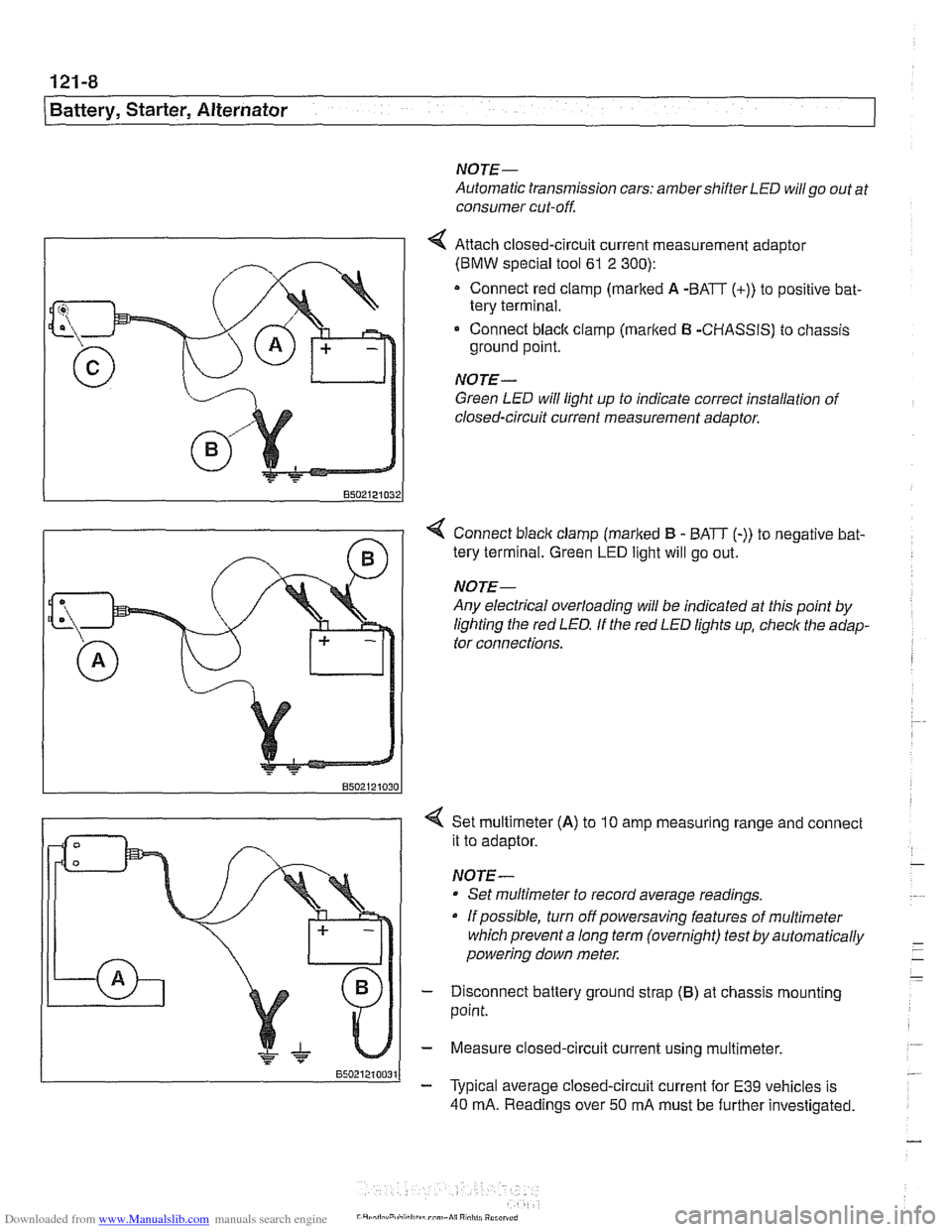

NOTE-

Automatic transmission cars: ambershifier LED willgo out at

consumer cut-off.

4 Attach closed-circuit current measurement adaptor

(BMW special tool

61 2 300):

Connect red clamp (marked A -BATT (+)) to positive bat-

tery terminal.

Connect

black clamp (marked B -CHASSIS) to chassis

ground point.

NOTE-

Green LED will light up to indicate correct installation of

closed-circuit current measurement

adaotor.

< Connect blaclc clamp (marked B - BATT (-)) to negative bat-

tery terminal. Green

LED light will go out.

NOTE-

Any electrical overloading will be indicated at this point by

lighting the red

LED. If the red LED lights up, check the adap-

tor connections.

< Set multimeter (A) to 10 amp measuring range and connect

it to adaptor.

NOTE -

Set multimeter to record average readings.

Ifpossible, turn offpowersaving features of multimeter

which prevent a long term (overnight) test by automatically

powering down

meter.

- Disconnect battery ground strap (B) at chassis mounting

point.

- Measure closed-circuit current using multimeter.

- Typical average closed-circuit current for E39 vehicles is

40 mA. Readings over 50 mA must be further investigated.

Page 375 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-9

Battery, Starter, ~lternatorl

Battery charging

Discharged batteries can be recharged using a batterycharg-

er. Remove the battery from the trunk during charging.

Prolonged charging causes electrolyte evaporation to a level

that can damage the battery. It is best to use a low-current

charger

(6 amperes or less) to prevent battery damage

caused by overheating.

WARNING -

Hydrogen gas given off by the battery during charging is ex-

plosive. Do not smoke.

Keep open flames away from the top

ofthe batte~ and prevent electrical sparks by turning off the

battery charger before connecting or disconnecting it.

Battery electrolyte (sulfuric acid) can damage the car. If

electrolyte is spilled, clean the area with a solution

ofbak-

ing soda and water.

Always allow a frozen battery to thaw before attempting

to recharge it.

Always disconnect both battery cables and remove bat-

tery from vehicle during battery charging. Do not ex-

ceed

16.5 charging voltage at the battery

Battery safety terminal, replacing

If the battery safety terminal has been triggered, investigate

and correct the cause prior to replacement.

- Working in right side of luggage compartment, remove bat-

tery trim panel.

- Disconnect negative (-) battery terminal and cover with

insulator.

- Disconnect positive (+) cable from battery.

- Release positive (+) cable from cable brackets on luggage

compartment wall. Lay new repair cable parallel to positive

cable.

- Mark off length of new cable on old cable. Allow 10 cm

(2.5 in) of slack.

- Saw through old cable.

Do not use bolt cutters or similar tools to cut through cable.

A cable end that has been squashed

flat will not fit into the

Page 377 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-11

Battery, Starter, ~lternatorl

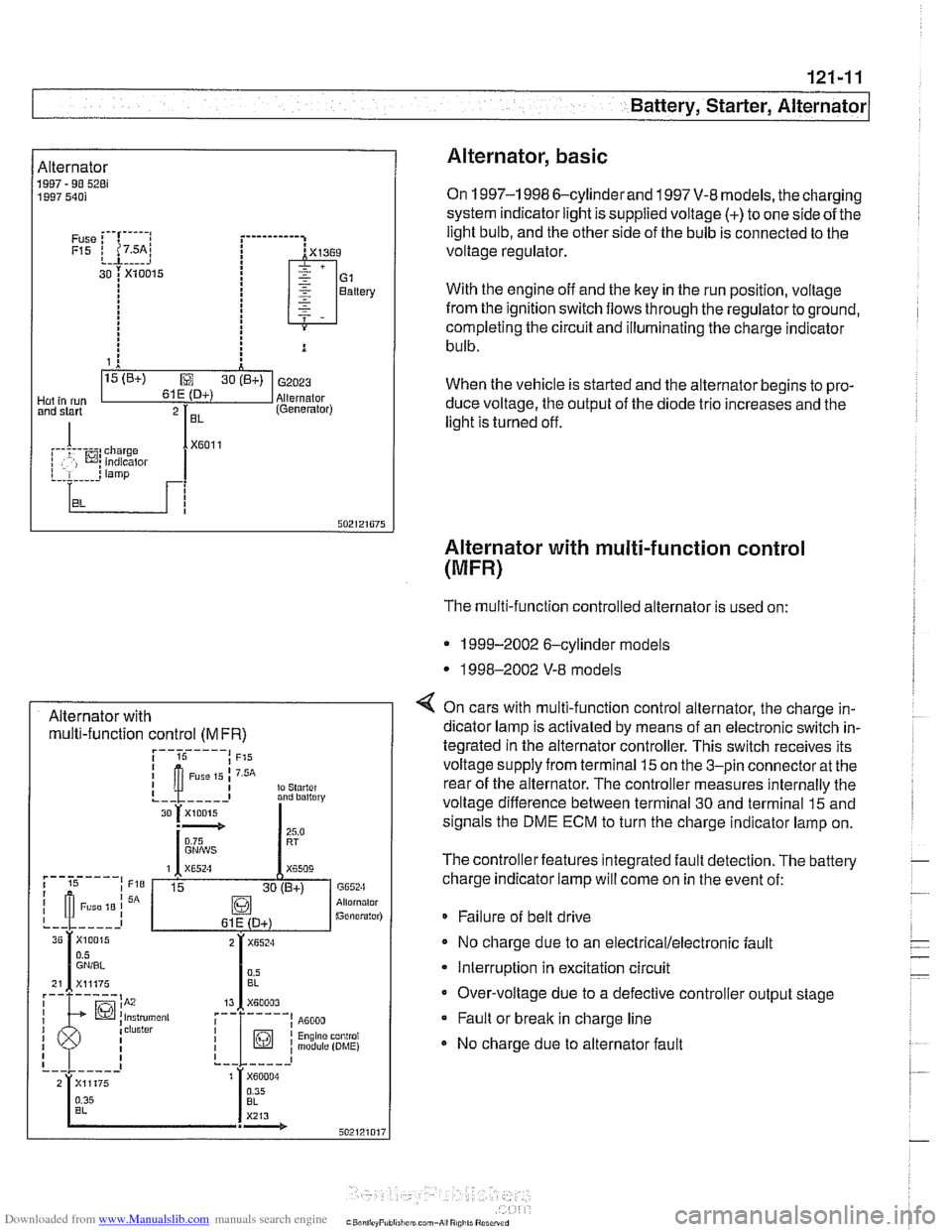

Alternator 1997 - 98 5281 1997 540i

/-- -----,

I'

-----------

F15 / 7.5A/ :

&.. .... , 30 1 Xi0015

Battery

Hol in run 61 E (D+) Alternator

and stsrt

lBL

(Generator)

1 .--------,charge , . I , indicator I xGoli i

I <"9,7,a,T

Alternator, basic

On 1997-1 998 6-cylinderand 1997 V-8 models, the charging

system indicator light is supplied voltage

(+) to one side of the

light bulb, and the other side of the bulb is connected to the

voltage regulator.

With the engine off and the key in the run position, voltage

from the ignition switch flows through the regulator to ground,

completing the circuit and illuminating the charge indicator

bulb.

When the vehicle is started and the alternator begins to pro-

duce voltage, the output of the diode trio increases and the

light is turned off.

Alternator with multi-function control

(MFR)

Alternator with multi-function control

(MFR)

The multi-function controlled alternator is used on:

* 1999-2002 6-cylinder models

* 1998-2002 V-8 models

4 On cars with multi-function control alternator, the charge in-

dicator lamp is activated by means of an electronic switch in-

tegrated in the alternator controller. This switch receives its

voltage supply from terminal

15 on the 3-pin connector at the

rear of the alternator. The controller measures internally the

voltage difference between terminal 30 and terminal

15 and

signals the DME ECM to turn the charge indicator lamp on.

The controller features integrated fault detection. The battery

charge indicator lamp will come on in the event of:

* Failure of belt drive

No charge due to an

electrical/electronic fault

Interruption in excitation circuit

Over-voltage due to a defective controller output stage Fault or break in charge line

No charge due to alternator fault

Page 379 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

Charging system quick-check

Use a digital multimeter to measure voltage across the bat-

tery terminals with key off and then again with engine running.

Battery voltage should be about 12.6 volts with key off and be-

tween 13.5 and 14.5 volts with engine running.

NOTE-

The regulated voltage (engine running) should be between

13.2 and 14.5, depending on temperature andoperating con-

ditions.

If the voltage is higher than 14.8, the voltage regula-

tor or

mulitfunction controller is most likely faulty

Check for clean and tight battery cables. Check ground cable

running from negative

(-) battery terminal to chassis and

ground cable running from engine to chassis. Check alterna-

tor drive belt condition and tension.

Charging system, checking

CAUTIOI\C

* Do not disconnect the battery while the engine is running.

Damage to the alternator and/or engine electronic systems

may result.

Only use a digital multimeter when testing charging

system components.

--7

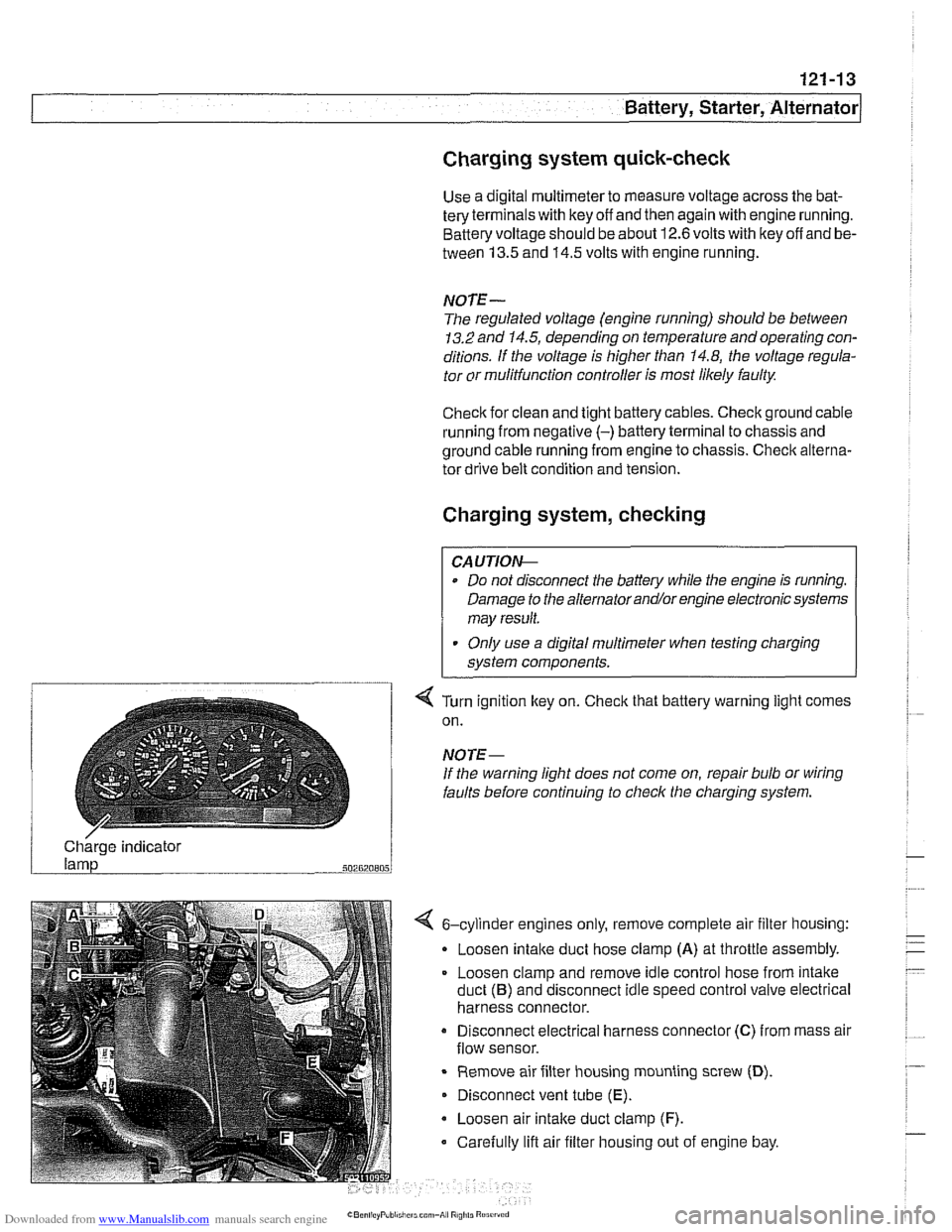

4 Turn ignition key on. Check that battery warning light comes

on.

NOTE-

If the warning light does not come on, repair bulb or wiring

faults before continuing to checlc the charging system.

/ Charge indicator

502820805

4 6-cylinder engines only, remove complete air filter housing:

Loosen

intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw

(D).

Disconnect vent tube (E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Page 380 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

/Battery, Starter, Alternator -- - -. - --I

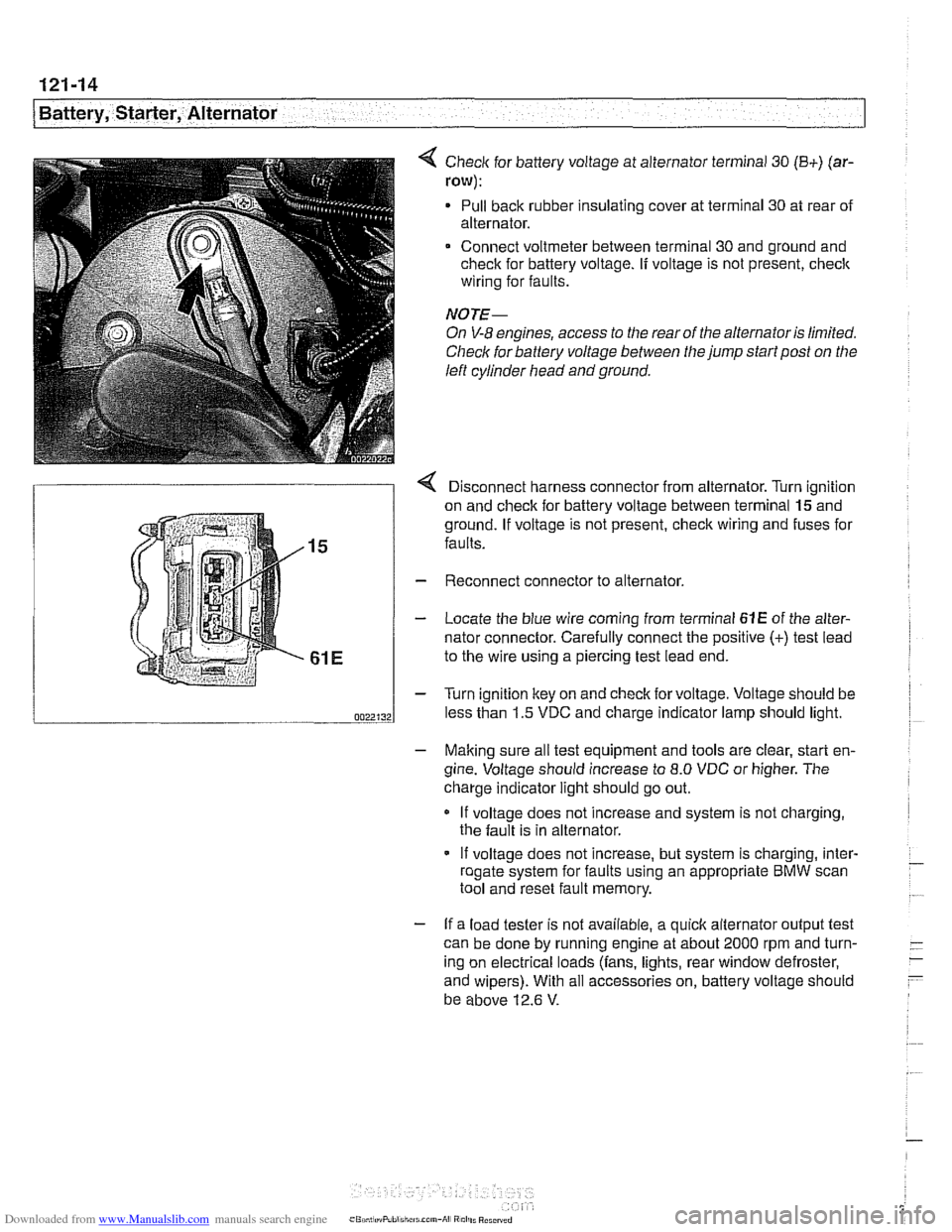

< Check for battery voltage at alternator terminal 30 (B+) (ar-

row):

Pull back rubber insulating cover at terminal 30 at rear of

alternator.

Connect voltmeter between terminal 30 and ground and

check for battery voltage.

If voltage is not present, check

wiring for faults.

NOTE-

On V-8 engines, access to the rear of the alternator is limited.

Check for battery voltage between the jump start post on the

left cylinder head and ground.

r Disconnect harness connector from alternator. Turn ianition

on and check for battery voltage between terminal

lgand

ground. If voltage is not present, check wiring and fuses for

faults.

Reconnect connector to alternator.

Locate the blue wire coming from terminal

61E of the alter-

nator connector. Carefully connect the positive

(+) test lead

to the wire using a piercing test lead end.

Turn ignition key on and check for voltage. Voltage should be

less than 1.5 VDC and charge indicator lamp should light.

- Making sure all test equipment and tools are clear, start en-

gine. Voltage should increase to

8.0 VDC or higher. The

charge indicator light should go out.

If voltage does not increase and system is not charging,

the fault is in alternator.

- If voltage does not increase, but system is charging, inter- - roaate svstem for faults usina an appropriate BMW scan - .. . tool and'reset fault memory.

- If a load tester is not available, a quick alternator output test

can be done by running engine at about 2000 rpm and turn-

- -

ing on electrical loads (fans, lights, rear window defroster, -

- and wipers). With all accessories on, battery voltage should

be above 12.6

V.