troubleshooting BMW 528i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 354 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-6

lgnition System

lgnition system, troubleshooting

Troubleshooting ignition system faults should begin with an

interrogation of the On-Board Diagnostics (OBD

II) system.

The OBD

II system detects ignition system misfire and other

related faults. When faults are detected, the OBD

II system

stores a Diagnostic Trouble Code (DTC) in the Engine Con-

trol Module (ECM) along with other pertinent fault information.

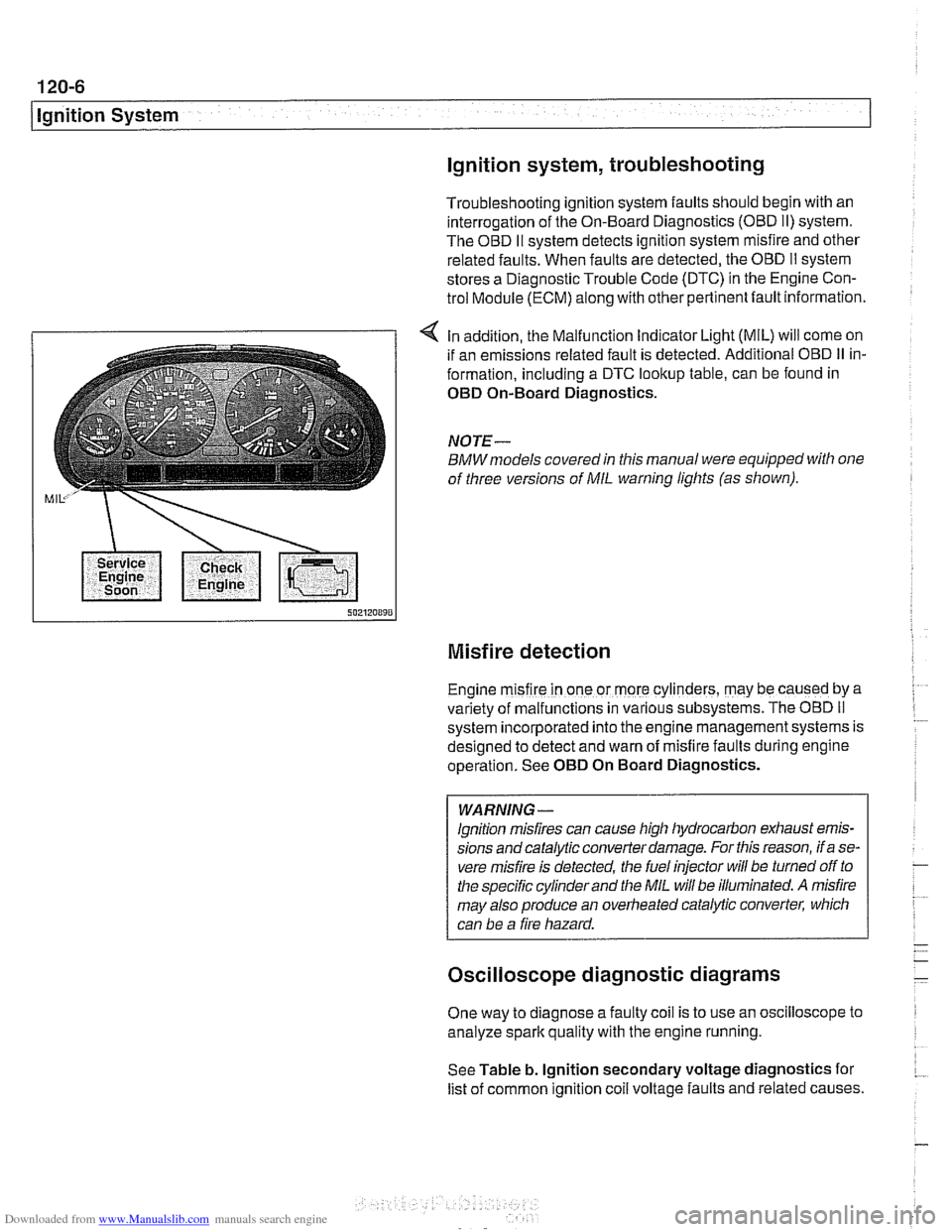

4 In addition, the Malfunction Indicator Light (MIL) will come on

if an emissions related fault is detected. Additional OBD

II in-

formation, including a DTC lookup table, can be found in

OED On-Board Diagnostics.

NOTE-

BMWmodels covered in this manual were equipped with one

of three versions of

MIL warning lights (as shown).

Misfire detection

Engine m~sfire in one or more cylinders, may be caused by a

var~ety of malfunctions in various subsystems. The OBD II

system ~ncorporated into the engine management systems is

des~gned to detect and warn of misfire faults during englne

operat~on. See OED On Board Diagnostics.

WARNING -

lgnition misfires can cause high hydrocarbon exhaust emis-

sions andcatalytic converter damage. For this reason, if a se-

vere misfire is detected, the fuel injector

will be turned off to

the specific cylinder and the

MIL will be illuminated. A misfire

may also produce an overheated catalytic converter, which

can be a fire hazard.

Oscilloscope diagnostic diagrams

One way to diagnose a faulty coil is to use an oscilloscope to

analyze spark quality with the engine running.

See Table b. lgnition secondary voltage diagnostics for

list of common ignition

coil voltage faults and related causes.

Page 367 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-1

121 Battery. Starter. Alternator

General ........................... .I2 1.2

Special tools ........................ .I2 1.2

Engine electrical system ............... .I2 1.2

Battery Safety Terminal ............... .I2 1.3

Warnings and cautions ................. 121 -4

Battery ............................ 121-5

Battery testing ...................... .I2 1.5

Hydrometer testing ................... .I2 1.5

Battery open-circuit voltage test ......... .I2 1.6

Battery load voltage test ................ 121 -6

Closed-circuit current measurement ..... .I2 1.7

Battery charging ...................... 121 -9

Battery safety terminal, replacing ......... 121-9

Alternator (generator) ............. .I2 1.10

Alternator. basic .................... .I2 1.11

Alternator with multi-function

control (MFR)

...................... .I2 1.11

Water-cooled alternator ............... 121 -12

Charging System Troubleshooting . 121-12

Charging system quick-check .......... 121-13

Charging system. checking ............ 121-13

Alternator. removing and installing

(6-cylinder engine)

.................. 121 -1 5

Alternator. removing and installing

(M62 engine. air cooled)

.............. 121-16

Alternator. removing and installing

(M62 TU engine. water cooled) ......... 121-1 8

Starter ........................... 121 -1 9

Starter troubleshooting ............... 121 -1 9

Starter. removing and installing

(6-cylinder engine)

.................. 121-20

Starter. removing and installing

(V-8 engine)

........................ 121 -21

Solenoid switch. removing and installing . . 121-23

Page 368 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Battery, Starter, Alternator

This section covers the battery, alternator, starter and associ-

ated components of the electrical system.

Troubleshooting information

forthese components isfound in

Table a. Battery, alternator and starter troubleshooting.

For additional electrical troubleshooting information, see

600 Electrical System-General.

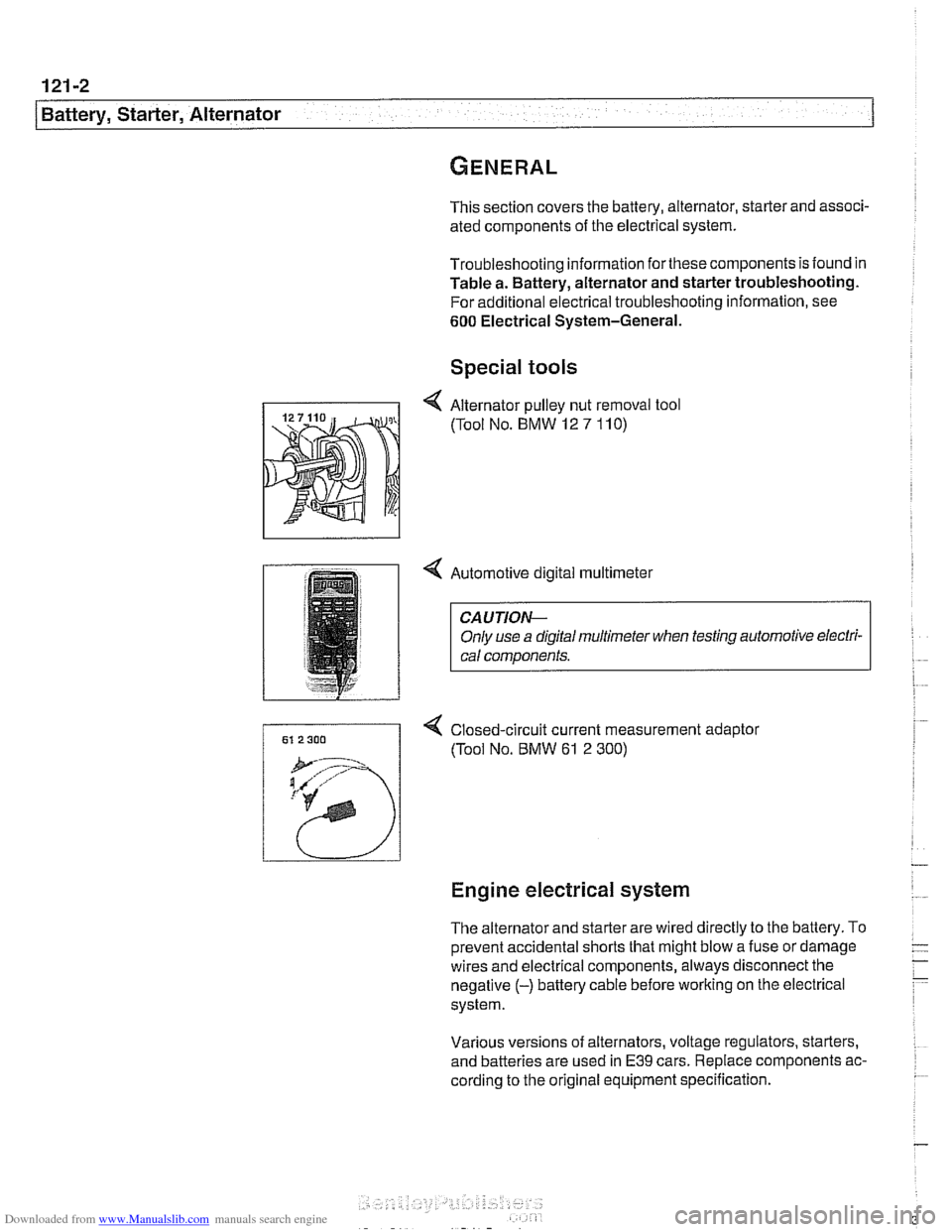

Special tools

4 Automotive digital multimeter

CAUTION-

Only use a digital multirneter when testing automotive electri- I) cal components.

4 Closed-circuit current measurement adaptor

(Tool No.

BMW 61 2 300)

Engine electrical system

The alternator and starter are wired directly to the battery. To

prevent accidental shorts that might blow a fuse or damage

wires and electrical components, always disconnect the

negative

(-) battery cable before working on the electrical

system.

Various versions of alternators, voltage regulators, starters,

and batteries are used in

E39 cars. Replace components ac-

cording to the original equipment specification.

Page 369 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

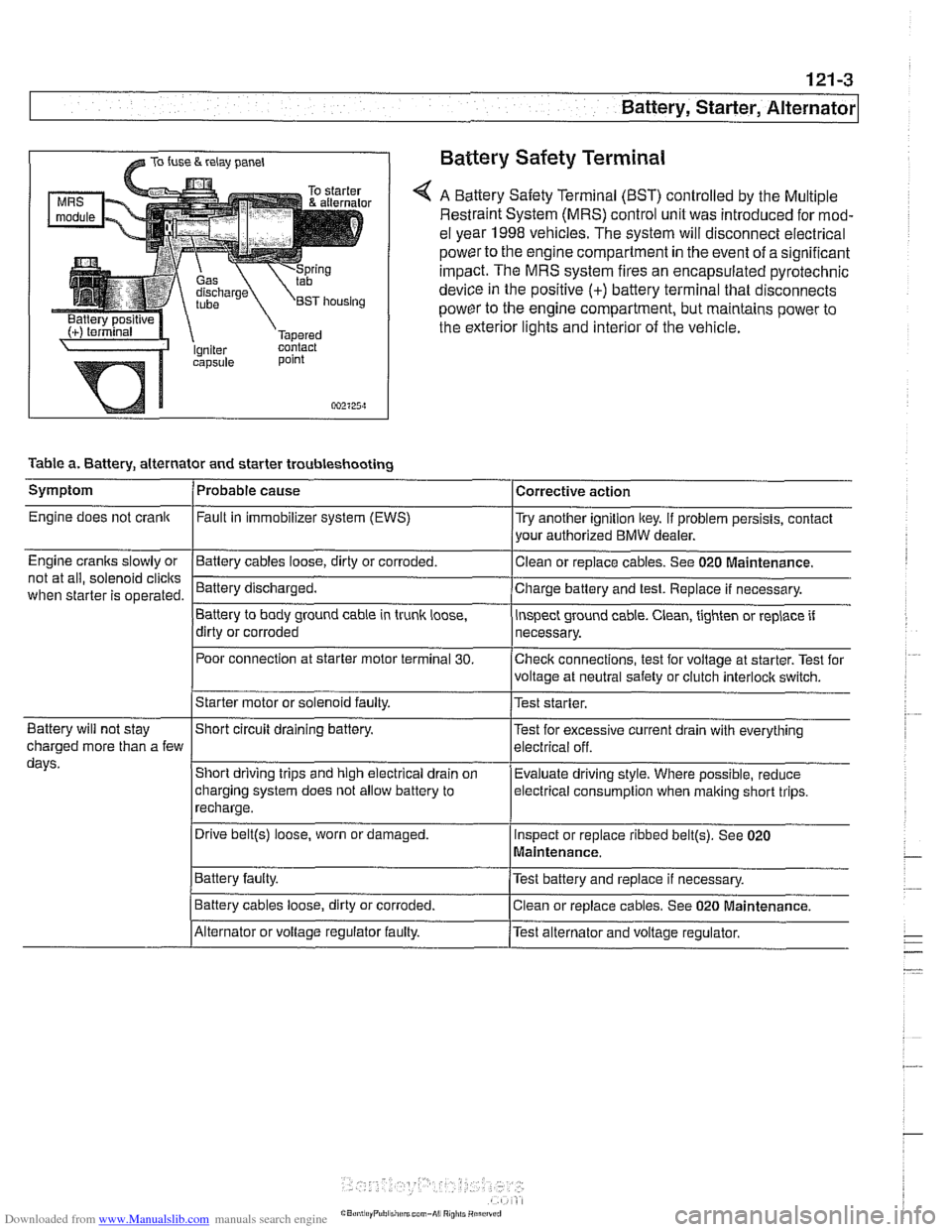

@ TO fuse & relay panel Battery Safety Terminal

A Battery Safety Terminal (BST) controlled by the Multiple

Restraint System (MRS) control unit was introduced for mod-

el year 1998

vehicles. The system will disconnect electrical

power to the engine compartment

in the event of a significant

impact. The MRS system fires an encapsulated pyrotechnic

device

in the positive (+) battery terminal that disconnects

power to the engine compartment, but maintains power to

the exterior lights and interior of the vehicle.

point

002125~1

Table a. Battery, alternator and starter troubleshooting

1-

/Starter motor or solenoid faulty. l~est starter.

Symptom

Engine does not crank

Engine cranks slowly or

not at all, solenoid

clicits

when starter is operated.

I I

Battery will not stay IShort circuit draining battery. l~est for excessive current drain with everything

Probable cause

Fault

in immobilizer system (EWS)

-Clean Battery cables loose, dirty or corroded.

Battery discharged.

Battery to body ground cable in trunk

loose,

dirty or corroded

Poor connection at starter motor terminal

30.

Corrective action

Try another ignition key. If problem persists, contact

your authorized BMW dealer.

or replace cables. See 020

~aintenance.

Charge battery and test. Replace if necessary.

inspect ground cable. Clean, tighten or replace if

necessary.

Checlc connections, test for voltage at starter. Test for

voltage at neutral safety or clutch

interloclc switch.

charged more than a few

days.

I~atter~ faulty. /Test battery and replace if necessary.

Short driving trips and high electrical drain

on

charging system does not allow battery to

recharge.

. I

I Battery cables loose, dirty or corroded. Iclean or replace cables. See 020 Maintenance.

Evaluate driving

style. Where possible, reduce

electrical

consumption when malting short trips.

Drive

belt@) loose, worn or damaged.

IAlternator or voltage regulator faulty. /Test alternator and voltage regulator.

Inspect

or replace ribbed

belt@). See 020

Maintenance.

Page 378 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, Alternator

Water-cooled alternator

The water-cooled alternator, used on 1999 and later M62 TU

engines, is a sealed unit housed inside the engine block wa-

ter jacket. It is cooled via the engine cooling system. It is a

"brushless" sealed unit that cannot be serviced. Maintaining

consistent alternator temperatures increases the life span of

the alternator, and elimination of the alternator cooling fan re-

duces alternator noise

significantly.

The M62 TU water-cooled alternator incorporates load start

reduction. This function is intended to shorten the duration of

engine starting, particularly at low ambienttemperatures. The

current load is limited to

20 amps during starting in order to re-

duce alternator braking torque on the engine. Following the

current limiting phase, full power output is then progressively

reached.

Charging system diagnostics requires special test equip-

ment. If the test equipment is not available, charging system

fault diagnosis can be performed by an authorized

BMW

dealer or other qualified repair shop. See Table a. Battery,

alternator and starter troubleshooting for general electri-

cal component troubleshooting.

Before checking the alternator, make sure the battery is fully

charged and capable of holding a charge. Check that the bat-

tery terminals are clean and tight and the alternator drive belt

is properly tensioned and not severely worn.

NOTE-

Some model require up to 15 second to reacli full alternator

output.

CA UTIOG

If the charge indicator light in the instrument cluster remains

on, the charge warning circuit in the instrument cluster may

be faulty. Check that the ground lead is securely

affached to

the grounding stud on the cylinder head

(A). Replacing the

instrument cluster before repairing the ground lead will both

damage the instrument cluster and cause the failure to

reoccur.

Page 385 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, Alternator

- Installation is reverse of removal, noting the following:

Replace alternator rubber sealing O-ring.

* Fill and bleed cooling system as described in 170 Radiator

and Cooling System.

Tightening torques

Fan clutch to coolant pump

with

BMW special tool 11 5 040 30 Nm (22 ft-lb)

without

BMW special tool 11 5 040 40 Nm (29 ft-lb)

Terminal 30 (Bc) wire to alternator (ME) 13 Nm (10 ft-lb)

STARTER

Starter troubleshooting

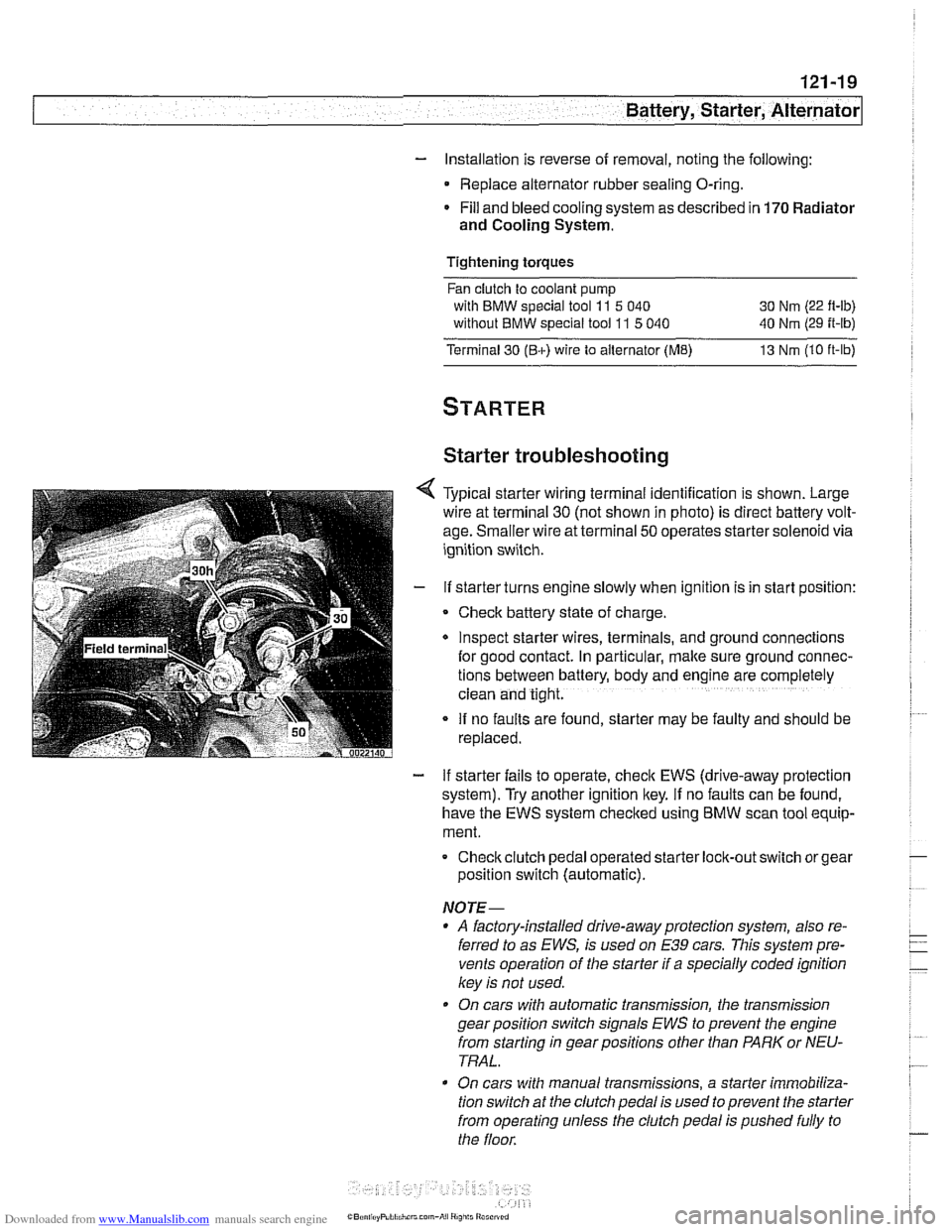

Typical starter wiring terminal identification is shown. Large

wire at terminal

30 (not shown in photo) is direct battery volt-

age. Smaller wire at terminal

50 operates starter solenoid via

ignition switch.

If starter turns engine slowly when ignition is in start position:

Check battery state of charge.

Inspect starter wires, terminals, and ground

connectlons

for good contact. In particular, make sure ground connec-

tions between battery, body and

englne are completely

clean and tight.

If no faults are found, starter may be faulty and should be

replaced.

- If starter fails to operate, check EWS (drive-away protection

system). Try another ignition key.

If no faults can be found,

have the EWS system checked using

BMW scan tool equip-

ment.

Checkclutch pedal operated

starter lock-out switch or gear

position switch (automatic).

NOTE-

* A factory-installed drive-away protection system, also re-

ferred to as

EWS, is used on E39 cars. This system pre-

vents operation of the starter if a specially coded ignition

key is not used.

On cars with automatic transmission, the transmission

gear position switch signals

EWS to prevent the engine

from starting in gear positions other than PARK or NEU-

TRAL.

On cars with manual transmissions, a starter immobiliza-

tion switch

at the clutch pedal is used to prevent the starter

from operating unless the clutch pedal is pushed fully to

the floor.

Page 392 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-2

/Fuel Injection

This repair group covers service and repair of the Bosch and

Siemens engine management systems used on

1997

through 2002 E39 models. Additional engine management

service and repair information may also be found in the fol-

lowing repair groups:

0 020 Maintenance

120 Ignition System

160 Fuel Tank and Fuel Pump

610 Electrical Component Locations

OBD On Board Diagnostics

NOTE-

Camshaft position sensor, crankshaft speed sensor and

knoclc sensors are covered in 120 Ignition System.

Table a. Engine management system applications

- - ~ ~

1 ~odellmodel year / Engine IDME system I - I

5281, 1997-1 998 IM52. 2.8 liter ISiemens MS 41 .I I 1

528i. 1999ZO00 1~52 TU, 2.8 liter ]siemens MS 42.0 I I

5251, 2001-2002 1~54, 2.5 liter 1 Siemens MS 43.0 I I

530i, 2001-2002 1~54, 3.0 liter ISiemens MS 43.0

5401 1999-2001 1~62 TU, 4.4 liter l~osch ME 7.2

I

OBI) II software and hardware is incorporated in the engine

management control systems. The

OED II system monitors

components that influence exhaust and evaporative emis-

sions. If a problem is detected, the

OED I1 system stores the

associated fault code and condition.

540i. 1997

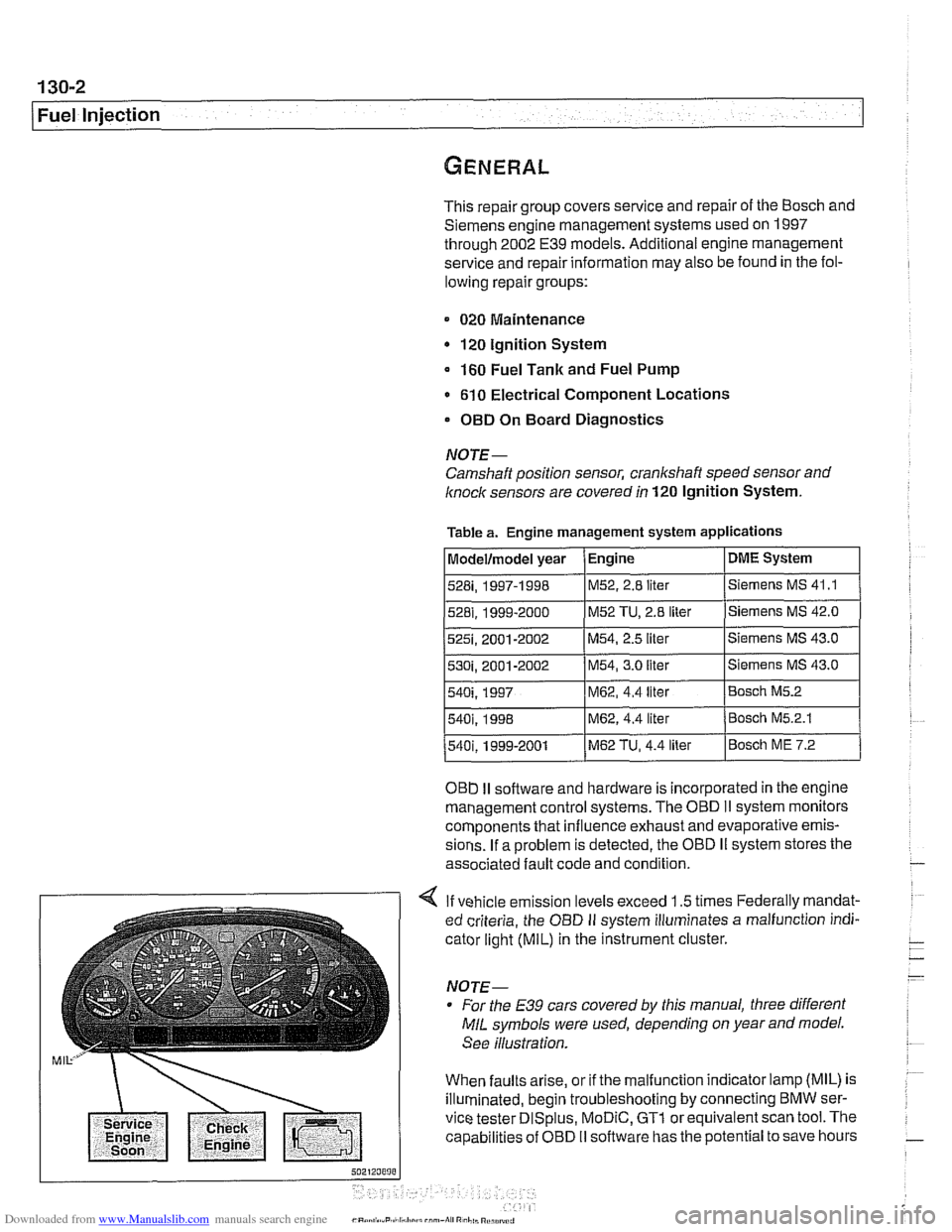

4 If vehicle emission levels exceed 1.5 times Federally mandat-

ed criteria, the

OED II system illuminates a malfunction indi-

cator light

(MIL) in the instrument cluster.

For the

E39 cars covered by this manual, three different

MIL symbols were used, depending on year and model.

See illustration.

When faults arise, or if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus, MoDiC, GTl or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

540i. 1998 IM62, 4.4 liter /Bosch M5.2.1

M62, 4.4 liter Bosch M5.2

Page 396 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-6

Fuel Injection

Fuel supply to the injection system is provided by a high pres-

sure electric pump mounted inside the fuel tank. The pump is

powered via the fuel pump relay. If the relay is faulty, the fuel

pump will not run and the engine will not start.

NOTE-

* Fuel delivery volume and fuel pressure are critical to prop-

er operation. Fuel pressure direcfly influences fuel deliv-

ery

Fuel pump relay, fuel pressure and fuel volume tests are

given in 160 Fuel Tank and Fuel Pump.

Relieving system fuel pressure

The fuel system retains fuel pressure in the system when the

engine is off. To prevent fuel from spraying on a hot engine,

system fuel pressure should be relieved beforedisconnecting

fuel lines. One method is to tightly wrap

ashop towel around a

fuel line fitting and loosen or disconnect the fitting. Cleanli-

ness is essential when working with fuel components. Thor-

oughly clean the unions before disconnecting fuel lines.

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also iiluminates if an emissions-related fault is detected

When faults arise, or if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus. MoDiC, GTI or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CAUTION-

- The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the

MIL. Affer all testing is completed,

access and clear DJC fault memory using an

OED I1 or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

0 Only use a digital multimeter for electrical tests.

. Relay positions can vary Be sure to confirm relay posi-

tion by identifying the wiring in the socket using the wir-

ing diagrams found in ELE Electrical Wiring

Diagrams.

Page 413 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Fuel Injection

SIEMENS MIS 42.0 AND 43.0

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also illuminates

if an emissions-related fault is detected.

When faults arise, or

if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus, MoDiC, GTI or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CAUTION-

* The tests in this section may set fault codes (DTCs) in tlie

ECM and illuminate the MIL. After all testing is completed,

access and clear DTC fault

memory using an OBD I/ or

BMW compatible scan tool. See

OBD On-Board Diag-

nostics.

Only use a

dgital multimeter for electrical tests.

Relay positions can vary. Be sure to confirm

relayposi-

tion by identifying the wiring in the socket using the wir-

ing diagrams found in

ELE Electrical Wiring

Diagrams.

NOTE-

- OBD I1 fault memory. (including an illuminated MIL! can

only be reset using the special scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault memory.

The BMW-dedicated 20-pin diagnostic

linlc connector

(DLC) is in the right rear of the engine compartment The

20-pin DLC is discontinued on models after

6/2000.

The 1 &pin OBD I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

The MS

42.0 and MS 43.0 systems manage the following

functions.

- Air:

Idle speed valve

Electronic throttle

Hot film mass air flow (MAF) sensor

Resonance-turbulence intake control

- Fuel:

* Fuel supply

Running losseslnon return

Fuel injection

Page 436 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-46

Fuel Injection

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also illuminates if an emissions-related fault is detected.

When faults arise, or

if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus. MoDiC, GTI or equivalent scan tool. The

capabilities of

OED II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CA UTIOiU-

The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the MIL. After ail testing is completed,

access and clear DTC fault

memory using an OED I/ or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

Only use a digital

multimeter for electrical tests.

Relay positions can vary. Be sure to confirm relay

posi-

. tion by identifying the wiring in the socket using the wir-

ing diagrams-found in ~~~~lectrical Wiring

Diagrams.

NOTE-

OED I1 fault memory (including an illuminated MIL) can

only be reset

using~the special scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault

memory.

The BMW-dedicated 20-pin diagnostic link connector

(DLC) is in the right rear of the engine compartment.

The 16-pin OBD

I1 diagnostic connector (arrow) is located

inside the car on

the lower left dash panel.