troubleshooting BMW 528i 1998 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 740 of 1002

Downloaded from www.Manualslib.com manuals search engine

---

Rear Suspension

ELECTRONIC HEIGHT CONTROL

(EHC) COMPONENT REPLACEMENT

Sport Premium rear suspension is an option on Sport Wagon

models and standard on

1999 and later V-8 Sport Wagons.

This suspension incorporates electronic height control

(EHC)

using air springs.

With vehicle lifted off the ground,

if the rear air springs can be

compressed by hand, either the spring is defective or the sys-

tem is depressurized.

Locate

EHC faults using BMW scan tools DIS or MoDiC. EHC

description and some troubleshooting is covered in 300 Sus-

pension, Steering and Brakes-General.

Air spring replacement is covered earlier in this chapter. See

Air spring, removing and installing.

CAUTION-

Maintain high levels of cleanliness around air line connec-

tions when disassembling and assembling air suspension

components. Even

small dirt particles can cause leakage in

the pressurized system.

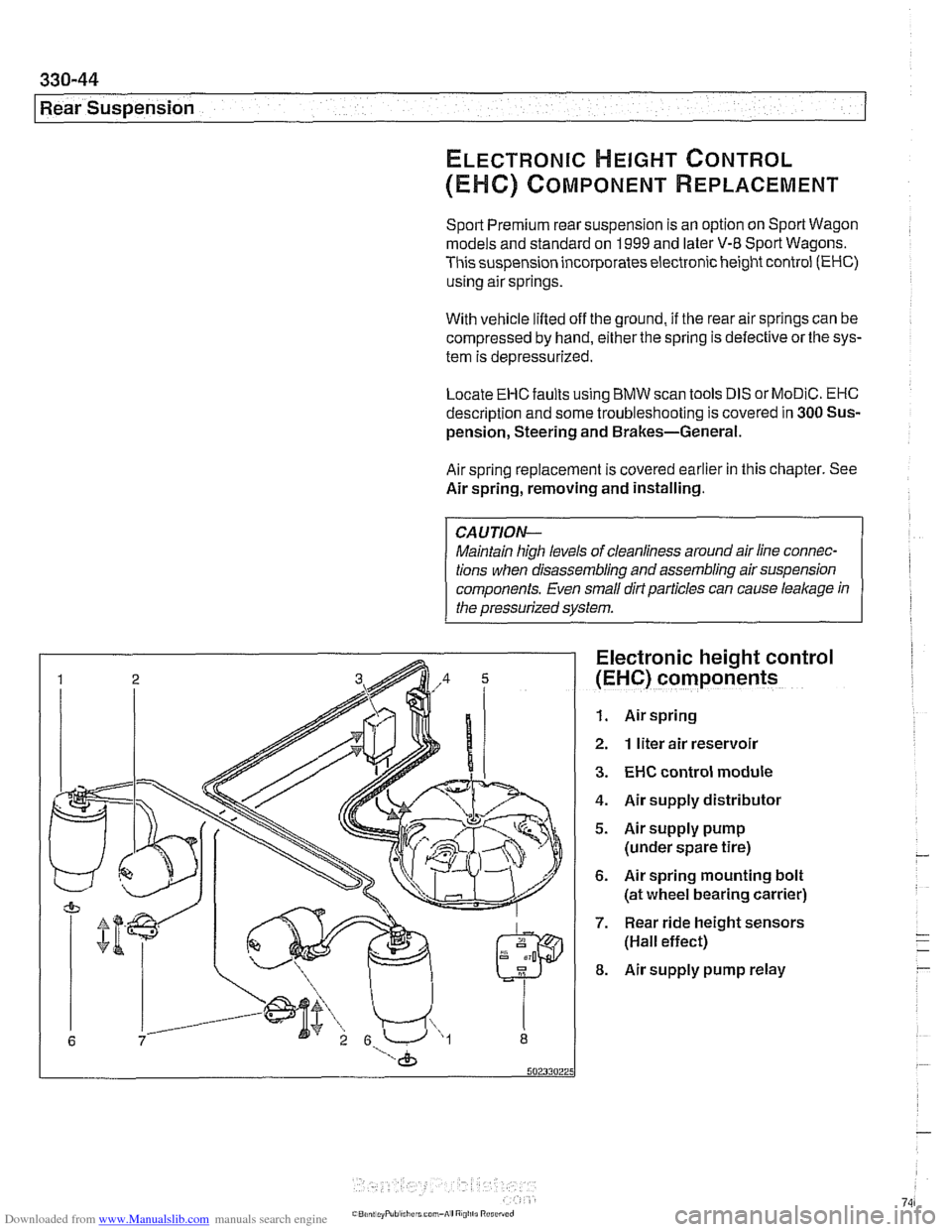

Electronic height control

(EHC) components

1. Air spring

2. 1 liter air reservoir

3. EHC control module

4. Air supply distributor

5. Airsupply pump

(under spare tire)

6. Air spring mounting bolt

(at wheel bearing carrier)

7. Rear ride height sensors

(Hall effect)

8. Air supply pump relay

Page 763 of 1002

Downloaded from www.Manualslib.com manuals search engine

General ........................... .34 0.2

Special Tools

....................... .34 0.2

E39 brake system

.................... .34 0.4

Electronic braking and stability control

.... .34 0.4

Troubleshooting

..................... .34 0.5

Warnings and cautions

................ .34 0.7

Bleeding Brakes ................... .34 0.8

Brakes, bleeding

..................... .34 0.9

Brake Pads, Calipers and Rotors ... .34 0.1 1

Braking system components .......... .34 0.11

Brake pads,

checking and replacing ..... .34 0.12

Brake rotors, removing and installing

.... .34 0.15

Master Cylinder .................. .34 0.16

Master cylinder, removing and installing

. .34 0.17

Brake Booster .................... .349 0.1

Brake booster check valve

............ .34 0.19

Brake booster, removing and installing

.. .34 0.20

Parking Brake .................... .34 0.22

Parking brake components

............ .34 0.22

Parking

brake, adjusting .............. .34 0.22

Parking bralte shoes, removing

and installing

....................... .34 0.23

Parking

brake cable, replacing ......... .34 0.24

ABS Component Replacement ..... 340-26

Wheel speed sensor. replacing

......... 340-26

ABS impulse wheel

.................. 340-27

DSC lateral acceleration or

rotational rate (yaw) sensor. replacing

... 340-27

DSC steering angle sensor.

removing and installing

............... 340-28

DSC precharge pump.

removing and installing (1998 models)

... 340-29

DSC pressure sensor

(1 999 - 2002 models) ................ 340-30

ABS /traction electronic control

module

(1 997 -1 998 models) .......... 340-31

ABS

/ DSC control module

(1 999

- 2002 models) ................ 340-31

ABS

/ traction control hydraulic unit.

removing and installing

............... 340-31

Page 767 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Troubleshooting

Brake performance is mainly affected by three things:

Q Level and condition of brake fluid

Ability of bralte system to create and maintain pressure

Condition of friction components

Air in bralte fluid will

make the brake pedal feel spongy during

braking

orwill increase the bralte pedal force required to stop.

Fluid contaminated by moisture or dirt can corrode the sys-

tem. lnspect the brake fluid inside the reservoir. If it is dirty or

murky, or is more then two years old, replace fluid.

To

check the function of the master cylinder hold the bralte

pedal down hard with the engine running. If the pedal slowly

falls to the floor, either the master cylinder is leaking internal-

ly, or fluid is leaking externally.

lnspect the rotors for glazing, discoloration and scoring.

Steering wheel vibration while braking at speed is often

caused by warped rotors, but can also be caused by worn

suspension components.

When troubleshooting, keep in mind that tire inflation, wear

and temperature can all have an affect on braking. See

300

Suspension, Steering and Brakes-General for additional

suspension and brake system troubleshooting.

The table Brake system troubleshooting lists symptoms of

brake problems, probable causes, and suggested corrective

actions. Unless noted otherwise, relevant repairs are de-

scribed later in this repair group.

Page 768 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-6

1 Brakes

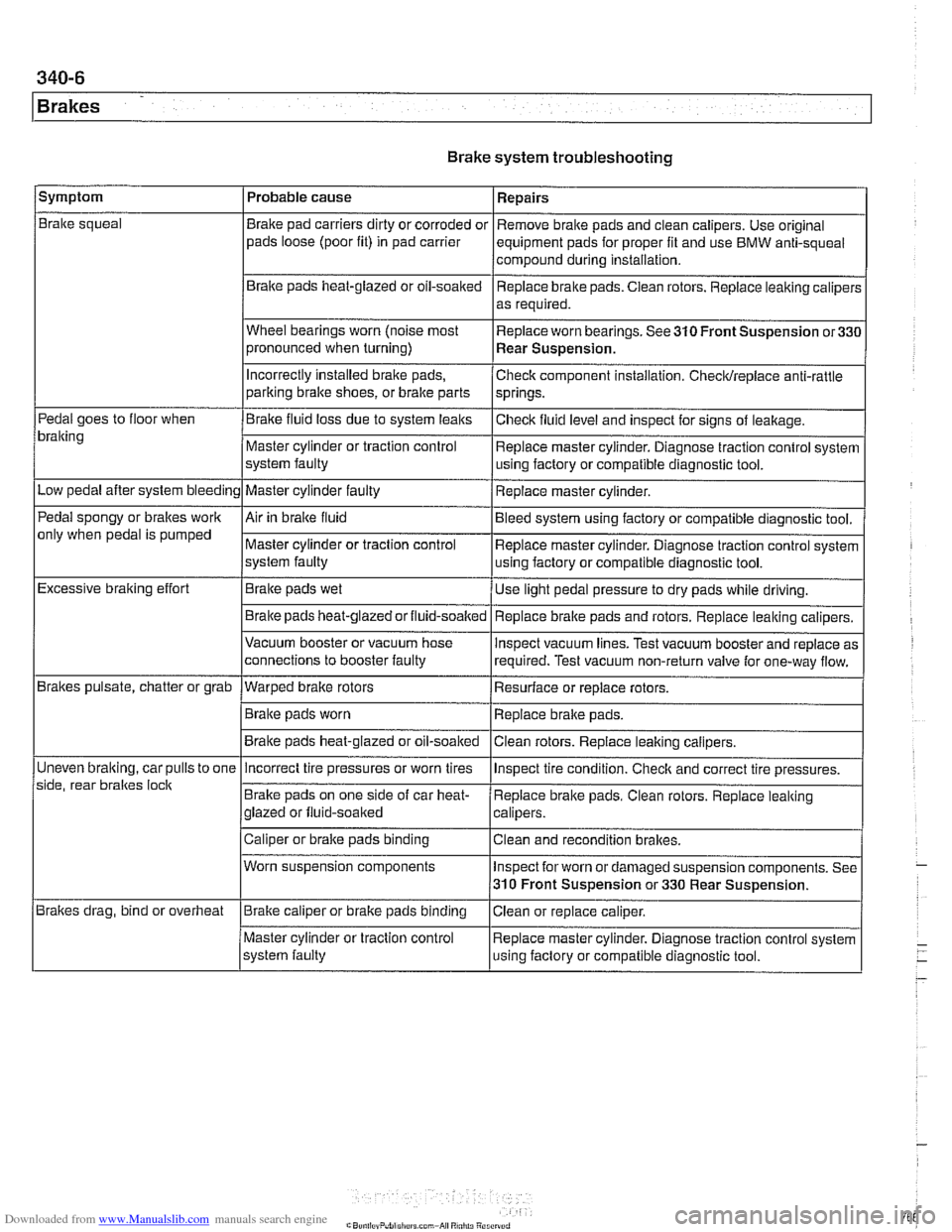

Brake system troubleshooting

/symptom I Probable cause 1 Repairs

Brake squeal

Pedal goes to floor when

bralting

Low pedal after system bleeding

Pedal spongy or brakes work

only when pedal is pumped

Excessive braking effort

Brakes pulsate, chatter or grab

Uneven

bralting, car pulls to one

side, rear braltes

loclt

Brakes drag, bind or overheat Brake

pad carriers dirty or corroded or

pads loose (poor fit) in pad carrier

Braite pads heat-glazed or oil-soaked

Wheel bearings worn (noise most

pronounced when turning)

Incorrectly Installed brake pads,

parking bralte shoes, or bralte parts

Brake fluid loss due to system leaks

Master cylinder or traction control

system faulty

Master cylinder faulty

Air in braite fluid

Master cylinder or traction control

system faulty

Brake pads wet

Brake pads

heat-glazedorfluid-soalted

Vacuum booster or vacuum hose

connections to booster faulty

--- Warped brake rotors

Brake pads worn

Brake pads heat-glazed or oil-soaked Remove

brake pads and clean calipers. Use original

equipment pads for proper fit and use BMW anti-squeal

compound during installation,

Replace brake pads. Ciean rotors. Replace leaking caliper:

as required.

Replace worn bearings. See 310 Front Suspension

or33C

Rear Suspension.

Check component installation. Checldreplace anti-rattle

springs.

Checlt fluid level and inspect for signs of leakage.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Replace master cylinder.

Bleed system using factory or compatible diagnostic tool.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Use light pedal pressure to dry pads while driving.

Replace

bralte pads and rotors. Replace leaking calipers.

lnspect vacuum lines. Test vacuum booster and replace as

required. Test vacuum non-return valve for one-way flow.

Resurface or replace rotors.

Replace brake pads.

Clean rotors. Replace leaiting calipers.

Incorrect tire pressures or worn tires

Brake pads on one side of car heat-

glazed or fluid-soaked

Caliper or brake pads binding

Worn suspension components

Brake caliper or brake pads binding

Master cylinder or traction control

system faulty lnspect

tire condition. Checlt and correct tire pressures.

Replace brake pads. Clean rotors. Replace leaking

calipers.

Clean and recondition brakes.

Inspect for worn or damaged suspension components. See

310 Front Suspension or 330 Rear Suspension.

Ciean or replace caliper.

Replace master cylinder. Diagnose traction control system

using faclory or compatible diagnostic tool.

Page 802 of 1002

Downloaded from www.Manualslib.com manuals search engine

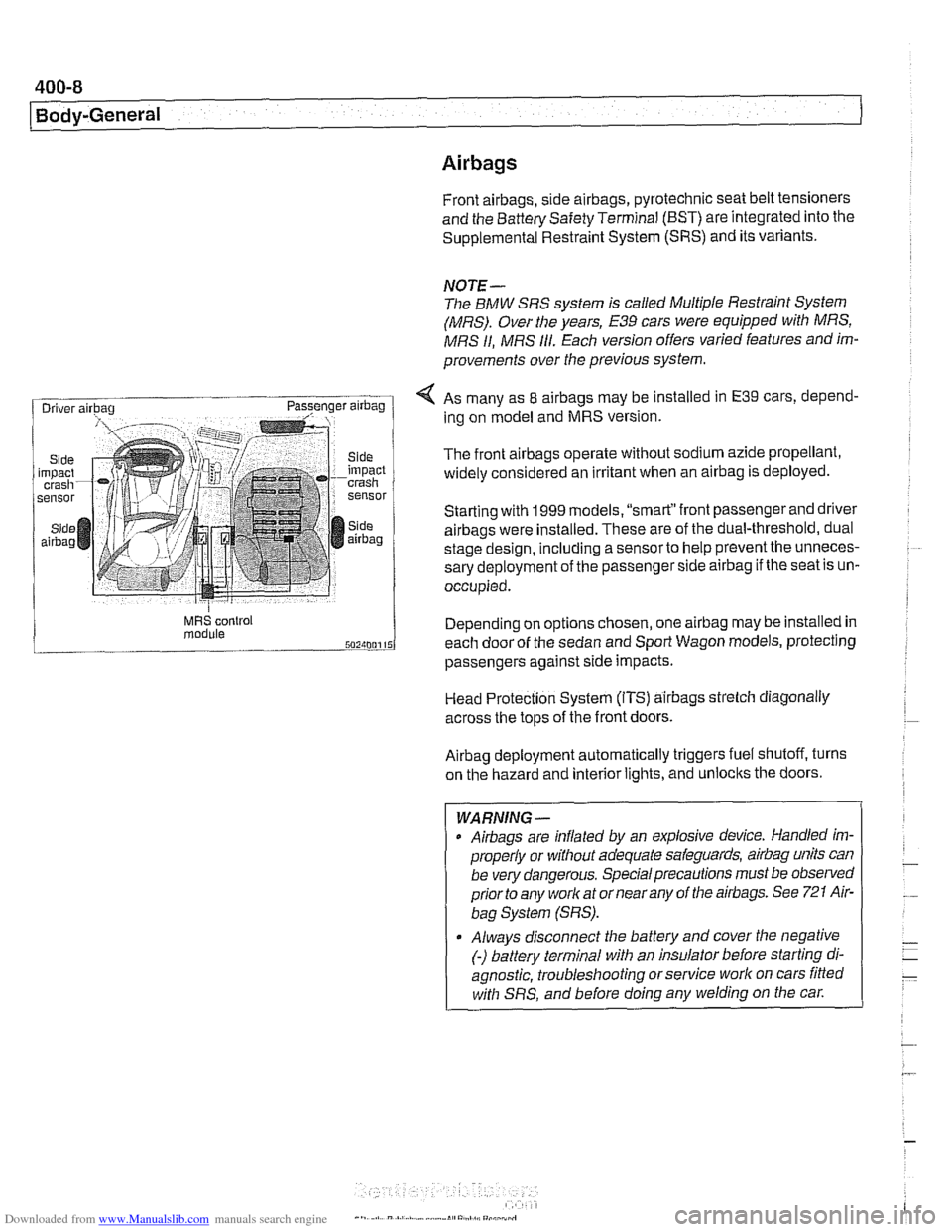

400-8

Body-General

Airbags

Front airbags, s~de a~rbags, pyrotechnic seat belt tensioners

and the Battery Safety Terminal (BST) are integrated into the

Supplemental Restraint System (SRS) and its variants.

NOTE-

The BMW SRS system is called Multiple Restra~nt System

(MRS). Over the years,

E39 cars were equipped with MRS,

MRS

11, MRS 111. Each version offers varied features and im-

provements over the previous system.

< As many as 8 airbags may be installed in E39 cars, depend-

ing on model and MRS version.

The front

airbags operate without sodium azide propellant,

widely considered an irritant when an

airbag is deployed.

Starting with

1999 models. "smart"front passenger and driver

airbags were installed. These are of the dual-threshold, dual

stage design, including a

sensorto help prevent the unneces-

sary deployment of the passenger side

airbag if the seat is un-

occupied.

MRS control Depend~ng on options chosen, one airbag may be installed in module each door of the sedan and Sport Wagon models, protecting

passengers against

s~de impacts.

Head Protection System (ITS)

airbags strelch diagonally

across the tops of the front doors.

Airbag deployment automatically triggers fuel shutoff, turns

on the hazard and interior lights, and unlocks the doors.

- -

WARNING -

Airbags are inflated by an explosive device. Handled im-

properly or without adequate safeguards,

airbag units can

be very dangerous. Special precautions must be observed

prior to any worlc at or near any of the airbags. See

721 Air-

bag System (SRS).

Always disconnect the battery and cover the negative

(-) battery terminal with an insulator before starting di-

agnostic, troubleshooting or service work on cars fitted

with SRS, and before doing any welding on the

car.

Page 939 of 1002

Downloaded from www.Manualslib.com manuals search engine

........... General ........................... .72 0.2 Rear Seat Belt Assembly 720-8

......... Troubleshooting ..................... .72 0.2 Rear seat belt assembly (sedan) 720-8

................ Rear seat belts (sedan) 720-9

... .......... Front Seat Assembly '720-4 Rear seat belt assembly (Sport Wagon) 720-9

Front seat belt tensioner,

......... Rear seat belts (Sport Wagon) 720-10

removing and installing ................ .72 0.4

Front seat belt assembly

.............. .72 0.6

Front seat belt reel. removing and

installing (sedan and Sport Wagon models)

.72 0.6

Page 940 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Seat Belts

This section covers repairs to the following seat belts sys-

tems. See the table below.

IMultIple Restraint Systems I

Years

311 996 - 811 997

Multiple Restraint System electronics integrate seat belt op-

erations and

airbag deployment. Airbag repair information is

covered

in 721 Airbag System (SRS).

Troubleshooting

The seat belt reel should lock when driving quicltly through

curves,

during severe braking or in case of a collision. The au-

tomatic reel does not require any servicing and should never

be opened.

- In case of an accident, follow the seat belt troubleshooting

procedures presented

in the table below.

Troubleshooting procedures

Belt creased, unraveled, pinched, cut or

melted. Belt buckle or belt loclt plastic casing Repairs

Replace complete automatic

seat belt.

Also

checlt and replace, if necessary, seat

Problem

Damage to seat

belt.

worn, damaged or missing.

Seat belt bucltle is not ejected with spring

pressure when red button on seat belt loclt is

>--- I I

Automatic belt soueaks when fastened or I~xcessive friction in belt guides. I Replace reel assembly.

Probable

cause

Accident in which bumper impact absorbers

were permanently deformed.

Seat belts aged or worn.

pressed.

Seat belt automatic reel does not lock when

pulled out suddenly.

Seat belt automatic reel jams when pulled

out.

Seat belt does not retract automatically

(see note below).

Automatic reel loose. Return sorino broken inside reel. belt mounting on car body and

seat belt

mounting on seat runner.

Replace complete automatic seat belt.

Seat belt

loclt mechanism worn or

damaged.

Tighten reel mounting bolt Replace reel assembly.

Replace seat belt lock.

Automatic reel defective.

Automatic reel loose. Return spring

broken inside reel.

Automatic reel loose.

Return spring brolten inside reel. Replace reel

assembly.

Tighten reel mounting

bolt.

Replace reel assembly.

Tighten reel mounting bolt. Replace reel assembly.

~ ~-~~ , - I'

Replace complete automatic seat belt.

Also check retaining bracket of belt

Seat belt

pyrotechnic tensioner triggered. Accident triggered pyrotechnic deployment.

Page 953 of 1002

Downloaded from www.Manualslib.com manuals search engine

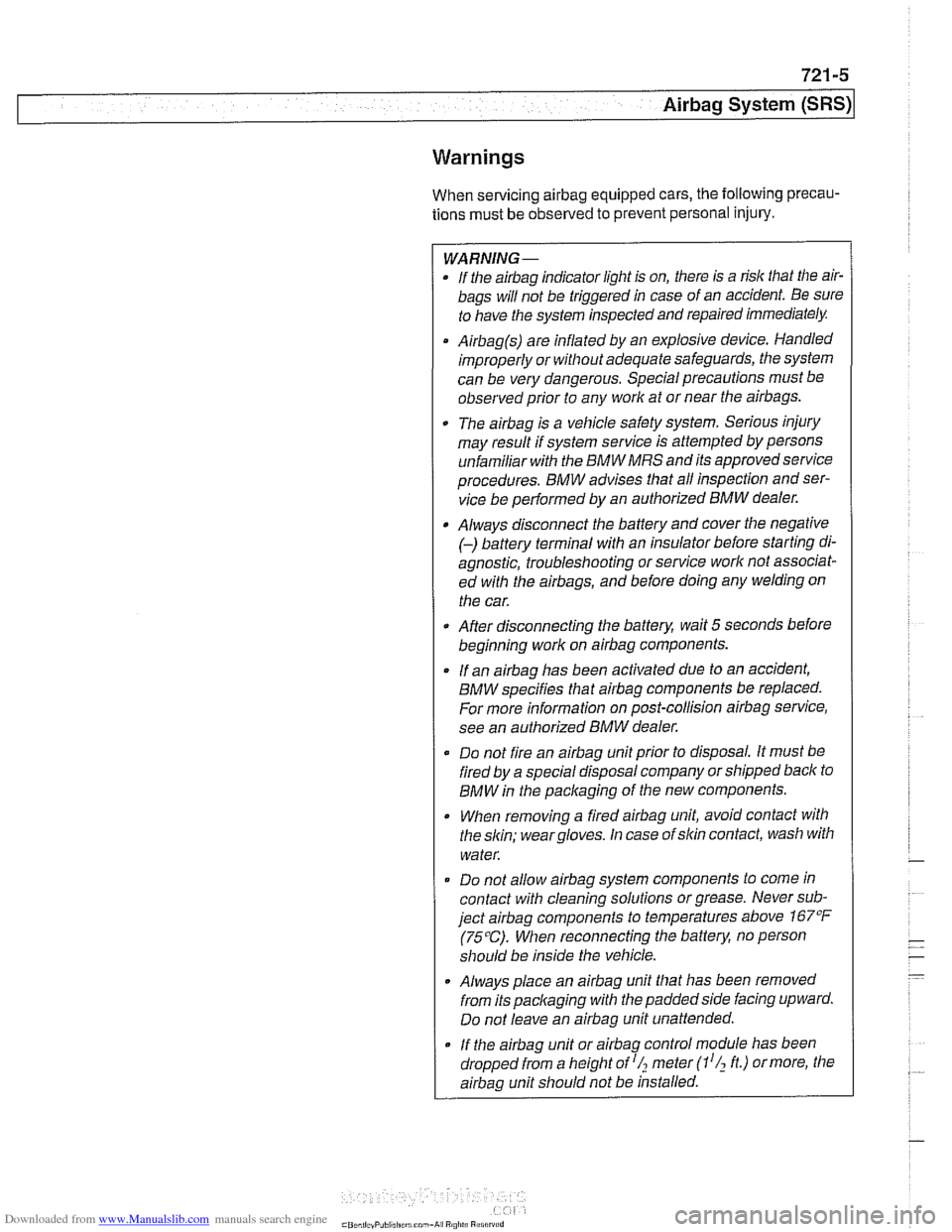

Airbag System (SRS)~

Warnings

When servicing airbag equipped cars, the following precau-

tions must be

observed to prevent personal injury.

WARNING-

. If the airbag indicator light is on, there is a risk that the air-

bags will not be triggered in case of an accident Be sure

to have the system inspected and repaired immediately

Airbag(s) are inflated by an explosive device. Handled

improperly or witliout adequate safeguards, the system

can be very dangerous. Special precautions must be

observed prior to any work at or near the airbags.

0 The airbag is a vehicle safety system. Serious injury

may result if system service is attempted by persons

unfamiliar with the BMW

MRS and its approved service

procedures. BMW advises that all inspection and ser-

vice be performed by an authorized BMW dealer.

Always disconnect the battery and cover the negative

(-) battery terminal with an insulator before starting di-

agnostic, troubleshooting or service

work not associat-

ed

with the airbags, and before doing any welding on

the car.

0 After disconnecting the battery, wait 5 seconds before

beginning work on

airbag components.

* If an airbag has been activated due to an accident,

BMW specifies that

airbag components be replaced.

For more information on post-collision

airbag service,

see an authorized BMW dealer.

Do not fire an

airbag unit prior to disposal. It must be

fired by a special disposal company or shipped back to

BMW in the packaging of the new components.

When removing a fired

airbag unit, avoid contact with

the

skin; weargloves. In case ofskin contact, wash with

water.

Do not allow

airbag system components to come in

contact with cleaning solutions or grease. Never sub-

ject

airbag components to temperatures above 167°F

(75°C). When reconnecting the battery, no person

should be inside the vehicle.

Always place an

airbag unit that has been removed

from its

packaging with the paddedside facing upward.

Do not leave an

airbag unit unattended.

0 If the airbag unit or airbag control module has been

dropped from a height of

'/? meter (I//: ft.) or more, the

airbag unit should not be installed.

Page 992 of 1002

Downloaded from www.Manualslib.com manuals search engine

2 INDEX

Battery, starter, alternator

alternator (generator)

121-10

6-cylinder engine, removingi

installing 121-15

M62 engine 121-16

M62 TU engine (water cooled)

121-18

battery

121-5 charging 121-9

safety terminal 121-3

testing 121-5 charging system, troubleshooting

121-12

starter

121-1 9

6-cylinder engine, removingi instaliinq 121-20 . V-8 engine, rernovinglinsialiing

121-21

solenoid, removinglinstalling

121-23 troubleshooting 121-19

see also Maintenance

Bearing, wheel

see Front suspension

see also Rear suspension

Belts see Maintenance, drive belts

Blade, wiper

see Wipers and Washers

Blower motor see

A/C

BMW emblem

see Exterior trim

BMW special tools 010-18 see also special tools section at

beginning

of each repair group

Body dimensions 400-2

interior features

400-9 salety and security 400-7

Body side molding

see Exterior trim

Bonnet see Engine hood

Boot see Trunk

Brake fluid

020-24, 340-8

Brake fluid pressure sensor

340-30

Brakes

ABS, ASC or DSC system

300-12

component replacement 340-26

ASCIDSC switch

see Switches

bleeding

bralces 340-8

brake booster 340-1 9 bralce Dads. caiioers and rotors ,., 340-1 1

descriotion 300-10

e~ectrdnic brake & stability 300-11

light switch

see Switches

master cylinder

340-16 pariking brake 340-22

troubleshooting 340-5

Bulbs see Lights

Bumper

lront 510-6 height, adjusting 510-12

rear 510-9

Bus system

600-4

Camber

320-33

Camshaft

removingiinslaiiing

M52 engine 116-12

M52 TU

/ M54 engine 116-1 9 M62 engine 11 6-39

wear

116-6

Camshaft position sensors

see ignition system

Camshaft timing chain

adjusting M52 engine

117-22

M52 TU I M54 engine 117-43

M62 engine 117-79 removinglinstalling

M52 engine 117-26

M52TU 1 M54 engine 113-46.116-

28

M62 engine 117-66

Capacities, fluid

020.10

Car rnemorvlicev memorv . . 600-10

see also Centrai

lociking

Carbon canister, activated

see Fuel

tank

Caster

320-33

Catalytic converter and oxygen sensor 020-19

see also Exhaust system: exhaust

manilolds

Cautions

001-3

CD changer

650-4

Center bearing, driveshaft

see Driveshait

Center brake light

sedan

630-13

Center console

513-3

Centrai body electronics (ZKE 111)

600-6

Central locking

car memoryiey memory 515.12 general module iunctions 515-2

remote entry (FZV) 515-8

remote lkey initialization 515-10 single lociddouble ioclk 515-6

switch 515-4

Chain

see Camshaft liming chain

Characteristic map (electrically heated) thermostat

see Electrically heated thermostat

Charging system

see Battery, starter, alternator

Cluster see instruments

Clutch fluid see Maintenance

hydraulics

210-4

mechanical 210-9

switch

see Switches, pedal ciuster

variations

210.10

Codes, fault OED-1

Coil

see Ignition system

Coil spring

see Front suspension

see also Rear

suspe nsion

Page 993 of 1002

Downloaded from www.Manualslib.com manuals search engine

WARNING

Your common sense, good

judgement, and general alertness are

crucial lo sale and

successlul service

work. Belore attempling any work on

your BMW, be sure to read 001

General Warnings and Cautions

and lhe copyright page

a1 llle Iron1 01

the manual. Review lliese warnings

and cautions each time you prepare

lo work on your

BMW Please also

read any warnings and

caulions lhal

accompany the procedures In !he

manual.

Component locations

see Electrical system

Compression test

113-5

Compressor see

AlC

Condenser see

AlC

Constant velocity (CV) joint

see Maintenance

see also

Driveshall

see also Drive axles

Consumer cutoff

600-10

Control arm see Front suspension

see also Rear suspension,

suspension arms

Coolant (antifreeze) see Maintenance

see also Cooling system

Coolant pump

see Cooling system Cooling system

coolant bleeding

170-14 6-cylinder engine, draininglfilling

170-10

V-8 engine, draininglfilling 170-12

coolant pump 170-3

6-cyiinder engine, replacing 170-1 9

V-8 engine, replacing 170-20 cooling fan 170-4

viscous ciutch fan, removingi

installing 170-14

electric fan, removlngiinstailing 170-1 5

expansion tank, removinglinstalling

170-22

electrically heated (ciiaracterislic

map) therrnostat 170-4

radiator, removinglinstaliing 170-22

service

see Maintenance

therrnostat 170-16

transmission fluid heat exchanger

170-5 troubleshooting 170-7

combuslion leal( test 170-10

pressure test

170-9

Crankshaft oil seals

iront

117-6

rear 11 9-6

Crankshaft speed sensor

see Ignition syslem

Crash sensor

see

Airbag system (SRS), side-impact

airbag crasii sensor

Cruise control clutch switch 612-9

CV joint

see Maintenance

see also Driveshalt

see also Drive axles

CV joint boot

see Maintenance

see also Drive axles

Cylinder head removinglinslaliing

M52 engine 113-8

M52 TU / M54 engine 113-22

M62 engine 113-56

Cylinder head and valvetrain

hydraulic lifters, checking and

replacing

116-7 leak test 116-5 valves 11 6-56

see

alsocylinder head Dashboard

513-7

Deck

lid

seeTrunk lid

Diagnostic monitors

OED-4

Diagnostic trouble codes

(DTCs)

080-7

Digital multimetel

010-17

Differential see Final drive

DLC (data

link connector) 020-4, OED-4

DME (digital motor electronics)

see

130 under appropriate fuel

injection system

see also ignition system

DM-TL (detection module-tank leak)

see

Fuel lank, leak deteclion unit

Drive

belts

see Maintenance

Dome light

seeLighls, interior lights

Door

door

check, replacing 411-4

hinge adjustment 41 1-5

loci(

see Door lock see also Central locking

removinglinslaliing 41

1-2

panel, removinglinstaliing 41 1-7 window

see Door window

Door

check

see Door

Door

handle

see Door lock

Door glass

see Door window

Door

lock

handles and loci(s 515-16

see also Central locking

Door

molding

510-13

Door panel see Door