Fuel system BMW 528i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 307 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

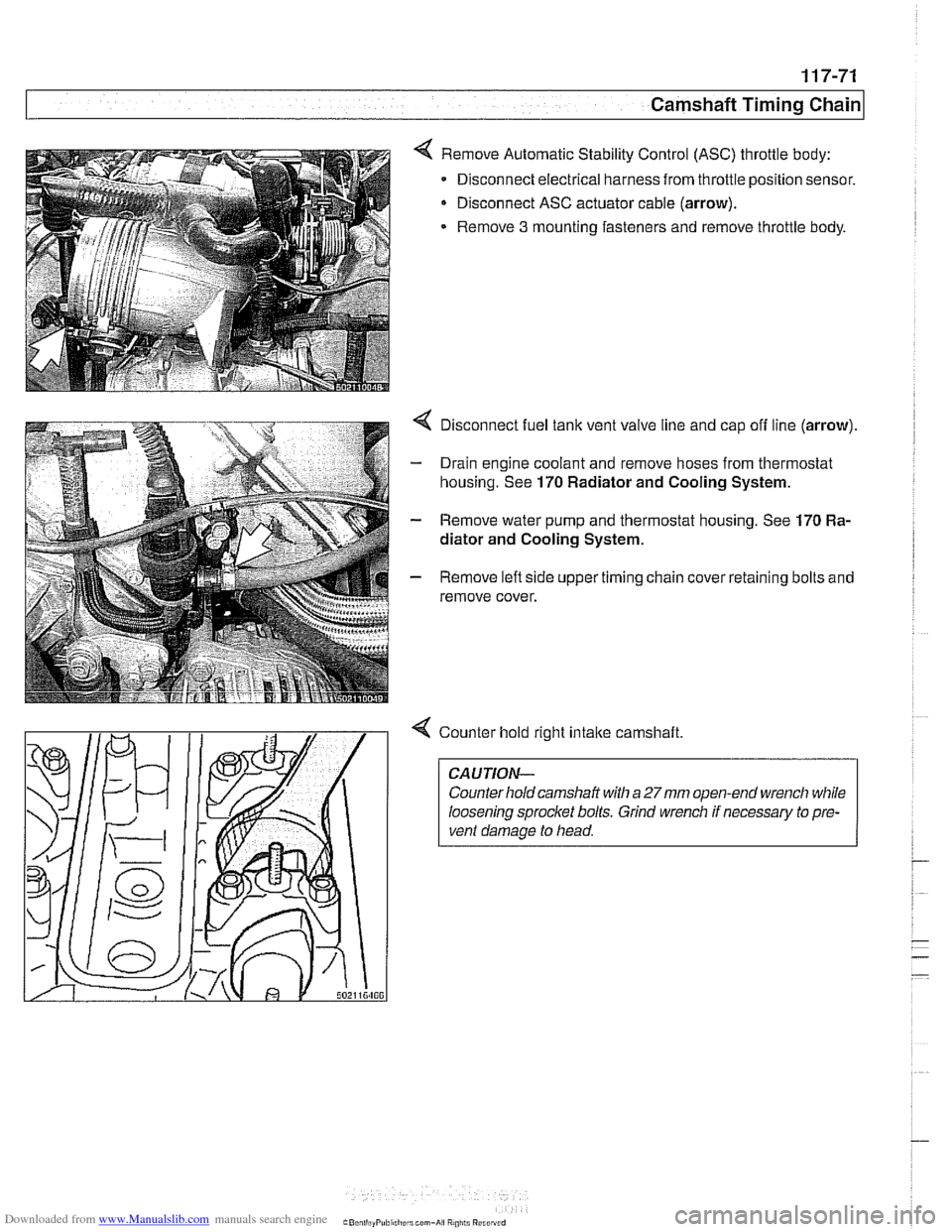

< Remove Automatic Stability Control (ASC) throttle body:

Disconnect electrical harness from throttle position sensor.

Disconnect ASC actuator cable (arrow).

Remove

3 mounting fasteners and remove throttle body.

4 Disconnect fuel tank vent valve line and cap off line (arrow).

- Drain engine coolant and remove hoses from thermostat

housing. See

170 Radiator and Cooling System.

- Remove water pump and thermostat housing. See 170 Ra-

diator and Cooling System.

- Remove left side upper timing chain cover retaining bolts and

remove cover.

4 Counter hold right intake camshaft

CAUTION-

Counter hold camshaft with a 27mm open-end wrench while

loosening sprocket bolts. Grind wrench if necessary to pre-

vent damage to head.

Page 330 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-1 0

Lubrication System

Oil pan, removing and installing

(6-cylinder)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Raise car and place securely on jack stands.

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjackstands designed for

- Remove splash shield from under engine.

- Drain engine oil as described in 020 Maintenance.

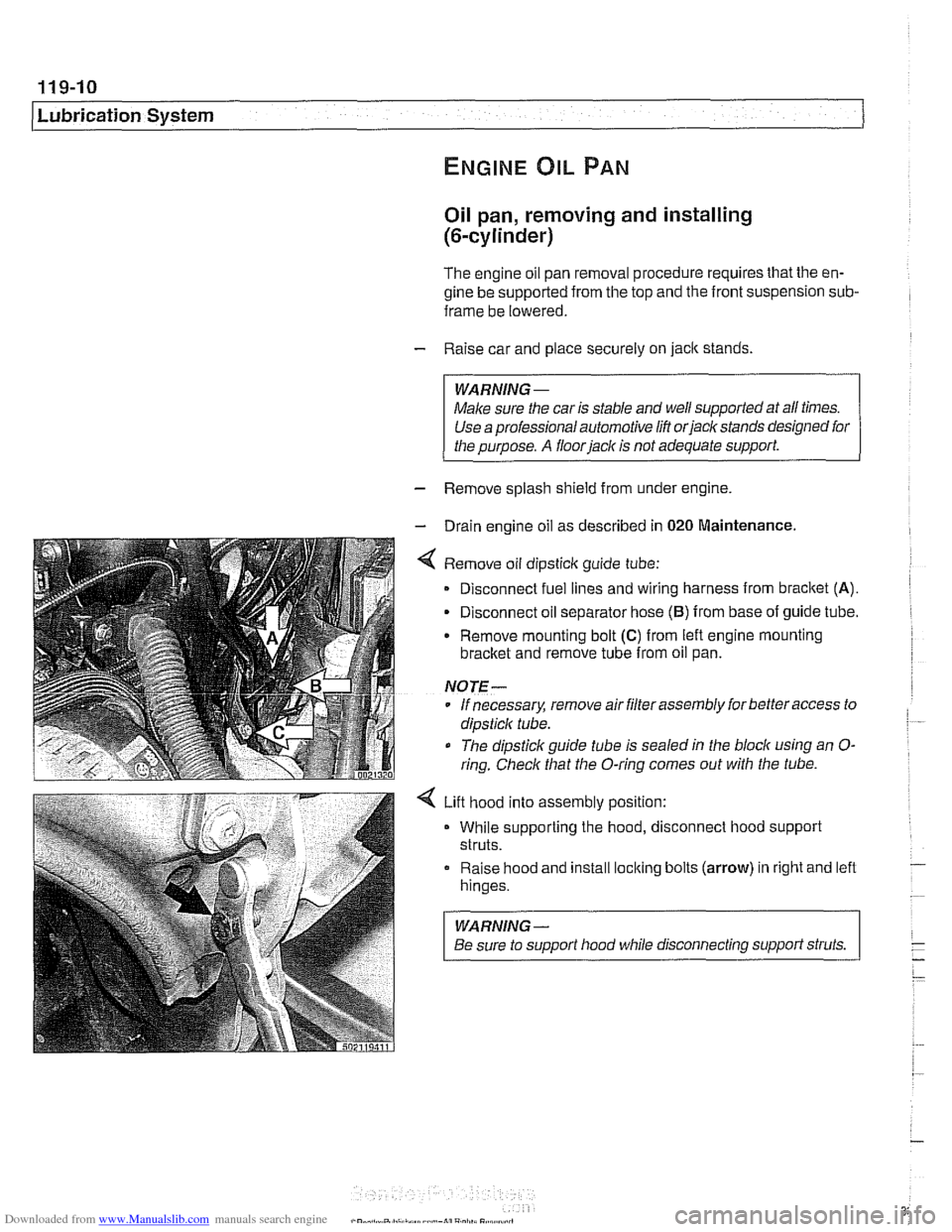

4 Remove oil dipsticlc guide tube:

Disconnect fuel lines and wiring harness from

bracket (A).

- Disconnect oil separator hose (B) from base of guide tube.

Remove mounting bolt

(C) from left engine mounting

bracket and remove tube from oil pan.

NOTE-

* If necessary, remove air filter assembly for better access to

dipsticlc tube.

The dipstick guide tube is sealed in the block using an

O-

ring. Check that the O-ring comes out with the tube.

4 Lift hood into assembly position:

While supporting the hood, disconnect hood support

struts.

Raise hood and install

loclting bolts (arrow) in right and left

hinges.

WARNING-

Be sure to support hood while disconnecting support struts.

Page 350 of 1002

Downloaded from www.Manualslib.com manuals search engine

Ignition System

This repair group covers component troubleshooting and re-

placement information for the ignition system.

When diagnosing engine management problems, including

on-board diagnostics (OBD

11) fault code analysis, also refer

to these repair groups:

* 130 Fuel Injection

* ELE Electrical Wiring Diagrams

OED On-Board Diagnostics

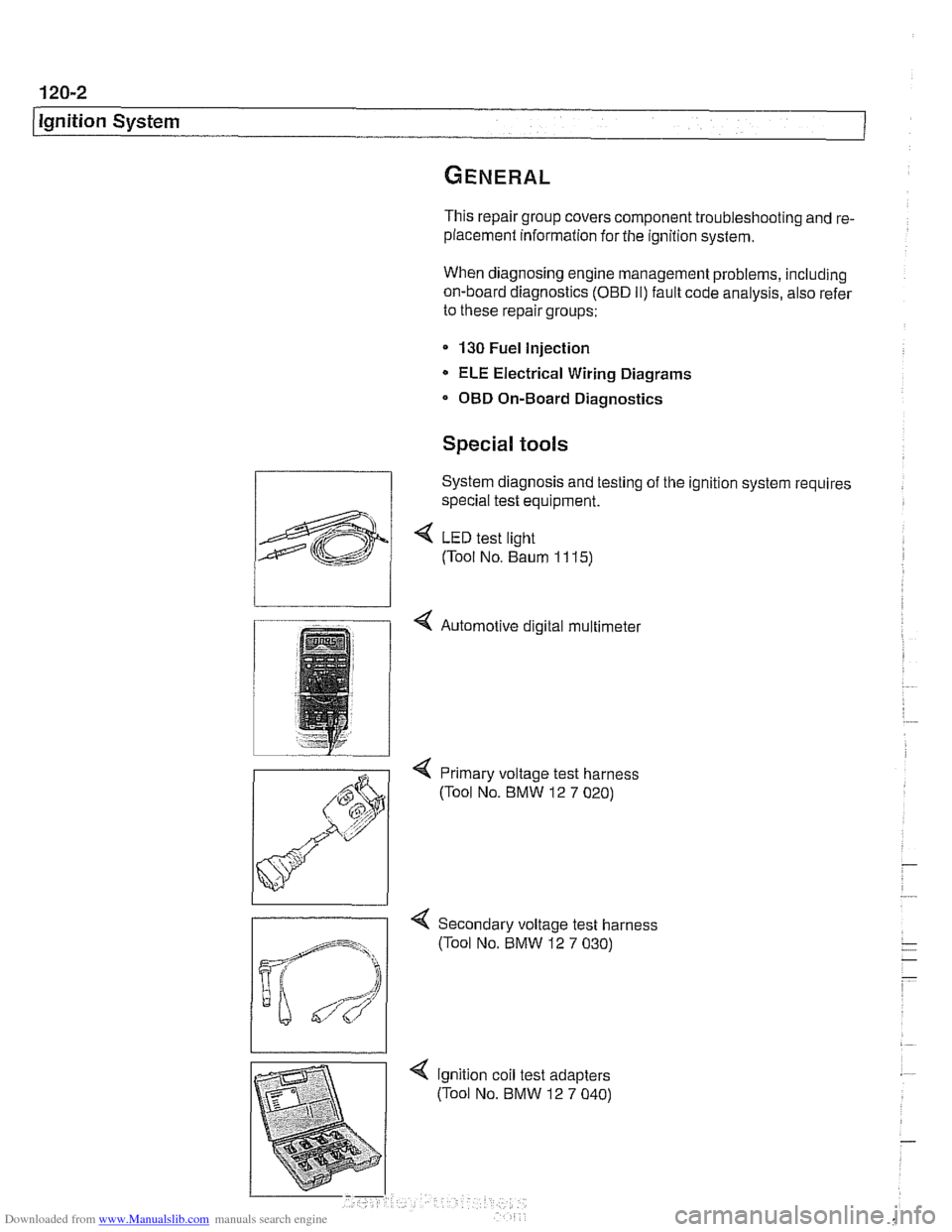

Special tools

System diagnosis and testing of the ignition system requires

special test equipment.

4 LED test light

(Tool No. Baum

1 1 15)

4 Automotive digital multimeter

4 Primary voltage test harness

(Tool No. BMW 12

7 020)

-

4 Secondary voltage test harness

(Tool No. BMW 12

7 030)

Page 351 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-3

Ignition System

Warnings and cautions

The ignition system produces dangerous high voltage. In ad-

dition the sensitive electronic components can be damaged

if

proper precautions are not adhered to.

WARNING-

* Do not touch or disconnect any cables from the coils while

the engine is running or being

cranked by the starter.

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when working on a car with the ignition

switched on or the engine running.

- Connect and disconnect tlie DME system wiring and

test equipment leads only when the ignition is

OFF:

Before operating the starter without starting the engine

(for example when

making a compression test) always

disable the ignition.

CA

U TIOW-

Do not attempt to disable the ignition by removing the coils

from the spark plugs.

Connect or disconnect ignition system wires, multiple

wire connectors, and ignition test equipment leads only

while the ignition is

off Switch multimeter functions or

measurement ranges only with the test probes discon-

nected.

* Do not disconnect the battery while the engine is run-

ning.

A high impedance digital multimeter should be used for

all voltage and resistance tests. An LED test light

should be used in place of an incandescent-type test

lamp.

In general, make test connections only as specified by

BMW as described in this manual, or as described by

the instrument manufacturer.

Engine management

BMW €39 engines use an advanced engine management

system known as Digital Motor Electronics (DME). DME in-

corporates on-board diagnostics, fuel injection, ignition and

other engine control functions. DME variants are listed in

Table a. Engine management systems.

Second generation On-Board Diagnostics

(OED II) is incor-

porated into the engine management systems used on the

cars covered by this manual. Use a BMW-specific electronic

scan tool, or a "Generic"

OED II scan tool to access Diagnos-

tic Trouble Codes (DTCs). DTCs can help pinpoint ignition

ine management problems.

Page 354 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-6

lgnition System

lgnition system, troubleshooting

Troubleshooting ignition system faults should begin with an

interrogation of the On-Board Diagnostics (OBD

II) system.

The OBD

II system detects ignition system misfire and other

related faults. When faults are detected, the OBD

II system

stores a Diagnostic Trouble Code (DTC) in the Engine Con-

trol Module (ECM) along with other pertinent fault information.

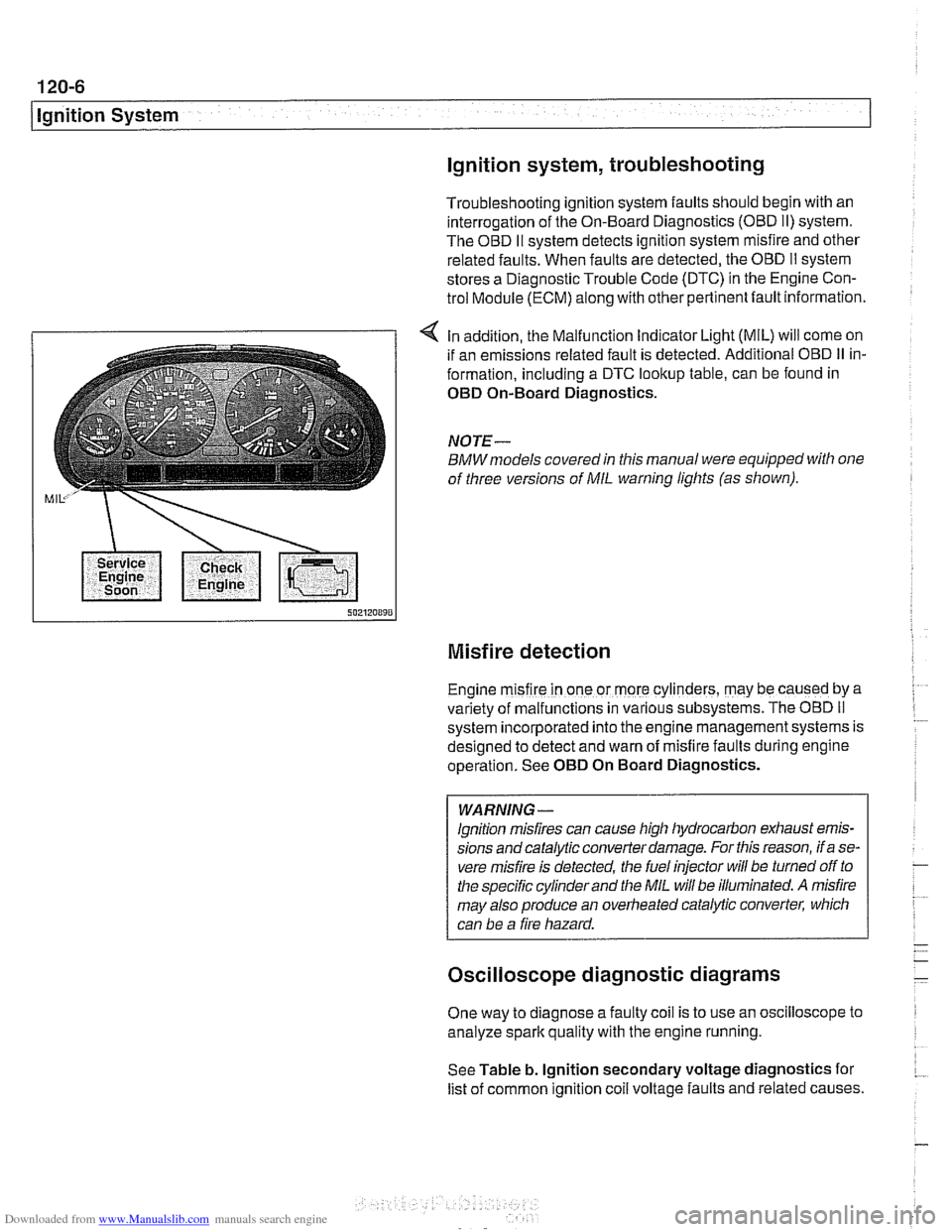

4 In addition, the Malfunction Indicator Light (MIL) will come on

if an emissions related fault is detected. Additional OBD

II in-

formation, including a DTC lookup table, can be found in

OED On-Board Diagnostics.

NOTE-

BMWmodels covered in this manual were equipped with one

of three versions of

MIL warning lights (as shown).

Misfire detection

Engine m~sfire in one or more cylinders, may be caused by a

var~ety of malfunctions in various subsystems. The OBD II

system ~ncorporated into the engine management systems is

des~gned to detect and warn of misfire faults during englne

operat~on. See OED On Board Diagnostics.

WARNING -

lgnition misfires can cause high hydrocarbon exhaust emis-

sions andcatalytic converter damage. For this reason, if a se-

vere misfire is detected, the fuel injector

will be turned off to

the specific cylinder and the

MIL will be illuminated. A misfire

may also produce an overheated catalytic converter, which

can be a fire hazard.

Oscilloscope diagnostic diagrams

One way to diagnose a faulty coil is to use an oscilloscope to

analyze spark quality with the engine running.

See Table b. lgnition secondary voltage diagnostics for

list of common ignition

coil voltage faults and related causes.

Page 355 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-7

Ignition System

Spark plug electrode gap /Too small /TOO big

Table

b. Ignition secondary voltage diagnostics

Secondary

voltage low

Fuel air mixture

I I Too lean

Secondary

voltage high

Spark plug electrode

Worniburnt

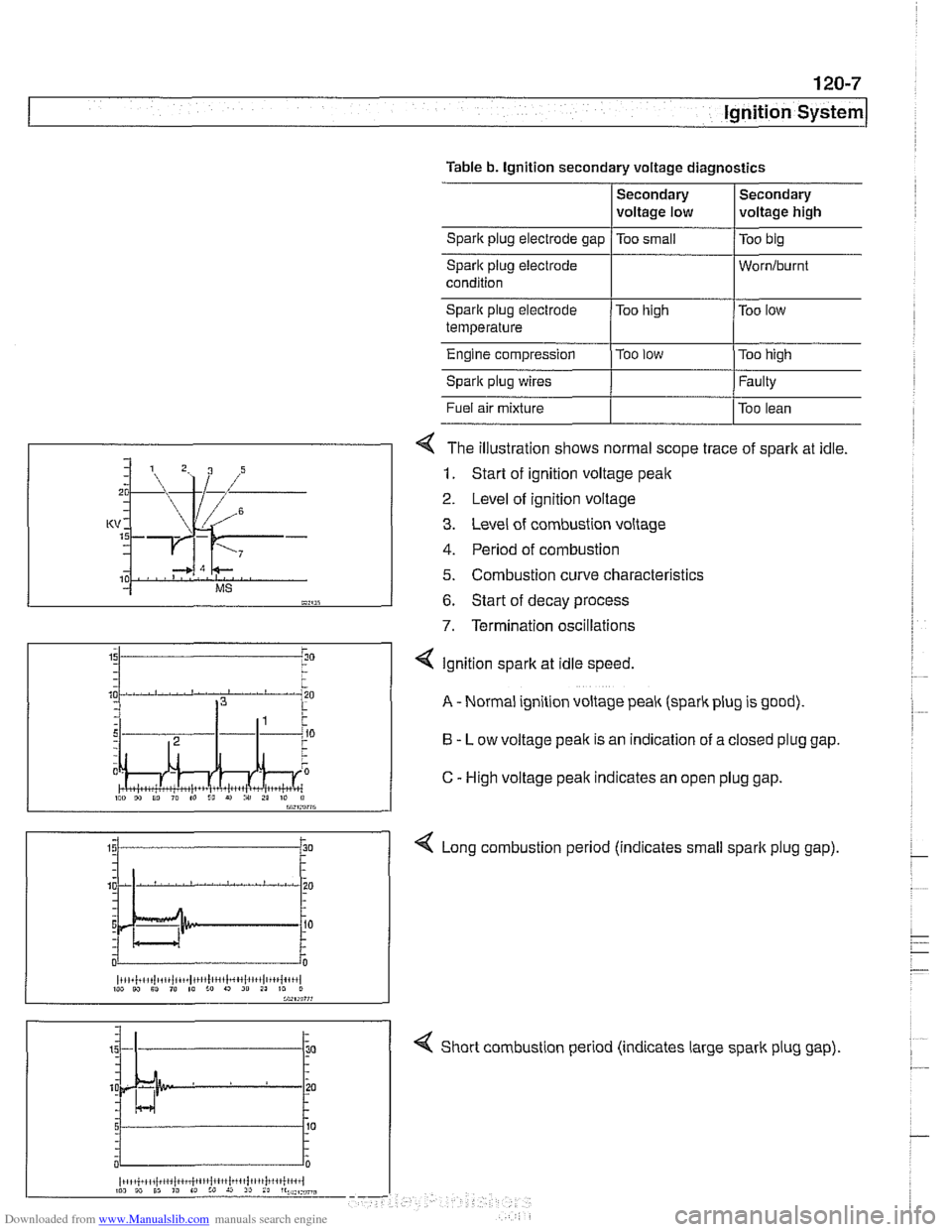

4 The illustration shows normal scope trace of spark at idle.

1. Start of ignition voltage peak

2 Level of ignition voltage

3. Level of combustion voltage

4. Period of combustion

5. Combustion curve characteristics

6. Start of decay process

7. Termination oscillations

Spark plug electrode

temperature

Engine compression

Spark plug wires

4 Short combustion period (indicates large spark plug gap).

Too

high

Too

low

I"" 9, 10 I" to I!, r) i" 21 10 il bW,rn?7G

Too low

Too high

Faulty

4 Ignition spark at idle speed.

A - Normal ignition voltage peak (spark plug is good).

B - Low voltage peak is an indication of a closed plug gap.

C

- High voltage peak indicates an open plug gap.

< Long combustion period (indicates small spark plug gap).

~i,+i!,~,i~tiii~iit~~,t1!lc,',l~~4~l~,~,l,~+~{+',,l 1W W Sl ,@ 10 :o 9 20 21 10 0

Page 357 of 1002

Downloaded from www.Manualslib.com manuals search engine

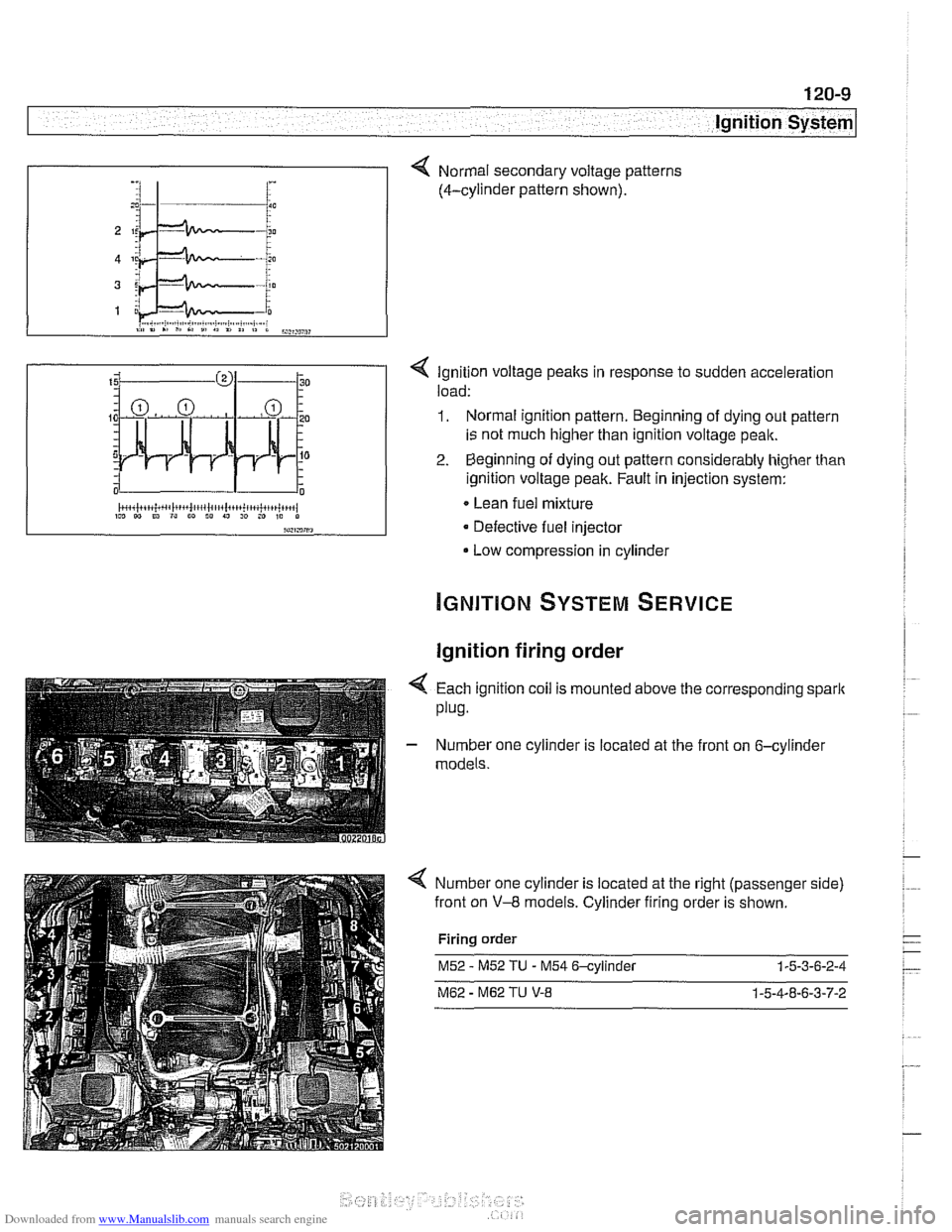

< Ignition voltage peaks in response to sudden acceleration

load:

1. Normal ignition pattern. Beginning of dying out pattern

is not much higher than ignition voltage peak.

2. Beginning of dying out pattern considerably higher than

ignition voltage peak. Fault in injection system:

Lean fuel mixture

Defective fuel injector

Low compression in cylinder

-, :I 1- i :

Ignition firing order

Normal secondary voltage patterns

(4-cylinder pattern shown).

4 Each ignition coil is mounted above the corresponding spark

plug.

- Number one cylinder is located at the front on 6-cylinder

models.

Number one cylinder is located at the right (passenger side)

front on

V-8 models. Cylinder firing order is shown.

Firing order

M52 - M52 TU - M54 6-cylinder 1-5-3-6-2-4

M62 - M62 TU V-8 1-5-4-8-6-3-7-2

Page 358 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

ignition System

Disabling ignition system

The ignition system operates in a lethal voltage range and

should be disabled any time engine service or repair work is

being done that requires the ignition to be switched on.

The engine management system can be disabled by remov-

ing the DME main relay. The relay is located in the electronics

box (E-box) in the left rear of the engine

compartment, be.

neath the interior microfilter housing.

CAUTION- Relay locations may

vary. Use care when identifying relays.

See

610 Electrical Component Locations.

Checking for spark

CAUTION-

If

a spark test is done incorrecth damage to the Engine Con-

trol Module

(ECM) or the ignition coils may result.

NOTE-

Spark plug replacement is covered in 020 Maintenance.

Check~ng for spark is d~fflcult on englnes wlth d~str~butorless

ignition systems.

Try removing the spark plugs and inspecting for differences between them.

A poor-firing plug may be wet with fuel and/or ~. - ~

black and sooty, but not always. If a coil is not operating, the

engine management system will electrically disable the fuel

injector to that cylinder. The key is to look for differences be-

tween cylinders.

Ignition coil assembly, testing and

replacing

C4 UTION-

Use a digital multimeter for the following tests. I

- Remove plastic engine cover from top of valve cover by pry-

ing off bolt covers and removing cover mounting bolts.

- Raise car slowly while constantly checking position of jack

and car.

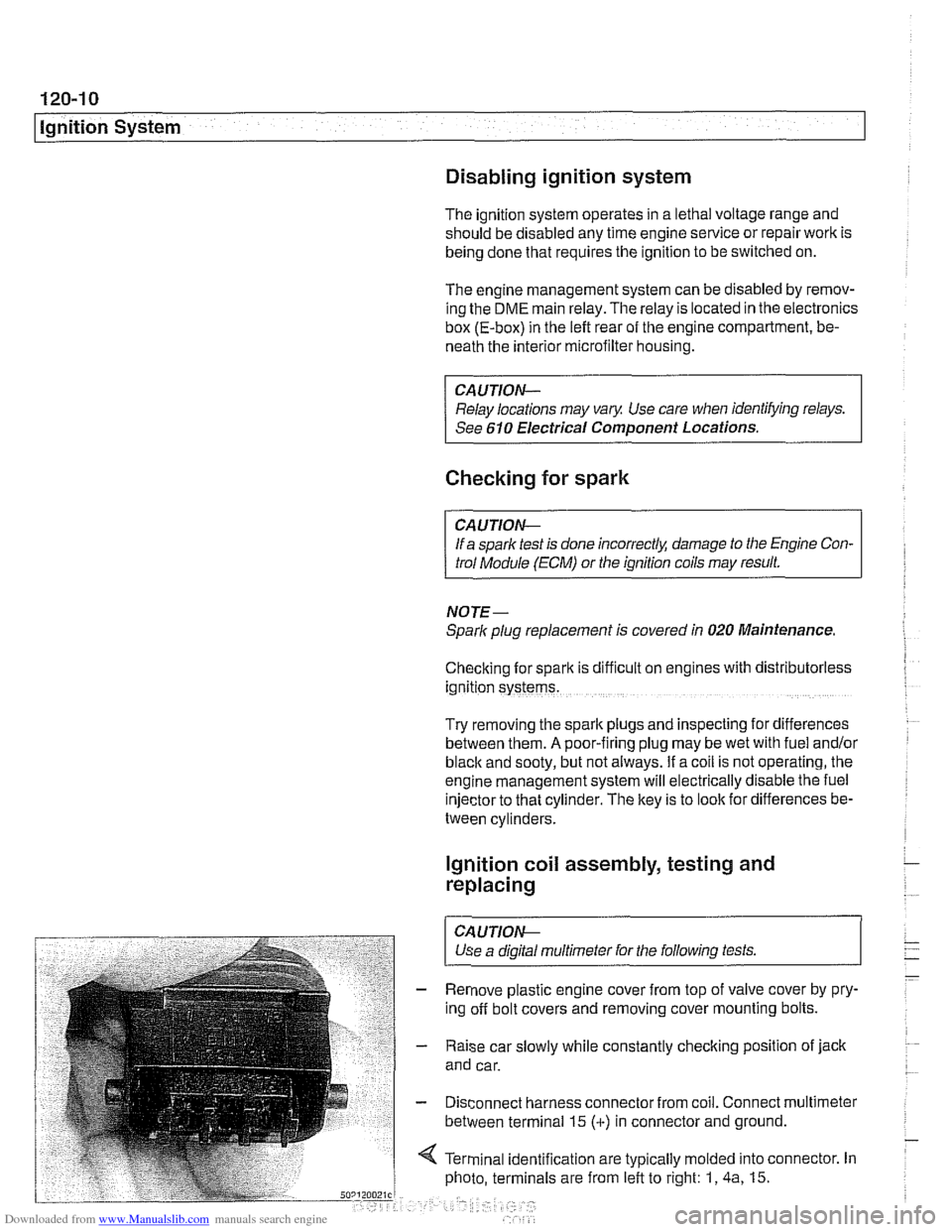

- Disconnect harness connector from coil. Connect multimeter

between terminal 15

(+) in connector and ground.

4 Terminal identification are typically molded into connector. In

photo, terminals are from left to right: 1,

4a, 15.

Page 362 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Ignition System

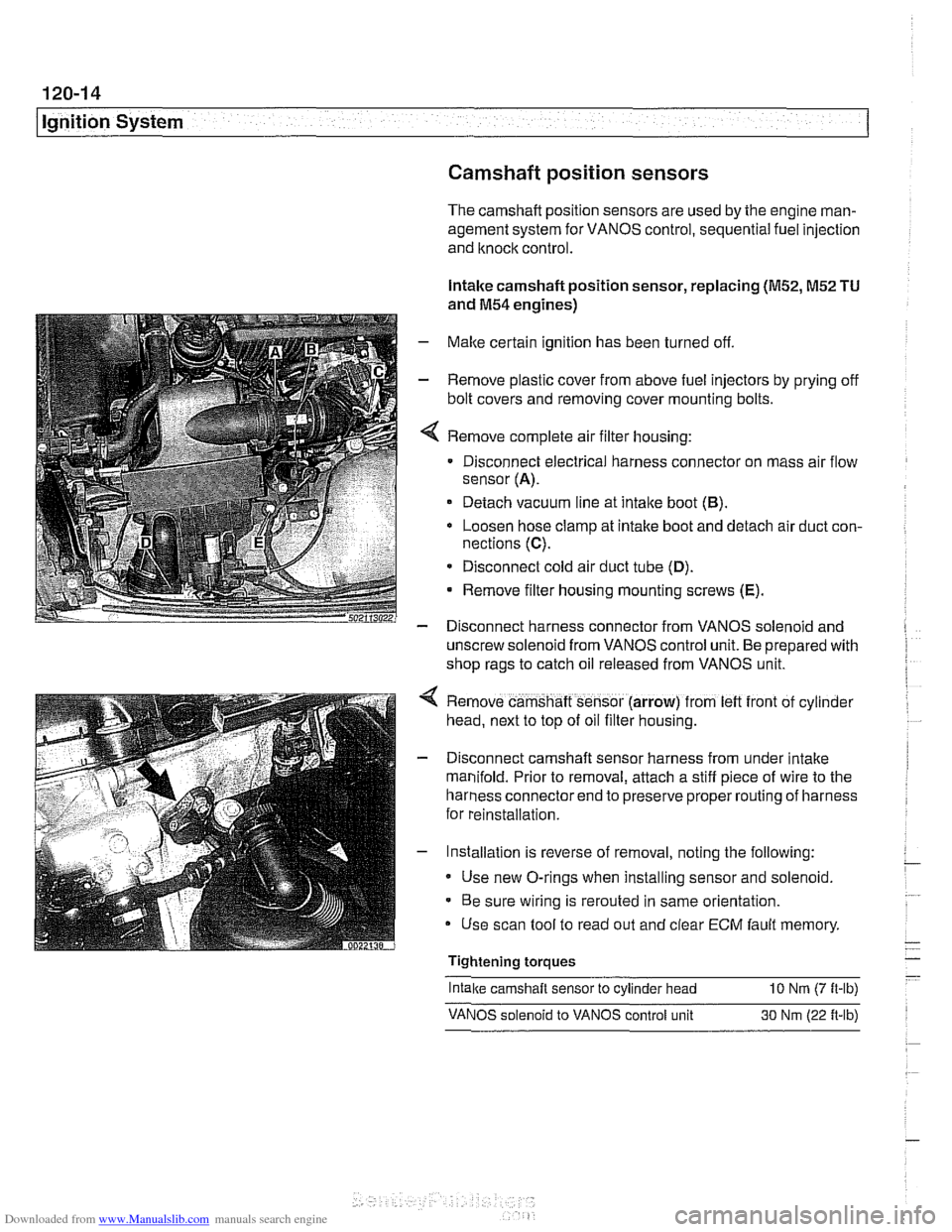

Camshaft position sensors

The camshaft position sensors are used by the englne man-

agement system for VANOS control, sequential fuel injection

and knock control.

Intake camshaft position sensor, replacing

(M52,M52 TU

and M54 engines)

- Make certain ignition has been turned off.

- Remove plastic cover from above fuel injectors by prying off

bolt covers and removing cover mounting bolts.

Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Detach vacuum line at intake boot (B).

Loosen hose clamp at intake boot and detach air duct con-

nections

(C).

* Disconnect cold air duct tube (D).

Remove filter housing mounting screws (E).

- Disconnect harness connector from VANOS solenoid and

unscrew solenoid from VANOS control unit. Be prepared with

shop rags to catch oil released from VANOS unit.

Remove camshaft sensor (arrow) from

left front of cyl~nder

head, next to top of oil filter housing.

Disconnect camshaft sensor harness from under intake

manifold. Prior to removal, attach a stiff piece of wire to the

harness connector end to preserve proper routing of harness

for reinstallation.

Installation is reverse of removal, noting the following:

Use new O-rings when installing sensor and solenoid.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear

ECM fault memory

Tightening torques

-

Intake camshaft sensor to cylinder head 10 Nrn (7 ft-lb)

VANOS solenoid to VANOS control unit 30 Nm (22 ft-lb)

Page 386 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Battery, Starter, Alternator

- Check for battery voltage at terminal 50 of starter motor with

key in start position. If voltage is not present, check wiring be-

tween ignition switch and starter terminal. Check the EWS

system and other inputs that disrupt terminal

56 to the start-

er. See ELE Electrical

Wiring Diagrams. If voltage is

present and no other visible wiring faults can be found, prob-

lem is most likely in starter motor.

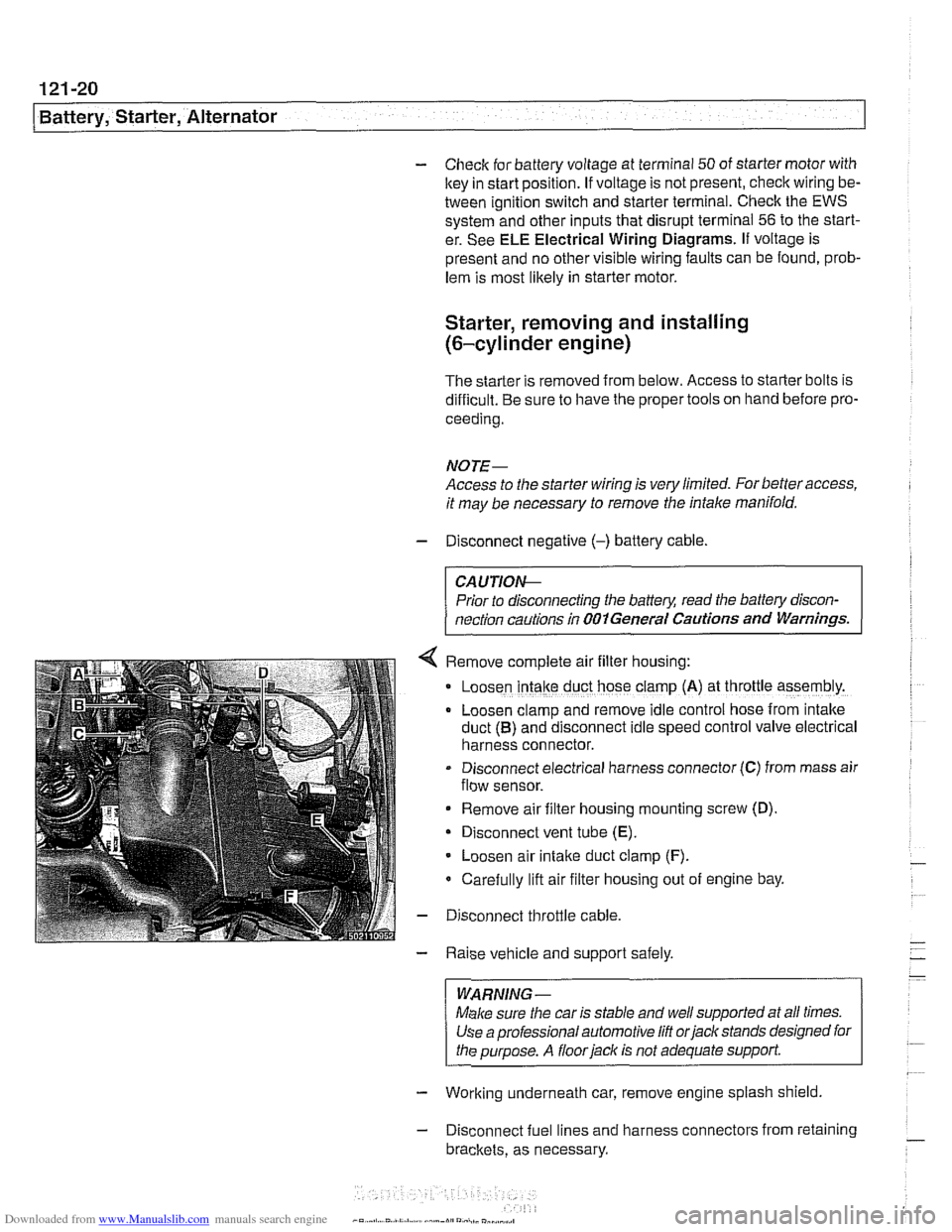

Starter, removing and installing

(6-cylinder engine)

The starter is removed from below. Access to starter bolts is

difficult. Be sure to have the proper tools on hand before pro-

ceeding.

NOTE-

Access to the starter wiring is very limited. Forbetteraccess,

it may be necessary to remove the intake manifold.

- Disconnect negative (-) battery cable.

CAUTIOI\C

Prior to disconnecting the battern read the baltery discon-

nection cautions

in OOlGeneral Cautions and Warnings.

Remove complete air filter hous~ng:

Loosen intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw (D)

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Disconnect throttle cable.

Raise vehicle and support safely.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjack stands designed for

the purpose. A

floorjaclc is not adequate support

- Working underneath car, remove engine splash shield

- Disconnect fuel lines and harness connectors from retaining

brackets, as necessary.