Fuel system BMW 528i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 448 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection Evaporative fuel system pressure leak

diagnosis, overview

(M5.2.1 only)

1998 540i models are equipped with an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leak diagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting

leaks. This sys-

tem is capable of detecting a leak as small as 0.5 mm.

The LDP, located in the left rear wheel housing, is a unitized

component that contains the following:

Vacuum chamber. Pneumatic pump chamber.

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

ECM).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is integrated into the LDP, which is

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C, purge valve always closed).

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

Fuel Injection

I 68 1 / Not used

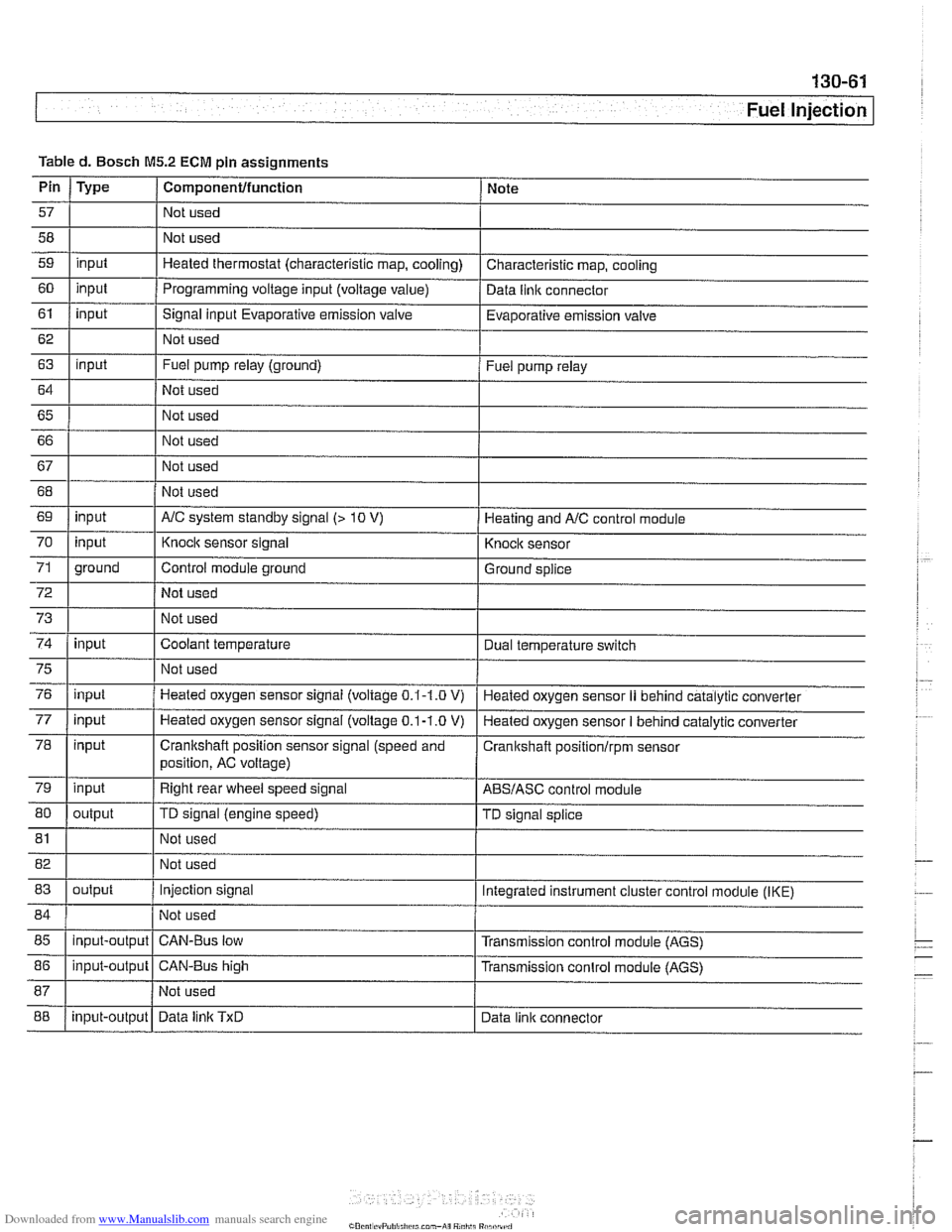

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 456 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also illuminates

if an emissions-related fault is detected.

When faults arise, or

if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus, MoDiC, GTl or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CA UTIOI\C

The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the MIL. After all testing is completed,

access and clear DTC fault memory using an OBD

I1 or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

. Only use a digital multimeter for electrical tests.

Relay positions can vary. Be sure to confirm relay posi-

tion by identifying the wiring in the

socket using the wir-

ing diagrams found in ELE Electrical Wiring

Diaqrams.

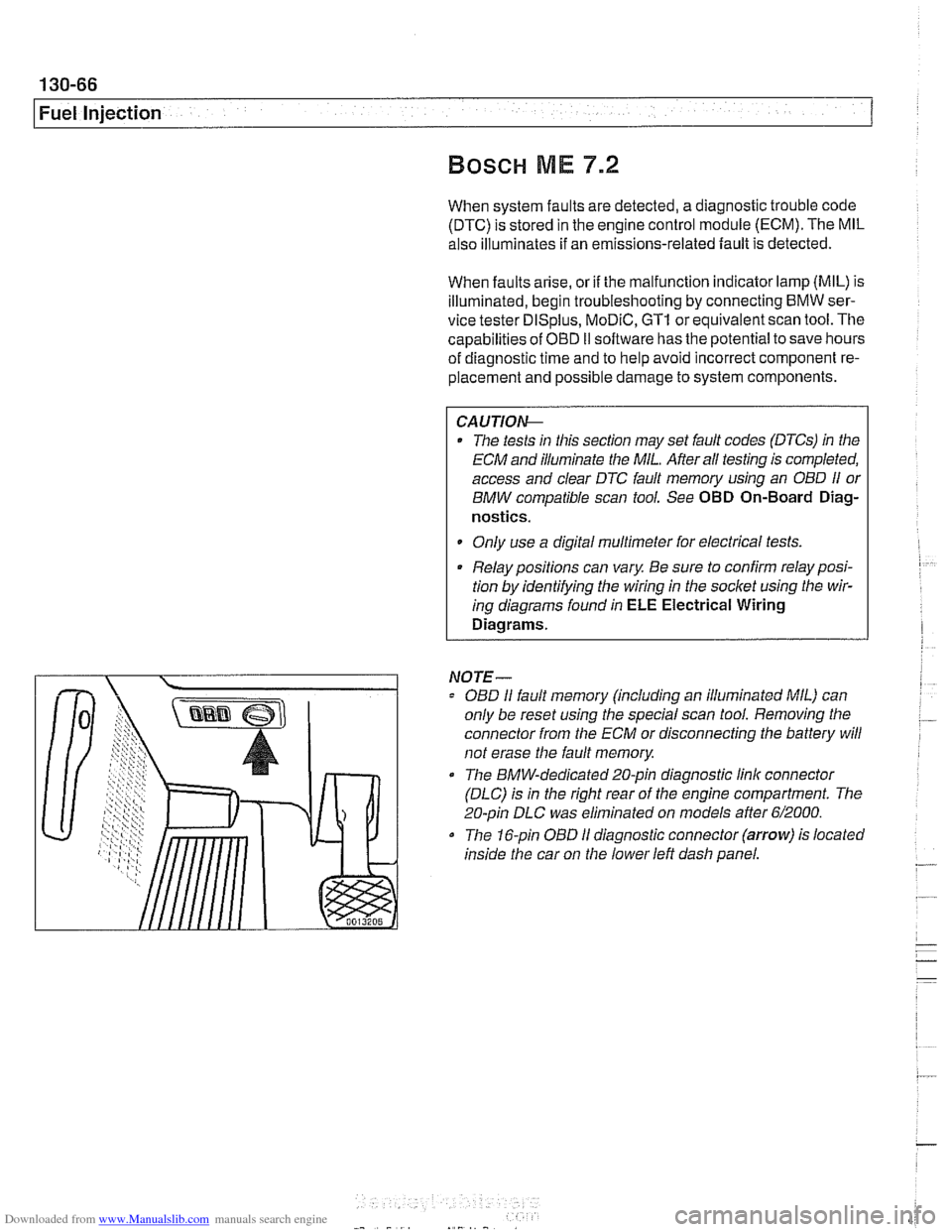

NOTE-

= OBD I1 fault memory (including an illuminated MIL) can

only be reset using the special scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault memory.

0 The BMW-dedicated 20-pin diagnostic link connector

(DLC) is in the right rear of the engine compartment. The

20-pin DLC was eliminated on models after

6/2000.

The 16-pin OBD I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

Page 457 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-67

Fuel Injection /

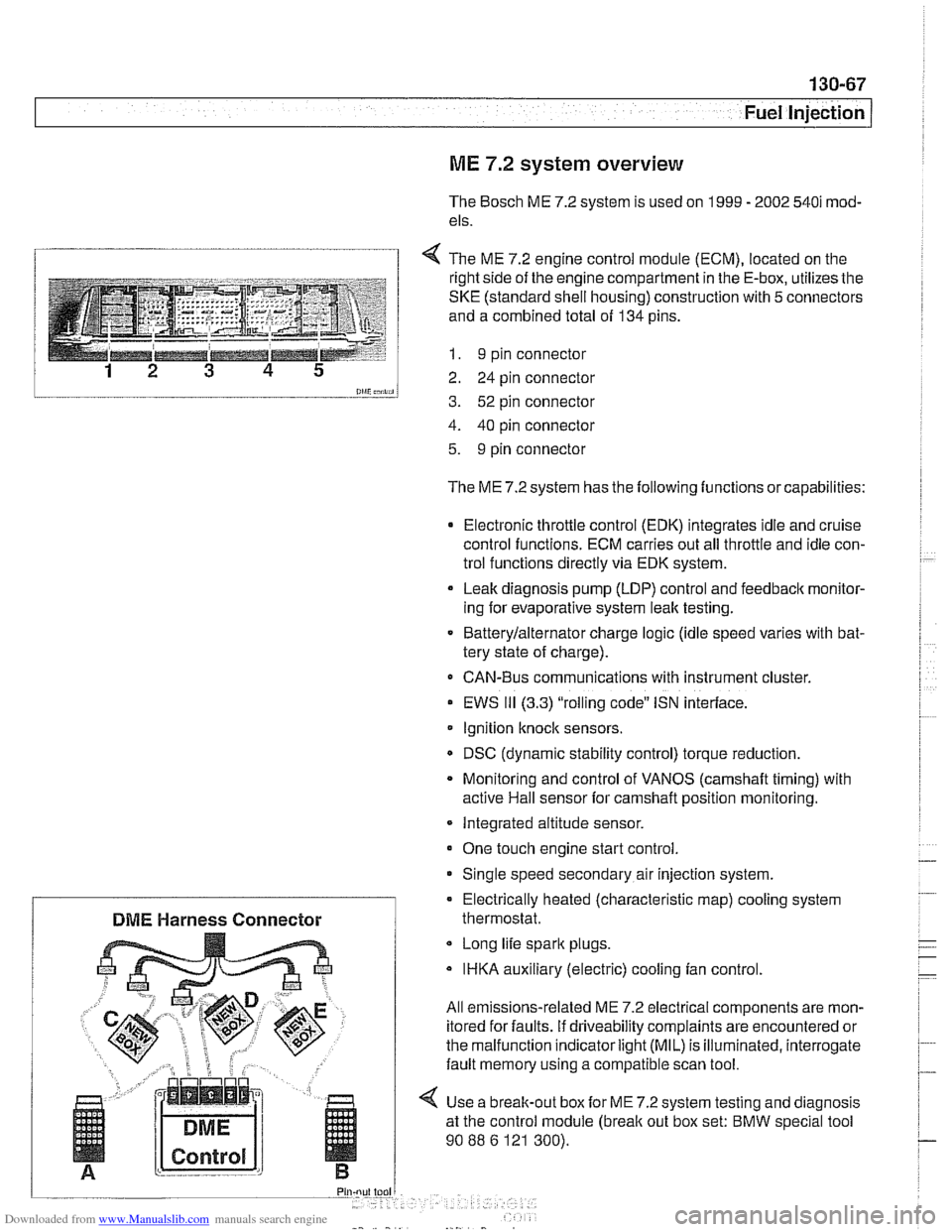

ME 7.2 system overview

The Bosch ME 7.2 system is used on 1999 - 2002 540i mod-

els.

1 4 The ME 7.2 enaine control module (ECM). located on the

l and a combined total of 134 pins.

--__-- 1 I. 9 pin connector

12 3 4 5 2 24 pin connector

0lliC;nii, 3. 52 pin connector

4. 40 pin connector

5. 9 pin connector

The ME 7.2 system has the following functions or capabilities:

Electronic throttle control (EDK) integrates idle and cruise

control functions. ECM carries out all throttle and idle con-

trol functions directly via EDK system.

Leak diagnosis pump

(LDP) control and feedback monitor-

ing for evaporative system leak testing.

Batterylalternator charge logic (idle speed varies with bat-

tery state of charge).

CAN-Bus communications with instrument cluster.

EWS

111 (3.3) "rolling code" ISN interface.

Ignition

knock sensors.

DSC (dynamic stability control) torque reduction.

Monitoring and control of VANOS

(camshaft timing) with

active Hail sensor for camshaft position monitoring.

Integrated altitude sensor.

One touch engine start control

Single speed secondary air injection system.

Long life spark plugs.

IHKA auxiliary (electric) cooling fan control.

All emissions-related ME 7.2 electrical components are mon-

itored for faults. if driveability complaints are encountered or

the malfunction indicator

light (MIL) is illuminated, interrogate

fault memory using a compatible scan tool.

4 Use a break-out box for ME 7.2 system testing and diagnosis

at the control module

(break out box set: BMW special tool

90

88 6 121 300).

Electrically heated (characteristic

map) cooling system

DME Harness Connector thermostat.

Page 458 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-68

Fuel Injection

0

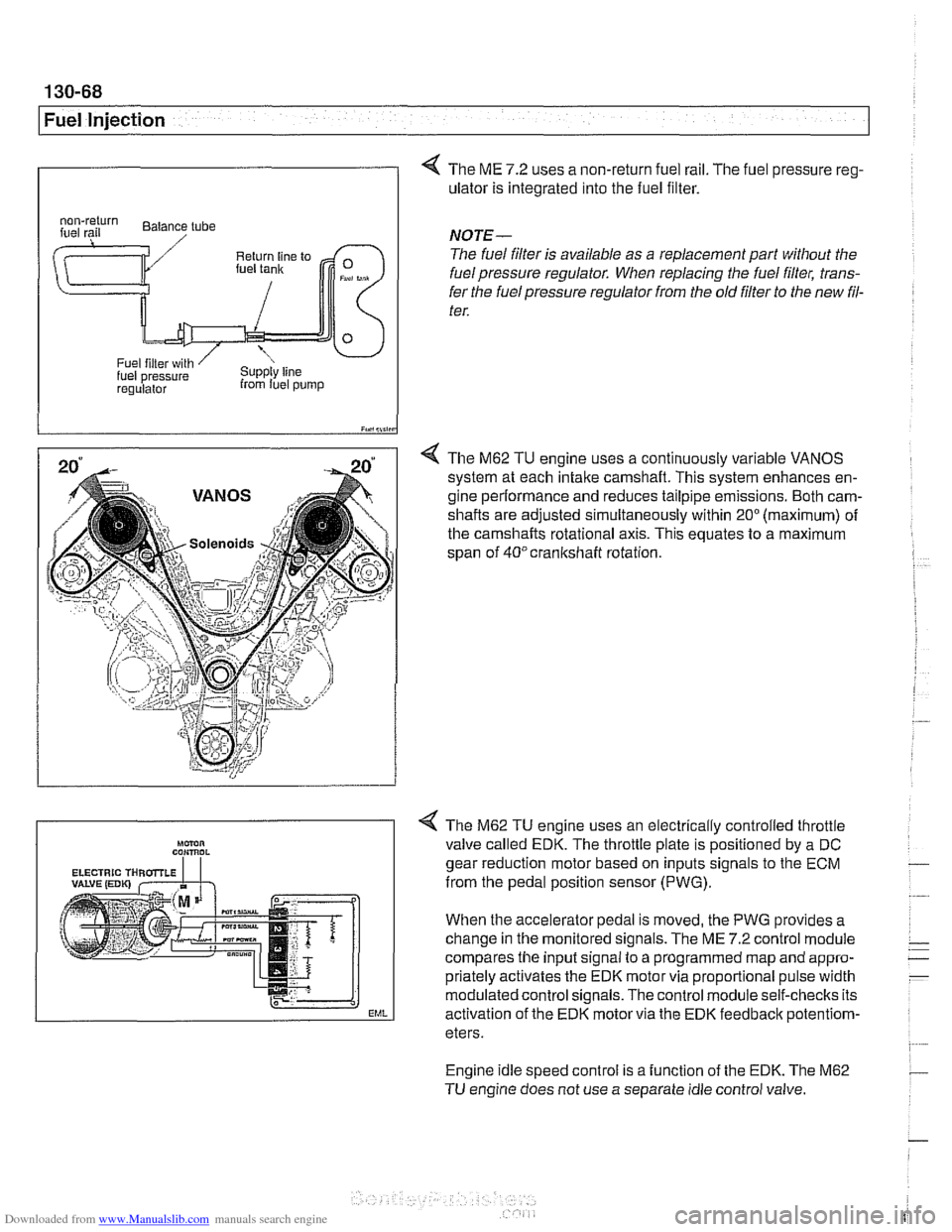

4 The ME 7.2 uses a non-return fuel rail. The fuel pressure reg-

ulator is integrated into the fuel filter.

I iY.,lii,in

4 The M62 TU engine uses a continuously variable VANOS

system at each intake camshaft. This system enhances en-

gine performance and reduces tailpipe emissions. Both cam-

shafts are adjusted simultaneously within

20" (maximum) of

the camshafts rotational axis. This equates to a maximum

span of

40°crankshaft rotation.

regulalor from luel pump

NOTE-

The fuel filter is available as a replacement part without the

fuel pressure regulator. When replacing the fuel filter, trans-

fer the fuel pressure regulator from the old

filter to the new fil-

ter.

Engine idle speed control is a function of the EDK. The M62

TU engine does not use a separate idle control valve.

Mmn CON,ROL

EML

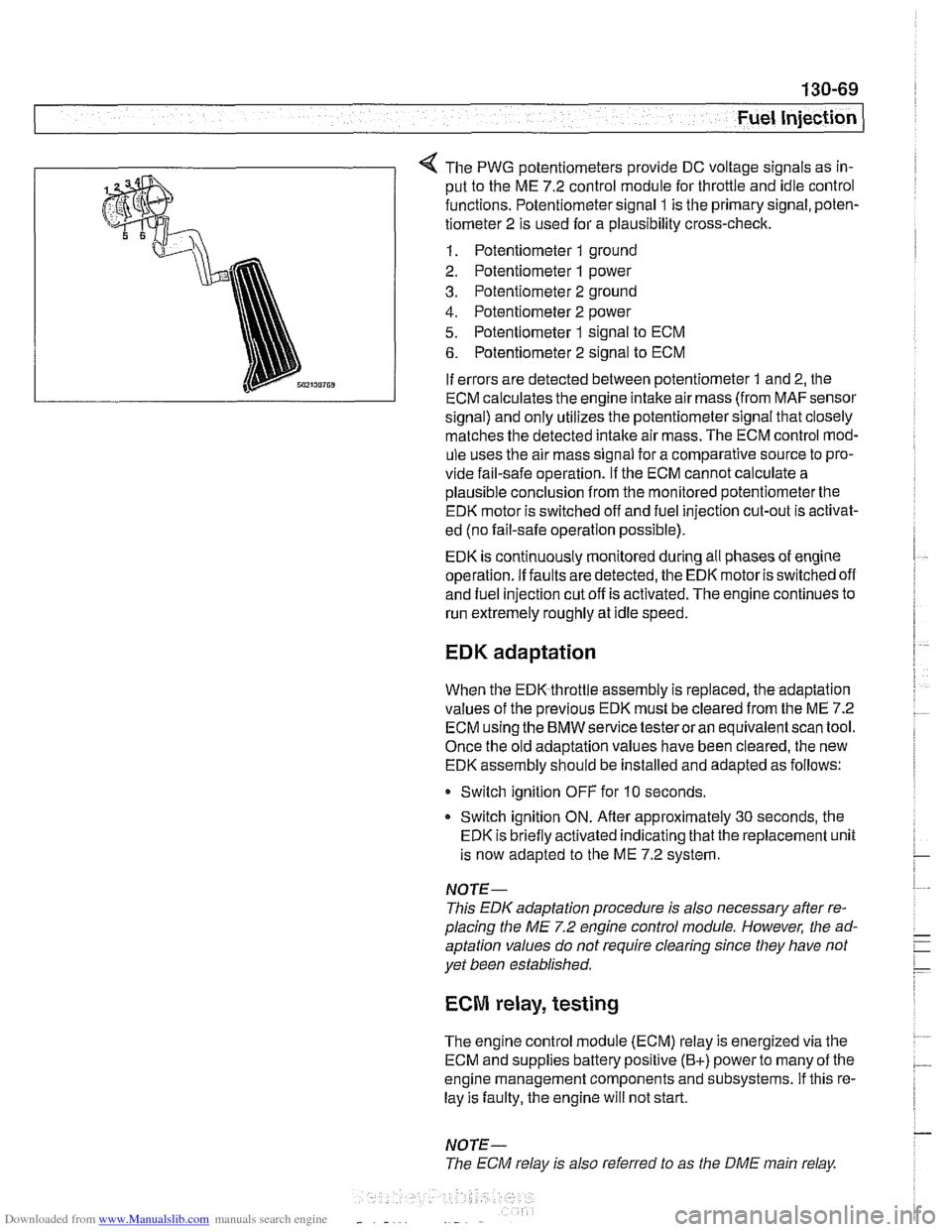

< The M62 TU engine uses an electrically controlled throttle

valve called EDK. The throttle plate is positioned by a DC

gear reduction motor based on inputs signals to the ECM

from the pedal position sensor (PWG).

When the accelerator pedal is moved, the PWG provides a

change in the monitored signals. The ME

7.2 control module

compares the input signal to a programmed map and appro-

priately activates the EDK motor via proportional pulse width

modulated control signals. The control module self-checks its

activation of the EDK motor via the EDK feedbaclc

potentiom-

eters.

Page 459 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Fuel Injection I

The PWG potentiometers provide DC voltage signals as in-

put to the ME 7.2 control module for throttle and idle control

functions. Potentiometer signal

1 is the primary signal, poten-

tiometer 2 is used for a plausibility cross-check.

1. Potentiometer 1 ground

2. Potentiometer

1 power

3. Potentiometer 2 ground

4. Potentiometer 2 power

5. Potentiometer 1 signal to ECM

6. Potentiometer 2 signal to ECM

If errors are detected between potentiometer

1 and 2, the

ECM calculates the engine intake air mass (from

MAFsensor

signal) and only utilizes the potentiometer signal that closely

matches the detected

intake air mass. The ECM control mod-

ule uses the air mass signal for a comparative source to pro-

vide fail-safe operation.

If the ECM cannot calculate a

plausible conclusion from the monitored potentiometerthe

EDK motor is switched off and fuel injection cut-out is activat-

ed (no fail-safe operation possible).

EDK is continuously monitored during all phases of engine

operation. If faults are detected, the EDK motor is switched off

and fuel injection cut off is activated. The engine continues to

run extremely roughly at idle speed.

EDK adaptation

When the EDK throttle assembly is replaced, the adaptation

values of the previous EDK must be cleared from the ME 7.2

ECM using the BMW service testeroran equivalentscan tool.

Once the old adaptation values have been cleared, the new

EDK assembly should be installed and adapted as follows:

0 Switch ignition OFF for 10 seconds.

* Switch ignition ON. Afler approximately 30 seconds, the

EDK is briefly activated indicating that the replacement unit

is now adapted to the ME 7.2 system.

NOTE-

This EDK adaptation procedure is also necessary after re-

placing the

ME 7.2 engine control module. However, the ad-

aptation values do not require clearing since they have not

yet been established.

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine management components and subsystems. If this re-

lay is faulty, the engine will not start.

NOTE-

The ECM relay is also referred to as the DME main relay

Page 462 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-72

Fuel Injection

I Oxygen sensors, replacing

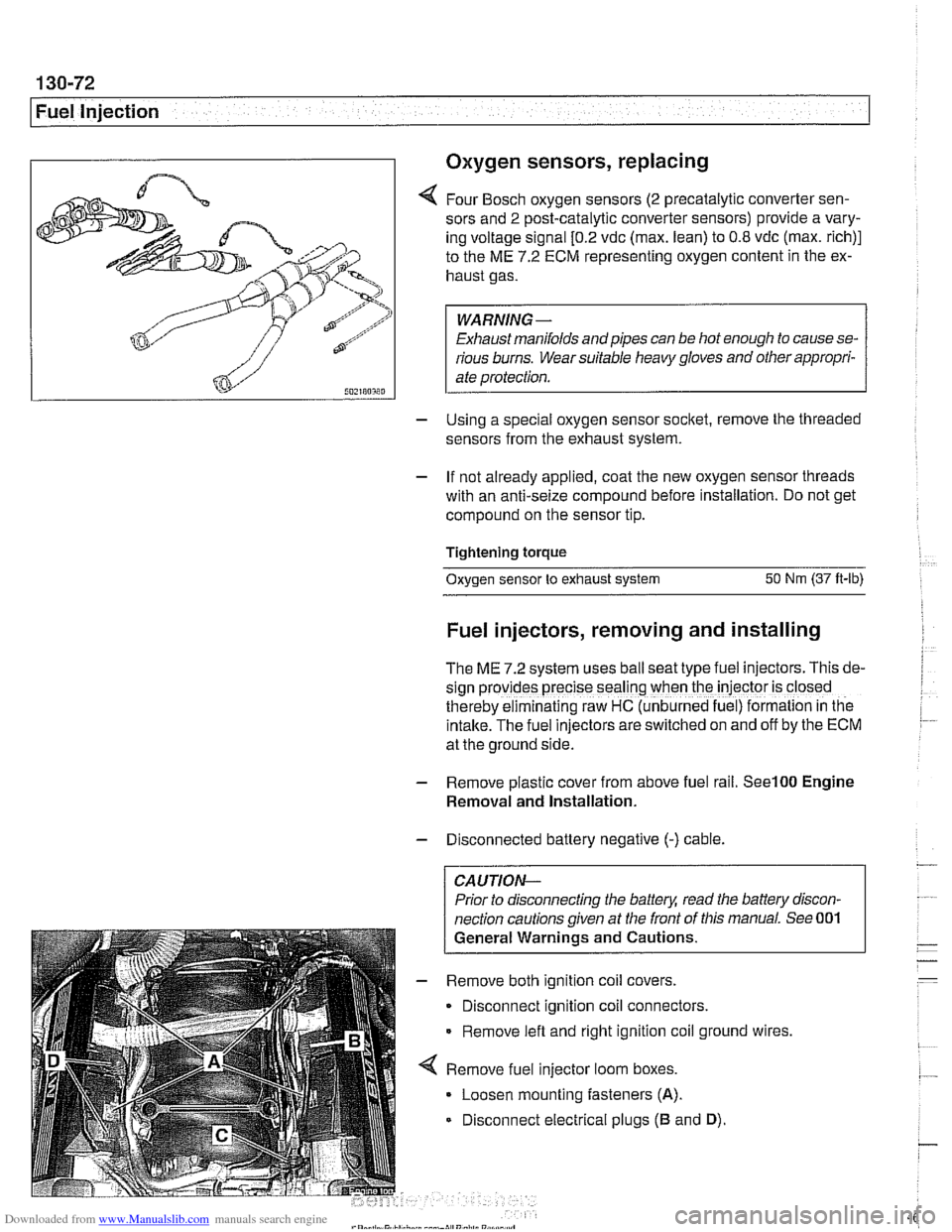

4 Four Bosch oxygen sensors (2 precatalytic converter sen-

sors and

2 post-catalytic converter sensors) provide a vary-

ing voltage signal

[0.2 vdc (max. lean) to 0.8 vdc (max. rich)]

to the ME

7.2 ECM representing oxygen content in the ex-

haust gas.

WARNING-

Exhaust manifolds and pipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

- Using a special oxygen sensor socltet, remove the threaded

sensors from the exhaust system.

- If not already applied, coat the new oxygen sensor threads

with an anti-seize compound before installation. Do not get

compound on the sensor tip.

Tightening torque

Oxygen sensor to exhaust system

50 Nm (37 ft-lb)

Fuel injectors, removing and installing

The ME 7.2 system uses ball seat type fuel injectors. This de-

sign

prov:des precise seal'ng when the iniector is closed

therebv eiminalinq raw HC (unb~rned fue ) formalion in tne

intake.-~he fuel inkctors areswitched on and off by the ECM

at the ground side.

- Remove plastic cover from above fuel rail. See100 Engine

Removal and Installation.

- Disconnected battery negative (-) cable.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given at the front of this manual. See 001

General Warnings and Cautions.

- Remove both ignition coil covers.

Disconnect ignition coil connectors.

Remove left and right ignition coil ground wires,

4 Remove fuel injector loom boxes.

Loosen mounting fasteners

(A).

Disconnect electrical plugs (B and D).

Page 464 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-74

I Fuel Injection

Evaporative system pressure leak

diagnosis, overview

The M62 TU engine is equipped wlth an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leakdiagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting leaks.

This system iscapable of detecting a

lealcas small as0.5 mm.

The LDP, located in the left rear wheel housing, contains the

following:

Vacuum chamber. Pneumatic pump chamber

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

DME).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is

~ntegrated into the LDP, which IS

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C. purge valve always closed).

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

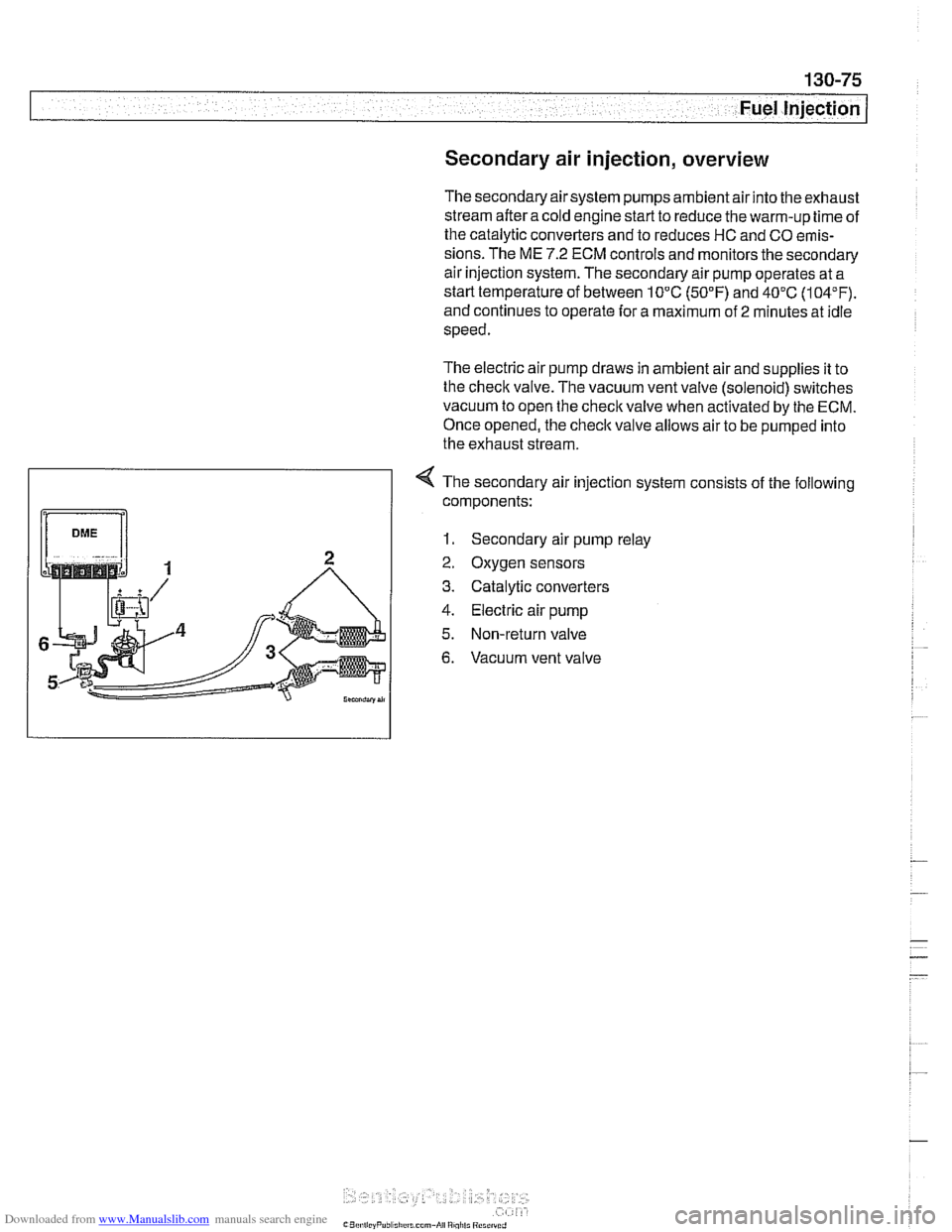

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 471 of 1002

Downloaded from www.Manualslib.com manuals search engine

160 Fuel Tank and Fuel Pump

General ........................... .I6 0.2

Special tools ........................ .I6 0.2

Fuel pump ......................... .I6 0.3

Fuel tank evaporative control system ..... .I6 0.3

Evaporative system troubleshooting ..... .I6 0.4

Warnings and cautions ................ .I6 0.5

Fuel System Troubleshooting ...... .I6 0.6

Fuel pump fuse and relay .............. .I6 0.6

Operating fuel pump for tests ........... .I6 0.6

Fuel pump electrical circuit, testing ...... .I6 0.7

Fuel pump power consumption, testing ... .I6 0.9

Fuel pressure gauge, installing

(6-cylinder models)

................. .I6 0.1 0

Fuel pressure gauge, installing

(V-8 models) ....................... .I6 0.1 1

Fuel delivery, testing ................ .I6 0.12

Fuel Pump and Fuel Level Sender . . 160-15

Fuel level sender (right side) and

fuel pump. removing and installing

...... 160-15

Fuel level sender (left side).

removing and installing

............... 160-17

Siphon pump. removing and installing .... 160-1 9

Fuel Tank and Fuel Lines .......... 160-20

Fuel tank. draining ................... 160-20

Fuel tank. removing and installing ....... 160-21

Fuel expansion tank. removing

and installing

....................... 160-23

Activated carbon canister I fuel tank

leak detection unit

(LDP or DMTL).

removing and installing ............... 160-24

Running losses (312-way) valve.

removing and installing

............... 160-24