Fuel system BMW 528i 1998 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 391 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1

130 Fuel injection

General ........................... .I3 0.2

Tools and test equipment .............. .I3 0.3

Warnings and cautions ................ .I3 0.5

Fuel Supply ....................... .I3 0.6

Relieving system fuel pressure .......... .I3 0.6

Siemens MS 41 . 1. ................... 1 30-7

ECM relay. testing .................... .I3 0.7

Mass air flow (MAF) sensor.

checking and replacing

................ .I3 0.9

Engine coolant temperature (ECT) sensor.

testing and replacing

.................. 130-10

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.1 1

Throttle position sensor (TPS).

testing and replacing

.................. 130-1 2

ldle speed control valve.

checking and replacing

............... .I3 0.1 3

Fuel injectors. checking and replacing .... 130-15

Evaporative emissions. overview ....... .I3 0.1 6

Secondary air injection. overview ....... .I3 0-17

Engine control module (ECM).

removing and installing

................ 130-18

Siemens MS 41.1 ECM pin assignments . .I3 0.19

Siemens MS 42.0 and MS 43.0. ..... .I3 0.23

ECM relay. testing ................... .I3 0.27

Mass air flow (MAF) sensor.

checking and replacing

............... .I3 0.28

Engine coolant temperature (ECT) sensor.

testing and replacing

................. .I3 0.30

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.31

MS 42.0 throttle valve assembly. replacing . 130-32

MS 43.0 throttle valve assembly. replacing . 130-35

Throttle cable. adjusting (MS 42.0) ...... .I3 0.38

ldle speed control valve. checking

and replacing

....................... .I3 0.38

Evaporative emissions control diagrams . . 130- 39

Evaporative emissions control.

(MS

42.0 and MS 43.0). .............. .I3 0.39

Engine control module (ECM).

removing and installing

................ 130-40

Siemens MS 42.0 and MS 43.0

ECM pin assignments ................. 130-41

Bosch M5.2 (M62 up to 911997)

BOSC~ M5.2.1 (M62 911997 to 911998) 130-46

M5.2 system features ................. 130-47

M5.2.1 system features ............... 130-47

ECM relay. testing ................... 130-49

Oxygen sensors. checking ............. 130-51

Fuel injectors. checking and replacing .... 130-52

Mass air flow (MAF) sensor. replacing .... 130-53

ldle speed control valve. testing

and replacing

....................... 130-54

Throttle position sensor (TPS).

testing and replacing

................. 130-55

Engine coolant temperature (ECT) sensor.

testing and replacing

................. 130-55

Intake air temperature (IAT) sensor.

testing and replacing

................. 130-57

Auxiliary throttle valve (ADS) (M62 and

M62 TU engine). replacing ..... 130-57

Evaporative system pressure

leak diagnosis. overview

(5.2.1 only) ..... 130-58

Bosch 5.2 ECM pin assignments

(M62 UP to 911 997) ................... 130-59

~osch 5.2.1 ECM pin assignments

(M62 911 997 to 911 998) ............... 130-62

BOSC~ ME 7.2 ..................... 1 30-66

ME 7.2 system overview ............... 130-67

EDK adaptation ..................... 130-69

ECM relay. checking .................. 130-69

Engine coolant temperature

(ECT) sensor. testing

................. 130-71

Engine coolant temperature

(ECT) sensor. replacing

............... 130-71

Oxygen sensors. replacing ............. 130-72

Fuel injectors. removing and installing .... 130-72

Mass air flow (MAF) sensor.

removing and installing

................ 130-73

Evaporative system pressure

leak diagnosis. overview

............... 130-74

Secondary air injection. overview ........ 130-75

Bosch ME 7.2 ECM pin assignments .... 130-76

Page 392 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-2

/Fuel Injection

This repair group covers service and repair of the Bosch and

Siemens engine management systems used on

1997

through 2002 E39 models. Additional engine management

service and repair information may also be found in the fol-

lowing repair groups:

0 020 Maintenance

120 Ignition System

160 Fuel Tank and Fuel Pump

610 Electrical Component Locations

OBD On Board Diagnostics

NOTE-

Camshaft position sensor, crankshaft speed sensor and

knoclc sensors are covered in 120 Ignition System.

Table a. Engine management system applications

- - ~ ~

1 ~odellmodel year / Engine IDME system I - I

5281, 1997-1 998 IM52. 2.8 liter ISiemens MS 41 .I I 1

528i. 1999ZO00 1~52 TU, 2.8 liter ]siemens MS 42.0 I I

5251, 2001-2002 1~54, 2.5 liter 1 Siemens MS 43.0 I I

530i, 2001-2002 1~54, 3.0 liter ISiemens MS 43.0

5401 1999-2001 1~62 TU, 4.4 liter l~osch ME 7.2

I

OBI) II software and hardware is incorporated in the engine

management control systems. The

OED II system monitors

components that influence exhaust and evaporative emis-

sions. If a problem is detected, the

OED I1 system stores the

associated fault code and condition.

540i. 1997

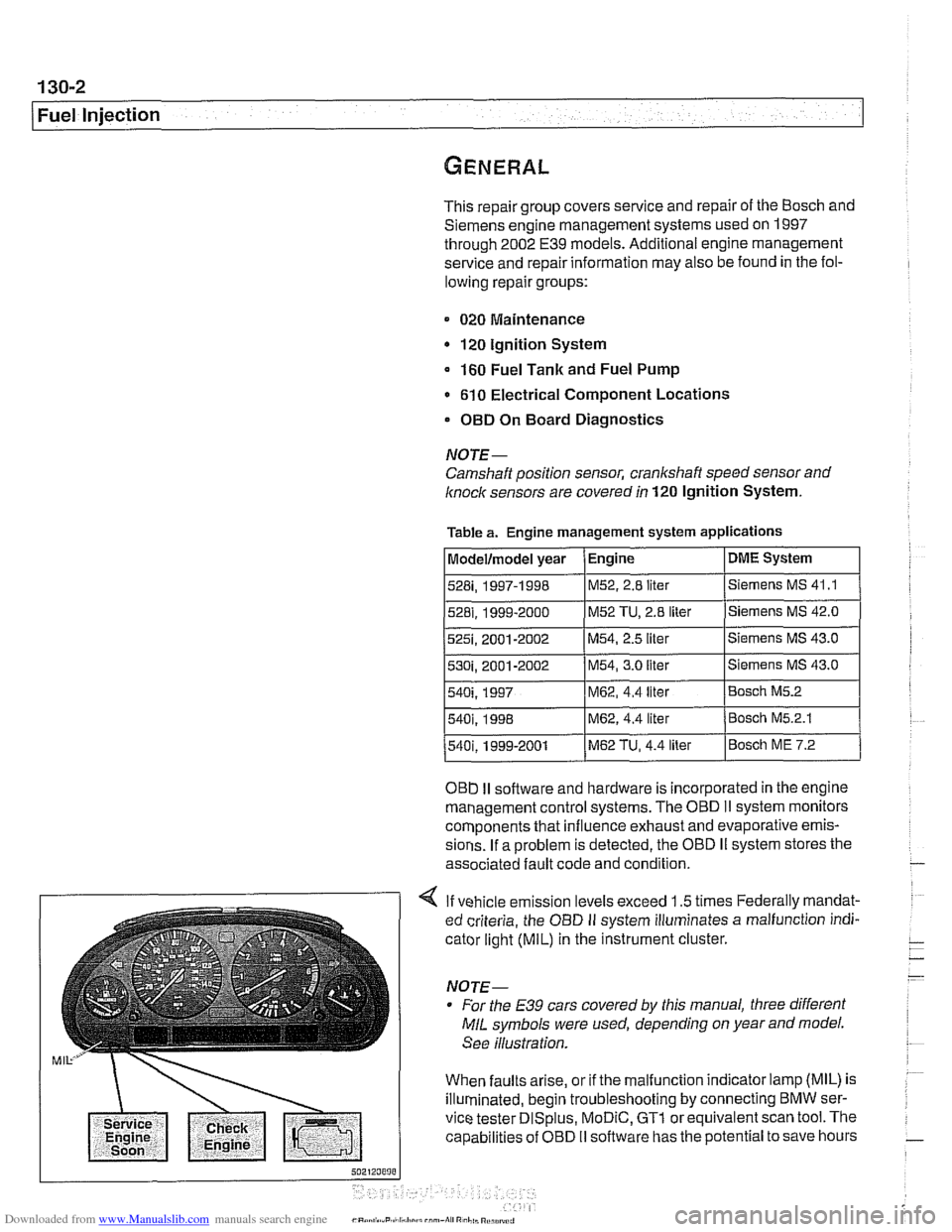

4 If vehicle emission levels exceed 1.5 times Federally mandat-

ed criteria, the

OED II system illuminates a malfunction indi-

cator light

(MIL) in the instrument cluster.

For the

E39 cars covered by this manual, three different

MIL symbols were used, depending on year and model.

See illustration.

When faults arise, or if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus, MoDiC, GTl or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

540i. 1998 IM62, 4.4 liter /Bosch M5.2.1

M62, 4.4 liter Bosch M5.2

Page 393 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

NOTE-

* Professional diagnostic scan tools available at the time of

this printing include the BMW factory tools and a small

number of aftermarket BMW-specific tools. The

CS2000

from Baum Tools Unlimited, the Retriever from Assenma-

chef Specialty Tools, and the MT2500 from Snap-on are

three examples.

In addition to the BMW-specific professional line of scan

tools, there are inexpensive generic OBD

I1 scan tool soft-

ware programs and

handheld units available. Although

these tools have limited capabilities as compared to the

dedicated tools, they are powerful diagnostic tools.

For the

DIY owner, simple aftermarltet DTC readeris avail-

able through

http://www.pealteresearch.com. This tool is

capable of checlting for

DTCs as well as turning off the il-

luminated

MIL and resetting the service indicator lights.

Tools and test equipment

If the equipment required to do the job is unavailable, it is rec-

ommended that these repairs be left to an authorized

BMW

dealer or other qualified BMW repair facility.

4 Low current test light ("noid")

(Tool No. Baum 11 15a)

Page 395 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Warnings and cautions

For personal safety, as well as the protection of sensitive

electronic components, adhere to the warnings and cautions

on the following pages.

WARNING-

Gasoline is highly flammable and its vapors are explosive.

Do not smoke or work on a car near heaters or other fire

hazards when diagnosing and repairing fuel system prob-

lems. Have a fire extinguisher available in case of an emer-

gency

Renew fuel system hoses, clamps and O-rings any

time they are removed.

When working on an open fuel system, wear suitable

hand protection, as prolonged contact

with fuel can

cause illnesses and skin disorders.

* The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

CAUTION-

- Disconnecting the battery may erase fault code($ storedin

memory Check for fault codes prior to disconnecting the

battery cables. Read the battery disconnection cautions in

001 General Warnings and Cautions.

a Connect and disconnect the DME system wiring and

1 test equipment leads only when the ignition is switched

off.

Wait at least 1 minute after turning off the ignition be-

fore removing the engine control module (ECM) con-

nector. If the connector is removed before this time,

residualpower in the system relay may damage the

control module.

Fuel system cleaners and other chemical additives oth-

er than those specifically recommended by BMW may

damage the catalytic converter, the oxygen sensor or

other fuel supply components.

* Do not connect any test equipment that delivers a 12-

volt power supply to terminal 15 (+) of the ignition coil.

The current flow may damage the ECM. In general,

connect test equipment only as specified by BMW or

the equipment maker.

Only use a digital

multirneter for electrical tests. Only

use an LED test light for

quiclc tests.

Page 396 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-6

Fuel Injection

Fuel supply to the injection system is provided by a high pres-

sure electric pump mounted inside the fuel tank. The pump is

powered via the fuel pump relay. If the relay is faulty, the fuel

pump will not run and the engine will not start.

NOTE-

* Fuel delivery volume and fuel pressure are critical to prop-

er operation. Fuel pressure direcfly influences fuel deliv-

ery

Fuel pump relay, fuel pressure and fuel volume tests are

given in 160 Fuel Tank and Fuel Pump.

Relieving system fuel pressure

The fuel system retains fuel pressure in the system when the

engine is off. To prevent fuel from spraying on a hot engine,

system fuel pressure should be relieved beforedisconnecting

fuel lines. One method is to tightly wrap

ashop towel around a

fuel line fitting and loosen or disconnect the fitting. Cleanli-

ness is essential when working with fuel components. Thor-

oughly clean the unions before disconnecting fuel lines.

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also iiluminates if an emissions-related fault is detected

When faults arise, or if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus. MoDiC, GTI or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CAUTION-

- The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the

MIL. Affer all testing is completed,

access and clear DJC fault memory using an

OED I1 or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

0 Only use a digital multimeter for electrical tests.

. Relay positions can vary Be sure to confirm relay posi-

tion by identifying the wiring in the socket using the wir-

ing diagrams found in ELE Electrical Wiring

Diagrams.

Page 397 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection 1

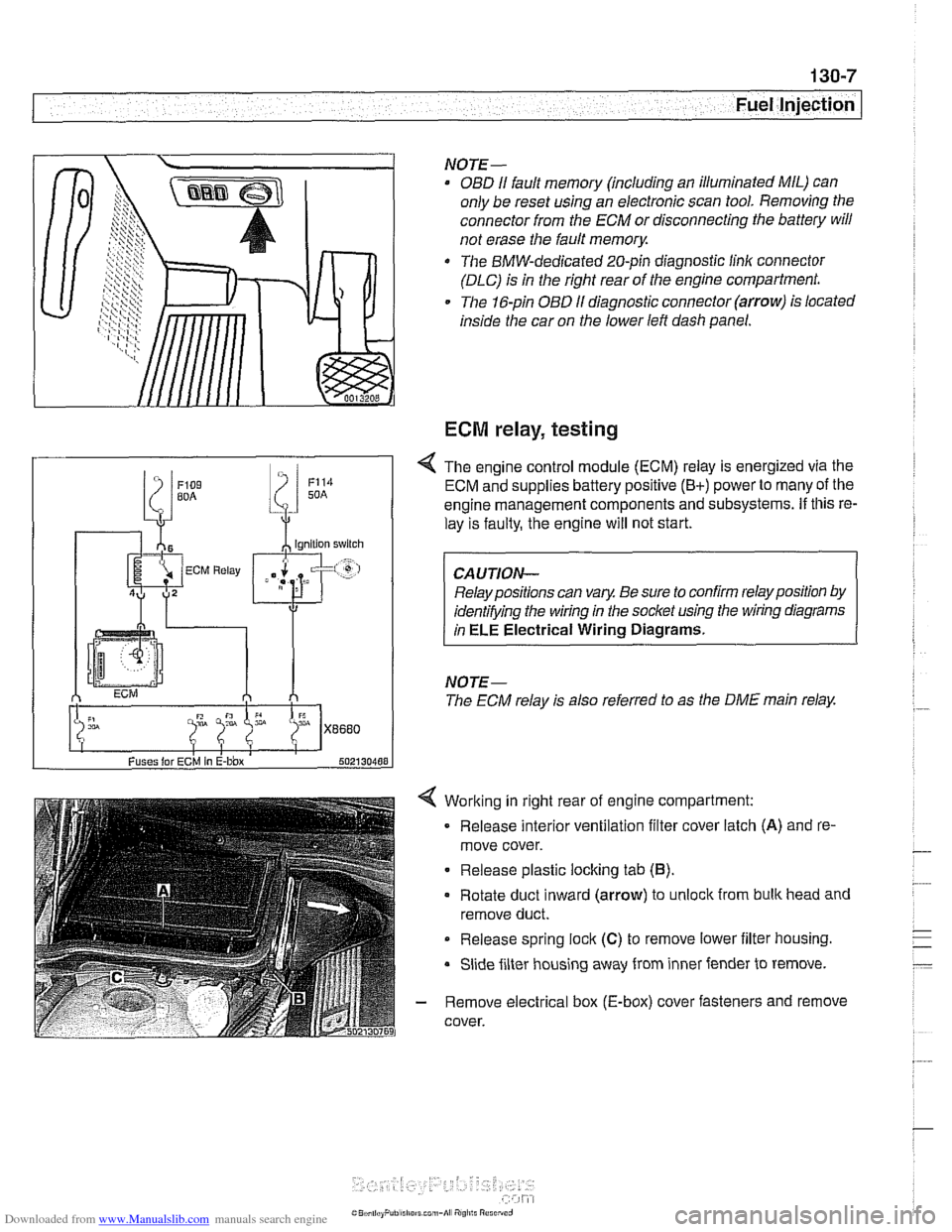

Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(6).

Rotate duct inward (arrow) to unlock from bulk head and

remove duct.

Release spring

lock (C) to remove lower iilter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

NOTE-

OBD I1 fault memory (including an illuminated MIL) can

only be reset using an electronic scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault

memory.

The BMW-dedicated 20-pin diagnostic linlc connector

(DLC) is in the right rear of the engine compartment.

The 16-pin OBD

I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

ECM relay, testing

Fuses lor ECM In E-bbx 502130488

4 The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine management components and subsystems.

If this re-

lay is faulty, the engine will not start.

Relay positions can vary. Be sure to confirm relay position by

identifying the wiring in the socket using the wiring diagrams

in

ELE Electrical Wiring Diagrams.

NOTE-

The ECM relay is also referred to as the DME main relay.

Page 398 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-8

Fuel Injection

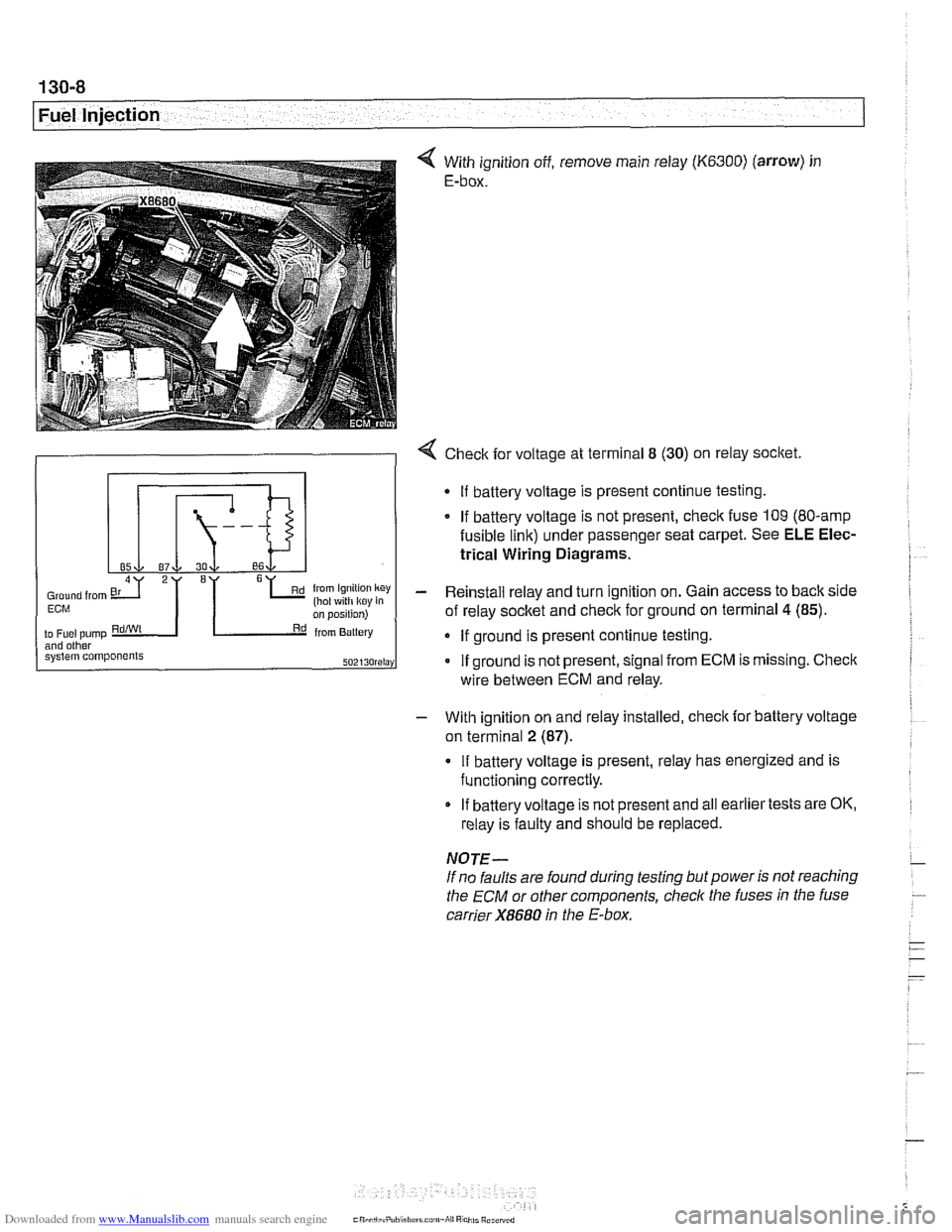

With ignition off, remove main relay (K6300) (arrow) in

E-box.

- With ignition on and relay installed, check for battery voltage

on terminal

2 (87).

4 Check for voltage at terminal 8 (30) on relay socket.

If battery voltage is present, relay has energized and is

functioning correctly.

Gmund from 6L (hot ~4th k~y key in Ern

2I '1

on position)

to

Fuel pump RdiWt Rd from Battery and other system components SOZI~O~~I~Y

If battery voltage is not present and all earlier tests are OK,

relay is faulty and should be replaced.

If

battery voltage is present continue testing.

If battery voltage is not present, check fuse 109 (80-amp

fusible link) under passenger seat carpet. See ELE Elec-

trical Wiring Diagrams.

- Reinstall relay and turn ignition on. Gain access to back side

of relay socket and check for ground on terminal

4 (85).

If ground is present continue testing.

If ground is not present, signal from ECM is missing. Check

NOTE-

If no faults are found during testing but power is not reaching

the

ECM or other components, check the fuses in the fuse

carrier

X8680 in the E-box.

wire

between ECM and relay.

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

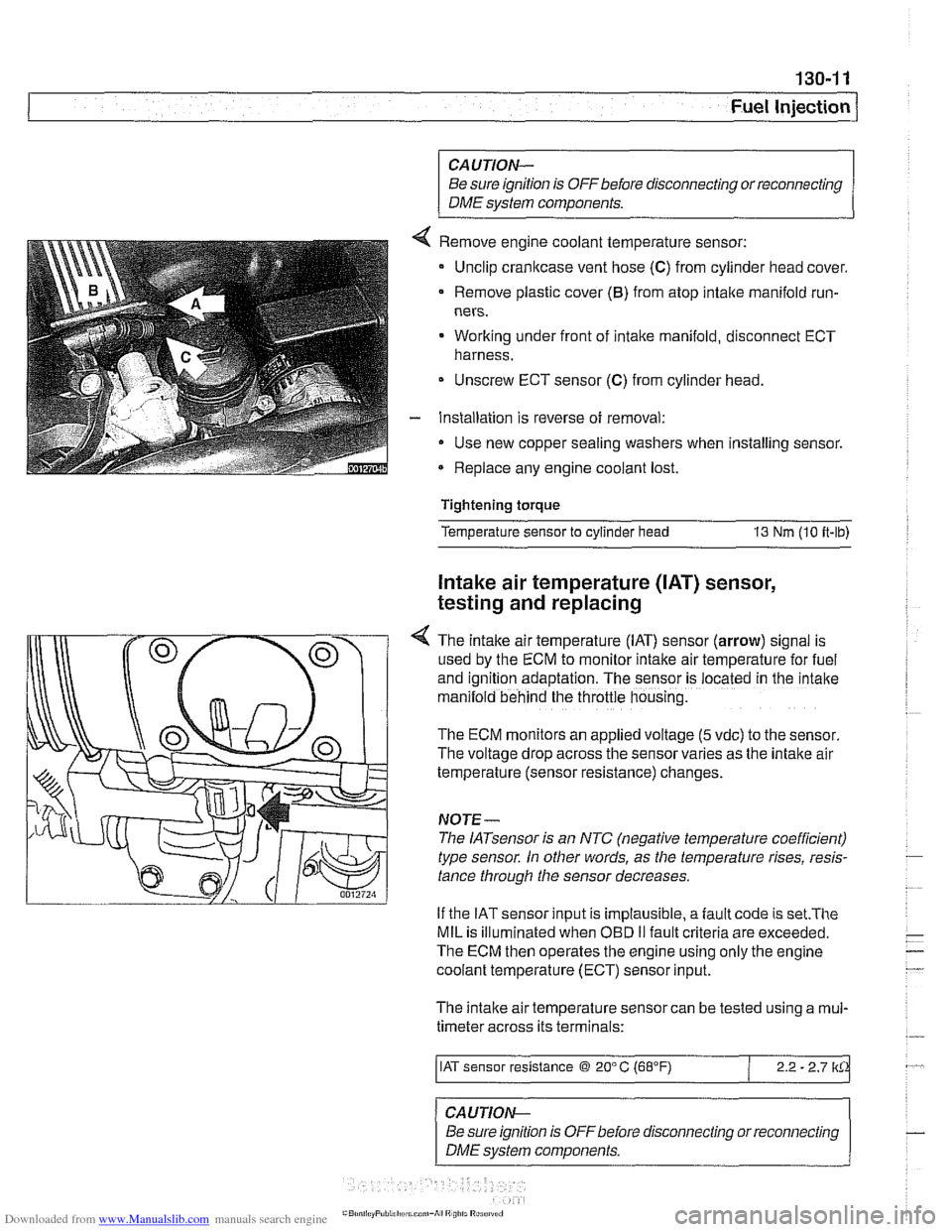

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.

Page 403 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 3

Fuel Injection I

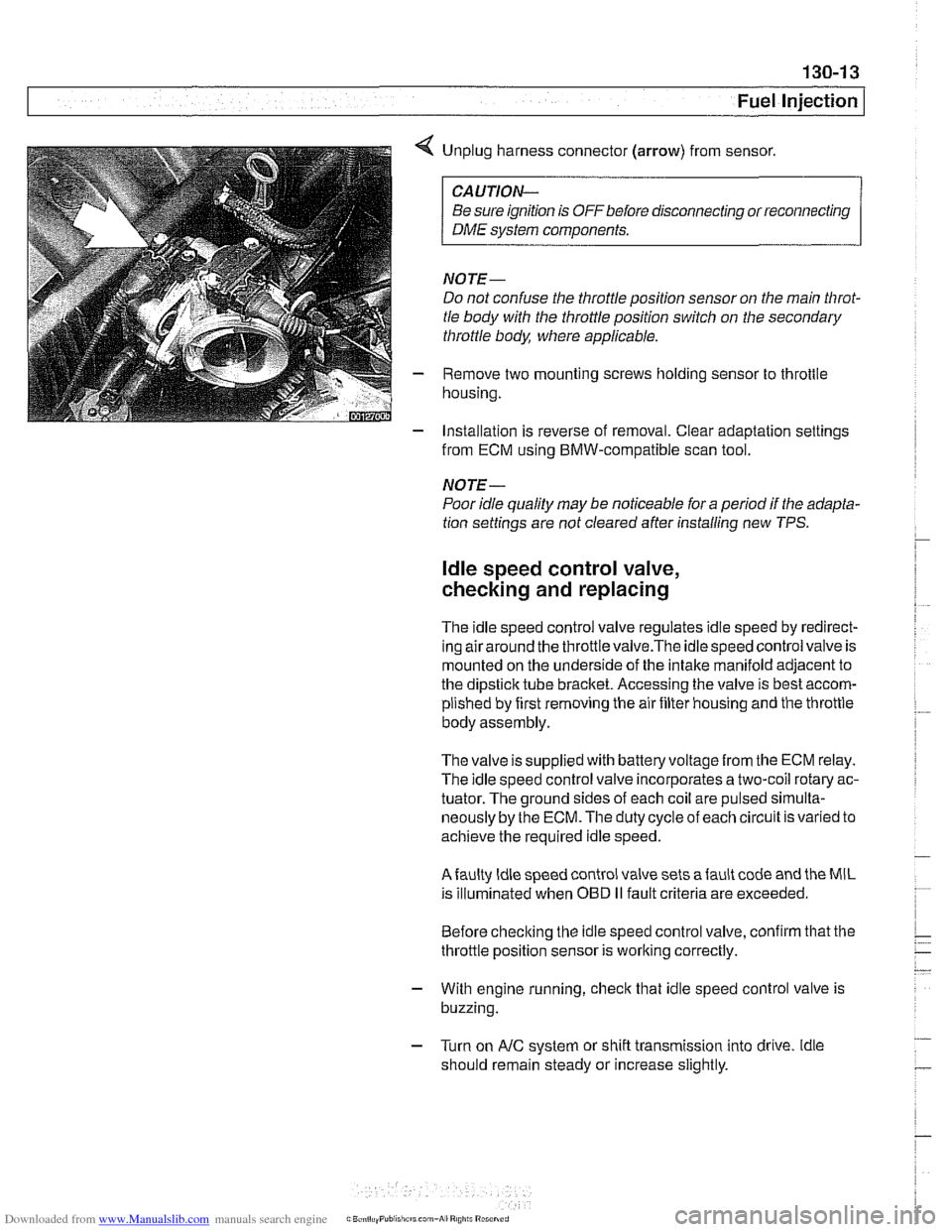

< Unplug harness connector (arrow) from sensor.

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

NOTE-

Do not confuse the throttle position sensor on the main Nirot-

tle body with the throttle position switch on the secondary

throttle body, where applicable.

- Remove two mounting screws holding sensor to throttle

housing.

- Installation is reverse of removal. Clear adaptation settings

from ECM using BMW-compatible scan tool.

NOTE-

Poor idle quality may be noticeable for a period if the adapta-

tion settings are not cleared after installing new TPS.

ldle speed control valve,

checking and replacing

The idle speed control valve regulates idle speed by redirect-

inq airaround the throttlevalve.The idlespeed control valve is

mounted on the underside of the intake manifold adjacent to

the dipstick tube bracket. Accessing the valve is best accom-

plished by first removing the air filter housing and the throttle

body assembly.

The valve issupplied with

batteryvoltagefrom the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed

sirnulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

Afaulty ldle speed control valve sets afault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

Page 404 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

connector

CAUTION-

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

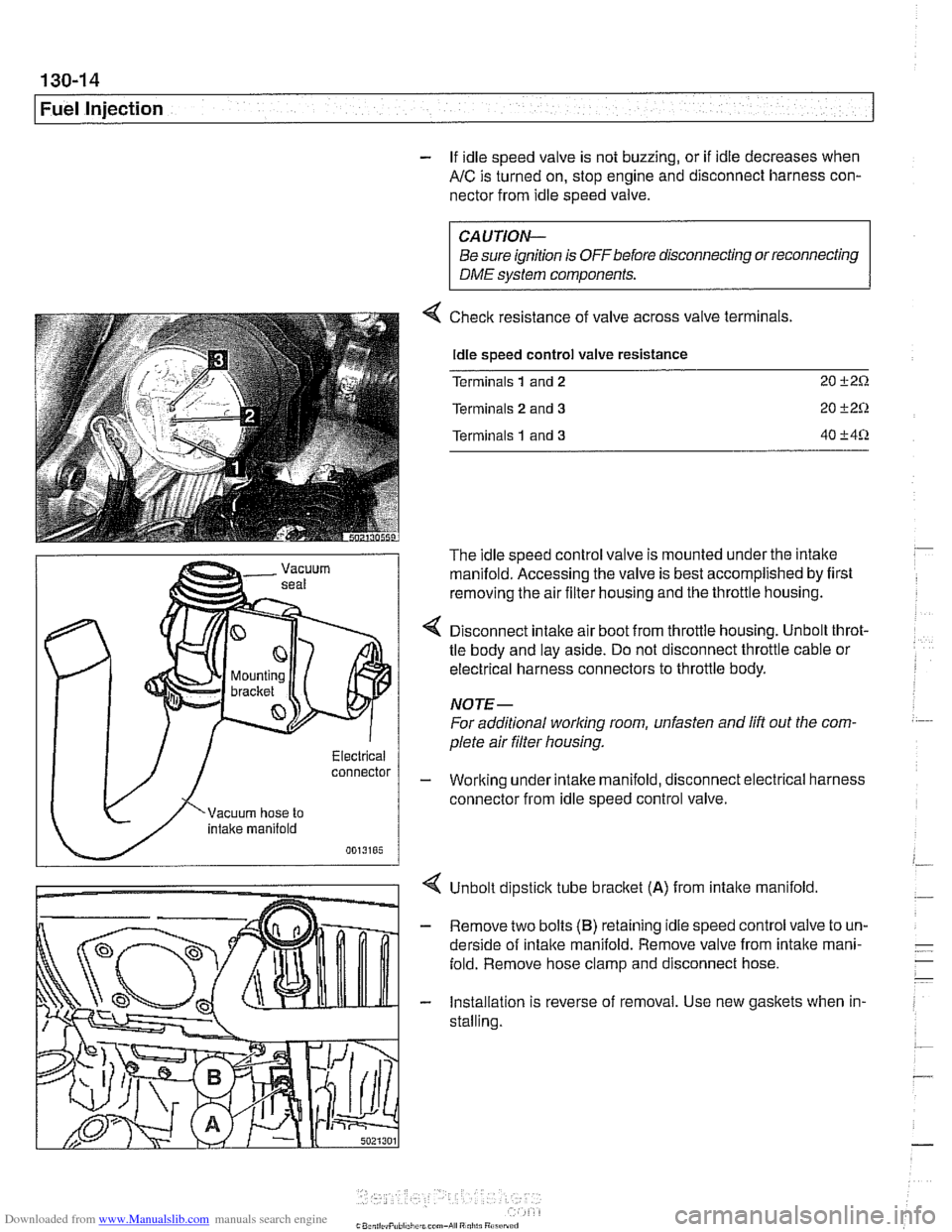

Checlc resistance of valve across valve terminals.

Idle speed control valve resistance

Terminals

1 and 2 20 i-2Q

Terminals 2 and 3 20 C2Q

Terminals 1 and 3 40 C4Q

The idle speed control valve is mounted under the intake

manifold. Accessing the valve is best accomplished by first

removing the air filter housing and the throttle housing.

< Disconnect intake air boot from throttle housing. Unbolt throt-

tle body and lay aside. Do not disconnect throttle cable or

electrical harness connectors to throttle body.

NOTE-

For additional worlcing room, unfasten and lift out the com.

plete air filter housing.

- Working under intake manifold, disconnect electrical harness

connector from idle speed control valve.

Unbolt dipstick tube

bracket (A) from intalte manifold.

- Remove two bolts (B) retaining idle speed control valve to un-

derside of intalte manifold. Remove valve from intalte mani-

fold. Remove hose clamp and disconnect hose.

- Installation is reverse of removal. Use new gaskets when in-

stalling.