EWS BMW 528i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

General Module

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 900 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-6

(Central Locking and Anti-Theft

Each rear door is equipped with the child lock-out lever, pre-

venting the door from being opened from the inside regard-

less of loclc button position.

Starting with models produced afler

911997, the General

Module and electronic immobilizer (EWS) interface via the

K-

Bus to monitor double lock status and to initiate double loclc

override. This feature allows the doors to be opened from the

inside if a key accepted by EWS is switched on in the ignition.

See Single lock and double lock function.

The door loclc buttons are mechanically uncoupled from the

actuators when locked. The remote keyless entry system

(FZV) is standard equipment. This allows for elimination of

the passengers side door

loclt cylinder.

Another function of the locking system is the

sofl close trunk

(SCA) system, where applicable.

Single lock and double lock function

(2000 and later models)

On models produced after

911999, each door lock actuator in-

corporates two motors:

Single lock motor controls the mechanical loclc mechanism

when the central lock switch is pressed to single loclc the

vehicle. The loclc mechanism is fully locked at this point but

can stil. be openeo from

the interor by pulng the appropri-

are interior door nandle lwce or by pressing rhe central

lock switch again. When single

lock'function is activated,

the fuel filler flap actuator is not locked.

Double lock motor, also known as central arrest, is activat-

ed only when the vehicle is locked from the outside at the

driver's door lock with a key or when the GM receives a

lock request from the remote entry (FZV) system. In this

case the double lock motor is activated simultaneously

with the single lock motor. The function of the double loclc

motor is to mechanically offset an internal rod in the loclc

actuator, disabling it from unlocking the vehicle from the in-

terior. This prevents the doors from being unloclted by any

means except from an unlock request at the driver's door

or via the FZV remote key.

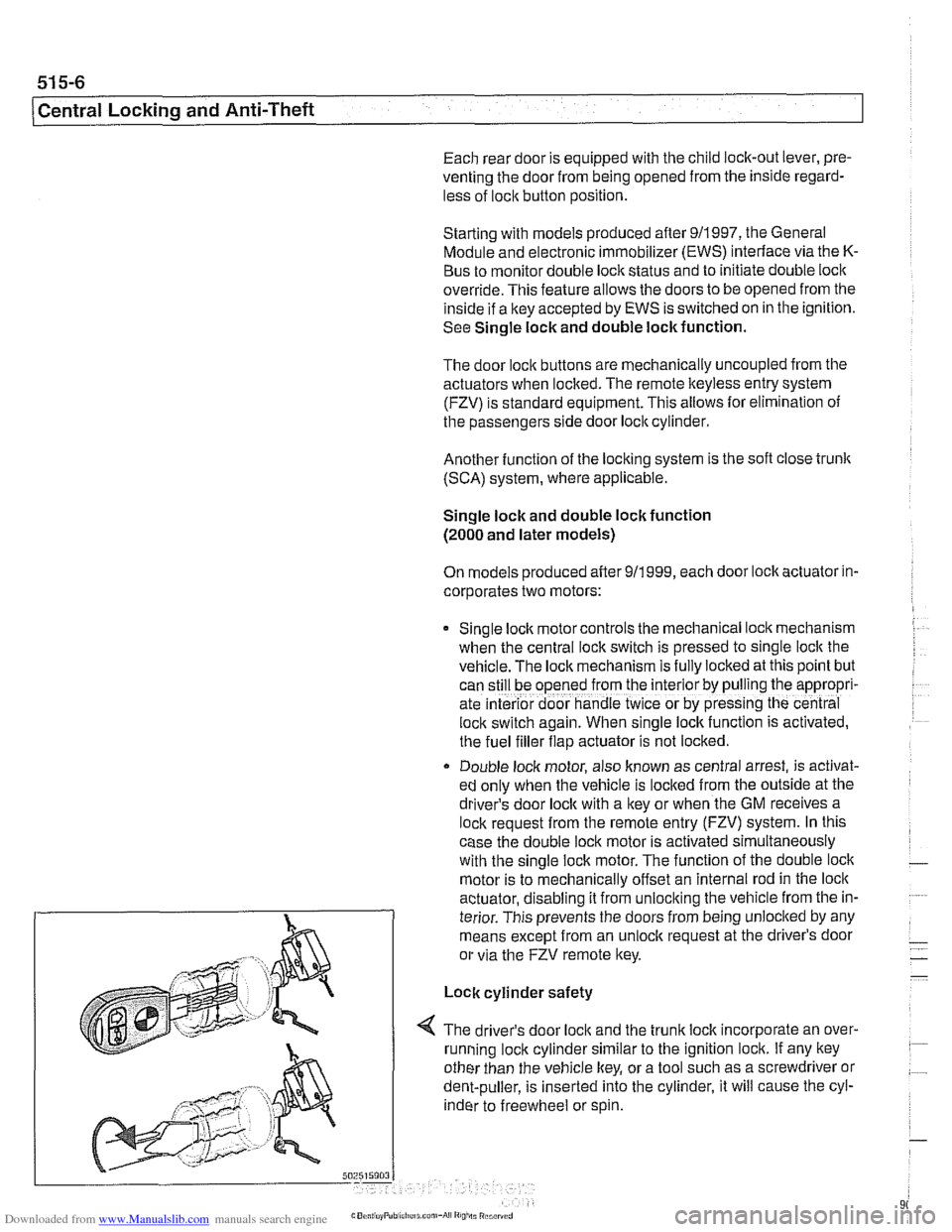

Lock cylinder safety

4 The driver's door loclc and the trunk loclc incorporate an over-

running loclc cylinder similar to the ignition lock. If any key

other than the vehicle key, or a tool such as a screwdriver or

dent-puller, is inserted into the cylinder, it will cause the cyl-

inder to freewheel or spin.

Page 904 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Central Locking and Anti-Theft

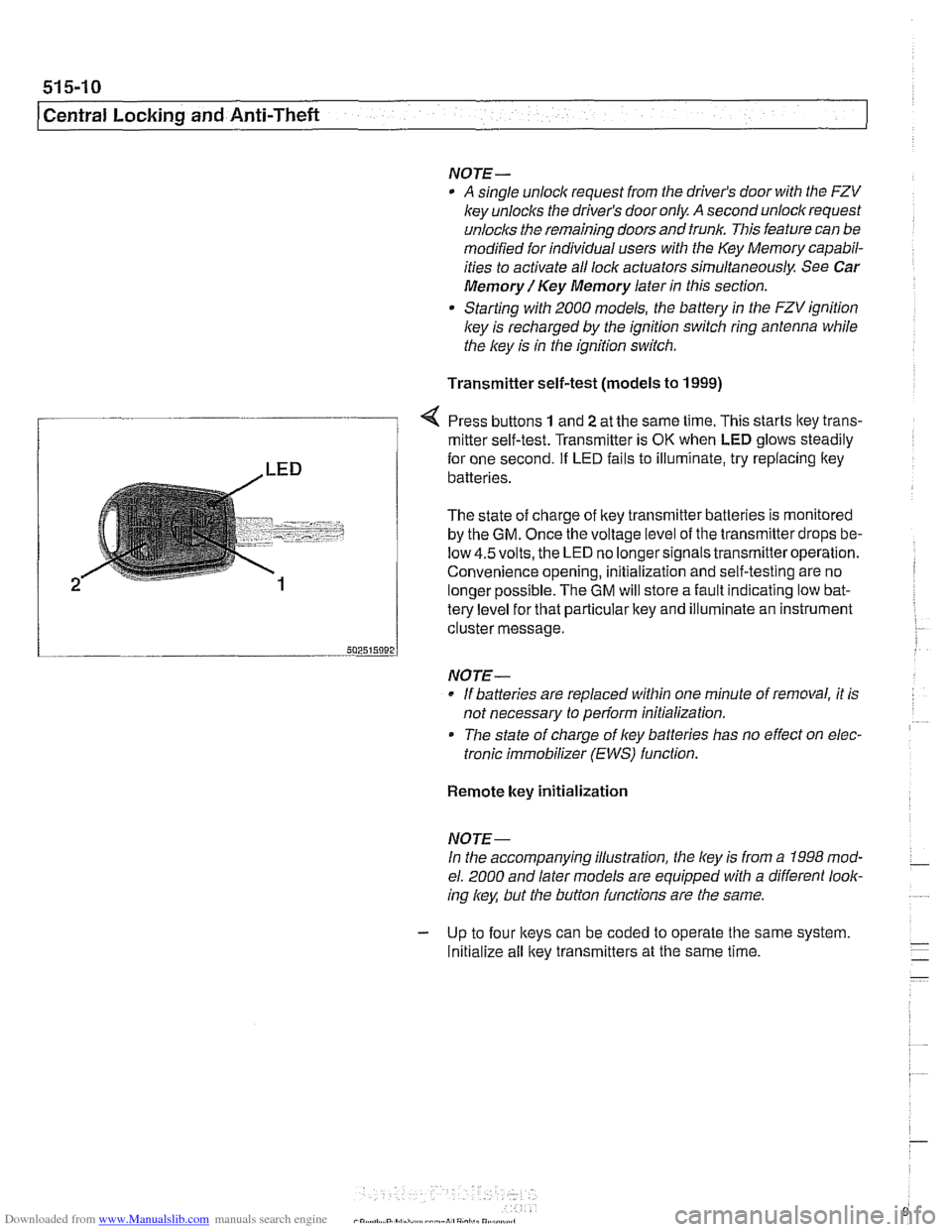

NOJE-

A single unlock request from the driver's door with the FZV

key unlocks the driver's door only.

A second unlock request

unlocls the remaining doors and trunk. This feature can be

modified for individual users with the Key Memory capabil-

ities to activate all lock actuators simultaneously See Car

Memory

/ Key Memory later in this section.

Starting with 2000 models, the battery in the FZV ignition

Icey is recharged by the ignition switch ring antenna while

the ley is in the ignition switch.

Transmitter self-test (models to

1999)

Press buttons 1 and 2 at the same time. This starts ltey trans-

/ mitter self-test. Transmitter is OK when LED glows steadily

te{le"el for that particular key and illuminate an instrument

cluster message.

-- 502515092 J

NO JE-

If batteries are replaced within one minute of removal, it is

not necessary to

periorm initialization.

Tlie state of charge of key batteries has no effect on elec-

tronic immobilizer (EWS) function.

2

Remote key initialization

for one second. If LED fails to illuminate, try replacing ltey~

batteries.

The state of charge of key transmitter batteries is monitored

by the

GM. Once the voltage level of the transmitter drops be-

low

4.5volts, the LED no longersignals transmitteroperation.

Convenience opening, initialization and self-testing are no

lonaer ~ossible. The GM will store a fault indicatina low bat-

NOJE-

In the accompanying illustration, the key is from a 1998 mod-

el. 2000 and later models are equipped with a different look-

ing

/

Initialize all key transmitters at the same time.

Page 910 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-1 6

Central Locking and Anti-Theft

DOOR HANDLES AND LOCKS

In the procedures that follow, door handle removal, door lock

cylinder removal and door latch removal are covered for the

left front door. Other doors are similar although simpler, due

to the

lack of lock cylinder.

Inside door release removal is covered in the procedure for

inner door

ane el removal. See 411 Doors.

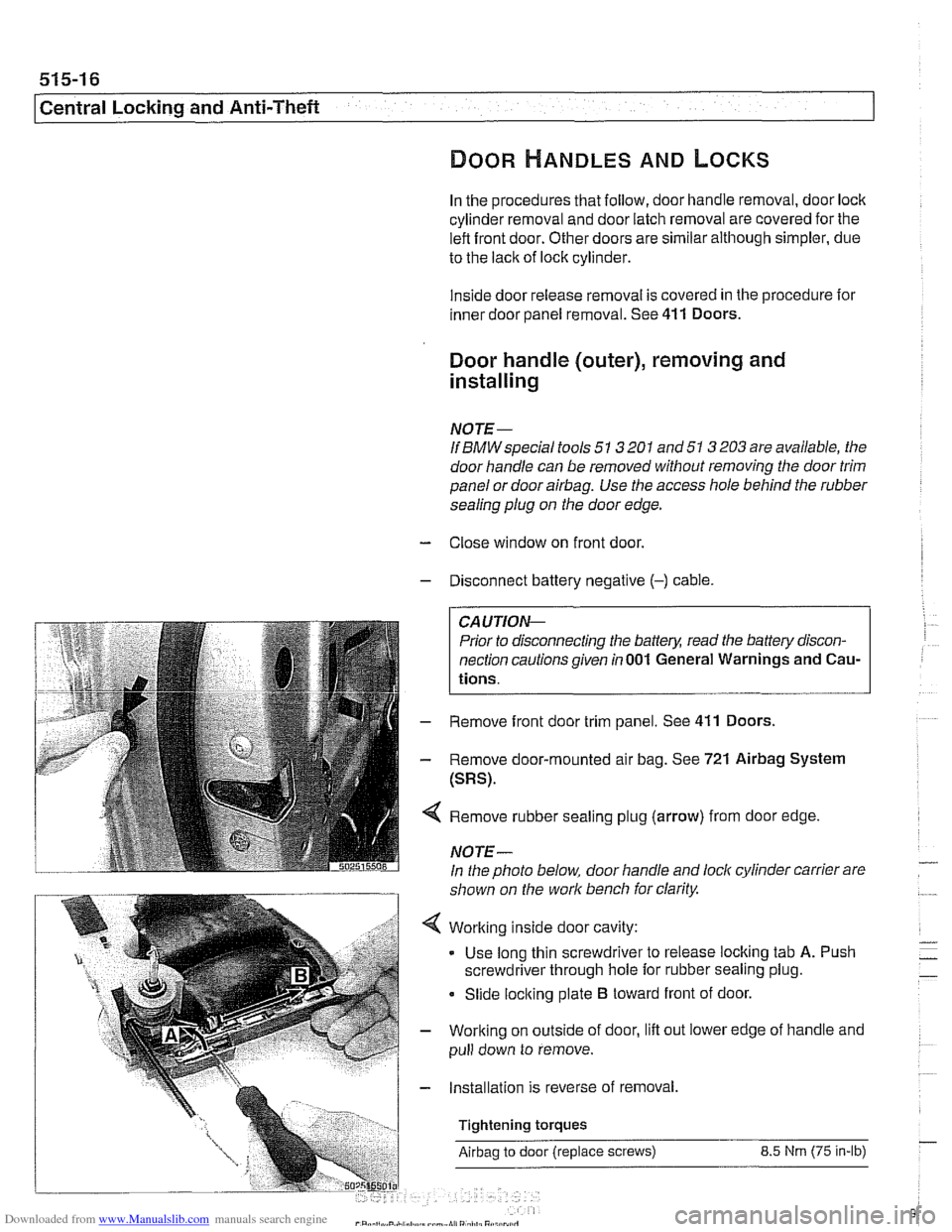

Door handle (outer), removing and

installing

NOTE-

IfBMWspecial tools 51 3201 and51 3 203 are available, the

door handle can be removed without removing the door trim

panel or door

airbag. Use the access hole behind the rubber

sealing plug on the door edge.

- Close window on front door.

- Disconnect battery negative (-) cable.

CAUTlOG

Prior to disconnecting the batter)! read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

tions.

Remove front door trim panel. See 411 Doors.

Remove door-mounted air bag. See 721

Airbag System

(SRS).

Remove rubber sealing plug (arrow) from door edge

NOTE-

In the photo below, door handle and lock cylinder carrier are

shown on the work bench for clarity.

Working inside door cavity:

- Use long thin screwdriver to release locking tab A. Push

screwdriver through hole for rubber sealing plug.

Slide locking plate

B toward front of door.

Working on outside of door, lift out lower edge of handle and

pull down to remove.

Installation is reverse of removal,

Tightening torques

Airbag to door (replace screws) 8.5 Nrn (75 in-lb)

Page 912 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-1 8

I Central Locking and Anti-Theft

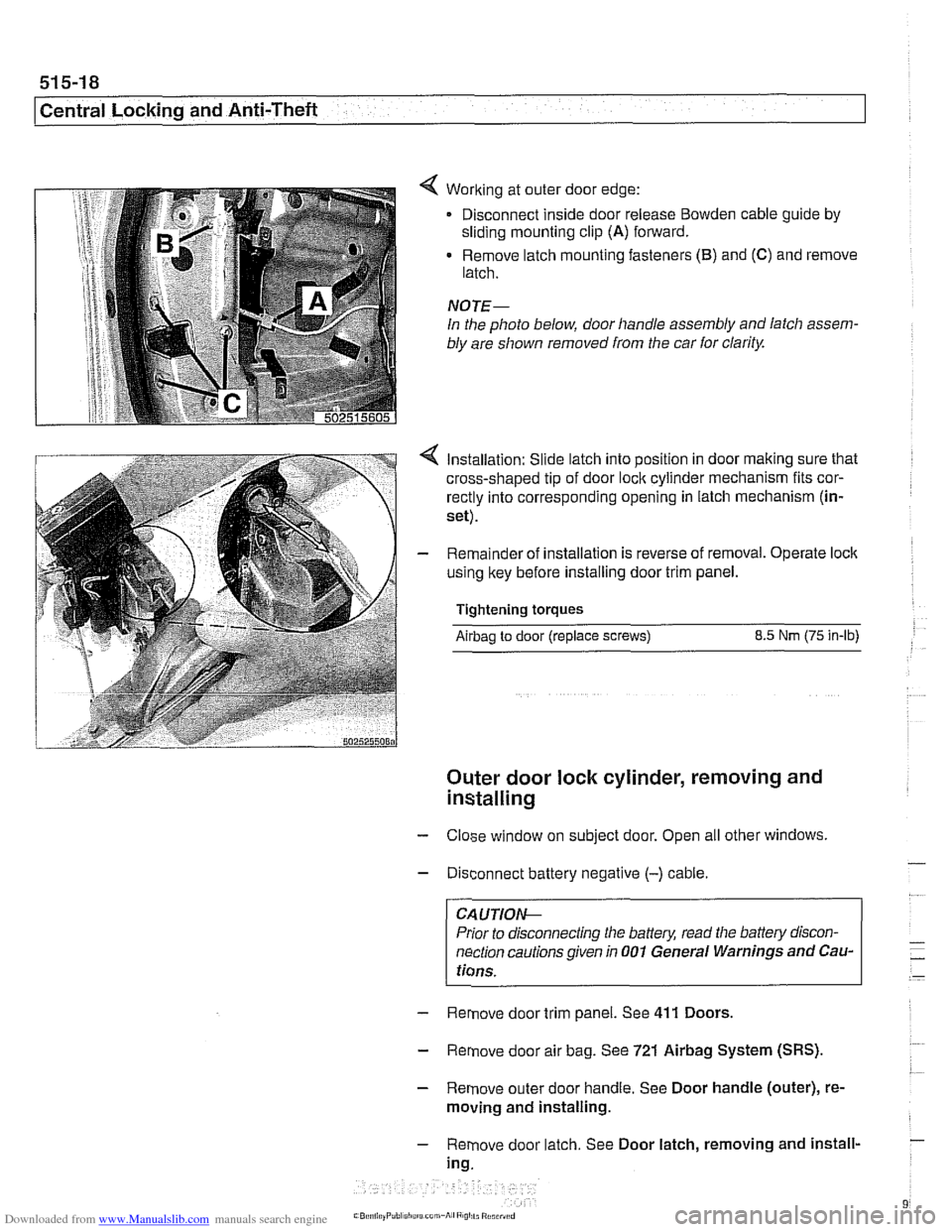

< Working at outer door edge:

Disconnect inside door release

Bowden cable guide by

sliding mounting clip (A) forward.

Remove latch mounting fasteners

(B) and (C) and remove

latch.

NOTE-

In the photo below, door handle assembly and latch assem-

bly are shown removed from the car

for clarity.

Installation: Slide latch into position in door making sure that

cross-shaped tip of door

loclc cylinder mechanism fits cor-

rectly into corresponding opening in latch mechanism (in-

set).

Remainder of installation is reverse of removal. Operate

loclc

using key before installing door trim panel.

Tightening torques

Airbag to door (replace screws) 8.5 Nm (75 in-lb)

Outer door lock cylinder, removing and

installing

- Close window on subject door. Open all other windows

- Disconnect battery negative (-) cable.

CA UTIOIG

Prior to disconnecting the baffeg read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

- Remove door trim panel. See 411 Doors.

- Remove door air bag. See 721 Airbag System (SRS).

- Remove outer door handle. See Door handle (outer), re-

moving and installing.

- Remove door latch. See Door latch, removing and install-

ing.

Page 913 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

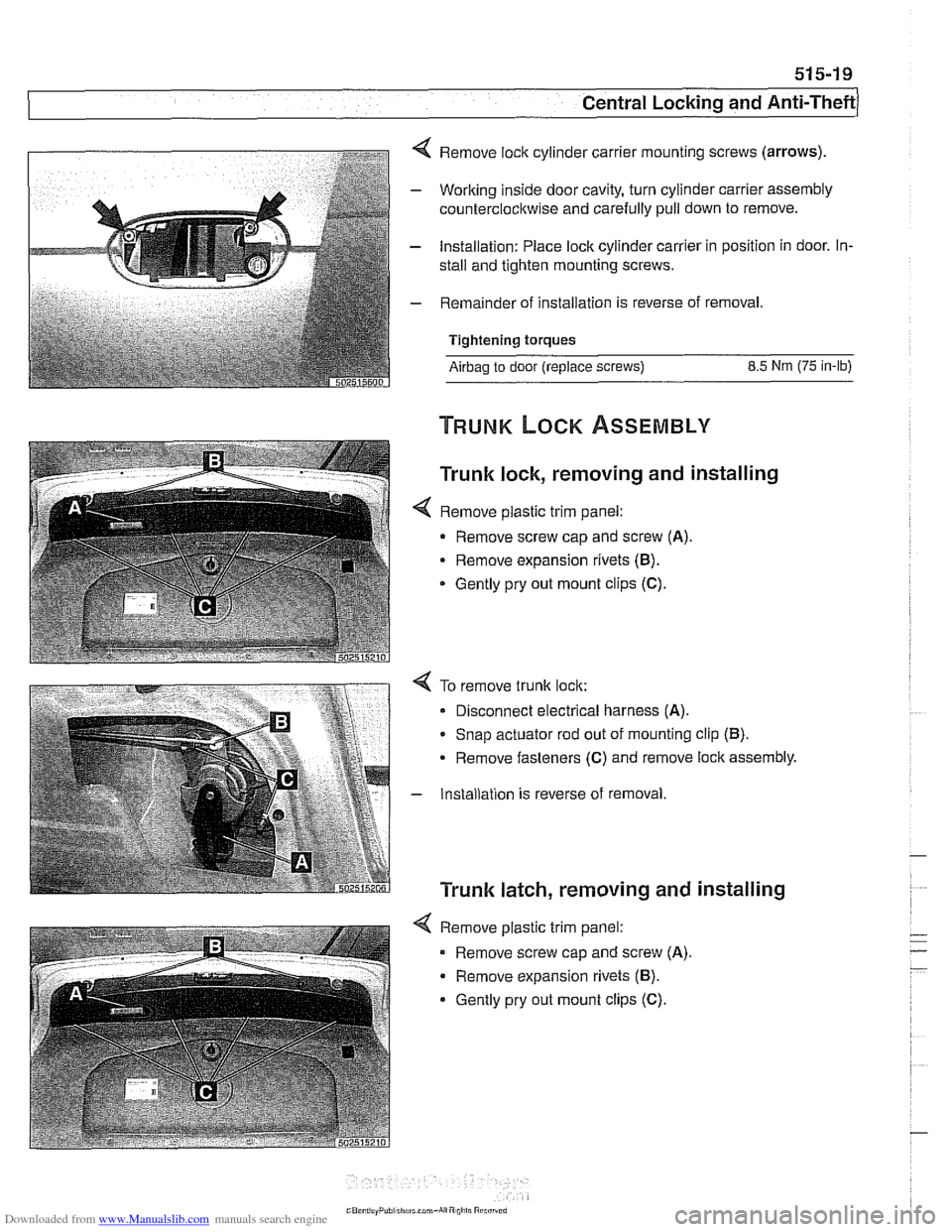

4 Remove lock cylinder carrier mounting screws (arrows).

- Working inside door cavity, turn cylinder carrier assembly

counterclockwise and carefully pull down to remove.

- Installation: Place lock cylinder carrier in position in door. In-

stall and tighten mounting screws.

- Remainder of installation is reverse of removal.

Tightening torques

Airbag to door (replace screws) 8.5 Nm (75 in-lb)

Trunk lock, removing and installing

< Remove plastic trim panel:

- Remove screw cap and screw (A).

Remove expansion rivets (B).

* Gently pry out mount clips (C).

4 To remove trunk lock:

Disconnect electrical harness

(A).

* Snap actuator rod out of mounting clip (B).

Remove fasteners (C) and remove lock assembly.

- Installation is reverse of removal

Trunk latch, removing and installing

4 Remove plastic trim panel:

Remove screw cap and screw

(A).

Remove expansion rivets (B).

Gently pry out mount clips (C).

Page 915 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-21

Central Locking and Anti-Theft

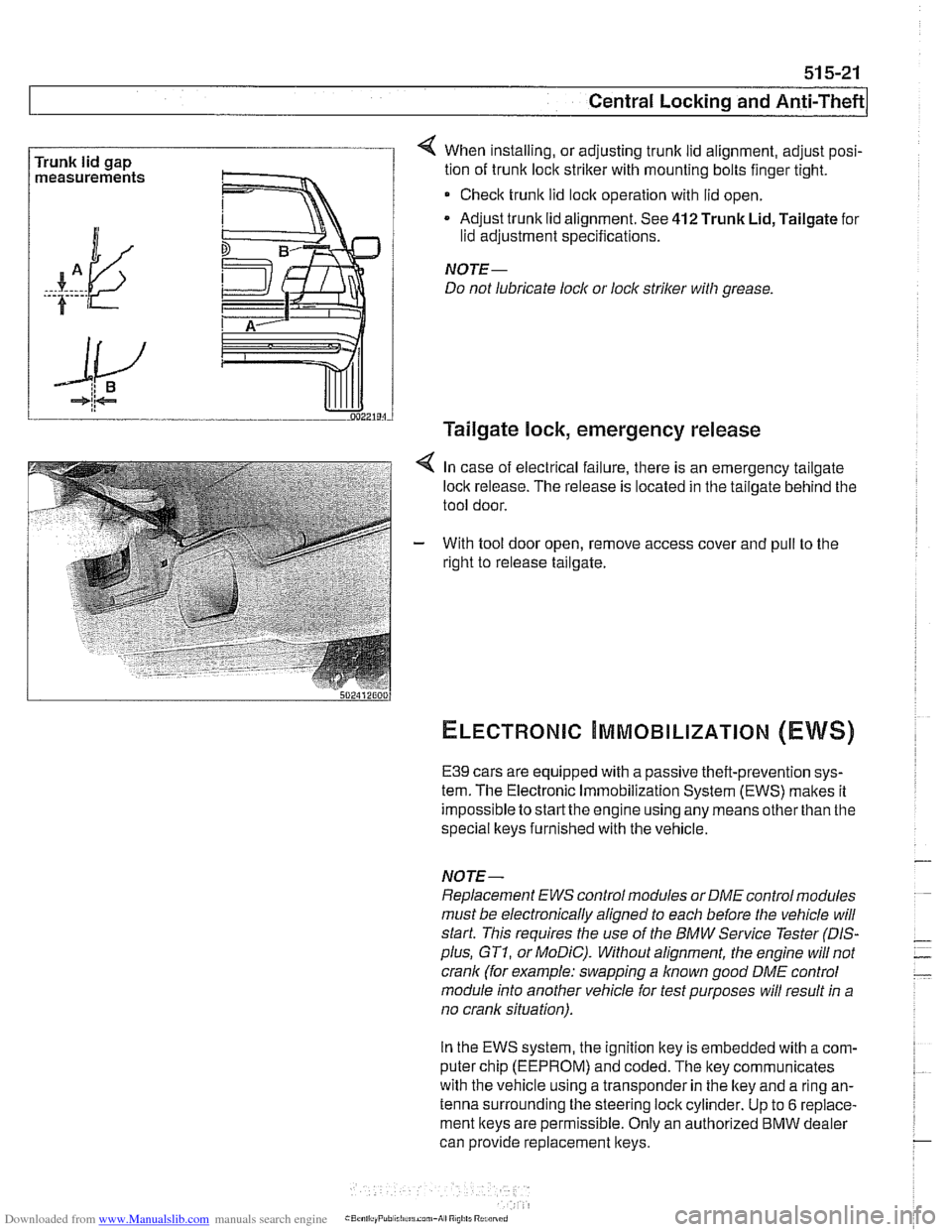

Trunk lid gap

measurements 4 When installing, or adjusting trunk lid alignment, adjust posi-

tion of trunk

loclc striker with mounting bolts finger tight.

* Check trunk lid loclc operation with lid open.

Adjust trunk lid alignment. See

412 Trunk Lid, Tailgate for

lid adjustment specifications.

NOTE-

Do not lubricate lock or lock striker with grease.

Tailgate lock, emergency release

4 In case of electrical failure, there is an emergency tailgate

loclk release. The release is located in the tailgate behind the

tool door.

- With tool door open, remove access cover and pull to the

right to release tailgate.

ELECTRONIC ~MMOBILIZATION (EWS)

E39 cars are equipped with a passive theft-prevention sys-

tem. The Electronic Immobilization System (EWS) makes it

impossible to

startthe engine using any means other than the

special lkeys furnished with the vehicle.

NOTE-

Replacement EWS control modules or DME control modules

must be electronically aligned to each before the vehicle will

start. This requires the use of the BMW Service Tester

(DIS-

plus, GT1, or MoDiC). Without alignment, the engine will not

crank (for example: swapping a

known good DME control

module into another vehicle for test purposes will result in a

no crank situation).

In the EWS system, the ignition key is embedded with

acom-

puter chip (EEPROM) and coded. The key communicates

with the vehicle using a transponder in the lkey and a ring an-

tenna surrounding the steering lock cylinder. Up to

6 replace-

ment keys are permissible. Only an authorized

BMW dealer

can provide replacement keys.

Page 916 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anii-Theft

- If the starter engages, the following EWS inputs are function-

ing normally:

Ignition key

Code function

Transmission range switch or clutch position switch

Engine speed sensor

NO JE -

If a vehicle key is lost or stolen, the electronic authorization

for that key

can be cancelled using the BMW scan and di-

agnostic tools

DISplus, GTl or MoDiC.

Force applied to a ley can damage the electronic circuitry

in the key A damaged ley will not start the engine. In that

case, a new key should be purchased and initialized

by an

authorized BMW dealer.

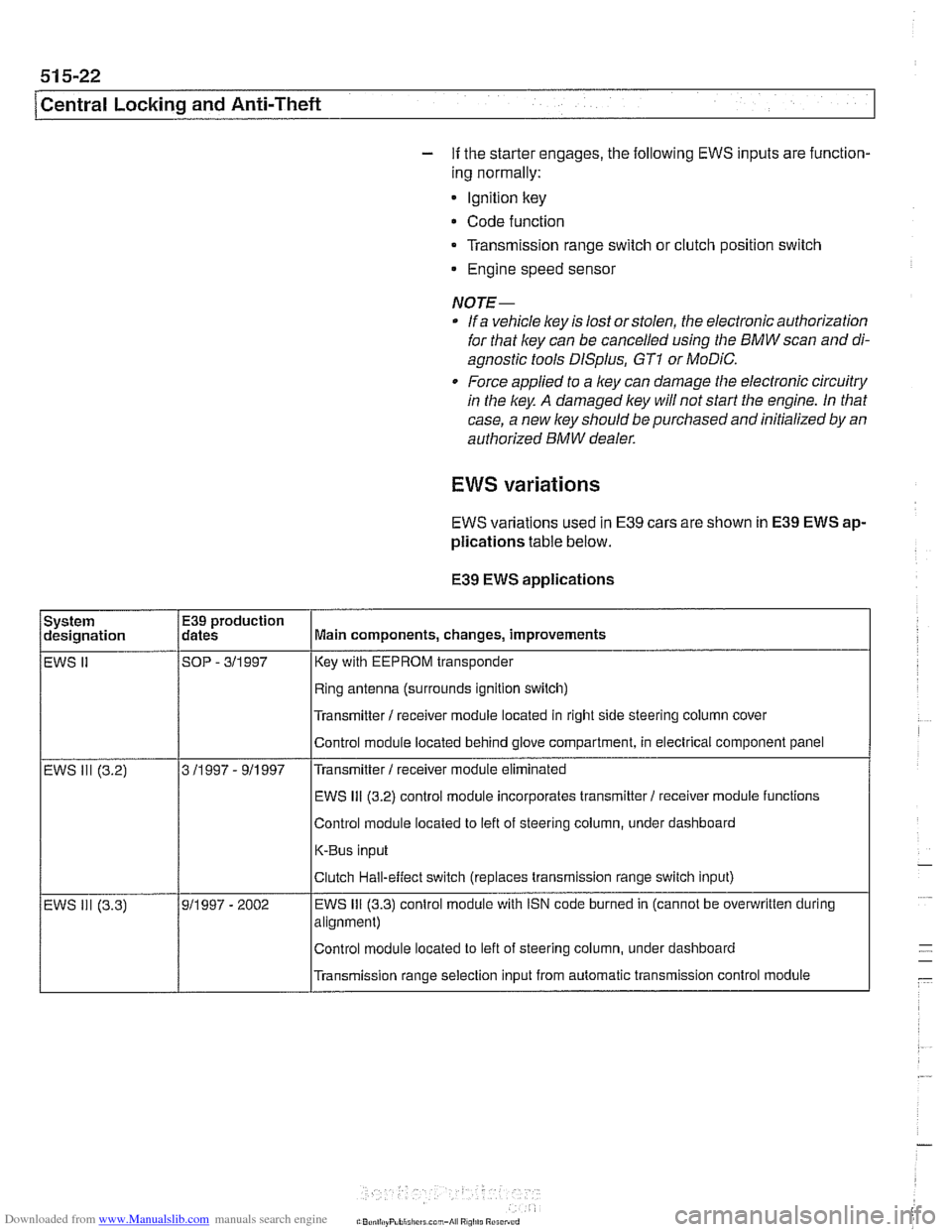

EWS variations

EWS variations used in E39 cars are shown in E39 EWS ap-

plications

table below.

E39

EWS applications

I I Ifling antenna (surrounds ignition switch) I

System

designation

EWS

II

I I l~ransmitter I receiver module located in right side steering column cover I

E39 production

dates

SOP

- 311 997

I I IEWS 111 (3.2) control module incorporates transmitter1 receiver moduie functions /

Main components, changes, improvements

Key with EEPROM transponder

Control moduie located behind glove compartment, in electrical component panel

Control module located to left of steering column, under dashboard

K-Bus input

Transmitter

I receiver module eliminated

EWS 111 (3.2)

Transmission range selection input from automatic transmission control module

3

11997 - 911997

- EWS ill (3.3) Clutch

Hall-effect switch (replaces transmission range switch input)

911997 - 2002 EWS 111 (3.3) control

module with iSN code burned in (cannot be overwritten during

alignment)

Control module located to left of steering column, under dashboard

Page 917 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Lockina and ~nti- heft

EWS control module, replacing

NOTE-

EWS control module location varies depending on version of

EWS installed.

Checlc the table €39 EWS applications.

- Disconnect battery negative (-) cable.

CA UTIOI\C

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

- EWS II: Control module is accessible from behind glove com-

partment.

Remove trim below glove compartment.

Lower relay and module holder to access EWS control

module

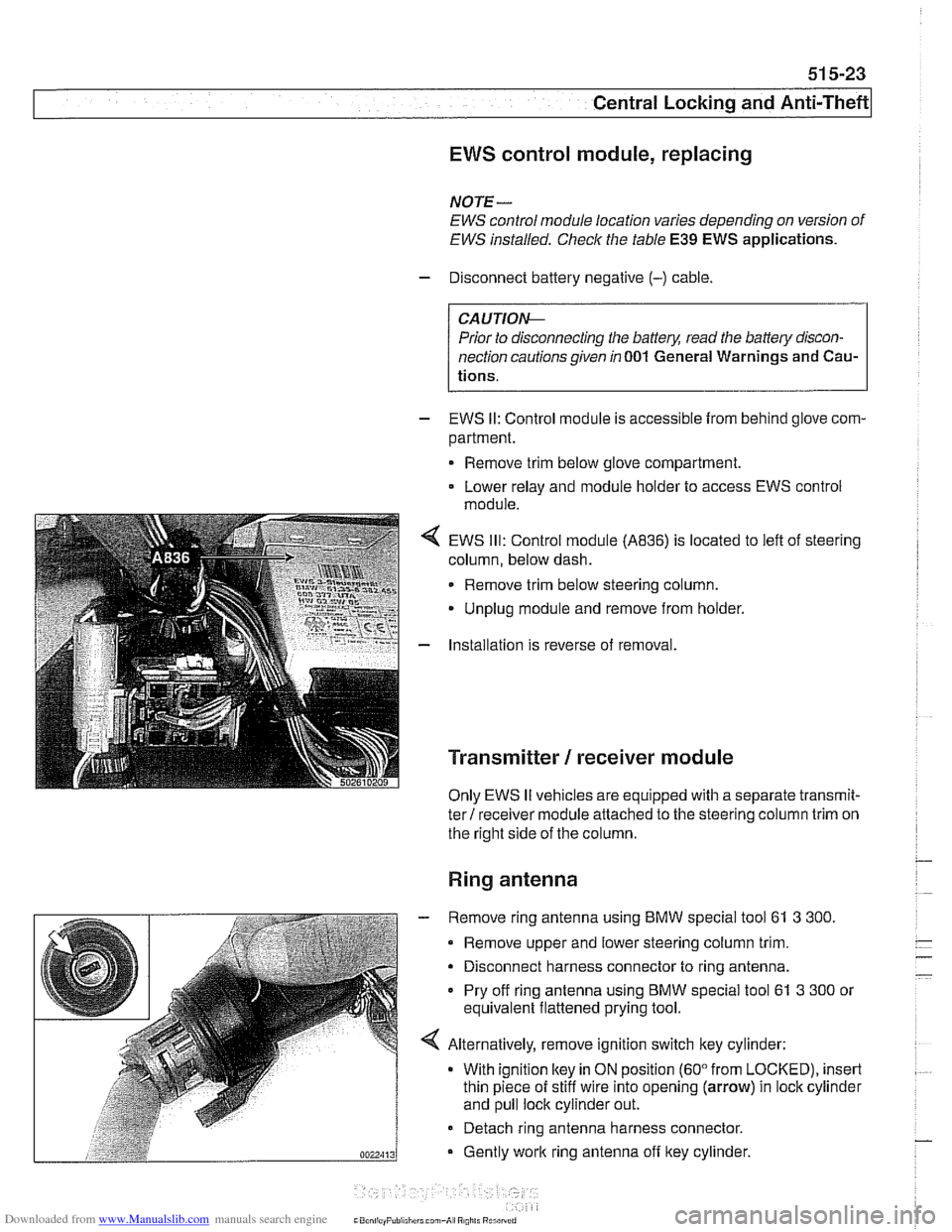

EWS

Ill: Control module (A836) is located to left of steering

column, below dash.

Remove trim below steering column.

Unplug module and remove from holder.

Installation is reverse of removal.

Transmitter / receiver module

Only EWS II vehicles are equipped with a separate transmit-

ter! receiver module attached to the steering column trim on

the right side of the column.

Ring antenna

- Remove ring antenna using BMW special tool 61 3 300.

Remove upper and lower steering column trim.

Disconnect harness connector to ring antenna.

Pry off ring antenna using

BMW special tool 61 3 300 or

equivalent flattened prying tool.

Alternatively, remove ignition switch key cylinder: With ignition

ltey in ON position (60" from LOCKED), insert

thin piece of stiff wire into opening (arrow) in lock cylinder

and pull lock cylinder out.

- Detach ring antenna harness connector.

Gently

work ring antenna off ltey cylinder.

CaonliayPuliiliirrl can,-A, R0,il. Rurilrrrri

Page 918 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-24

l~entral Locking and Anti-Theft

ANTI-THEFT SYSTEM (DWA)

When the anti-then system (DWA) is armed, the doors, hood,

windows, trunk lid or tailgate are monitored against forcible

entry by switches and sensors. The vehicle is protected

against being jacked up or towed away by a tilt sensor.

The control electronics for DWA are integrated in the General

Module (GM). In addition to the control electronics, the sys-

tem includes the following components.

* DWA horn

DWA LED indicator

- Tilt sensor

- Monitoring switches and sensors

The system can be armed or disarmed from the driver's door

lock,

trunklid lock, tailgate lockorthe remote transmitter (FZV

Itey). When armed, the alarm horn

soundsfor30seconds and

the low beam headlights and turn signals flash for

5 minutes.

The electronic immobilizer (EWS) is also activated when

DWA is activated.

The alarm is switched off immediately if key is inserted in door

loclt or FZV key button is used.

DWA LED Status

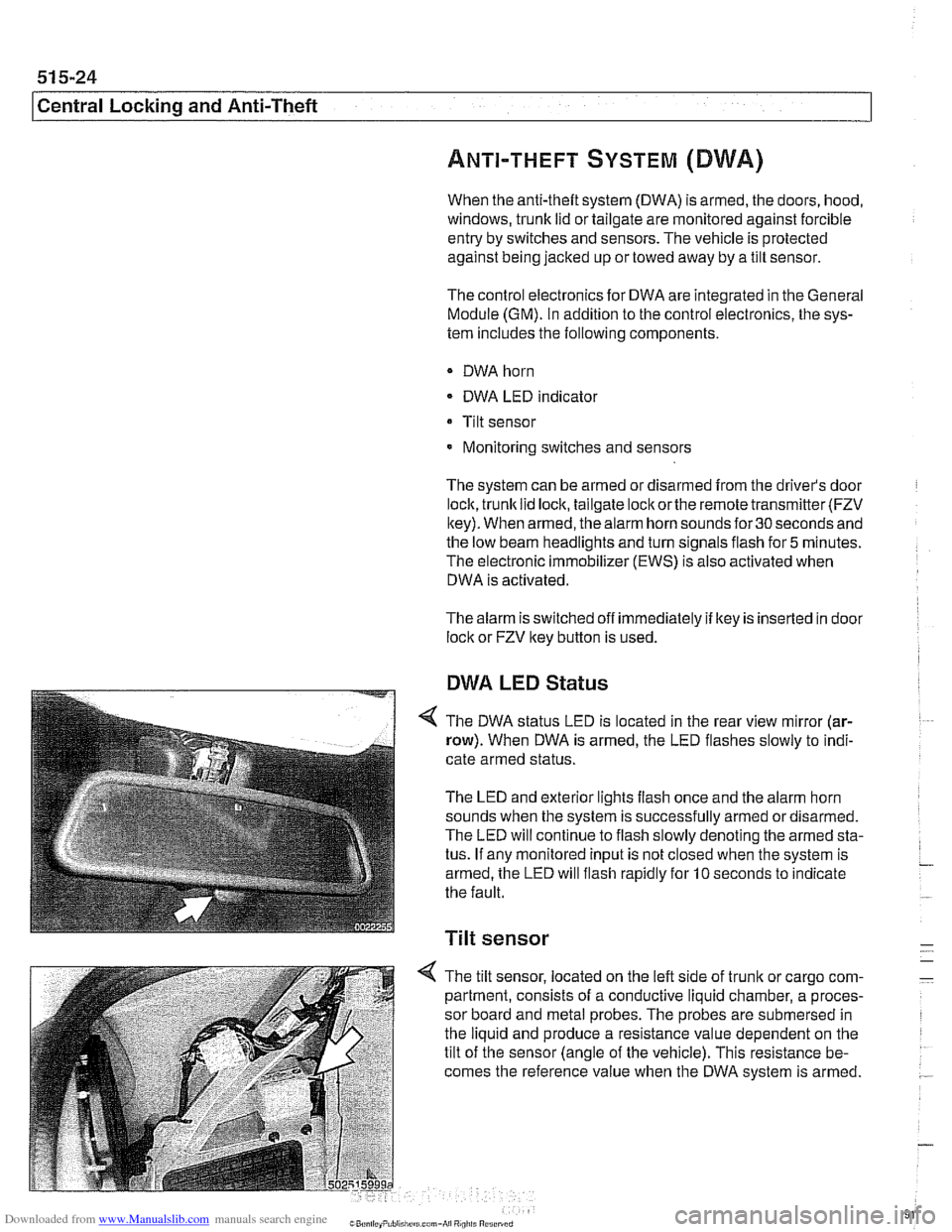

The DWA status LED is located in the rear view mirror (ar-

row). When DWA is armed, the LED flashes slowly to indi-

cate armed status.

The LED and exterior lights flash once and the alarm horn

sounds when the system is successfully armed ordisarmed.

The LED will continue to flash slowly denoting the armed sta-

tus. If any monitored input is not closed when the system is

armed, the LED will flash rapidly for

10 seconds to indicate

the fault.

Tilt sensor

-

4 The tilt sensor, located on the left side of trunlt or cargo com- -

partment, consists of a conductive liquid chamber, a proces-

sor board and metal probes. The probes are submersed in

the liquid and produce a resistance value dependent on the

tilt of the sensor (angle of the vehicle). This resistance be-

comes the reference value when the DWA system is armed.

.-