boot BMW 530i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 530i, Model: BMW 530i 1998 E39Pages: 1002

Page 419 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

A faulty MAF sensor can produce the following problems:

Difficult to restart when engine is hot

Engine starts then stalls

* Engine starts and runs only with accelerator pedal de-

pressed

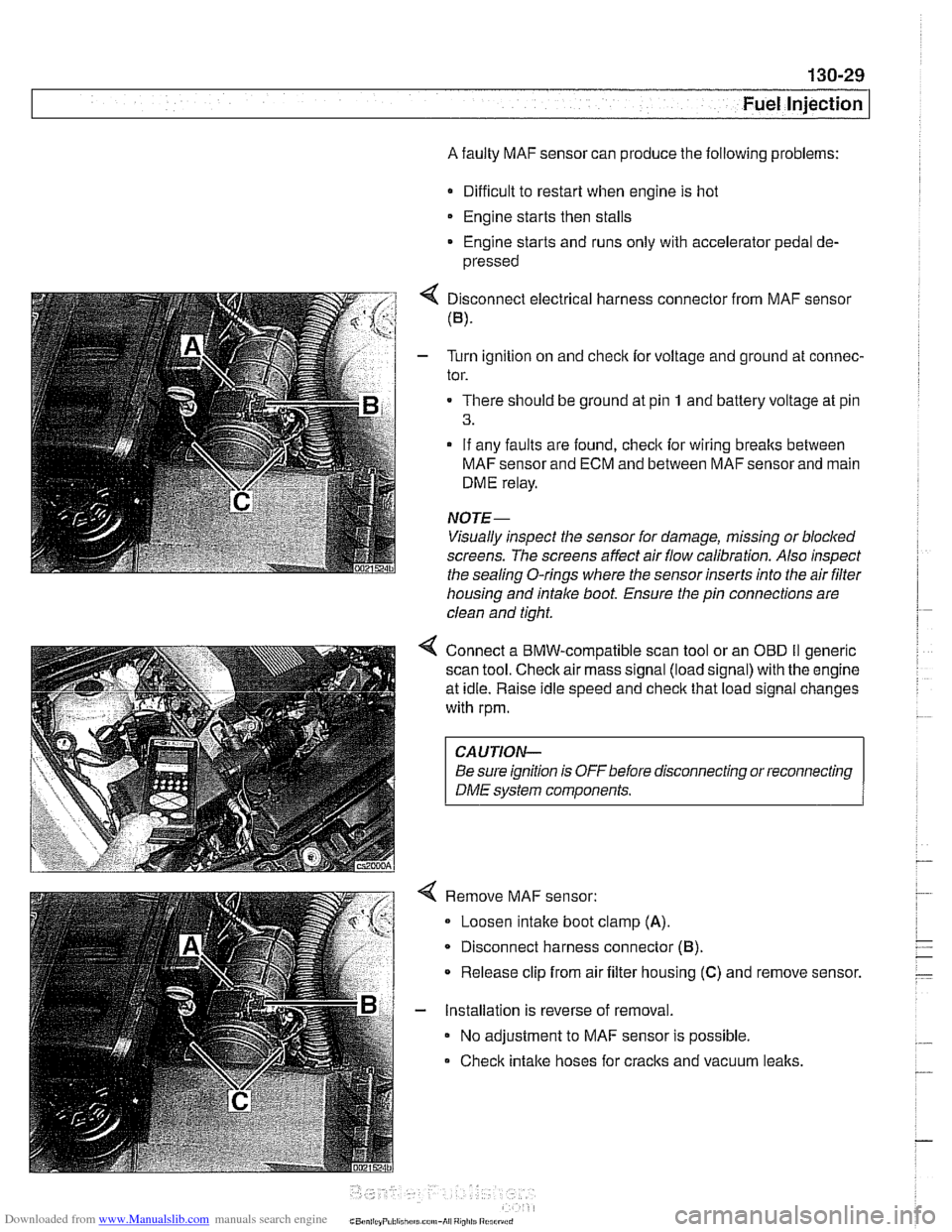

4 Disconnect electrical harness connector from MAF sensor

(B).

- Turn ignition on and checlc for voltage and ground at connec-

tor.

There should be ground at pin

1 and battery voltage at pin

3.

- If any faults are found, checlc for wiring breaks between

MAF sensor and ECM and between MAF sensor and main

DME relay.

NOTE-

Visually inspect the sensor for damage, missing or blocked

screens. The screens affect air flow calibration. Also inspect

the sealina

0-rinas where the sensor inserts into the air filter - - housing and intake boot. Ensure the pin connections are

clean and tight.

4 Connect a BMW-compatible scan tool or an OED II generic

scan tool.

Checlc air mass signal (load signal) with the engine

at idle. Raise idle speed and

checlc that load signal changes

with rpm.

CAUTION-

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

Remove MAF sensor:

Loosen intake boot clamp

(A).

Disconnect harness connector (6).

* Release clip from air filter housing (C) and remove sensor.

- Installation is reverse of removal.

No adjustment to MAF sensor is possible.

Check intake hoses for cracks and vacuum

lealts.

Page 423 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lniection I

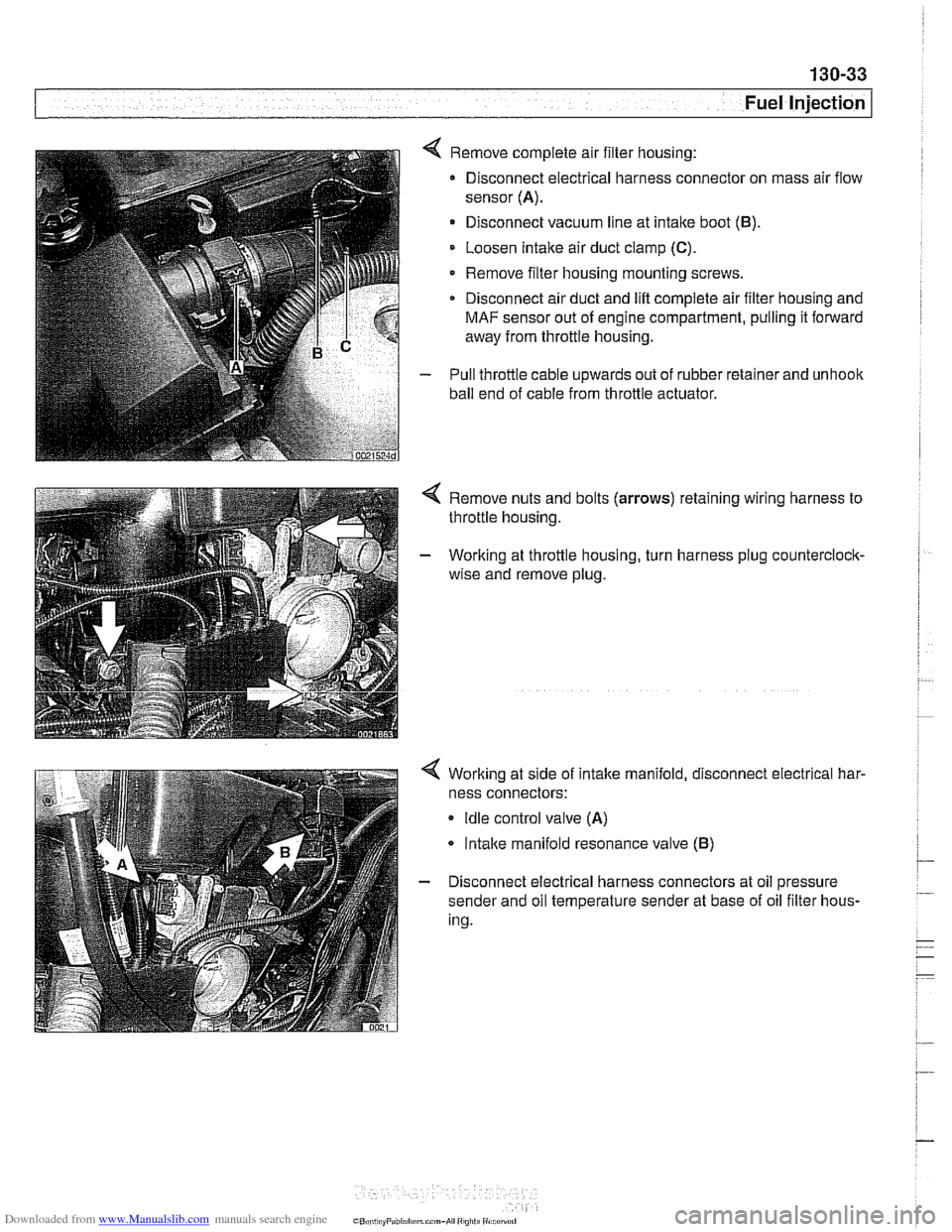

4 Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Disconnect vacuum line at intake boot (B).

Loosen Intake air duct clamp (C).

Remove filter housing mounting screws

Disconnect air duct and

lift complete air filter housing and

MAF sensor out of engine compartment, pulling it forward

away from throttle housing.

- Pull throttle cable upwards out of rubber retainer and unhoolc

ball end of cable from throttle actuator.

4 Remove nuts and bolts (arrows) retaining wiring harness to

throttle housing.

- Working at throttle housing, turn harness plug counterclock-

wise and remove plug.

4 Working at side of intake manifold, disconnect electrical har-

ness connectors:

Idle control valve (A)

lntalce manifold resonance valve (B)

- Disconnect electrical harness connectors at oil pressure

sender and oil temperature sender at base of oil filter hous-

ing.

CO,l,> ti,, "F"bl,rl,irrm.,-AI ",",>ti

Page 425 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

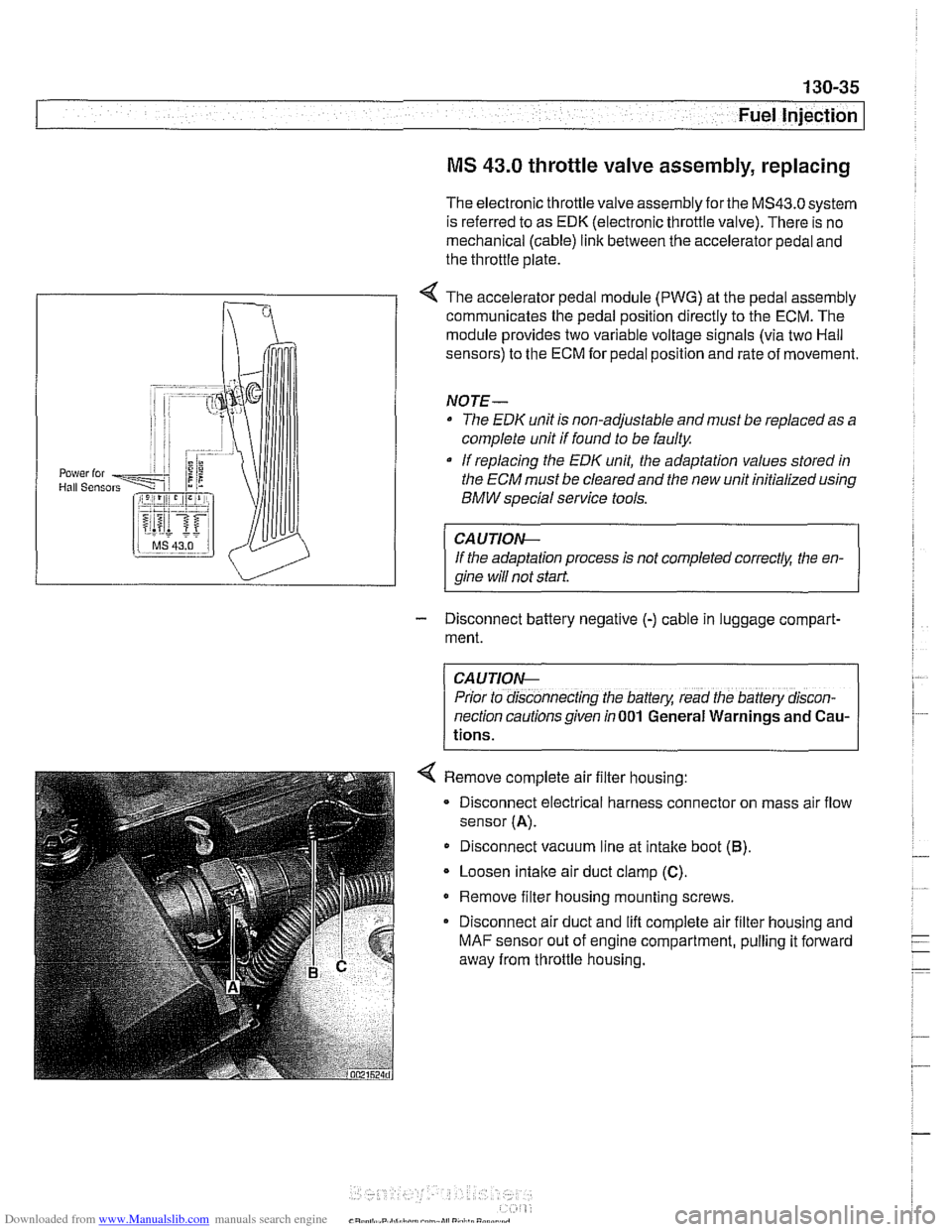

MS 43.0 throttle valve assembly, replacing

The electronic throttle valve assembly forthe MS43.0 system

is referred to as

EDK (electronic throttle valve). There is no

mechanical (cable) link between the accelerator pedal and

the throttle plate.

< The accelerator pedal module (PWG) at the pedal assembly

communicates the pedal position directly to the ECM. The

module provides two variable voltage signals (via two Hail

sensors) to the ECM for pedal position and rate of movement.

NOTE-

The EDK unit is non-adjustable and must be replaced as a

complete unit if found to be faulty

If replacing the

EDK unit, the adaptation values stored in

the

ECM must be cleared and the new unit initialized using

BMW special service tools.

CAUTIOIG

If the adaptation process is not completed correctk the en-

qine will not start

- Disconnect battery negative (-) cable in luggage compart-

ment.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

< Remove complete air filter housing:

- Disconnect electrical harness connector on mass air flow

sensor

(A).

Disconnect vacuum line at intake boot (6).

Loosen intaite air duct clamp (C).

Remove filter housing mounting screws.

Disconnect air duct and lift complete air filter housing and

MAF sensor out of engine compartment, pulling it forward

away from throttle housing.

Page 429 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

Fuel Injection

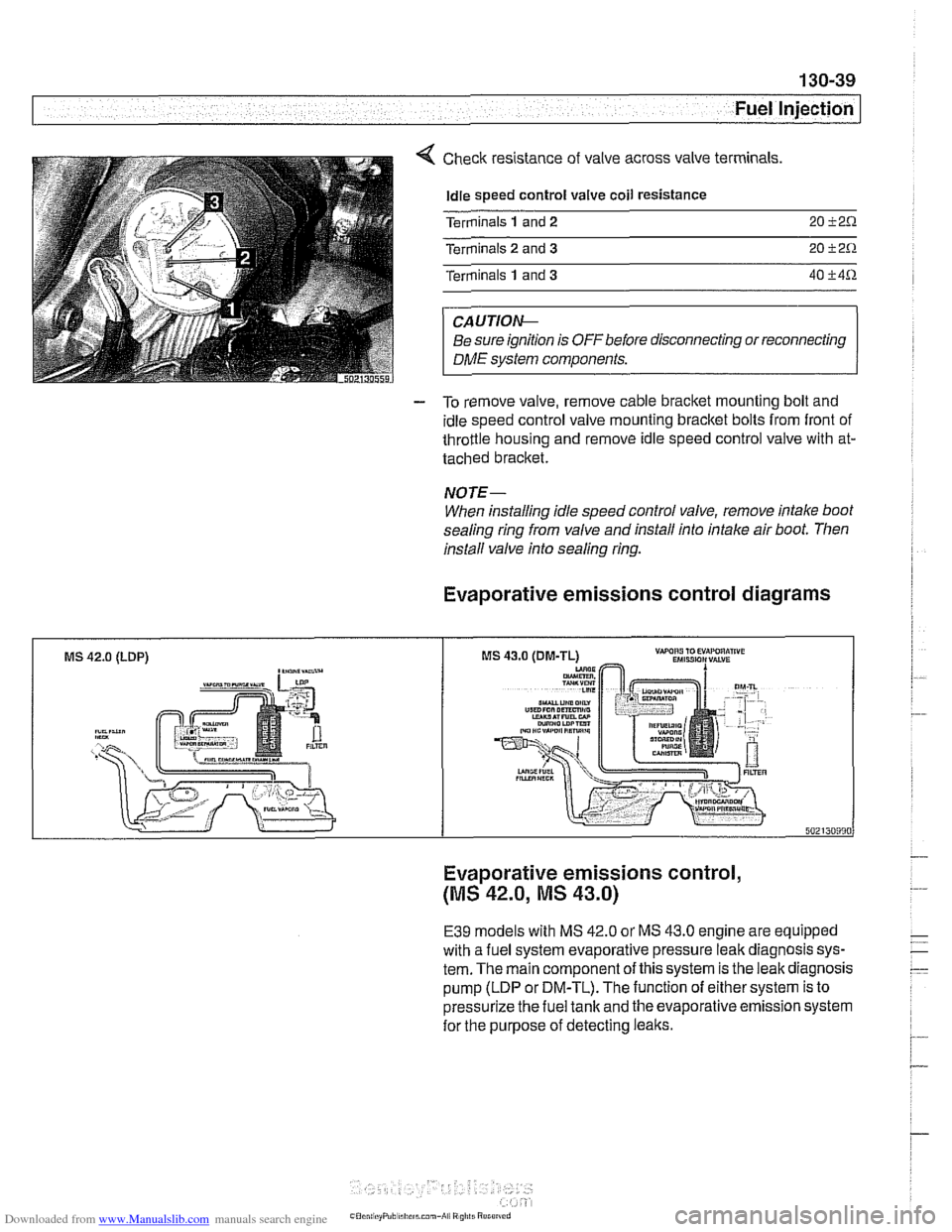

Check resistance of valve across valve terminals

Idle speed control valve coil resistance

Terminals

1 and 2 20 i2.0.

Terminals 2 and 3 20 i2.0.

Terminals 1 and 3 40 i4.0.

CAUTIOIG

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

- To remove valve, remove cable bracket mounting bolt and

idle speed control valve mounting bracket bolts from front of

throttle housing and remove idle speed control valve with at-

tached bracket.

NOTE-

When installing idle speed control valve, remove intake boot

sealing ring from valve and install into intake air boot. Then

install valve info sealing

ring.

Evaporative emissions control diagrams

MS 42.0 (LDP) ,-a"-

Evaporative emissions control,

(MS 42.0, MS 43.0)

E39 models with MS 42.0 or MS 43.0 engine are equipped

with a fuel system evaporative pressure leak diagnosis sys-

tem. The main component of this system is the leak diagnosis

pump (LDP or DM-TL). The function of either system is to

pressurize the fuel tank and the evaporative emission system

for the purpose of detecting leaks.

Page 446 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel lniection

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeff-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MILis il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(8OoC/176"F) to maintain engine

operation. The ignition timing is set to a

conservativelsafe ba-

sic setting.

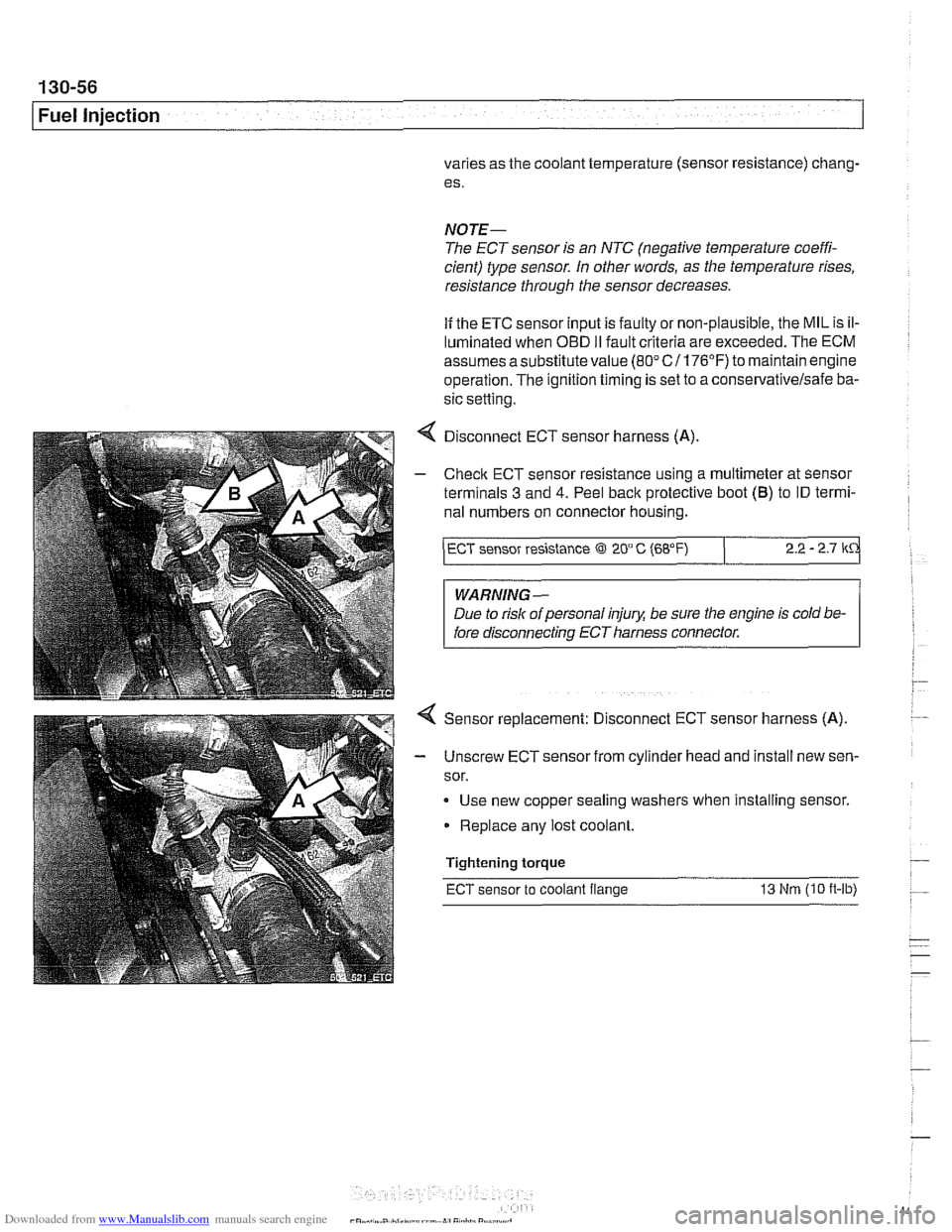

4 Disconnect ECT sensor harness (A)

- Checlc ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

/ ECT sensor resistance @l 2O" C (68°F) 2.2 - 2.7 kd

WARNING -

Due to risk of personal injug be sure the engine is cold be-

fore disconnecting ECT harness connector.

Sensor replacement: Disconnect ECT sensor harness (A).

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers

when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (I0 it-lb)

Page 447 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Intake air temperature

([AT) sensor,

testing and replacing

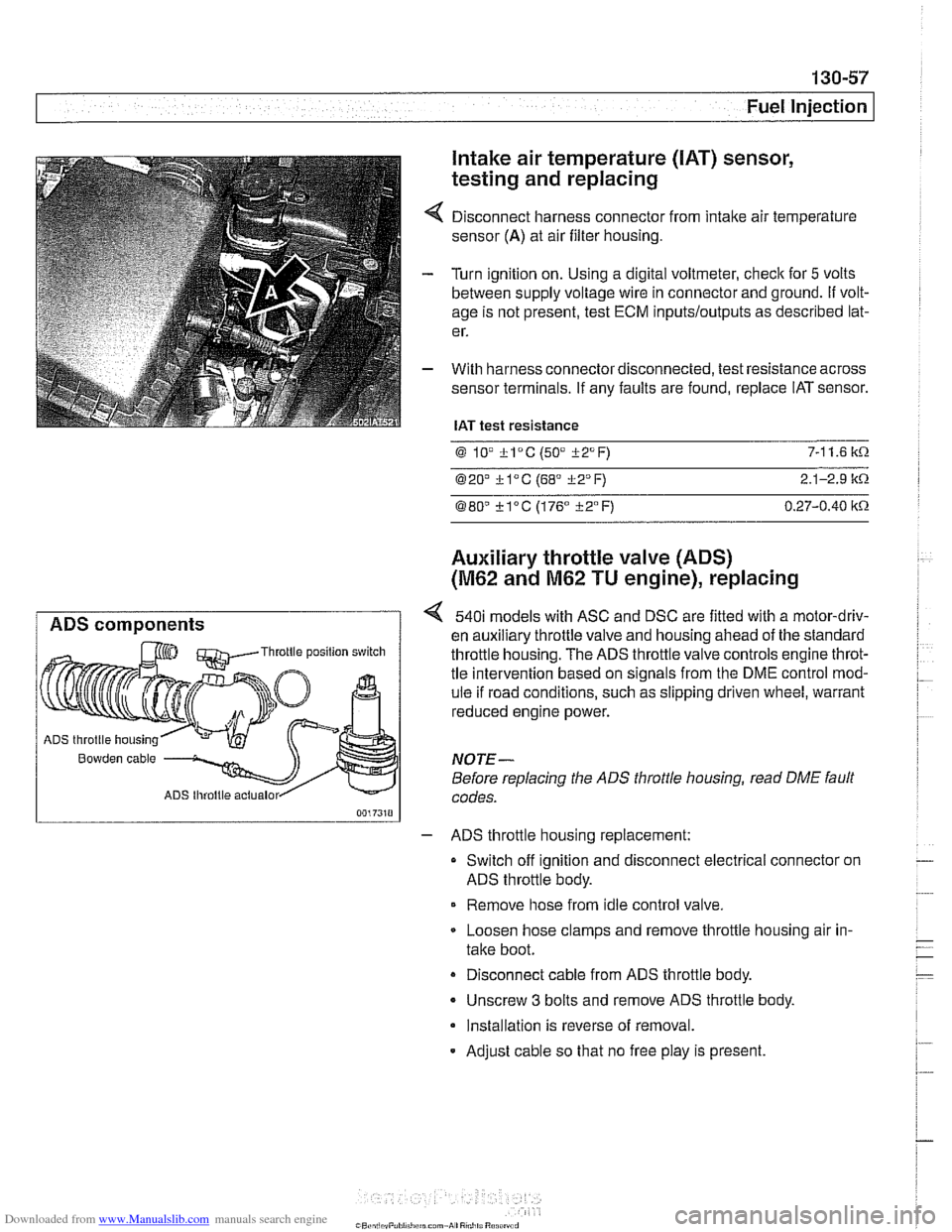

Disconnect harness connector from intake air temperature

sensor

(A) at air filter housing.

Turn ignition on. Using a digital voltmeter, check for

5 volts

between supply voltage wire in connector and ground.

If volt-

age is not present, test ECM

inputs/outputs as described lat-

er.

With harness connector disconnected, test resistance across

sensor terminals. If any faults are found, replace IAT sensor.

IAT test resistance

0 lV *lac (50" i-2°F) 7-1 1.6 k.0.

020' kl°C (68' 322°F) 2.1-2.9 it.0.

080" ?lac (176" i-2°F) 0.27-0.40 itn

Auxiliary throttle valve (ADS)

(M62 and M62 TU engine), replacing

ADS components 540i models with ASC and DSC are fitted with a motor-driv-

en auxiliary throttle valve and housing ahead of the standard Throttle position switch throttle housing. The ADS throttle valve controls engine throt-

tle intervention based on signals from the DME control mod-

ule if road conditions, such as slipping driven wheel, warrant

reduced engine power.

ADS throttle housing

Bowden cable NOTE-

Before replacing the ADS throttle housing, read DME fault

ADS lhroltle actualor codes.

- ADS throttle housing replacement:

Switch off ignition and disconnect electrical connector on

ADS throttle body.

Remove hose from idle control valve.

Loosen hose clamps and remove throttle housing air in-

take boot.

Disconnect cable from ADS throttle body.

- Unscrew 3 bolts and remove ADS throttle body.

Installation is reverse of removal.

- Adjust cable so that no free play is present.

Page 461 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

Engine coolant temperature (ECT) sensor,

testing

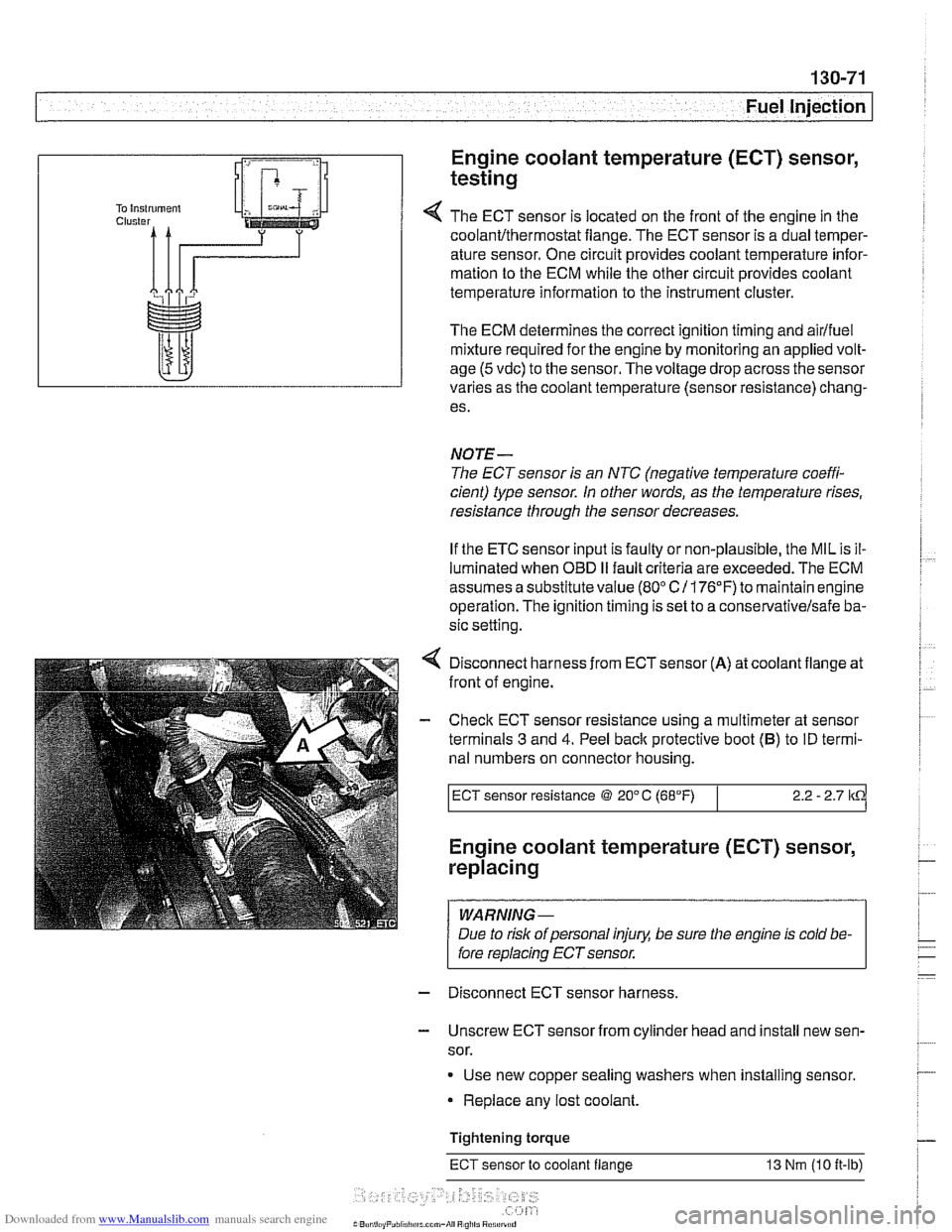

The ECT sensor is located on the front of the engine in the

coolant~thermostat flange. The ECT sensor is a dual temper-

ature sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. Thevoltage drop across the sensor

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(80" C/ 176°F) to maintain engine

operation. The ignition timing is set to a

conse~ativelsafe ba-

sic setting.

Disconnect harness from

ECTsensor (A) at coolant flange at

front of engine.

- Check ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

I ECT sensor resistance @ 20" C (68°F) I 2.2 - 2.7 lkCi

Engine coolant temperature (ECT) sensor,

replacing

I WARNING-

/ Due to risk ofpersonal injury, be sure the engine is cold be- I

I fore replacin~~~~sensor. -

-

I

- Disconnect ECT sensor harness.

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (10 it-lb)

Page 581 of 1002

Downloaded from www.Manualslib.com manuals search engine

--.

- - Manual Transmission

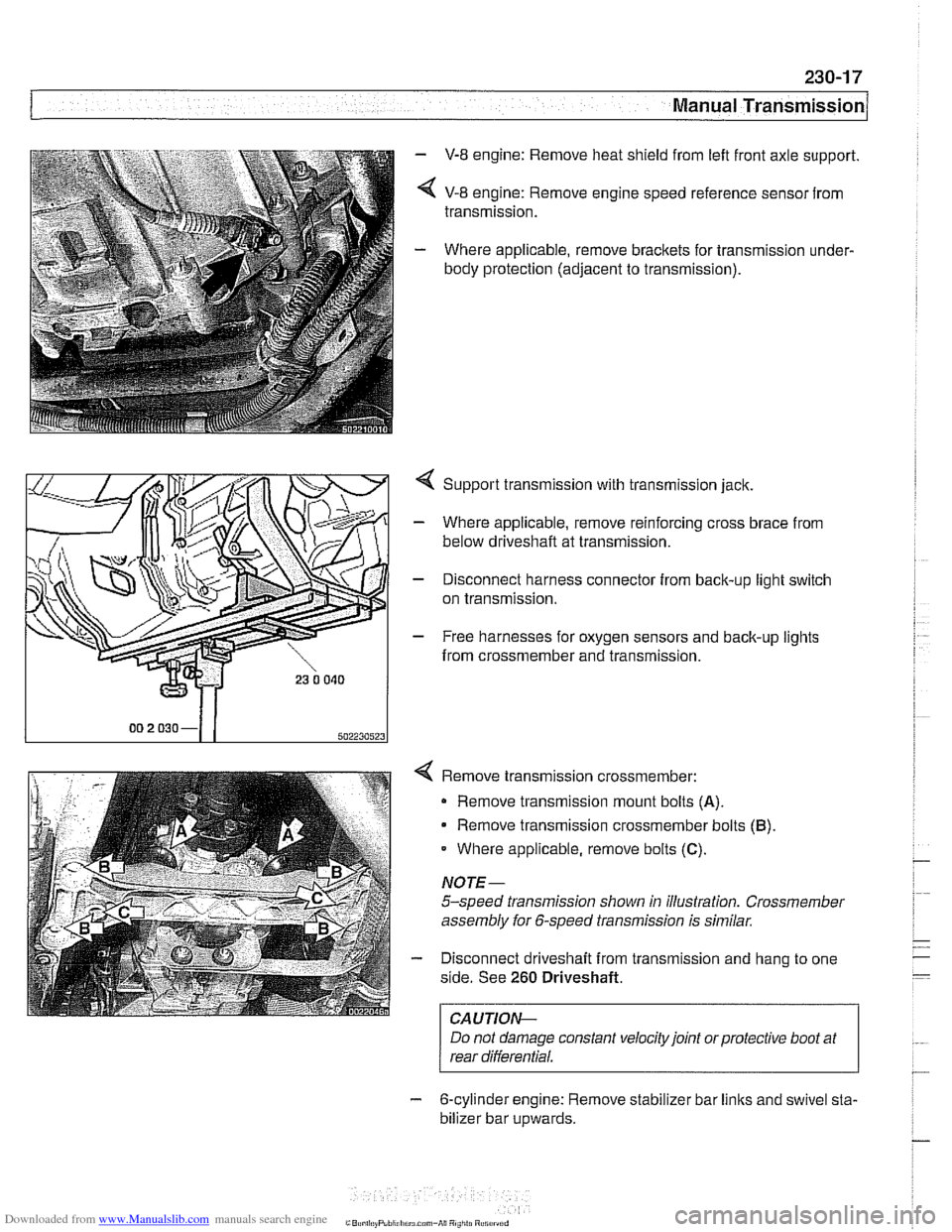

- V-8 engine: Remove heat shield from left front axle support.

< V-8 engine: Remove engine speed reference sensor from

transmission.

- Where applicable, remove brackets for transmission under-

body protection (adjacent to transmission).

4 Support transmission with transmission jack.

- Where applicable, remove reinforcing cross brace from

below driveshaft at transmission.

- Disconnect harness connector from back-up light switch

on transmission.

- Free harnesses for oxygen sensors and back-up lights

from crossmember and transmission.

Remove transmission crossmember: Remove transmission mount bolts

(A).

Remove transmission crossmember bolts (B)

Where applicable, remove bolts (C).

NOTE-

5-speed transmission shown in illustration. Crossmember

assembly for 6-speed transmission is similar.

Disconnect driveshaft from transmission and hang to one

side. See

260 Driveshaft.

I CAUTION- I

Do not damage constant velocity joint orprotective boot at

rear differential.

- 6-cylinder engine: Remove stabilizer bar links and swivel sta-

bilizer bar

u~wards.

Page 600 of 1002

Downloaded from www.Manualslib.com manuals search engine

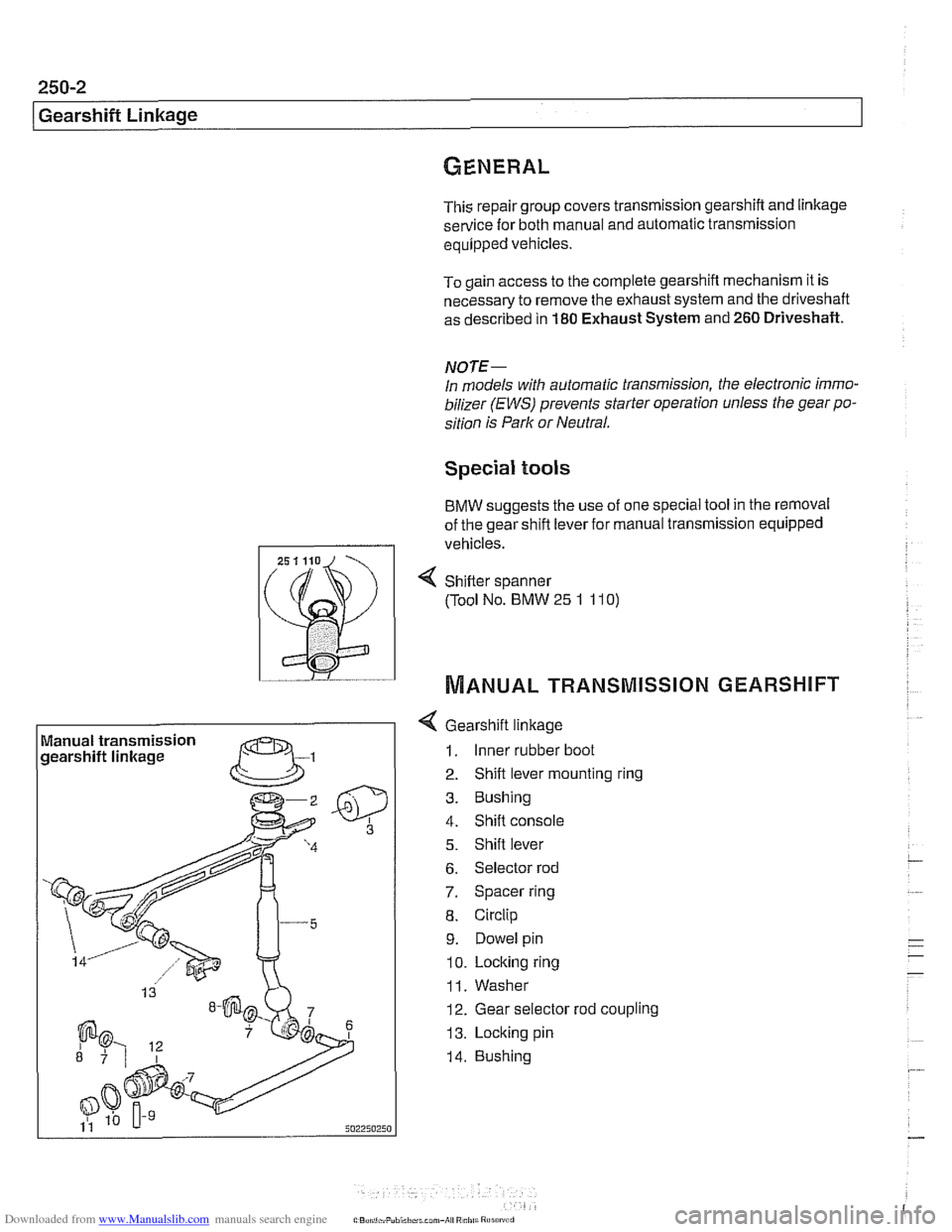

250-2

I Gearshift Linkage

This repair group covers transmission gearshift and linkage service for both manual and automatic transmission

equipped vehicles.

To gain access to the complete gearshift mechanism it is

necessary to remove the exhaust system and the driveshaft

as described in

180 Exhaust System and 260 Driveshaft.

NOTE-

In models with automatic transmission, the electronic immo-

bilizer

(EWS) prevents starter operation unless the gear po-

sition is Park or Neutral.

Special tools

BMW suggests the use of one special tool in the removal

of the gear shift lever for manual transmission equipped

I I vehicles.

Manual transmission

gearshift linkage

--

4 Gearshift linkage

1. Inner rubber boot

2. Shift lever mounting ring

3. Bushing

4. Shift console

5. Shift lever

6. Selector rod

7. Spacer ring

8. Circlip

9. Dowel pin

10. Locking ring

11. Washer

12. Gear selector rod coupling

13. Locking pin

14. Bushing

4 Sh~fter spanner

(Tool No. BMW

25 1 11 0)

MANUAL TRANSMISSION GEARSHIFT

Page 601 of 1002

Downloaded from www.Manualslib.com manuals search engine

Gearshift ~inkaael

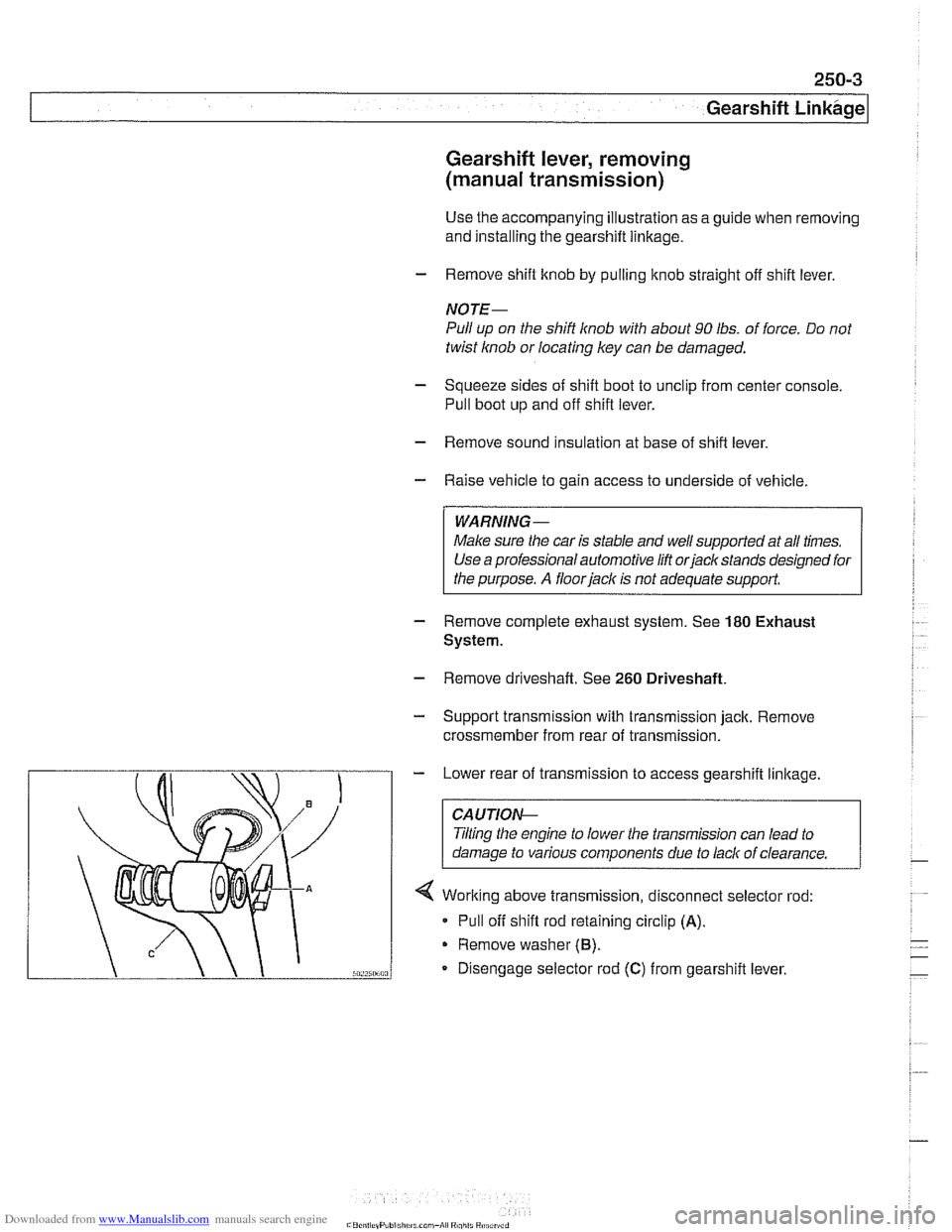

Gearshift lever, removing

(manual transmission)

Use the accompanying illustration as a guide when removing

and installing the gearshift linkage.

- Remove shift knob by pulling knob straight off shift lever.

NOTE-

Pull up on the shift knob with about 90 lbs. of force. Do not

twist

knob or locating key can be damaged.

- Squeeze sides of shift boot to unclip from center console.

Pull boot up and off shift lever.

- Remove sound insulation at base of shift lever.

- Raise vehicle to gain access to underside of vehicle.

- --

WARNING-

Male sure the car is stable and well supported at all tfmes.

Use a professional automotwe hft orjaclc stands designed for

the purpose.

A floorjaclc 1s not adequate support.

- Remove complete exhaust system. See 180 Exhaust

System.

- Remove driveshaft. See 260 Driveshaft.

- Support transmission with transmission jack. Remove

crossmember from rear of transmission.

- Lower rear of transmission to access gearshift linkage.

CA UTIOI\C

Tilting the engine to lower the transmission can lead to

damage to various components due to lack of clearance.

4 Working above transmission, disconnect selector rod:

* Pull off shift rod retaining circlip (A).

Remove washer (6).

Disengage selector rod (C) from gearshift lever.