boot BMW 530i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 530i, Model: BMW 530i 1998 E39Pages: 1002

Page 602 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-4

I Gearshift Linkage

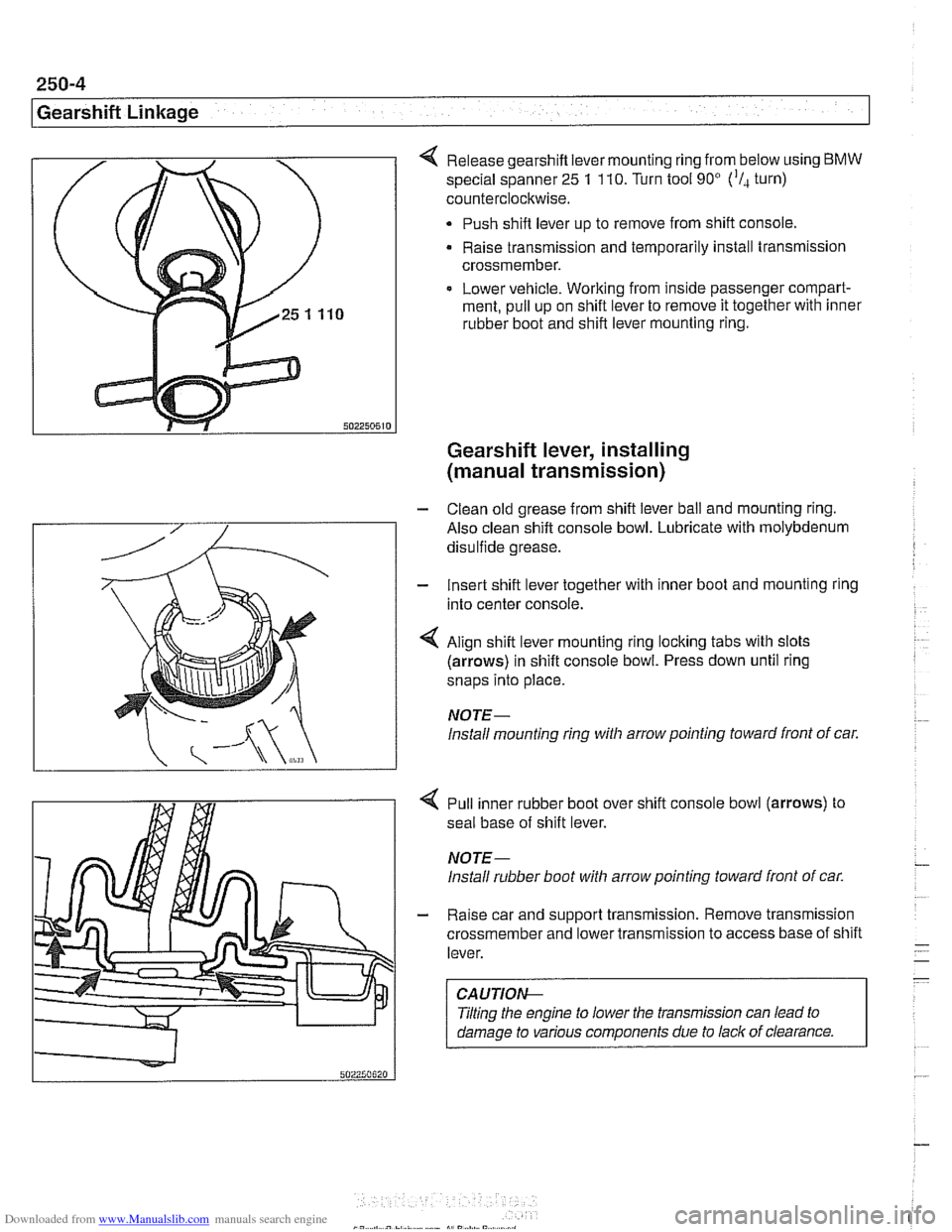

Release gearshift lever mounting ring from below using BMW

special spanner 25 1 110. Turn tool 90' ('I, turn)

counterclockwise.

Push shift lever up to remove from shift console,

Raise transmission and temporarily install transmission

crossmember.

Lower vehicle. Working from inside passenger compart-

ment, pull up on shift lever to remove it together with inner

rubber boot and shift lever mounting ring.

Gearshift lever, installing

(manual transmission)

- Clean old grease from shift lever ball and mounting ring.

Also clean shift console bowl. Lubricate with molybdenum

disulfide grease.

- Insert shift lever together with inner boot and mounting ring

into center console.

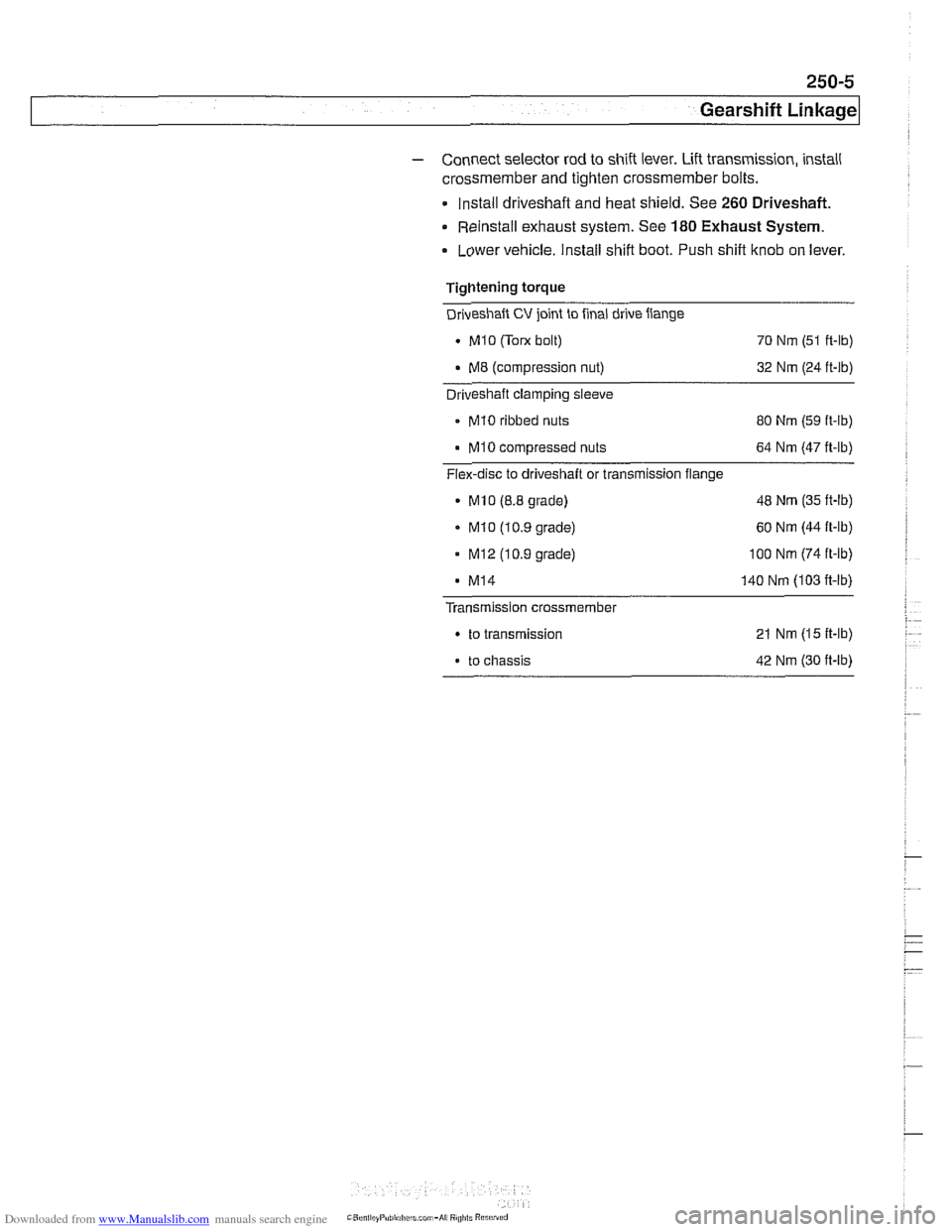

4 Align shift lever mounting ring locking tabs with slots

(arrows) in shift console bowl. Press down until ring

snaps into place.

NOTE-

lnstall mounting ring witli arrow pointing toward front of car.

4 Pull inner rubber boot over shift console bowl (arrows) to

seal base of shift lever.

NOTE-

lnstall rubber boot witli arrow pointing toward front of car.

- Raise car and support transmission. Remove transmission

crossmember and lower transmission to access base of shift

lever.

CAUTIOI\C

Tilting the engine to lower the transmission can lead to

damage to various components due to lack of clearance.

Page 603 of 1002

Downloaded from www.Manualslib.com manuals search engine

Gearshift Linkage

- Connect selector rod to shift lever. Lift transmission, install

crossmember and tighten crossmember bolts.

Install driveshaft and heat shield. See

260 Driveshaft.

Reinstall exhaust system. See 180 Exhaust System.

. Lower vehicle. Install shift boot. Push shift ltnob on lever.

Tightening torque

Driveshaft

CV joint to final drive flange

. MI0 (Tom bolt)

70 Nm (51 ft-lb)

. M8 (compression nut) 32 Nm (24 ft-lb) - Driveshaft clamping sleeve

- MI0 ribbed nuts

80 Nm (59 ft-lb)

MI0 compressed nuts 64 Nm (47 ft-lb)

Flex-disc to driveshaft or transmission flange

MlO (8.8 grade) 48

Nm (35 ft-lb)

. MI0 (10.9 grade) 60

Nm (44 ft-lb)

- MI2 (10.9 grade) 100 Nm (74 ft-ib)

MI4 140 Nm (103 fi-lb)

Transmission crossmember

. to transmission 21 Nm (15 ft-lb)

. to chassis 42 Nm (30 ft-lb)

Page 615 of 1002

Downloaded from www.Manualslib.com manuals search engine

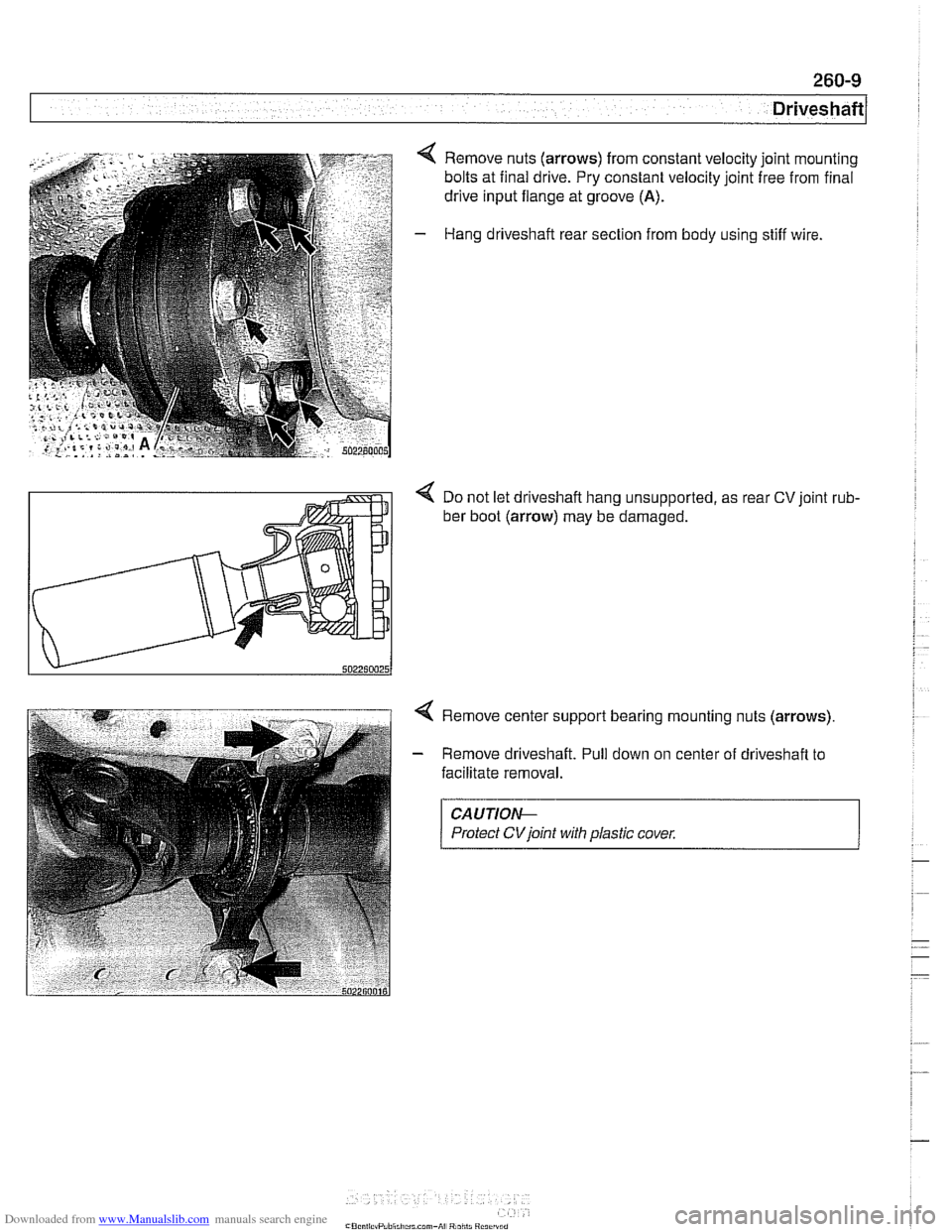

4 Remove nuts (arrows) from constant velocity joint mounting

bolts at final drive. Pry constant velocity joint free from final

drive input flange at groove

(A).

- Hang driveshaft rear section from body using stiff wire.

< Do not let driveshaft hang unsupported, as rear CV joint rub-

ber boot (arrow) may be damaged.

4 Remove center support bearing mounting nuts (arrows)

- Remove driveshaft. Pull down on center of driveshaft to

facilitate removal.

CAUTIOI\C

Protect CVjoint with plastic cover.

Page 620 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-14

Driveshaft

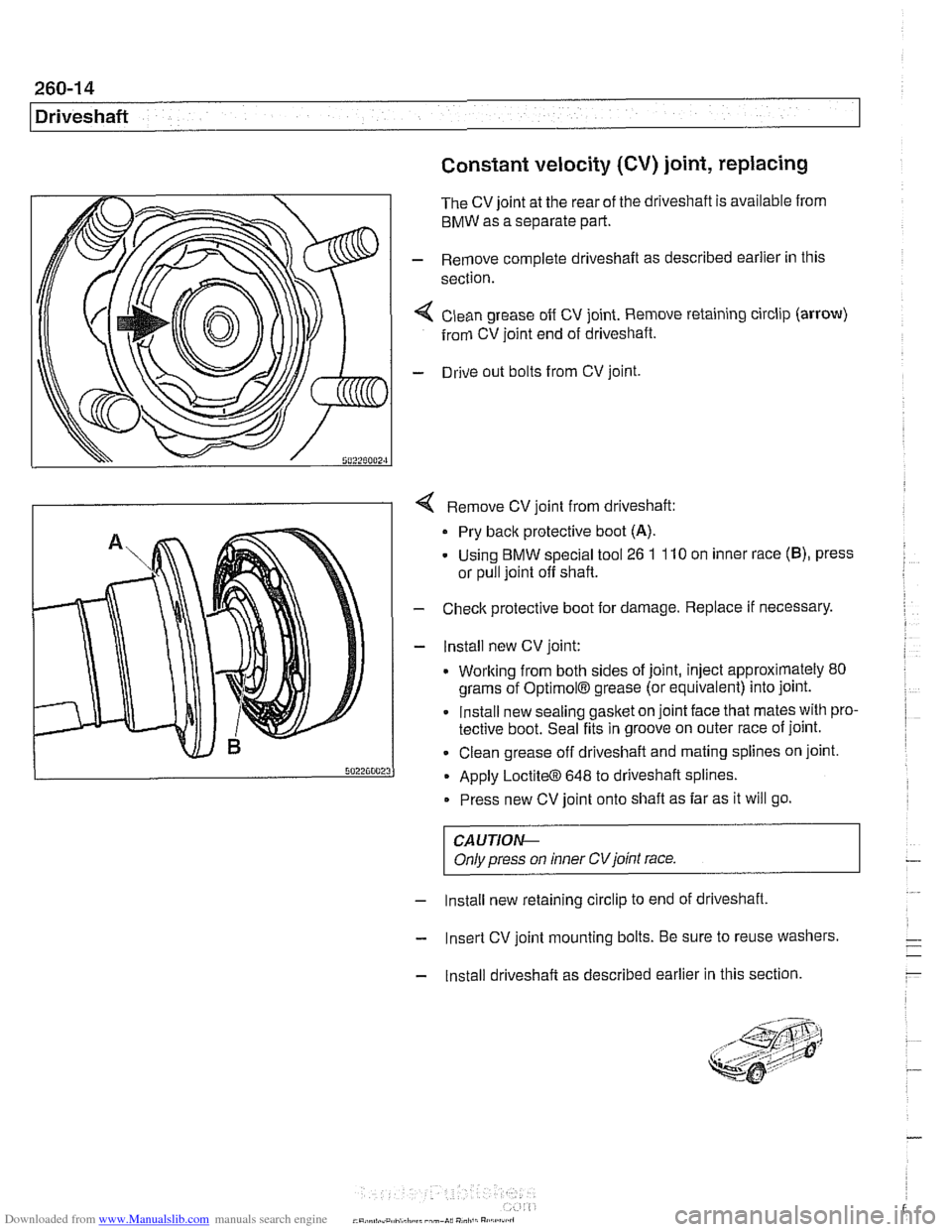

Constant velocity (CV) joint, replacing

The CV joint at the rear of the driveshaft is available from

BMW as a separate part.

- Remove complete driveshaft as described earlier in this

section.

< Clean grease off CV joint. Remove retaining circlip (arrow)

from CV joint end of driveshaft.

- Drive out bolts from CV joint.

4 Remove CV joint from driveshaft:

Pry back protective boot

(A).

- Using BMW special tool 26 1 110 on inner race (B), press

or pull joint off shaft.

- Check protective boot for damage. Replace if necessary.

- lnstall new CV joint:

. Working from both sides of joint, inject approximately 80

grams of

OptimolB grease (or equivalent) into joint.

Install new sealing gasket on joint face that mates with pro-

tective boot. Seal fits in groove on outer race of joint.

Clean grease off driveshaft and mating splines on joint.

Apply

LoctiteO 648 to driveshaft splines.

Press new CV joint onto shaft as far as it will go.

CAUTIOI\C

Only press on inner CVjoint race.

- Install new retaining circlip to end of driveshaft,

- Insert CV joint mounting bolts. Be sure to reuse washers.

- Install driveshaft as described earlier in this section.

Page 645 of 1002

Downloaded from www.Manualslib.com manuals search engine

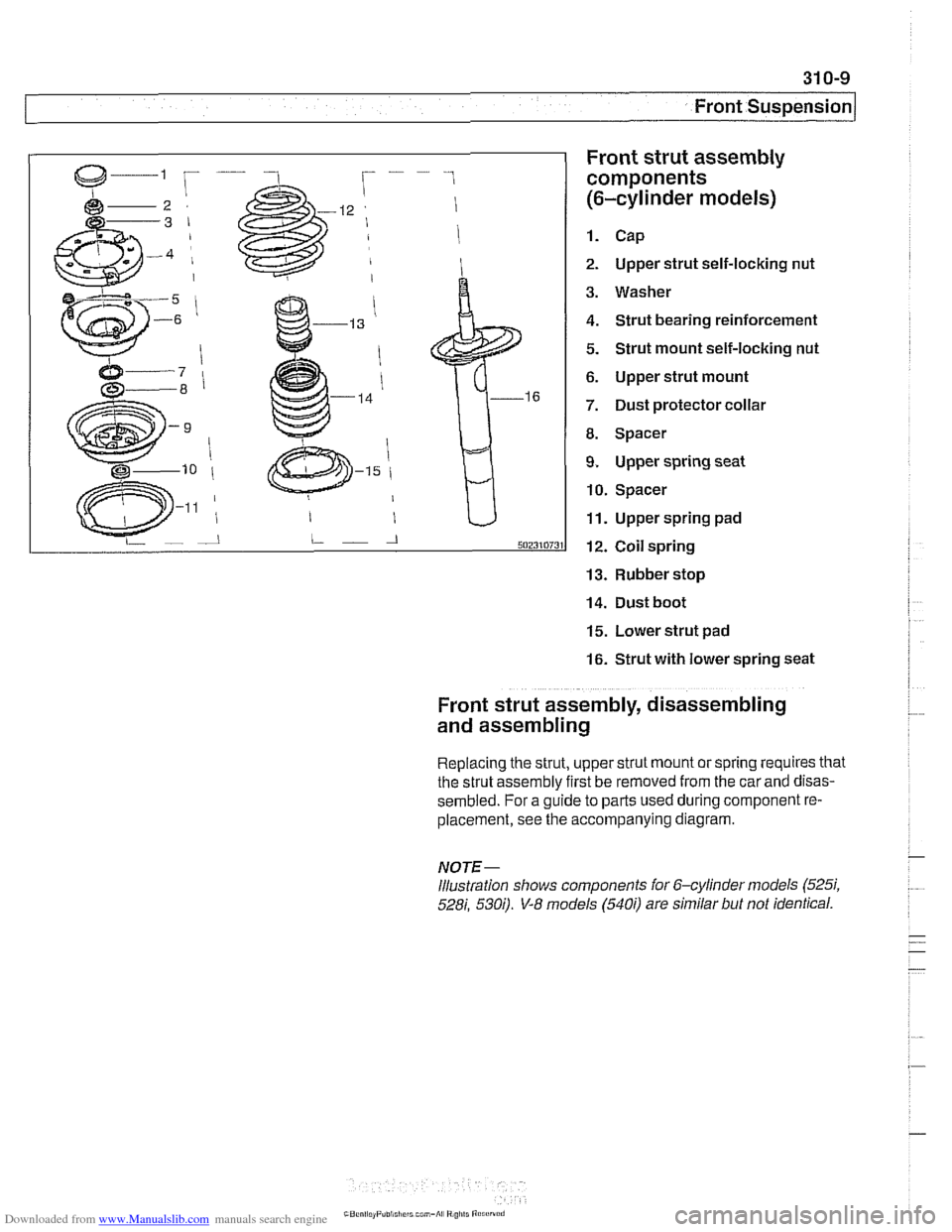

31 0-9

Front Suspension

Front strut assembly

components

(6-cylinder models)

1. Cap

2. Upper strut self-locking nut

3. Washer

4. Strut bearing reinforcement

5. Strut mount self-locking nut

6. Upper strut mount

7. Dust protector collar

8. Spacer

9. Upper spring seat

10. Spacer

11. Upper spring pad

12. Coil spring

13. Rubber stop

14. Dust boot

15. Lower strut pad

16. Strut with lower spring seat

Front strut assembly, disassembling

and assembling

Replacing the strut, upper strut mount or spring requires that

the strut assembly first be removed from the car

and disas-

sembled. For a guide to parts used during component re-

placement, see the accompanying diagram.

NOTE-

Illustration shows components ior 6-cylinder models (525i,

528i, 530;). V-8 models (540i) are similar but not identical.

Page 646 of 1002

Downloaded from www.Manualslib.com manuals search engine

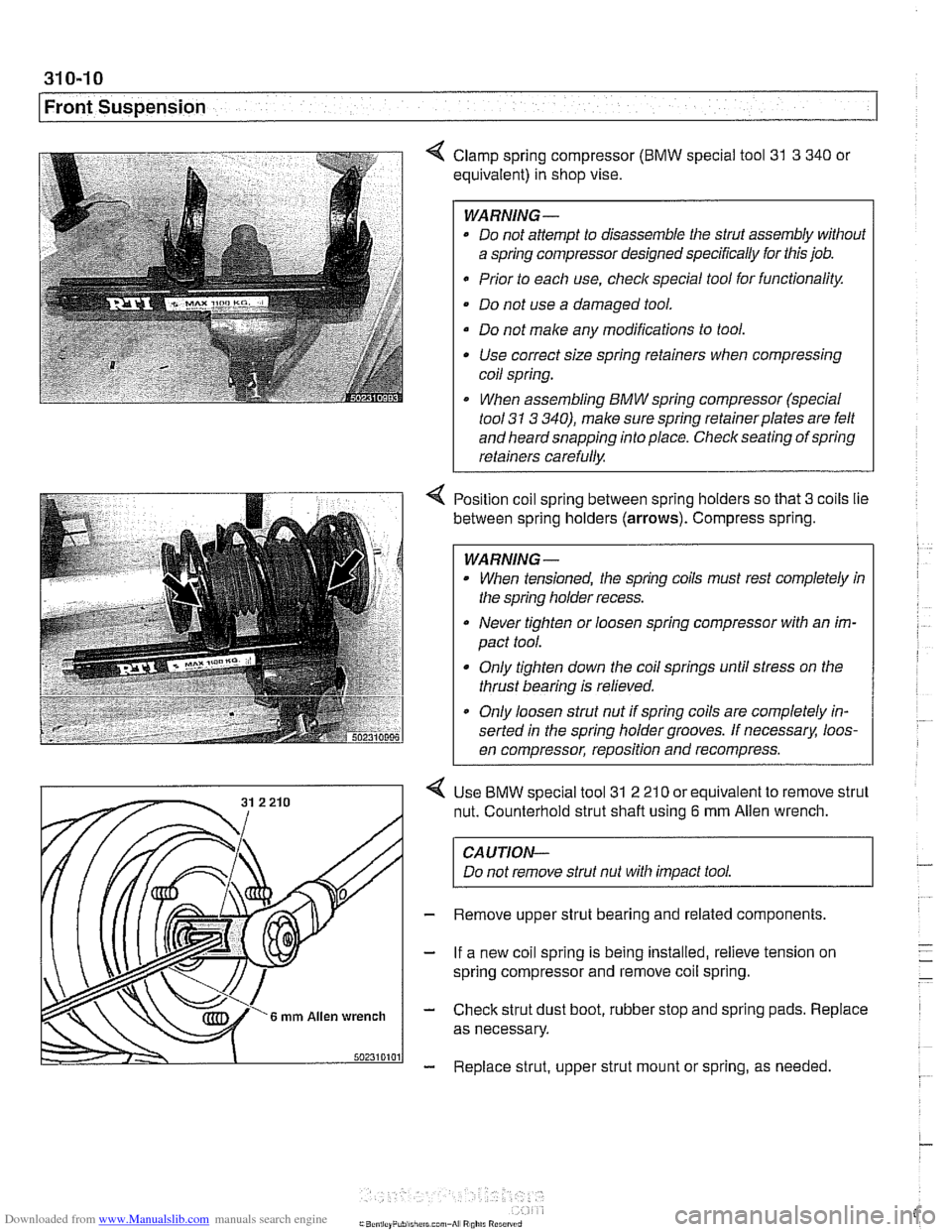

31 0-1 0

Front Suspension

4 Clamp spring compressor (BMW special tool 31 3 340 or

equivalent) in shop vise.

WARNING-

* Do not attempt to disassemble the strut assembly without

a spring compressor designed specifically for this job.

Prior to each use,

checlc special tool for functionality.

Do not use a damaged tool.

Do not make any modifications to tool. Use correct size spring retainers when compressing

coil spring.

I When assembling BMW spring compressor (special

tool

31 3 340), make sure spring retainerplates are felt

and heard snapping into place. Check seating of spring

retainers carefully.

Position coil spring between spring holders so that

3 coils lie

between spring holders

(arrows). Compress spring.

WARNING -

When tensioned, the spring coils must rest completely in

the spring holder recess.

Never tighten or loosen spring compressor with an im-

pact tool.

Only tighten down the coil springs until stress on the

thrust bearing is relieved.

a Only loosen strut nut if spring coils are completely in-

serted in the spring holder grooves. If

necessarx loos-

en compressor, reposition and recompress.

Use

BMW special tool 31 2 21 0 or equivalent to remove strut

nut. Counterhold strut shaft using

6 mm Allen wrench.

CAUTION-

Do not remove strut nut with impact tool.

Remove upper strut bearing and related components.

If a new coil spring is being installed, relieve tension on

spring compressor and remove coil spring.

Check strut dust boot, rubber stop and spring pads. Replace

as necessary.

Replace strut, upper strut mount or spring, as needed

Page 659 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 320 Steering and Wheel Alignment

General ........................... .32 0.2

Special tools

........................ .32 0.2

Steering system

..................... .32 0.4

Steering system variations

............. .32 0.5

Steering system warnings and cautions

... .32 0.6

Steering Wheel .................... .32 0.7

Steering wheel. removal and installation

.. .32 0.7

Steering Column ................. .32 0.1 0

Steering column components .......... .32 0.10

Steering column trim, removing

and replacing

...................... .32 0.10

lgnition switch ring antenna (EWS).

removing and installing

............... .32 0.1 1

lgnition lock cylinder.

removing and installing

............... .32 0-1 1

Steering column lock. removing

and installing

....................... .32 0.12

lgnition

interloclc cable. removing and installing

(models with automatic transmission)

... .32 0.13

Interlock cable. adjusting

(models with automatic transmission)

... .32 0.14

Steering column. removing and installing

. .32 0.14

Steering column adjustment motors.

removing and installing

............... .32 0.16

Power Steering Pump ............. .32 0.17

Power steering pump. removing

and installing

....................... .32 0.1 7

Power steering system.

bleeding and filling

.................. .32 0.18

Rack and Pinion Steering

(6-cylinder models)

............... 320-19

Rack and pinion steering components

(6-cylinder models)

.................. 320-1 9

Steering rack. removing and installing

.... 320-19

Steering

rack boot. replacing ........... 320-22

Tie rod (outer). replacing

.............. 320-22

Tie rod (inner). replacing

.............. 320-23

Steering Gearbox (V-8 models) .... 320-24

Steering gearbox system components

. .

(V-8 models) ....................... 320-24

Steering gearbox, removing and installing 320-25

Pitman arm. removing and installing ..... 320-28

Pitman arm. adjusting ................ 320-29

Steering idler arm. removing

and installing

....................... 320-30

Idler arm bushing. replacing ........... 320-31

Center tie rod. replacing

.............. 320-32

Wheel Alignment .................. 320-33

Camber

........................... 320-33

Caster

............................ 320-33

Front toe and toe difference angle

....... 320-34

Reartoe ........................... 320-34

Preparing for alignment

............... 320-35

Alignment specifications tables

......... 320-35

Page 662 of 1002

Downloaded from www.Manualslib.com manuals search engine

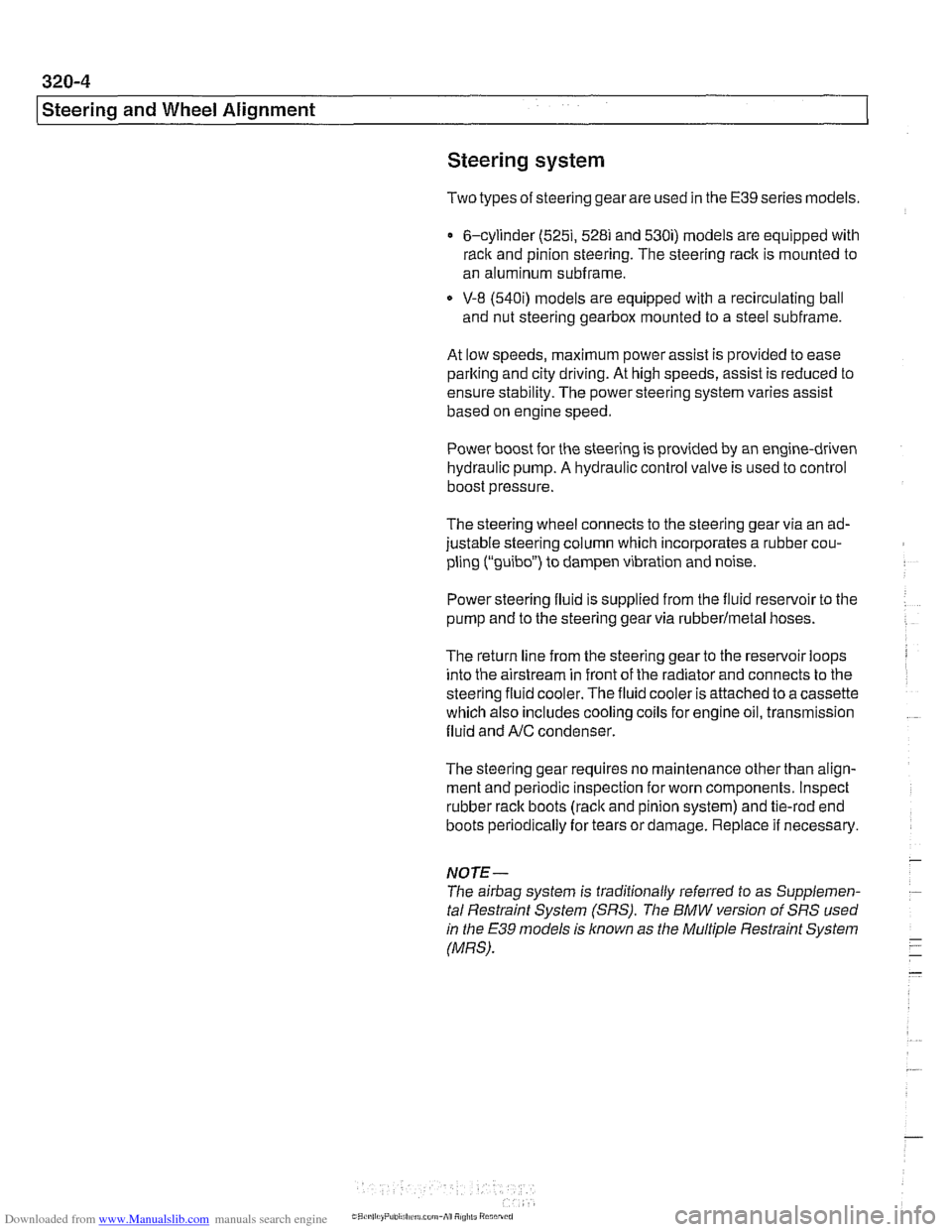

I Steerina and Wheel Alianment

Steering

system

Two types of steering gear are used in the E39 series models.

6-cylinder

(5251, 528i and 530i) models are equipped with

rack and pinion steering. The steering rack is mounted to

an aluminum subframe.

V-8

(540i) models are equipped with a recirculating ball

and nut steering gearbox mounted to a steel subframe.

At low speeds, maximum power assist is provided to ease

parking and city driving. At high speeds, assist is reduced to

ensure stability. The power steering system varies assist

based on engine speed.

Power boost for the steering is provided by an engine-driven

hydraulic pump. A hydraulic control valve is used to control

boost pressure.

The steering wheel connects to the steering gear via an ad-

justable steering column which incorporates a rubber cou-

pling ("guibo") to dampen vibration and noise.

Power steering fluid is supplied from the fluid

reservoir to the

pump and to the steering gear via rubberlmetal hoses.

The return line from the steering gear to the

reservoir loops

into the airstream in front of the radiator and connects to the

steering fluid cooler. The fluid cooler is attached to a cassette

which also includes cooling coils for engine oil, transmission

fluid and AIC condenser.

The steering gear requires no maintenance other than align-

ment and periodic inspection for worn components. Inspect

rubber rack boots

(rack and pinion system) and tie-rod end

boots periodically for tears or damage. Replace

if necessary.

-

NOTE-

The airbag system is traditionally referred to as Supplemen-

tal Restraint System (SRS). The

BMW versfon of SRS used

m the E39 models is known as the Multiple Restraint System - (MRS). - -

Page 677 of 1002

Downloaded from www.Manualslib.com manuals search engine

i Steering and Wheel Alignment

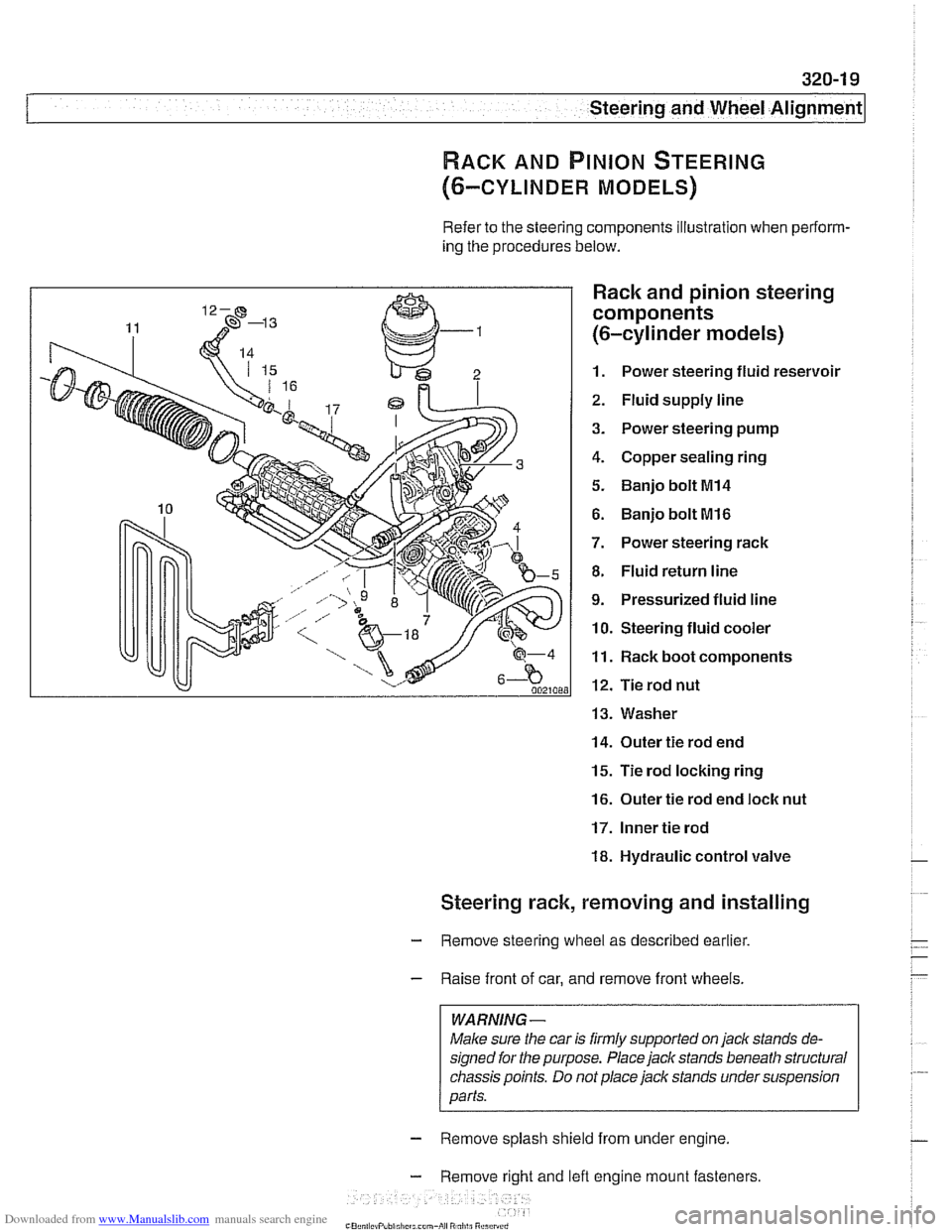

RACK AND PINION STEERING

(6-CYLINDER MODELS)

Refer to the steering components illustration when perform-

ing the procedures below.

Rack and pinion steering

components

(6-cylinder models)

1. Power steering fluid reservoir

2. Fluid supply line

3. Power steering pump

4. Copper sealing ring

5. Banjo bolt MI4

6. Banjo bolt MI6

7. Power steering rack

8. Fluid return line

9. Pressurized fluid line

10. Steering fluid cooler

11. Rack boot components

12. Tie rod nut

13. Washer

14. Outer tie rod end

15. Tie rod locking ring

16. Outer tie rod end loclc nut

17. Inner tie rod

18. Hydraulic control valve

Steering rack, removing and installing

- Remove steering wheel as described earlier.

- Raise front of car, and remove front wheels.

WARNING -

Male sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do

not place jack stands under suspension

parts.

- Remove splash shield from under engine.

- Remove right and lefl engine mount fasteners

-" ., - , . ,

Page 680 of 1002

Downloaded from www.Manualslib.com manuals search engine

--. --

Steering and Wheel Alignment

Steering rack boot, replacing

- Remove outer tie rod end. See Tie rod (outer), replacing

- Cut rack boot band clamps and remove boot.

- Cut rack boot band clamp and slide bellows back. Inspect

boot for any sign of damage. Replace

if necessary.

NOTE-

New rack boot lit comes with new band clamp.

- Grease tie rod taper so that small end of rack boot slides on

tie rod when tie rod is tightened, preventing raclc boot from

twisting.

- Slide new boot into position and replace band clamps

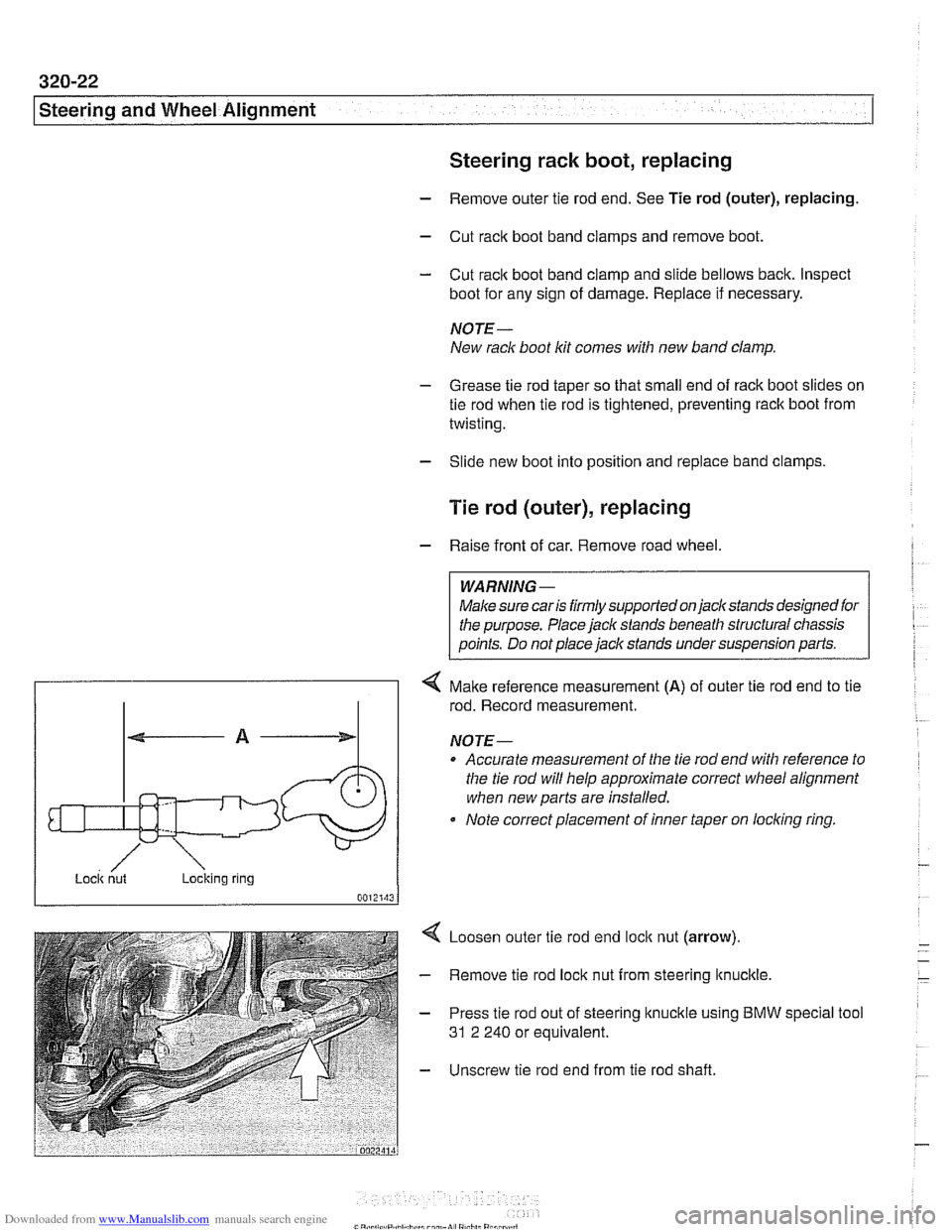

Tie rod (outer), replacing

LOCI( nut Locking ring

- Raise front of car. Remove road wheel

WARNING-

Male sure caris firmly suppoiiedon jackstands designed for

the purpose. Place jack stands beneath structural chassis

ooints. Do not olace iack stands under

susoension oaiis.

4 Make reference measurement (A) of outer tie rod end to tie

rod. Record measurement.

NOTE-

Accurate measurement of the tie rod end with reference to

the tie rod will help approximate correct

wheel alignment

when new parts are installed.

Note correct placement of inner taper on

loclcing ring.

Loosen outer tie rod end

loclc nut (arrow).

Remove tie rod lock nut from steering

ltnuclcle.

Press tie rod out of steering knuckle using BMW

31 2 240 or equivalent. special tool

Unscrew tie rod end from tie rod shaft.