Ecu BMW 530i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 530i, Model: BMW 530i 2000 E39Pages: 1002

Page 132 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-38

I Cylinder Head Removal and Installation

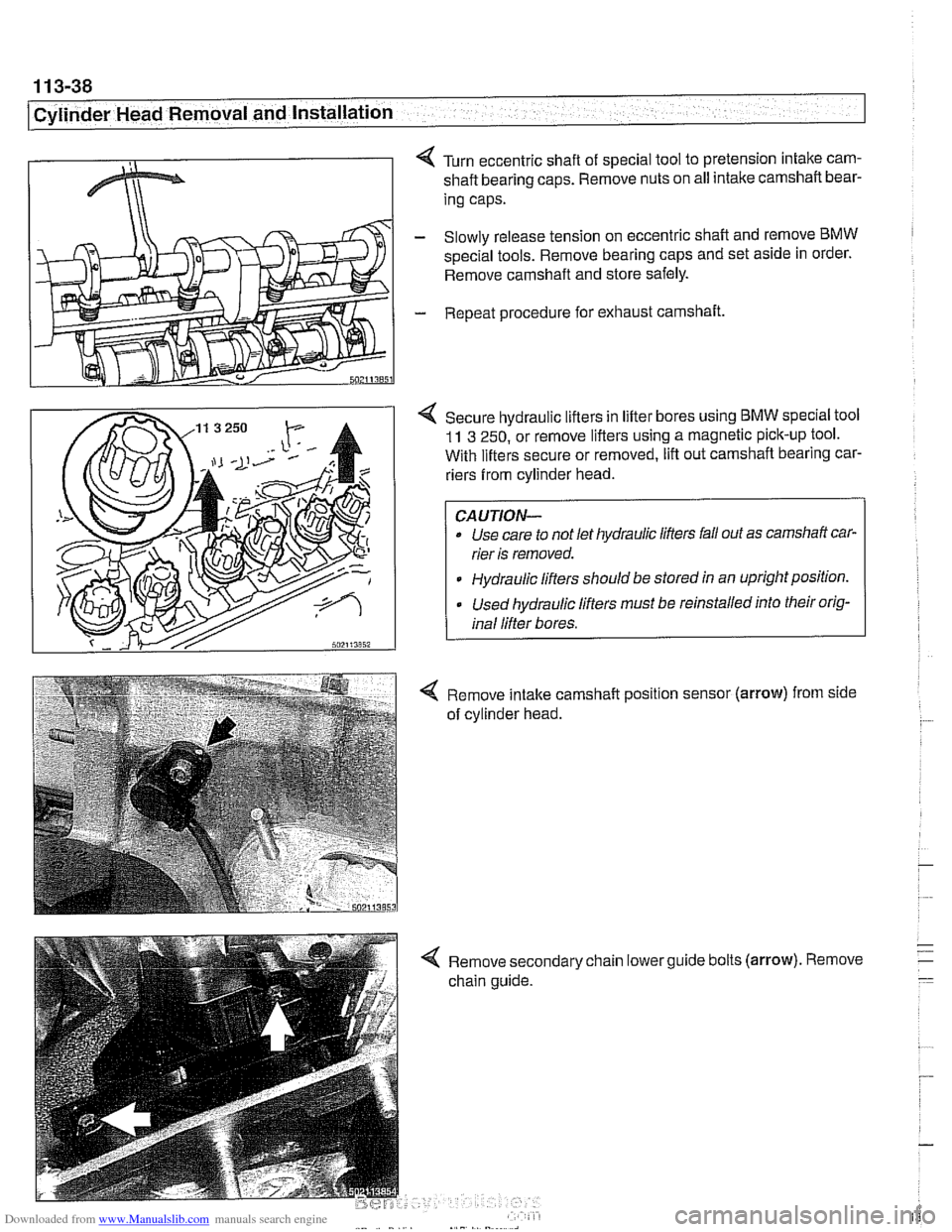

< Turn eccentric shaft of special tool to pretension intake cam-

shaft bearing caps. Remove nuts on all intake camshaft bear-

ing caps.

- Slowly release tension on eccentric shaft and remove BMW

spec~al tools. Remove bearing caps and set as~de in order.

Remove camshaft and store safely.

- Repeat procedure for exhaust camshaft.

4 Secure hydraulic lifters in lifter bores using BMW speclal tool

11 3 250, or remove lifters using a magnetic pick-up tool.

With lifters secure or removed, lift out camshaft bearing car-

riers from cylinder head.

Use care to not let hydraulic lifters fall out as camshaft car-

rier is removed.

Hydraulic lifters should be stored

ln an uprightpositlon.

Used hydraulic lifters must be reinstalled into their orig-

inal lifter bores.

4 Remove intake camshaft position sensor (arrow) from side

of cylinder head.

4 Remove secondary chain lowerguide bolts (arrow). Remove

chain guide.

Page 135 of 1002

![BMW 530i 2000 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

. - ..

Cylinder Head Removal and installation] --

- Secure cylinder head bolts by torquing an additional 90"

each for Stage 2 and 3.

T BMW 530i 2000 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

. - ..

Cylinder Head Removal and installation] --

- Secure cylinder head bolts by torquing an additional 90"

each for Stage 2 and 3.

T](/img/1/2822/w960_2822-134.png)

Downloaded from www.Manualslib.com manuals search engine

. - ..

Cylinder Head Removal and installation] --

- Secure cylinder head bolts by torquing an additional 90"

each for Stage 2 and 3.

Tightening torques

Cylinder head to engine block

(aluminum block)

Stage

1 40 Nm (30 it-lb)

Stage 2 +90°

Stage 3 80'

4 lnstall intake camshaft position sensor (arrow).

4 Install lower secondary chain guide. Tighten tom bolts to

specifications. The bolt on the intake camshaft side is long

and extends into the engine block.

4 Install and tighten cylinder head-to-lower timing chain cover

bolts (arrows). (Photo shows camshafts in place).

Tightening torque Secondary chain guide to cylinder head

10 Nm (89 in-lb)

Cylinder head to lower timing chain cover

M6 10 Nm (89 in-lb)

M7 15 Nm (1 1 it-lb)

Page 138 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-44

I Cylinder Head Removal and Installation

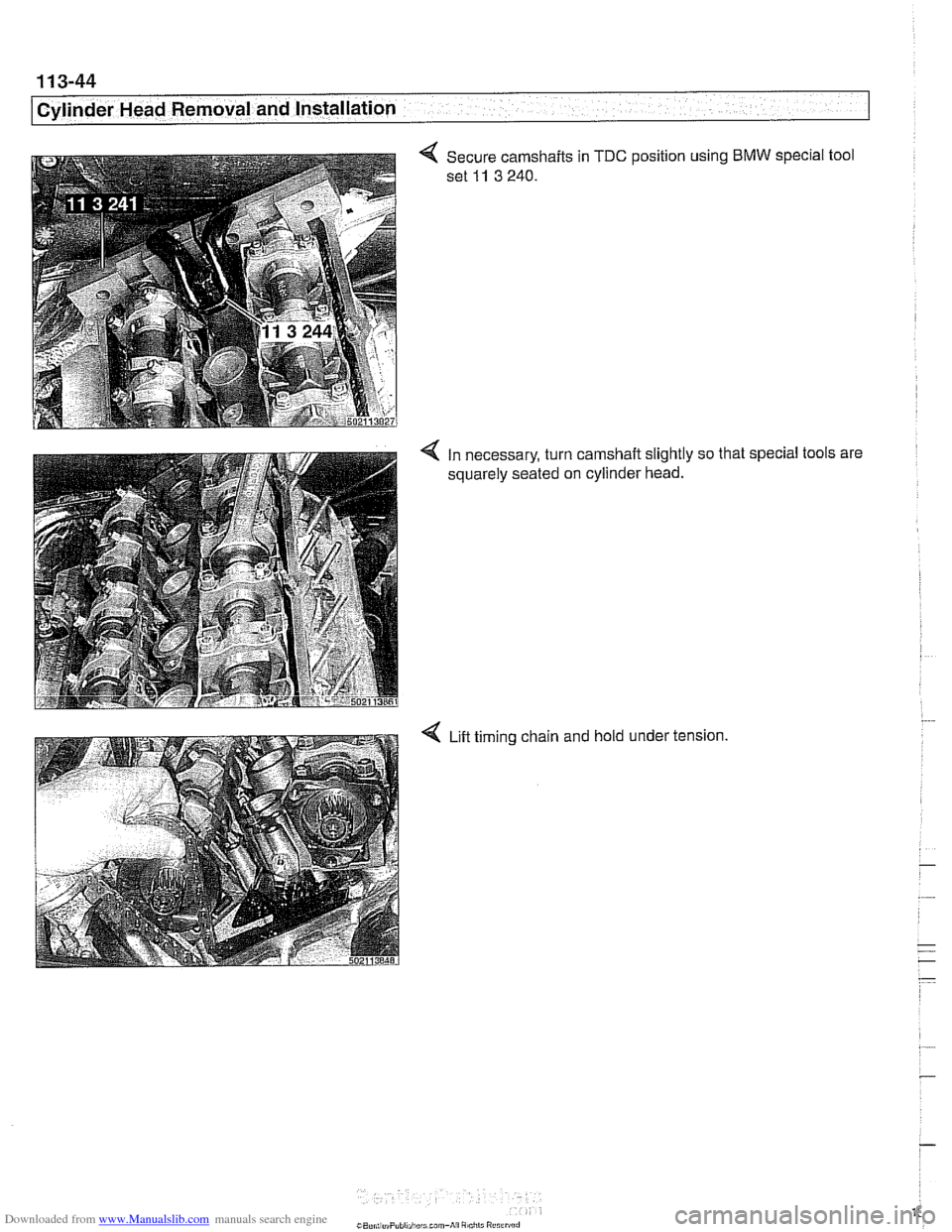

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

4 In necessary, turn camshaft slightly so that special tools are

squarely seated on cylinder head.

4 Lift timing chain and hold under tension.

Page 146 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

Cylinder Head Removal and Installation

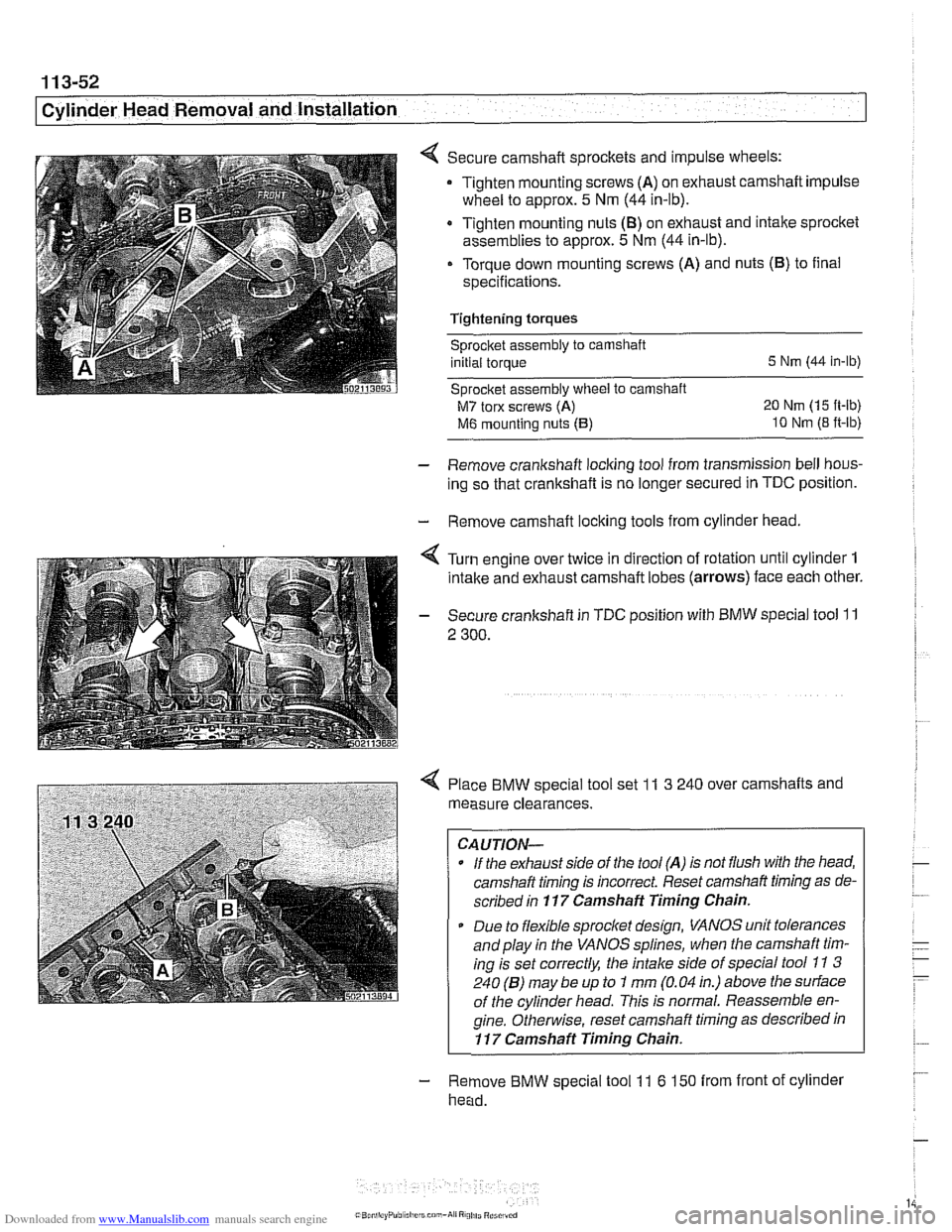

Secure camshaft sprockets and impulse wheels:

Tighten mounting screws

(A) on exhaust camshaft impulse

wheel to approx.

5 Nm (44 in-lb).

Tighten mounting nuts

(8) on exhaust and intake sprocket

assemblies to approx.

5 Nm (44 in-lb).

Torque down mounting screws (A) and nuts (B) to final

specifications.

Tightening torques

sprocket assembly to camshaft

initial torque

5 Nm (44 in-lb)

Sprocket assembly

wheel to camshaft

M7 torx screws (A) 20 Nm (15 ft-lb)

M6 mounting nuts (5) 10 Nm (8 ft-lb)

- Remove crankshaft locking tool from transmission bell hous-

ing so that crankshaft is no longer secured in

TDC position.

- Remove camshaft locking tools from cylinder head.

4 Turn engine over twice in direction of rotation until cylinder 1

intake and exhaust camshaft lobes (arrows) face each other.

- Secure crankshaft in TDC position with BMW special tool 11

2 300.

4 Place BMW special tool set 11 3 240 over camshafts and

measure clearances.

CAUTION-

- If the exhaust side of the tool (A) is not flush with tlie head,

camshaft timing is incorrect Reset camshaft timing as de-

scribed in

117 Camshaft Timing Chain.

* Due to flexible sprocket design, VANOS unit tolerances

and play in the VANOS splines, when the camshaft tim-

ing is set correctly, the intake side of special tool

11 3

240 (6) may be up to 1 mm (0.04 in.) above the surface

of the cylinder head. This is normal. Reassemble en-

gine.

Othe~lise, reset camshaft timing as described in

11 7 Camshaft Timing Chain.

- Remove BMW special tool 11 6 150 from front of cylinder

head.

Page 148 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." ".

[Cylinder Head Removal and Installation - .. - -1 -

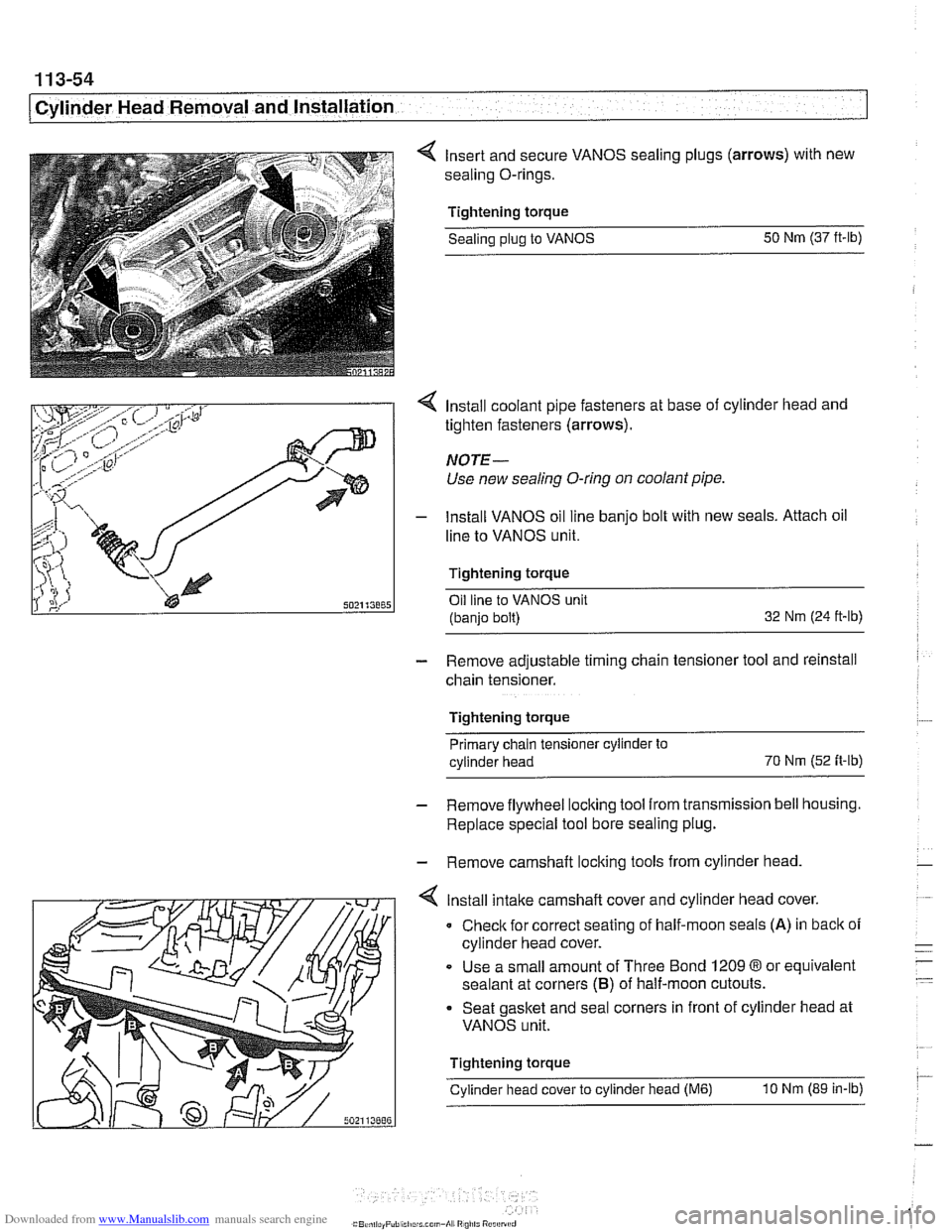

4 Insert and secure VANOS sealing plugs (arrows) with new

sealing O-rings.

Tightening torque Sealing

plug to VANOS 50

Nm (37 ft-lb)

4 Install coolant pipe fasteners at base of cylinder head and

tighten fasteners (arrows).

NOTE-

Use new sealing O-ring on coolant pipe.

- lnstall VANOS oil line banjo bolt with new seals. Attach oil

line to VANOS unit.

Tightening torque Oil line to VANOS unit

(banjo bolt) 32

Nm (24 ft-ib)

- Remove adjustable timing chain tensioner tool and reinstall

chain tensioner.

Tightening torque Primary chain tensioner cylinder to

cylinder head 70

Nm

(52 fi-ib)

- Remove flywheel locking tool from transmission bell housing.

Replace special tool bore sealing plug.

- Remove camshaft locking tools from cylinder head

4 lnstall intake camshaft cover and cylinder head cover.

0 Check for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealant at corners

(B) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

Page 159 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-65

Cylinder Head Removal and Installation /

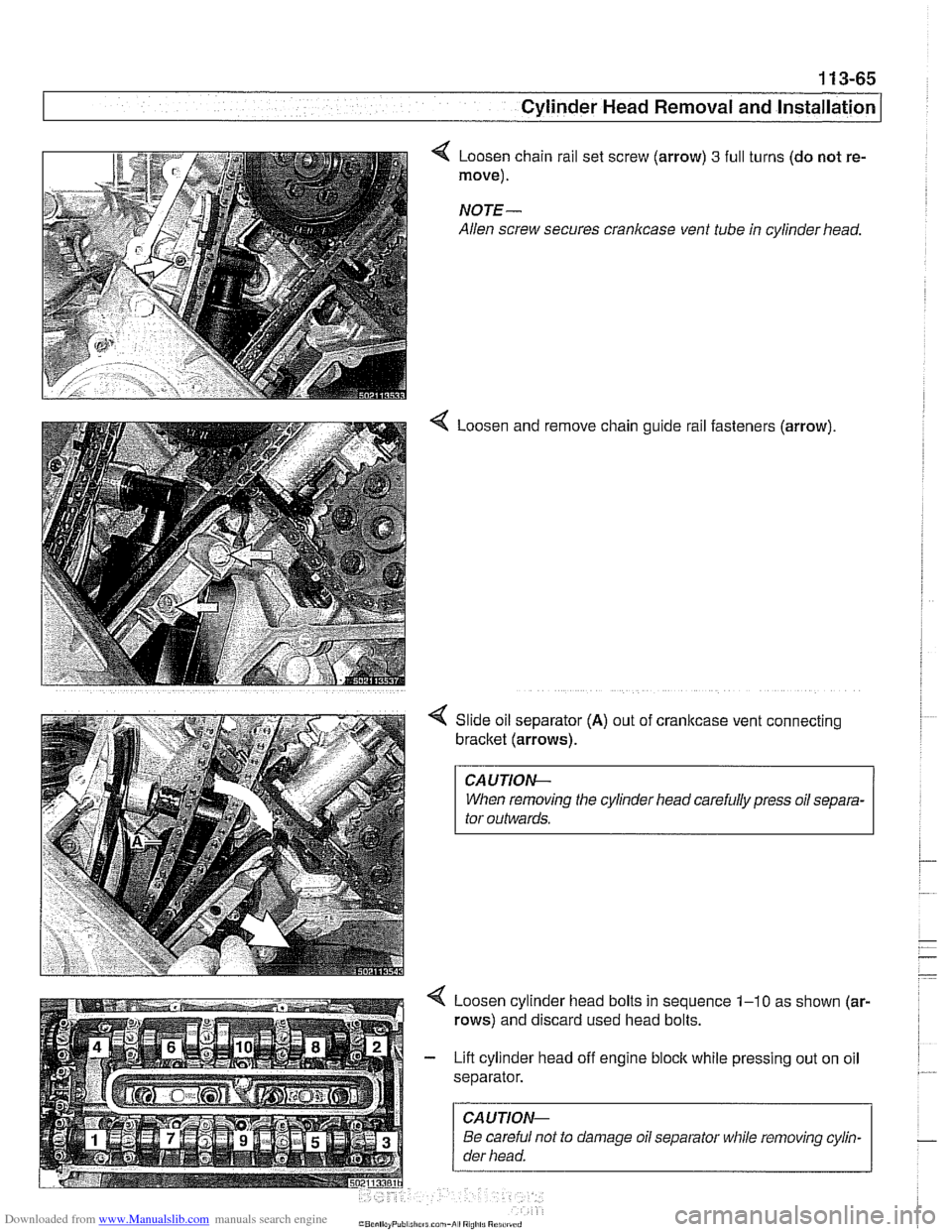

Loosen chain rail set screw (arrow) 3 full

move).

NOTE-

Allen screw secures crankcase vent tube

4 Loosen and turns

(do not re-

in cylinder head.

remove chain guide rail fasteners (arrow).

Slide oil separator

(A) out of cranltcase vent connecting

bracket (arrows).

CAUTIOI\C

When removing the cylinder head carefully press oil separa-

tor outwards.

Loosen cylinder head bolts in sequence

1-10 as shown (ar-

rows) and discard used head bolts.

Lift cylinder head off engine block while pressing out on oil

separator.

CAUTIOI\C

Be careful not to damage oil separator while removing cylin-

der head.

Page 161 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-67

Cylinder Head Removal and lnstaKI --

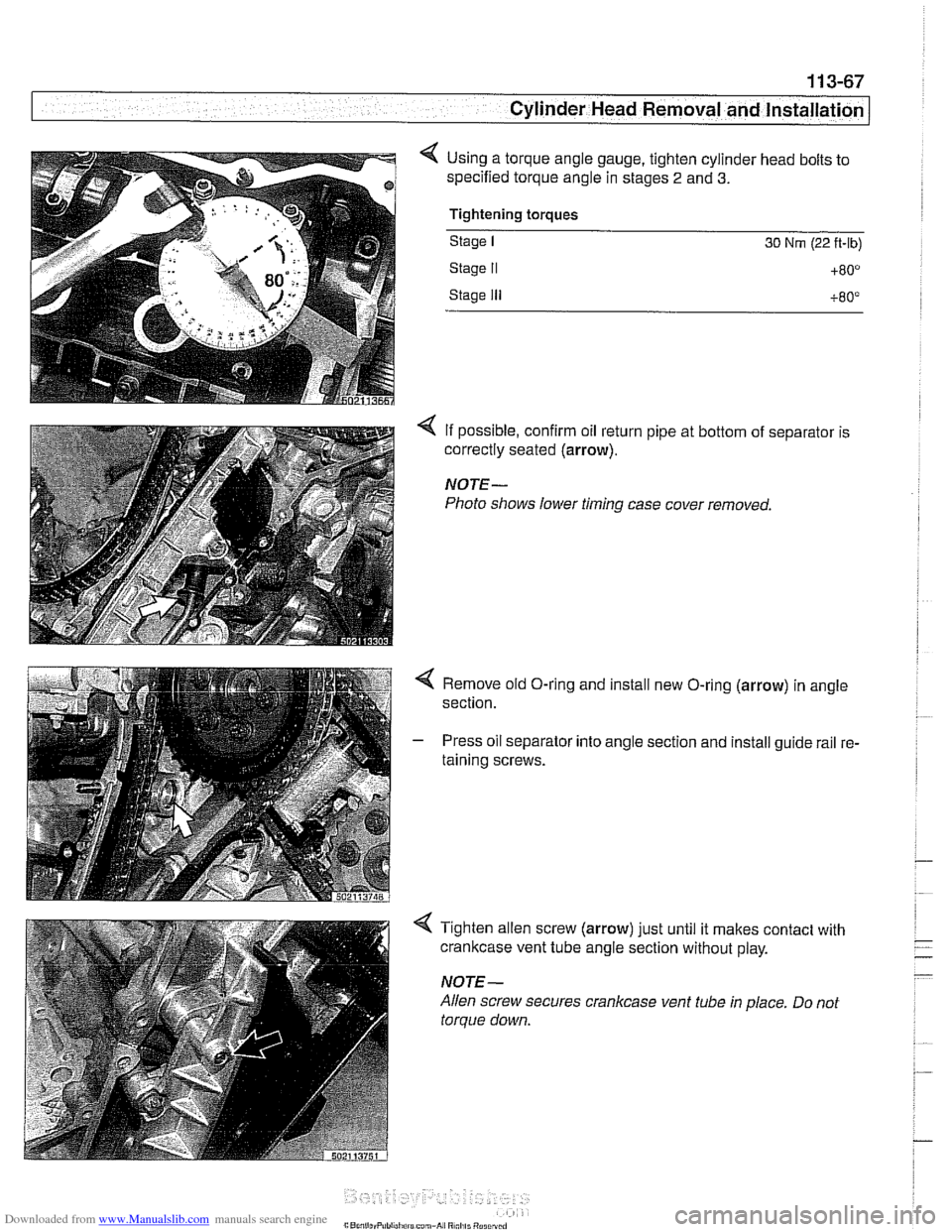

< Using a torque angle gauge, tighten cylinder head bolts to

specified torque angle in stages

2 and 3.

Tightening torques

Stage I 30 Nrn (22 ft-lb)

Stage II +80°

Stage Ill +80°

4 If possible, confirm oil return pipe at bottom of separator is

correctly seated

(arrow).

NOTE-

Photo shows lower timing case cover removed.

< Remove old O-ring and install new O-ring (arrow) in angle

section.

- Press oil separator into angle section and install guide rail re-

taining screws.

4 Tighten allen screw (arrow) just until it makes contact with

crankcase vent tube angle section without play.

NOTE-

Allen screw secures crankcase vent tube in place. Do not

torque down.

Page 193 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

4 Secure hydraulic lifters in lifter bores using BMW special tool

11 3 250, or remove lifters using a magnetic pick-up tool.

4 Remove camshaft bearing carrier from cylinder head.

CA UTION-

Camshaftbearing carriers must be reinstalledin their original

/ locations (E for ir;fal

Do not let hydraulic lifters fall out as the camshaft carrier is

removed.

Hydraulic lifters should be stored in an upright position.

Used hydraulic lifters

must be replaced into original lifter

bores.

Camshafts and lifters, installing

(M52 Engine)

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic liflers, friction washers, splined shafts and spline hubs

with assembly lubricant before installation.

Make sure

the cranltshaft, which had been rotated approxi-

mately

30" opposite the direction of engine rotation from

TDC, is still in thatposition before lowering the

camshaffs into

position. All pistons must be out of TDC position to prevent

valve/piston interference when the camshalts are installed.

Before installing camshaft carriers, examine bearing bores

(arrows) on hydraulic lifter bores for signs of wear.

Page 201 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

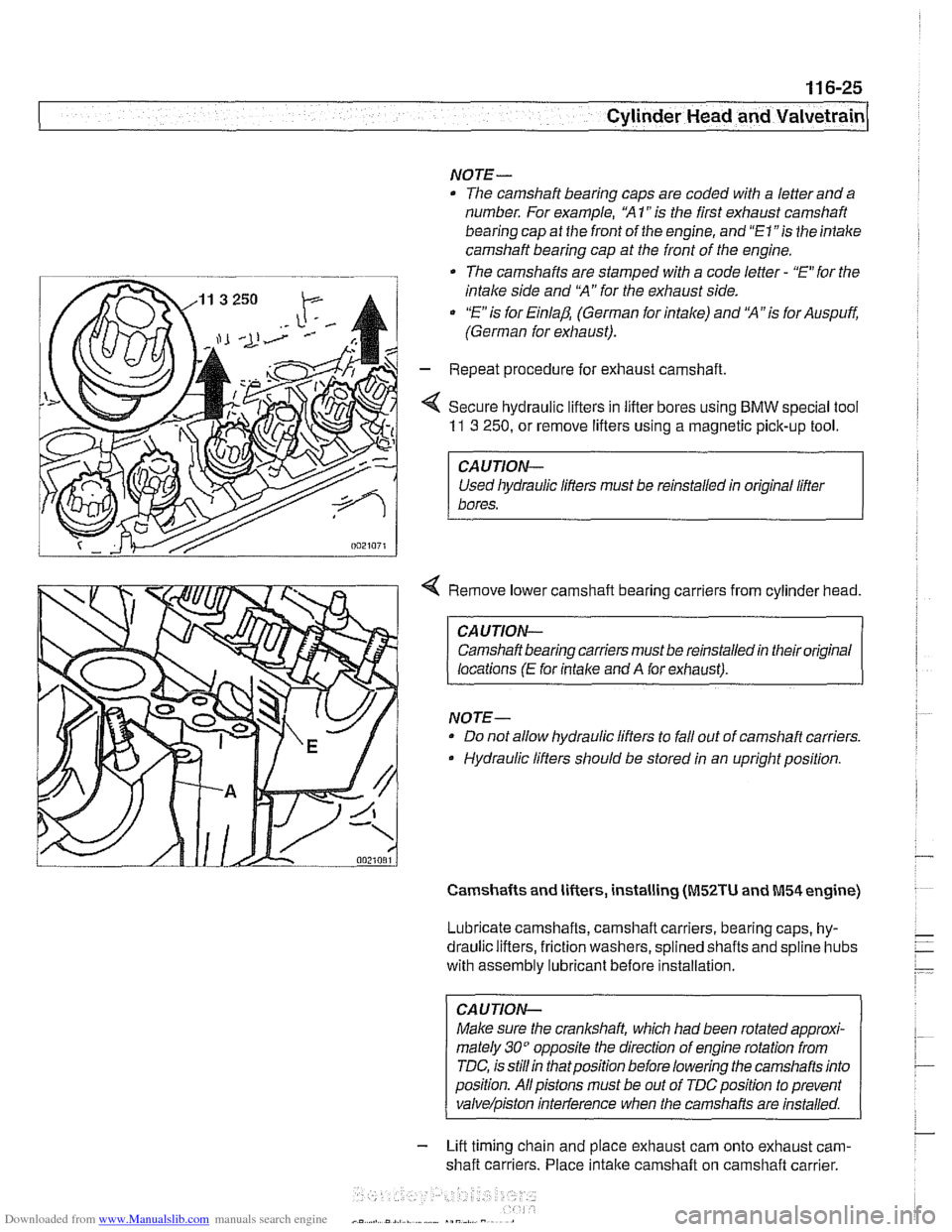

NOTE-

The camshaft bearing caps are coded with a letter and a

number. For example, "A

1" is the first exhaust camshaft

bearing cap

at the front of the engine, and "El "is the intake

camshaft bearing cap at the front of the engine.

-. -

The camshafts are stamped with a code letter - "E for the

intake side and

'X" for the exhaust side.

"E is for Einlap. (German for intake) and 'XA7s for Auspuff.

(German for exhaust).

- Repeat procedure for exhaust camshaft

< Secure hydraulic lifters in lifter bores using BMW special tool

11 3 250, or remove lifters using a magnetic pick-up tool.

I CAUTION-

Used liydraulic lifters must be reinstalled in original lifter

1 bores.

4 Remove lower camshaft bearing carriers from cylinder head.

CAUTION- Camshaft bearing carriers must be reinstalled in their original

locations

(E for intalce and A for exhaust).

NOTE- Do not allow hydraulic lifters to fall out of camshaft carriers.

Hydraulic lifters should be stored in an upright position.

Camshafts and lifters, installing (M52TU and M54 engine)

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and

spline hubs

with assembly

lubricant before installation.

CAUTION-

Make sure the crankshaft, which had been rotated approxi-

mately

30" opposite the direction of engine rotation from

TDC, is

stillin thatposition before lowering the camshafts into

position. Allpistons must be out of

TDCposition to prevent

valve/piston inteiference when the carnshafis are installed.

- Lift timing chain and place exhaust cam onto exhaust cam-

shaft carriers. Place

intake camshaft on camshaft carrier.

Page 205 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Cylinder Head and valvetrain1

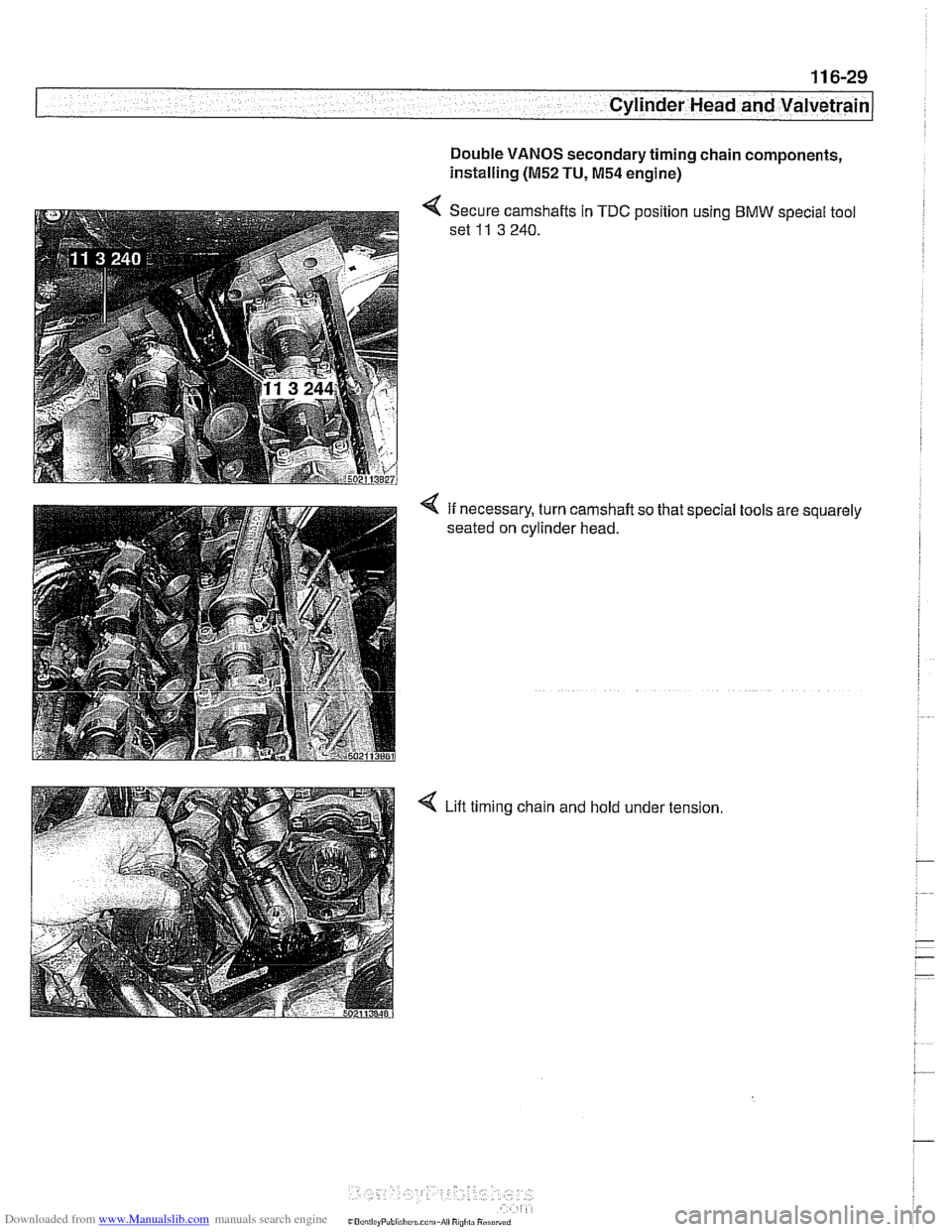

Double VANOS secondary timing chain components,

installing

(M52 TU, M54 engine)

< Secure camshafts in TDC position using BMW special tool

set

11 3 240.

4 If necessary, turn camshaft so that special tools are squarely

seated on cylinder head.

4 Lift timing chain and hold under tension