fuel type BMW 540i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 431 of 1002

Downloaded from www.Manualslib.com manuals search engine

. -

Fuel Injection I

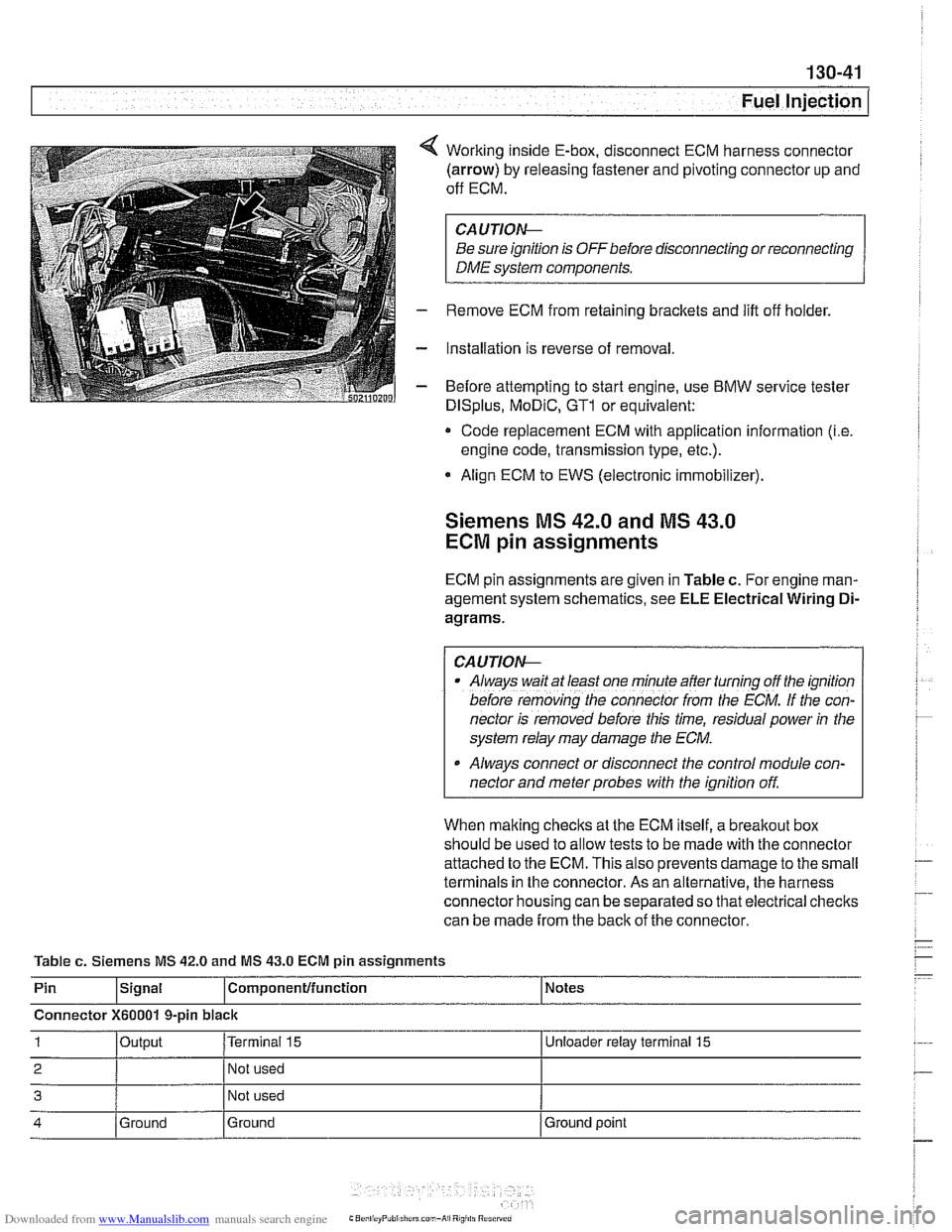

Working inside E-box, disconnect ECM harness connector

(arrow) by releasing fastener and pivoting connector up and

off ECM.

CA UTIOW

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove ECM from retaining brackets and lift off holder.

Installation is reverse of removal

Before attempting to start engine, use

BMW service tester

DISplus, MoDiC, GTl or equivalent:

* Code replacement ECM with application information (i.e

engine code, transmission type, etc.).

Align ECM to EWS (electronic immobilizer).

Siemens MS 42.0 and MS 43.0

ECM pin assignments

ECM pin assignments are given in Table c. For engine man-

agement system schematics, see

ELE Electrical Wiring Di-

agrams.

/ CAUTIOW I

Al~ays wait at least one mfnule after turning off the ignition

before

remov;ng [he connecror irom rhe ECM. If the con-

nector is removed before this time, residual power

in the

system relay may damage the

ECM.

Always connect or disconnect the control module con-

nector and meter probes with the ignition off.

When making checks at the ECM itself, a

breakout box

should be used to allow tests to be made with the connector

attached to the ECM. This also prevents damage to the small

terminals in the connector. As an alternative, the harness

connector housing can be separated so that electrical checks

can be made from the back of the connector.

Table

c. Siemens MS 42.0 and MS 43.0 ECM pin assignments

Pin

lslgnal l~om~onentlfunction 1 Notes

Connector

X60001 9-pin black

1 loutput I~erminai 15 I Unloeder relay terminal 15

2 I 1 Not used I

3 Not used

4 Ground

Ground Ground

point

Page 445 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- If voltage is present as described above, check wiring be-

tween ECM and valve. If no wiring faults are found, check

ECM signal to valve.

- When replacing idle speed control valve, clean and inspect

all sealing areas.

. Inspect sealing ring in throttle body and replace if neces-

sary.

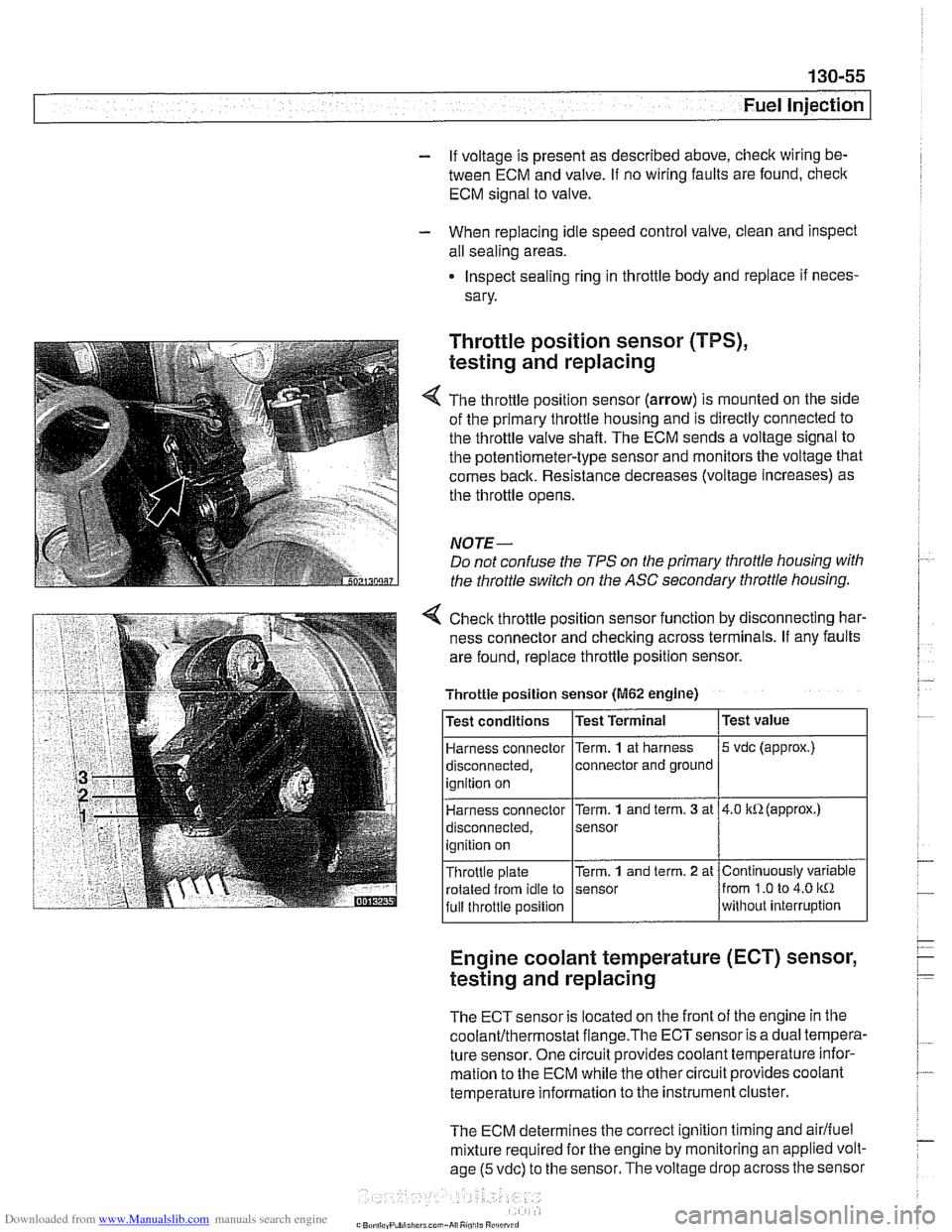

Throttle position sensor (TPS),

testing and replacing

The throttle position sensor (arrow) is mounted on the side

of the primary throttle housing and is directly connected to

the throttle valve shaft. The ECM sends a voltage signal to

the potentiometer-type sensor and monitors the voltage that

comes back. Resistance decreases (voltage increases) as

the throttle opens.

NOTE-

Do not confuse the TPS on the primary throttle housing with

the throttle switch on the

ASC secondary throttle housing.

4 Check throttle position sensor function by disconnecting har-

ness connector and checking across terminals. If any faults

are found, replace throttle position sensor.

Engine coolant temperature (ECT) sensor,

testing and replacing

Throttle position sensor (M62 engine)

The ECT sensor is located on the front of the engine in the

coolanVthermostat flange.The ECTsensor is a dual tempera-

ture sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

Test

value

5 vdc (approx.)

4.0 kR(approx.)

Continuously variable

from

1.0 to 4.0 kR

without interruption

Test

conditions

Harness connector

disconnected, ignition on

Harness connector

disconnected,

ignition on

Throttle plate rotated from idle to

full throttle position Test Terminal

Term.

1 at

harness

connector and ground

Term.

1 and term. 3 at

sensor

Term.

1 and term. 2 at

sensor

Page 446 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel lniection

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeff-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MILis il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(8OoC/176"F) to maintain engine

operation. The ignition timing is set to a

conservativelsafe ba-

sic setting.

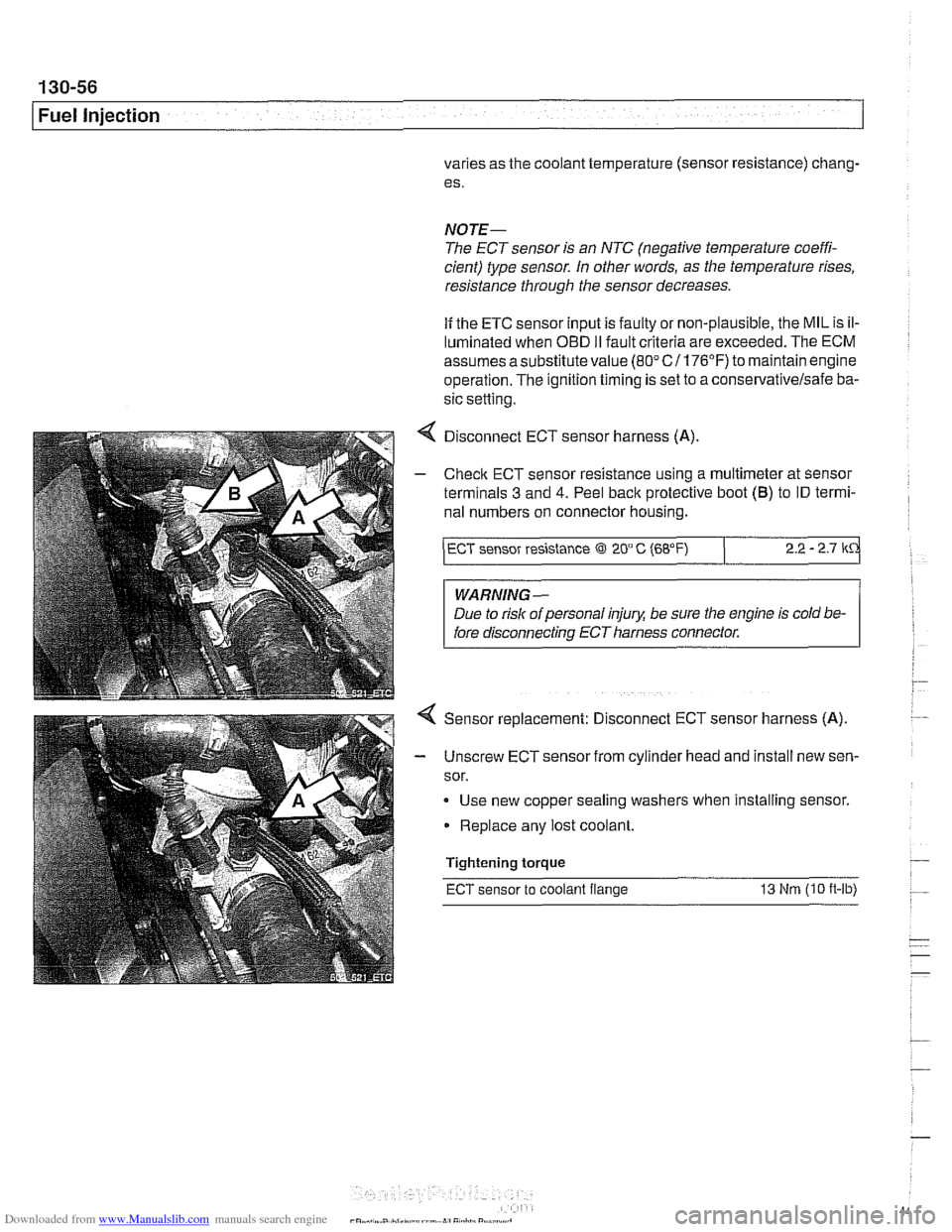

4 Disconnect ECT sensor harness (A)

- Checlc ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

/ ECT sensor resistance @l 2O" C (68°F) 2.2 - 2.7 kd

WARNING -

Due to risk of personal injug be sure the engine is cold be-

fore disconnecting ECT harness connector.

Sensor replacement: Disconnect ECT sensor harness (A).

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers

when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (I0 it-lb)

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

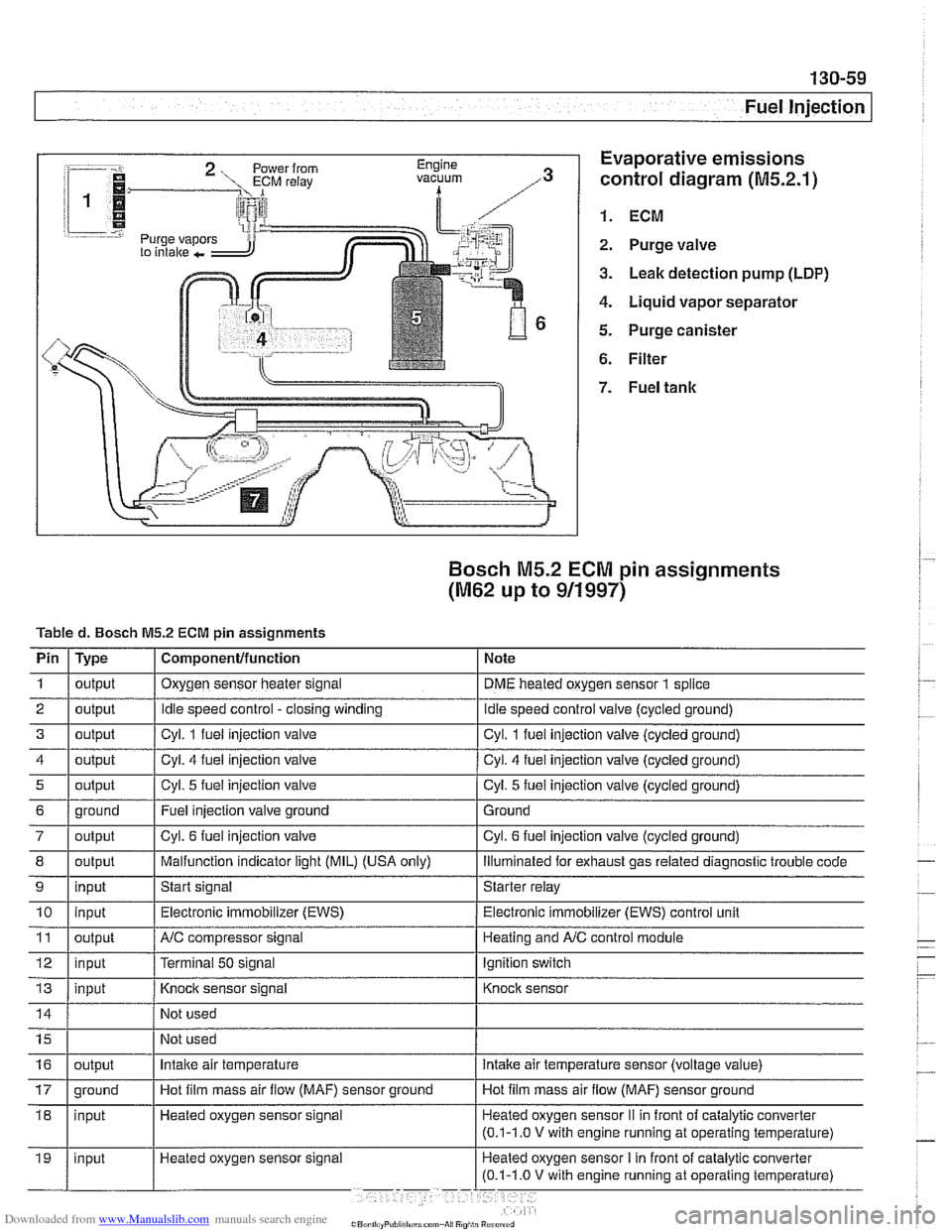

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

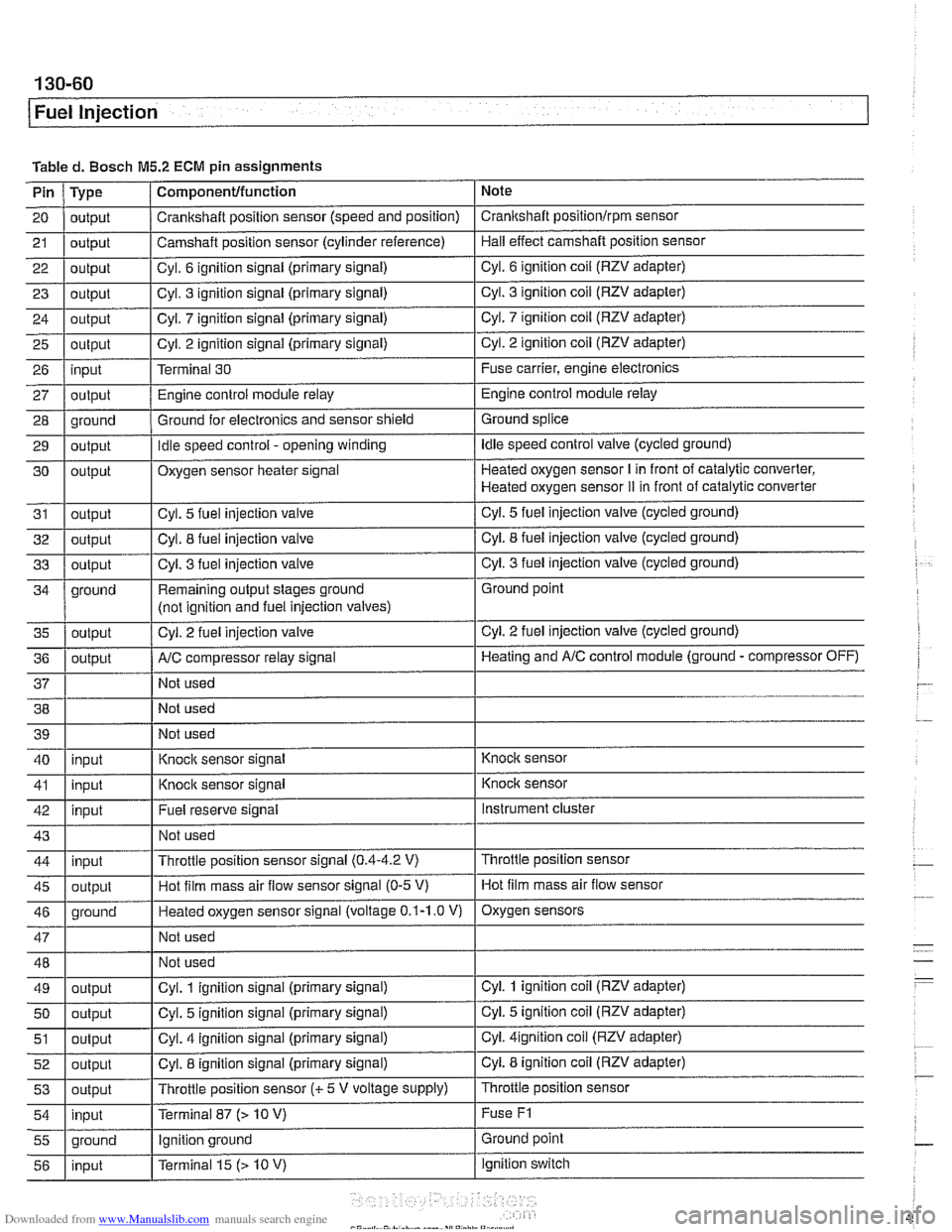

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 450 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-60

/Fuel lniection

Tabled. Bosch M5.2 ECM pin assignments

Note

Pin

21

20 I output / Crankshaft position sensor (speed and position) I Crankshaft positionlrpm sensor

23

I - I I 29 1 output I Idle speed control - opening winding I Idle speed control valve (cycled ground)

Type

22

1 output I Cvl. 6 ignition signal (primary signal) I Cyl. 6 ignition coil (RZV adapter)

output

25

26

27

28

Component/function

24 1 outout I Cvl. 7 iqnition siqnal (primary signal) I Cyl. 7 ignition coil (RZV adapter)

output

4 outbut I' I - I Cyl. 3

fuel injection valve I Cyl. 3 fuel injection valve (cycled ground)

Camshaft position

sensor (cylinder reference)

output input

output

oround

30

31

32

ground Hall effect camshaft position sensor

Cyl. 3 ignition signal (primary signal)

output

I

Cyl. 3 ignition coil (RZV adapter)

. - . .. . .

Cyl. 2 ignition signal (primary signal)

Terminal 30

Engine control module relay

Ground for electronics and sensor shield

output

output

outout

Remaining output stages ground

(not iclnition and fuel iniection valves) Cyl.

2 ignition coil (RZV adapter)

Fuse carrier, engine electronics

Engine control module relay

Ground splice ,

Cyl. 2 fuel injection valve

Oxygen sensor heater signal

Cyl. 5

fuel injection valve

Cvl. 8 fuel iniection valve

AIC comuressor relav sianal

Heated oxygen sensor I in front of catalytic converter,

Heated oxygen sensor

iI in front of catalytic converter

Cyl.

5 fuel injection valve (cycled ground)

Cvl. 8 fuel iniection valve (cycled ground)

. -

Not used Ground point

Cyl.

2 fuel injection valve (cycled ground)

Heatinq and AIC control module (ground - compressor OFF)

38 Not used

40 39

1 I Not used

I'

I . I

I' I -. I

46 1 ground I Heated oxygen sensor signal (voltage 0.1-1.0 V) I Oxygen sensors

41

1 inuut I Knock

sensor signal I Knock sensor

input

I

I I

Instrument cluster

I' I I 55 1 ground I Ignition ground I Ground point

Knock sensor signal

43

1 I Not used I

Fuel reserve signal

42

Throttle position sensor

47

48

49

50

51

52

53

54

Knoclc sensor

input

45

1 outout I Hot film mass air flow sensor signal (0-5 V) I Hot film mass air flow sensor

Throttle position sensor signal

(0.4-4.2 V) 44

input

output

output

output

output

output

inout

I - I

Not used

Not used

Cyl. 1 ignition signal (primary signal)

Cyl. 5 ignition signal (primary signal)

Cyl. 4 ignition signal (primary signal)

Cyl. 8 ignition signal (primary signal)

Throttle position sensor

(c 5 V voltage supply)

Terminal 87

f> 10 V)

ignition switch

56

Cyl. 1 ignition coil (RZV adapter)

Cyi. 5 ignition coil (RZV adapter)

Cyi.

4ignition coil (RZV adapter)

Cyl. 8 ignition coil (RZV adapter)

Throttle position sensor

Fuse

F1

input Terminal 15 (> 10 V)

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

Fuel Injection

I 68 1 / Not used

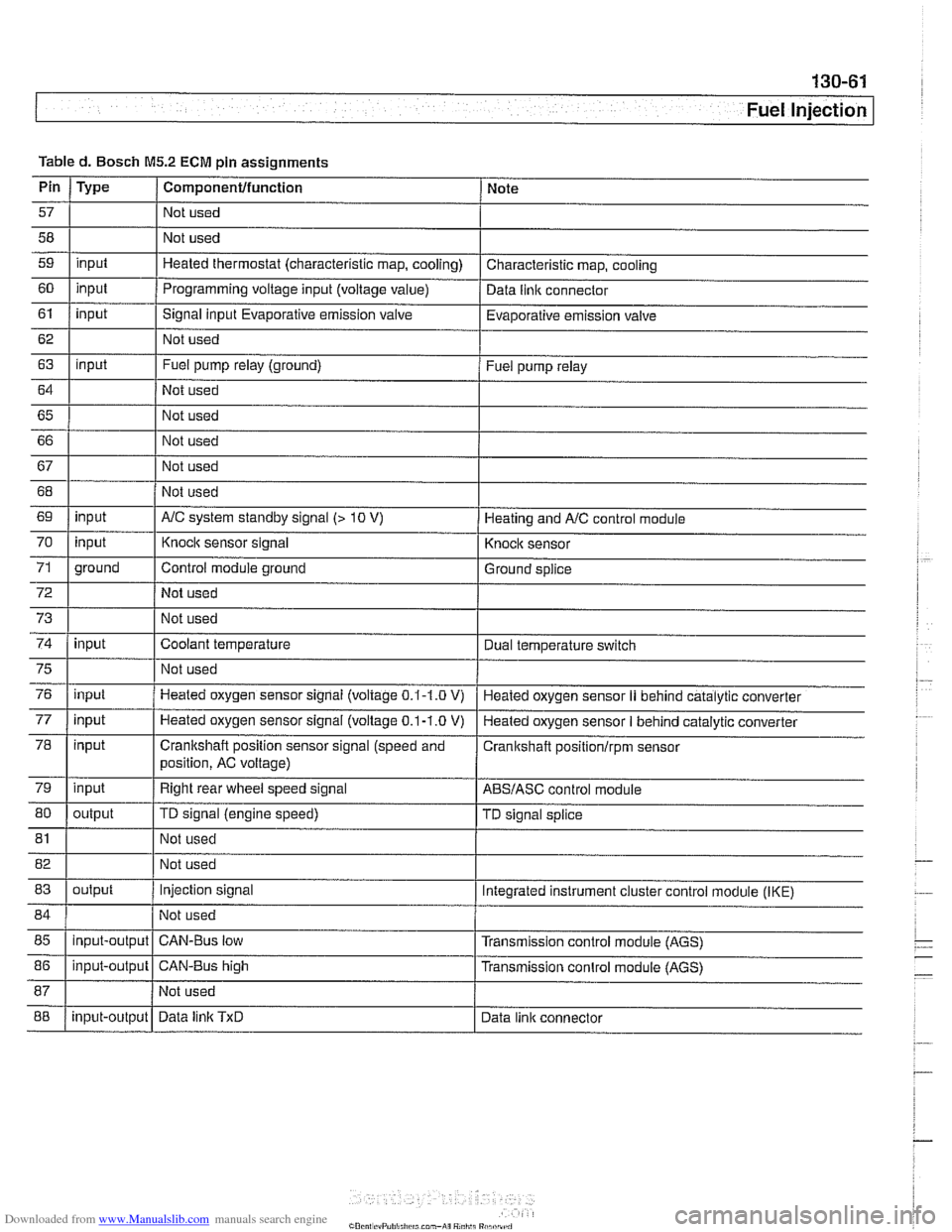

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 461 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

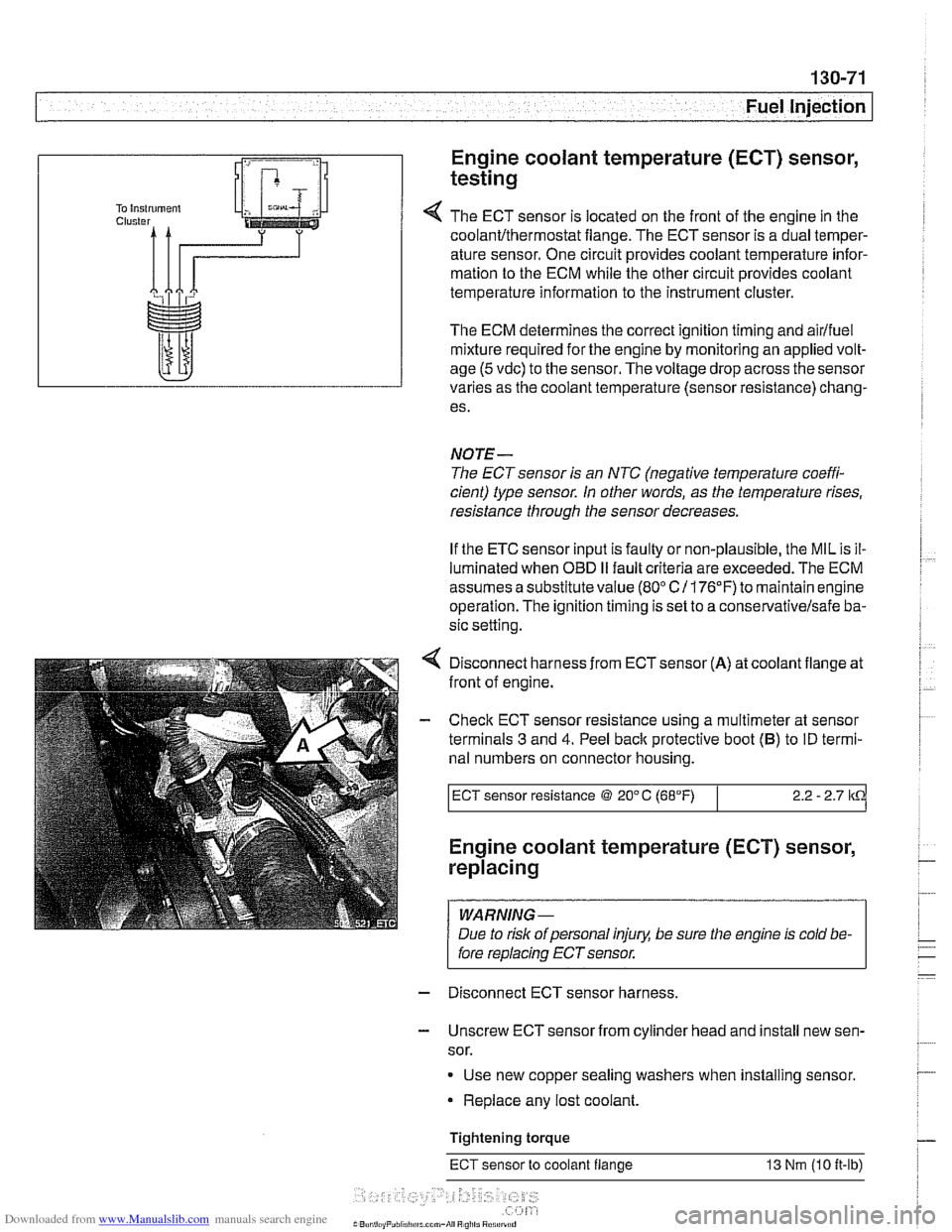

Engine coolant temperature (ECT) sensor,

testing

The ECT sensor is located on the front of the engine in the

coolant~thermostat flange. The ECT sensor is a dual temper-

ature sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. Thevoltage drop across the sensor

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(80" C/ 176°F) to maintain engine

operation. The ignition timing is set to a

conse~ativelsafe ba-

sic setting.

Disconnect harness from

ECTsensor (A) at coolant flange at

front of engine.

- Check ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

I ECT sensor resistance @ 20" C (68°F) I 2.2 - 2.7 lkCi

Engine coolant temperature (ECT) sensor,

replacing

I WARNING-

/ Due to risk ofpersonal injury, be sure the engine is cold be- I

I fore replacin~~~~sensor. -

-

I

- Disconnect ECT sensor harness.

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (10 it-lb)

Page 462 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-72

Fuel Injection

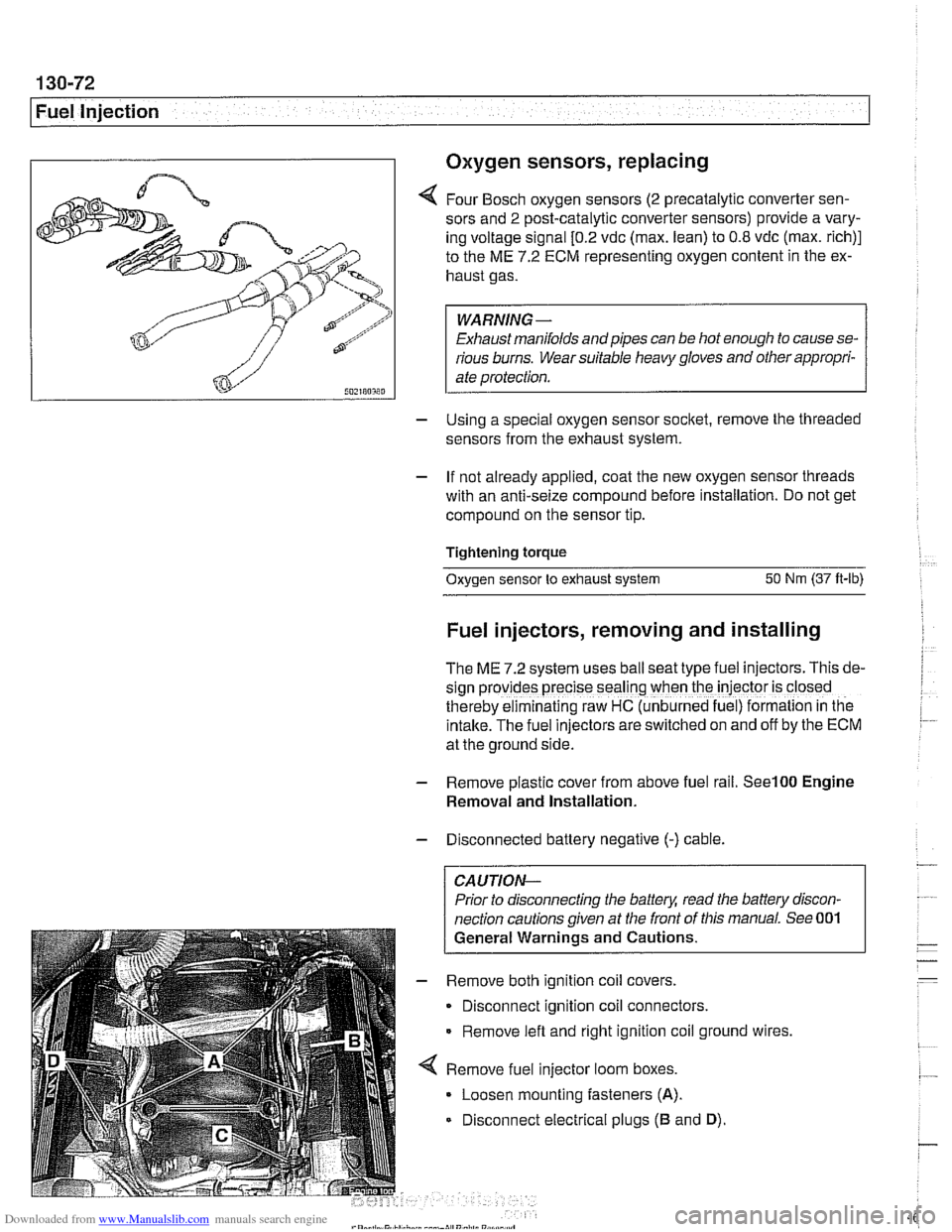

I Oxygen sensors, replacing

4 Four Bosch oxygen sensors (2 precatalytic converter sen-

sors and

2 post-catalytic converter sensors) provide a vary-

ing voltage signal

[0.2 vdc (max. lean) to 0.8 vdc (max. rich)]

to the ME

7.2 ECM representing oxygen content in the ex-

haust gas.

WARNING-

Exhaust manifolds and pipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

- Using a special oxygen sensor socltet, remove the threaded

sensors from the exhaust system.

- If not already applied, coat the new oxygen sensor threads

with an anti-seize compound before installation. Do not get

compound on the sensor tip.

Tightening torque

Oxygen sensor to exhaust system

50 Nm (37 ft-lb)

Fuel injectors, removing and installing

The ME 7.2 system uses ball seat type fuel injectors. This de-

sign

prov:des precise seal'ng when the iniector is closed

therebv eiminalinq raw HC (unb~rned fue ) formalion in tne

intake.-~he fuel inkctors areswitched on and off by the ECM

at the ground side.

- Remove plastic cover from above fuel rail. See100 Engine

Removal and Installation.

- Disconnected battery negative (-) cable.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given at the front of this manual. See 001

General Warnings and Cautions.

- Remove both ignition coil covers.

Disconnect ignition coil connectors.

Remove left and right ignition coil ground wires,

4 Remove fuel injector loom boxes.

Loosen mounting fasteners

(A).

Disconnect electrical plugs (B and D).

Page 466 of 1002

Downloaded from www.Manualslib.com manuals search engine

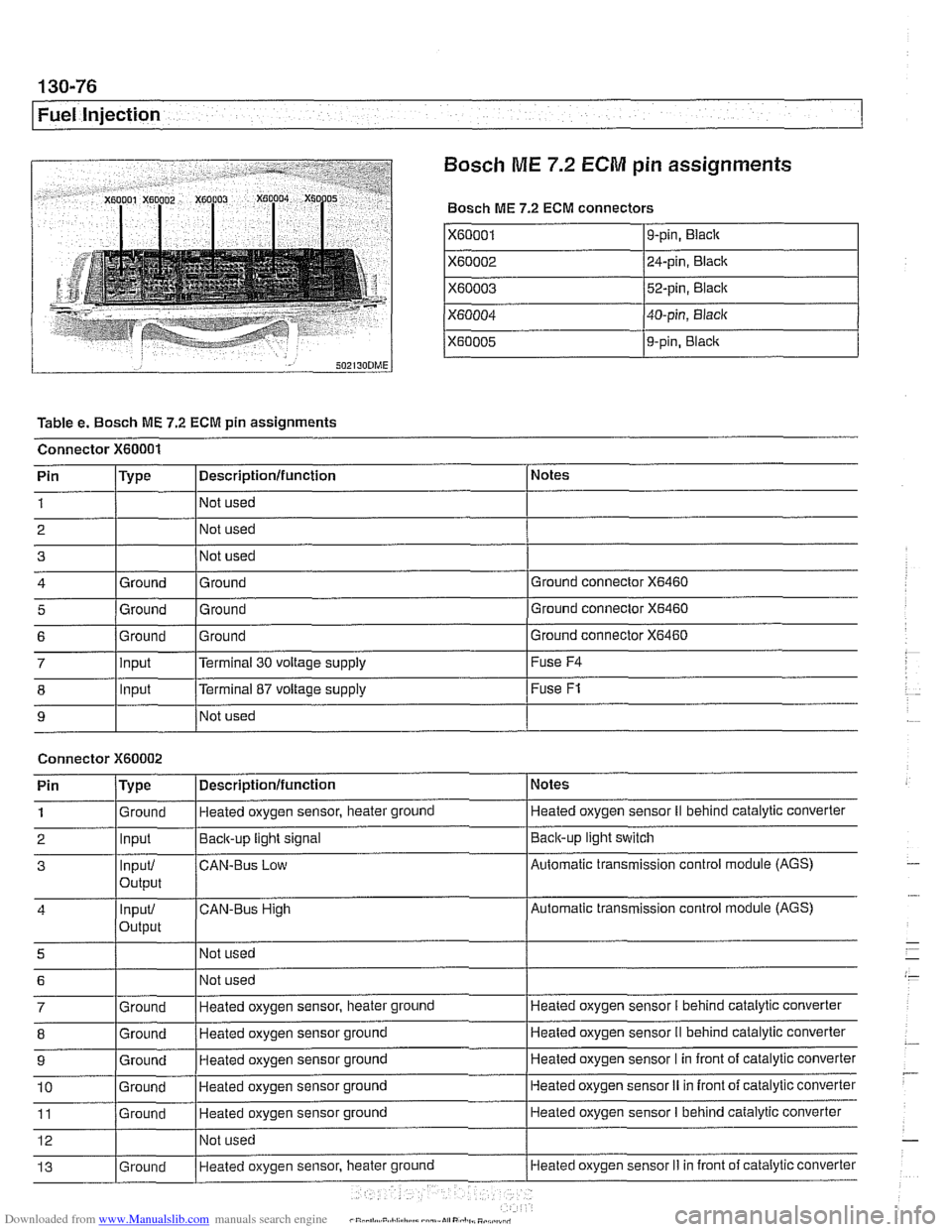

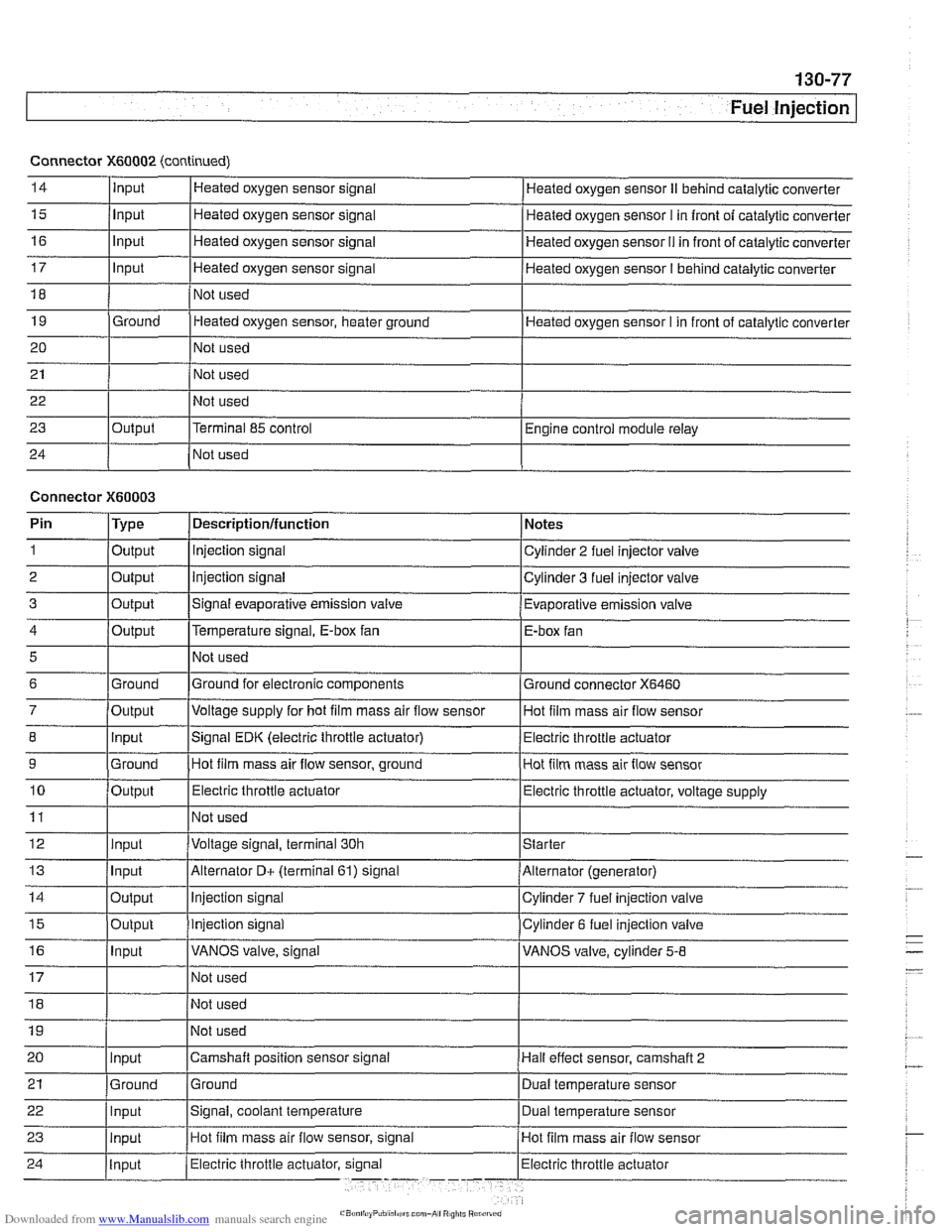

130-76

Fuel Injection

Bosch

ME 7.2 ECM pin assignments

Bosch ME 7.2 ECM connectors

X60001

X60002

X60003

X60004

X60005

Table e. Bosch ME 7.2 ECM pin assignments

Connector

X60001

I I I

8 1 lnput [Terminal 87 voltage supply I Fuse F1

9-pin, Black

24-pin, Black

52-pin, Black

40-pin, Black

9-pin,

Blaclc

I I I

9 I NO^ used I

Notes

Ground connector

X6460

Ground connector X6460

Pin 1

2 3

4

5

Connector X60002

Ground connector X6460 6

Pin

/Type I Descriptionlfunction 1 Notes

Type

Ground

Ground

7 llnput l~errninai 30 voltage supply I Fuse F4

Descriptionlfunction

Not used

Not used

Not used

Ground Ground

Ground Ground

1

2

3

4

5

6

7

8

9

10

11

12

13

. . - Ground Input

Input/

output

input/

Output

Ground

Ground

Ground

Ground

Ground

Ground Heated oxygen sensor, heater ground

Back-up

light signal

CAN-BUS Low

CAN-Bus High

Not used Not used

Heated oxygen sensor, heater ground

Heated oxygen sensor ground

Heated oxygen sensor ground

Heated oxygen sensor ground

Heated oxygen sensor ground

Not used

Heated oxvaen sensor, heater

ground

Heated oxygen sensor II behind catalylic converter

Baclcup light switch

Automatic transmission control module (AGS)

Automatic transmission control module (AGS)

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor

II behind catalytic converter

Heated oxygen sensor I in front of catalytic converter

Heated oxygen sensor

II in front of catalytic converter

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor

Ii in front of catalytic converter

Page 467 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lnjection

I 1- I

4 /output l~em~erature signal. E-box fan I E-box fan

Connector

X60002 (continued)

14

15

16

17

18

19

20

21

22

23

24

5

6

7

8

9

10

11

12

13

14

15

16

Input

Input

Input

Input

Ground

Output Heated

oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Not used

Heated oxygen sensor, heater ground

Not used

Not used

Not used

Terminal 85 control

Not used Heated oxygen sensor

II behind catalytic converter

Heated oxygen sensor

I in front of catalytic converter

Heated oxygen sensor

I1 in front of catalytic converter

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor I in front of catalytic converter

Engine control module relay

Connector

X60003

Ground

Output Input

Ground

Output

Input

Input

Output

Output

Input

Pin 1

2

3

Not used

Ground for electronic components

Voltage supply for hot

film mass air flow sensor

Signal EDK (electric throttle actuator) Hot film mass air flow sensor, ground

Electric throttle actuator

Not used

Voltage signal, terminal 30h

Alternator

D+ (terminal 61) signal

Injection signal

Injection signal

VANOS valve, signal

Type

Output

Output

Output

Ground connector

X6460

Hot film mass air flow sensor

Electric throttle actuator

Hot film mass air flow sensor

Electric throttle actuator, voltage supply

Starter

Alternator (generator)

Cylinder

7 fuel injection valve

Cylinder 6 fuel injection valve

VANOS valve, cylinder

5-8

Descriptionlfunction

Injection signal

Injection signal

Signal evaporative emission valve Notes

Cylinder 2 fuel injector valve

Cylinder 3 fuel injector valve

Evaporative emission valve