jack BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 8 of 1002

Downloaded from www.Manualslib.com manuals search engine

I General Warnings and Cautions

WARNINGS (continued)

. The air conditioning system is filled with chemical refrigerant,

which is hazardous. The AIC system should be serviced only by

trained technicians using approved refrigerant recoverylrecycling

equipment, trained in related safety precautions, and familiar with

regulations governing the discharging and disposal of automotive

chemical refrigerants.

. Do not expose any part of the AIC system to high temperatures

such as open flame. Excessive heat will increase system pres-

sure and may cause the system to burst.

Some aerosol tire inflators are highly flammable. Be extremely

cautious when repairing a tire that may have been inflated using

an aerosol tire inflator. Keep sparks, open flame or other sources

of ignition away

from the tire repair area. Inflate and deflate the

tire at least four

times before breaking the bead from the rim.

Completely remove the tire from the rim before attempting any re-

pair.

Cars covered by this manual are equipped with a supplemental

restraint system (SRS), that automatically deploys

airbags and

pyrotechnic seat belt tensioners

In the event oi a frontal or side

impact. These are explosive devices. Handled improperly or with-

out adequate safeguards, they can be accidently activated and

cause serious injury.

- The ignition system produces high voltages that can be fatal.

Avoid contact with exposed terminals and use extreme care when

working on a car with the engine running or the ignition switched

on.

. Place jack stands only at locations specified by the manufacturer.

The vehicle

illtino iack su~olied with the vehicle is intended fortire -. , . changes only. A heavy duty floor jack should be used lo lift vehicle

before installing

jacl( stands. See 010 General.

- Battery acid (electrolyte) can cause severe burns. Flush contact

area

with water, seek medical attention.

Aerosol cleaners and solvents may contain hazardous or deadly

vapors and are highly flammable. Use only in a well ventilated ar-

ea. Do not use on hot surfaces (engines, brakes, etc.).

Do not remove

coolant reservoir or radiator cap with the engine

hot. Danger of burns and engine damage.

CAUTIONS-

See also WARNINGS

- if you lack the slqills, tools and equipment, or a suitable worl(shop

for any procedure described in this manual, leave such repairs to

an authorized BMW dealer or other qualified shop.

BMW is constantly improving its cars and sometimes these

changes, both in parts and specifications, are made applicable to

earlier models. Therefore, part numbers listed in this manual are

for reference only. Always check with your authorized BMW deal-

er parts department for the latest information.

Before starting a job, make certain that you have all the neces-

sary tools and parts on hand. Read ail the instructions thorough-

ly, and do not attempt shortcuts. Use tools appropriate to the

work and use only replacement parts meeting BMW specifica-

tions.

Use pneumatic and electric tools only to loosen threaded parts

and fasteners. Never use these tools to tighten fasteners, espe-

cially on light alloy parts. Always use a torque wrench to tighten

fasteners to the tightening torque specification listed.

Be mindful of the environment and ecology. Before you drain the

crankcase, find out the proper way to dispose of the

oil. Do not

pour

oil onto the ground, down a drain, or into a stream, pond or

lake. Dispose of waste in accordance with Federal, State and

Local laws.

The control module for the anti-lock brake system

(ABS) cannot

withstand temperatures from a paint-drying booth or a heat

lamp

in excess of 203" F (95°C) and should not be subjected to tem-

peratures in excess of 185°F

(8S°C) for more than two hours.

- Before doing any electrical welding on cars equipped with ABS,

disconnect the battery negative

(-) terminal (ground strap) and

the ABS control module connector.

- Always make sure ignition is off before disconnecting battery.

Label battery cables before disconnecting. On some models, bat-

tery cables are not color coded.

Disconnecting the battery may erase fault code@) stored in control

module memory. Using special BMW diagnoslic equipment, check

lor

iauit codes prior to disconnecting the battery cables. If the mal-

I.mct on ndicator Ignt (MIL) s I. ..minaled. see OBD On-Board

Diaanostics

Tl11s iant is iuenlfted as lne Check Ena~ne oht

(1997-2000 models jor~ervlce Engine Soon light (2061 andlater

models). If any other system iaults have been detected (indicated

by an illuminated warning light), see an authorized BMW dealer.

If a normal

or rapid charger is used to charge battery, the battery

must be disconnected and removed from the vehicle in order to

avoid damaging the vehicle.

- Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

* Connect and disconnect a battery charger only with the battery

charger switched off.

- Sealed or "maintenance free" batteries should be slow-charged

only, at an amperage rate that is approximately 10% of the bat-

tery's ampere-hour (Ah)

rating.

. Do not allow battery charging voltage to exceed 16.5 volts. If the

battery begins producing gas or boiling violently, reduce the

charging rate.

Boosting a sulfated battery at a high charging rate

can cause an explosion.

Page 11 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-1

010 General

General ........................... .01 0.2

How to Use this Manual ............ .01 0.2

Warnings. cautions and notes ........... .0l 0.3

Getting Started .................... .0i 0.5

Safety ............................. .O1 0.5

Lifting the car ........................ .O1 0.5

Raising car ......................... .O1 0.5

Working under car .................... .O1 0.6

Advice for the Beginner ............ .O1 0.7

Planning ahead ...................... .O1 0.7

Workshop practices ................... .O1 0.7

Non-reusable fasteners ................ .O1 0.7

Tightening fasteners .................. .O1 0.8

Gaskets and seals .................... .O1 0.9

Electrical testing .................... .O1 0.10

Wire repairs ........................ .O1 0.10

Buying Parts ..................... .01 0.11

Genuine BMW parts ................. .O1 0.11

Non-returnable parts ................. .O1 0.11

Information you need to know .......... .0l 0.12

Service ........................... 01 0-1 3

TOOIS ............................. 010-13

Basic tool requirements ............... 01 0-1 4

Jack stands ......................... 01 0-1 6

Oil change equipment ................. 01 0-1 6

Torque wrench ...................... 01 0-17

Digital multimeter .................... 010-17

BMW special tools ................... 01 0-1 8

Emergencies ...................... 01 0-1 8

Changing a tire ...................... 01 0-1 8

Jump starting ....................... 01 0-1 9

Indicator and warning lights ............ 01 0-1 9

Towing ............................ 010-20

Spare parts kit ...................... 010-21

Page 15 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

Much of the necessary maintenance and minor repairthat an

automobile will need can be done with ordinary tools. Below

you'll find important information on how to work safely, a dis-

cussion of what tools will be needed and how to use them.

Safety

Although an automobile presents many hazards, common

sense and good equipment can help ensure safety. Many ac-

cidents happen because of carelessness. Pay attention and

stick to the safety rules in this manual.

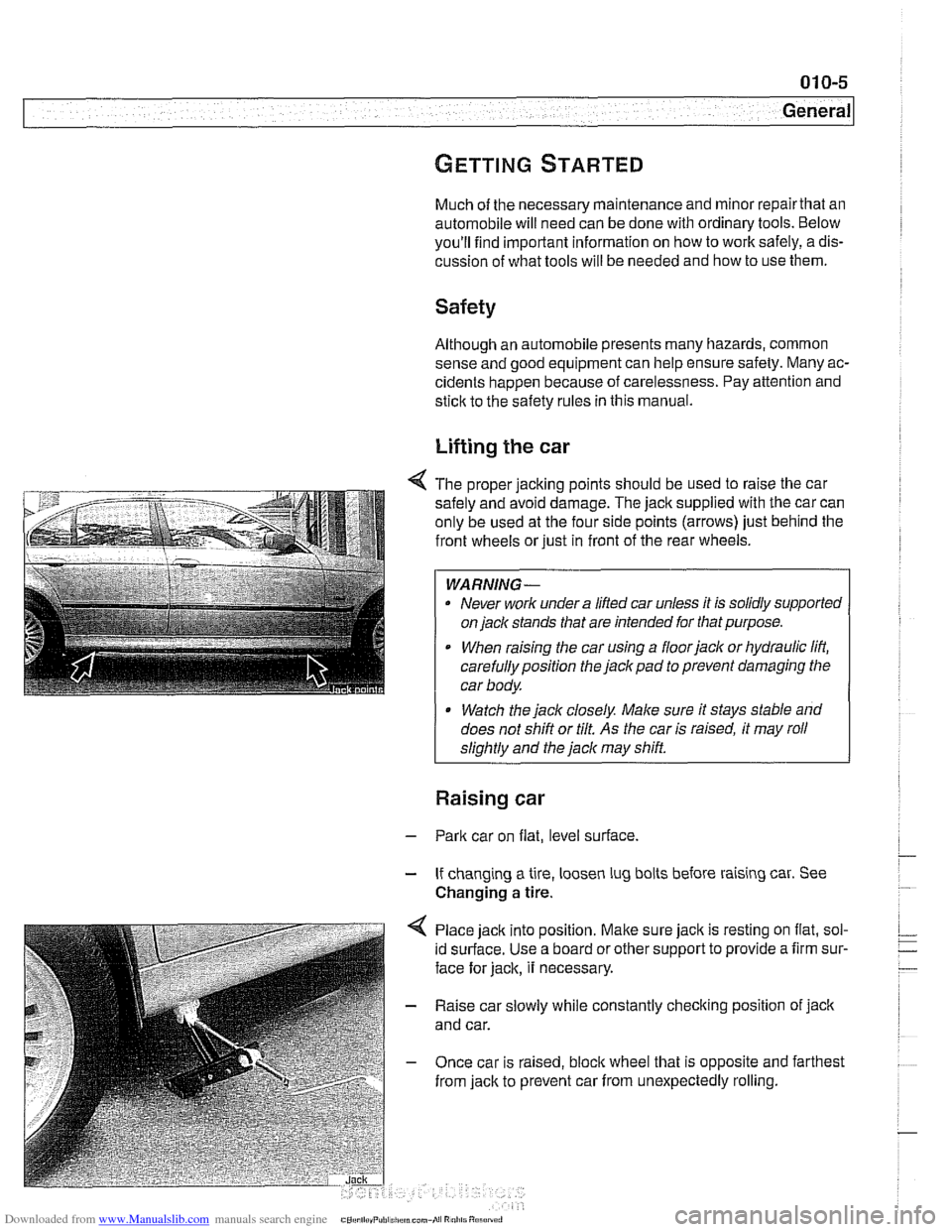

Lifting the car

4 The proper jacking points should be used to raise the car

safely and avoid damage. The

jack supplied with the car can

only be used at the four side points (arrows) just behind the

front wheels or just in front of the rear wheels.

WARNING-

. Never work under a lifted car unless it is solidly supported

on

jack stands that are intended for that purpose.

When raising the car using a floorjack or hydraulic lift,

carefully position the jack pad to prevent damaging the

car body.

* Watch the jack closely. Male sure it stays stable and

does not shift or tilt.

As the car is raised, it may roll

sliahtlv and the

jack mav shift.

Raising car

- Park car on flat, level surface.

- If changing a tire, loosen lug bolts before raising car. See

Changing

a tire.

Place jack into position.

Malte sure jack is resting on flat, sol-

id surface. Use a board or other support to provide a firm sur-

face for jack, it necessary.

- Raise car slowly while constantly checking position of jack

and car.

- Once car is raised, bloclc wheel that is opposite and farthest

from jack to prevent car from unexpectedly rolling.

Page 16 of 1002

Downloaded from www.Manualslib.com manuals search engine

(General

WARNING-

Do not rely on the transmission or the parking brake to

keep the car from rolling. They are not

a substitute forpos-

itively bloclcing the opposite wheel.

Never

work undera car that is supported only by a jaclc.

Use jack stands designed to support the car. See

Tools.

Working under car

- Disconnect negative (-) cable from battery so that car cannot

be started. Let others know what you will be doing.

CAUTION-- Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Raise car slowly as described above.

- Use at least two jack stands to support car. Use jack stands

designed for the purpose of supporting a car. See Tools.

WARNING-

* A jaclc is a temporary lifting device and should not be used

alone to support the car while you are under it.

Do not use wood, concrete

blocks, or bricks to support

a

ca,: Wood may split Blocks and bricks, while strong,

are not designed for that kind of load, and may break or

- Place jaclc stands on firm, solid surface. If necessary, use a

flat board or similar solid object to provide a firm footing.

- Lower car slowly until its weight is fully supported by jack

stands. Watch to

make sure that the jack stands do not tip or

lean as the car settles on them.

- Observe all jacking precautions again when raising car to re-

move jack stands.

Page 26 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

General

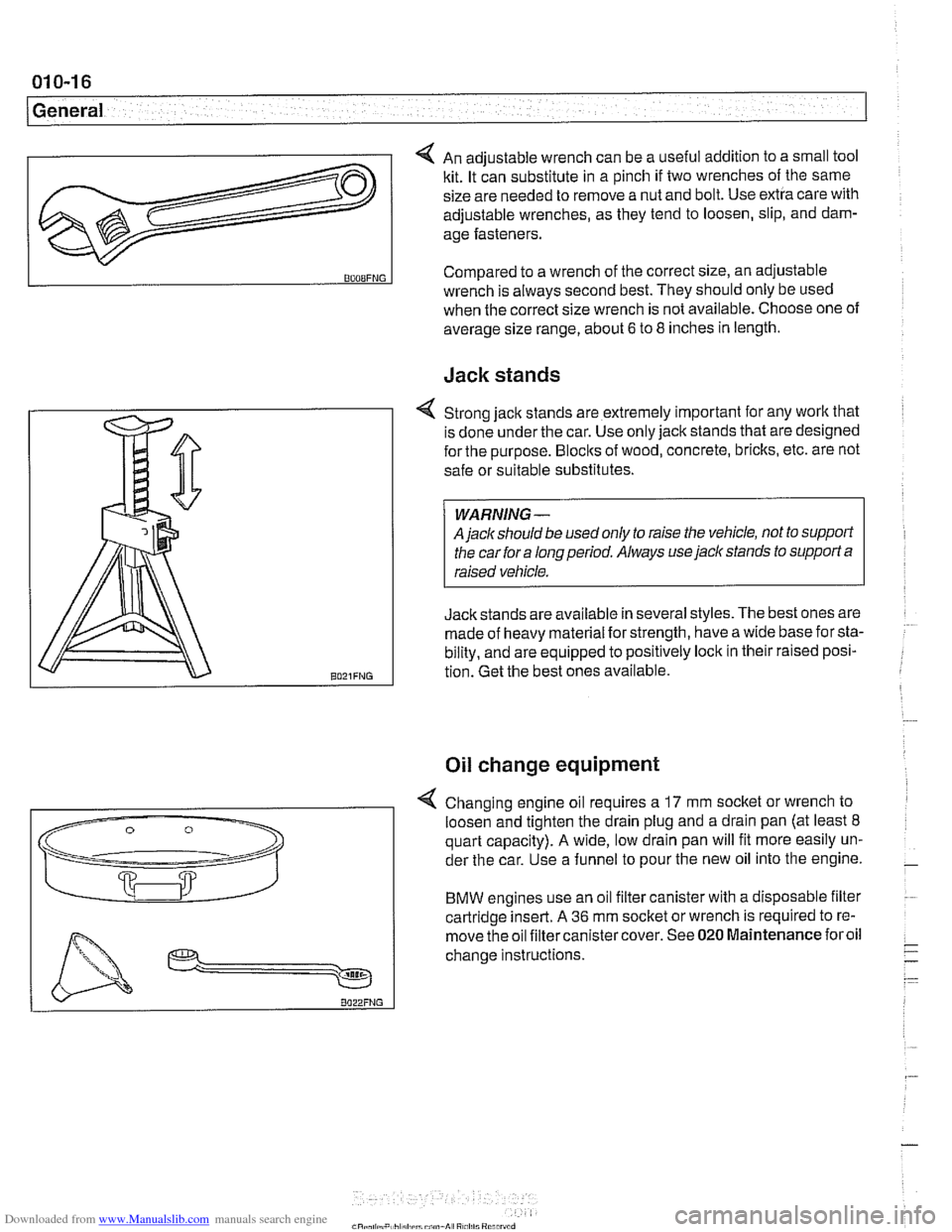

4 An adjustable wrench can be a useful addition to a small tool

kit. It can substitute in a pinch if two wrenches of the same

size are needed to remove a nut and bolt. Use extra care with

adjustable wrenches, as they tend to loosen, slip, and dam-

age fasteners.

Jack stands

v

BOOBFNG

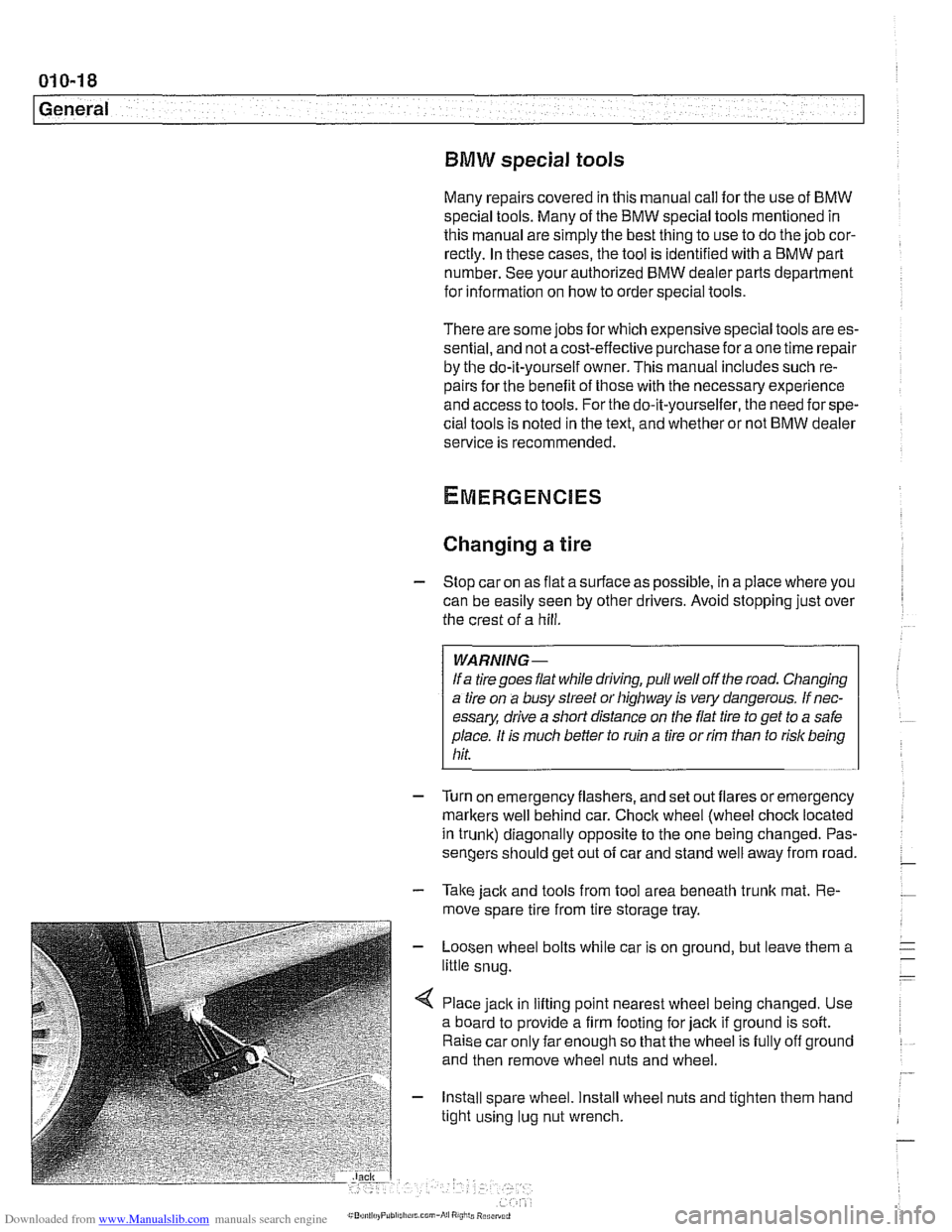

4 Strong jack stands are extremely important for any work that

is done under the car. Use only jack stands that are designed

for the purpose.

Blocks of wood, concrete, bricks, etc. are not

safe or suitable substitutes.

A

jaclc should be used only to raise the vehicle, not to support

the car for a long period. Always use

jack stands to support a

Jackstands are available in several styles. The best ones are

:

made of heavy material for strength, have a wide base for sta-

bility, and are equipped to positively lock in their raised posi-

tion. Get the best ones available.

Compared to

a wrench of the correct size, an adjustable

Oil change equipment

wrench is always second best. They should only be used

when the correct size wrench is not available. Choose one of

average size range, about

6 to 8 inches in length.

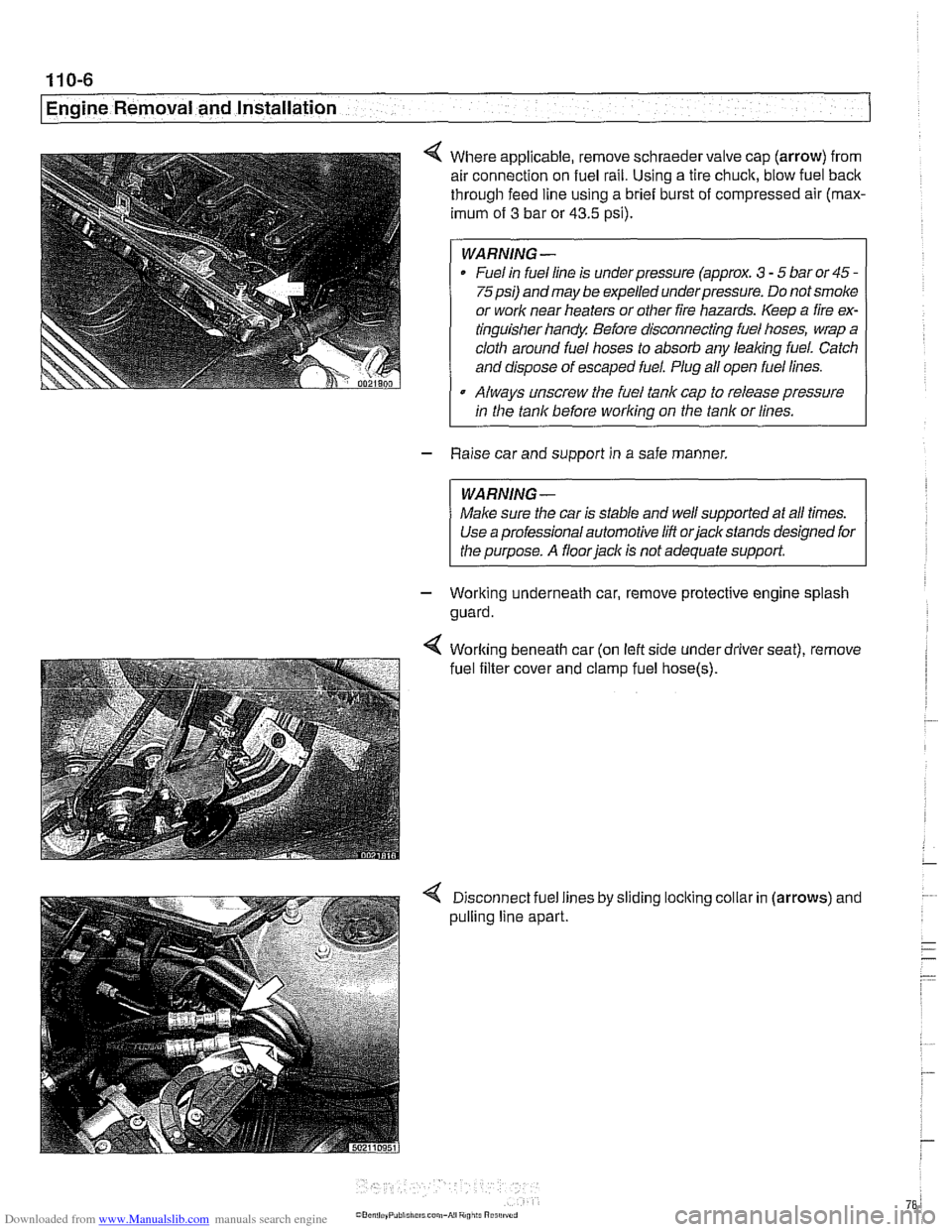

4 Changing engine oil requires a 17 mm socket or wrench to

loosen and tighten the drain plug and a drain pan (at least

8

quart capacity). A wide, low drain pan will fit more easily un-

der the car. Use a funnel to pour the new oil into the engine.

BMW engines use an oil filter canister with a disposable filter

cartridge insert. A

36 mm socket or wrench is required to re-

move the oil filtercanistercover. See

020 Maintenance foroil

change instructions.

Page 28 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

General

BMW special tools

Many repairs covered in this manual call for the use of BMW

special tools. Many of the BMW special tools mentioned in

this manual are simply the best thing to use to do the job cor-

rectly. In these cases, the tool is identified with a

BMW parl

number. See your authorized BMW dealer parts department

for information on how to order special tools.

There are some jobs for which expensive special tools are es-

sential, and not a cost-effective purchase for a one time repair

by the do-it-yourself owner. This manual includes such re-

pairs for the benefit of those with the necessary experience

and access to tools. For the do-it-yourselfer, the need for spe-

cial tools is noted in the text, and whether or not BMW dealer

service is recommended.

Changing a tire

- Stop car on as flat a surface as possible, in a place where you

can be easily seen by other drivers. Avoid stopping just over

the crest of a hill.

WARNING -

If a tire goes flat while driving, pull well off the road. Changing

a tire on a busy slreet or liigliway is very dangerous. If

nec-

essag drive a short distance on the flat tire to get to a safe

place. It is much better to ruin a tire or rim than to

risk being

hit.

-

- Turn on emergency flashers, and set out flares or emergency

markers well behind car.

Choclc wheel (wheel chock located

in trunk) diagonally opposite to the one being changed. Pas-

sengers should get out of car and stand well away from road.

- Take jaclc and tools from tool area beneath trunk mat. Re-

move spare tire from tire storage tray.

- Loosen wheel bolts while car is on ground, but leave them a

little snug.

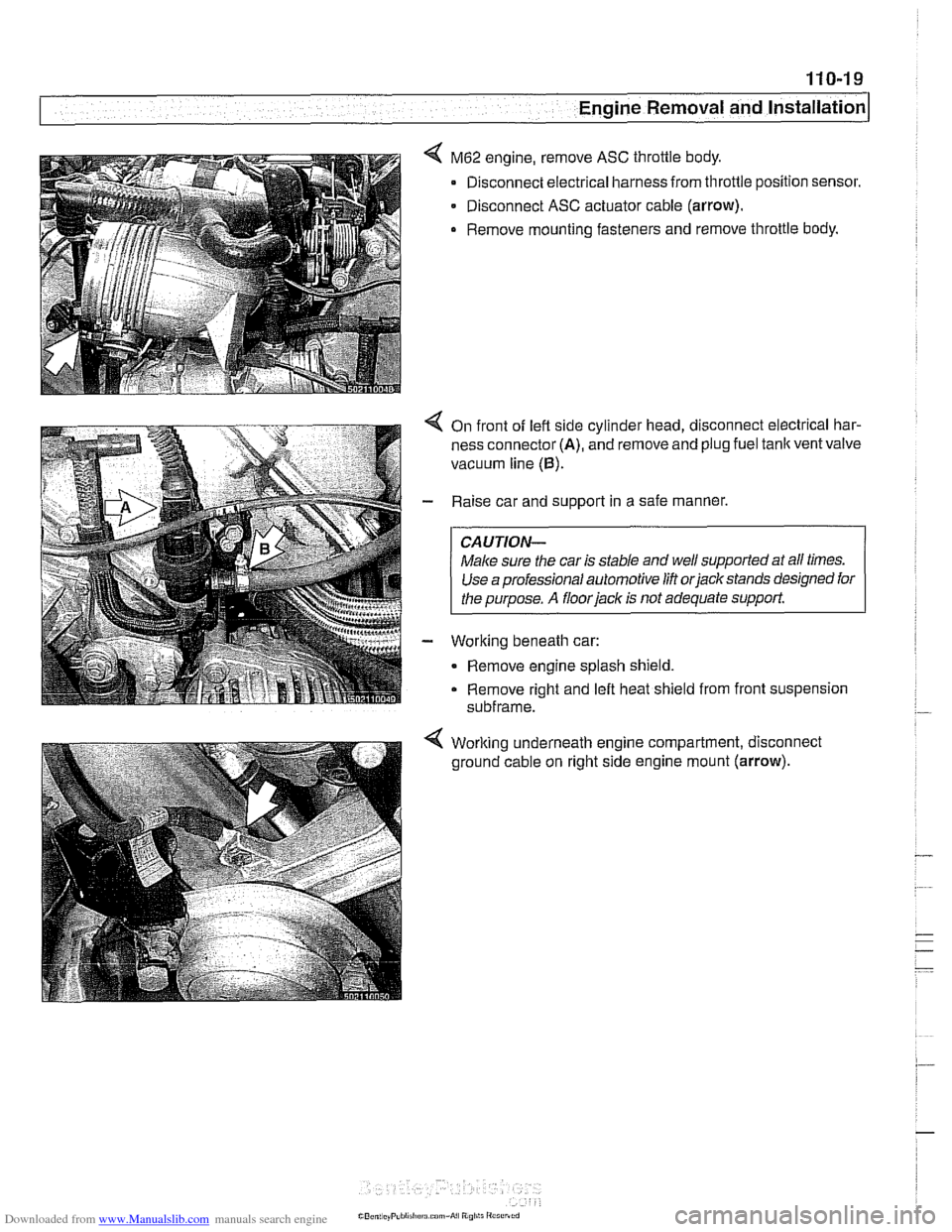

< Place jack in lifting point nearest wheel being changed. Use

a board to provide a firm footing for jack if ground is soft.

Raise car only far enough so that the wheel is fully off ground

and then remove wheel nuts and wheel.

- Install spare wheel. Install wheel nuts and tighten them hand

tight using lug nut wrench.

Page 78 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

I Engine Removal and Installation I

4 Where applicable, remove schraedervalve cap (arrow) from

air connection on fuel rail. Using a tire chuck, blow fuel back

through feed line using a brief burst of compressed air

(rnax-

imum of 3 bar or 43.5 psi).

WARNING -

Fuel in fuel line is under pressure (approx. 3 - 5 bar or 45 -

75psi) andmay be expelled underpressure. Do not smoke

or work near heaters or other fire hazards. Keep a fire ex-

tinguisher handy Before disconnecting fuel hoses, wrap

a

cloth around fuel hoses to absorb any leaking fuel. Catch

and dispose of escaped fuel. Plug all open fuel lines.

Alwavs unscrew the Fuel tank cao to release

oressure

I in the tank before working on the tank or lines. I

- Raise car and support in a safe manner.

WARNING-

Male sure the car is stable and we/ supported at all times.

Use a professional automotive lift orjackstands designed for

the purpose. A floor jack is not adequate support

- Working underneath car, remove protective engine splash

guard.

4 Disconnect fuel lines by sliding locking collar in (arrows) and

pulling line apart.

Page 91 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-19

Engine Removal and Installation

M62 engine, remove ASC throttle body.

Disconnect electrical harness from throttle position sensor.

- Disconnect ASC actuator cable (arrow).

. Remove mounting fasteners and remove throttle body.

On front of left side cylinder head, disconnect electrical har-

ness connector

(A), and remove and plug fuel tank vent valve

vacuum line

(0).

Raise car and support in a safe manner.

CAUTION-

Male sure the car is stable and well supported at aN times.

Use a professional automotive

lifi orjackstands designed for

I the ouroose. A floor jack is not adequate support.

Working beneath car:

- Remove engine splash shield.

Remove right and left heat shield from front suspension

subframe.

Working underneath engine compartment, disconnect

ground cable on right side engine mount

(arrow).

Page 118 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

Cylinder Head Removal and Installation

- Working at side of intake manifold near left strut tower, dis-

connect intake manifold resonance valve electrical harness

connector.

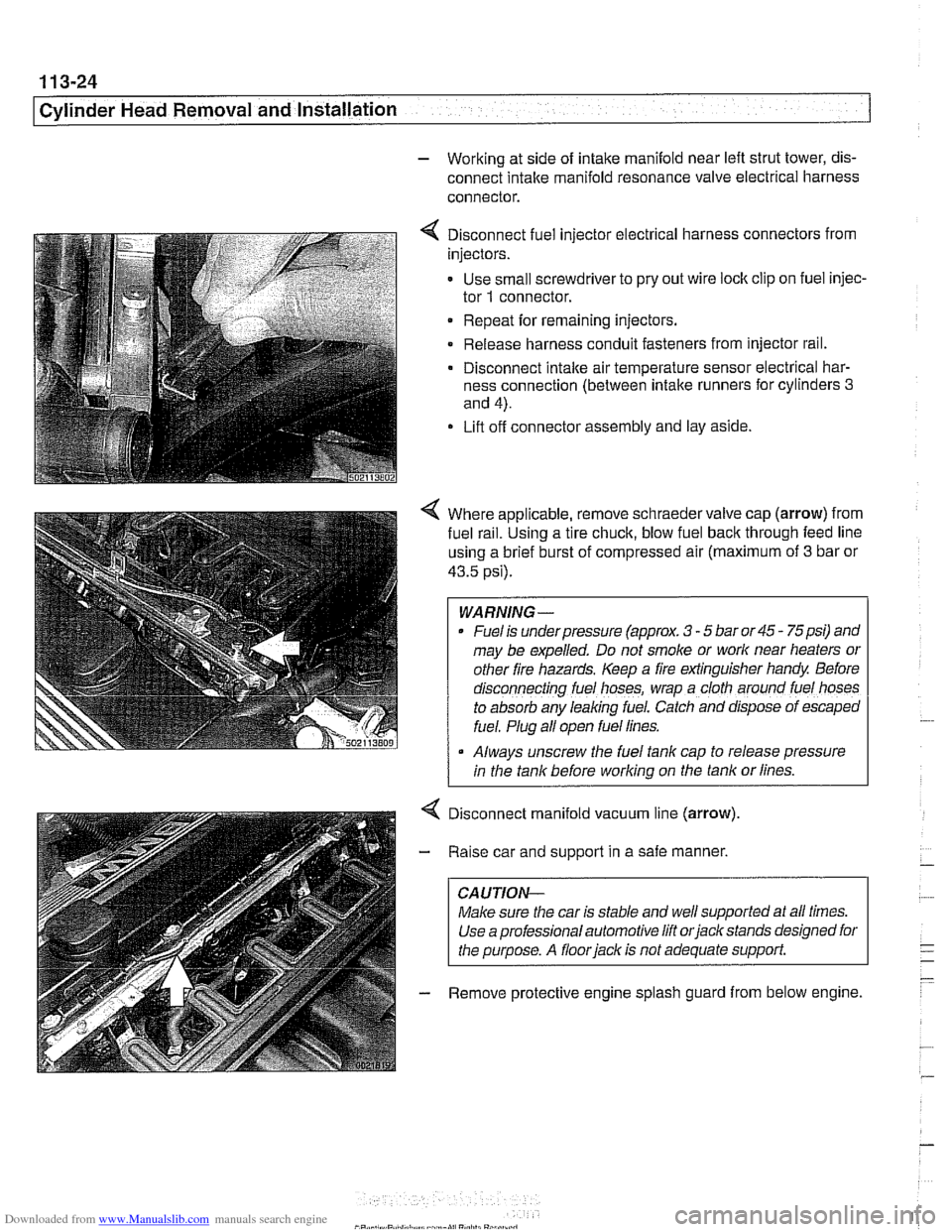

4 Disconnect fuel injector electrical harness connectors from

injectors.

- Use small screwdriver to pry out wire lock clip on fuel injec-

tor

1 connector.

Repeat for remaining injectors.

Release harness conduit fasteners from injector rail.

- Disconnect intake air temperature sensor electrical har-

ness connection (between intake runners for cylinders

3

and 4).

Lift off connector assembly and lay aside.

4 Where applicable, remove schraeder valve cap (arrow) from

fuel

ra~l. Using a tire chuck, blow fuel back through feed line

using a brief burst of compressed air (maximum of

3 bar or

43.5 psi).

WARNING-

Fuel is underpressure (approx. 3 - 5 bar or 45 - 75psi) and

may be expelled. Do not smoke or

work near heaters or

other fire hazards. Keep a fire extinguisher handy Before

d~sconnecting fuel hoses, wrap a cloth around fuel hoses

to absorb any leaking fuel. Catch and

dfspose of escaped

fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

I in the tank before working on the tank or lines.

Disconnect manifold vacuum line (arrow)

Raise car and support in a safe manner,

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A

floorjack is not adequate support.

Remove protective engine splash guard from below engine.

Page 330 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-1 0

Lubrication System

Oil pan, removing and installing

(6-cylinder)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Raise car and place securely on jack stands.

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjackstands designed for

- Remove splash shield from under engine.

- Drain engine oil as described in 020 Maintenance.

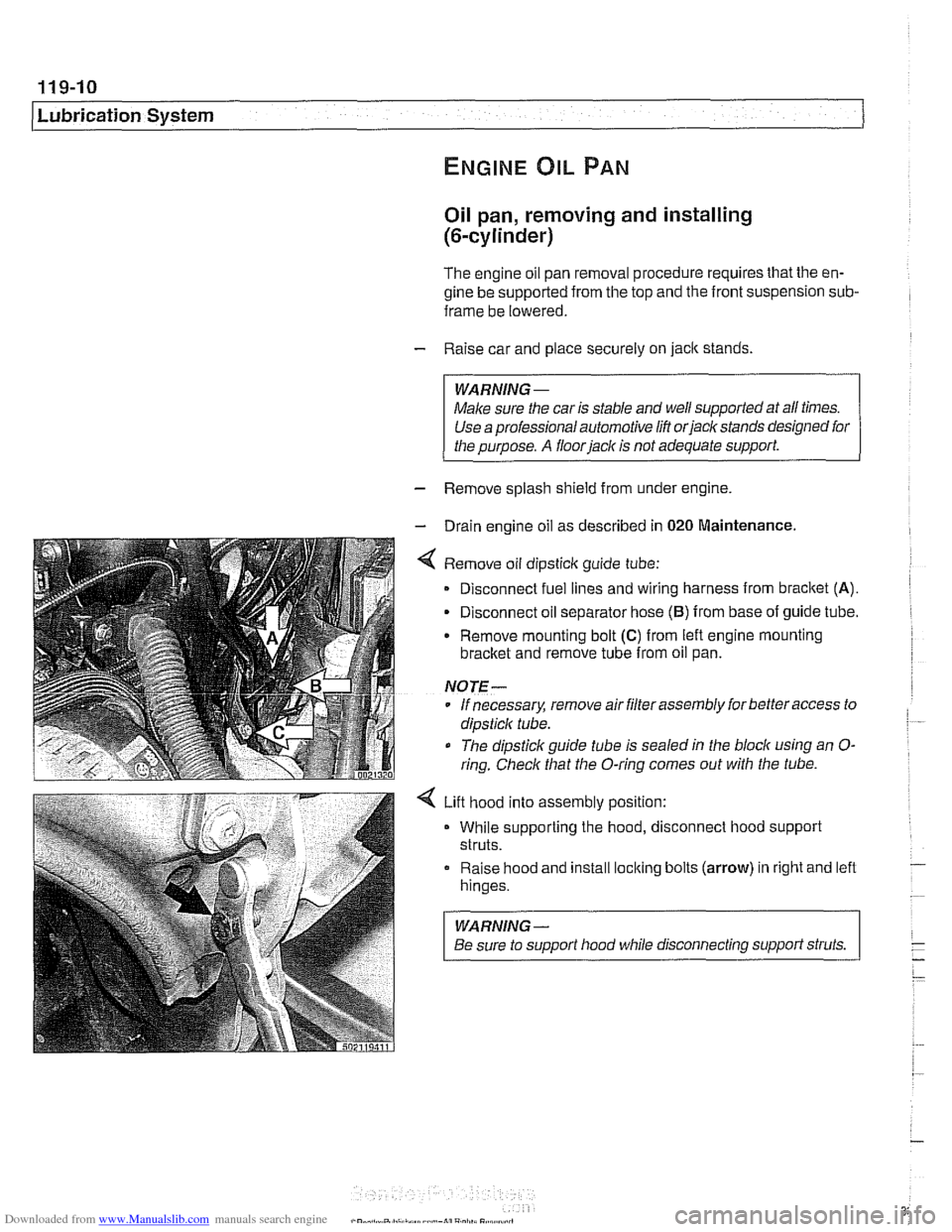

4 Remove oil dipsticlc guide tube:

Disconnect fuel lines and wiring harness from

bracket (A).

- Disconnect oil separator hose (B) from base of guide tube.

Remove mounting bolt

(C) from left engine mounting

bracket and remove tube from oil pan.

NOTE-

* If necessary, remove air filter assembly for better access to

dipsticlc tube.

The dipstick guide tube is sealed in the block using an

O-

ring. Check that the O-ring comes out with the tube.

4 Lift hood into assembly position:

While supporting the hood, disconnect hood support

struts.

Raise hood and install

loclting bolts (arrow) in right and left

hinges.

WARNING-

Be sure to support hood while disconnecting support struts.