key BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 36 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-4

Maintenance

1997 to 2000 models

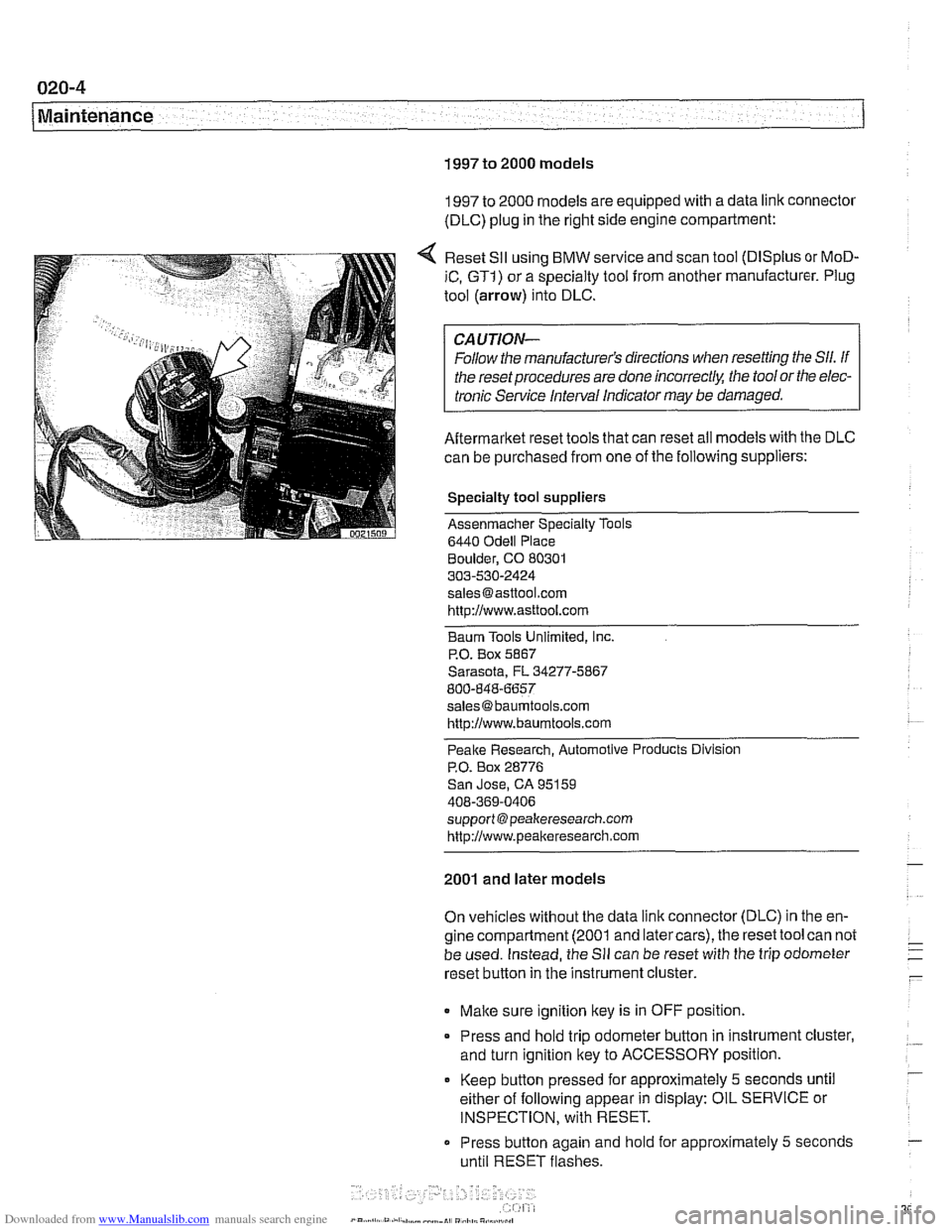

1997 to 2000 models are equipped with a data link connector

(DLC) plug in the right side engine compartment:

Reset

SII using BMW service and scan tool (DISplus or MoD-

iC, GTI) or a specialty tool from another manufacturer. Plug

tool (arrow) into DLC.

CAUTION-

Follow the manufacturer's directions when resetting the Sll. If

the reset procedures are done

incorrect& the tool or the elec-

tronic Service Interval Indicator

may be damaged.

Aftermarket reset tools that can reset all models with the DLC

can be purchased from one of the following suppliers:

Specialty tool suppliers

Assenmacher Specialty Tools

6440

Odell Place

Boulder, CO 80301

303-530-2424

[email protected] http://www.asttool.com

Baum Tools Unlimited,

Inc.

P.O. Box 5867

Sarasota, FL 34277-5867

800-848-6657

[email protected]

http://www.baumtools.com

Peake Research. Automotive Products Division

P.O. Box 28776

San Jose, CA 95159

408-369-0406

support @peakeresearch.com

http://www.peal~eresearch.com

2001 and later models

On vehicles without the data link connector (DLC) in the en-

gine compartment (2001 and latercars), the reset tool can not

be used. Instead, the

Sll can be reset with the trip odometer

reset button in the instrument cluster.

Make sure ignition key is in OFF position.

* Press and hold trip odometer button in instrument cluster,

and turn ignition key to ACCESSORY position.

Keep

button pressed for approximately 5 seconds until

either of following appear in display: OIL SERVICE or

INSPECTION, with RESET.

Press button again and

hold for approximately 5 seconds

until RESET flashes.

Page 243 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaff Timing Chain

NOTE-

Mark direction of belt rotation if reusing belt.

- Remove vibration damper mounting bolts and remove vibra-

tion damper and pulley from hub.

NOTE- The M52

6-cylinder engine uses a 2-piece vibration damper

and hub assembly.

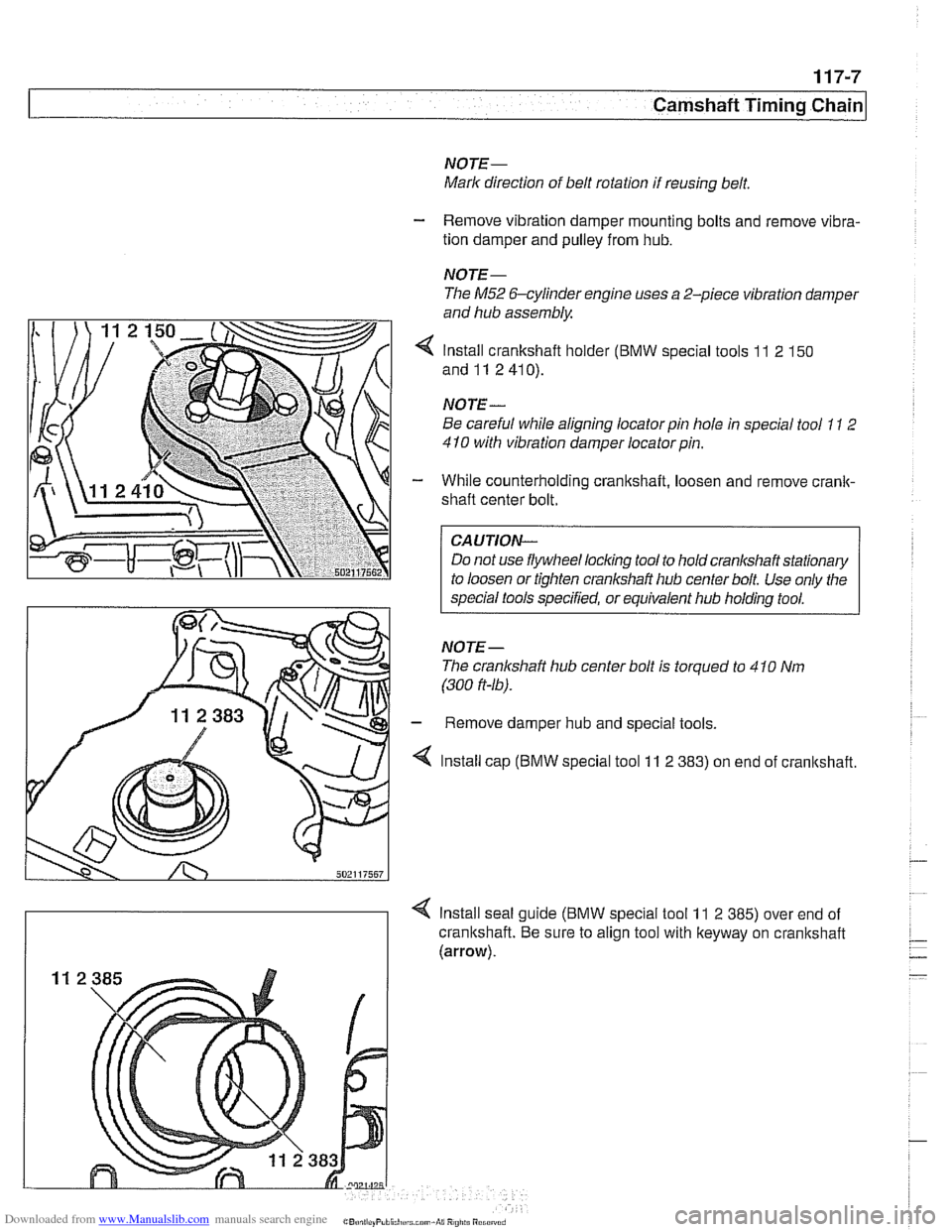

4 Install crankshaft holder (BMW special tools 11 2 150

and11 2410).

NOTE

-

Be careful while aligning locator pin hole in special tool 11 2

410 with vibration damper locatorpin.

- While counterholding crankshaft, loosen and remove crank-

shaft center bolt.

CAUTION-

Do not use flywheel locking tool to hold crankshaft stationary

to loosen or tighten crankshaft hub center bolt Use only the

special tools specified, or equivalent hub holding tool.

NOTE- The cranlshaft hub center bolt is torqued to 4

10 Nm

(300

ft-16).

- Remove damper hub and special tools.

4 Install cap (BMW special tool 11 2 383) on end of cranltshaft.

4 Install seal guide (BMW special tool 11 2 385) over end of

crankshaft. Be sure to align tool with keyway on crankshaft

(arrow).

Page 244 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-8

Camshaft Timing Chain

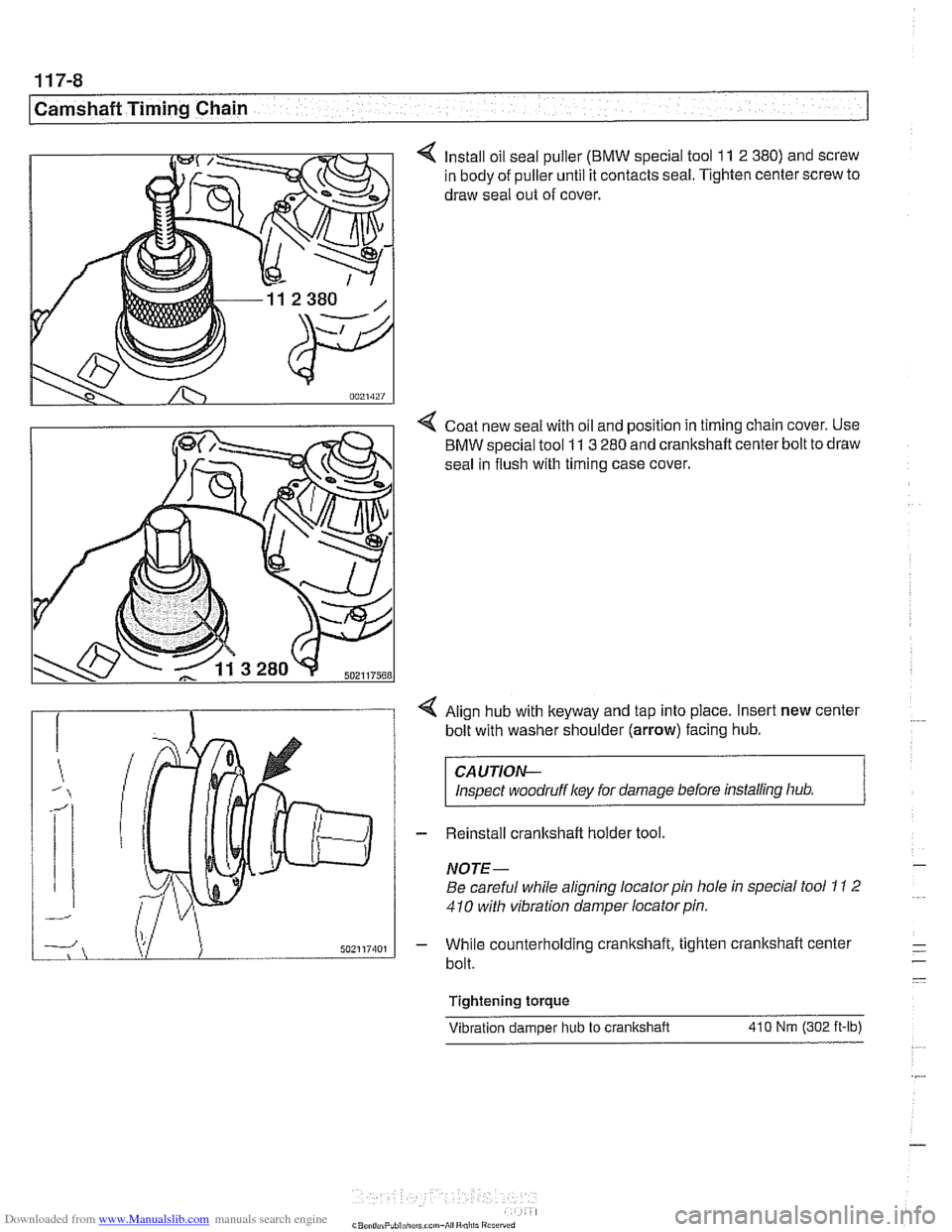

4 Install oil seal puller (BMW special tool 11 2 380) and screw

in body of puller until it contacts seal. Tighten center screw to

draw seal out of cover.

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool

11 3 280 and crankshaft center bolt to draw

seal in flush with timing case cover.

4 Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder

(arrow) facing hub.

CAUTION-

Inspect woodruffl

NOTE-

Be careful while aligning locator pin hole in special tool 1 I 2

410 with vibration damper locator pin.

- While counterholding cranltshaft, tighten crankshaft center

bolt.

Tightening torque Vibration damoer hub

to crankshaft 410 Nm (302 ft-lb)

Page 247 of 1002

![BMW 540i 1998 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center BMW 540i 1998 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center](/img/1/2822/w960_2822-246.png)

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center bolt to draw

seal in flush with timing case cover.

- Align vibration damper assembly with keyway and tap into

place. Insert new center bolt with washer.

CA

UTIOG

Inspect woodruff key for damage before installing hub

assembly.

- Install crankshaft holding tool malting sure tool locks into

place in openings in damper assembly. While counterholding

cranltshaft, tighten crankshaft center bolt.

- Attach special tools 11 8 20011 1 8 190 to damper assembly.

Counterhold damper with 11 8 190 while tightening center

bolt.

Tightening

torque

Vibration damper hub to crankshaft 410 Nm (302 it-ib)

- Installation is reverse of removal noting the following:

Install drive belts. See 020 Maintenance.

Install cooling fan. See 170 Radiator and Cooling Sys-

tem.

Crankshaft oil seal, replacing

(M62 and M62 TU engines)

- Disconnect negative (-) cable from battery

CAUTIOG

Disconnecting the battery may erase fault code(s) storedin

control module memory. Check for fault codes using spe-

cial BMW diagnostic equipment.

* Prior to disconnecting the battery, read the battery dis-

connection cautions in

001 General cautions and

warnings.

- Remove splash guard from beneath engine

- Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

NOTE

-

Cooling fan nut (32 mm wrench) has left-hand threads.

- Remove drive belts. See 020 Maintenance.

NOTE-

Marlc direction of belt rotation if reusing belt.

Page 268 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Chain 1

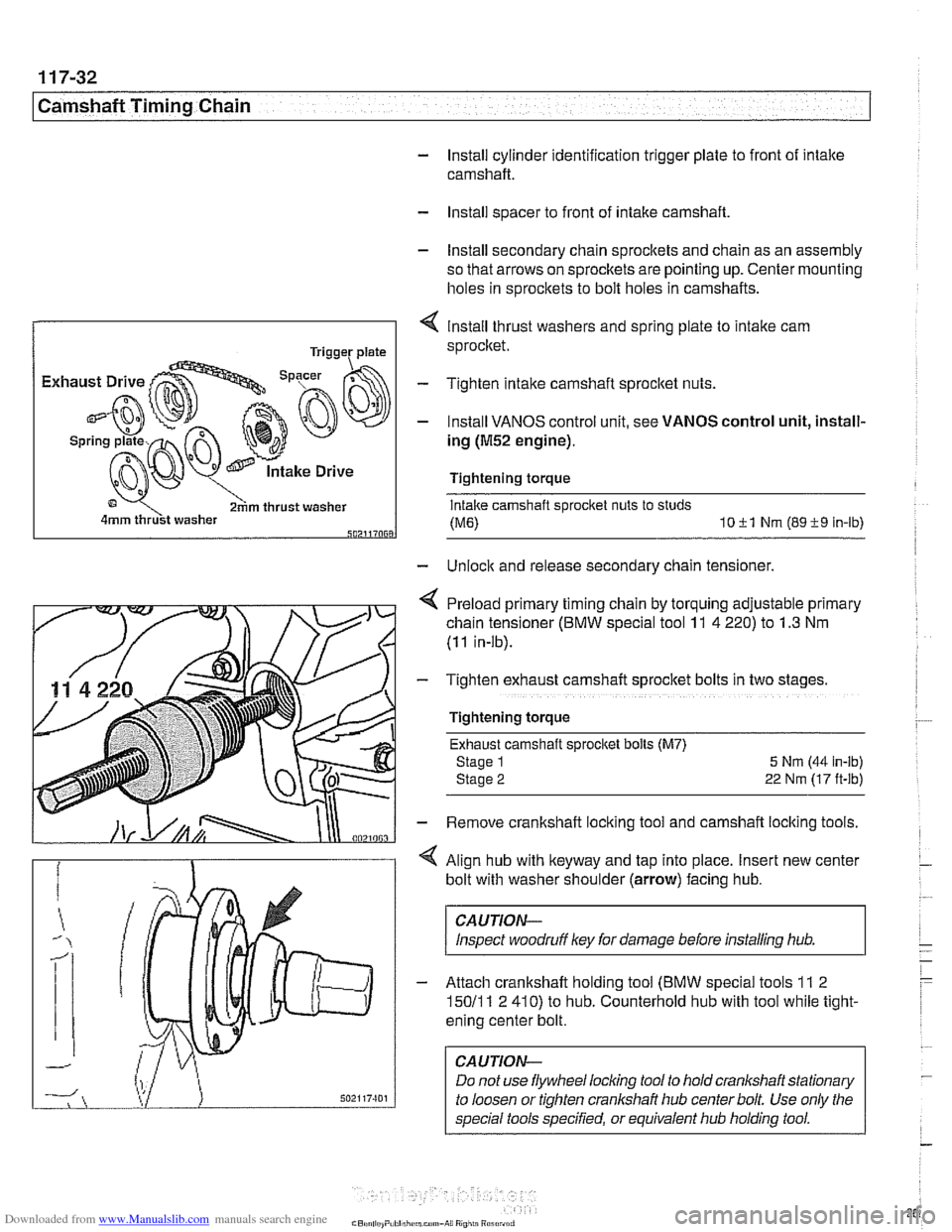

- Install cylinder identification trigger plate to front of intake

camshaft.

- Install spacer to front of intake camshaft

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

4 lnstall thrust washers and spring plate to intake cam

sprocket.

Tighten intake camshaft sprocket nuts.

- Install VANOS control unit, see VANOS control unit, install-

ing

(M52 engine).

Tightening torque

Intake camshaft sprocket nuts to studs

(ME) 1011 Nm (8919 In-lb) 502117068

- Unlock and release secondary chain tensioner,

4 Preload primary timing chain by torquing adjustable primary

chain tensioner (BMW special tool

11 4 220) to 1.3 Nm

(11 in-lb).

- Tighten exhaust camshaft sprocket bolts in two stage

Tightening torque Exhaust camshaft sprocket bolls (M7)

Stage 1

5 Nrn (44 in-lb)

Stage

2 22 Nm (17 ft-lb)

- Remove crankshaft locking tool and camshaft locking tools.

< Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder (arrow) facing hub.

CAUTION-

Inspect woodruff ley for damage before installing hub.

- Attach crankshaft holding tool (BMW special tools 11 2

15011 1 2 410) to hub. Counterhold hub with tool while tight-

ening center bolt.

CAUTION-

Do not use flywheel locling tool to hold crankshaft stationary

to loosen or tighten

cranlshaft hub center bolt. Use only the

special tools specified, or equivalent hub holding tool.

Page 286 of 1002

Downloaded from www.Manualslib.com manuals search engine

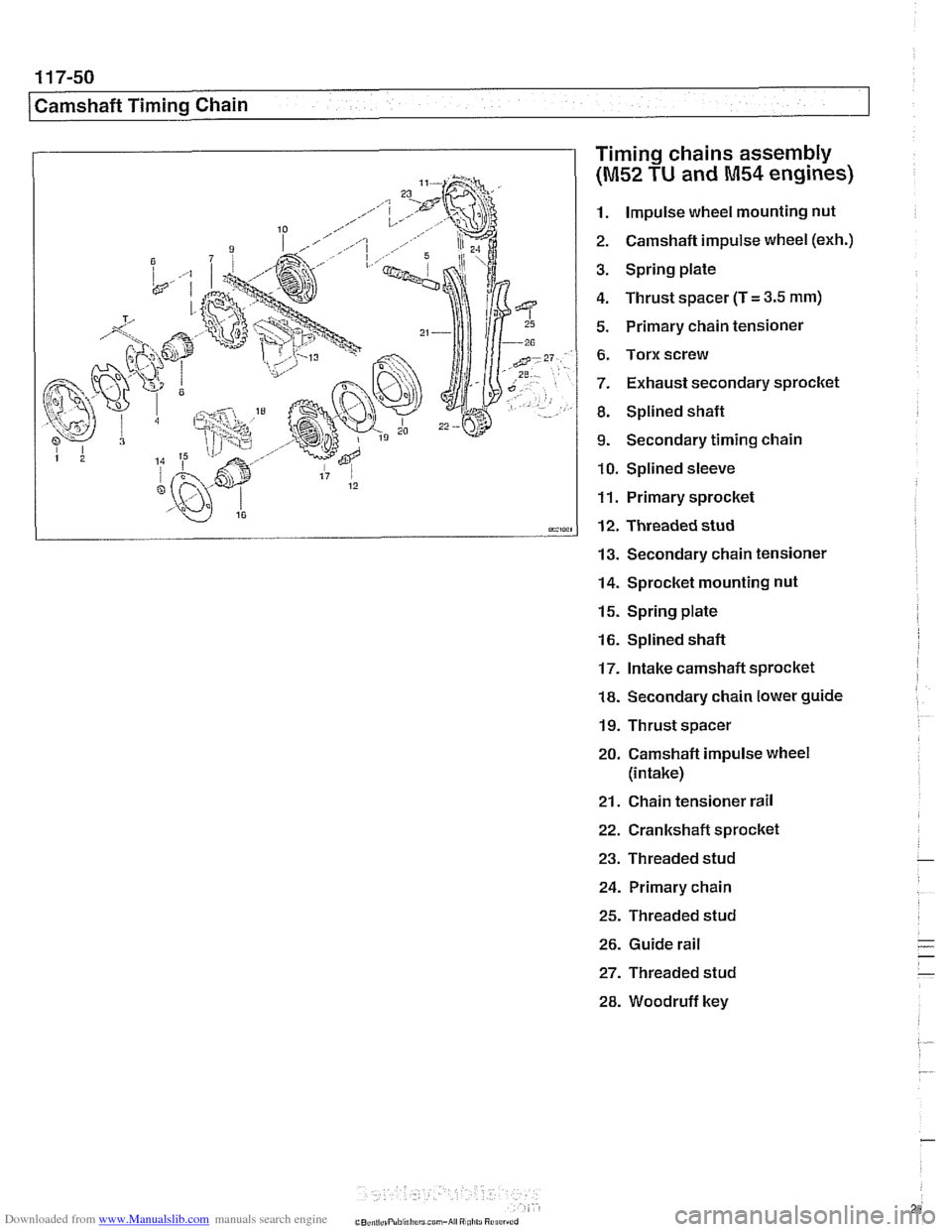

11 7-50

/Camshaft Timing Chain

Timing chains assembly

(M52 TU and M54 engines)

1. Impulse wheel mounting nut

2. Camshaft impulse wheel

(exh.)

3. Spring plate

4. Thrust spacer (T

= 3.5 mm)

5. Primary chain tensioner

6. Torx screw

7. Exhaust secondary sprocket

8. Splined shaft

9. Secondary timing chain

10. Splined sleeve

11. Primary sprocket

12. Threaded stud

13. Secondary chain tensioner

14. Sprocket mounting nut

15. Spring plate

16. Splined shaft

17. Intake camshaft sprocket

18. Secondary chain lower guide

19. Thrust spacer

20. Camshaft impulse wheel

(intake)

21. Chain tensioner rail

22. Crankshaft sprocket

23. Threaded stud

24. Primary chain

25. Threaded stud

26. Guide rail

27. Threaded stud

28. Woodruff key

Page 293 of 1002

Downloaded from www.Manualslib.com manuals search engine

... -.

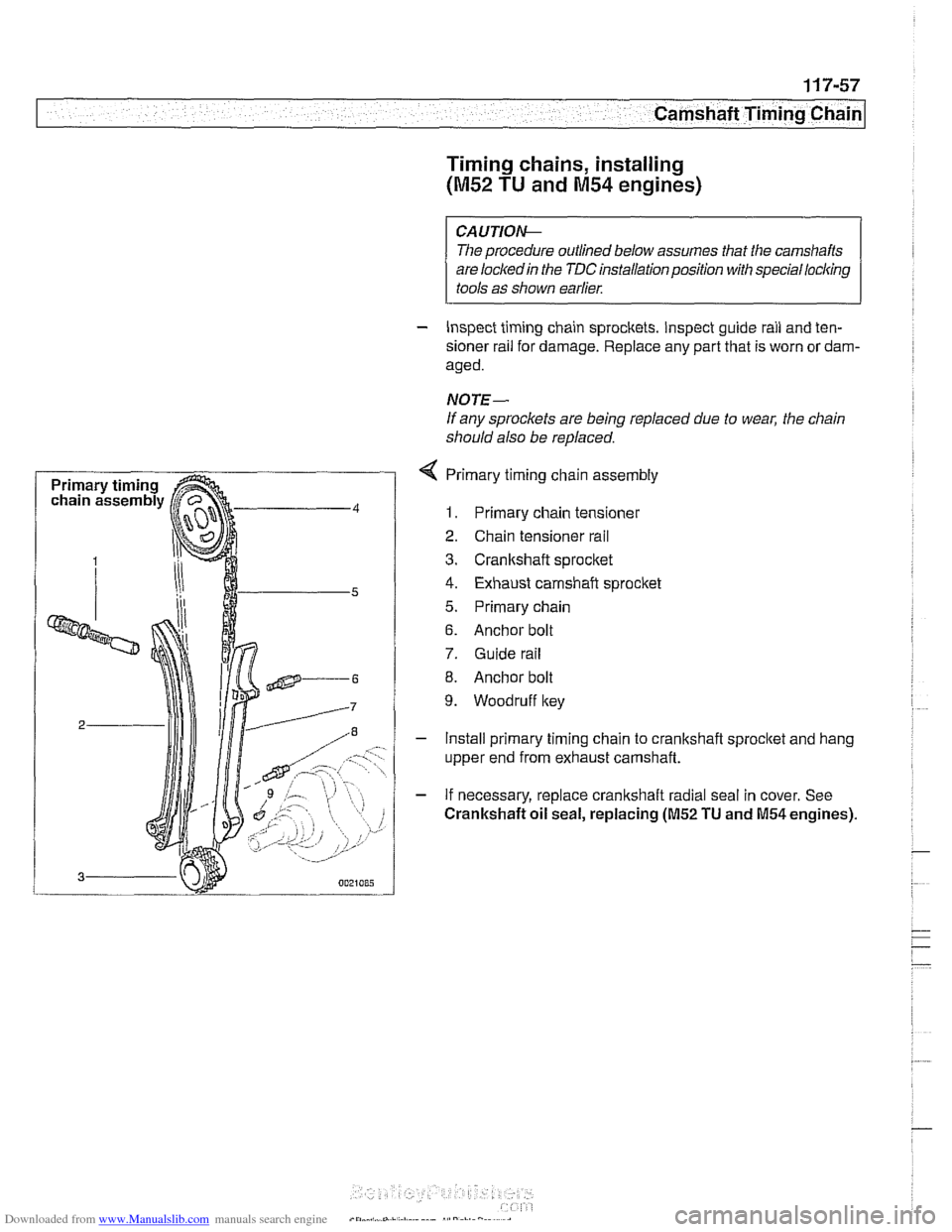

rpp- --- Camshaft Timing Chain1

Timing chains, installing

(M52 TU and M54 engines)

CAUTIOI\C

The procedure outlined below assumes that the camshaits

are lockedin the

TDC installation position with speciallocling

tools as shown earliel:

- inspect timing chain sprockets. Inspect guide rail and ten-

sioner rail for damage. Replace any part that is worn

or dam-

aged.

NOTE-

If any sprockets are being replaced due to wear, the chain

should also be replaced.

4 Primary timing chain assembly

1. Primary chain tensioner

2. Chain tensioner rail

3. Cranltshaft sprocket

4. Exhaust camshaft sprocket

5. Primary chain

6. Anchor bolt

7. Guide rail

8. Anchor bolt

9. Woodruff key

- Install primary timing chain to crankshaft sprocltet and hang

upper end from exhaust camshaft.

- If necessary, replace crankshaft radial seal in cover. See

Crankshaft oil seal, replacing (M52 TU and M54 engines).

Page 294 of 1002

Downloaded from www.Manualslib.com manuals search engine

(camshaft Timing Chain

- To install lower timing case cover:

- Clean cover and cylinder block sealing surfaces

Use new

gaskets and coolant pipe O-ring.

Remove timing chain cover dowel pins from engine block.

Drive timing cover dowels in until they just protrude slightly

from sealing surface.

Apply a small bead of silicon sealer (Three Bond 1209

63

or equivalent) to corners of cylinder head where timing

cover meets cylinder head and engine block.

Tap cover into position until firmly seated.

lnstall all bolts hand tight, including two Torx bolts from

above.

Install secondary chain lower guide.

Tighten cover mounting bolts alternately and in stages.

Tightening torque

Lower timing cover to cylinder

bloclc (M6) 10 Nrn (89 in-lb)

- Install oil pan with new gasket. See 119 Lubrication Sys-

tem.

Tightening torque

Oil pan

to engine bloclc (M6)

8.8 grade

10.9 grade 10 Nrn (89 in-lb)

12 Nm

(9 ft-lb)

- Align damper assembly with lteyway and tap into place. In-

sert new center bolt with washer.

CAUTION-

Inspect woodruff key for damage before installing hub

assembly.

- Attach special tools 11 8 20011 1 8 190 to damper assembly.

Counterhold damper with

11 8 190 while tightening center

bolt.

CAUTION-

Do not use BMW special tool 1 I 2 300 to hold crankshaft

stationary to tighten cranl(shaft hub center bolt. Use only

the special tools specified, or equivalent hub holding tool.

Have a second person hold special tool

11 8 190 while

tightening center crankshaft bolt.

Tightening torque Crankshaft hub to crankshaft 410 Nrn

(300

ft-lb)

Page 358 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

ignition System

Disabling ignition system

The ignition system operates in a lethal voltage range and

should be disabled any time engine service or repair work is

being done that requires the ignition to be switched on.

The engine management system can be disabled by remov-

ing the DME main relay. The relay is located in the electronics

box (E-box) in the left rear of the engine

compartment, be.

neath the interior microfilter housing.

CAUTION- Relay locations may

vary. Use care when identifying relays.

See

610 Electrical Component Locations.

Checking for spark

CAUTION-

If

a spark test is done incorrecth damage to the Engine Con-

trol Module

(ECM) or the ignition coils may result.

NOTE-

Spark plug replacement is covered in 020 Maintenance.

Check~ng for spark is d~fflcult on englnes wlth d~str~butorless

ignition systems.

Try removing the spark plugs and inspecting for differences between them.

A poor-firing plug may be wet with fuel and/or ~. - ~

black and sooty, but not always. If a coil is not operating, the

engine management system will electrically disable the fuel

injector to that cylinder. The key is to look for differences be-

tween cylinders.

Ignition coil assembly, testing and

replacing

C4 UTION-

Use a digital multimeter for the following tests. I

- Remove plastic engine cover from top of valve cover by pry-

ing off bolt covers and removing cover mounting bolts.

- Raise car slowly while constantly checking position of jack

and car.

- Disconnect harness connector from coil. Connect multimeter

between terminal 15

(+) in connector and ground.

4 Terminal identification are typically molded into connector. In

photo, terminals are from left to right: 1,

4a, 15.

Page 369 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

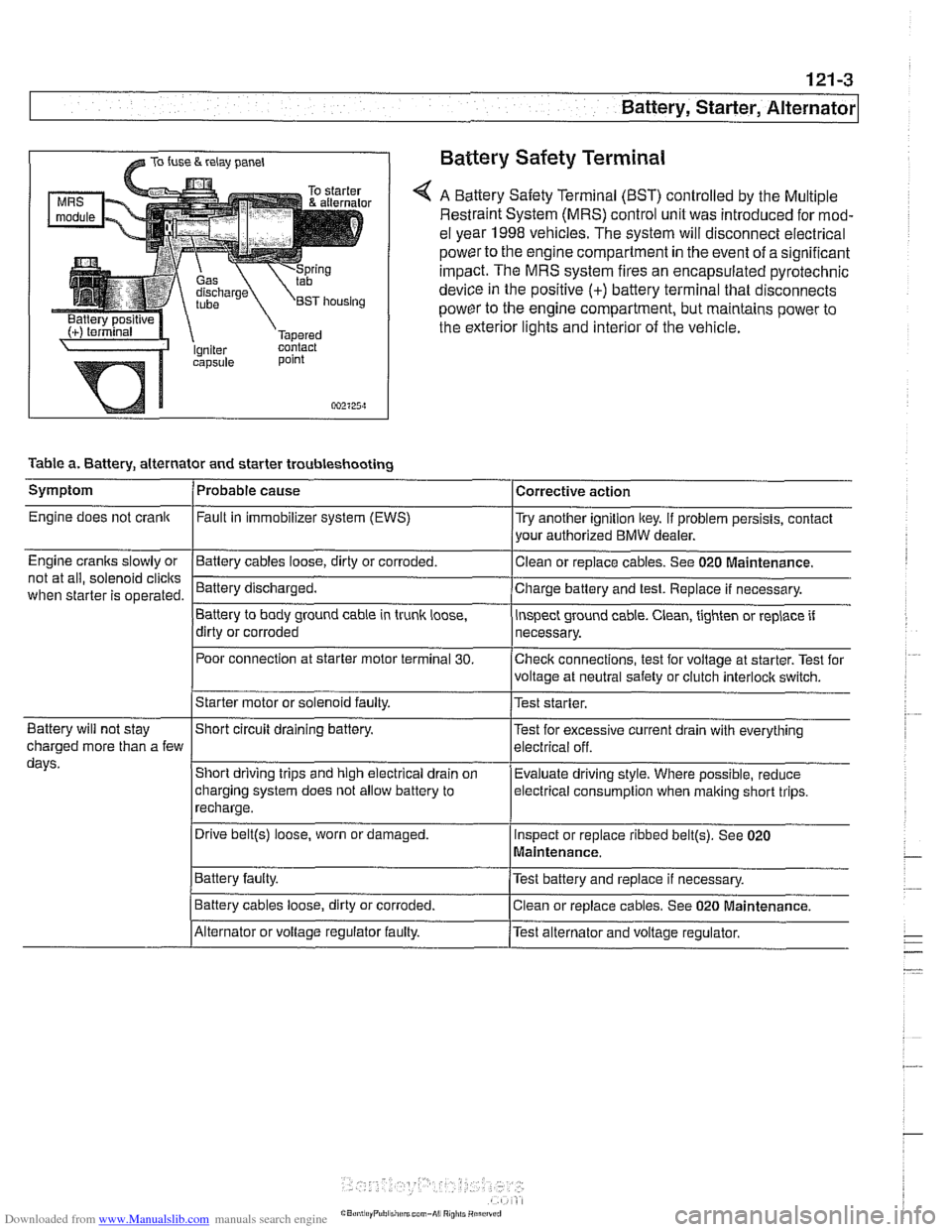

@ TO fuse & relay panel Battery Safety Terminal

A Battery Safety Terminal (BST) controlled by the Multiple

Restraint System (MRS) control unit was introduced for mod-

el year 1998

vehicles. The system will disconnect electrical

power to the engine compartment

in the event of a significant

impact. The MRS system fires an encapsulated pyrotechnic

device

in the positive (+) battery terminal that disconnects

power to the engine compartment, but maintains power to

the exterior lights and interior of the vehicle.

point

002125~1

Table a. Battery, alternator and starter troubleshooting

1-

/Starter motor or solenoid faulty. l~est starter.

Symptom

Engine does not crank

Engine cranks slowly or

not at all, solenoid

clicits

when starter is operated.

I I

Battery will not stay IShort circuit draining battery. l~est for excessive current drain with everything

Probable cause

Fault

in immobilizer system (EWS)

-Clean Battery cables loose, dirty or corroded.

Battery discharged.

Battery to body ground cable in trunk

loose,

dirty or corroded

Poor connection at starter motor terminal

30.

Corrective action

Try another ignition key. If problem persists, contact

your authorized BMW dealer.

or replace cables. See 020

~aintenance.

Charge battery and test. Replace if necessary.

inspect ground cable. Clean, tighten or replace if

necessary.

Checlc connections, test for voltage at starter. Test for

voltage at neutral safety or clutch

interloclc switch.

charged more than a few

days.

I~atter~ faulty. /Test battery and replace if necessary.

Short driving trips and high electrical drain

on

charging system does not allow battery to

recharge.

. I

I Battery cables loose, dirty or corroded. Iclean or replace cables. See 020 Maintenance.

Evaluate driving

style. Where possible, reduce

electrical

consumption when malting short trips.

Drive

belt@) loose, worn or damaged.

IAlternator or voltage regulator faulty. /Test alternator and voltage regulator.

Inspect

or replace ribbed

belt@). See 020

Maintenance.