alignment BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

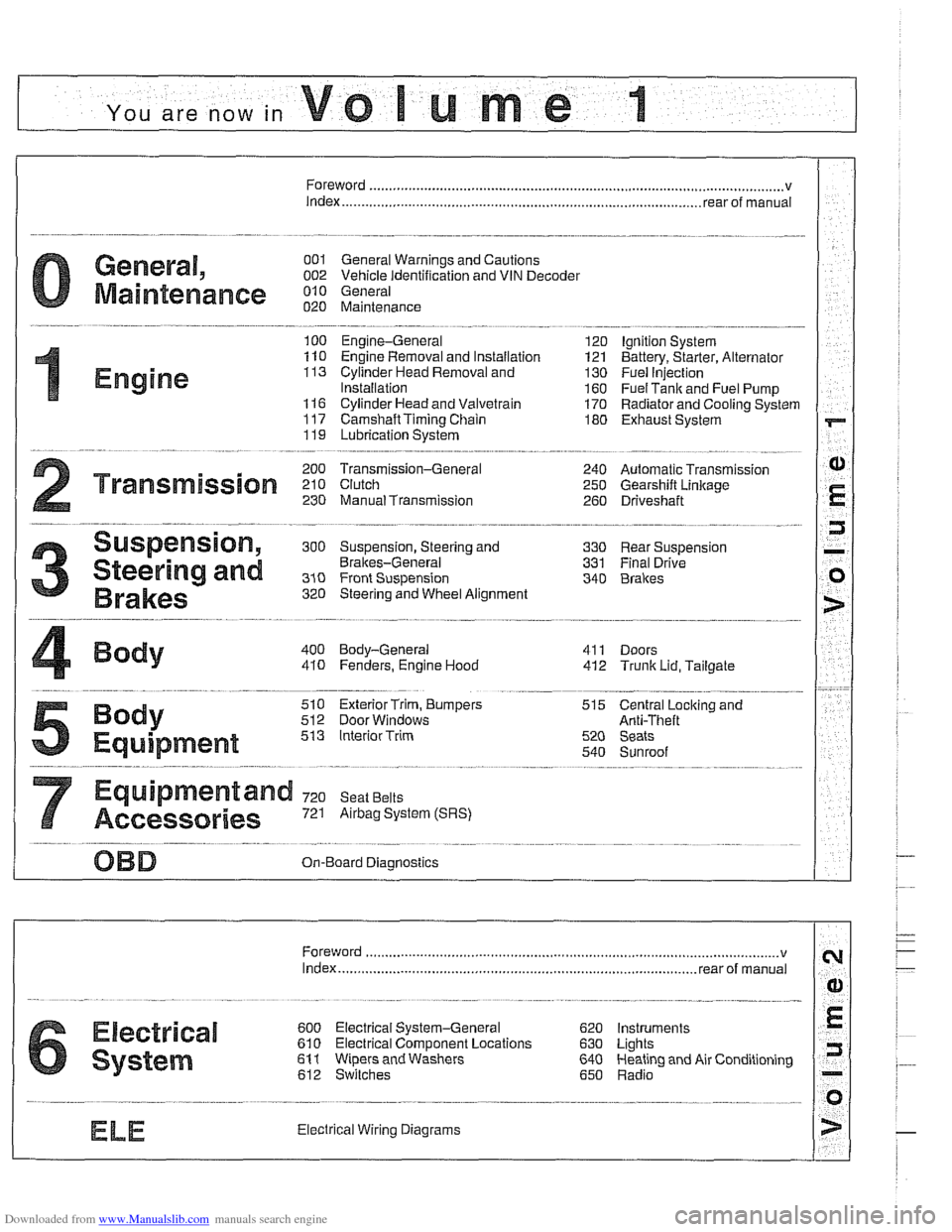

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 18 of 1002

Downloaded from www.Manualslib.com manuals search engine

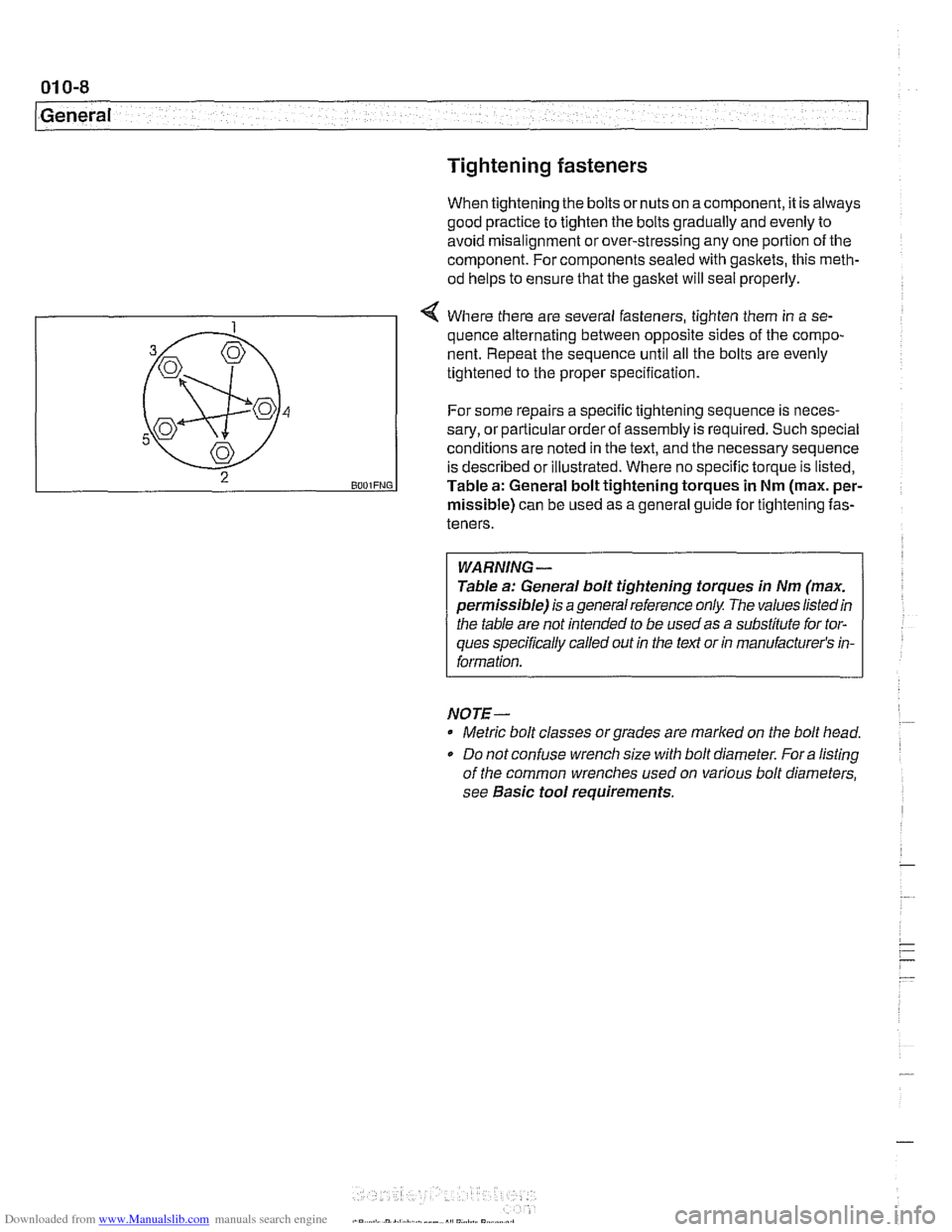

General Tightening fasteners

When tightening the bolts ornuts on acomponent, it is always

good practice to tighten the bolts gradually and evenly to

avoid misalignment or over-stressing any one portion of the

component. For components sealed with gaskets, this meth-

od helps to ensure that the

gasket will seal properly.

WARNING

-

Table a: General bolt tightening torques in Nm (max.

permissible) is

a general reference only The values listedin

the table are not intended to be usedas a substitute for tor-

ques specifically called out in the text or in manufacturer's in-

formation.

4 Where there are several fasteners, tighten them in a se-

NOTE-

* Metric bolt classes or grades are rnarlced on the bolt head.

* Do not confuse wrench size with bolt diameter. Fora listing

of the common wrenches used on various bolt

diameters,

see Basic tool requirements.

2 BOO~FNG

quence alternating between opposite sides of the compo-

nent. Repeat the sequence until all the bolts are evenly

tightened to the proper specification.

For some repairs a specific tightening sequence is

neces-

sary, or particular order of assembly is required. Such special

conditions are noted in the text, and the necessary sequence

is described or illustrated. Where no specific torque is listed,

Table

a: General bolt tightening torques in Nm (max. per-

missible) can be used as a general guide for tightening fas-

teners.

Page 39 of 1002

Downloaded from www.Manualslib.com manuals search engine

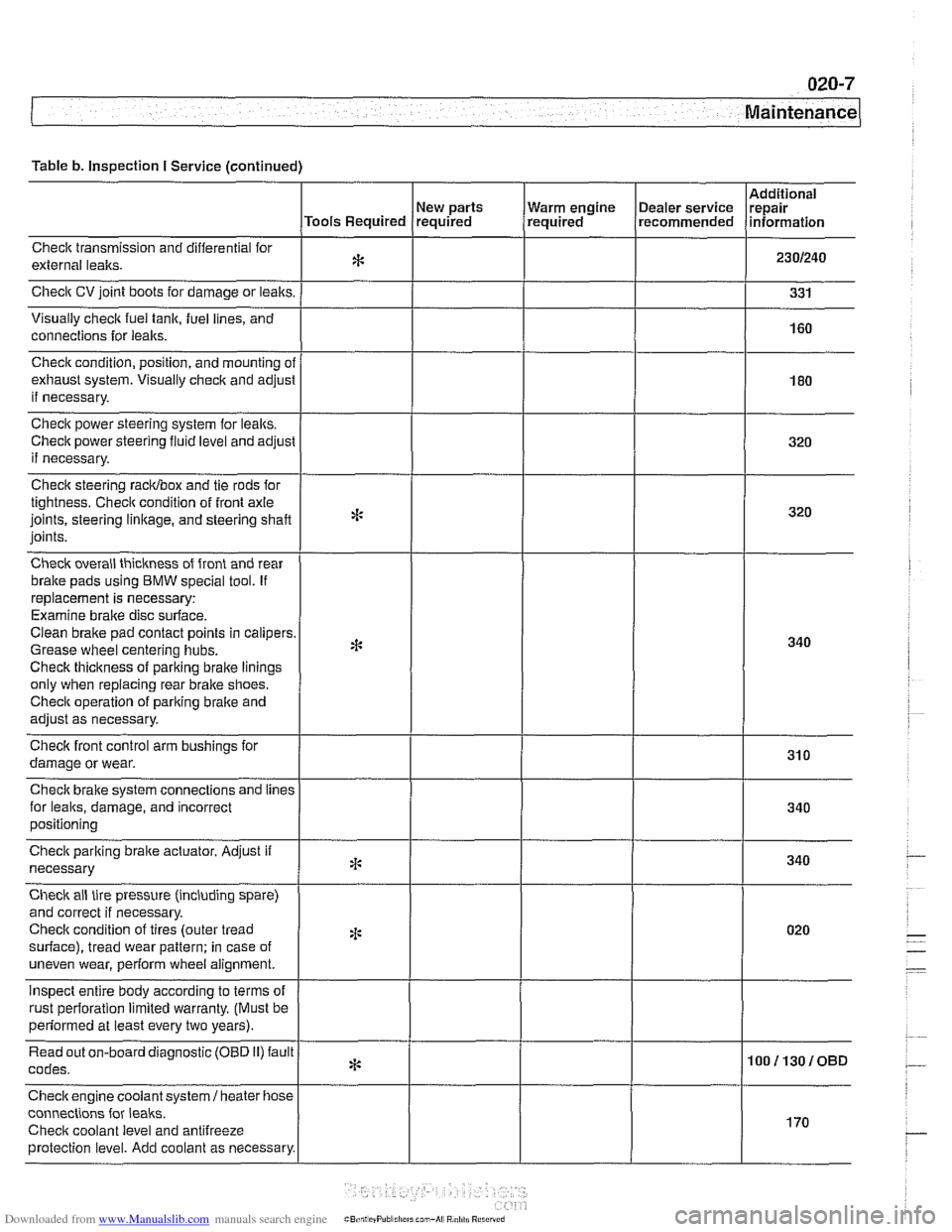

Table b. Inspection I Service (continued)

Checlt transmission and differential for

external lealts.

Check CV joint boots for damage or leaks.

Visually

check fuel tank, fuel lines, and

connections for

leaks.

New parts

Tools Required required

Check condition, position, and mounting

ol

exhaust system. Visually check and adjusl

if necessary.

Check power steering system for lealts.

Check power steering

fluid level and adjust

if necessary.

Check steering racidbox and tie rods for

tightness. Checit condition of front axle

joints, steering

linkage, and steering shaft

joints.

Check overall thickness of front and rear

bralte pads using

BMW special tool. If

replacement is necessary:

Examine brake disc surface.

Clean brake pad contact points in calipers

Grease wheel centering hubs.

Checlt thickness of parking brake linings

only when replacing rear brake shoes.

Checit operation of pariting brake and

adjust as necessary.

Checlt front control arm bushings for

damage or wear.

Check brake system connections and

lines

for leaks, damage, and incorrect

positioning Warm

engine

(~ealer service Irepair , required recommended lnformat~on

Check parking braite actuator. Adjust if

necessary

Check ail tire pressure (including spare)

and correct if necessary.

Checlt condition of tires (outer tread

surface), tread wear pattern: in case of

uneven wear, perform wheel alignment.

inspect entire body according to terms of

rust oerforation limited warrantv. (Must be

*:

4:

2 ~ perfdrmed at least every two years). I

Read out on-board diagnostic (OBD 11) fault

codes.

Checkengine coolant

system1 heater hose

connections for

leaks.

Checit coolant level and antifreeze

protection level. Add coolant as necessary.

* 100113010BD

I

170

Page 59 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-. -

Maintenance

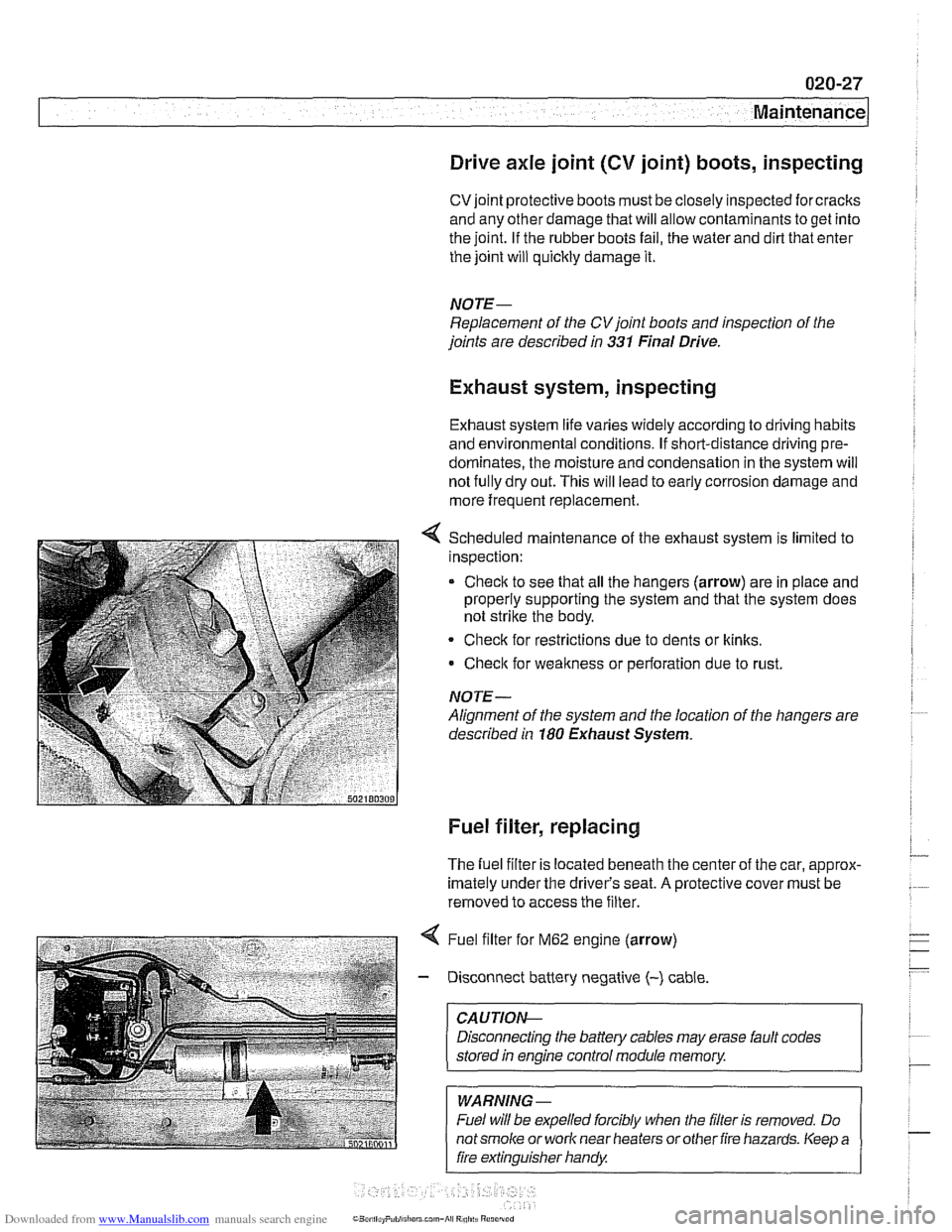

Drive axle joint

(CV joint) boots, inspecting

CVjoint protective boots must be closely inspected forcracks

and any other damage that will allow contaminants to get into

the joint.

If the rubber boots fail, the water and dirt that enter

the joint will quickly damage it.

NOTE-

Replacement of the CVjoint boots and inspection of the

joints are described

in 331 Final Drive.

Exhaust system, inspecting

Exhaust system life varies widely according to driving habits

and environmental conditions. If short-distance driving pre-

dominates, the moisture and condensation in the system will

not fully dry out. This will lead to early corrosion damage and

more frequent replacement.

Scheduled maintenance of the exhaust system is limited to

inspection:

* Check to see that all the hangers (arrow) are in place and

properly supporting the system and that the system does

not strike the body.

Check for restrictions due to dents or

kinlts,

Check for weakness or perforation due to rust.

NOTE-

Alignment of the system and the location of the hangers are

described in

180 Exhaust System.

Fuel filter, replacing

The fuel filter is located beneath the center of the car, approx-

imately under the driver's seat.

A protective cover must be

removed to access the filter.

4 Fuel filter for M62 engine (arrow)

- Disconnect battery negative (-) cable

CAUTIOI\C

Disconnecting the battery cables may erase fault codes

stored

in engine control module memory.

WARNING -

Fuel will be expelled forcibly when the filter is removed. Do

notsmoke or work near heaters orother fire hazards. Keep a

fire extinguisher handy

Page 62 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-30

Maintenance

fluid use and the most-up-to-date information regarding

transmission operating fluids.

The automatic transmission is not equipped with a dipstick.

Therefore, checking the ATF level is an involved procedure

which includes measuring and maintaining a specified ATF

temperature during the checking procedure.

For more complete

ATF service information, including

checking

ATF level and ATF filter replacement procedures,

see

240 Automatic Transmission.

Transmission service, manual

Manual transmission service consists of inspecting for leaks

and checking the fluid. Evidence of transmission leaks is

like-

ly to be seen around the driveshaft mounting flange and at the

bottom of the bellhousing.

NOTE-

For more information on identifying oil

leaks and their

causes, see 230 Manual Transmission and210 Clutch.

Transmission fluid, checking and filling

(manual transmission)

Tne manual transmss'on inslalleo 'n rne E39 models s f;lled

with a special liierime iluid (ivlTF-LT-I). oi. ordinarily

does

not need to be changed.

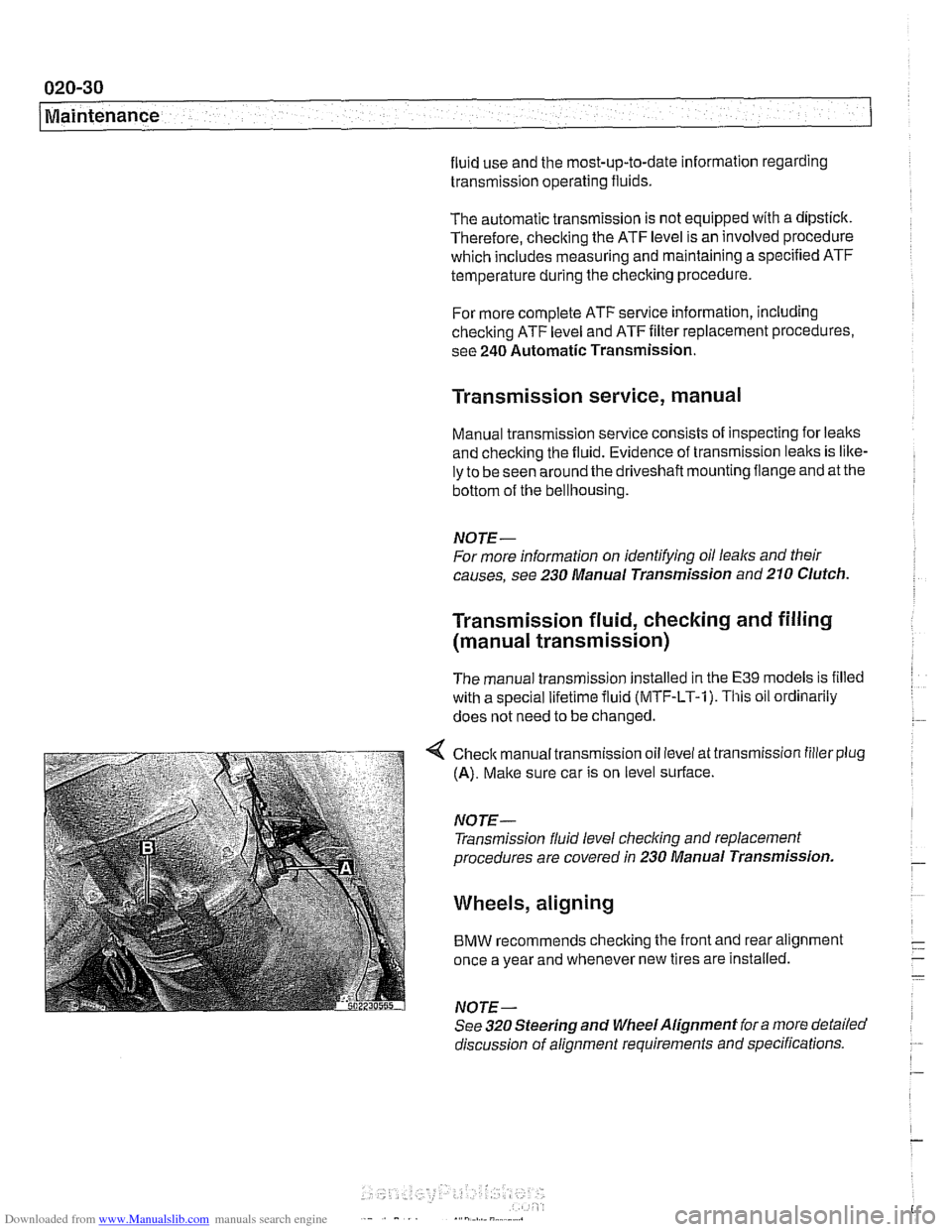

< Check manual transmission oil level at transmission filler plug

(A). Make sure car is on level surface.

NOTE- Transmission fluid level

checking and replacement

procedures are covered in 230 Manual Transmission.

Wheels, aligning

BMW recommends checking the front and rear alignment

once a year and whenever new tires are installed.

NOTE-

See 320 Steering and Wheel Alignment for a more detailed

discussion of alignment requirements and specifications.

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

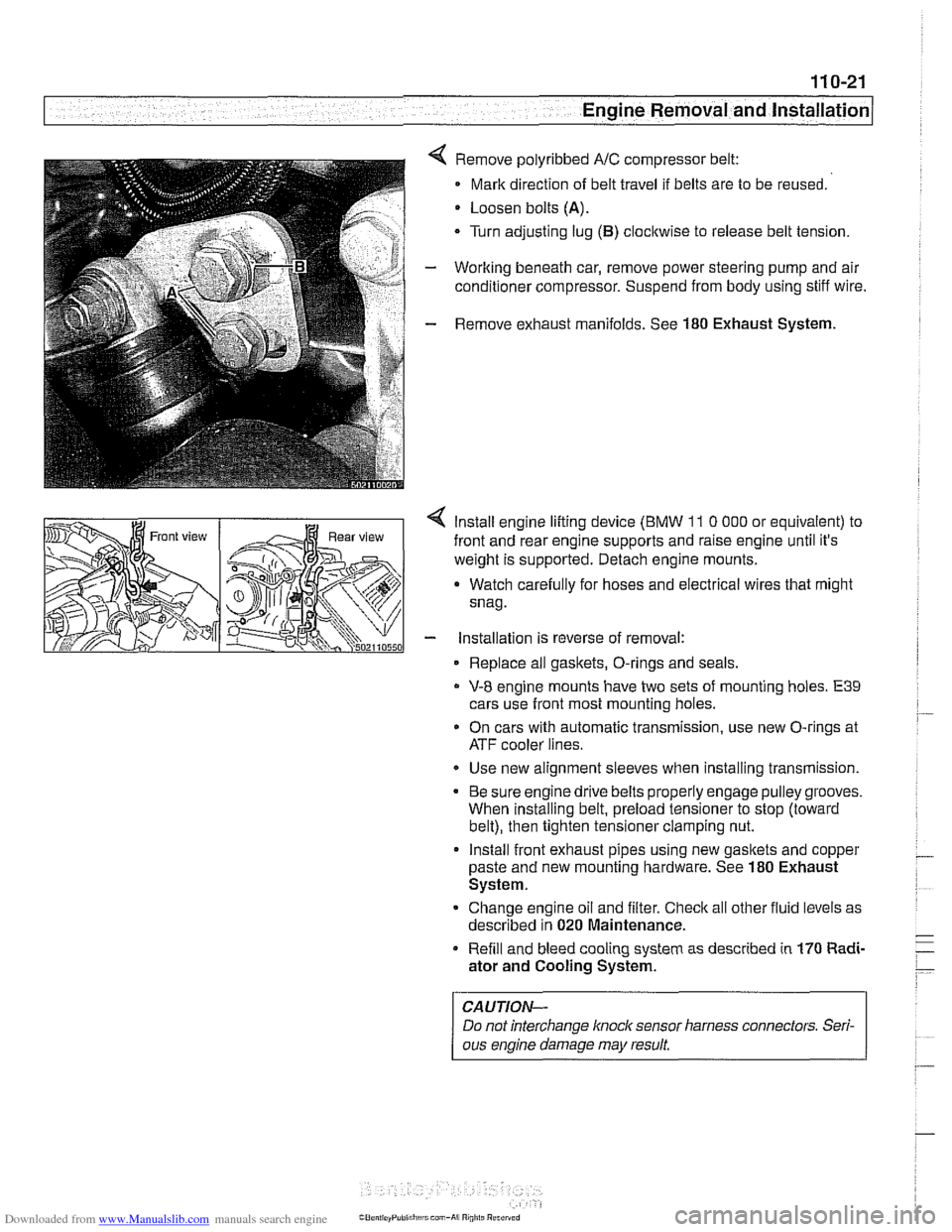

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 255 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

VANOS control unit, installing (M52 engine)

CAUTION-

Incorrect installation of the VANOS control unit may result in

damage to the engine.

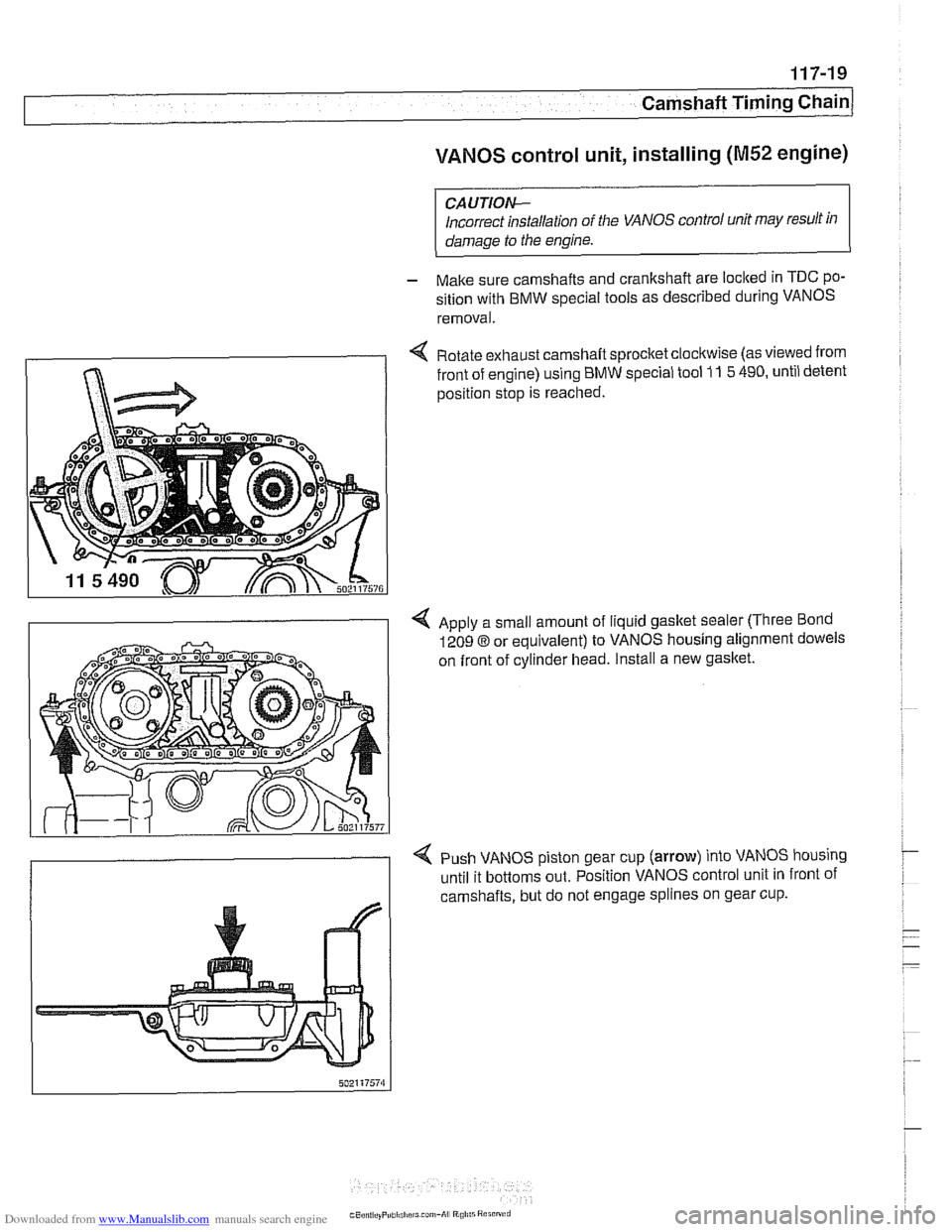

- Make sure camshafts and crankshaft are loclted in TDC po-

sition with BMW special tools as described during VANOS

removal.

< Rotate exhaust camshaft sprocket clocltwise (as viewed from

front of engine) using BMW special tool

11 5 490, until detent

position stop is reached.

4 Apply a small amount of liquid gasket sealer (Three Bond

1209

8 or equivalent) to VANOS housing alignment dowels

on front of cylinder head. Install a new

gasket.

< Push VANOS piston gear cup (arrow) into VANOS housing

until it bottoms out. Position VANOS control unit in front of

camshafts, but do not engage splines on gear cup.

Page 322 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-2

Lubrication System

This repair group covers lubrication system troubleshooting

as well as oil pan removal and oil pump replacement.

In 6-cylinder models, removal of the oil pan requires the re-

moval of the exhaust system and some front suspension

components. Those procedures are fully covered in:

180 Exhaust System

210 Clutch

230 Manual Transmission

0 240 Automatic Transmission

310 Front Suspension

320 Steering and Wheel Alignment

NOTE-

Oil change procedure and oil filter replacement are covered

in

020 Maintenance.

CAUTIOG

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to check oil bolts and

nut tightness whenever the

oilpump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

Band torque to specifications.

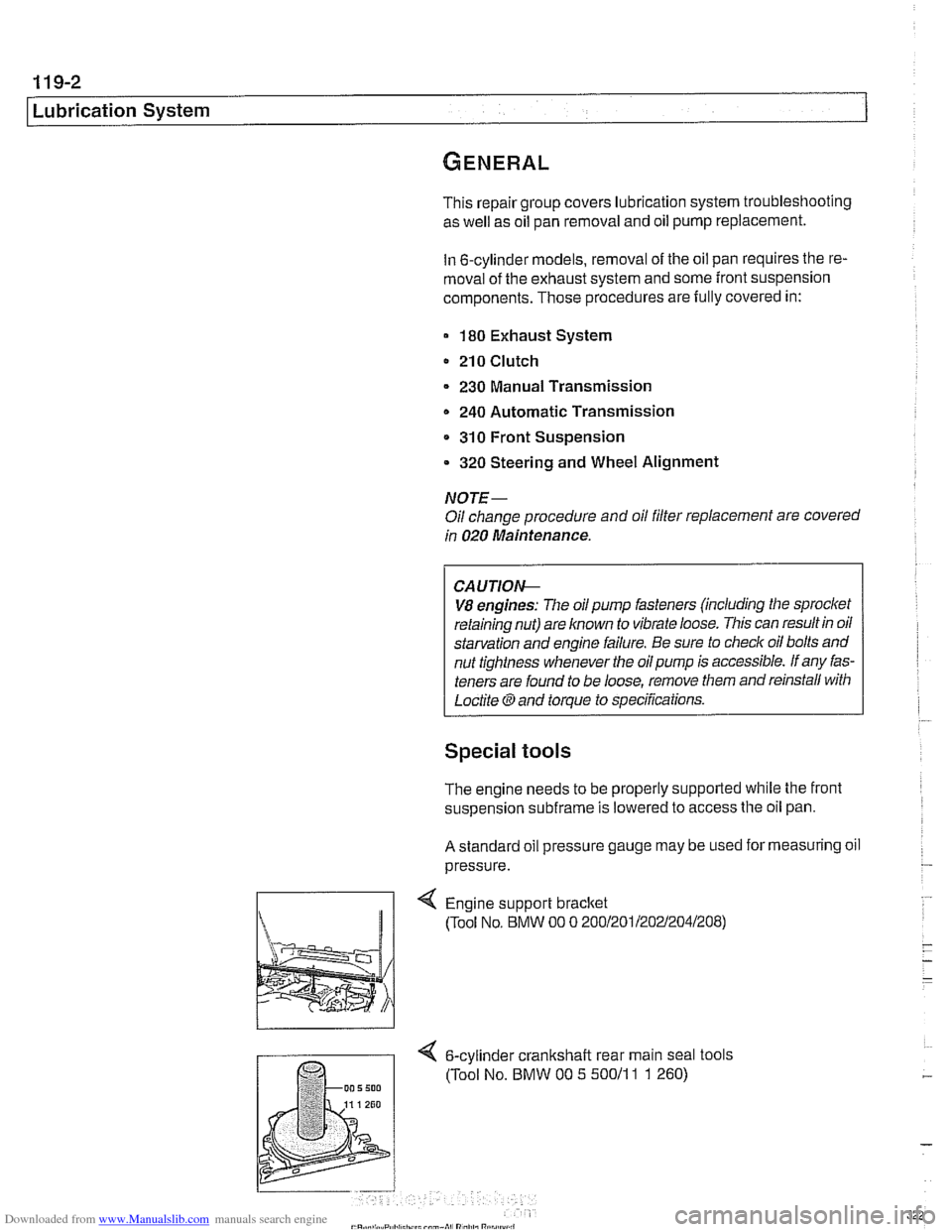

Special tools

The engine needs to be properly supported while the front

suspension

subframe is lowered to access the oil pan.

A standard oil pressure gauge may be used for measuring oil

pressure.

Engine support bracket

(Tool No, BMW 00 0 20012011202~2041208)

4 6-cylinder crankshalt rear main seal tools

(Tool No. BMW 00 5 50011

1 1 260)

Page 331 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication system/

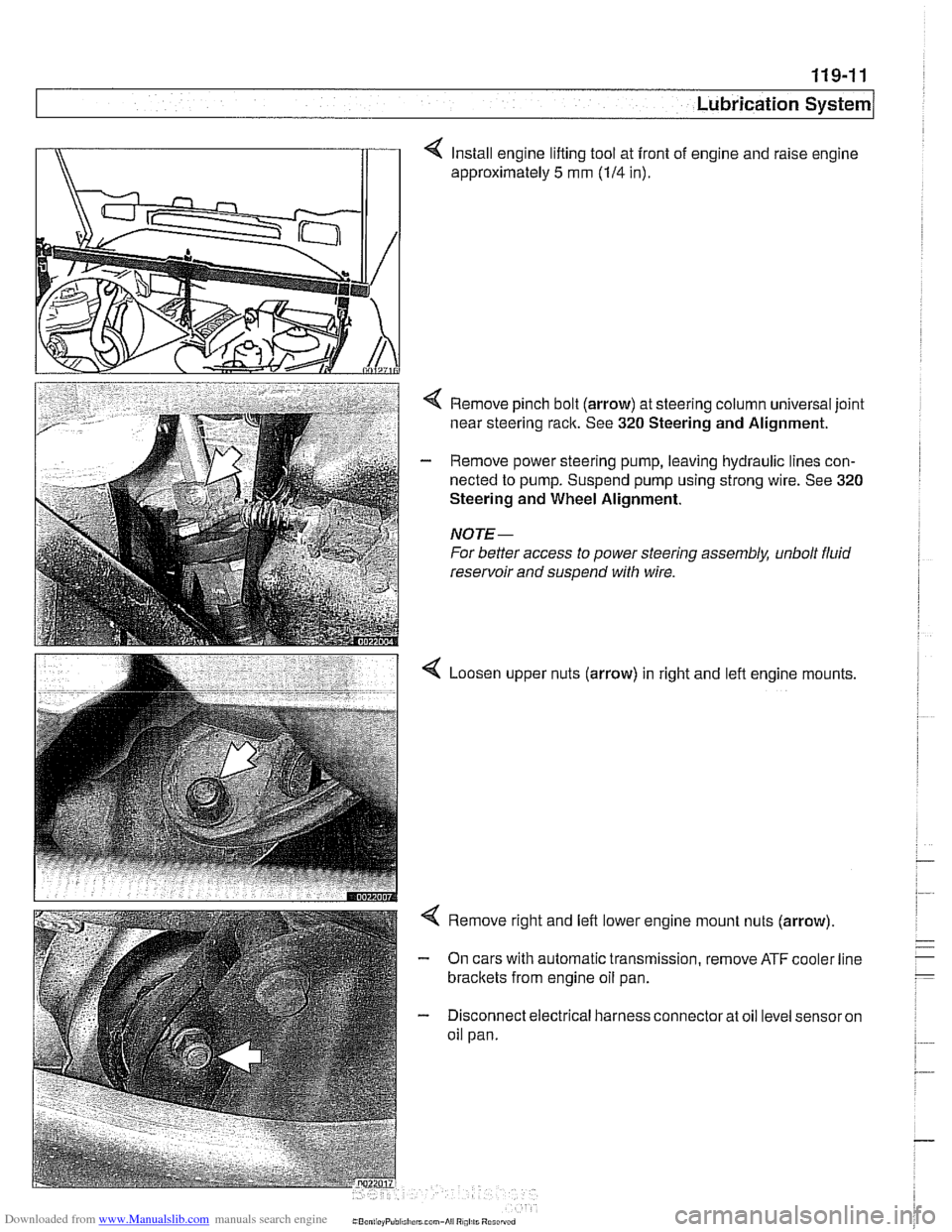

4 Install engine lifting tool at front of engine and raise engine

approximately

5 mm (114 in).

< Remove pinch bolt (arrow) at steering column universal joint

near steering rack. See

320 Steering and Alignment.

- Remove power steering pump, leaving hydraulic lines con-

nected to pump. Suspend pump using strong wire. See

320

Steering and Wheel Alignment.

NOTE-

For better access to power steering assembly, unbolt fluid

reservoir and suspend with wire.

Loosen upper nuts (arrow) in right and lefl engine mounts,

< Remove right and left lower engine mount nuts (arrow)

- On cars with automatic transmission, remove ATF cooler line

brackets from engine oil pan.

- Disconnect electrical harness connector at oil level sensor on

oil pan.

Page 333 of 1002

![BMW 540i 2000 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

-- . - .. . - Lubrication system]

- Remainder of installation is reverse of removal.

Replace self-locking nuts when reinstalling front BMW 540i 2000 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

-- . - .. . - Lubrication system]

- Remainder of installation is reverse of removal.

Replace self-locking nuts when reinstalling front](/img/1/2822/w960_2822-332.png)

Downloaded from www.Manualslib.com manuals search engine

-- . - .. . - Lubrication system]

- Remainder of installation is reverse of removal.

Replace self-locking nuts when reinstalling front suspen-

sion components.

Use new oil dipstick tube sealing O-ring.

After adding engine oil, start and run engine. Raise engine

speed to 2,500 rpm until oil pressure warning light goes out

(about 5 seconds).

NOTE-

BMW does not specify a front end alignment following this

procedure.

Tightening torques Front subfrarne to body rail

(M12, use new bolts)

8.8 grade

10.9 grade

12.9 grade 77 Nrn

(57 ft-lb)

105 Nrn (77 ft-lb)

110 Nrn (81 ft-lb)

Stabilizer bar link to stabilizer bar

65 Nrn (48 ft-lb)

Steering shaft universal joint clamping bolt

(use new bolt)

19 Nrn (14 it-lb)

Lower oil pan, removing and installing (V-8)

- The V-8 engine is equipped with a 2-piece oil pan. The fas-

teners in

V-8 engine oil pump assembly, including the

sprocket retaining nut, are known to loosen and fall off into

the oil pan. Be sure to install these fasteners with Loctite

O

or equivalent thread locking product and torque to specifica-

tions.

CAUTION-

It is recommended that the oil pump retaining bolts and oil

pump drive sprocket retaining nut tightening torque be

checkedany time the

oilpan is removed.

- Raise car and place securely on jack stands.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

- Remove splash shield from under engine.

- Drain engine oil

- On cars with automatic transmission, remove ATF cooler line

brackets from oil pan.