alignment BMW 540i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 337 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 19-1 7

Lubrication System

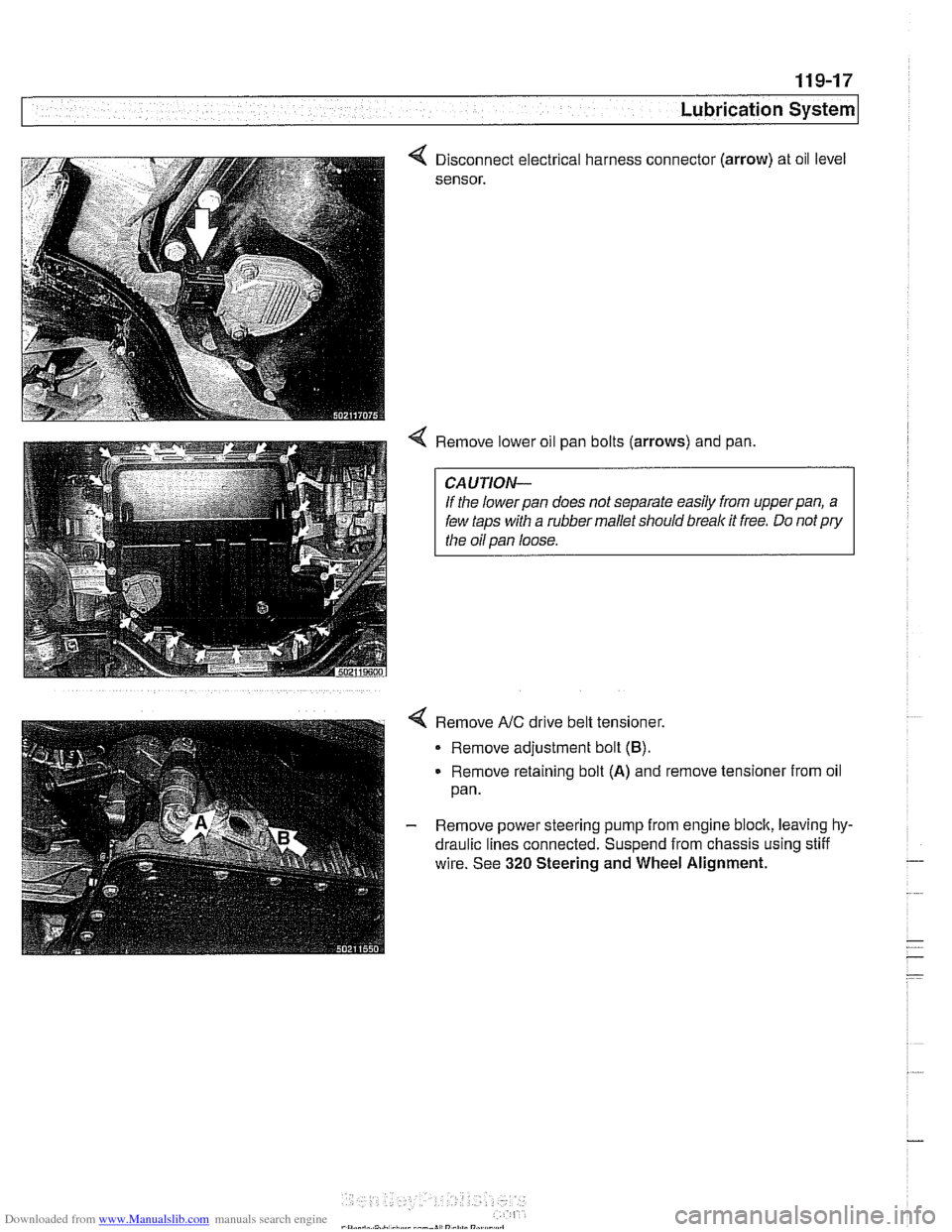

Disconnect electrical harness connect01

sensor.

. (arrow)

4 Remove lower oil pan bolts (arrows) and pan, oil

level

CAUTION-

If the lowerpan does not separate easily from upperpan, a

few taps with a rubber mallet should break it free. Do not pry

the oil pan loose.

Remove

NC drive belt tensioner.

Remove adjustment bolt

(B).

Remove retaining bolt (A) and remove tensioner from oil

pan.

- Remove power steering pump from engine block, leaving hy-

draulic lines connected. Suspend from chassis using stiff

wire. See

320 Steering and Wheel Alignment.

Page 545 of 1002

Downloaded from www.Manualslib.com manuals search engine

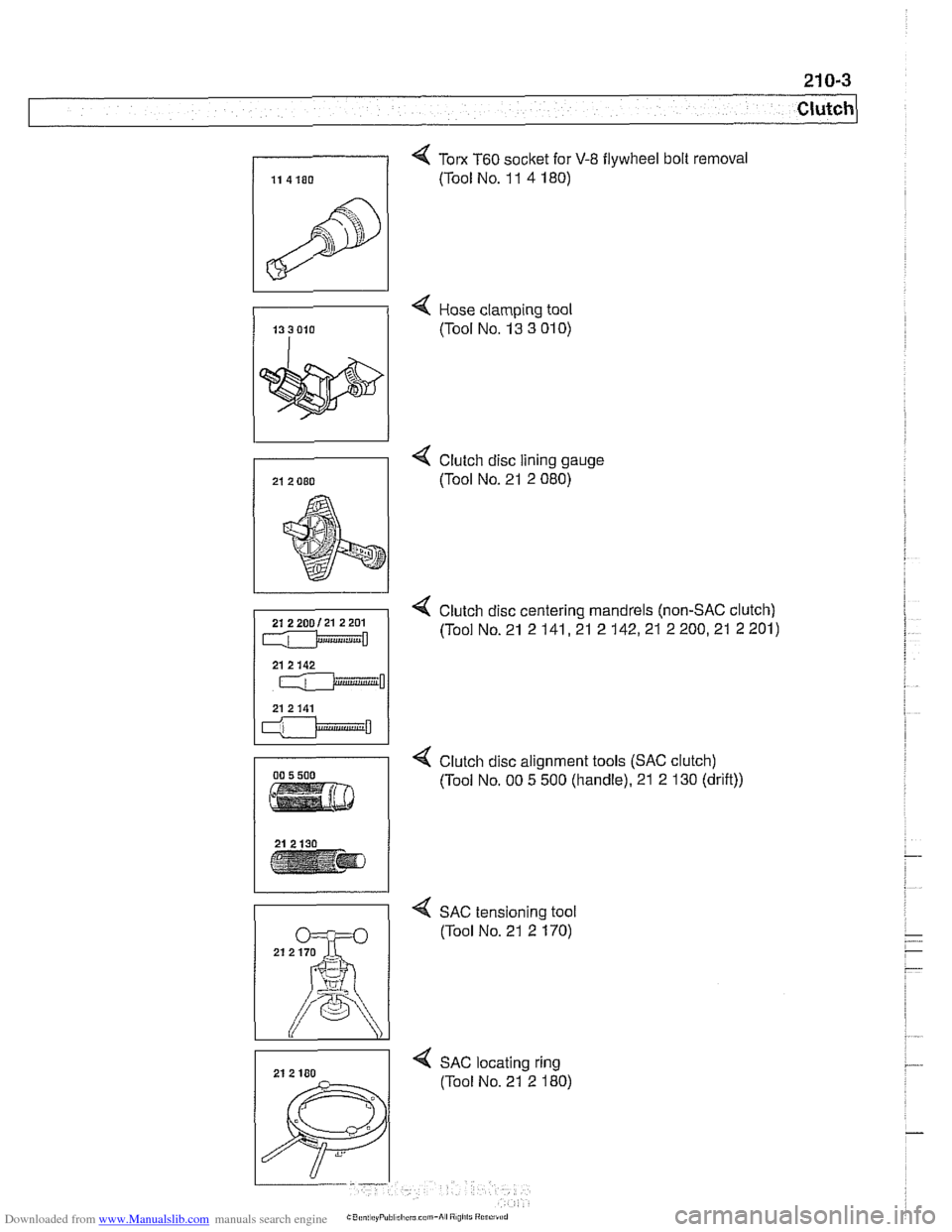

4 Tom T60 socket for V-8 flywheel bolt removal

(Tool No. 1 1 4 180)

4 Hose clamping tool

(Tool No. 13 3

01 0)

4 Clutch disc lining gauge

(Tool No. 21 2 080)

4 Clutch disc centering mandrels (non-SAC clutch)

(Tool No. 21 2

141,21 2 142,21 2 200,21 2 201)

4 Clutch disc alignment tools (SAC clutch)

(Tool No. 00 5 500 (handle). 21 2 130 (drift))

4 SAC tensioning tool

(Tool No. 21 2 170)

4 SAC locating ring

(Tool No. 21 2 180)

Page 551 of 1002

Downloaded from www.Manualslib.com manuals search engine

- Raise and safely support vehicle

WARNING-

Make sure the car is stable and well supporied at all times.

Use a professional automotive /iff orjack stands designed for

the

ournose. A floor jack is not adeouate suooort.

- If necessary, remove transmission splash shield.

- Disconnect fluid line from slave cylinder on lefl side of trans-

mission. Place pan under hose to catch dripping fluid.

4 Working underneath transmission, remove slave cylinder

mounting nuts (arrow) from clutch housing and remove

cylinder.

- Installation is reverse of removal, noting the following:

Check for wear on slave cylinder. Any wear except on tip is

caused by misalignment of clutch components.

Lightly coat

pushrod tip with molybdenum disulfide grease

(MolyltoteIB Longterm or equivalent).

. During installation be sure pushrod tip engages recess in

clutch release lever.

Fill fluid reservoir with clean fluid.

. Bleed clutch hydraulics as described earlier.

Tightening

toraues - -.

Clutch slave cylinder to transmission 22 Nm (16 R-lb)

Fluid line to slave cylinder 17 Nm (13 ft-lb)

The transmission must be removed from the engine to access

the clutch mechanical components. It is recommended that

the clutch disc, pressure plate and release bearing be re-

placed during a clutch overhaul.

Besure tocheck the bottom of the bellhousing foroil. If engine

oil is found, check for a faulty rear crankshaft main oil seal.

See

119 Lubrication for rear main seal replacement.

Clutch variations

Two versions of the clutch are used:

1997 528i (6 cylinder) uses traditional clutch components.

All

540i (V-8) and 1998 and later 6 cylinder models from

use a self-adjusting clutch (SAC).

Page 583 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission

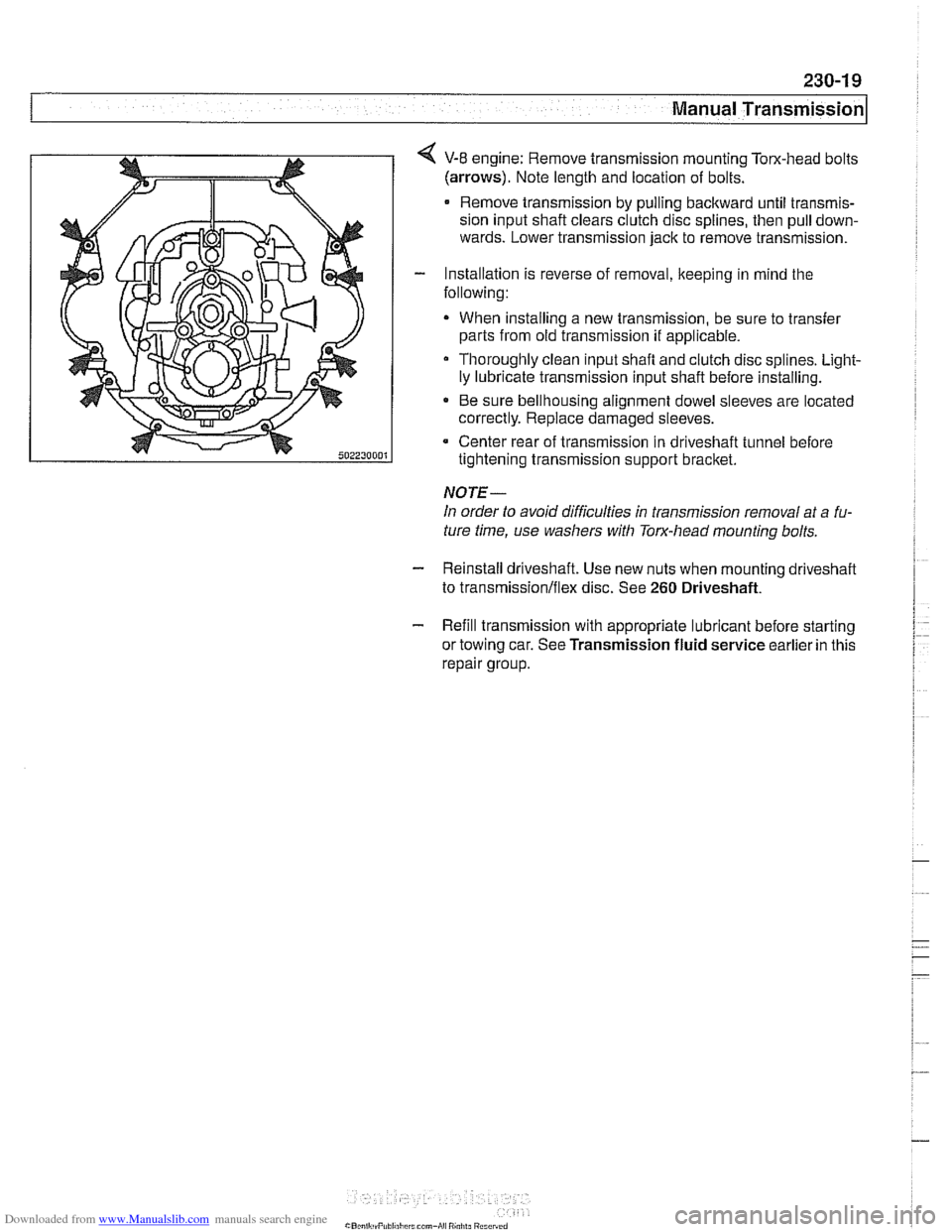

4 V-8 engine: Remove transmission mounting Tom-head bolts

(arrows). Note length and location of bolts.

Remove transmission by pulling backward until transmis-

sion input shaft clears clutch disc splines, then pull down-

wards. Lower transmission jack to remove transmission.

- Installation is reverse of removal, keeping in mind the

following:

When installing a new transmission, be sure to transfer

parts from old transmission

if applicable.

Thoroughly clean input shafl and clutch disc splines. Light-

ly lubricate transmission input shaft before installing.

* Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Center rear of transmission in driveshaft tunnel before

tightening transmission support bracket.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

- Reinstall driveshaft. Use new nuts when mounting driveshaff

to transmission/flex disc. See 260 Driveshaft.

- Refill transmission with appropriate lubricant before starting

or towing car. See Transmission fluid service earlier in this

repair group.

Page 587 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-3

Automatic Transmission

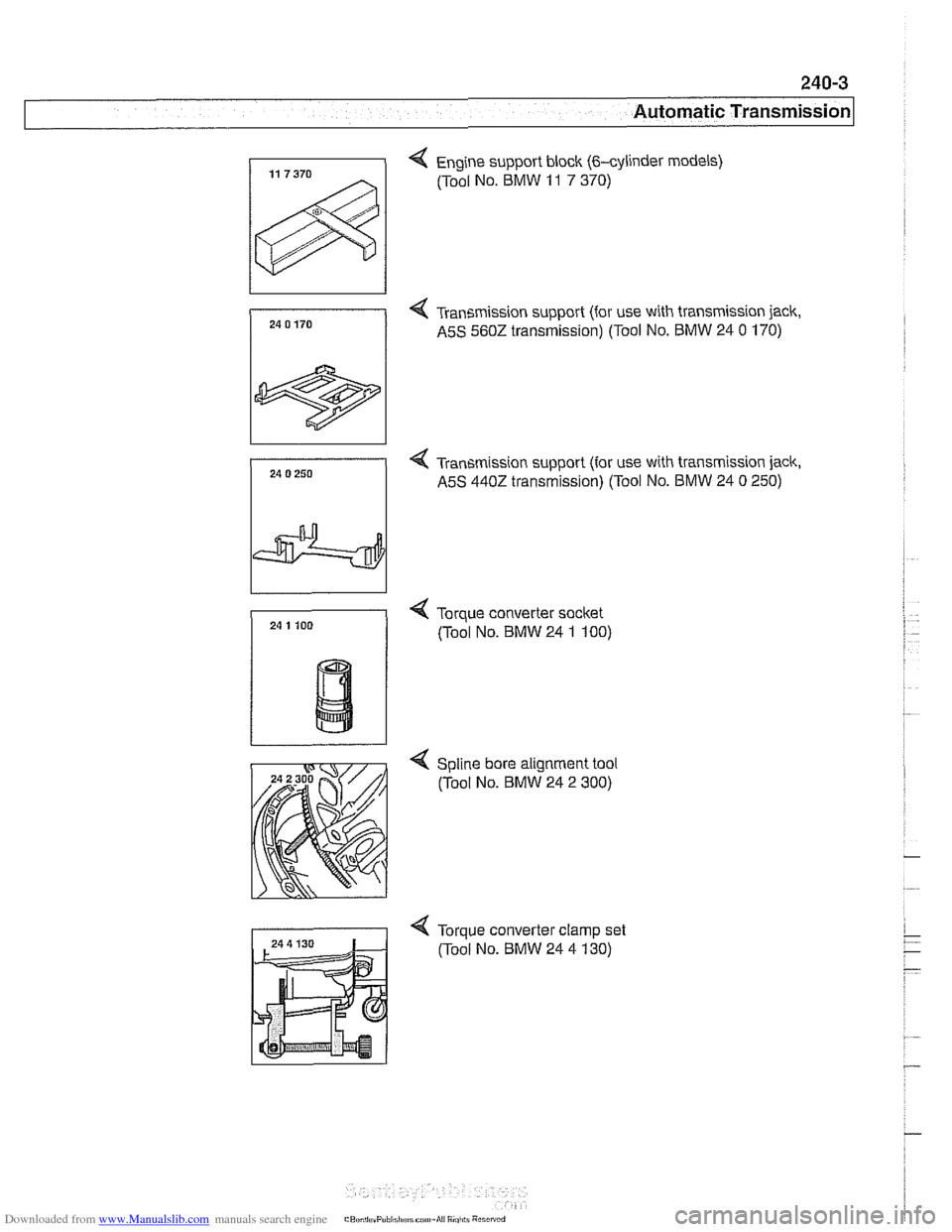

4 Engine support block (&cylinder models)

(Tool No. BMW

11 7 370)

4 Tran5mission support (for use with transmission jack,

A5S 560Z transmission) (Tool No. BMW 24

0 170)

4 Transmission support (for use with transmission jack,

A5S

4402 transmission) (Tool No. BMW 24 0 250)

4 Torque converter socket

(Tool No. BMW 24 1 100)

< Spline bore alignment tool

(Tool No.

BMW 24 2 300)

Page 597 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 3

Automatic ~ransmissionl

- Blow out oil cooler lines with low-pressure compressed air

and flush cooler with clean ATF twice before reattaching lines

to transmission.

CA UTIOG

Wear safety glasses when worling with compressed air:

@ Do not reuse ATF used for flushing.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Reinstall driveshafl using new nuts.

Install new sealing washers on transmission cooling line

banjo bolts.

Install new O-rings on transmission cooler lines, where

applicable.

Inspect engine drive plate (flywheel) for cracks or elongat-

ed holes. Replace

if necessary.

Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Checlc to be sure torque converter is seated correctly in

transmission during final installation.

Use

BMW special tool 24 2 300 to align three mounting

tabs on torque converter with indentations on drive plate

(flywheel).

Fill transmission with clean ATF until oil level is even with

fill hole. Then check fluid level as described earlier.

Adjust gearshift mechanism. See

250 Gearshift Linkage.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

Page 606 of 1002

Downloaded from www.Manualslib.com manuals search engine

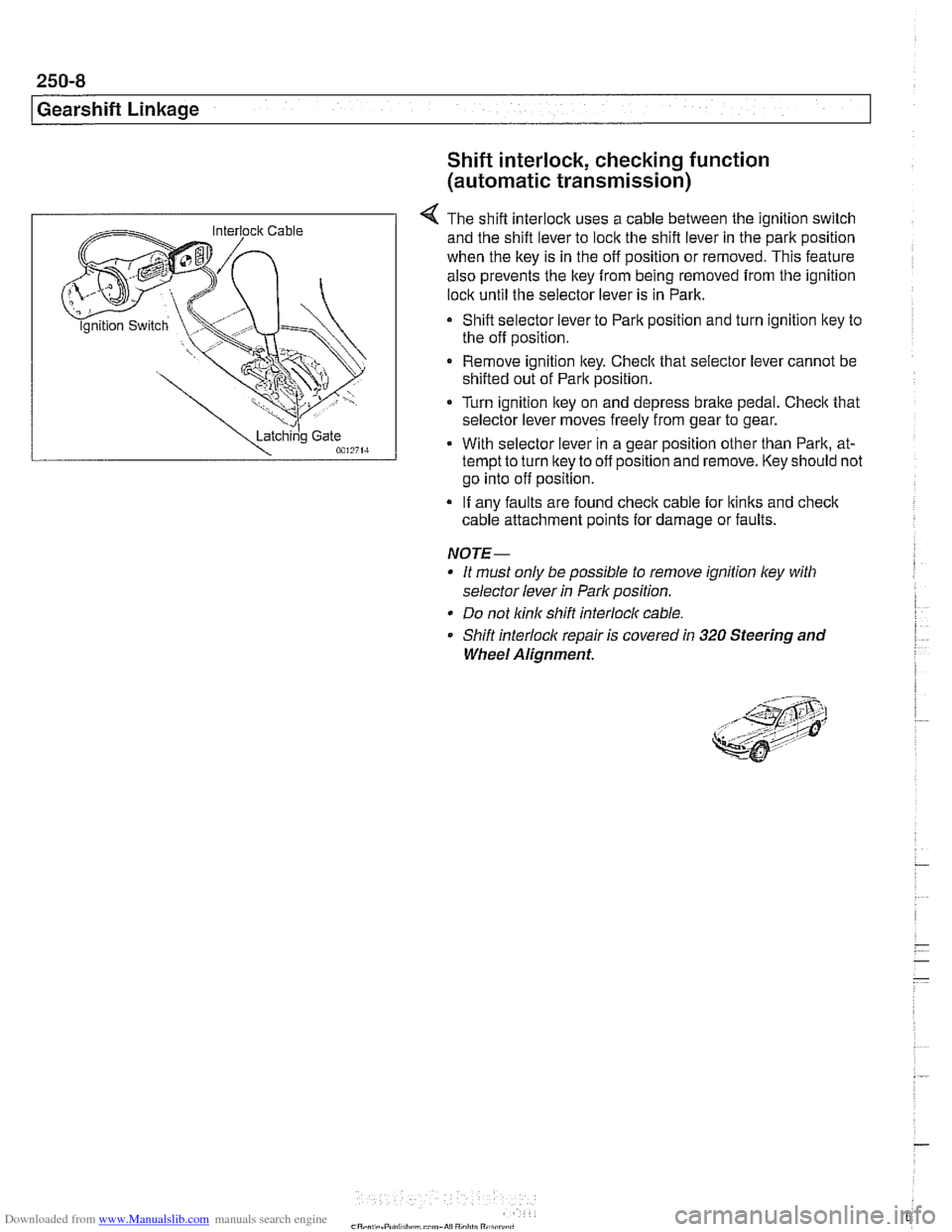

250-8

Gearshift Linkage

-;Ag Gate "",?it.,

Shift interlock, checking function

(automatic transmission)

4 The shift interlock uses a cable between the ignition switch

and the shift lever to lock the shift lever in the park position

when the key is in the off position or removed. This feature

also prevents the key

from being removed from the ignition

lock until the selector lever is in Park.

Shift selector lever to Park position and turn ignition key to

the off position.

Remove ignition key. Checlc that selector lever cannot be

shifted out of Park position.

Turn ignition lkey on and depress

brake pedal. Checlc that

selector lever moves freely from gear to gear.

With selector lever in a gear position other than Park, at-

tempt to turn lkey to off position and remove. Key should not

go into off position.

If any faults are found check cable for lkinks and

check

cable attachment points for damage or faults.

NOTE-

* It must only be possible to remove ignition ley with

selector lever

in Park position.

* Do not link shift interlocl( cable.

Shift interlock repair is covered

in 320 Steering and

Wheel Alignment.

Page 610 of 1002

Downloaded from www.Manualslib.com manuals search engine

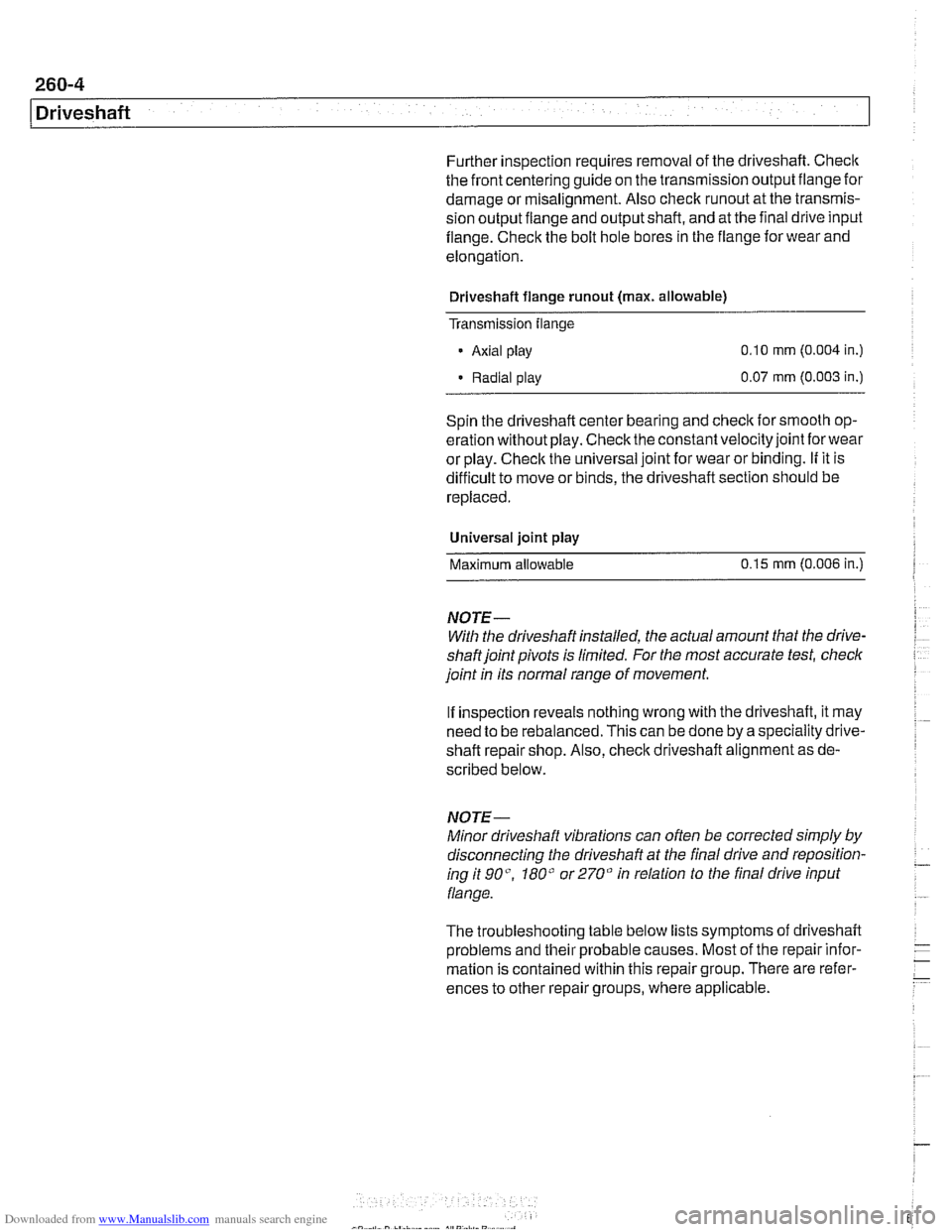

1 Driveshaft

Further inspection requires removal of the driveshaft. Checlc

the front centering guide on the transmission output flange for

damage or

misalignment. Also check runout at the transmis-

sion output fiange and output shaft, and at the final drive input

fiange. Check the bolt hole bores in the flange for wear and

elongation.

Driveshaft flange

runout (max. allowable)

Transmission

flange

- Axial play 0.10 mm (0.004 in.)

Radial play 0.07

mm (0.003 in.)

Spin the driveshaft center bearing and

check ior smooth op-

eration without play. Check the constant velocity joint

forwear

or play. Checlc the universal joint for wear or binding. If it is

difficult to move or binds, the driveshaft section should be

replaced.

Universal joint

play

Maximum allowable 0.15

mm (0.006 in.)

NOTE-

With the driveshaft installed, the actual amount that the drive-

shaftjoint pivots is limited. For the most accurate test, check

joint

in its normal range of movement.

If inspection reveals nothing wrong with the driveshaft, it may

need to be rebalanced. This can be done by a speciality drive-

shaft repair shop. Also,

checlc driveshaft alignment as de-

scribed below.

NOTE-

Minor driveshaft vibrations can often be corrected simply by

disconnecting the driveshaft at the final drive and reposition-

ing it go", 180" or 270" in relation to the final drive input

flange.

The troubleshooting table below lists symptoms

oi driveshaft

problems and their probable causes. Most of the repair infor-

mation is contained within this repair group. There are refer-

ences to other repair groups, where applicable.

Page 611 of 1002

Downloaded from www.Manualslib.com manuals search engine

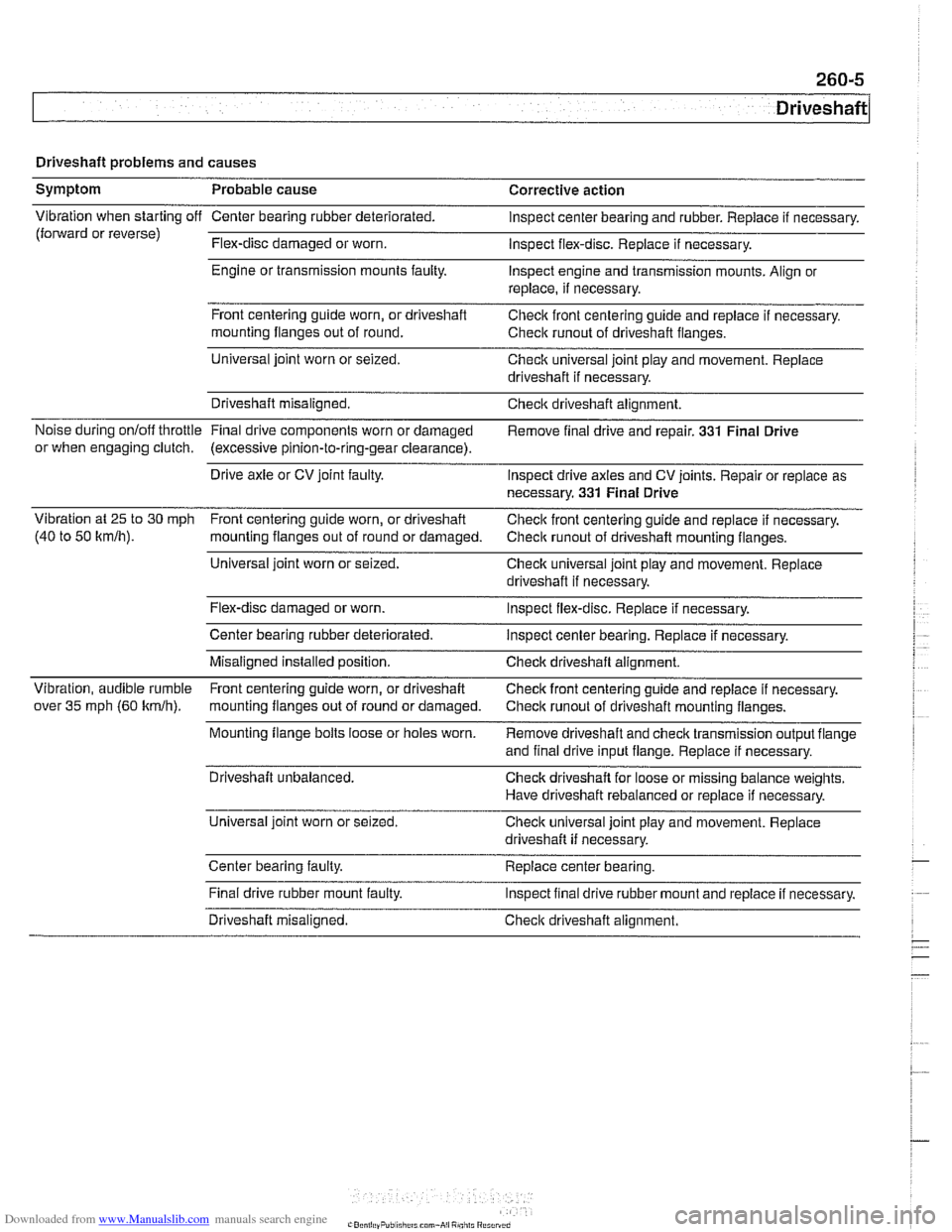

Driveshaft

Driveshaft problems and causes

Symptom Probable cause Corrective action

Vibration when starting off Center bearing rubber deteriorated. Inspect center bearing and rubber. Replace if necessary.

(forward or reverse)

Flex-disc damaged or worn.

Inspect flex-disc. Replace

if necessary.

Engine or transmission mounts

faulty. Inspect engine and transmission mounts. Align or

replace, if necessary.

Front centering guide worn, or driveshaft

Checic front centering guide and replace

if necessary.

mounting flanges out of round.

Check

runout of driveshaft flanges.

Universal joint worn or seized.

Check universal joint play and movement. Replace

driveshaft if necessary.

Driveshaft misaligned. Check driveshaft alignment.

Noise during onloff throttle Final

drive components worn or damaged

Remove final drive and repair. 331 Final Drive

or when engaging clutch. (excessive pinion-to-ring-gear clearance).

Drive axle or CV joint faulty.

Inspect drive axles and CV joints. Repair or replace as

necessary.

331 Final Drive

Vibration at 25 to

30 mph

Front centering guide worn, or driveshaft

Check front centering guide and replace if necessary.

(40 to 50

kmlh). mounting flanges out of round or damaged.

Check runout of driveshaft mounting flanges.

Universal joint worn or seized.

Check universal joint play and movement. Replace

driveshaft if necessary.

Flex-disc damaged or worn.

Inspect flex-disc. Replace if necessary.

Center bearing rubber deteriorated.

Inspect center bearing. Replace if necessary.

Misaligned installed position. Check driveshaft alignment.

Vibration, audible rumble Front centering guide worn, or driveshaft

Check front centering guide and replace

if necessary.

over

35 mph (60 kmlh). mounting flanges out of rouncl or damaged.

Check runout of driveshaft mounting flanges. - -

Mounting flange bolts loose or holes worn.

Remove driveshaft and check transmission output flange

and final drive input flange. Replace if necessary.

Driveshaft unbalanced. Check driveshaft for loose or missing balance weights.

Have driveshaft rebalanced or replace if necessary.

Universal ioint worn or seized.

Check universal ioint

~lav and movement. Reolace ' .. driveshaft if necessary.

Center bearing faulty.

Replace center bearing.

.

Final drive rubber mount faulty.

Inspect final drive rubber mount and repiace if necessary.

Driveshaft misaligned.

Check driveshaft alignment.

Page 613 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft, aligning

The alignment of the driveshaft does not normally need to be

checked unless the engineltransmission or the final drive

have been removed and installed. if ail other parts of the

driveshaft have been inspected and found to be okay, but

there is still noise or vibration, driveshaft alignment should be

checked.

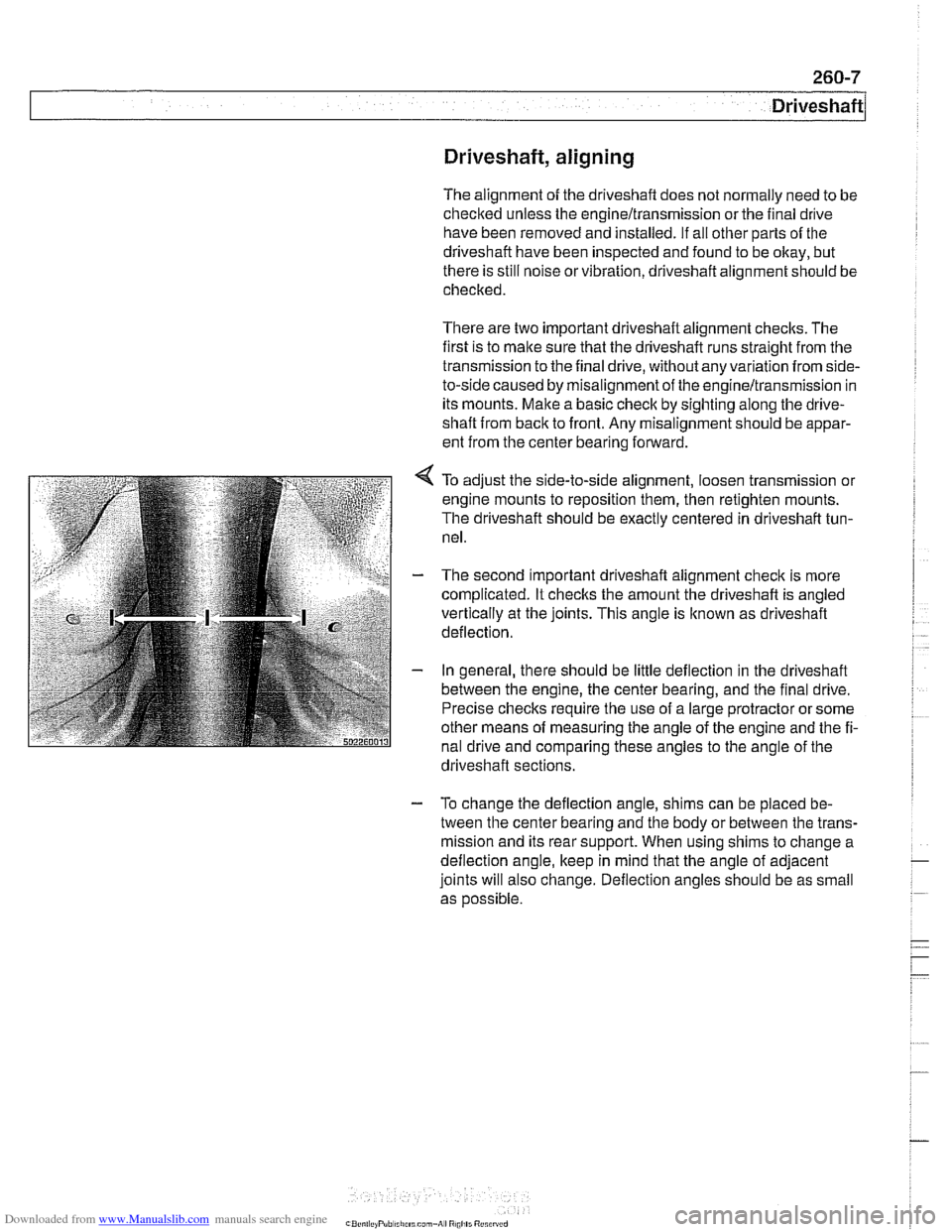

There are two important driveshaft alignment checks. The

first is to make sure that the driveshaft runs straight from the

transmission to the final drive, without any variation from

side-

to-side caused by misalignment of the engineltransmission in

its mounts. Make a basic check by sighting along the

drive-

shaft from back to front. Any misalignment should be appar-

ent from the center bearing forward.

To adjust the side-to-side alignment, loosen transmission or

engine mounts to reposition them, then retighten mounts.

The driveshaft should be exactly centered in driveshaft tun-

nel.

The second important driveshaft alignment check is more

complicated. It checlts the amount the driveshaft is angled

vertically at the joints. This angle is

lknown as driveshaft

deflection.

In general, there should be little deflection in the driveshaft

between the engine, the center bearing, and the final drive.

Precise checks require the use of a large protractor or some

other means of measuring the angle of the engine and the fi-

nal drive and comparing these angles to the angle of the

. . driveshaft sections.

- To change the deflection angle, shims can be placed be-

tween the center bearing and the body or between the trans-

mission and its rear support. When using shims to change a

deflection angle, keep in mind that the angle of adjacent

joints will also change. Deflection angles should be as small

as

oossible.